A Study on the Calibration of Wheat Seed Interaction Properties Based on the Discrete Element Method

Abstract

:1. Introduction

2. Materials and Methods

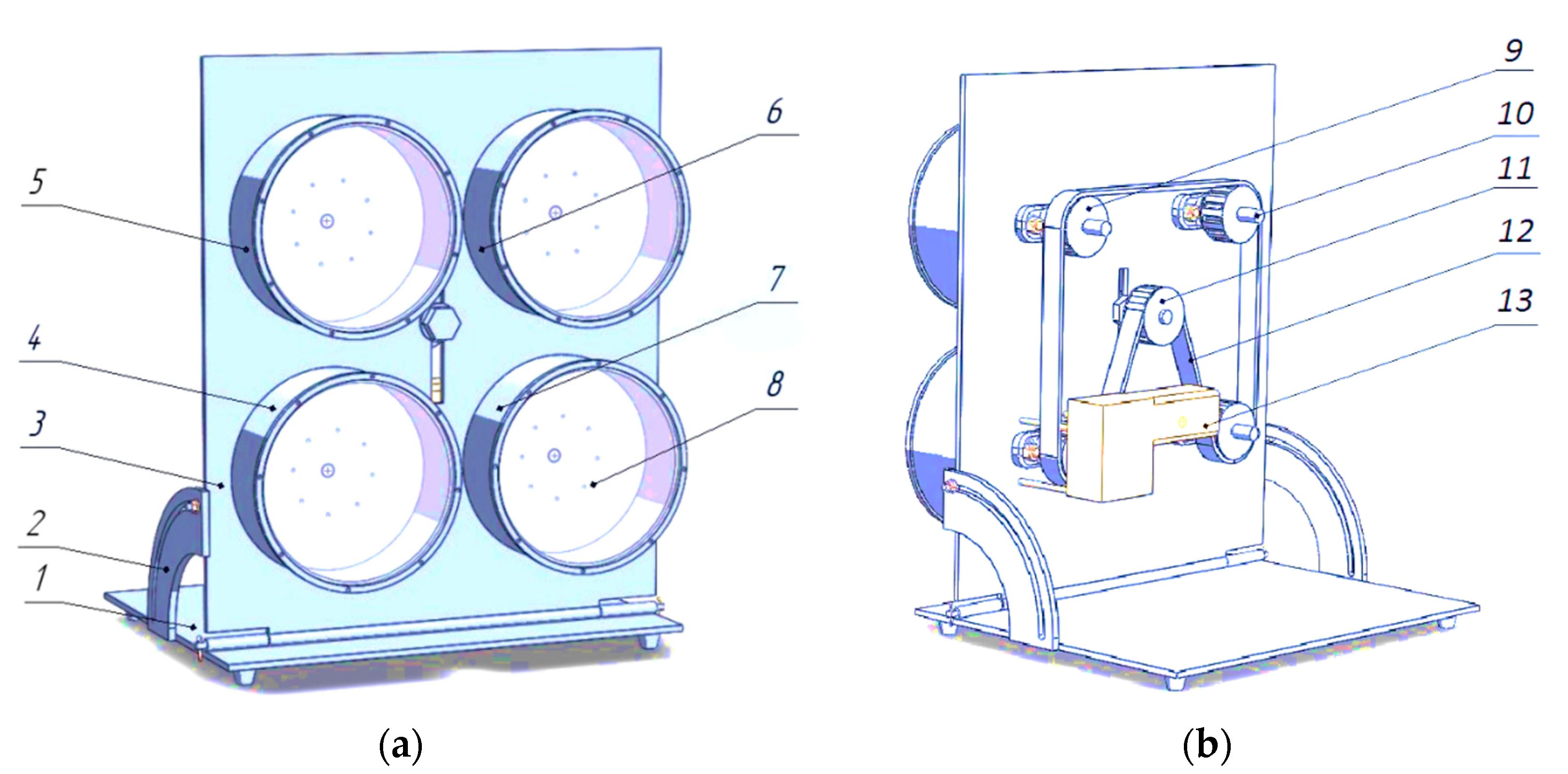

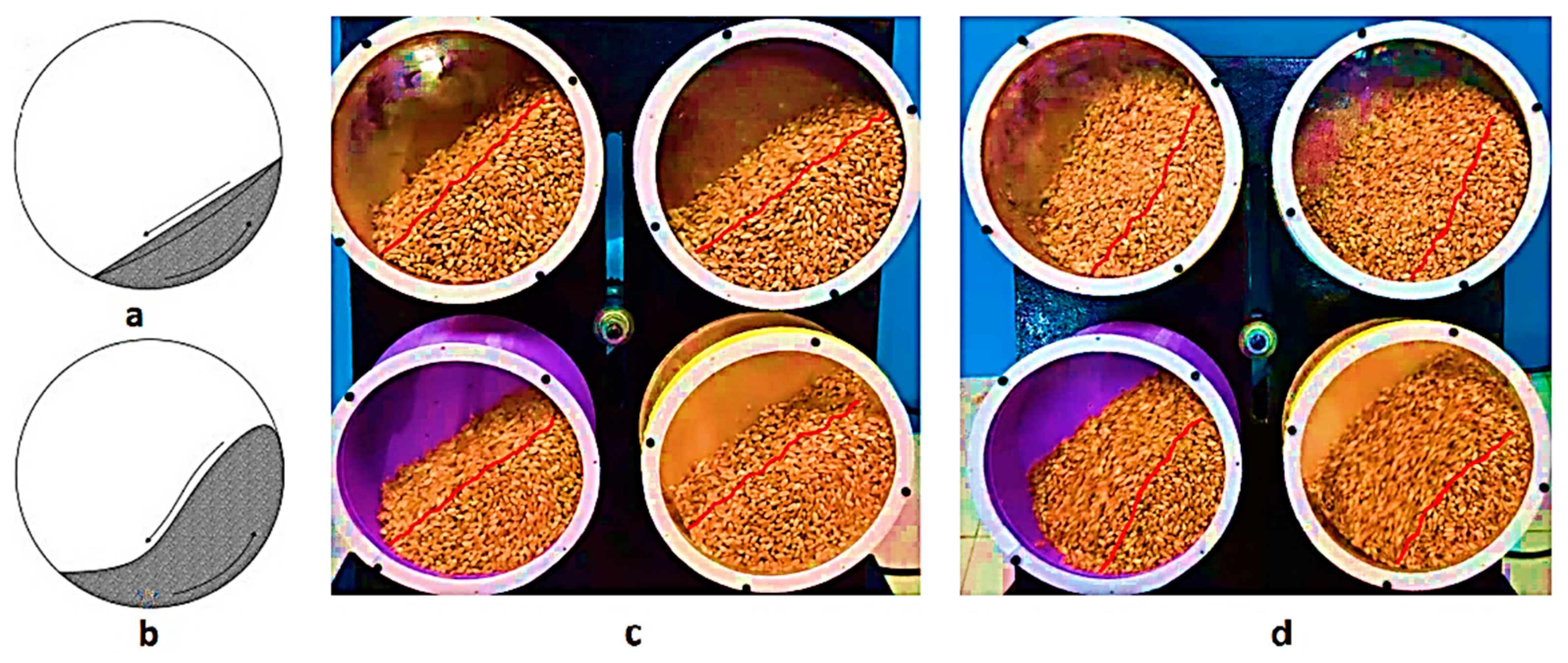

2.1. Rotary Drum Equipment

2.2. Experimental Procedure

2.2.1. Real Experiment Procedure

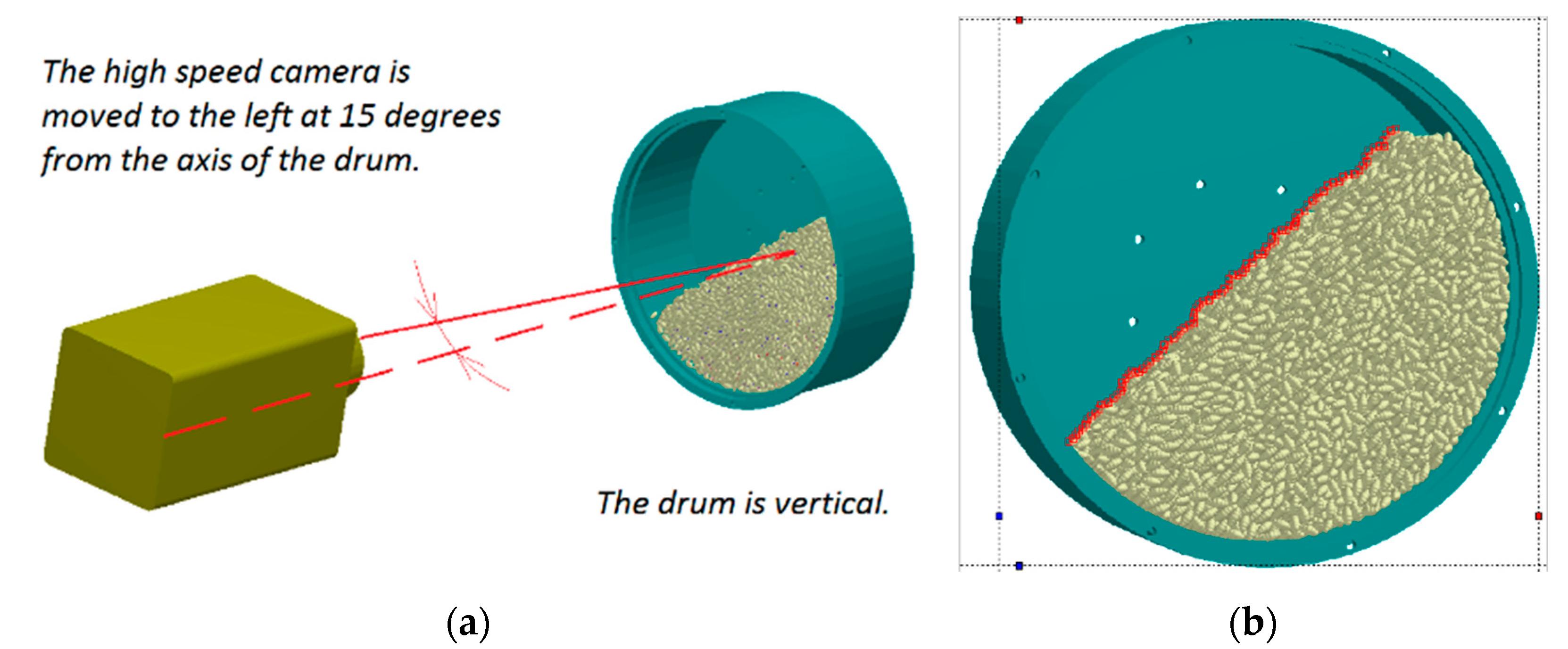

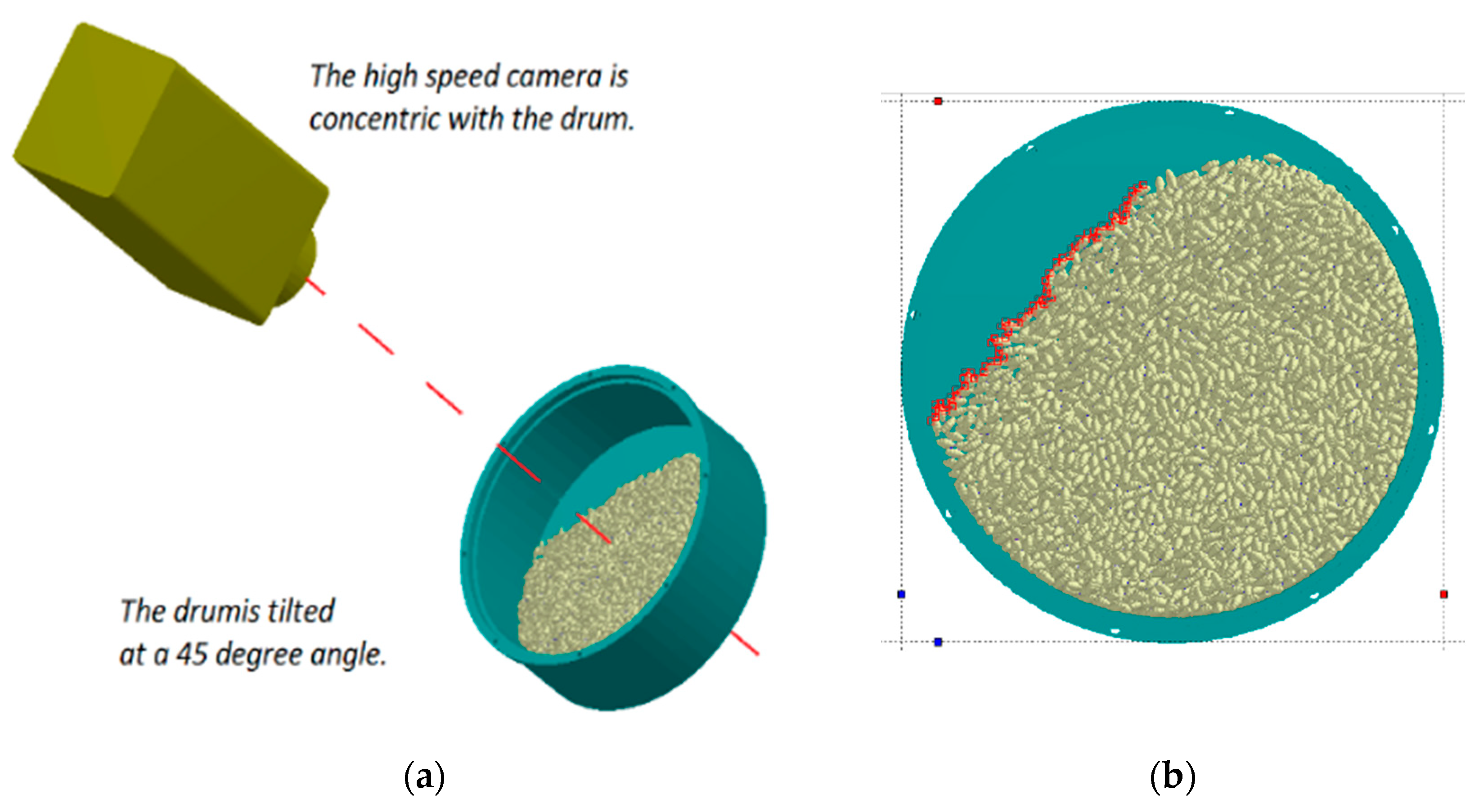

2.2.2. Measurement of the AOR of the Seeds Pile Depending on Rotary Drum Tilt

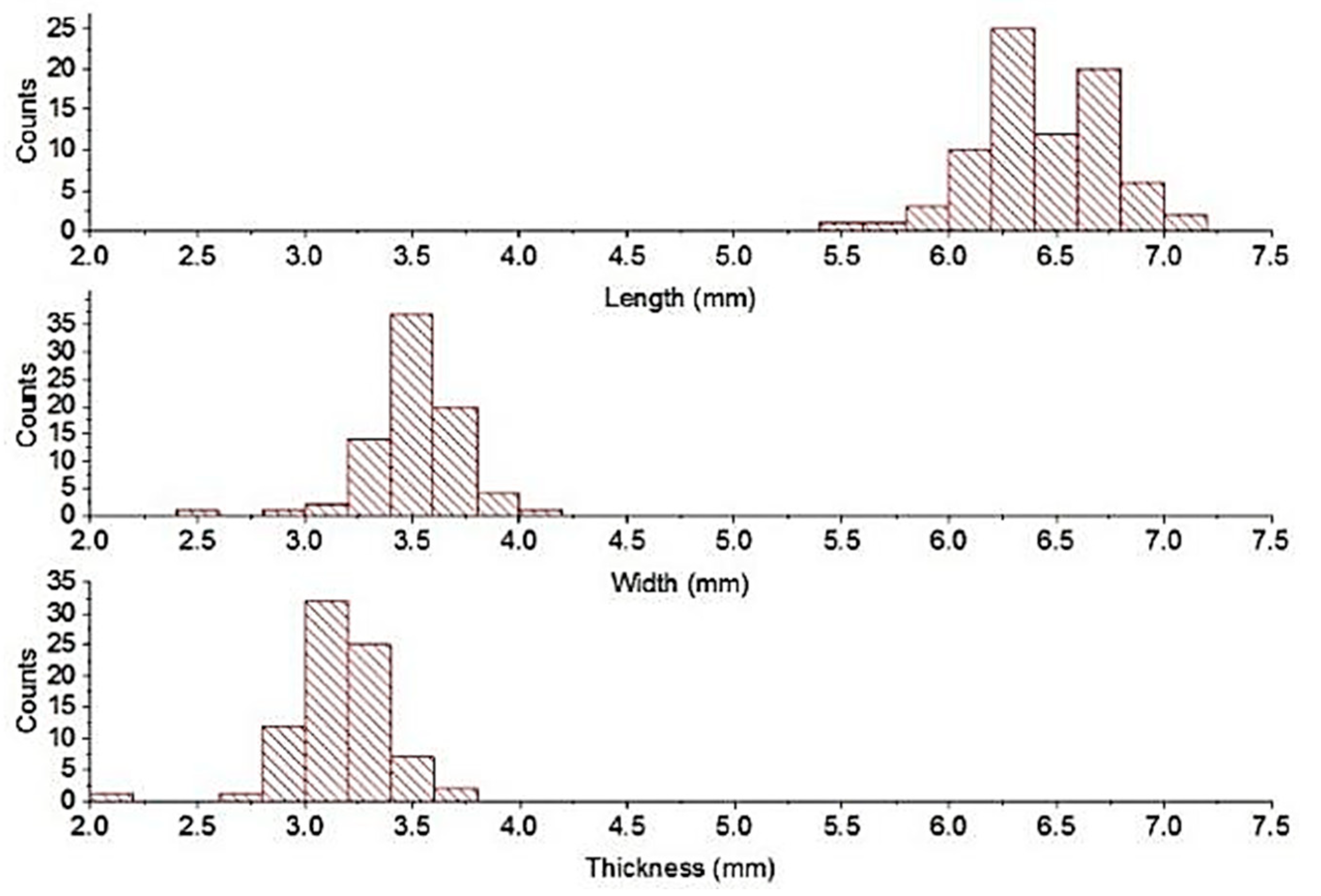

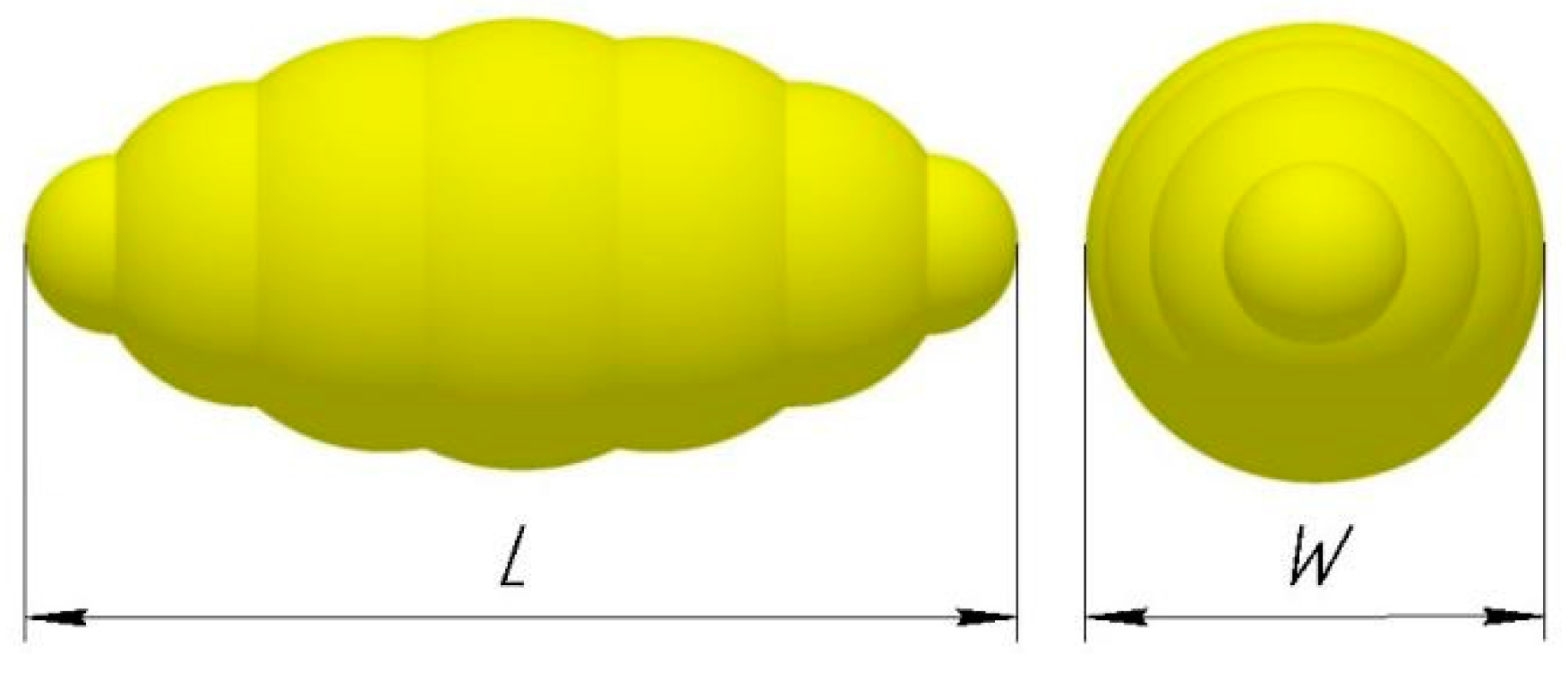

2.2.3. Measurement of Seed Sizes and Seed Generation on DEM

2.2.4. DEM Input Parameters

2.2.5. Verification of the Shape, Size, and Density of the Wheat Seeds and Simulation on DEM

3. Results and Discussion

3.1. Results of Real Experiments and One-Way ANOVA of the Results of Real Experiments

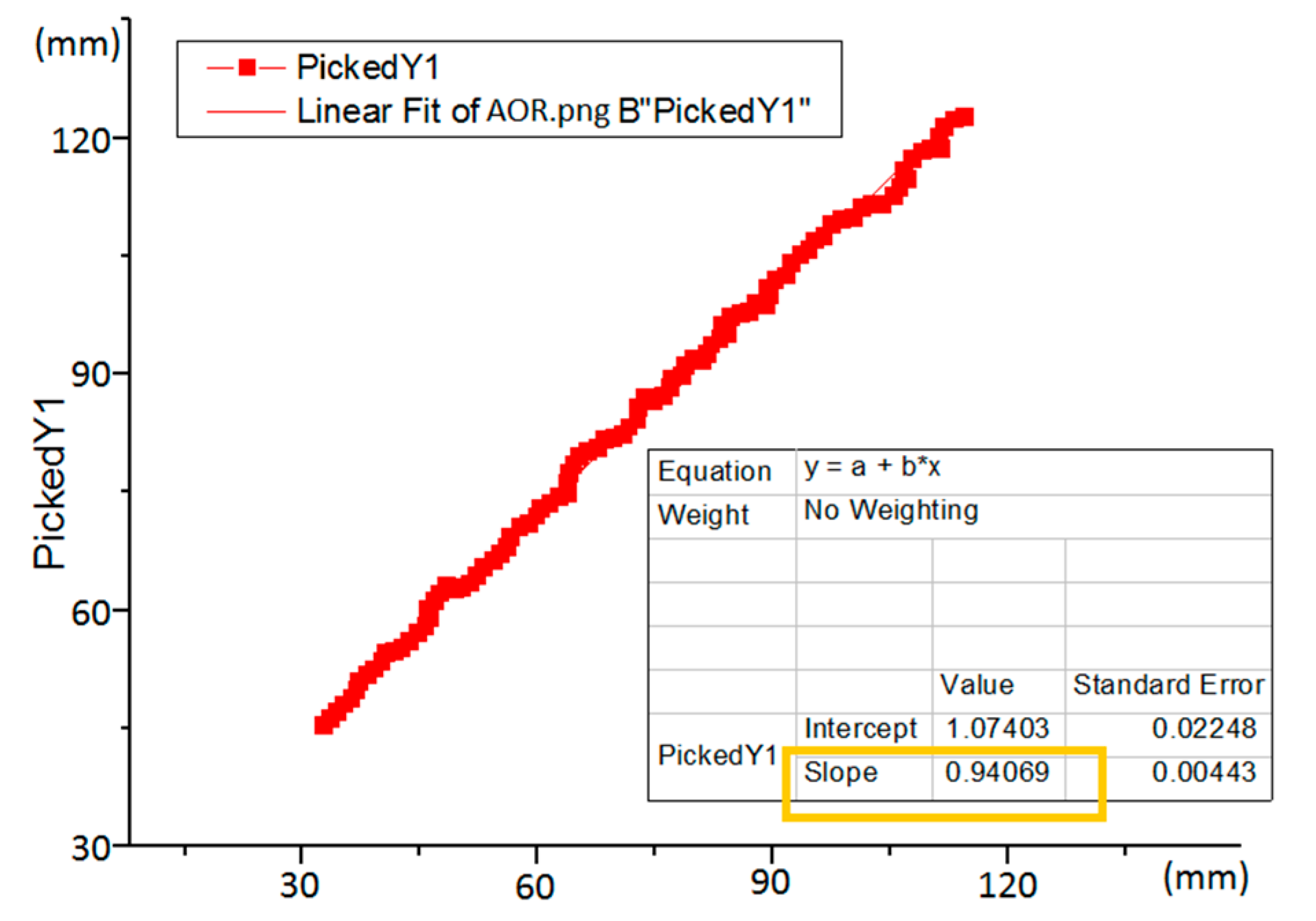

