Numerical Simulation and Optimization of Peanut Sheller Air–Screen Cleaning Device

Abstract

:1. Introduction

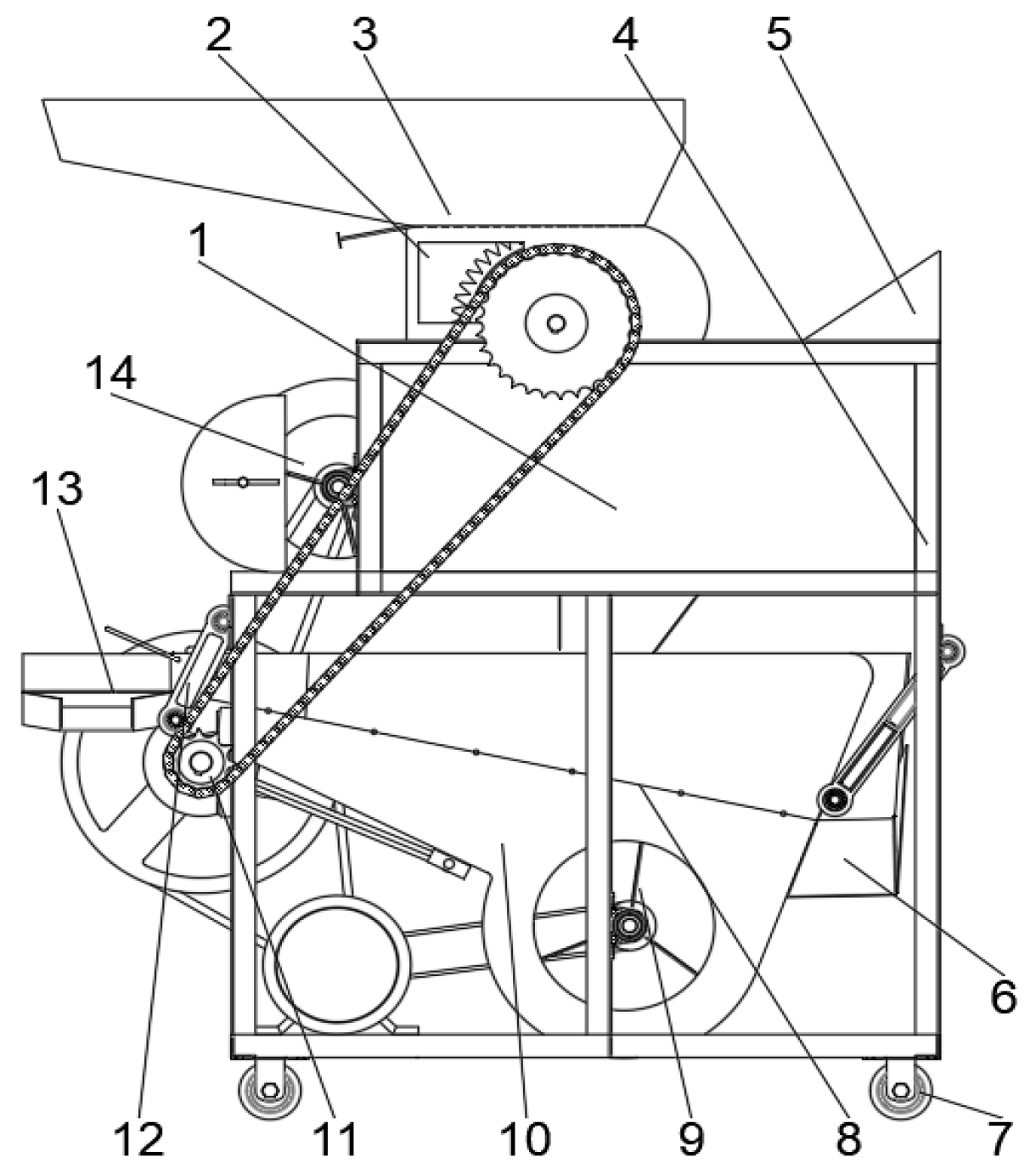

2. The Structure and Working Principle of the Peanut Sheller

2.1. The Complete Machine Structure

2.2. Working Principle

2.3. The Preliminary Cleaning Test and Analysis of Influencing Factors

2.3.1. Test Conditions and Methods

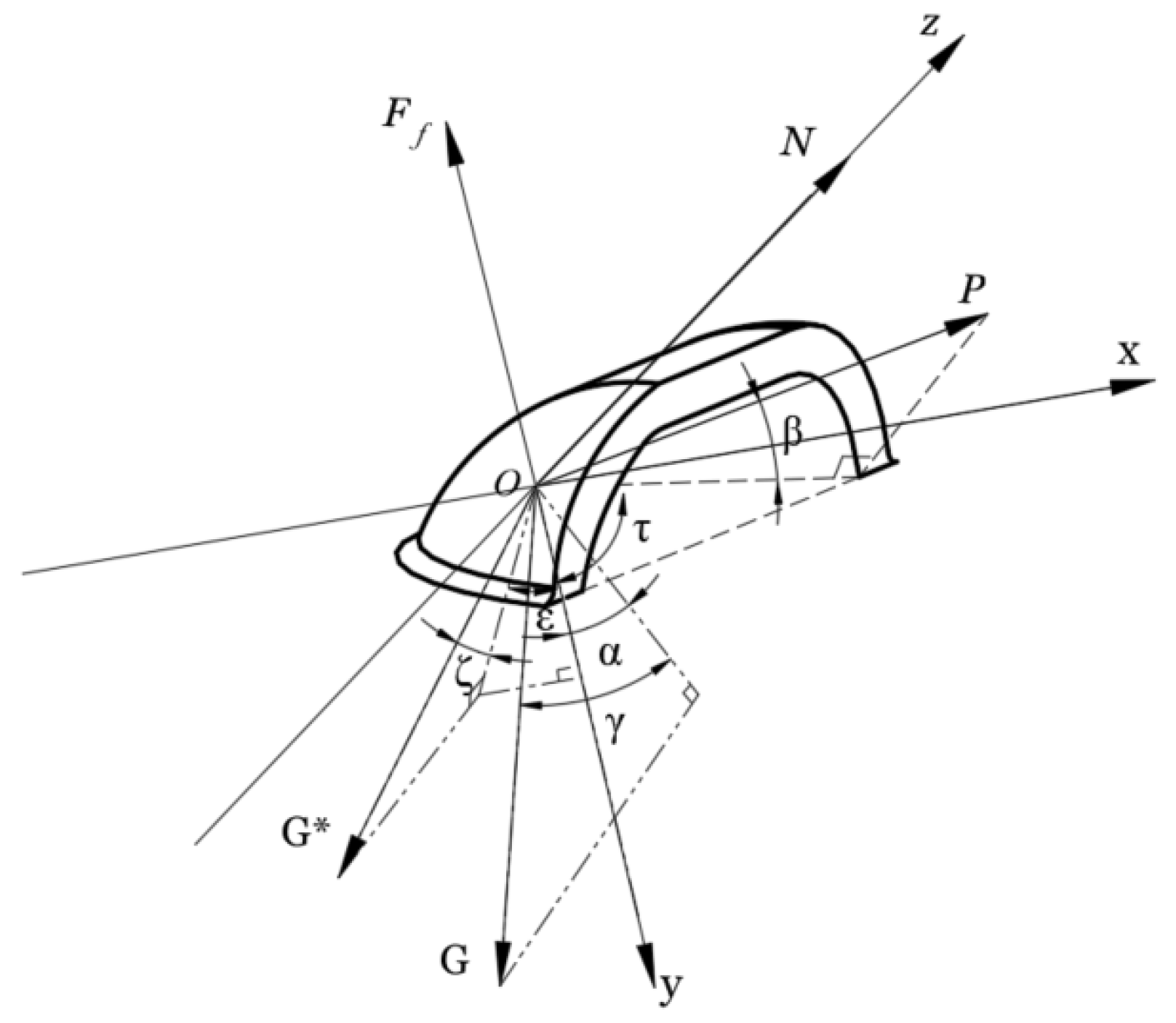

2.3.2. Force Analysis of Extrudates on the Screen Slope of Fish Scale

2.3.3. Force Analysis of Extrudates on the Screen Plane of Fish Scale

3. The Simulation and Optimization of the Airflow Field

3.1. The CFD Model Establishment

3.2. Parameter Settings

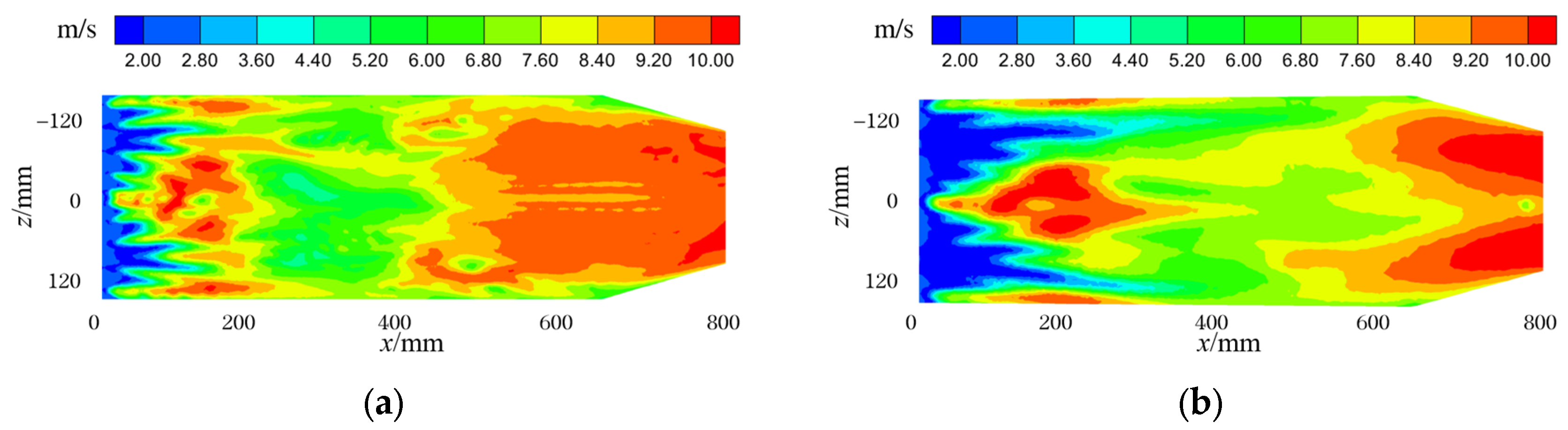

3.3. Airflow Field Analysis

3.4. Optimization of the Airflow Field

3.4.1. Optimization of Goals

3.4.2. Optimization of Results Analysis

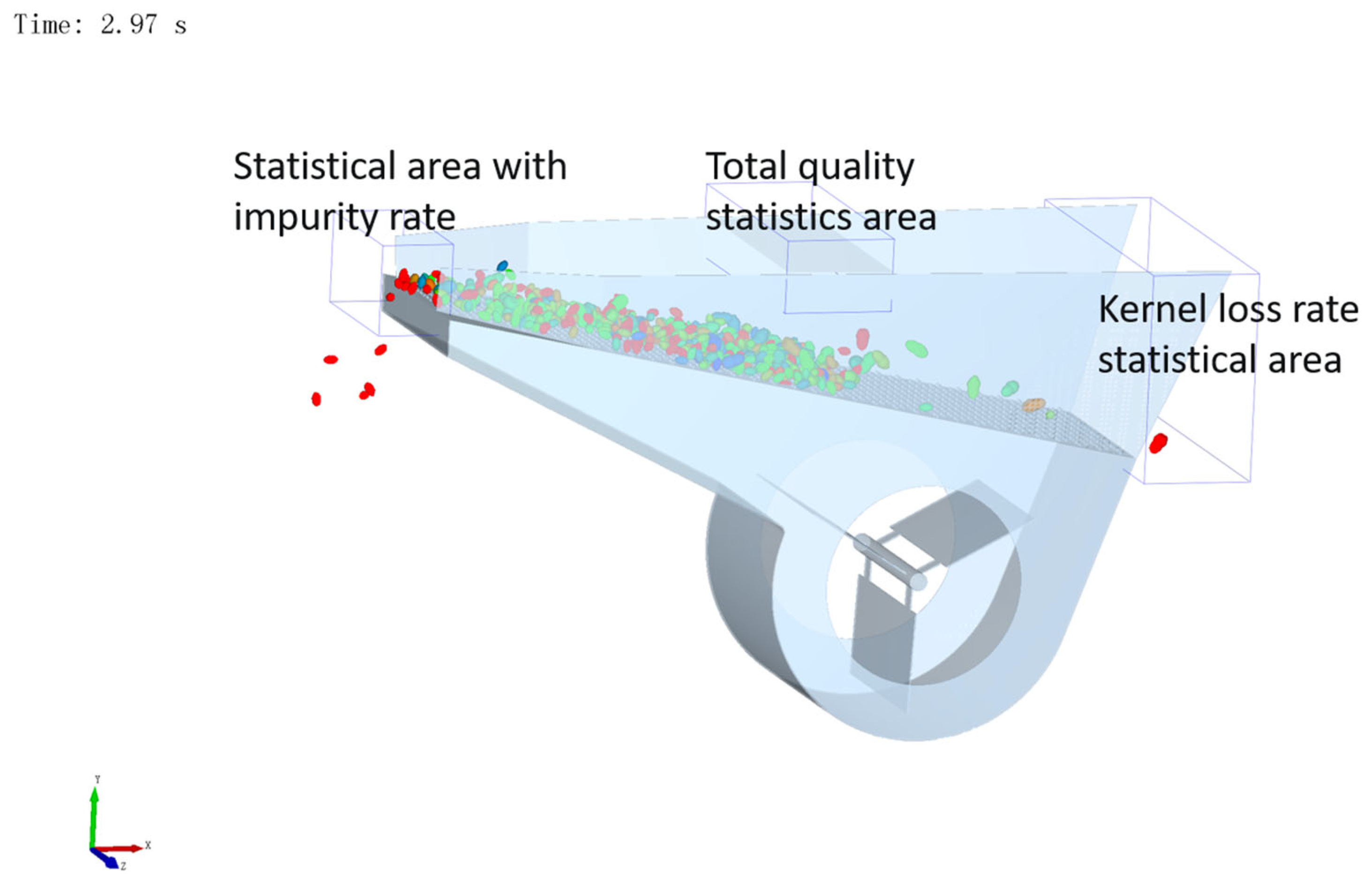

4. Simulation of Gas–Solid Two-Phase Flow

4.1. The DEM Model Establishment

