Design and Test of Stripping and Impurity Removal Device for Spring-Tooth Residual Plastic Film Collector

Abstract

:1. Introduction

2. Materials and Methods

2.1. Structure and Working Principles

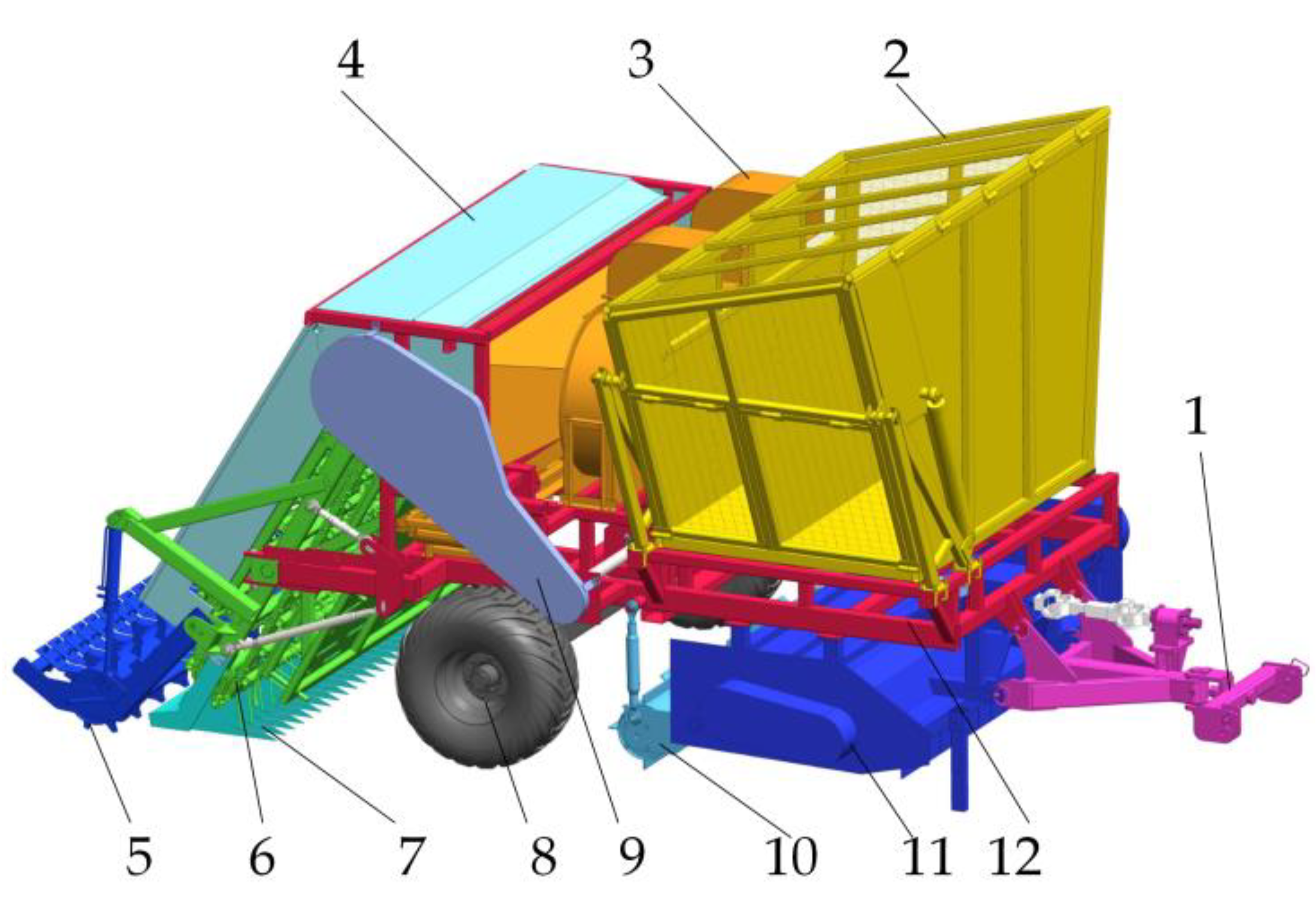

2.1.1. Machine Structure and Working Principle of the SRPFC

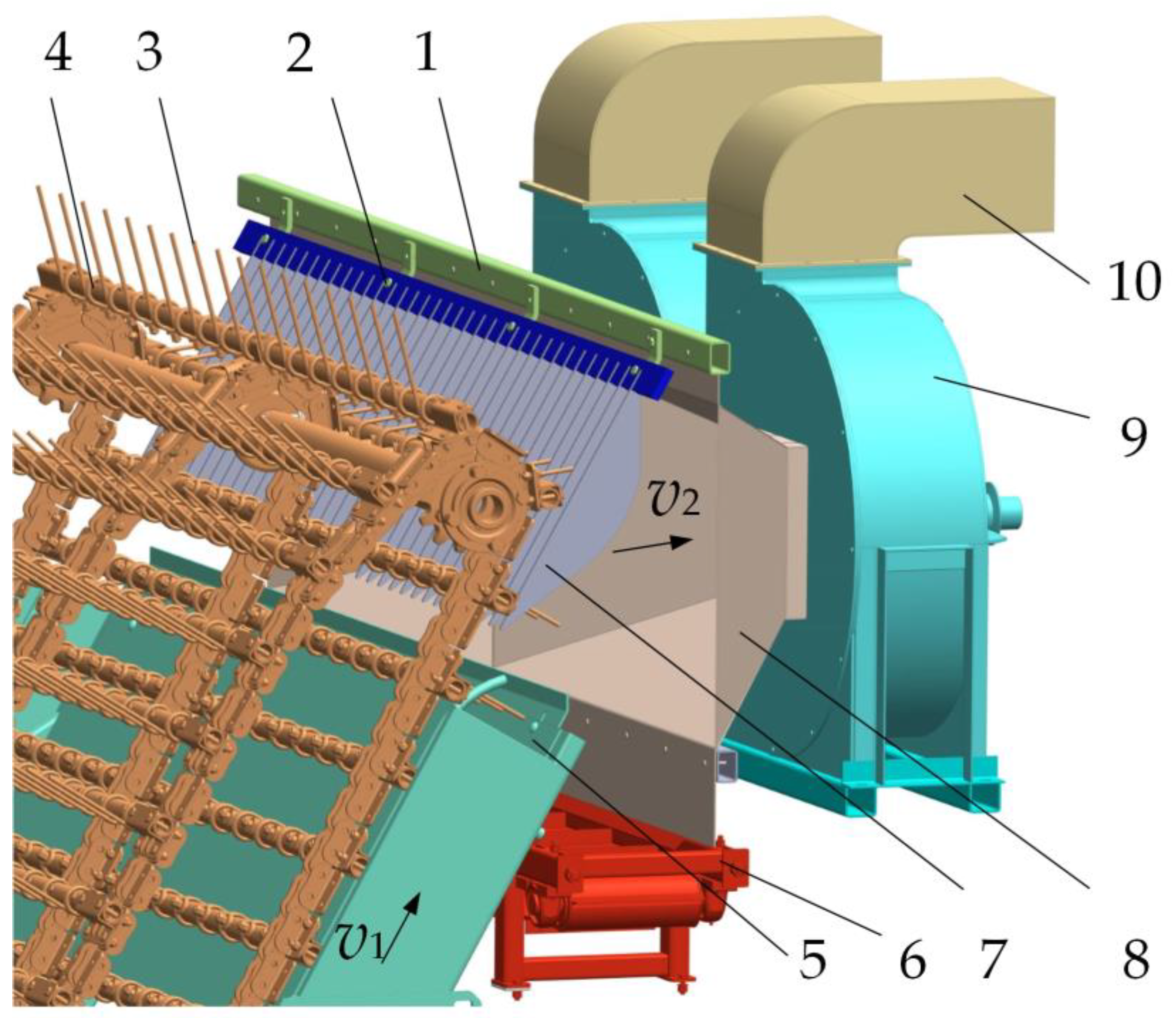

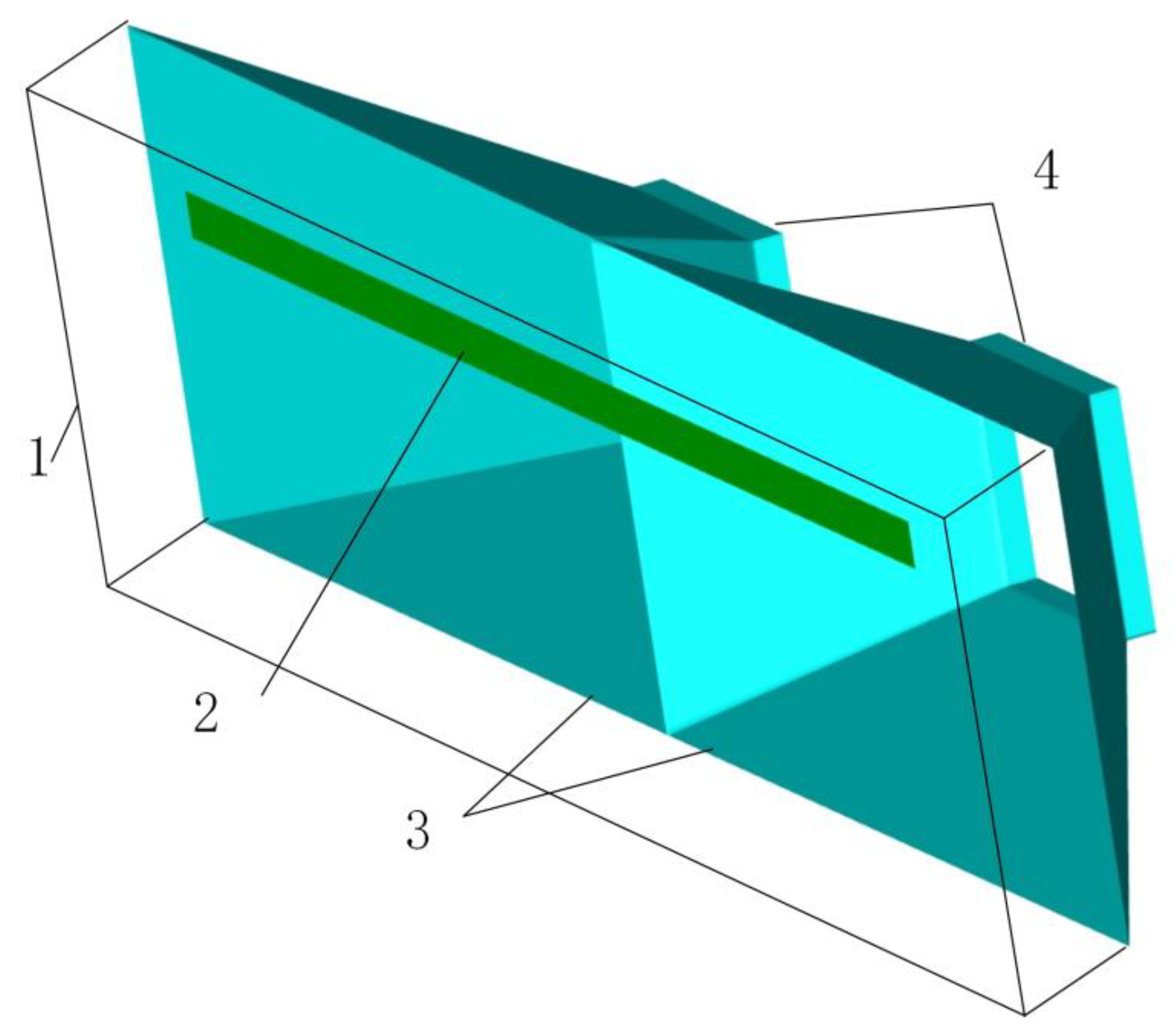

2.1.2. Machine Structure and Working Principle of the SIRD

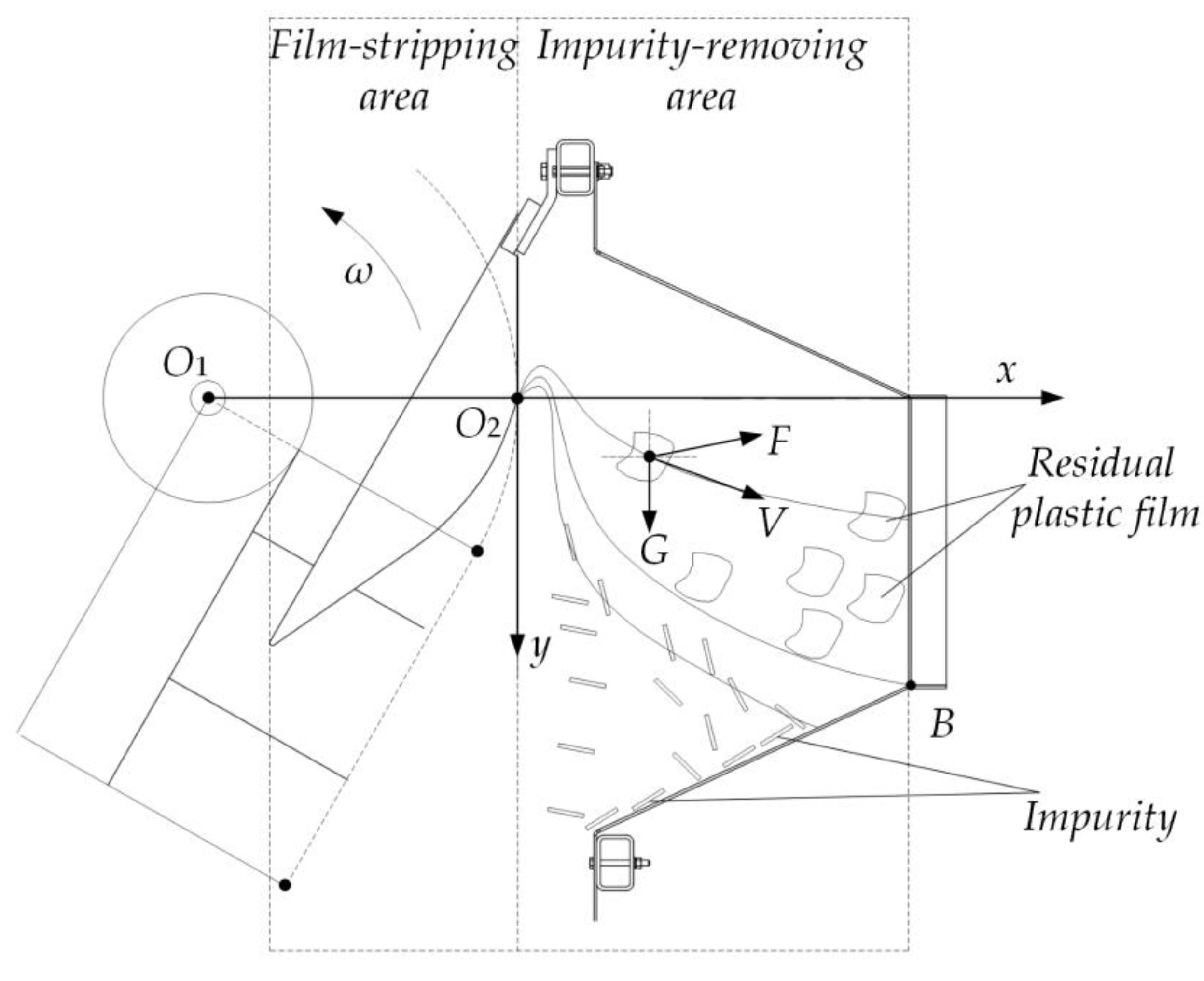

2.2. Analysis of the Film-Stripping Process and Shape Design of the FTP

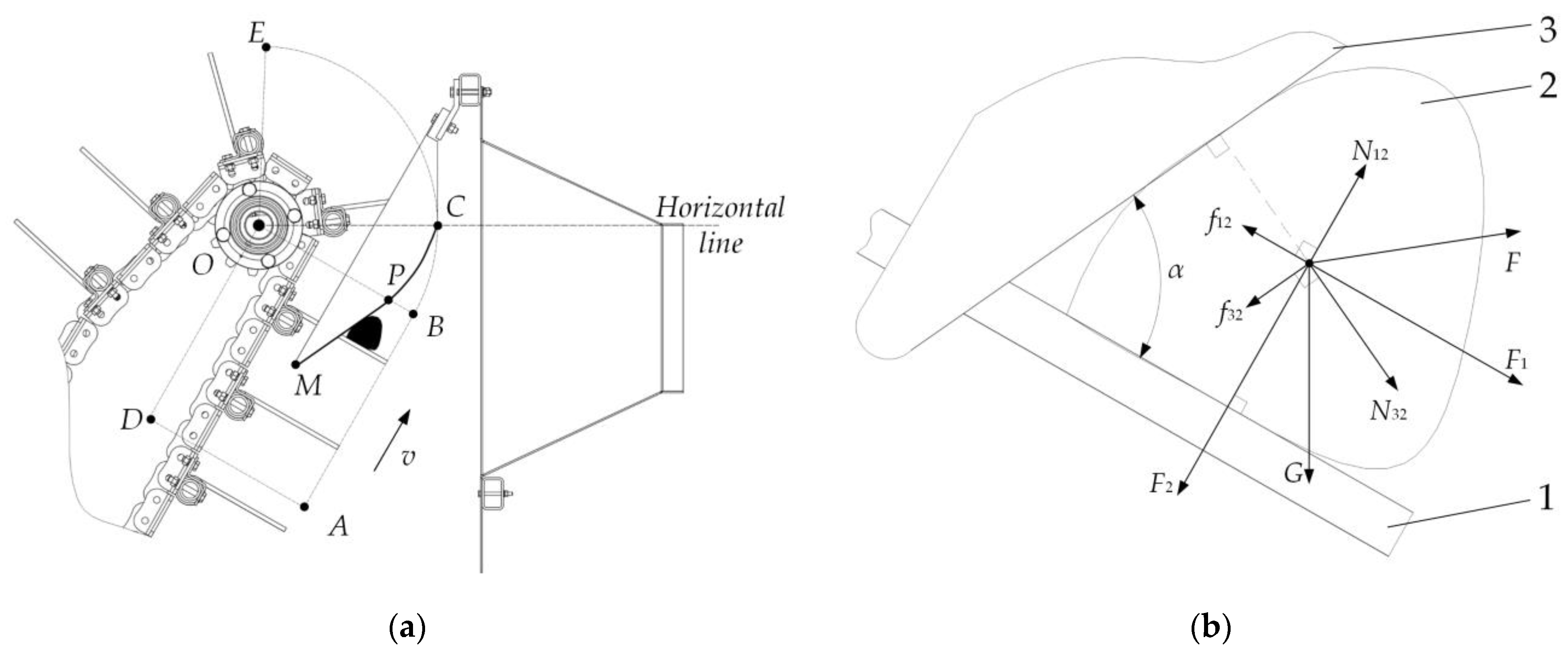

