Numerical Analysis of Friction-Filling Performance of Friction-Type Vertical Disc Precision Seed-Metering Device Based on EDEM

Abstract

1. Introduction

2. Seed-Metering Device Structure and Friction Seed Method Principle

3. Materials and Methods

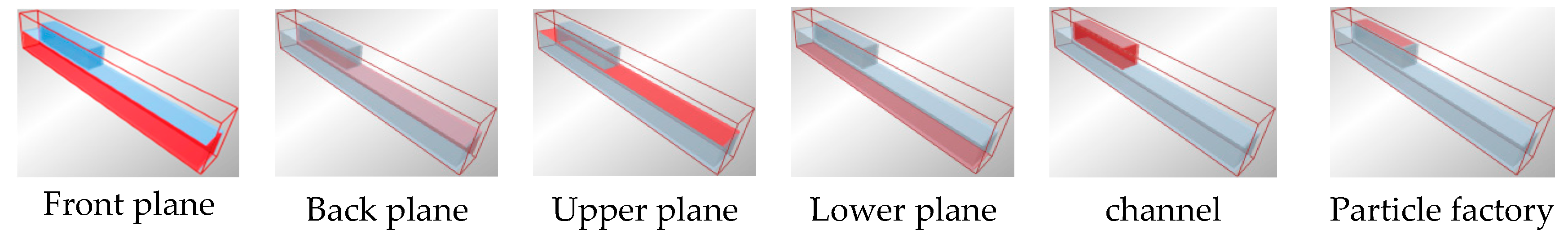

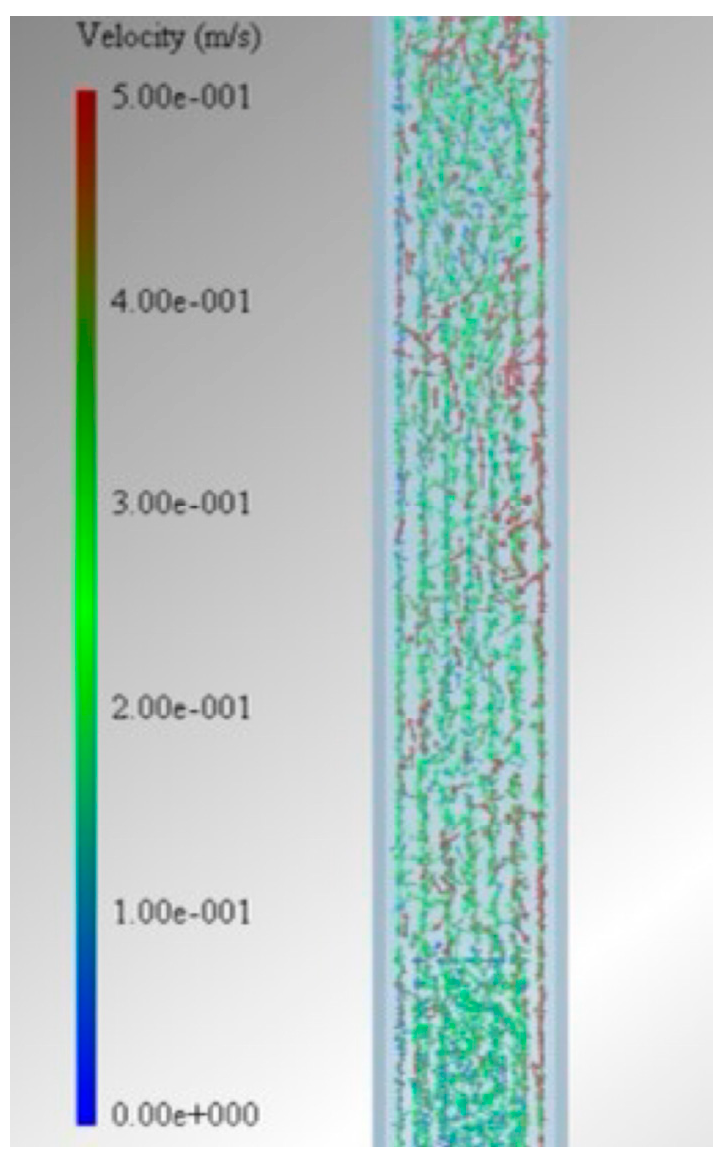

3.1. Description of the Simulation System

3.1.1. Mechanical Contact Model

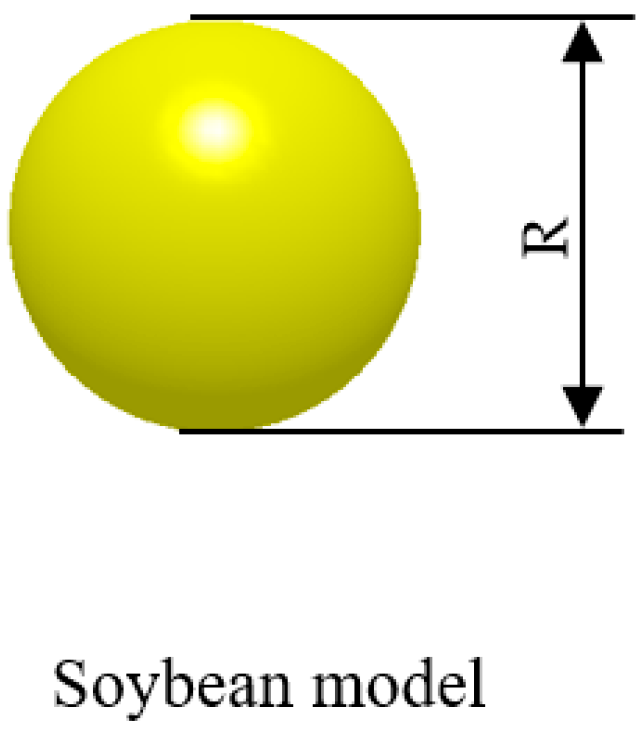

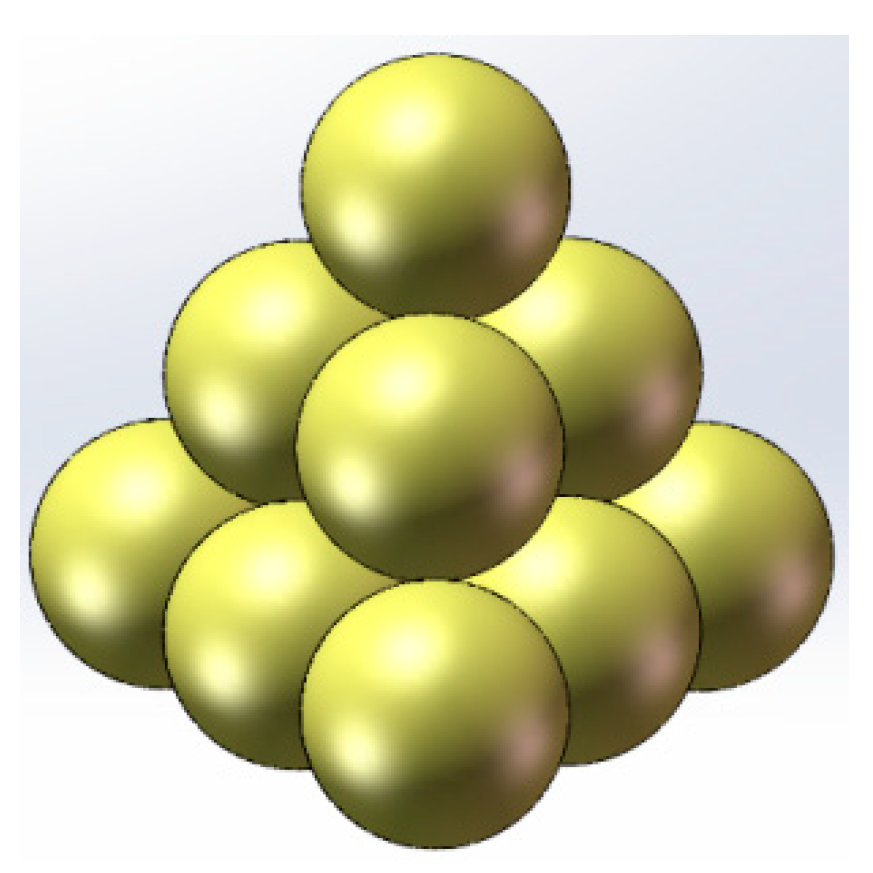

3.1.2. DEM Model of Particles and Geometry

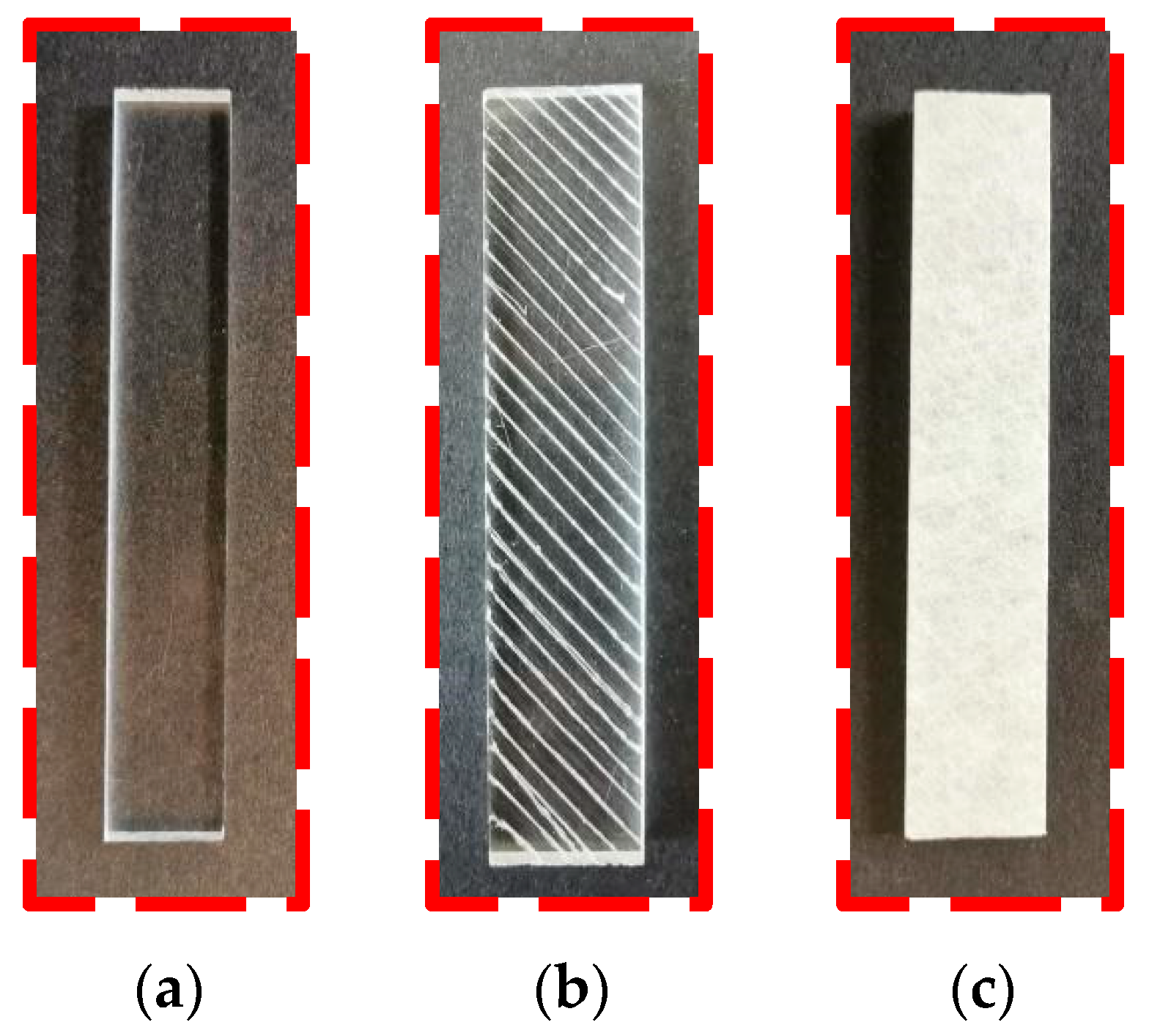

3.2. Experimental Setup and Procedure

4. Results and Discussion