4.2. Parameter Settings

4.3. The Single-Factor Simulation Test

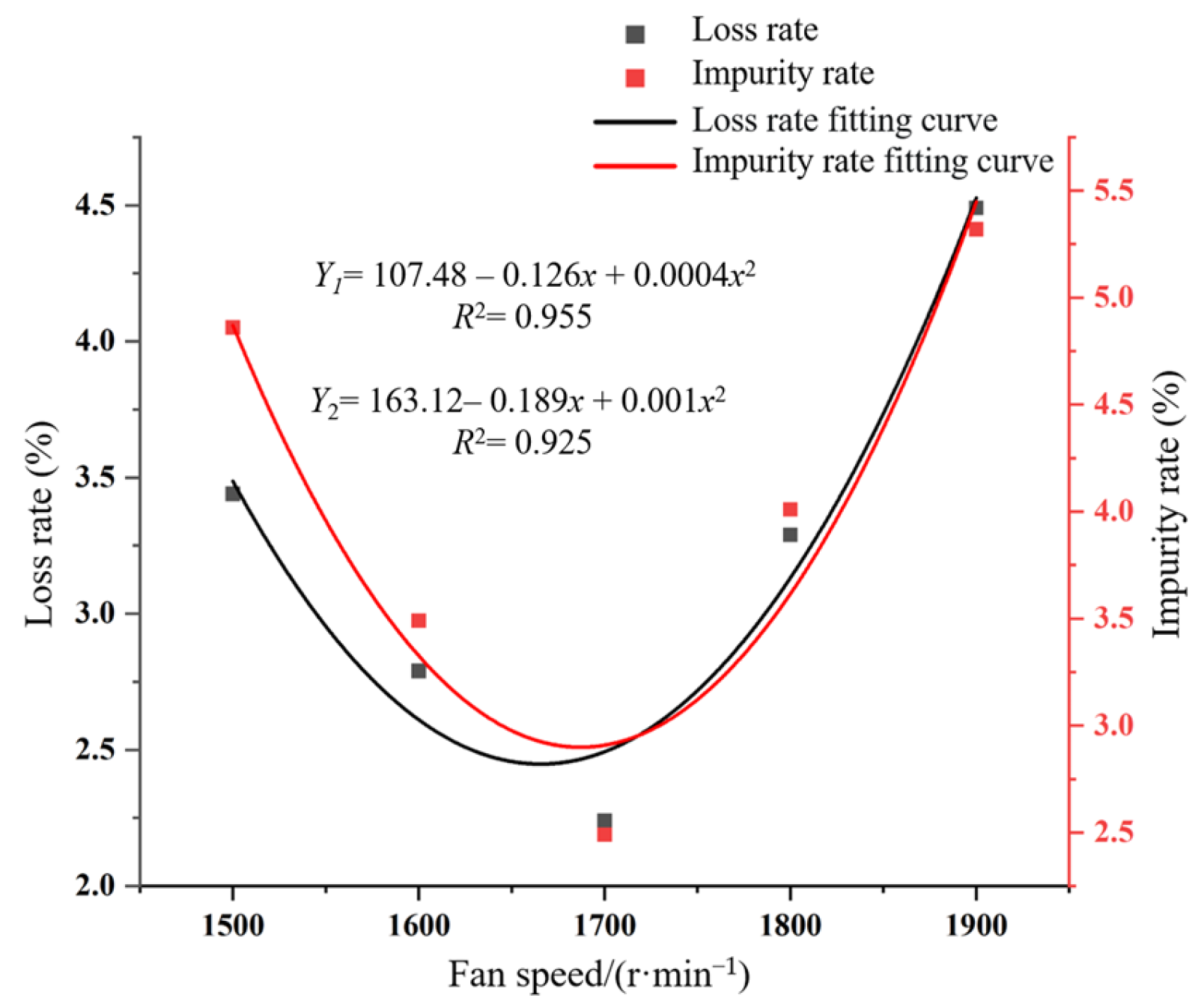

4.3.1. Effect of the Fan Speed on the Cleaning Performance

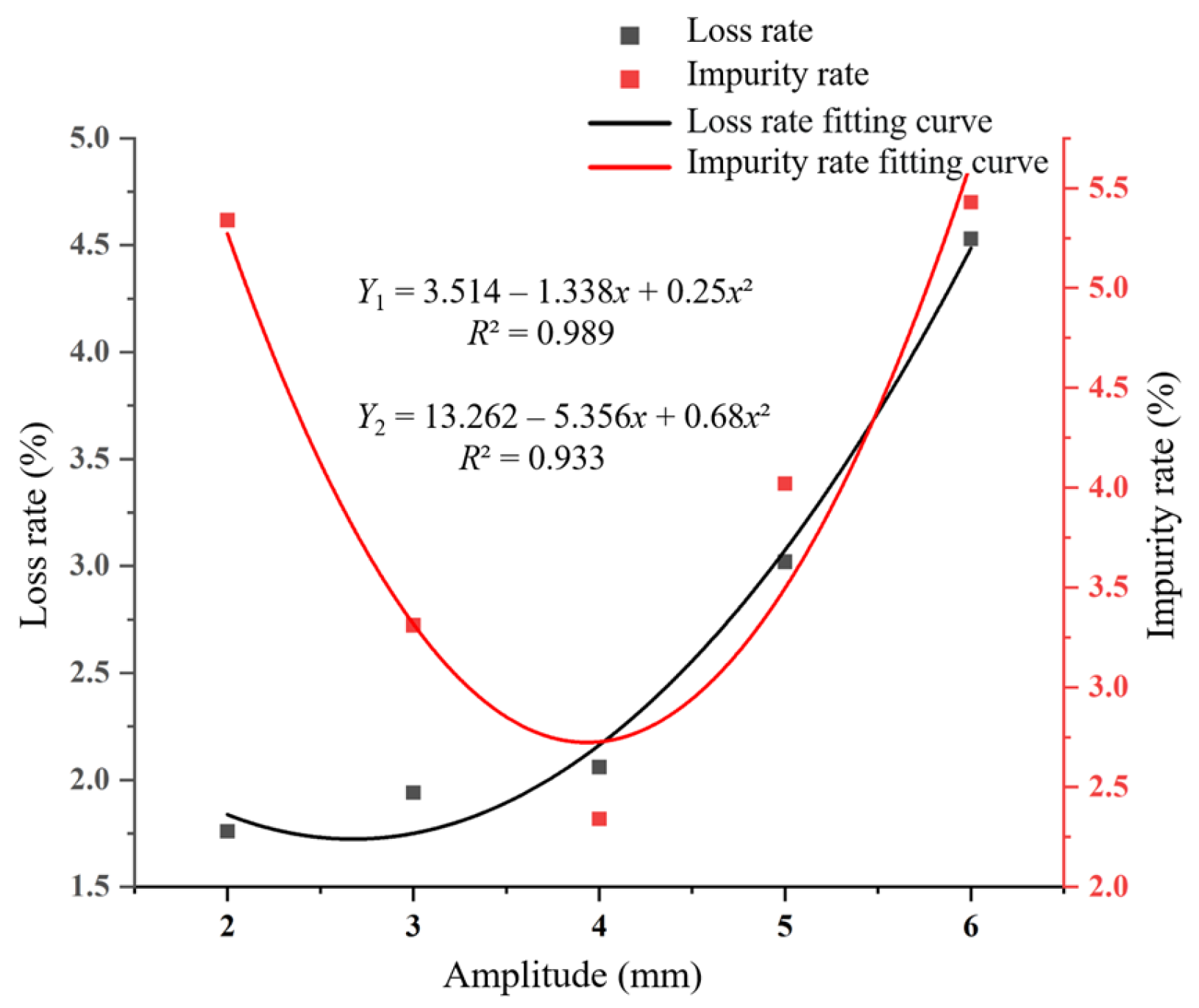

4.3.2. Effect of Amplitude on the Cleaning Performance

4.3.3. Effect of Frequency on the Cleaning Performance

4.4. Analysis of Simulation Results

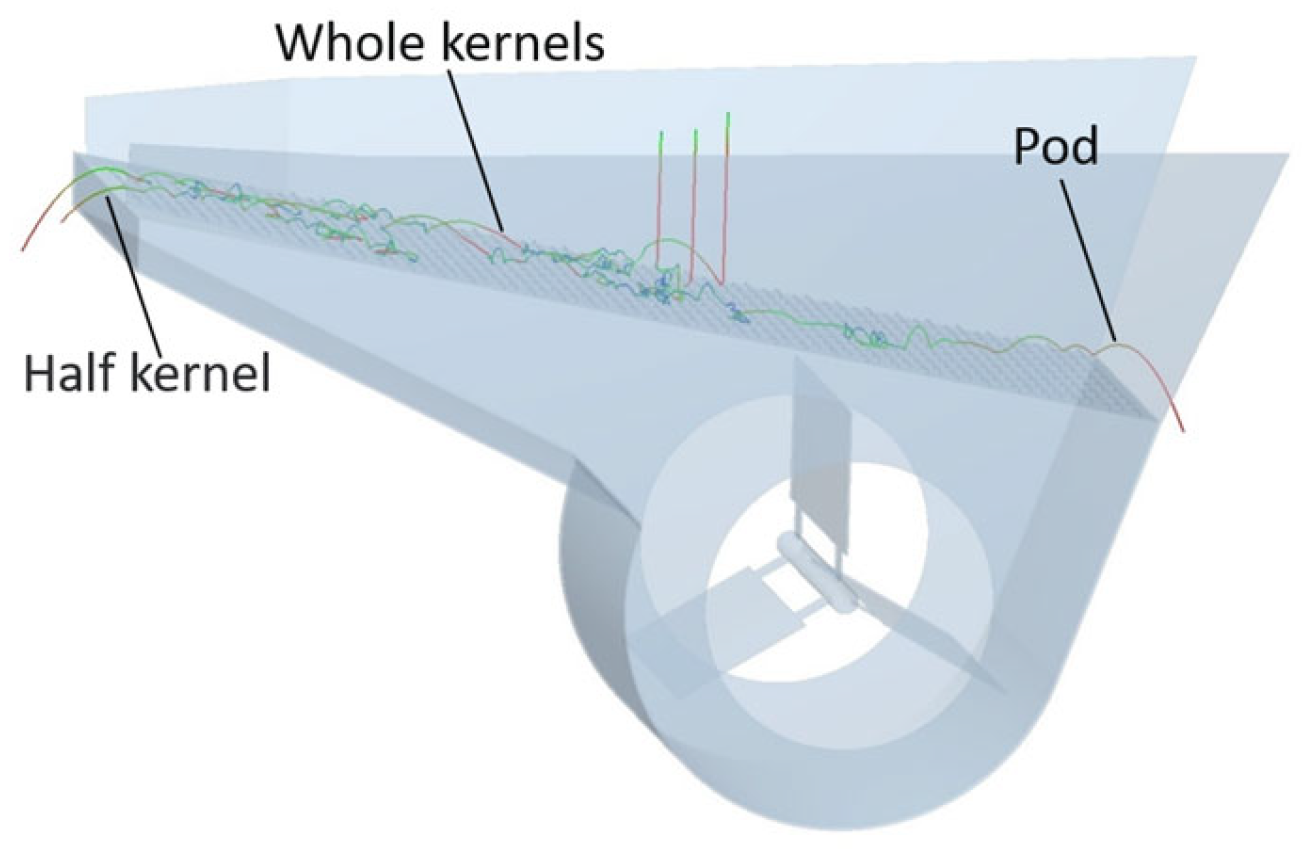

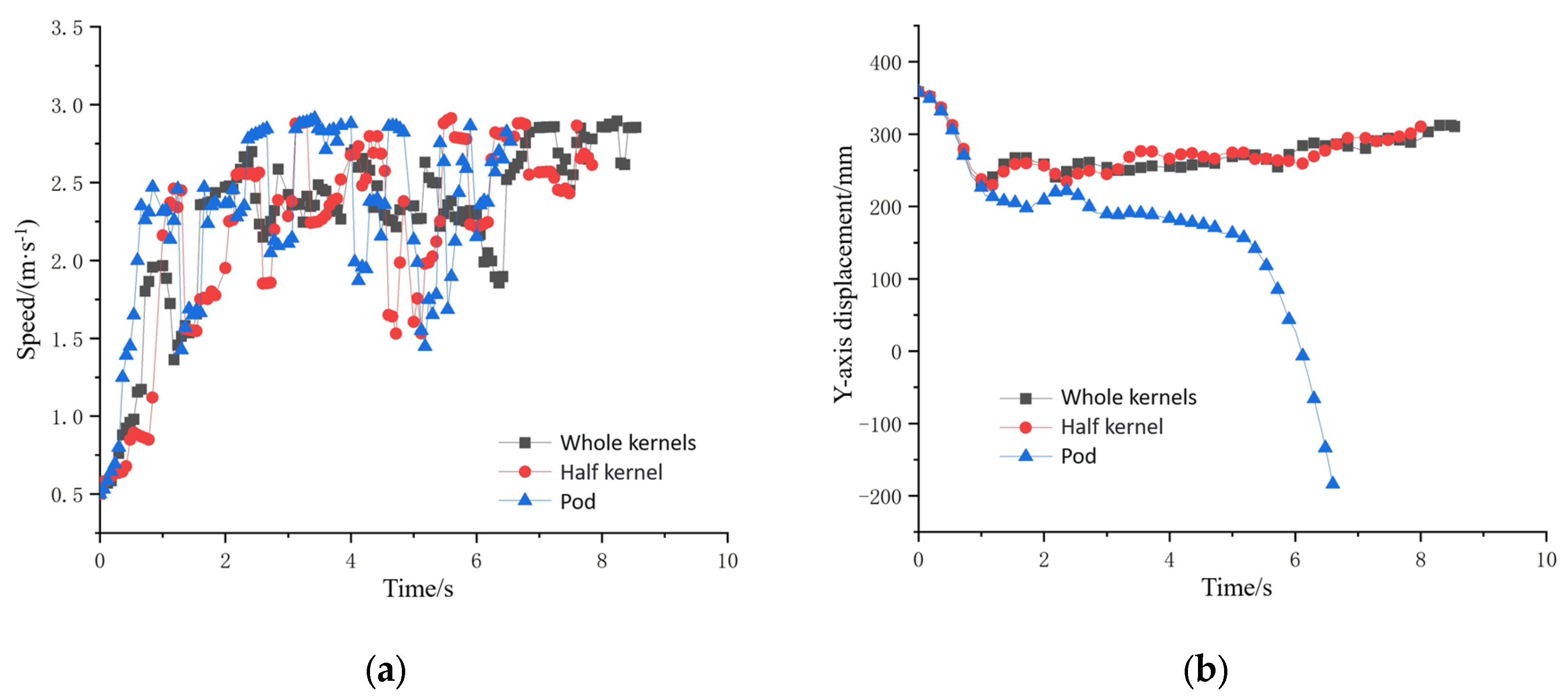

4.4.1. Analysis of the Movement Law of Extrudates

4.4.2. Mechanism of the Motion Separation of Extrudates

4.5. Orthogonal Simulation Test and Analysis of Results

4.5.1. Orthogonal Experimental Design

4.5.2. Regression Models and a Test of Significance

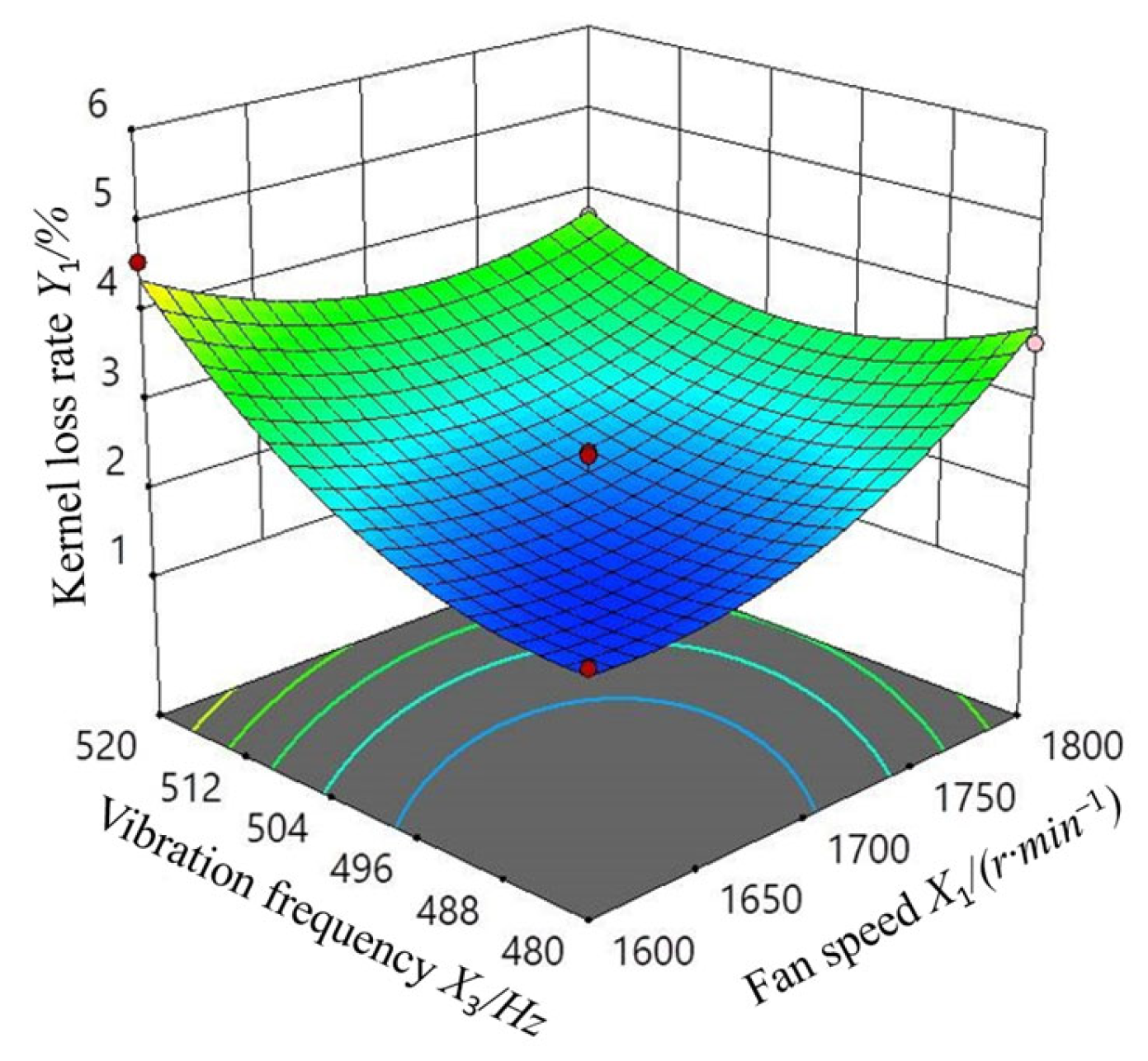

4.5.3. The Effect of the Interaction Factors on Kernel Loss Rates

4.5.4. The Effect of the Interaction Factors on Impurity Rate

4.6. Parameter Optimization

4.7. Validation Experiments

5. Conclusions

- (1)