2.2.1. Stress Analysis of RPF during the Film-Stripping Process

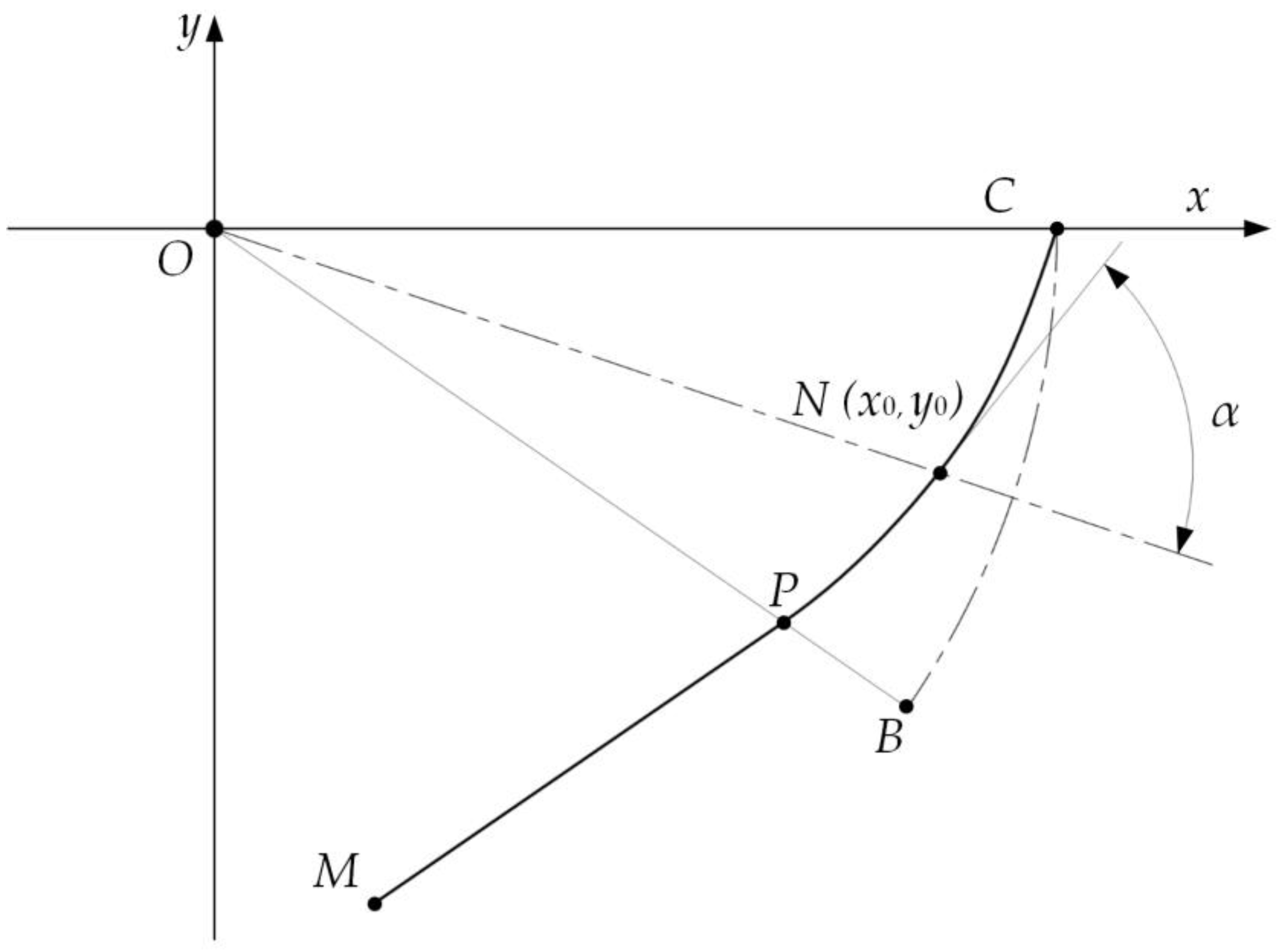

2.2.2. Solution of FTP Line

2.3. Analysis of the Impurity Removal Process and Numerical Calculation of the DPM

2.3.1. Force and Motion Analysis of RPF in the Impurity Removal Area

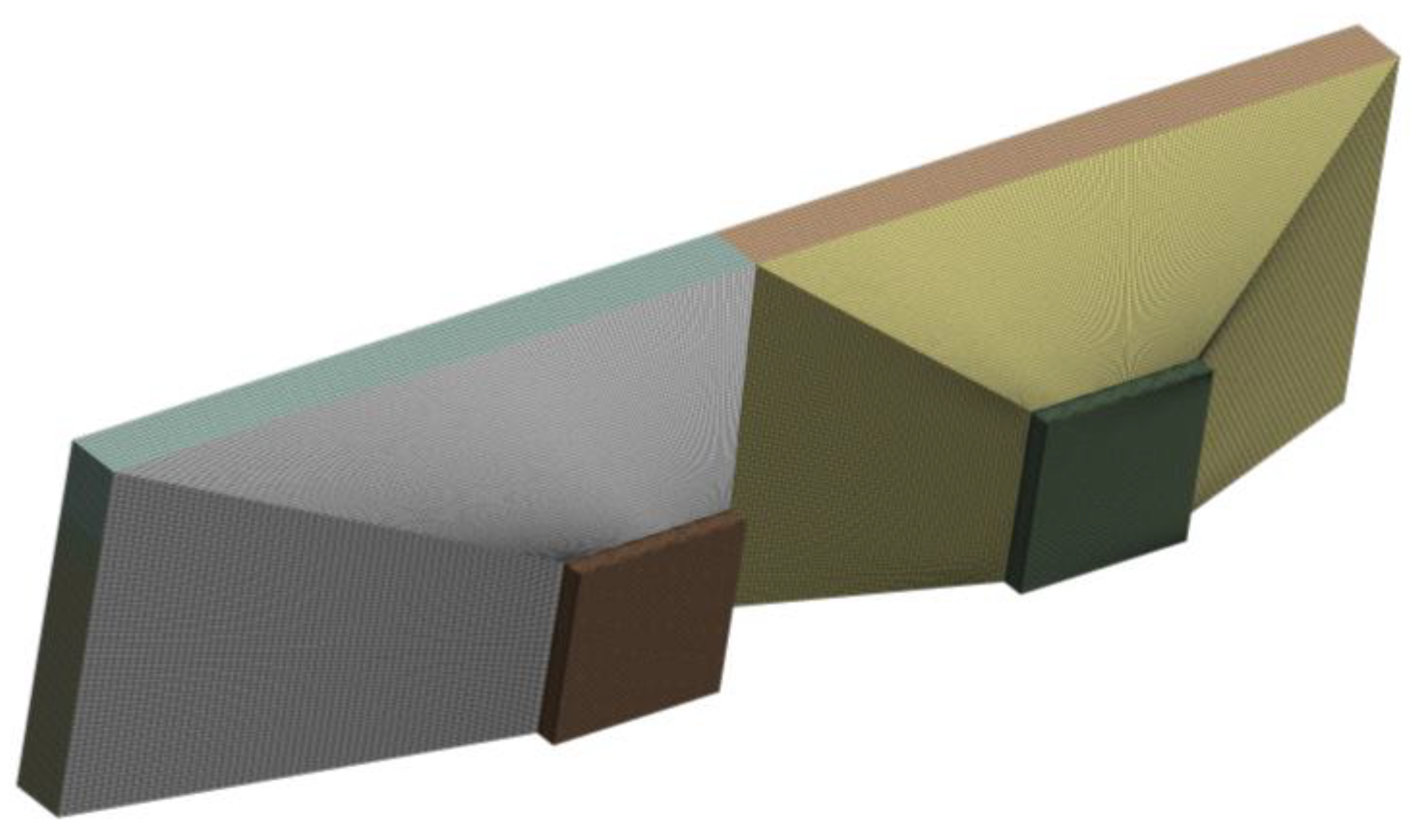

2.3.2. Equivalent Simplified Model Building

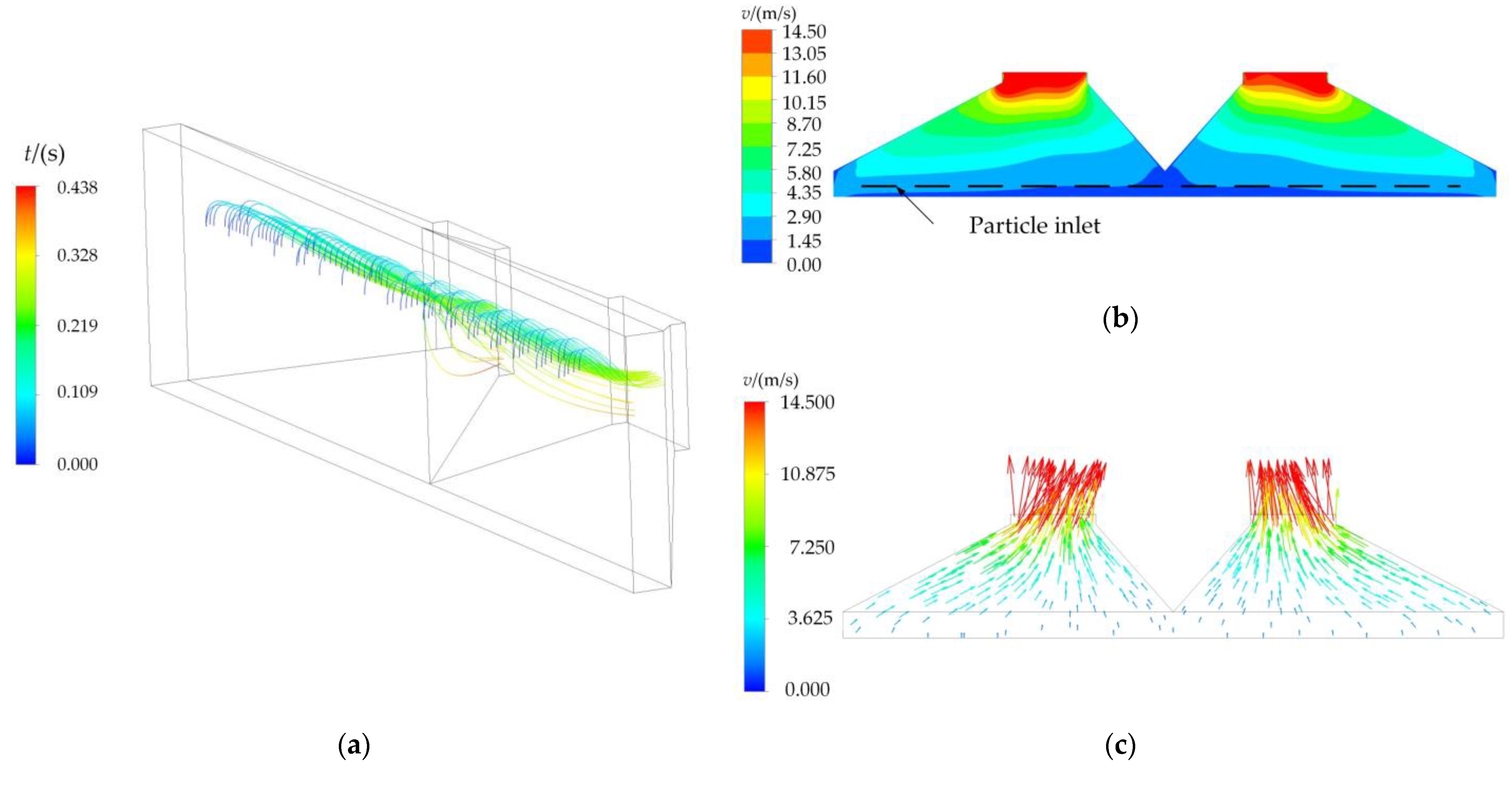

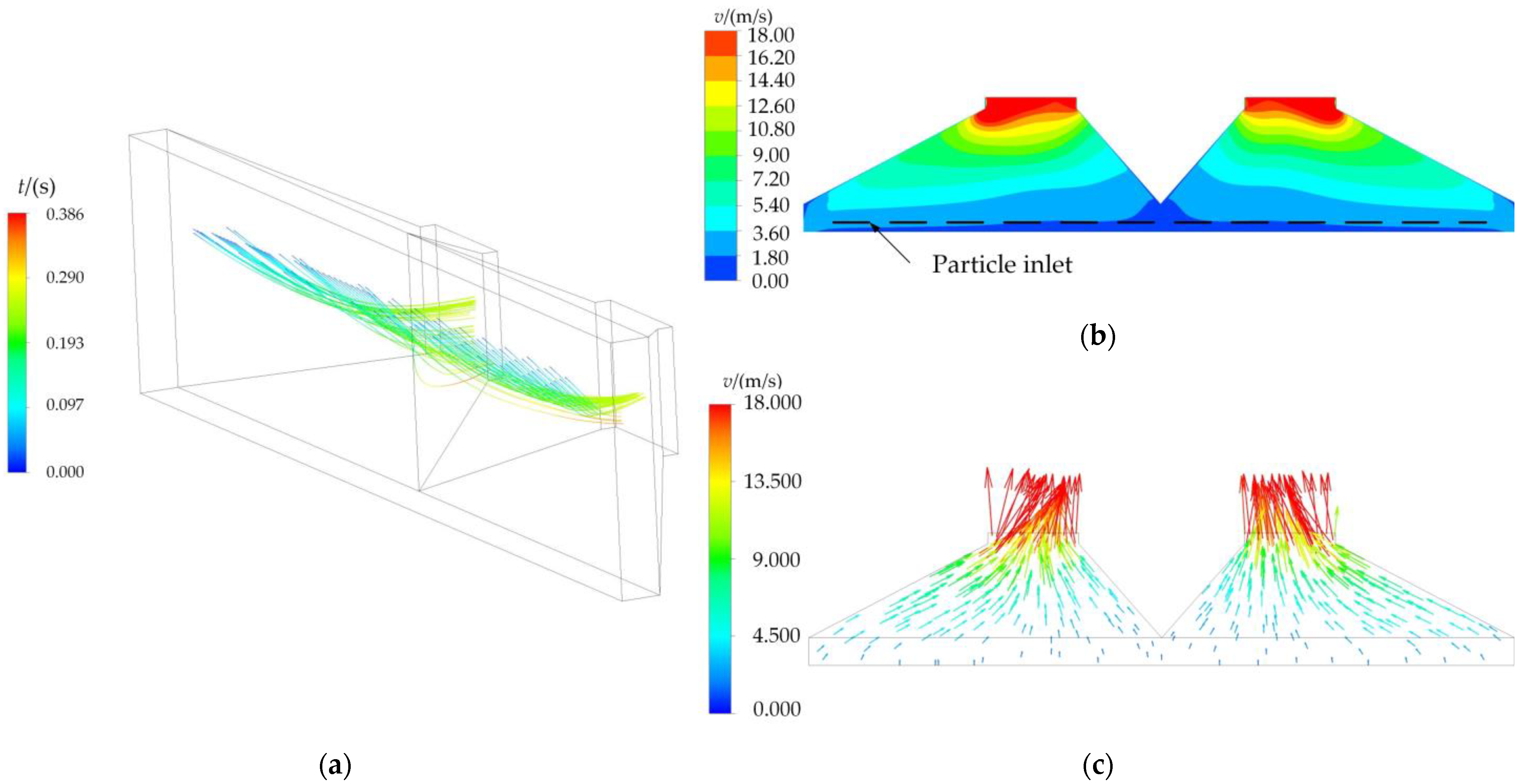

2.3.3. Numerical Computation of DPM

2.4. Materials and Methods of Field Experiment

2.4.1. Test Conditions