3.2. Results of the Seed Size Measurement and Generation on DEM

3.3. DEM Input Parameters

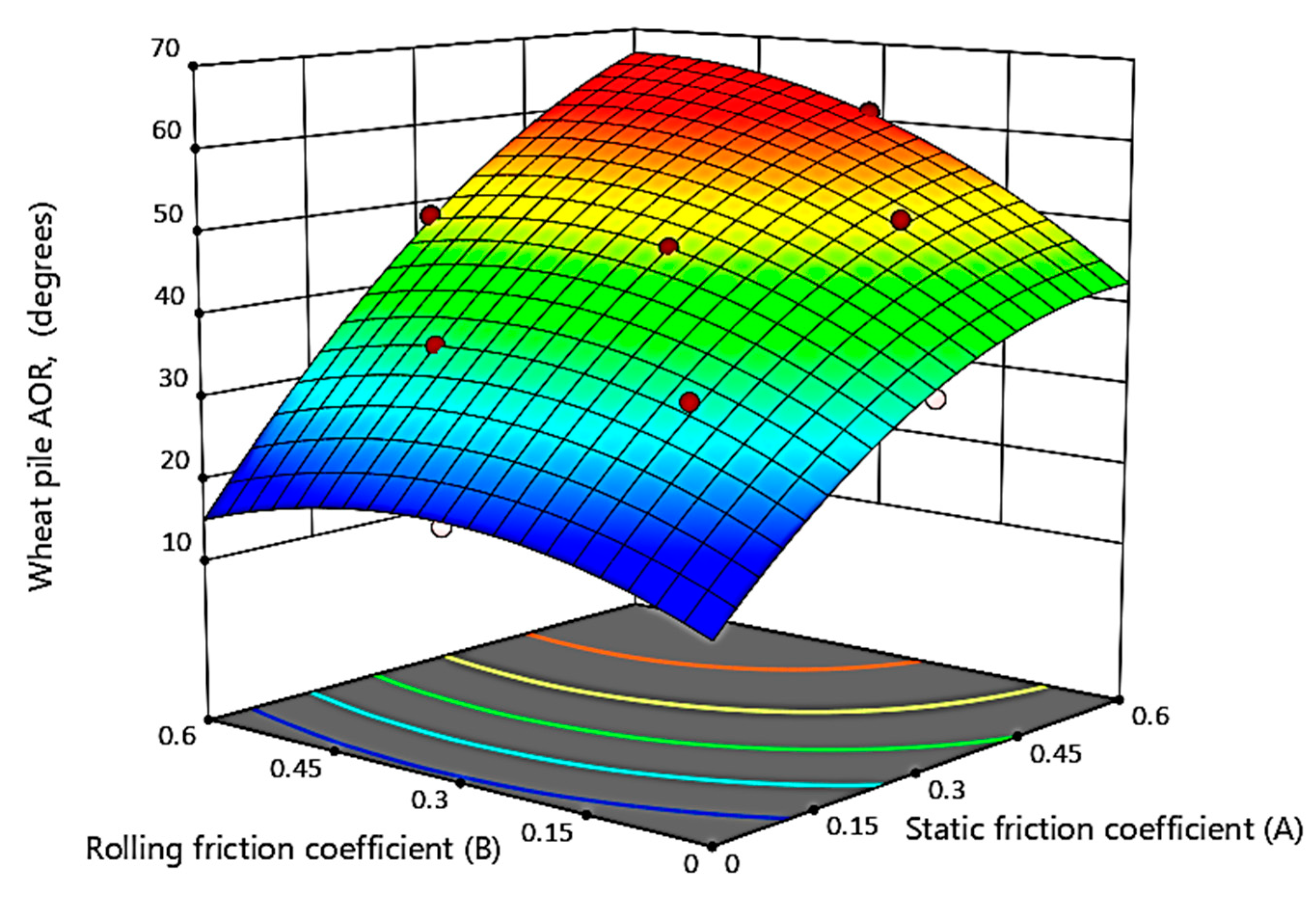

3.4. Simulation Results

3.4.1. ANOVA of the Simulation Results of the Particle–Particle Interaction Properties

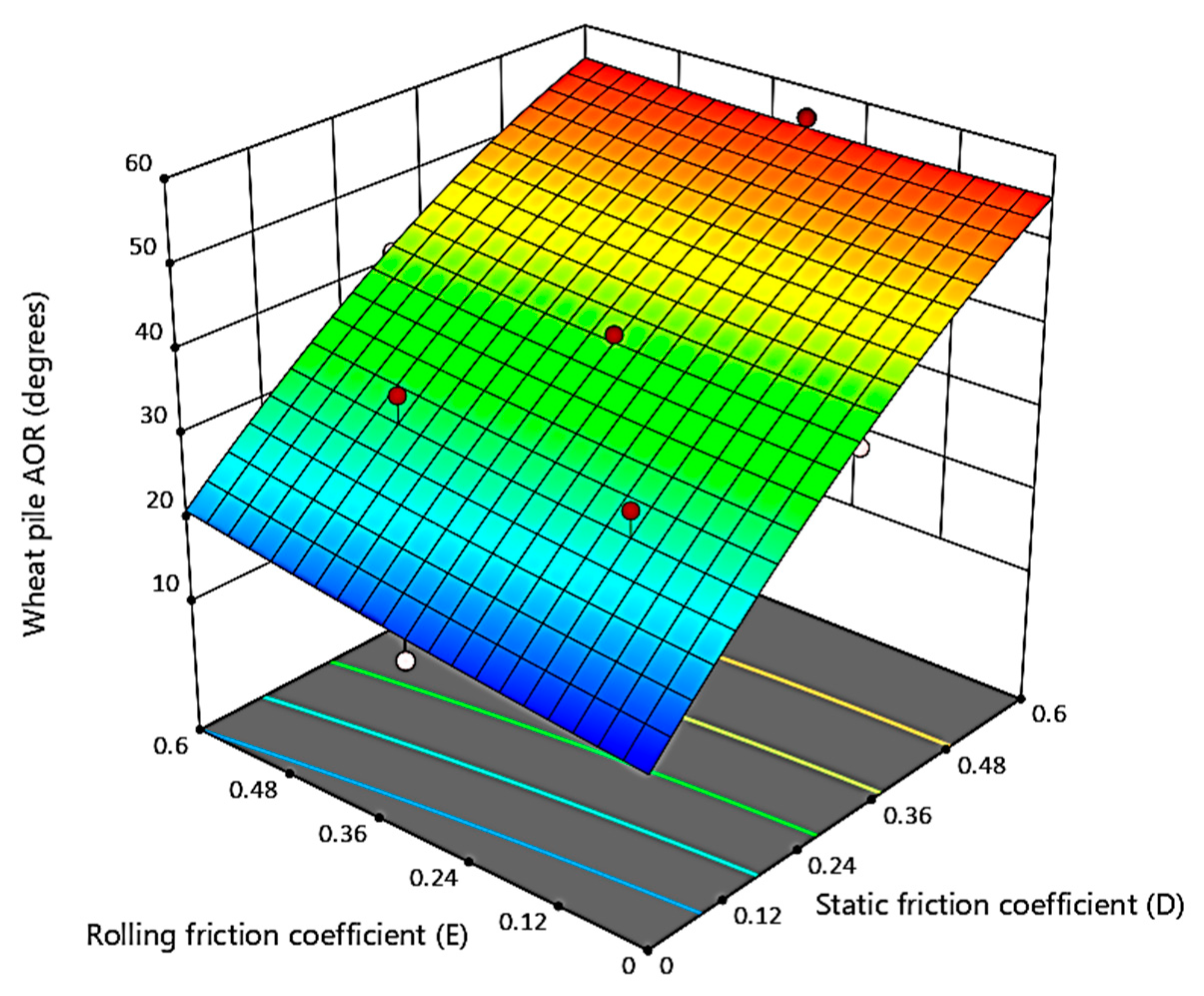

3.4.2. ANOVA of the Simulation Results of the Particle–Material Interaction Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sugirbay, A.; Zhao, J.; Nukeshev, S.; Chen, J. Determination of pin-roller parameters and evaluation of the uniformity of granular fertilizer application metering devices in precision farming. Comput. Electron. Agric. 2020, 179, 105835. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, Y.; Chen, J.; Zheng, Z.; Hu, C.; Cao, J. Design and Experiment of the Buckwheat Hill-Drop Planter Hole Forming Device. Agriculture 2021, 11, 1085. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Richter, C.; Will, F. Introducing Metamodel-Based Global Calibration of Material-Specific Simulation Parameters for Discrete Element Method. Minerals 2021, 11, 848. [Google Scholar] [CrossRef]

- Golshan, S.; Sotudeh-Gharebagh, R.; Zarghami, R.; Mostoufi, N.; Blais, B.; Kuipers, J. Review and implementation of CFD-DEM applied to chemical process systems. Chem. Eng. Sci. 2020, 221, 115646. [Google Scholar] [CrossRef]

- Blagoeva, E.; Karkov, B.; Stoimenov, N. Review and Analysis of Robotized Feeding Systems. In Proceedings of the 2021 International Conference Automatics and Informatics (ICAI), Varna, Bulgaria, 30 September–2 October 2021; pp. 341–344. [Google Scholar]

- Alpeissov, Y.; Iskakov, R.; Issenov, S.; Ukenova. Obtaining a formula describing the interaction of fine particles with an expanding gas flow in a fluid layer. Eastern-European J. Enterp. Technol. 2022, 2, 87–97. [Google Scholar] [CrossRef]

- Nukeshev, S.; Eskhozhin, D.; Mamyrbayeva, I.; Karaivanov, D.; Gubasheva, A.; Tleumbetov, K.; Kosatbekova, D. Substantiation of the Parameters of Universal Scatterer for Bulk Materials. J. Comput. Theor. Nanosci. 2020, 17, 2975–2982. [Google Scholar] [CrossRef]

- Nukeshev, S.; A Kakabaev, N.; Romanyuk, N.N.; Troyanovskaya, I.P.; A Smelik, V.; A Voinash, S. Design and rationale for parametres of the seed-fertilizer seeder coulter for subsoil broadcast seeding. IOP Conf. Series Earth Environ. Sci. 2021, 677, 052010. [Google Scholar] [CrossRef]

- Roessler, T.; Richter, C.; Katterfeld, A.; Will, F. Development of a standard calibration procedure for the DEM parameters of cohesionless bulk materials—Part I: Solving the problem of ambiguous parameter combinations. Powder Technol. 2018, 343, 803–812. [Google Scholar] [CrossRef]

- Barrios, G.K.P.; de Carvalho, R.M.; Kwade, A.; Tavares, L.M. Contact parameter estimation for DEM simulation of iron ore pellet handling. Powder Technol. 2013, 248, 84–93. [Google Scholar] [CrossRef]

