Abstract

Because of the continuous improvement of technology, mechanization has emerged in various fields. Due to the different suitable seasons for the growth of agricultural plants, agricultural mechanization faces problems different from other industries. That is, agricultural machinery and equipment may be used frequently for a period of time, or may be idle for a long time. This leads to the aging of equipment no longer becoming regular, the maintenance time of spare parts is not fixed, the number of spare parts stored in the spare parts warehouse cannot be too large to occupy funds, and the number cannot be too small to meet the maintenance needs, so the prediction of agricultural machinery spare parts has become particularly important. Due to the lack of information, the difficulty of labeling, and the imbalance of positive and negative sample classification, this paper used a semi-supervised learning algorithm to solve the problem of agricultural machinery spare parts data classification. In order to forecast the demand for spare parts of agricultural machinery, this paper compared the IPSO-BP neural network algorithm and BP neural network algorithm. It was found that the IPSO-BP neural network was used to forecast the demand for spare parts of agricultural machinery, and the error between the predicted value and the actual value was small and met the accuracy requirements.

1. Introduction

Timely maintenance of agricultural machinery is significant, which provides strong guarantees for farmers’ crop harvesting and brings more economic benefits to the owners. During harvest, sufficient spare parts must be available to achieve high-efficiency agricultural equipment maintenance [1,2,3,4]. Accurate information on the demand for spare parts can help suppliers prepare the right number of spare parts, thus the labor cost and inventory costs can be reduced. Therefore, it is necessary to predict the need for spare parts of key components. There are three steps for predicting the number of agricultural machinery spare parts: data preprocessing, intelligent classification of spare parts, and prediction of the number of spare parts. Most existing classification algorithms that are obtained through minimizing prediction losses are supervised algorithms, which means that the more labeled the sample, the higher the prediction accuracy [5,6,7,8,9]. However, due to the difficulty of acquiring a sufficient label sample of agricultural machinery spare parts, the semi-supervision learning algorithm is widely used [10,11,12]. However, the existing research has not applied semi-supervised learning to the classification of spare parts of agricultural machinery. Semi-supervised learning is a learning algorithm between supervised learning and unsupervised learning, it needs a large number of unlabeled samples and a small number of labeled samples [13,14,15]. There are three types of methods for predicting the demand number of agricultural machinery spare parts: artificial intelligence-based prediction, prediction based on reliability, and time sequence-based prediction. Most pieces of agricultural machinery only have an intense working time of two or three months a year. It is difficult to forecast the repair time by dealing with the distribution of operating life because the working span of agricultural machinery is short, but the idle time is long. In addition, due to harsh working conditions and inappropriate maintenance, mechanical parts are prone to burst failures. Both of the above situations will damage the life of agricultural machinery. Therefore, the second method of reliability-based prediction is not feasible. At present, the prediction of time sequence models that mainly use the linear predictions function is more popular. However, the demand for spare parts is the result of multiple factors, and requires a multivariable nonlinear function to fit. Artificial neural networks, which have significant advantages in extraction and approaching of functions, are popular on their ability for self-organization, adaptive and self-learning, high error-tolerant rate, and great robustness [16,17,18,19,20]. The BP neural network is currently the most popular and best for agriculture in neural network models [21]. The staff at a warehouse of agricultural machinery spare parts will record a series of spare parts consumption data. The consumption data, which affect the need for spare parts during the sales and maintenance of agricultural machinery, can provide reliable data sources for the prediction of the BP neural network [22,23,24]. However, in the existing research, the accuracy of using the BP neural network to predict agricultural machinery spare parts is not high enough, and it is easy to fall into premature and overfitting. The improved particle swarm optimization (PSO) algorithm based on the BP neural network can overcome the neural network’s shortcoming of being easy to fall into premature and overfitting. First, the non-inertial weight coefficient and particle selection mutation strategy is applied to improve the PSO algorithm, and then the improved PSO algorithm is used to optimize the initial weights and thresholds of the BP neural network. Thus, the problem of BP neural network weights that are easy to fall into local minimum can be solved [25,26,27,28].