- Under the working conditions of a fan speed of 1900 r/min, amplitude of 3 mm, and vibration frequency of 520 Hz, the processes of peanut hulling and cleaning were carried out, and the disadvantages of the air–screen cleaning device were found. Through the force analysis of the extrudates, the key parameters that could affect its cleaning performance were obtained.

- (2)

- The improved scheme of optimizing the installation angle of the screen surface of the air–screen cleaning device was proposed, and through a simulation and comparative analysis before and after the structural improvement of the device, the uniformity of the fluid flow in the cleaning chamber was improved after the adjustment of the screen surface angle so that a more reasonable airflow distribution could be achieved.

- (3)

- The CFD–DEM coupling simulation technology was used to explore the movement trajectory, velocity, and displacement of each component of peanut extrudates in the cleaning chamber. In addition, the separation law of extrudates was characterized, and the parameter ranges for each factor were determined via a single-factor simulation experiment.

- (4)

- Based on the central composite Box–Behnken design, an orthogonal simulation optimization for the air–screen cleaning device was carried out, and the obtained optimal parameter combination is as follows: a fan speed of 1682.72 r/min, amplitude of 3.74 mm, and vibration frequency of 492.86 Hz.

- (5)

- Through the hulling and cleaning processes in the machine, the accuracy of the simulation results was verified. Using parameters of a fan speed of 1680 r/min, an amplitude of 3.7 mm and a vibration frequency of 490 Hz, the kernel loss rate and the impurity rate were 2.01% and 2.42%, 3.71 and 4.42 percentage points lower than those before optimization, respectively, which indicated that the cleaning performance of the device was significantly improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, R.; Gao, L.; Chen, C.; Butts, C.L. Characteristics