- Coetzee, C. Review: Calibration of the discrete element method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Sugirbay, A.; Zhao, J.; Sayakhat, N.; Chen, J.; Nikolay, Z.; Bu, L.; Sugirbayeva, Z.; Hu, G.; Marat, M.; Wang, Z. Calibration Strategy to Determine the Interaction Properties of Fertilizer Particles Using Two Laboratory Tests and DEM. Agriculture 2021, 11, 592. [Google Scholar]

- Fan, G.; Wang, S.; Shi, W.; Gong, Z.; Gao, M. Simulation Parameter Calibration and Test of Typical Pear Varieties Based on Discrete Element Method. Agronomy 2022, 12, 1720. [Google Scholar] [CrossRef]

- Fang, W.; Wang, X.; Han, D.; Chen, X. Review of Material Parameter Calibration Method. Agriculture 2022, 12, 706. [Google Scholar] [CrossRef]

- Ye, F.; Wheeler, C.; Chen, B.; Hu, J.; Chen, K.; Chen, W. Calibration and verification of DEM parameters for dynamic particle flow conditions using a backpropagation neural network. Adv. Powder Technol. 2018, 30, 292–301. [Google Scholar] [CrossRef]

- Cabiscol, R.; Finke, J.H.; Kwade, A. Calibration and interpretation of DEM parameters for simulations of cylindrical tablets with multi-sphere approach. Powder Technol. 2018, 327, 232–245. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, J.; Li, B.; Chen, J. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap. Trans. Chin. Soc. Agric. Eng. 2016, 32, 247–253. [Google Scholar]

- Linskson, P.B. Granulation of superphosphate in a rotary drum. Can. J. Chem. Eng. 1969, 47, 519–521. [Google Scholar] [CrossRef]

- Elmisaoui, S.; Khamar, L.; Benjelloun, S.; Khamar, M.; Ghidaglia, J.-M. Numerical Study of fertilizer granules dynamics within rotary drum granulator. In Computer Aided Chemical Engineering; Türkay, M., Gani, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 327–332. [Google Scholar]