Therefore, because this study combined the characteristics of information in agriculture machinery spare parts and agricultural machinery maintenance, semi-supervised learning methods were selected to solve the problem of the data classification of agricultural machinery spare parts. In order to solve the problem that the prediction accuracy of agricultural machinery spare parts in existing research is not high enough, and it is easy to fall into the shortcomings of prediction and overfitting, the IPSO-BP neural network was used to predict the demand for agricultural machinery spare parts.

2. Materials and Methods

2.1. The Overall Design of the Demand for Spare Parts

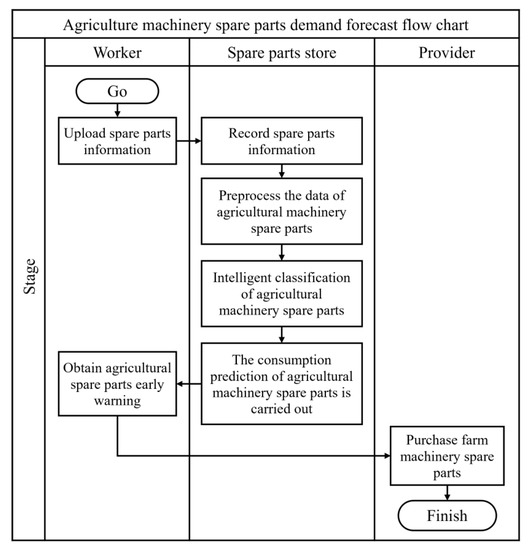

A total of five parts comprise the flow path for demand prediction: obtaining the spare parts information, analysis of factors affecting spare parts, training the semi-supervised learning, predicting the demand for spare parts, and reminding the spare parts center. First, the information on spare parts was uploaded to the system database by the workers at the spare parts center. Then, the factors for the impact on the spare parts information will be analyzed and sent to the semi-supervised learning models for training to work out the demand for spare parts. Finally, the information about the spare parts with high demand and less inventory will be sent to the client of the spare parts center to remind the staff to order or allocate the parts. The prediction flowchart of the specific agricultural machine spare parts is shown in Figure 1.

Figure 1.

Agricultural machine spare parts demand prediction flowchart.

The use of semi-supervised learning technology and combining the main features of agricultural machinery spare parts data to build prediction models can predict and optimize the demand for agricultural machinery spare parts and realize reasonable reserves of spare parts. The logic architecture of the spare parts demands prediction model can be divided into three steps: data preprocessing, intelligent classification of agricultural machinery spare parts, and the consumption prediction of agricultural machinery spare parts. First, data preprocessing can be realized according to the steps of data cleaning, data exchange, and data reduction, so that the problems of data deficiency, data abnormalities, and excessive data dimension can be solved. Simultaneously, it provides the foundation for the construction and verification of the demand for agricultural machinery spare parts. Second, the semi-supervised learning model will be used to classify and analyze the characteristics of agricultural machinery spare parts, and supply preparation for the prediction of the consumption of spare parts. Finally, the corresponding prediction strategies will be mapped on account of the results of the classification, and the BP neural networks, which can improve the prediction accuracy and stability, will be used for the consumption prediction of agricultural machinery spare parts.

2.2. Intelligent Classification Algorithm Based on Semi-Supervision

The first step is to classify the types of agricultural machinery spare parts because different spare parts have a different demand. The artificial classification of spare parts is a heavy workload and is vulnerable to subjective factors, so the results of classification are inaccurate. There are problems with the data classification tasks of spare parts such as (1) there is a lot of sample data but there is less labeled samples; (2) the proportion of positive and negative samples of the labeled data has a large gap; and (3) the task of labeling the sample data is difficult. In this paper, a classification algorithm based on semi-supervised learning was proposed that mainly surrounded the samples in the minority categories of the target data. A set of unlabeled data around the minority positive sample of each minority category is:

Then, the clustering algorithm was used for all the data in D of a sample with no labels. The main purpose of this algorithm is to solve the problem that the classifier overfits the large proportion of data during the process of training, which is aimed at the character of the large gap in the proportion of sample data in the target data. The credible positive aggregate is P’, which is the most similar category aggregate with the positive labeled aggregate P in D, and was used to expand the positive sample to relieve the uneven distribution of samples in the data. Finally, the classification can be acquired by training the model with expanded data.

