Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors

Abstract

:1. Introduction

2. Materials and Methods

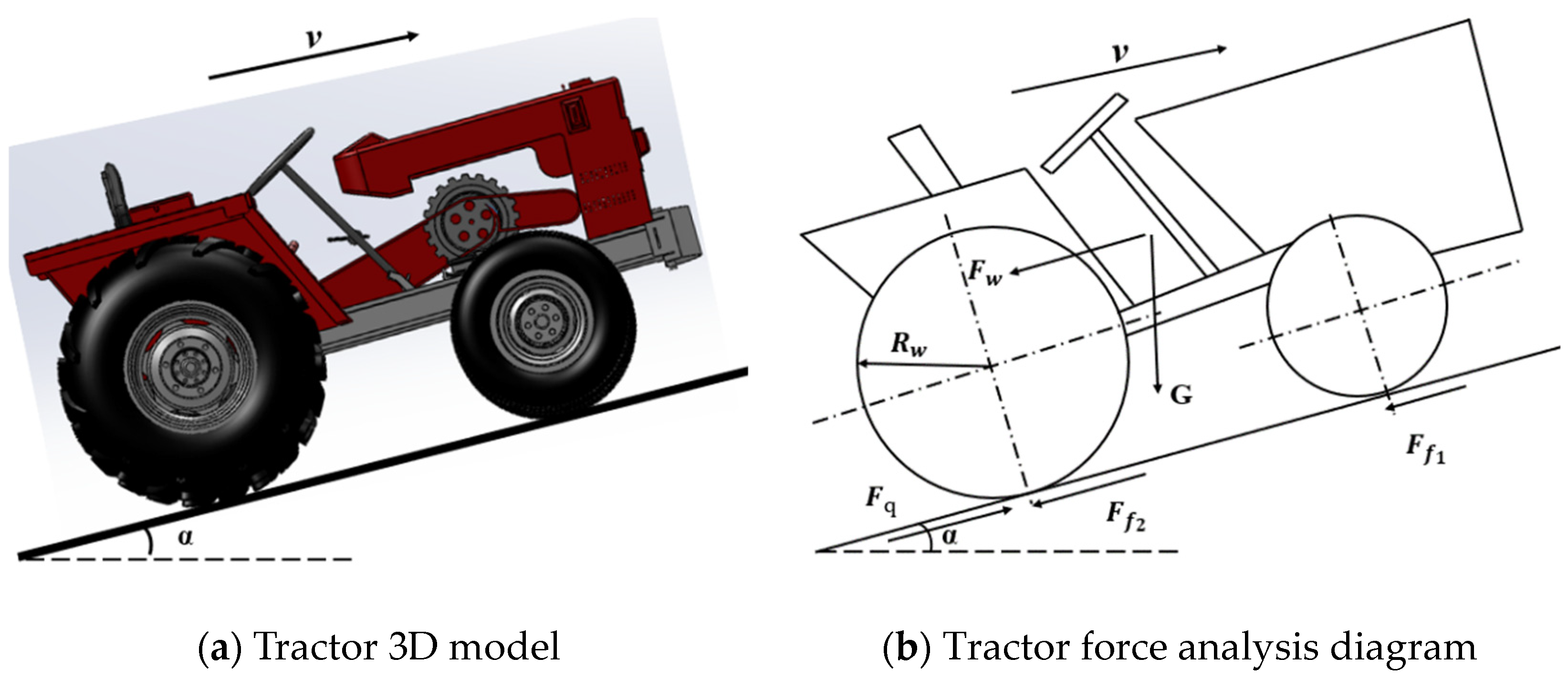