4.1. Model Validation

4.2. Simulation Results and Analysis

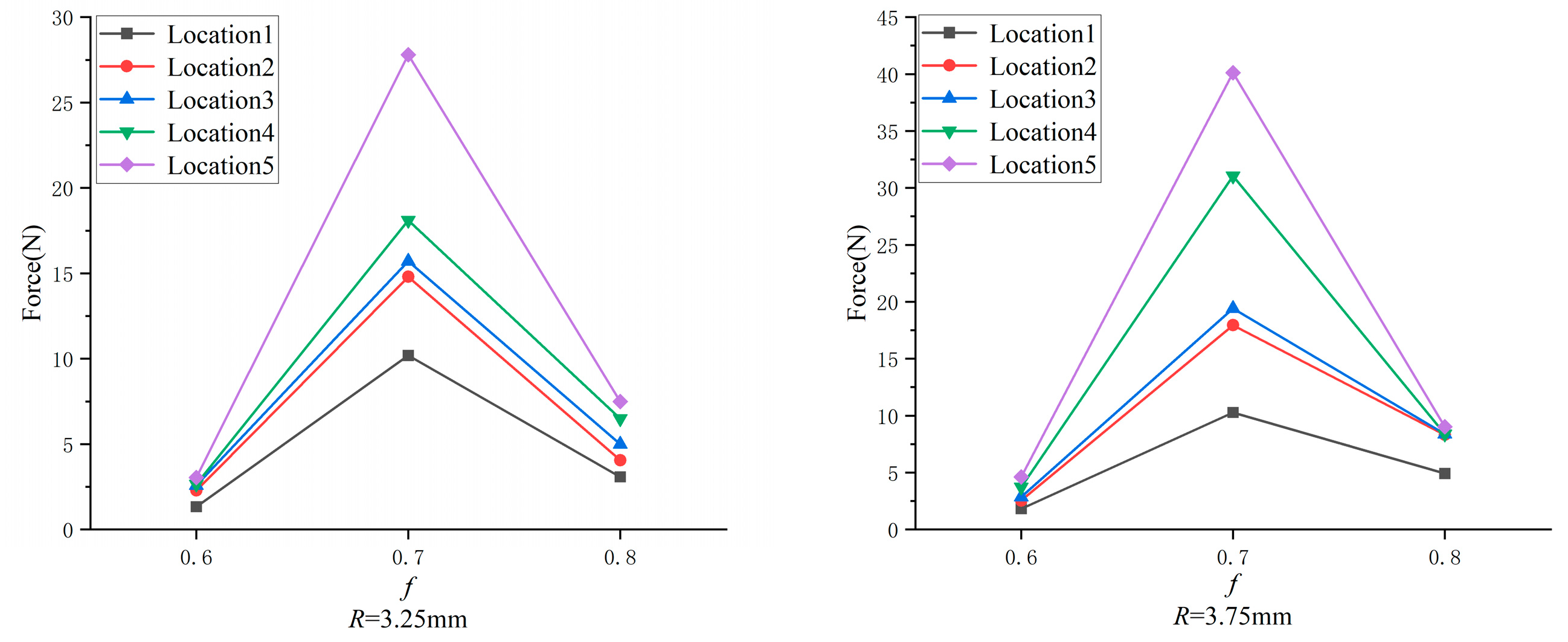

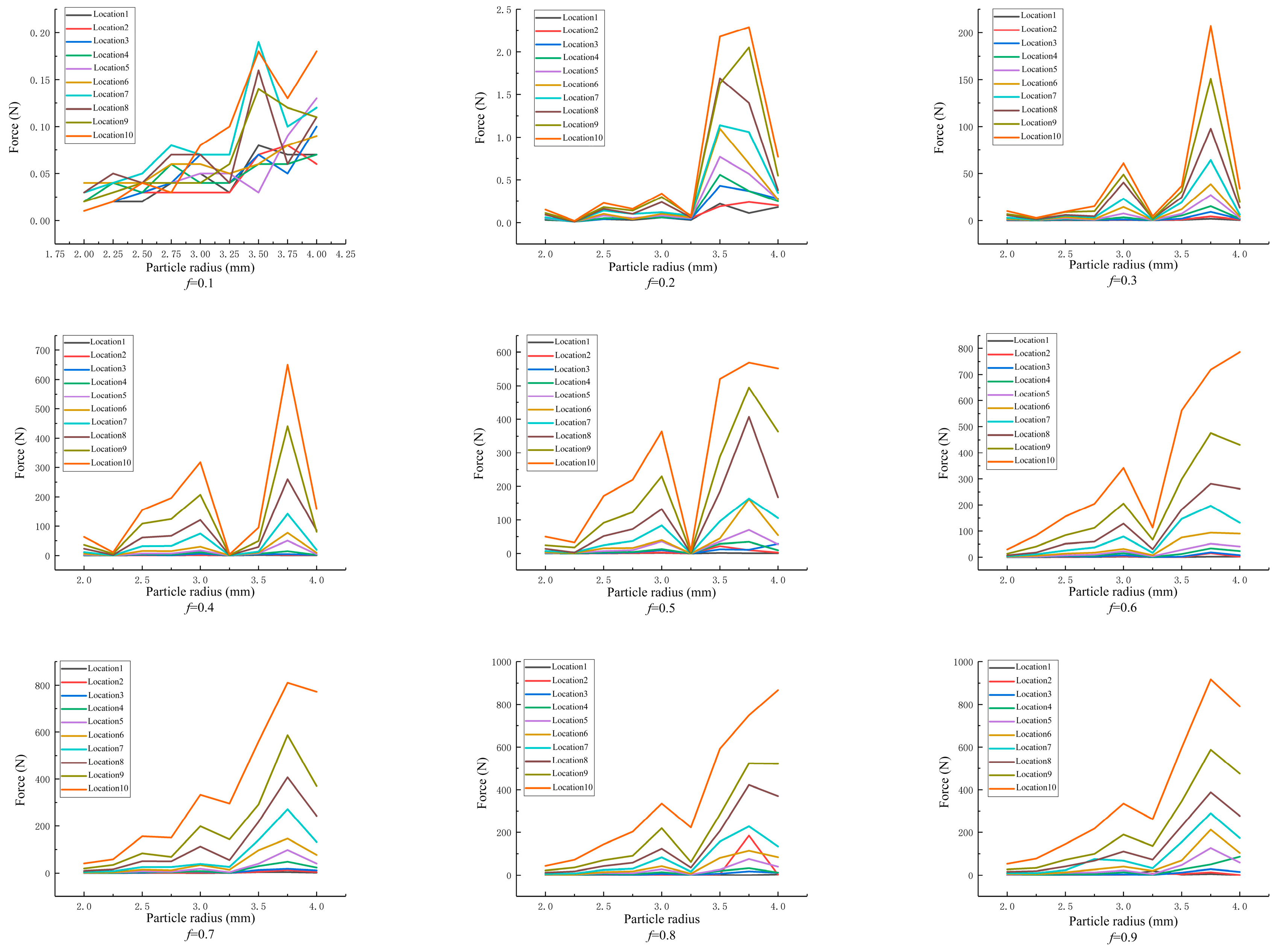

4.2.1. The Effect of Position on the Force on the Granules

4.2.2. Effect of Friction Coefficient on the Force on the Granules

4.2.3. Effect of Width-to-Diameter Ratio on the Force on the Granules

4.3. Discussion

- In this paper, the effects of different friction coefficients and different particle sizes on the particle-filling properties were verified via numerical analysis and experiments. The experimental results are basically consistent with the numerical simulation results, which verifies