2.4.2. Test Method

2.4.3. Experimental Design

3. Results and Discussion

3.1. Results

3.2. Discussion

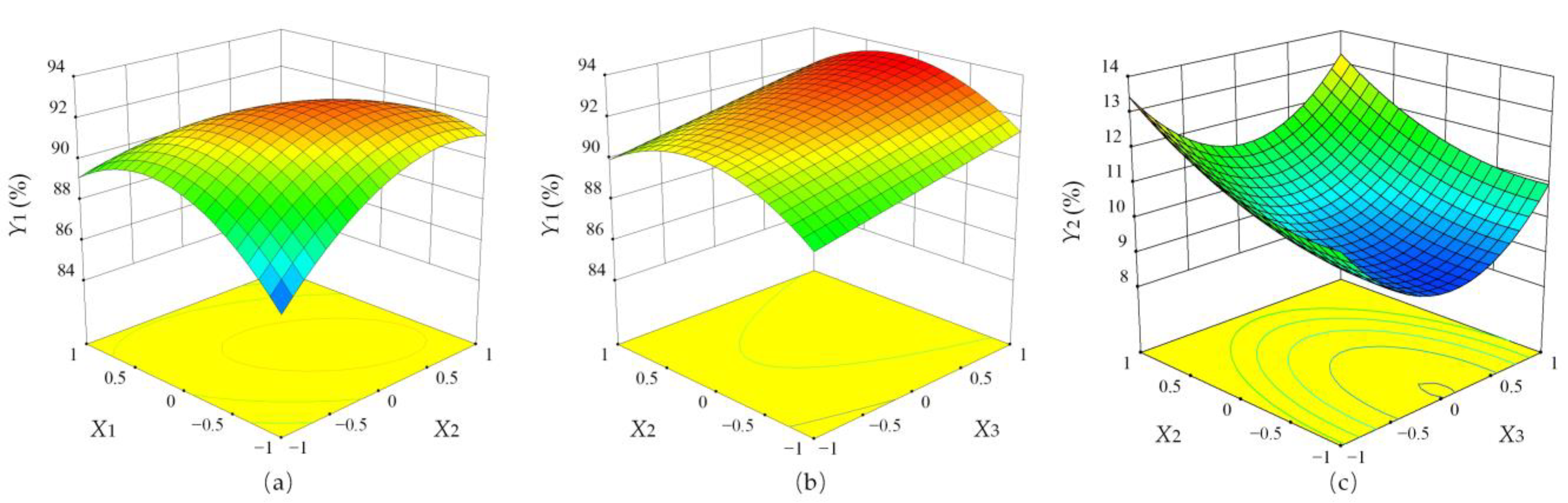

- (1)

- Analysis of the effect of factor interaction on the RRRF

- (2)

- Analysis of the effect of factor interaction on IRF

3.3. Optimization of Operation Parameters and Test Verification

4. Conclusions

- (1)

- Through the force analysis of the RPF in the process of film-stripping, it is determined to use the FTP for film-stripping, and the corresponding arc calculation formula is obtained. The drawing method was used to obtain the external