2.1. Modeling of Electric Tractor Drive

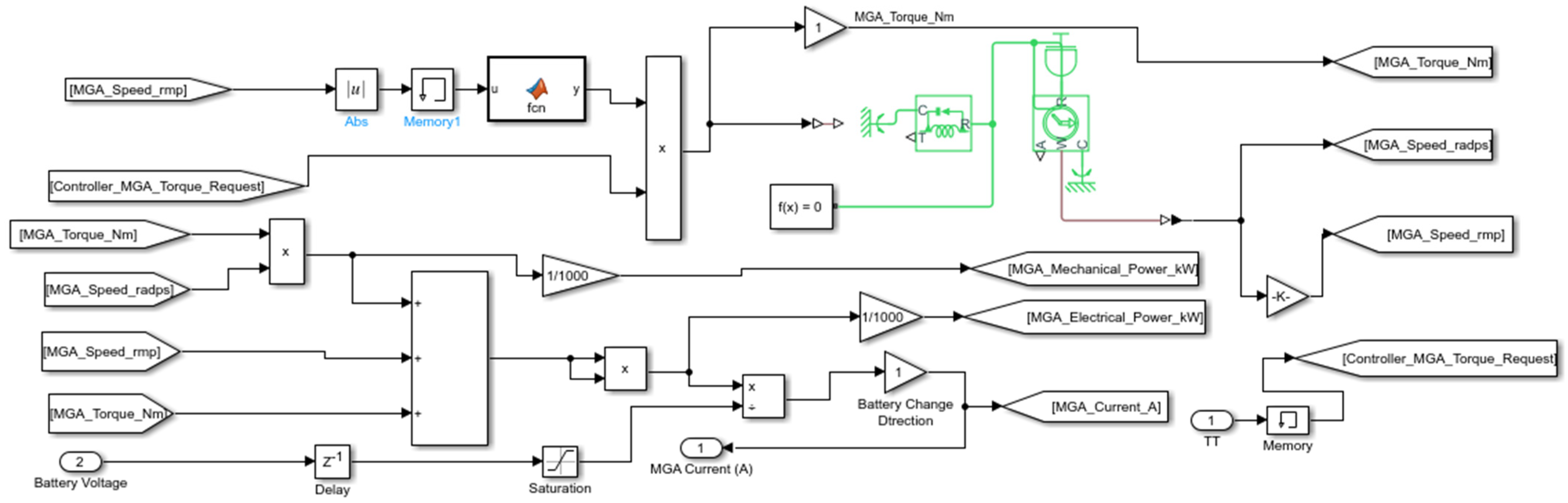

2.1.1. Motor Model