the correctness of the numerical simulation. In addition, the effects of different friction coefficients and particle sizes on the filling properties were also considered, which provides a theoretical basis for the optimization of the particle-filling process.

- However, there are some shortcomings in this study. First of all, only the seeds of one crop were selected for study in the experiment, and the seed-filling performance of other crops was not studied. Second, there may be some assumptions and simplifications in the numerical simulation, and the complexity of the actual situation may not be fully considered. Based on the results of this study, possible future research directions include the following: further study on the seed-filling performance of different crops via exploring the filling characteristics and optimization methods of different crops’ seeds; further improvement of the numerical simulation method via considering more practical factors and improving the accuracy of simulation results; and studying the flow and accumulation characteristics in the particle-filling process to provide more theoretical support for the design and optimization of particle-filling equipment.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.T.; Ying, H.; Chen, M.Y.; Bai, J.; Xue, Y.; Yin, Y.; Batchelor, W.D.; Yang, Y.; Bai, Z.; Du, M.; et al. Optimization of China’s maize and soy production can ensure feed sufficiency at lower nitrogen and carbon footprints. Nat. Food 2021, 2, 426–433. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.C.; Wang, Y.X.; Zhao, M.Y.; Wang, K.C.; Li, S.; Gao, Z.Z.; Shi, X.Y.; Chu, Q.Q. Prospects for soybean production increase by closing yield gaps in the Northeast Farming Region, China. Field Crops Res. 2023, 293, 108843. [Google Scholar] [CrossRef]

- FAOSTAT. FAO Statistical Database. 2022. Available online: https://www.fao.org/faostat (accessed on 1 July 2023).