of peanut hulling and processing technology in the United States and inspiration. Trans. Chin. Soc. Agric. Eng. 2019, 35, 287–298. [Google Scholar]

- Li, H.; Wang, Q.; Li, J.; Zhang, Y. Design and experiment of destoned cleaning device of half–fed peanut combine harvester. J. Chin. Agric. Mech. 2021, 42, 29–33. [Google Scholar]

- Liu, D.; Sun, Q.; Liu, L.; Qian, K.; Jin, T.; Wang, D.; Li, X. Simulation analysis and test of air–suction peanut shell kernel cleaning device. J. Jiangsu Agric. Sci. 2022, 50, 162–167. [Google Scholar]

- Li, X.; Sun, Q.; Liu, L.; Liu, D.; Xu, W.; Qian, K.; Chen, K.; Wang, D.; Zhang, C. Design and test of strip–slit peanut kernel grading test bench. J. Shenyang Agric. Univ. 2022, 53, 701–708. [Google Scholar]

- Lu, R.; Gao, L.; Liu, Z.; Yang, D. Development status and prospect of peanut sheller technology in China. J. Shenyang Agric. Univ. 2020, 51, 124–133. [Google Scholar]

- Lu, R.; Liu, Z.; Gao, L.; Yang, D. Development of air suction and cleaning device for peanut sheller in vertical conical community. Trans. Chin. Soc. Agric. Eng. 2020, 36, 23–30. [Google Scholar]

- Wang, J.; Liu, J.; Hu, Z.; Xie, H.; Peng, B.; Yan, J.; Chen, Y. Optimization of key operating parameters of peanut seed belt cleaning equipment. Trans. Chin. Soc. Agric. Eng. 2018, 34, 33–41. [Google Scholar]

- Gao, L.; Hui, Z.; Dong, H.; Xu, Z.; Liu, Z.; Li, H. Design and experiment of peanut sheller for three–roller community breeding. Trans. Chin. Soc. Agric. Mach. 2016, 47, 159–165. [Google Scholar]

- Liu, C.; Wang, S.; Shi, Q.; Geng, L.; Yang, F. Design of test bench of peanut combine harvester cleaning system. J. Agric. Mech. Res. 2018, 40, 91–95. [Google Scholar]

- Guo, Z.; Qiu, Y.; Yan, X.; Wang, J.; Si, S.; Guo, F.; Zhang, F. Research on the Resistance Reduction Law of Self-Excited a Resonant Circular Arc-Surface Bulldozing Plate Based on the Discrete Element Method. Agriculture 2023, 13, 1880. [Google Scholar] [CrossRef]