2.1.2. Battery Selection

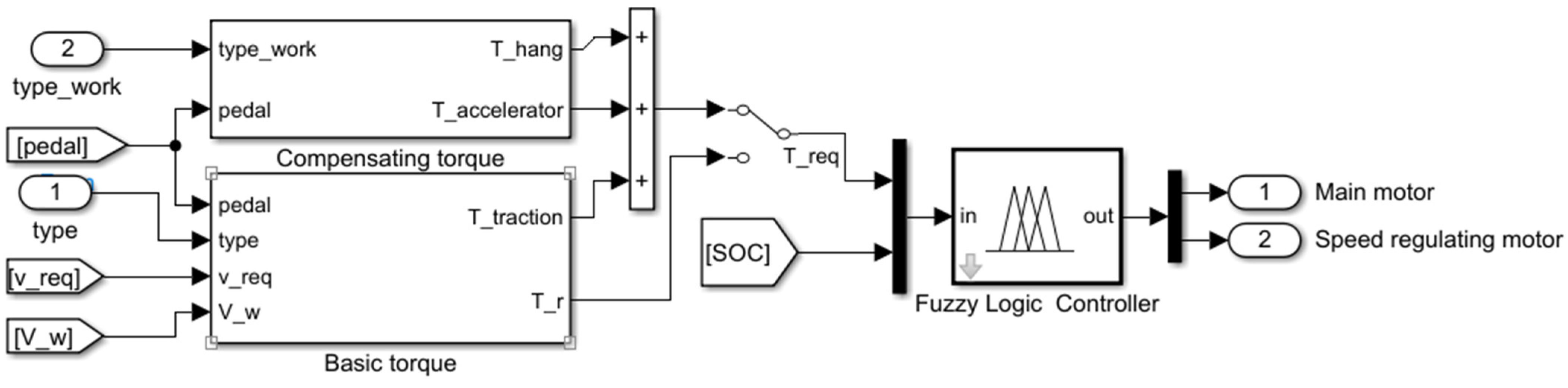

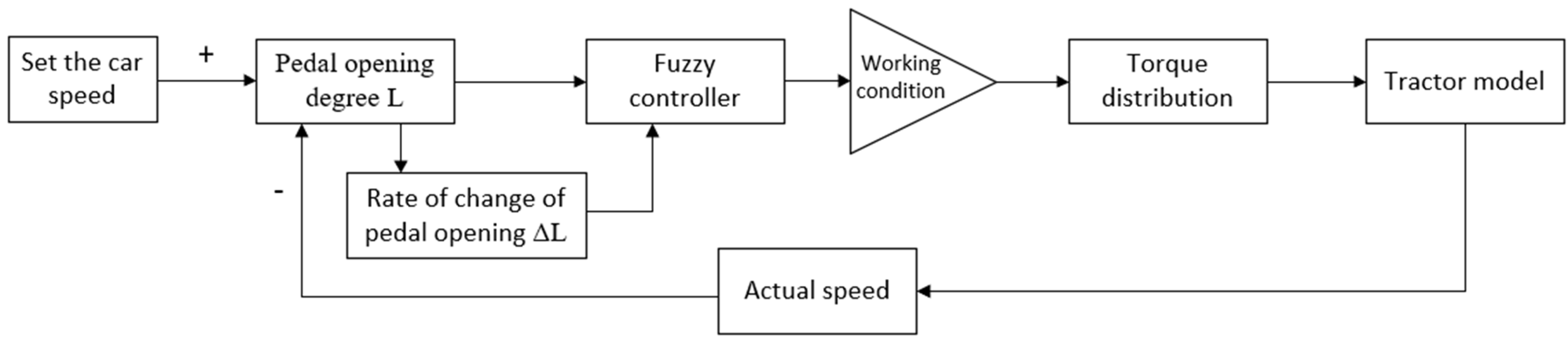

2.2. Torque Calculation Strategy