- Obraniak, A.; Orczykowska, M.; Olejnik, T.P. The effects of viscoelastic properties of the wetting liquid on the kinetics of the disc granulation process. Powder Technol. 2018, 342, 328–334. [Google Scholar] [CrossRef]

- Tan, Y.; Yu, Y.; Fottner, J.; Kessler, S. Automated measurement of the numerical angle of repose (aMAoR) of biomass particles in EDEM with a novel algorithm. Powder Technol. 2021, 388, 462–473. [Google Scholar] [CrossRef]

- Mellmann, J. The transverse motion of solids in rotating cylinders—Forms of motion and transition behavior. Powder Technol. 2001, 118, 251–270. [Google Scholar] [CrossRef]

- Rodrigues, R.F.; Leite, S.R.; Santos, D.A.; Barrozo, M.A. Drum granulation of single super phosphate fertilizer: Effect of process variables and optimization. Powder Technol. 2017, 321, 251–258. [Google Scholar] [CrossRef]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials; Routledge: Abingdon-on-Thames, UK, 1986. [Google Scholar]

- Zhu, H.P.; Zhou, Z.Y.; Yang, R.Y.; Yu, A.B. Discrete particle simulation of particulate systems: A review of major applications and findings. Chem. Eng. Sci. 2008, 63, 5728–5770. [Google Scholar] [CrossRef]

- Zhu, H.P.; Zhou, Z.Y.; Yang, R.Y.; Yu, A.B. Discrete particle simulation of particulate systems: Theoretical developments. Chem. Eng. Sci. 2007, 62, 3378–3396. [Google Scholar] [CrossRef]

- Widhate, P.; Zhu, H.; Zeng, Q.; Dong, K. Mixing of Particles in a Rotating Drum with Inclined Axis of Rotation. Processes 2020, 8, 1688. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, F.; Chen, J. Virtual vibration screening experiments of grain cleaning sieve based on DEM. Agric. Mech. Res. 2019, 2, 36–42. [Google Scholar]

- Li, H.; Zeng, S.; Luo, X.; Fang, L.; Liang, Z.; Yang, W. Design, DEM Simulation, and Field Experiments of a Novel Precision Seeder for Dry Direct-Seeded Rice with Film Mulching. Agriculture 2021, 11, 378. [Google Scholar] [CrossRef]

- Marigo, M.; Stitt, E.H. Discrete Element Method (DEM) for Industrial Applications: Comments on Calibration and Validation for the Modelling of Cylindrical Pellets. KONA Powder Part. J. 2015, 32, 236–252. [Google Scholar] [CrossRef]

- Moysey, P.; Thompson, M. Determining the collision properties of semi-crystalline and amorphous thermoplastics for DEM simulations of solids transport in an extruder. Chem. Eng. Sci. 2007, 62, 3699–3709. [Google Scholar] [CrossRef]

| α = 90° | α = 45° | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 1 | 2 | 3 | 4 | 5 | |

| (°) | (°) | (°) | (°) | (°) | (°) | (°) | (°) | (°) | (°) | |

| Soil | 36.64 | 36.86 | 37.95 | 38.14 | 44.29 | 56.75 | 61.74 | 58.30 | 63.88 | 65.96 |

| Steel | 31.00 | 32.05 | 33.05 | 33.27 | 37.13 | 45.74 | 46.01 | 46.54 | 48.18 | 45.04 |

| PLA | 34.63 | 37.63 | 36.81 | 38.75 | 36.99 | 39.79 | 39.66 | 38.3 | 44.86 | 38.96 |

| Acrylic | 36.43 | 33.67 | 33.10 | 37.80 | 37.37 | 42.96 | 43.00 | 39.74 | 46.25 | 46.30 |

| Source of Variation | SS | df | MS | F | p-Value | F Crit | |

|---|---|---|---|---|---|---|---|

| α = 90° | Between Groups | 14.53 | 3 | 4.84 | 0.49 | 0.68 | 3.23 |

| Within Groups | 155.71 | 16 | 9.73 | ||||

| Total | 170.25 | 19 | |||||

| α = 45° | Between Groups | 1348.48 | 3 | 449.49 | 52.69 | <0.00 | 3.23 |

| Within Groups | 136.46 | 16 | 8.52 | ||||

| Total | 1484.95 | 19 |

| Wheat | |||

|---|---|---|---|

| Length | Width | Thickness | |

| Length | 1 | 0.31 | 0.48 |

| Width | 0.31 | 1 | 0.46 |

| Thickness | 0.483 | 0.46 | 1 |

| Generated Wheat Particle Numbers | |||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| Length, mm | 5.75 | 6.00 | 6.25 | 6.50 | 6.75 | 7.00 | 7.25 |

| Width, mm | 2.75 | 3.00 | 3.25 | 3.50 | 3.75 | 4.00 | 4.25 |

| Distribution, % | 3.75 | 12.50 | 32.50 | 15.00 | 25.00 | 7.50 | 3.75 |

| Intrinsic Parameters | Shear Modulus (Pa) | Poisson’s Ratio | Density (kg m−3) |

|---|---|---|---|

| Wheat | 1.13 × 107 a | 0.22 a | 1370 |

| Soil | 106 b | 0.38 b | 1850 b |

| Steel | 8.23 × 1010 b | 0.30 b | 7850 b |

| Acrylic | 1.15 × 109 c | 0.35 c | 1385 c |

| PLA | 2.42 × 108 d | 0.36 d | 1050 d |

| Symbol | Interaction Parameters | Low Level | High Level |

|---|---|---|---|

| A | The particle–particle static friction coefficient | 0 | 0.60 |

| B | The particle–particle rolling friction coefficient | 0 | 0.60 |

| C | The particle–particle restitution coefficient | 0.20 | 0.60 |

| D | The particle–material static friction coefficient | 0 | 0.60 |

| E | The particle–material rolling friction coefficient | 0 | 0.60 |

| F | The particle–material restitution coefficient | 0.20 | 0.60 |

| STD Order | A | B | α = 90° | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | Average | |||