- Wu, F.; Geng, Y.; Zhang, Y.Q.; Ji, C.X.; Chen, Y.F.; Sun, L.; Xie, W.; Ali, T.; Fujita, T. Assessing sustainability of soybean supply in China: Evidence from provincial production and trade data. J. Clean. Prod. 2020, 244, 119006. [Google Scholar] [CrossRef]

- Xiong, D.Y.; Wu, M.L.; Xie, W.; Liu, R.; Luo, H.F. Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device. Appl. Sci. 2021, 11, 7223. [Google Scholar] [CrossRef]

- Jia, H.; Chen, Y.; Zhao, J.; Guo, M.; Huang, D.; Zhuang, J. Design and key parameter optimization of an agitated soybean seed metering device with horizontal seed filling. Int. J. Agric. Biol. Eng. 2018, 11, 76–87. [Google Scholar] [CrossRef]

- Cai, Y.Q.; Luo, X.; Hu, Z.B.; Li, J.W.; Guo, M.Y.; Wang, J. Theoretical and experimental analyses of high-speed seed filling in limited gear-shaped side space of cotton precision dibbler. Comput. Electron. Agric. 2022, 200, 107202. [Google Scholar] [CrossRef]

- Li, Z.D.; Zhong, J.Y.; Gu, X.; Zhang, H.; Chen, Y.X.; Wang, W.W.; Zhang, T.; Chen, L.Q. DEM Study of Seed Motion Model-Hole-Wheel Variable Seed Metering Device for Wheat. Agriculture 2022, 13, 23. [Google Scholar] [CrossRef]

- Wang, M.M.; Liu, Q.T.; Ou, Y.G.; Zou, X.P. Numerical Simulation and Verification of Seed-Filling Performance of Single-Bud Billet Sugarcane Seed-Metering Device Based on EDEM. Agriculture 2022, 12, 983. [Google Scholar] [CrossRef]

- Gao, X.J.; Cui, T.; Zhou, Z.Y.; Yu, Y.B.; Xu, Y.; Zhang, D.X.; Song, W. DEM study of particle motion in novel high-speed seed metering device. Adv. Powder Technol. 2021, 32, 1438–1449. [Google Scholar] [CrossRef]

- Wu, W.C.; Chang, C.; Li, T.; Hu, H.; Zhou, Z.; Yang, W.; Guo, J.; Zhu, P.; Li, J.; Hu, J.; et al. Seed-Filling Characteristics of a Centralized Seed-Metering Device for Rapeseed Caused by Vibration. Agriculture 2022, 12, 965. [Google Scholar] [CrossRef]

- Lai, Q.H.; Hua, Z.W.; Xing, J.L.; Ma, W. Simulation and verification for seed-filling performance of cell wheel precision seed metering device based on discrete element method. MATEC Web Conf. 2018, 169, 01035. [Google Scholar] [CrossRef][Green Version]

- Liu, R.; Liu, Z.; Zhao, J.; Lu, Q.; Liu, L.; Li, Y. Optimization and Experiment of a Disturbance-Assisted Seed Filling High-Speed Vacuum Seed-Metering Device Based on DEM-CFD. Agriculture 2022, 12, 1304. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, J.Q.; Yu, Y.J.; Zhang, Q. Validation of a coupled model of discrete element method with multibody kinematics to simulate the screening process of a swing-bar sieve. Powder Technol. 2019, 346, 193–202. [Google Scholar] [CrossRef]

- Han, Y.; Jia, F.; Zeng, Y.; Jiang, L.; Zhang, Y.; Cao, B. DEM study of particle conveying in a feed screw section of vertical rice mill. Powder Technol. 2017, 311, 213–225. [Google Scholar] [CrossRef]

- Gao, X.J.; Zhou, Z.Y.; Xu, Y.; Yu, Y.; Su, Y.; Cui, T. Numerical simulation of particle motion characteristics in quantitative seed feeding system. Powder Technol. 2020, 367, 643–658. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Jia, F.G.; Zeng, Y.; Han, Y.L.; Xiao, Y.W. DEM study in the critical height of flow mechanism transition in a conical silo. Powder Technol. 2018, 331, 98–106. [Google Scholar] [CrossRef]