- Shi, Y.; Xiang, S.; Xu, M.; Huang, D.; Liu, J.; Zhang, X.; Jiang, P. Design and Experimental Study of Ball-Head Cone-Tail Injection Mixer Based on Computational Fluid Dynamics. Agriculture 2023, 13, 1377. [Google Scholar] [CrossRef]

- El-Emam, M.A.; Zhou, L.; Omara, A.I. Predicting the performance of aero-type cyclone separators with different spiral inlets under macroscopic bio-granular flow using CFD–DEM modelling. Bio. Eng. 2023, 233, 125–150. [Google Scholar] [CrossRef]

- Zhang, Z.; Shi, G.; Li, J.; Wang, X.; Ding, L.; Wang, L. Analysis of jujube movement characteristics under positive and negative pressure airflow based on CFD-DEM. Comput. Electron. Agric. 2023, 210, 107902. [Google Scholar]

- Hou, J.; Liu, X.; Zhu, H.; Ma, Z.; Tang, Z.; Yu, Y.; Jin, J.; Wang, W. Design and Motion Process of Air-Sieve Castor Cleaning Device Based on Discrete Element Method. Agriculture 2023, 13, 1130. [Google Scholar] [CrossRef]

- Chen, X.; Hu, G.; Zhao, T.; Li, Z.; Zhou, J. Simulation study on negative pressure winnowing of walnut shell kernel mixture based on CFD–DEM coupling. J. Shandong Agric. Univ. 2021, 52, 1017–1027. [Google Scholar]

- Mu, G.; Lv, H.; Zhang, T.; Zheng, W.; Zhang, W.; Lv, Z. Gas–solid interaction simulation and experimental optimization of throwing device of sweet potato straw recycling machine. Trans. Chin. Soc. Agric. Mach. 2021, 52, 213–222. [Google Scholar]

- Shi, R.; Dai, F.; Zhao, W.; Liu, X.; Wang, T.; Zhao, Y. Simulation optimization and experiment of compound cleaning system of hilly and mountainous flax combine harvester. Trans. Chin. Soc. Agric. Mach. 2022, 53, 93–102. [Google Scholar]

- GB/T 2828.1-2012; Count Sampling Detection Procedure. China Standards Press: Beijing, China. Available online: https://www.doc88.com/p-7985024596928.html/ (accessed on 8 September 2022).

- GB/T 5262-2008; General Provisions for Methods for Determining Test Conditions for Agricultural Machinery. China Standards Press: Beijing, China. Available online: https://www.doc88.com/p-8532978484570.html/ (accessed on 7 September 2022).

- GB/T 5983-2013; Cleaning Machine Test Method. China Standards Press: Beijing, China. Available online: https://www.jianceye.com/biaozhun/gb-t-5983-2013/ (accessed on 8 September 2022).

- GB/T 5982-2017; Thresher Test Method. China Standards Press: Beijing, China. Available online: https://www.doc88.com/p-0963884986579.html (accessed on 7 September 2022).

- Li, H.; Li, Y.; Tang, Z.; Xu, L. Numerical simulation of CFD–DEM of material motion on vibrating screen of air screen cleaning device. Trans. Chin. Soc. Agric. Mach. 2012, 43, 79–84. [Google Scholar]

- Tong, S.; Shen, Q.; Tang, N. Numerical simulation and optimization test of mixed flow field of longitudinal axial flow cleaning device. Trans. Chin. Soc. Agric. Mach. 2016, 47, 135–142. [Google Scholar]

- Wang, J.; Gao, L.; Liu, Z.; Yang, D. Peanut pods mechanical properties research. J. Agric. Mech. Res. 2017, 39, 182–186. [Google Scholar]

- Gao, L.; Zhang, W.; Du, X.; Liu, X.; Yang, J.; Liu, M. Experiment on floating coefficient of outfall from peanut sheller. Trans. Chin. Soc. Agric. Mach. 2012, 28, 289–292. [Google Scholar]

- Gong, F.; Hu, M.; Bao, A.; LI, D.; Gao, T.; Wang, C. Parameter calibration and significance analysis of straw based on Hertz–Mindlin model. J. Xinan Univ. 2022, 44, 186–196. [Google Scholar]

- Lei, X.; Wu, W.; Deng, X.; Li, T.; Liu, H.; Guo, J.; Li, J.; Zhu, P.; Yang, K. Determination of Material and Interaction Properties of Granular Fertilizer Particles Using DEM Simulation and Bench Testing. Agriculture 2023, 13, 1704. [Google Scholar] [CrossRef]

- Qian, Z.; Jin, C.; Yuan, W.; Ni, Y.; Zhang, G. Frictional impact dynamics model of threshing process between flexible teeth and grains. J. Jilin Univ. 2021, 51, 1121–1130. [Google Scholar]

- Wang, B.; Yu, Z.; Hu, Z.; Cao, M.; Zhang, P.; Wang, B. Numerical simulation and experiment of flow field of peanut picking and harvesting machine three–wind system winnowing system. Trans. Chin. Soc. Agric. Mach. 2021, 52, 103–114. [Google Scholar]

- Liao, Q.; Yang, B.; Li, X.; Liao, Y.; Zhang, N. Simulation and test of air chamber flow field of internally inflated blown–type rapeseed precision seeder. Trans. Chin. Soc. Agric. Mach. 2012, 43, 51–54. [Google Scholar]

- Liu, H.; Gong, Y.; Zhang, B.; Chen, Y.; Zhou, M. Design and optimization of working parameters of fry sorter based on EDEM. Trans. Chin. Soc. Agric. Mach. 2020, 51, 114–121. [Google Scholar]

- Yang, M.; Zhang, Y.; Zhang, C.; Gu, F.; Yu, Z.; Hu, Z. Design and experiment of peanut membrane rice separation device combined by kneading and then separating air screen. Trans. Chin. Soc. Agric. Mach. 2020, 51, 112–121. [Google Scholar]

- Lu, R.; Yang, D.; Gao, L.; Liu, Z.; Liu, M.; Shen, Y. Design and experiment of vertical cone Drum Type Peanut sheller. Trans. Chin. Soc. Agric. Mach. 2019, 50, 114–123. [Google Scholar]