2.3. Similarity Expansion of the Positive Set Based on the K-MEANS Clustering

Many reasons affect the demand for agricultural machinery spare parts such as season, past demand, geographical environment, etc. The demand information of spare parts warehouses that have closer locations most possibly have the same category label because the location of the warehouse is closer, the seasons are more similar, and the number of agriculture machinery in this location is more equal. In conclusion, it conveniently classifies the spare parts of agriculture machinery that clusters unlabeled spare parts data according to the distance of the warehouse with the spare parts.

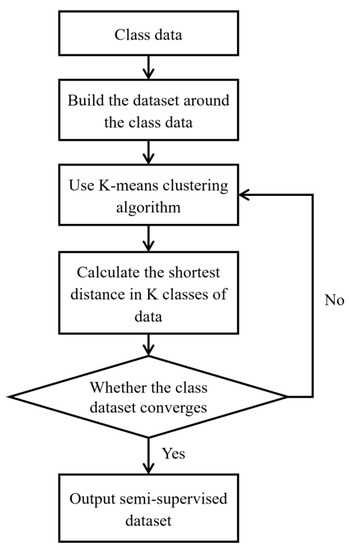

The K-MEANS cluster algorithm was used to cluster the unlabeled data of credible positive data P, relying on the cluster assumptions and smooth assumptions of the semi-supervision learning. The cluster assumption refers to the data belonging to the same cluster data with the same class labels. The smooth assumption refers to the data obtained at near spare parts warehouses having the same category label in high probability. By setting up a set of increasing K values, as the K value increases, the category obtained by the K-MEANS cluster is gradually meticulous. When the distance between the K category and the labeled data P starts to converge, it is time to stop the increase of K, and the corresponding categories are a credible positive set. Figure 2 shows the specific process of data expansion based on semi supervised learning.

Figure 2.

Flowchart of the date expansion based on semi-supervised learning.

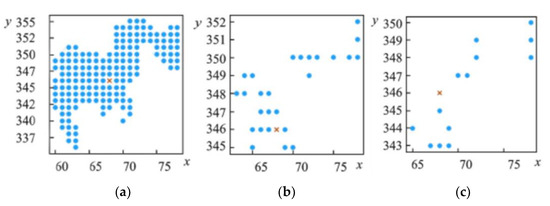

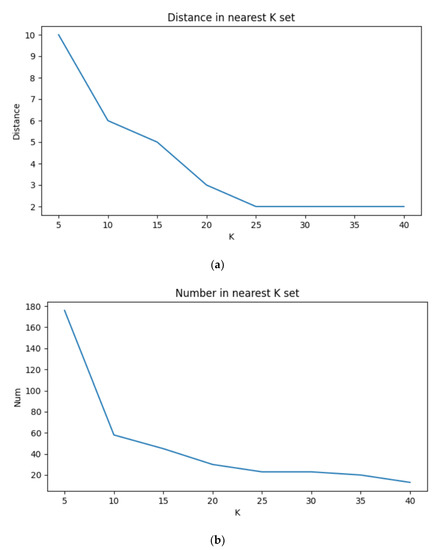

Figure 3 shows the recent K-MEANS clustering data distribution around a certain spare parts warehouse. In the diagram, K represents the value of K in the K-MEANS cluster algorithm, NUM represents the number of data in a set having the nearest spare parts warehouses as a result of K-MEANS clustering, and D represents the average distance from the spare parts warehouse in the set. The distance and the number of credible samples from the K cluster, which is the nearest to the spare parts warehouse, change with the value of K in K-MEANS. Figure 4 shows the number and distance of K clusters closest to the warehouse as a function of K value.

Figure 3.

The K-MEANS cluster change diagram of credible data P. (a) K = 5, Num = 175, d = 10; (b) K = 20, Num = 26, d = 3; (c) K = 40, Num = 13, d = 2.

Figure 4.

The variation diagram of the distance and number of K clustering. (a) Curve of the distance of the nearest K cluster to the warehouse as a function of K value; (b) Curve of the number of K-clusters nearest to the warehouse changing with K-value.

When the value of K increases, the number and distance decrease and converge, as shown in Figure 4.