dimensions in accordance with the formula, and then the FTP was processed. According to the analysis results of the movement and force of the RPF in the airflow field, an equivalent simplified sphere model of the RPF is established. By using the DPM method in Fluent software to numerically simulate the motion of the equivalent simplified spherical model in the fluid domain, it is clear that the required air volume range of the centrifugal fan is 5501.88~6829.92 m3/h;

- (2)

- Combined with the design principle of the Box Behnken experiment, the RPF recovery performance of the SRPFC was tested. The experiment was carried out by the orthogonal rotation combination of multiple factors. Through response surface analysis, the factors that affected the RRRF were, in the order of large to small: forward speed, rotating speed of the FCCH, and rotating speed of the fan; the factors affecting the IRF, from large to small, were: speed of the fan, speed of film conveying chain rake, and forward speed;

- (3)

- The Design-Expert software was used to optimize the regression equation, and the best working parameters of the SRPFC were obtained as follows: forward speed of 5 km/h, rotating speed of the FCCH of 235 r/min, and rotating speed of the centrifugal fan of 1978 r/min. Field tests were carried out with the parameters after rounding, and it was shown that the average RRRF was 92.07% and the average IRF was 9.56% under these parameters. The test results of the whole machine are good, and all the operation indexes meet the requirements of Chinese national and industry standards.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, H. Plastic Film and Ecological Environment Protection; Chemical Industry Press: Beijing, China, 2000. [Google Scholar]