- Tang, H.; Xu, F.D.; Xu, C.S.; Zhao, J.L.; Wang, W.J. The influence of a seed drop tube of the inside-filling air-blowing precision seed-metering device on seeding quality. Comput. Electron. Agric. 2023, 204, 107555. [Google Scholar] [CrossRef]

- Gao, X.; Xie, G.; Xu, Y.; Yu, Y.; Lai, Q. Application of a staggered symmetrical spiral groove wheel on a quantitative feeding device and investigation of particle motion characteristics based on DEM. Powder Technol. 2022, 407, 117650. [Google Scholar] [CrossRef]

- Ren, D.Z.; Yu, H.L.; Zhang, R.; Li, J.; Zhao, Y.; Liu, F.; Zhang, J.; Wang, W. Research and Experiments of Hazelnut Harvesting Machine Based on CFD-DEM Analysis. Agriculture 2022, 12, 2115. [Google Scholar] [CrossRef]

- Xiao, Y.; Ma, Z.; Wu, M.; Luo, H. Numerical Study of Pneumatic Conveying of Rapeseed through a Pipe Bend by DEM-CFD. Agriculture 2022, 12, 1845. [Google Scholar] [CrossRef]

- Han, L.; Yuan, W.; Yu, J.; Jin, J.; Xie, D.; Xi, X.; Zhang, Y.; Zhang, R. Simulation and Experiment of Spiral Soil Separation Mechanism of Compound Planter Based on Discrete Element Method (DEM). Agriculture 2022, 12, 511. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D. A discrete numerical model for granular assembles. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Dong, K.J.; Wang, B.; Yu, A.B. Modeling of Particle Flow and Sieving Behavior on a Vibrating Screen: From Discrete Particle Simulation to Process Performance Prediction. Ind. Eng. Chem. Res. 2013, 52, 11333–11343. [Google Scholar] [CrossRef]

- Wang, Y.C.; Qiu, L.C.; Zhang, W.J. Design and test of friction type vertical disc precision seed-metering device. Northeast Agric. Univ./Trans. Chin. Soc. Agric. Eng. 2012, 28, 22–26. [Google Scholar]

- Gao, Y.P. Design and Experiment of Clamping Corn Precision Seed Harvester. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2021. [Google Scholar] [CrossRef]

- Han, Y.L.; Jia, F.G.; Li, G.R.; Liu, H.R.; Li, J.M.; Chen, P.Y. Numerical analysis of flow pattern transition in a conical silo with ellipsoid particles. Adv. Powder Technol. 2019, 30, 1870–1881. [Google Scholar] [CrossRef]

- Di Renzo, A.; Di Maio, F.P. Comparison of contact-force models for the simulation of collisions in DEM-based granular flow codes. Chem. Eng. Sci. 2003, 59, 525–541. [Google Scholar] [CrossRef]

- Liu, S.D.; Zhou, Z.Y.; Zou, R.P.; Pinson, D.; Yu, A.B. Flow characteristics and discharge rate of ellipsoidal particles in a flat bottom hopper. Powder Technol. 2014, 253, 70–79. [Google Scholar] [CrossRef]

- Lei, X.L.; Liao, Y.T.; Liao, Q.X. Simulation of seed motion in seed feeding device with DEM-CFD coupling approach for rapeseed and wheat. Comput. Electron. Agric. 2016, 131, 29–39. [Google Scholar] [CrossRef]

- Zeng, Z.W.; Ma, X.; Cao, X.L.; Li, Z.H.; Wang, X.C. Application status and prospect of discrete element method in agricultural engineering research. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Eng. 2021, 52, 1–20. [Google Scholar]

- Xie, Z.Y.; Zhu, J.F. Simulation of screening process of vibrating screen of soybean combine harvester with discrete element method. Agric. Equip. Technol./Trans. Chin. Soc. Agric. Eng. 2021, 47, 45–47+50. [Google Scholar]