2.4. Prediction Algorithm of Spare Parts Consumption Based on BP Neural Network

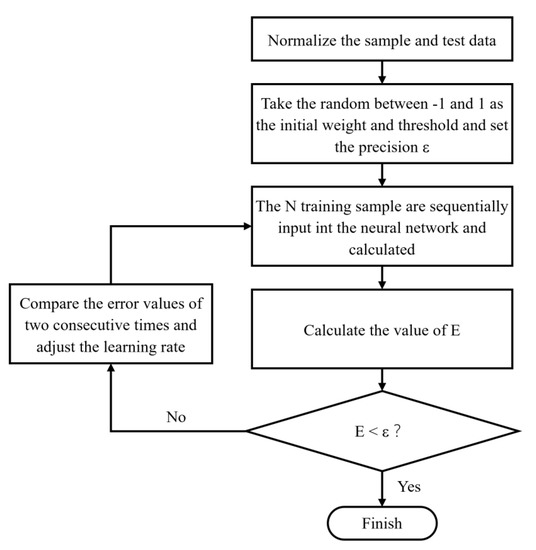

The neural network is a complex network system composed of a large number of simple neurons. It has a strong simulation ability for non-linear systems. The BP neural network is currently the most widely used network algorithm. The learning process of the BP neural network is composed of two processes including forward propagation and the backpropagation of information. The three-layer front-to-BP neural network can approach any nonlinear function of arbitrary accuracy and it only needs to establish a network relationship between the input and output to simulate and predict. Therefore, it is very effective to predict the demand for agricultural machinery spare parts with BP neural networks. The algorithm training steps are as follows:

(1) Normalization of sample data and test data.

(2) The random number, which is greater than −1 and less than 1, is used as the initial power and threshold and given precision ε and ε > 0.

(3) Input N training samples into the neural network in order and calculate.

(4) Calculate the value of E, if E < ε, it stops training, otherwise it will continue.

(5) Compare the error value of two consecutive times and adjust the learning rate.

(6) Repeat step 3 to step 5 until the error is within the predetermined accuracy.

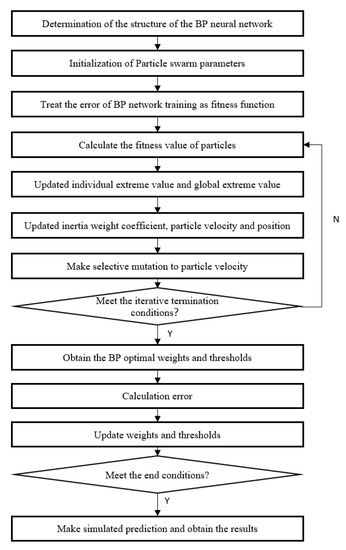

Figure 5 shows the algorithm flow of spare parts consumption prediction based on BP neural network. The convergence performance and the final stable state can be affected directly and fall into the local minimum easily; for this reason, the initial connection weights and thresholds of the traditional BP algorithm were set randomly. Updating the connection weights and threshold is the main duty in the learning process, but the traditional BP network tries to find the appropriate value through continuous training. The ideal result cannot be obtained under excessive training or a lack of training, and more unexpected phenomena such as overfitting can also be caused, which affects the network’s generalization ability. To overcome these weaknesses, this paper planned the IPSO algorithm to optimize the connection weight and threshold of BP neural network. Thus, the global optimization ability of PSO and local search of the BP algorithm can be fully used to overcome the problem of the BP neural network’s random assigning weights, and improve the generalization ability of the BP neural network as well as the learning ability of the neural network. The flowchart of a new BP neural network algorithm optimized by IPSO is shown in Figure 6.

Figure 5.

Prediction algorithm map of the spare parts consumption based on the BP neural network.

Figure 6.

Prediction algorithm map of spare parts consumption based on the IPSO-BP neural network.