- Hu, R.; Liu, D.; Wang, L.; Wan, X. Application and recycling experience of agricultural film in developed countries. World Agric. 2019, 2, 89–94. [Google Scholar]

- Yan, C.; Liu, E.; Shu, F.; Liu, Q.; Liu, S.; He, W. Review of agricultural plastic mulching and its residual pollution and prevention measures in China. J. Agric. Resour. Environ. 2014, 31, 95–102. [Google Scholar]

- Xie, H.; Li, Y.; Yang, S.; Wang, J.; Wu, X.; Wu, Z. Research on the influence of farmland residual film on soil environment and crop growth and development. J. Agro Environ. Sci. 2007, S1, 153–156. [Google Scholar]

- Li, D.; Zhan, W.; Xin, S.; Liu, X.; Qu, H.; Xu, Y. Research status and prospect of farmland residual film recycling technology. Chin. J. Agric. Mach. 2020, 41, 204–209. [Google Scholar]

- Zhao, Y.; Chen, X.; Wen, H.; Zheng, X.; Niu, Q.; Kang, J. Research status and prospect of control technology for residual plastic film pollution in farmland. Trans. Chin. Soc. Agric. Mach. 2017, 48, 1–14. [Google Scholar]

- Zhang, H.; Kang, J.; Zhang, G.; Wang, Y.; Du, H.; Sun, H. Analysis on the current situation and countermeasures of agricultural film pollution in the Huanghuaihai region. Chin. J. Agric. Mach. 2019, 40, 156–161. [Google Scholar]

- Lyu, Z.; Zhang, L.; Zhang, G.; Liu, S. Design and test of chain guide rail-type plastic film collector. Trans. Chin. Soc. Agric. Eng. 2015, 31, 48–54. [Google Scholar]

- Zheng, S.; Cao, S.; Wang, M.; Lu, Y.; Ying, Y.; Sun, B.; Zhao, Y. Design and experiment of rotary stripping type residual film recovery machine. J. Northwest A&F. Univ. (Nat. Sci. Ed.). 2020, 48, 146–154. [Google Scholar]

- Xie, J.; Zhang, F.; Chen, X.; Han, Y.; Tang, W. Design and parameter optimization of curved tooth rolling type residual film recovery machine. Trans. Chin. Soc. Agric. Eng. 2019, 35, 26–37. [Google Scholar]

- Zhao, Y.; Zheng, X.; Chen, X.; Niu, Q.; Ji, C.; Zhou, D. CMJY-1500 type farmland residual film picking and packing joint cooperation, design and experiment of industrial machine. Trans. Chin. Soc. Agric. Eng. 2017, 33, 1–9. [Google Scholar]

- Li, S. Design and Research on the Key Components of the Mulching Film Recycling Machine with Mulching and Hybridization; Shihezi University: Shihezi, China, 2020. [Google Scholar]

- Niu, Q.; Ji, C.; Zhao, Y.; Cheng, X.; Zheng, X.; Li, H. Design and experiment on collecting and separating device for strip plastic film baler. Trans. Chin. Soc. Agric. Mach. 2017, 48, 101–107. [Google Scholar]

- Jiang, D. Research and Experiment on Cleaning System of Profile Modeling Residual Film Recovery Machine; Shihezi University: Shihezi, China, 2020. [Google Scholar]

- Peng, W. Study on the Solid Particle Erosion Mechanism of Pipe Bend for Multiphase Flow; China University of Petroleum: Qingdao, China, 2017. [Google Scholar]

- Guo, W.; He, X.; Wang, L.; Zhao, P.; Hu, C.; Hou, S.; Wang, X. Development of a comb tooth loosening and pneumatic stripping plough layer residual film recovery machine. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–10. [Google Scholar]

- Yang, X. Research on MSW Compacting Separating Technology and Corresponding Mechanical Equipment; Xi’an University of Technology: Xi’an, China, 2004. [Google Scholar]

- Zhang, X.; Liu, J.; Shi, Z.; Jin, W.; Yan, J.; Yu, M. Design and parameter optimization of reverse membrane and soil separation device for residual film recovery machine. Trans. Chin. Soc. Agric. Eng. 2019, 35, 46–55. [Google Scholar]

- Jin, W.; Zhang, X.; Ding, Y.; Bai, S.; Liu, W.; Zhou, X. Experiment on suspension separation of residual film and impurity based on EDEM-Fluent coupling. Trans. Chin. Soc. Agric. Mach. 2022, 53, 89–98. [Google Scholar]

- Wen, X.; Jia, H.; Zhang, S.; Yuan, H.; Wang, G.; Chen, T. Test of suspension velocity of granular fertilizer based on EDEM-Fluent coupling. Trans. Chin. Soc. Agric. Mach. 2020, 51, 69–77. [Google Scholar]

- Versteeg, H.; Malalasekera, W. An Introduction to Computational Fluid Dynamics—The Finite Volume Method; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Cai, Z.; Long, T. Hydrodynamic Pump and Fan; China Architecture Press: Beijing, China, 2009. [Google Scholar]

- Ma, Y. Agricultural Materials; Chemical Industry Press: Beijing, China, 2015. [Google Scholar]

- Li, X. The Research of Winnowing Characteristics on Tobacco Cutting and Rebaking in the DPM Model; Kunming University of Science and Technology: Kunming, China, 2020. [Google Scholar]

- Yang, S. Design and Key Technology Research of Passive Cotton Field Residual Plastic Film Recycling Machine; Jilin University: Jilin, China, 2020. [Google Scholar]

- Dai, F.; Guo, X.; Zhao, W.; Xin, S.; Liu, X.; Wu, Z. Design and experiment of canvas belt combined operation machine for potato digging and plastic film collecting. Trans. Chin. Soc. Agric. Mach. 2018, 49, 104–113. [Google Scholar]

- Shi, G.; Li, J.; Ding, L.; Zhang, Z.; Ding, H.; Li, N.; Kan, Z. Calibration and Tests for the Discrete Element Simulation Parameters of Fallen Jujube Fruit. Agriculture 2022, 12, 38. [Google Scholar] [CrossRef]

- Horabik, J.; Wiacek, J.; Parafiniuk, P.; Banda, M.; Kobylka, R.; Stasiak, M.; Molenda, M. Calibration of discrete-element-method model parameters of bulk wheat for storage. Biosyst. Eng. 2020, 200, 298–314. [Google Scholar] [CrossRef]