- Mao, S.; Zhou, J.; Chen, Y. Experimental Design, 2nd ed.; China Statistics Press: Beijing, China, 2012. [Google Scholar]

- Wang, L.; Feng, X.; Wu, Z. Design and test of stepwise vibrating screen for corn combine harvester. Trans. Chin. Soc. Agric. Mach. 2018, 49, 115–123. [Google Scholar]

- Shi, L.; Hu, Z.; Gu, F. Design and parameter optimization of peanut residual film recycling machine for rake ridge cropping. Trans. Chin. Soc. Agric. Eng. 2017, 33, 8–15. [Google Scholar]

- Zhang, X.; Liu, J.; Shi, Z. Design and parameter optimization of reverse membrane–soil separation device of residual membrane recovery machine. Trans. Chin. Soc. Agric. Eng. 2019, 35, 46–55. [Google Scholar]

- Wang, L.; Ma, Y.; Feng, X.; Song, L.; Chai, J. Design and experiment of sectional vibrating screen cleaning device for maize grain harvester. Trans. Chin. Soc. Agric. Mach. 2020, 51, 89–100. [Google Scholar]

| Parameter | Numeric Value |

|---|---|

| Machine size (length × width × height), mm | 1280 × 650 × 1300 |

| Wind speed at the outlet of the removing impurities fan, m/s | 12 |

| fan speed, r/min | 1900 |

| Number of fan blades, pcs | 3 |

| Engine power, Kw | 1.5 |

| The size of the fish scale sieve (length × width), mm | 800 × 240 |

| The mounting angle of the fish scale sieve, ° | 10 |

| The frequency of the vibrating screen, Hz | 520 |

| The amplitude of the vibrating screen, mm | 3 |

| The mounting angle of the vibrating arm, ° | 30 |

| Test Indicators | Loss Rate (%) | Miscellaneous Content (%) |

|---|---|---|

| The industry standard values | ≤3 | ≤3 |

| Test results | 5.72 | 6.84 |

| Test results after parameter adjustment | 5.18 | 7.95 |

| Project | Pod | Whole Kernel | Half Kernel |

|---|---|---|---|

| Pod | 0.40/0.60 | ||

| Whole kernel | 0.06/0.18 | 0.06/0.42 | |

| Half kernel | 0.06/0.35 | 0.06/0.32 | 0.07/0.40 |

| Model | 0.10/0.40 | 0.03/0.20 | 0.06/0.30 |

| Project | Pod | Whole Kernel | Half Kernel |

|---|---|---|---|

| Pod | 0.26 | ||

| Whole kernel | 0.20 | 0.20 | |

| Half kernel | 0.30 | 0.20 | 0.50 |

| Model | 0.25 | 0.30 | 0.25 |

| Project | Pod | Whole Kernel | Half Kernel | Model |

|---|---|---|---|---|

| Poisson’s ratio | 0.4 | 0.32 | 0.32 | 0.3 |

| Shear modulus | 6.5 × 106 | 5.06 × 107 | 5.06 × 107 | 7.99 × 107 |

| Density/kg·m−3 | 420 | 1030 | 1030 | 7800 |

| Level | Experimental Factors | ||

|---|---|---|---|

| Fan Speed X1/(r min−1) | Amplitude X2/mm | Vibration Frequency X3/Hz | |

| −1 | 1600 | 3 | 480 |

| 0 | 1700 | 4 | 500 |

| 1 | 1800 | 5 | 520 |

| Serial Number | Factor | Loss Rate Y1/% | Impurity Rate Y2/% | ||

|---|---|---|---|---|---|

| X1 | X2 | X3 | |||

| 1 | 0 | 1 | 1 | 4.97 | 4.75 |

| 2 | 0 | 0 | 0 | 2.39 | 1.79 |

| 3 | 1 | −1 | 0 | 3.03 | 3.76 |

| 4 | 0 | 0 | 0 | 2.12 | 2.03 |

| 5 | −1 | 0 | 1 | 4.56 | 4.64 |

| 6 | −1 | 1 | 0 | 4.47 | 3.84 |

| 7 | 0 | −1 | 1 | 3.39 | 4.66 |

| 8 | 0 | 0 | 0 | 2.43 | 1.98 |

| 9 | 0 | 1 | −1 | 4.34 | 3.75 |

| 10 | 0 | 0 | 0 | 2.03 | 2.00 |

| 11 | 1 | 1 | 0 | 5.02 | 4.93 |

| 12 | 0 | −1 | −1 | 1.91 | 3.11 |

| 13 | 1 | 0 | 1 | 3.69 | 4.57 |

| 14 | 1 | 0 | −1 | 3.66 | 4.18 |

| 15 | −1 | −1 | 0 | 1.75 | 4.07 |

| 16 | 0 | 0 | 0 | 2.06 | 2.02 |

| 17 | −1 | 0 | −1 | 2.00 | 3.17 |

| Serial Number | Loss Rate (%) | Impurity Rate (%) |

|---|---|---|

| 1 | 2.14 | 2.45 |

| 2 | 1.97 | 2.29 |

| 3 | 2.10 | 2.41 |

| 4 | 1.89 | 2.57 |

| 5 | 1.95 | 2.38 |

| Average value | 2.01 | 2.42 |

| Original value | 5.72 | 6.84 |

| The industry standard values | ≤3 | ≤3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Yu, Y.; Wang, J.; Kang, Z.; He, F.; Gao, L. Numerical Simulation and Optimization of Peanut Sheller Air–Screen Cleaning Device. Agriculture 2023, 13, 1997. https://doi.org/10.3390/agriculture13101997

Liu Z, Yu Y, Wang J, Kang Z, He F, Gao L. Numerical Simulation and Optimization of Peanut Sheller Air–Screen Cleaning Device. Agriculture. 2023; 13(10):1997. https://doi.org/10.3390/agriculture13101997

Chicago/Turabian StyleLiu, Zhixia, Yongqiang Yu, Jing Wang, Zhiwei Kang, Fengyu He, and Lianxing Gao. 2023. "Numerical Simulation and Optimization of Peanut Sheller Air–Screen Cleaning Device" Agriculture 13, no. 10: 1997. https://doi.org/10.3390/agriculture13101997

APA StyleLiu, Z., Yu, Y., Wang, J., Kang, Z., He, F., & Gao, L. (2023). Numerical Simulation and Optimization of Peanut Sheller Air–Screen Cleaning Device. Agriculture, 13(10), 1997. https://doi.org/10.3390/agriculture13101997