The demand for agricultural machinery spare parts is affected by various factors such as seasons, past needs, working time of parts, parts prices, and the number of agricultural machinery in the region. Generally speaking, the spare parts of agricultural machinery in the area near the spare parts warehouse have stable working times and prices, so the recent needs, season, and the number of agricultural machinery in the region were chosen as the input of the BP neural network to normalize. Then, the normalized input and output were divided into training samples and test samples in a ratio of 8:2. First, the training sample was used for the training of the network. When the training times achieved the maximum training times or the training goal that had been set in advance, the network stopped training. The test sample was sent to the training goal for prediction, and the error of the prediction results was calculated by comparing and analyzing the results and reality.

3. Results and Discussion

The dataset required for the experiment was obtained through field investigation of spare parts warehouses in several provinces and the inquiry of the spare parts warehouse staff. The experimental data containing 1869 pieces of data were collected from a total of seventy spare parts warehouses in Henan Province, Anhui Province, Shandong Province, Zhejiang Province, Hubei Province, and Sichuan Province, respectively. The experimental data included the name of the spare parts, the cost of the maintenance materials, the urgency of maintenance, the number of suppliers, and the annual usage of maintenance. In this paper, the blockage sensor of rice machines in 17 spare parts centers in Shandong Province was selected as an example for experimental verification. Among them, there were only 120 credible positive data constructed based on the expansion method mentioned earlier in Section 3.1. and 300 labeled data. Enter the name of spare parts, cost of repair materials, urgency of maintenance, number of suppliers, and annual repair usage as parameters to predict the quantity of spare parts needed in the near future.

3.1. Performance Evaluation of Classification Algorithm Based on Semi-Supervised Learning

In the process of the experiment, 80% of the labeled dataset was the training dataset and the other 20% of the labeled dataset was as the test dataset. At the same time, credible positive data was added to the training dataset to construct the semi-supervised training dataset. The training dataset and semi-supervised training dataset were used for simulation training to obtain ordinary classifiers and semi-supervised classifiers. Then the experimental result was obtained by comparing the training dataset and the result of the classifier on the training dataset. The F1 score was as a classification indicator to determine the effectiveness of the classifier, and the F1 calculation formula is as follows:

where P is the predicted value, and R is the actual value. The result of the calculation is shown in Table 1. The accuracy of the traditional method was higher than the semi-supervised method, but the recall rate and value of F1 were zero. This means that the classifier training by the traditional method overfit the majority of dataset categories, and the classifier had no ability of classifying minority categories. However, the minority categories are also important in the classification of agricultural machinery spare parts and the semi-supervised learning method can classify the minority categories, so the semi-supervised learning method was used for classification in this paper.

Table 1.

Comparison between the traditional method and the semi-supervised method.

3.2. Performance Evaluation of Prediction Algorithm Based on IPS0-BP Neural Network

All data were divided independently into two part: the training set and the test set. The training dataset served to evaluate the model and determine the approximate range of layers and nodes of the network. The test dataset was used to verify the performance of the final selected model. This experiment selected the spare parts information of the blocking sensor of a rice machine from 2019–2021 in Shandong Province as the training dataset, the information of the blocking sensor of a rice machine from 2022 in Shandong Province as test dataset, and the IPSO-BP neural network as the prediction algorithm.

The related parameters in the IPSO-BP neural network are as follows: the input layer has five nodes, the implicit layer has 10 nodes, and the output layer has a node. The noninput layer and the output layer are implicit layers. The calculation formula of the nodes of the implicit layer is as follows:

where N is the number of nodes in the input layer; K is the number of nodes in the output layer; α is a number greater than 0 but less than 10; M is the number of nodes in the implicit layer. In the prediction, N = 5, K = 1, the maximum training is 1000 times, the maximum number of cycle intervals is 50, and the training convergence error is 0.001. Table 2 shows the prediction value of the IPSO-BP neural network.

Table 2.

IPSO-BP neural network training table.

Table 2 shows that the relative errors of IPSO-BP neural network prediction values are less than 0.5. The data were trained with the neural network and the training results were compared with IPSO-BP neural network. Table 3 shows the comparison between the IPSO-BP neural network and the BP neural network.

Table 3.

Comparison between the IPSO-BP neural network and the BP neural network.

Table 3 shows that the relative error and absolute error of IPSO-BP neural network prediction value are smaller than those of BP neural network prediction value. It can be seen that the relative error and absolute error between the prediction value and actual value were small, and the prediction accuracy of demand for agricultural machinery spare parts had been improved. Therefore, IPSO-BP is more stable and accurate than the BP neural network.