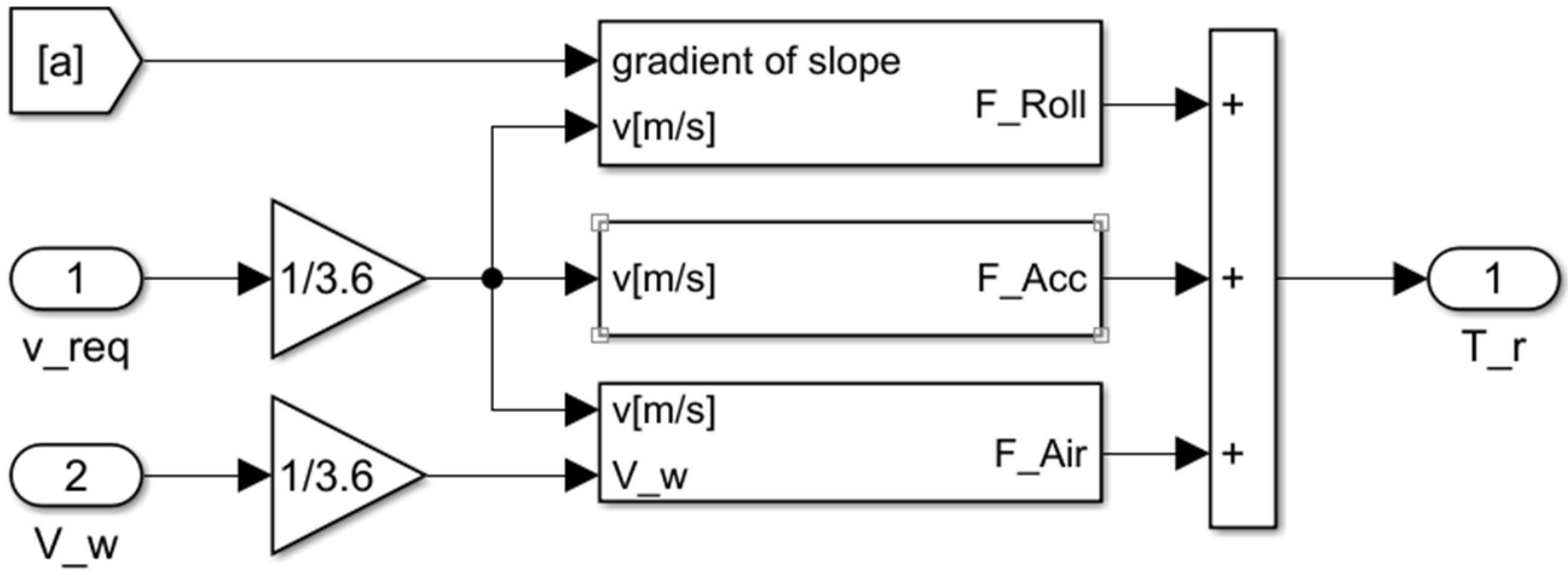

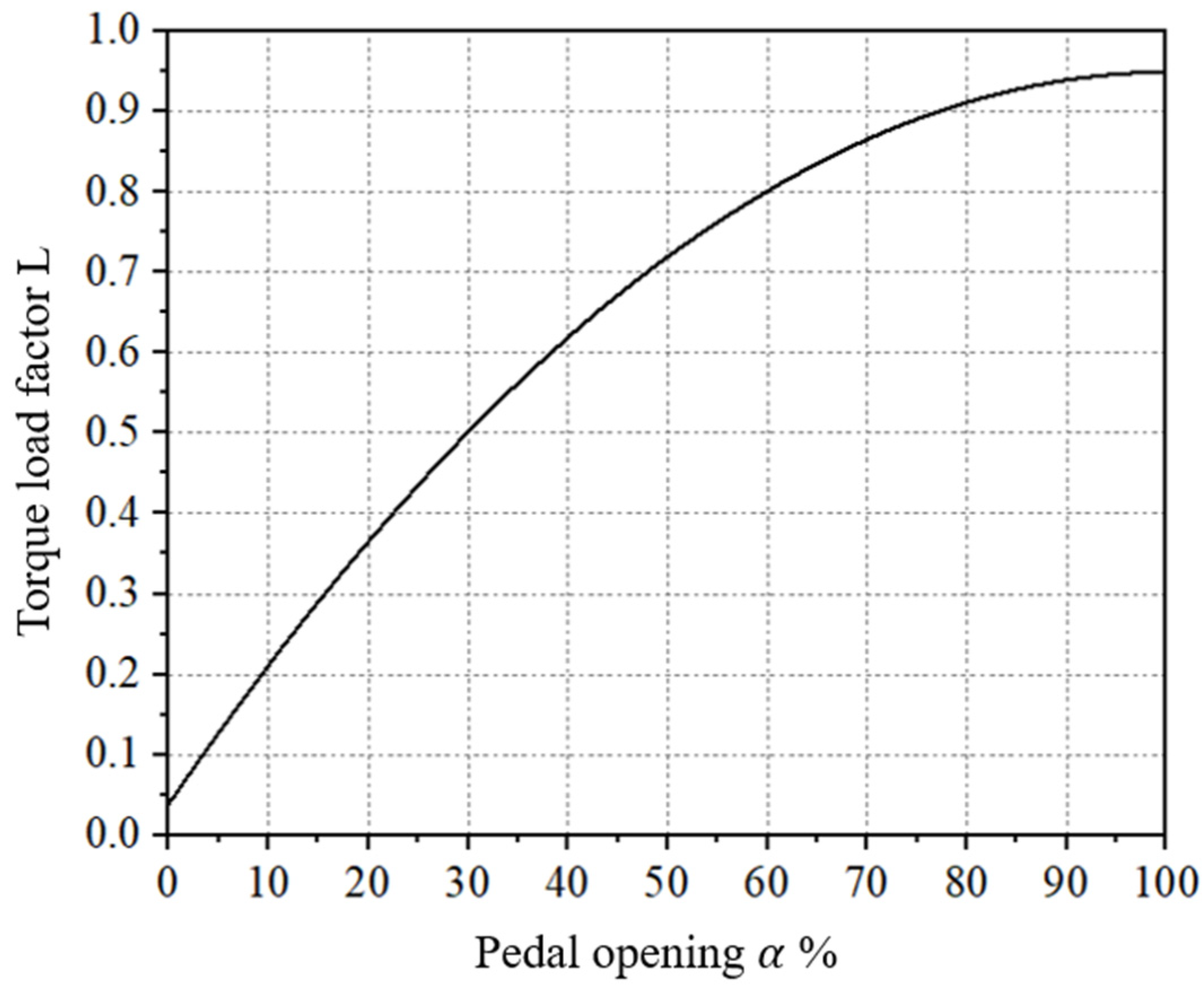

2.2.1. Basic Torque Calculation Module

- (1)