- Yan, D.X.; Yu, J.Q.; Wang, Y.; Zhou, L.; Yu, Y.J. A general modelling method for soybean seeds based on the discrete element method. Powder Technol. 2020, 372, 212–226. [Google Scholar] [CrossRef]

| Soybean Particle | Density, kg/m3 | 1257 |

| Poisson ratio | 0.4 | |

| Shear modulus, Pa | 6.3 × 107 | |

| number | 10,000 | |

| Organic glass | Density, kg/m3 | 1800 |

| Poisson ratio | 0.25 | |

| Shear modulus, Pa | 3.5 × 107 | |

| Steel | Density, kg/m3 | 7850 |

| Poisson ratio | 7.9 × 1011 | |

| Shear modulus, Pa | 0.3 | |

| Particle–particle | Restitution coefficient | 0.627 |

| Coefficient of static friction | 0.2 | |

| Coefficient of rolling friction | 0.02 | |

| Particle–organic glass | Restitution coefficient | 0.542 |

| Coefficient of static friction | 0.228 | |

| Coefficient of rolling friction | 0.05 | |

| Particle–steel | Restitution coefficient | 0.647 |

| Coefficient of static friction | 0.259 | |

| Coefficient of rolling friction | 0.02 | |

| Simulation | Time step, s | 20% |

| Number | Factors | (N) | ||

|---|---|---|---|---|

| R | f | L | ||

| 1 | 3.25 | 0.6 | 1 | 1.33 |

| 2 | 3.25 | 0.6 | 2 | 2.28 |

| 3 | 3.25 | 0.6 | 3 | 2.59 |

| 4 | 3.25 | 0.6 | 4 | 2.66 |

| 5 | 3.25 | 0.6 | 5 | 3.04 |

| 6 | 3.75 | 0.6 | 1 | 1.82 |

| 7 | 3.75 | 0.6 | 2 | 2.55 |

| 8 | 3.75 | 0.6 | 3 | 2.87 |

| 9 | 3.75 | 0.6 | 4 | 3.72 |

| 10 | 3.75 | 0.6 | 5 | 4.61 |

| 11 | 3.25 | 0.7 | 1 | 10.19 |

| 12 | 3.25 | 0.7 | 2 | 14.80 |

| 13 | 3.25 | 0.7 | 3 | 15.71 |

| 14 | 3.25 | 0.7 | 4 | 18.10 |

| 15 | 3.25 | 0.7 | 5 | 27.80 |

| 16 | 3.75 | 0.7 | 1 | 10.28 |

| 17 | 3.75 | 0.7 | 2 | 17.94 |

| 18 | 3.75 | 0.7 | 3 | 19.41 |

| 19 | 3.75 | 0.7 | 4 | 31.04 |

| 20 | 3.75 | 0.7 | 5 | 40.11 |

| 21 | 3.25 | 0.8 | 1 | 3.08 |

| 22 | 3.25 | 0.8 | 2 | 4.06 |

| 23 | 3.25 | 0.8 | 3 | 4.99 |

| 24 | 3.25 | 0.8 | 4 | 6.49 |

| 25 | 3.25 | 0.8 | 5 | 7.49 |

| 26 | 3.75 | 0.8 | 1 | 4.91 |

| 27 | 3.75 | 0.8 | 2 | 8.32 |

| 28 | 3.75 | 0.8 | 3 | 8.38 |

| 29 | 3.75 | 0.8 | 4 | 8.38 |

| 30 | 3.75 | 0.8 | 5 | 9.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Kang, X.; Wang, G.; Ji, W. Numerical Analysis of Friction-Filling Performance of Friction-Type Vertical Disc Precision Seed-Metering Device Based on EDEM. Agriculture 2023, 13, 2183. https://doi.org/10.3390/agriculture13122183

Wang Y, Kang X, Wang G, Ji W. Numerical Analysis of Friction-Filling Performance of Friction-Type Vertical Disc Precision Seed-Metering Device Based on EDEM. Agriculture. 2023; 13(12):2183. https://doi.org/10.3390/agriculture13122183

Chicago/Turabian StyleWang, Yecheng, Xueqi Kang, Guoqing Wang, and Wenyi Ji. 2023. "Numerical Analysis of Friction-Filling Performance of Friction-Type Vertical Disc Precision Seed-Metering Device Based on EDEM" Agriculture 13, no. 12: 2183. https://doi.org/10.3390/agriculture13122183

APA StyleWang, Y., Kang, X., Wang, G., & Ji, W. (2023). Numerical Analysis of Friction-Filling Performance of Friction-Type Vertical Disc Precision Seed-Metering Device Based on EDEM. Agriculture, 13(12), 2183. https://doi.org/10.3390/agriculture13122183