4. Conclusions

This article proposed a classification algorithm for agricultural machinery spare parts based on semi-supervised learning. The K-MEANS cluster algorithm was used to construct a batch of credible positive and semi-supervised data around the similarity of the data of the minority categories. The result shows that the algorithm was significantly better than the traditional method in the recall rate and F1 value. In this paper, the IPSO-BP neural network was the algorithm for predicting the demand for agricultural machinery spare parts, and the results showed that the relative error between the prediction value and actual value was less than 0.45.

The proposed prediction method is in line with actual situation. It basically meets the demand for the prediction of agricultural machinery spare parts, and has great potential in the management of agricultural machinery spare parts. In addition, we will continue to improve the system in the future.

Author Contributions

Conceptualization, C.Q. and B.Z.; data curation, C.Q. and S.L.; formal analysis, C.Q. and W.Z.; funding acquisition, L.Z.; investigation, Y.L.; methodology, C.Q. and R.G.; project administration, C.Q. and L.Z.; resources, S.L.; software, C.Q. and R.G.; supervision, W.Z. and B.Z.; visualization, C.Q. and Y.L.; writing—original draft, C.Q. and B.Z.; Writing—review & editing, C.Q. and B.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Guimaraes, C.B.; Marques, J.M.; Tortato, U. Demand forecasting for high-turnover spare parts in agricultural and construction machines: A case study. South Afr. J. Ind. Eng. 2020, 31, 116–128. [Google Scholar] [CrossRef]

- Haffar, I. “SPAM”: A computer model for management of spare-parts inventories in agricultural machinery dealerships. Comput. Electron. Agric. 1995, 12, 323–332. [Google Scholar] [CrossRef]

- Hu, Y.G.; Sun, S.; Wen, J.Q. Agricultural Machinery Spare Parts Demand Forecast Based on BP Neural Network. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Hangzhou, China, 2014; Volume 3485, pp. 635–637. [Google Scholar]

- Łukaszewski, K.; Buchwald, T.; Wichniarek, R. The FDM Technique in Processes of Prototyping Spare Parts for Servicing and Repairing Agricultural Machines: A General Outline. Int. J. Appl. Mech. Eng. 2021, 26, 145–155. [Google Scholar] [CrossRef]

- Ziouzios, D.; Baras, N.; Balafas, V.; Dasygenis, M.; Stimoniaris, A. Intelligent and Real-Time Detection and Classification Algorithm for Recycled Materials Using Convolutional Neural Networks. Recycling 2022, 7, 9. [Google Scholar] [CrossRef]

- Yang, H.; Li, X.; Liu, Z.; Wang, L.; Luo, Q. Trajectory time series classification algorithm based on convolutional self-attention mechanism. J. Phys. Conf. Ser. 2021, 1961, 012037. [Google Scholar] [CrossRef]

- Tsai, P.F.; Wang, C.H.; Zhou, Y.; Ren, J.; Jones, A.; Watts, S.O.; Chou, C.; Ku, W.S. A classification algorithm to predict chronic pain using both regression and machine learning—A stepwise approach. Appl. Nurs. Res. 2021, 62, 151504. [Google Scholar] [CrossRef]

- Sun, G.; Wang, Z.; Ding, Z.; Zhao, J. An Ensemble Classification Algorithm for Short Text Data Stream with Concept Drifts. IAENG Int. J. Comput. Sci. 2021, 48, 4. [Google Scholar]

- Chen, Z.; Chen, Y.; Xiao, T.; Wang, H.; Hou, P. A novel short-term load forecasting framework based on time-series clustering and early classification algorithm. Energy Build. 2021, 251, 111375. [Google Scholar] [CrossRef]

- Fu, Y.; Yan, M.; Zhang, X.; Xu, L.; Yang, D.; Kymer, J.D. Automated classification of software change messages by semi-supervised Latent Dirichlet Allocation. Inf. Softw. Technol. 2015, 57, 369–377. [Google Scholar] [CrossRef]