- Speed demand torque

- (2)

- Traction demand torque

2.2.2. Compensation Torque Calculation Strategy

- (1)

- Acceleration compensation torque

- (2)

- Suspension compensation torque

2.3. Torque Distribution Strategy

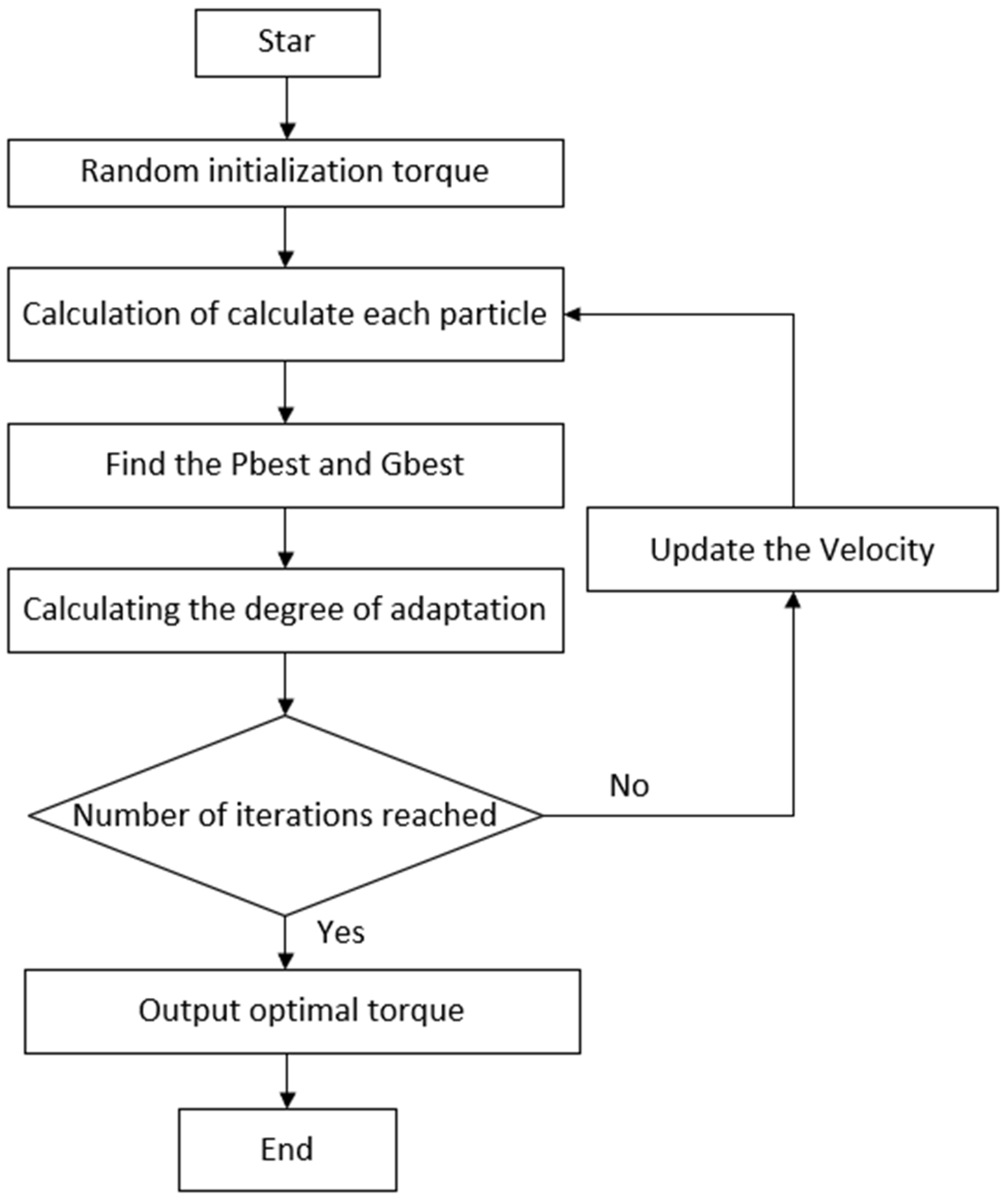

2.3.1. Torque Distribution Algorithm (PSO) Design

- (1)