- You, J.; Zhang, B.; Wen, H.; Kang, J.; Song, Y.; Chen, X. Design and test optimization on spade and tine combined residual plastic film device. Trans. Chin. Soc. Agric. Mach. 2017, 48, 97–104. [Google Scholar]

- Han, L.; Yuan, W.; Yu, J.; Jin, J.; Xie, D.; Xi, X.; Zhang, Y.; Zhang, R. Simulation and Experiment of Spiral Soil Separation Mechanism of Compound Planter Based on Discrete Element Method (DEM). Agriculture 2022, 12, 511. [Google Scholar] [CrossRef]

- Yan, W.; Hu, Z.; Wu, N.; Xu, H.; You, Z.; Zhou, X. Parameter optimization and experiment of film transmission mechanism of spade screen recovery machine. Trans. Chin. Soc. Agric. Eng. 2017, 33, 17–24. [Google Scholar]

- Wu, T.; Kong, F.; Shi, L.; Xie, Q.; Sun, Y.; Chen, C. Power Consumption Influence Test of Castor Disc-Cutting Device. Agriculture 2022, 12, 1535. [Google Scholar] [CrossRef]

- Hu, S.; Hu, Z.; Gu, F.; Wu, F.; Wu, P. Design on automatic un loading mechanism for teeth type residue plastic film collector. Trans. Chin. Soc. Agric. Eng. 2017, 33, 8–15. [Google Scholar]

| Level | Forward Speed X1/(km·h−1) | Rotating Speed of the FCCH X2/(r·min−1) | Rotating Speed of the Centrifugal Fan X3/(r·min−1) |

|---|---|---|---|

| −1 | 4 | 220 | 1800 |

| 0 | 5 | 240 | 1950 |

| 1 | 6 | 260 | 2100 |

| Serials No. | Coding | Response Values | |||

|---|---|---|---|---|---|

| X1 | X2 | X3 | Y1 | Y2 | |

| 1 | 0 | −1 | 1 | 90.9 | 11.03 |

| 2 | 1 | −1 | 0 | 88.3 | 9.27 |

| 3 | −1 | 0 | 1 | 90.74 | 11.15 |

| 4 | 0 | 0 | 0 | 92.13 | 9.36 |

| 5 | −1 | 1 | 0 | 92.2 | 10.73 |

| 6 | 0 | 0 | 0 | 93.3 | 9.87 |

| 7 | −1 | −1 | 0 | 87.13 | 9.27 |

| 8 | 0 | 0 | 0 | 92.97 | 10.27 |

| 9 | −1 | 0 | −1 | 88.85 | 12.69 |

| 10 | 1 | 0 | −1 | 88.23 | 11.43 |

| 11 | 0 | 0 | 0 | 93.36 | 8.67 |

| 12 | 1 | 0 | 1 | 92.14 | 11.13 |

| 13 | 0 | 0 | 0 | 91.14 | 9.19 |

| 14 | 0 | 1 | 1 | 91.78 | 13.95 |

| 15 | 0 | −1 | −1 | 89.7 | 10.53 |

| 16 | 0 | 1 | −1 | 90.03 | 13.21 |

| 17 | 1 | 1 | 0 | 85.34 | 11.43 |

| Source of Variance | Degree of Freedom | RRRF Y1 | Degree of Freedom | IRF Y2 | ||||

|---|---|---|---|---|---|---|---|---|

| Mean Square | F1-Value | p1-Value | Mean Square | F2-Value | p2-Value | |||

| Model | 9 | 8.25 | 5.83 | 0.0149 * | 9 | 3.53 | 6.69 | 0.0101 * |

| X1 | 1 | 3.01 | 2.13 | 0.1878 | 1 | 0.042 | 0.080 | 0.7860 |

| X2 | 1 | 1.38 | 0.97 | 0.3566 | 1 | 10.63 | 20.12 | 0.0028 ** |

| X3 | 1 | 9.57 | 6.76 | 0.0354 * | 1 | 0.045 | 0.085 | 0.7788 |

| X1X2 | 1 | 16.12 | 11.39 | 0.0118 * | 1 | 0.12 | 0.23 | 0.6447 |

| X1X3 | 1 | 1.02 | 0.72 | 0.4239 | 1 | 0.38 | 0.73 | 0.4218 |

| X2X3 | 1 | 0.076 | 0.053 | 0.8238 | 1 | 0.014 | 0.027 | 0.8735 |

| X12 | 1 | 25.79 | 18.23 | 0.0037 ** | 1 | 0.016 | 0.030 | 0.8670 |

| X22 | 1 | 14.61 | 10.32 | 0.0148 * | 1 | 1.73 | 3.28 | 0.1130 |

| X32 | 1 | 0.056 | 0.039 | 0.8484 | 1 | 17.98 | 34.05 | 0.0006 ** |

| Residual | 7 | 1.41 | 7 | 0.53 | ||||

| Lack of fit | 3 | 2.12 | 2.38 | 0.2104 | 3 | 0.72 | 1.89 | 0.2729 |

| Pure error | 4 | 0.89 | 4 | 0.38 | ||||

| Items | RRRF Y1/% | IRF Y2/% |

|---|---|---|

| Predicted Value | 92.53 | 9.32 |

| Test Value | 92.07 | 9.56 |

| relative error | 0.5 | 2.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Q.; Li, K.; Wang, X.; Zhang, G.; Kang, J. Design and Test of Stripping and Impurity Removal Device for Spring-Tooth Residual Plastic Film Collector. Agriculture 2023, 13, 42. https://doi.org/10.3390/agriculture13010042

Peng Q, Li K, Wang X, Zhang G, Kang J. Design and Test of Stripping and Impurity Removal Device for Spring-Tooth Residual Plastic Film Collector. Agriculture. 2023; 13(1):42. https://doi.org/10.3390/agriculture13010042

Chicago/Turabian StylePeng, Qiangji, Kaikai Li, Xiaoyu Wang, Guohai Zhang, and Jianming Kang. 2023. "Design and Test of Stripping and Impurity Removal Device for Spring-Tooth Residual Plastic Film Collector" Agriculture 13, no. 1: 42. https://doi.org/10.3390/agriculture13010042

APA StylePeng, Q., Li, K., Wang, X., Zhang, G., & Kang, J. (2023). Design and Test of Stripping and Impurity Removal Device for Spring-Tooth Residual Plastic Film Collector. Agriculture, 13(1), 42. https://doi.org/10.3390/agriculture13010042