- Pang, T.; Wong, J.H.D.; Ng, W.L.; Chan, C.S. Semi-supervised GAN-based Radiomics Model for Data Augmentation in Breast Ultrasound Mass Classification. Comput. Methods Programs Biomed. 2021, 203, 106018. [Google Scholar] [CrossRef]

- Xing, X.; Yu, Y.; Jiang, H.; Du, S. A multi-manifold semi-supervised Gaussian mixture model for pattern classification. Pattern Recognit. Lett. 2013, 34, 2118–2125. [Google Scholar] [CrossRef]

- Piroonsup, N.; Sinthupinyo, S. Semi-supervised cluster-and-label with feature based re-clustering to reduce noise in Thai document images. Knowl.-Based Syst. 2015, 90, 58–69. [Google Scholar] [CrossRef]

- Jing-Yu, C.; Ya-Jun, W. Semi-Supervised Fake Reviews Detection based on AspamGAN. J. Artif. Intell. 2022, 4, 17–36. [Google Scholar] [CrossRef]

- Hore, U.W.; Wakde, D.G. An Effective Approach of IIoT for Anomaly Detection Using Unsupervised Machine Learning Approach. J. IoT Soc. Mob. Anal. Cloud 2022, 4, 184–197. [Google Scholar]

- Lutkoski, S. Neural Network Numerosity. Am. Sci. 2019, 107, 207. [Google Scholar]

- Ding, S.; Su, C.; Yu, J. An optimizing BP neural network algorithm based on genetic algorithm. Artif. Intell. Rev. 2011, 36, 153–162. [Google Scholar] [CrossRef]

- Li, G.; Deng, L.; Chua, Y.; Li, P.; Neftci, E.O.; Li, H. Editorial: Spiking Neural Network Learning, Benchmarking, Programming and Executing. Front. Neurosci. 2020, 14, 276. [Google Scholar] [CrossRef]

- Han, J.-B.; Kim, S.-H.; Jang, M.-H.; Ri, K.S. Using Genetic Algorithm and NARX Neural Network to Forecast Daily Bitcoin Price. Comput. Econ. 2019, 2, 337–353. [Google Scholar] [CrossRef]

- Jain, A.K.; Goel, D.; Agarwal, S.; Singh, Y.; Bajaj, G. Predicting Spam Messages Using Back Propagation Neural Network. Wirel. Pers. Commun. 2020, 110, 403–422. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, Y.; Wang, C. Evaluation of borrower’s credit of P2P loan based on adaptive particle swarm optimisation BP neural network. Int. J. Comput. Sci. Eng. 2019, 19, 197–205. [Google Scholar] [CrossRef]

- Hong, Y.; Liao, H.; Jiang, Y. Construction Engineering Cost Evaluation Model and Application Based on RS-IPSO-BP Neural Network. J. Comput. 2014, 9, 1020–1025. [Google Scholar] [CrossRef]

- Jiang, J. BP Neural Network Algorithm Optimized by Genetic Algorithm and Its Simulation. Int. J. Comput. Sci. Issues 2013, 10, 516–519. [Google Scholar]

- Liu, K. The Prediction Model and System of Stock Rise and Fall Based on BP Neural Network. Acad. J. Bus. Manag. 2022, 4, 67–72. [Google Scholar]

- Kanungo, D.P.; Naik, B.; Nayak, J.; Baboo, S.; Behera, H.S. An Improved Pso Based Back Propagation Learning-MLP (IPSO-BP-MLP) for Classification. In Computational Intelligence in Data Mining-Volume 1; Springer: Berlin/Heidelberg, Germany, 2015; pp. 333–344. [Google Scholar]

- Li, S.; Quan, Y. Financial risk prediction for listed companies using IPSO-BP neural network. Int. J. Perform. Eng. 2019, 15, 1209. [Google Scholar] [CrossRef]

- Wen, L.; Liu, Y. A research about Beijing’s carbon emissions based on the IPSO-BP model. Environ. Prog. Sustain. Energy 2017, 36, 428–434. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, B.; Zhao, Y.; Pan, G. Wind Speed Prediction of IPSO-BP Neural Network Based on Lorenz Disturbance; IEEE Access: Piscataway, NJ, USA, 2018; Volume 6. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).