| (°) | (°) | (°) | (°) | (°) | |||

| 1 | 0.15 | 0.15 | 34.54 | 33.81 | 33.42 | 33.12 | 33.72 |

| 2 | 0.45 | 0.15 | 51.15 | 50.78 | 50.12 | 50.94 | 50.75 |

| 3 | 0.15 | 0.45 | 36.58 | 36.06 | 34.83 | 36.56 | 36.01 |

| 4 | 0.45 | 0.45 | 58.55 | 58.47 | 58.66 | 58.50 | 58.55 |

| 5 | 0.00 | 0.30 | 20.54 | 19.33 | 19.25 | 19.64 | 19.69 |

| 6 | 0.60 | 0.30 | 62.04 | 61.83 | 59.05 | 61.54 | 61.12 |

| 7 | 0.30 | 0.00 | 34.62 | 34.21 | 32.74 | 33.06 | 33.66 |

| 8 | 0.30 | 0.60 | 49.18 | 50.20 | 45.32 | 48.56 | 48.32 |

| 9 | 0.30 | 0.30 | 47.24 | 46.95 | 47.57 | 47.34 | 47.28 |

| 10 | 0.30 | 0.30 | 48.64 | 47.52 | 47.30 | 47.10 | 47.64 |

| 11 | 0.30 | 0.30 | 47.00 | 48.19 | 46.29 | 47.28 | 47.19 |

| 12 | 0.30 | 0.30 | 46.76 | 47.80 | 47.58 | 47.10 | 47.31 |

| 13 | 0.30 | 0.30 | 47.15 | 47.30 | 47.93 | 47.00 | 47.35 |

| STD Order | D | E | α = 45° | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | Average | |||

| (°) | (°) | (°) | (°) | (°) | |||

| 1 | 0.15 | 0.15 | 31.72 | 32.58 | 30.22 | 30.76 | 31.32 |

| 2 | 0.45 | 0.15 | 47.50 | 45.81 | 46.85 | 48.98 | 47.29 |

| 3 | 0.15 | 0.45 | 34.25 | 33.09 | 35.10 | 34.54 | 34.25 |

| 4 | 0.45 | 0.45 | 48.67 | 48.99 | 48.63 | 48.40 | 48.67 |

| 5 | 0.00 | 0.30 | 13.45 | 14.75 | 14.56 | 15.61 | 14.59 |

| 6 | 0.60 | 0.30 | 56.65 | 56.58 | 55.41 | 56.68 | 56.33 |

| 7 | 0.30 | 0.00 | 37.10 | 38.40 | 37.70 | 37.60 | 37.70 |

| 8 | 0.30 | 0.60 | 42.81 | 40.58 | 42.59 | 39.59 | 41.39 |

| 9 | 0.30 | 0.30 | 41.13 | 37.45 | 37.54 | 40.54 | 39.17 |

| 10 | 0.30 | 0.30 | 38.06 | 39.51 | 37.75 | 37.72 | 38.26 |

| 11 | 0.30 | 0.30 | 39.20 | 41.03 | 42.17 | 40.37 | 40.69 |

| 12 | 0.30 | 0.30 | 38.71 | 37.91 | 40.02 | 38.98 | 38.91 |

| 13 | 0.30 | 0.30 | 37.65 | 38.41 | 39.56 | 40.76 | 39.10 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 1483.40 | 5 | 296.68 | 366.70 | <0.00 ** |

| A | 1248.74 | 1 | 1248.74 | 1543.44 | <0.00 ** |

| B | 129.35 | 1 | 129.35 | 159.87 | <0.00 ** |

| AB | 7.60 | 1 | 7.60 | 9.39 | 0.01 * |

| A2 | 68.16 | 1 | 68.16 | 84.25 | <0.00 ** |

| B2 | 57.12 | 1 | 57.12 | 70.59 | <0.00 ** |

| Residual | 5.66 | 7 | 0.80 | ||

| Lack of Fit | 5.55 | 3 | 1.85 | 63.25 | 0.00 ** |

| Pure Error | 0.11 | 4 | 0.02 | ||

| Cor Total | 1489.06 | 12 | |||

| R2 = 0.99; Adj R2 = 0.99; Pred R2 = 0.96; Adeq precision = 66.77; CV = 2.20%. | |||||

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

| Model | 1114.81 | 5 | 222.96 | 43.39 | <0.00 ** |

| D | 1080.53 | 1 | 1080.53 | 210.30 | <0.00 ** |

| E | 11.39 | 1 | 11.39 | 2.22 | 0.18 |

| DE | 0.60 | 1 | 0.60 | 0.11 | 0.74 |

| D2 | 18.84 | 1 | 18.84 | 3.67 | 0.09 |

| E2 | 0.30 | 1 | 0.30 | 0.05 | 0.81 |

| Residual | 35.97 | 7 | 5.14 | ||

| Lack of Fit | 32.77 | 3 | 10.92 | 13.67 | 0.01 * |

| Pure Error | 3.20 | 4 | 0.79 | ||

| Cor Total | 1150.77 | 12 | |||

| R2 = 0.96; Adj R2 = 0.94; Pred R2 = 0.73; Adeq precision = 24.64; CV = 5.80%. | |||||

| Soil | Steel | PLA | Acrylic | |

|---|---|---|---|---|

| Particle–material static friction coefficient (D) | 0.51 | 0.40 | 0.30 | 0.36 |

| Particle–material rolling friction coefficient (E) | 0.38 | 0.33 | 0.35 | 0.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sugirbay, A.; Hu, G.-R.; Chen, J.; Mustafin, Z.; Muratkhan, M.; Iskakov, R.; Chen, Y.; Zhang, S.; Bu, L.; Dulatbay, Y.; et al. A Study on the Calibration of Wheat Seed Interaction Properties Based on the Discrete Element Method. Agriculture 2022, 12, 1497. https://doi.org/10.3390/agriculture12091497

Sugirbay A, Hu G-R, Chen J, Mustafin Z, Muratkhan M, Iskakov R, Chen Y, Zhang S, Bu L, Dulatbay Y, et al. A Study on the Calibration of Wheat Seed Interaction Properties Based on the Discrete Element Method. Agriculture. 2022; 12(9):1497. https://doi.org/10.3390/agriculture12091497

Chicago/Turabian StyleSugirbay, Adilet, Guang-Rui Hu, Jun Chen, Zhasulan Mustafin, Marat Muratkhan, Ruslan Iskakov, Yu Chen, Shuo Zhang, Lingxin Bu, Yerassyl Dulatbay, and et al. 2022. "A Study on the Calibration of Wheat Seed Interaction Properties Based on the Discrete Element Method" Agriculture 12, no. 9: 1497. https://doi.org/10.3390/agriculture12091497

APA StyleSugirbay, A., Hu, G.-R., Chen, J., Mustafin, Z., Muratkhan, M., Iskakov, R., Chen, Y., Zhang, S., Bu, L., Dulatbay, Y., & Mukhamed, B. (2022). A Study on the Calibration of Wheat Seed Interaction Properties Based on the Discrete Element Method. Agriculture, 12(9), 1497. https://doi.org/10.3390/agriculture12091497