- Iterative formula

- (2)

- Objective function

2.3.2. Torque Distribution Algorithm (PSO) Implementation

- (1)

- Star: The parameter settings are performed, as shown in Table 1 [29]. The number of particles set by the algorithm is determined according to the response time of the operating process. The algorithm has two search parameters—main motor torque and speed control motor torque, from which the particle dimension is determined. The learning factor is generally chosen as the default value of 2. The inertia weight and the number of iterations are determined according to the algorithm’s convergence Figure 9.

- (2)

- Calculate each particle: According to the objective function, calculate each particle i by the fitness function value.

- (3)

- (3) Find the : Compare the current particle with the best fitness function value of individual history, and if the current particle has a larger fitness function value, then update Pbest.

- (4)

- Find the : Compare the current particle with the global best fitness function value, and if the value of the fitness function of the current particle is greater, then update .

- (5)

- Update the Velocity: Update the velocity and position of each particle, according to the iterative formula.

- (6)

- Output optimal torque: After reaching the maximum number of iterations, the optimal torque and the fitness function value are output.

2.3.3. Torque Distribution Fuzzy Controller

2.4. MATLAB/Simulink Torque Distribution Simulation Experiment

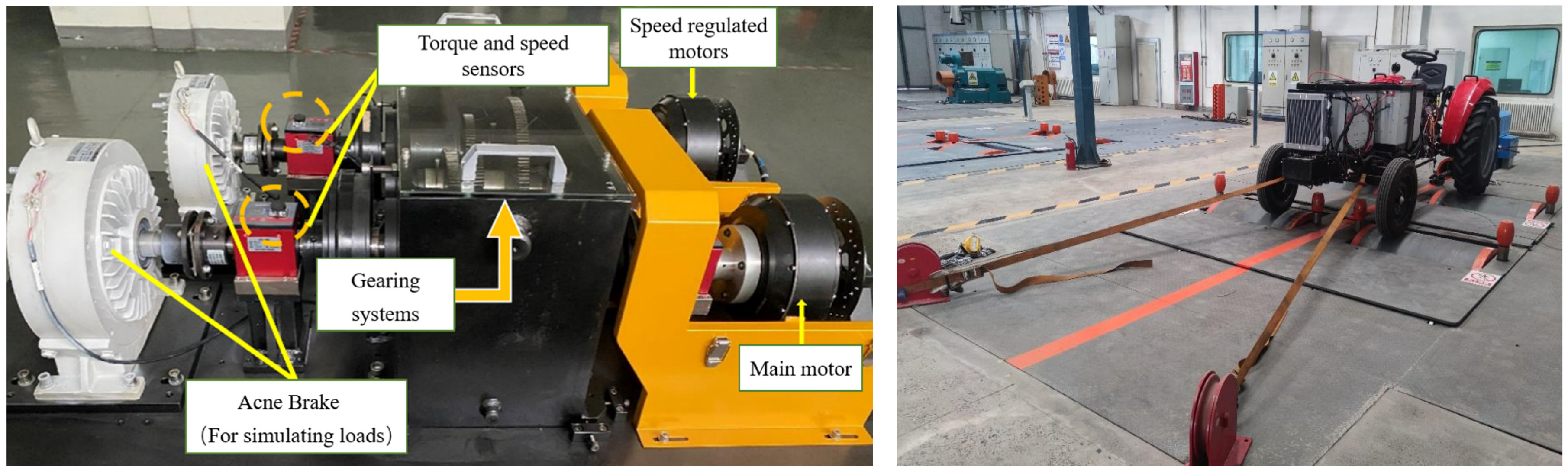

2.5. Performance Test of Motor Torque Distribution

3. Results and Discussion

3.1. Torque Calculation Strategy

- (1)

- Torque load factor of speed demand torque

- (2)

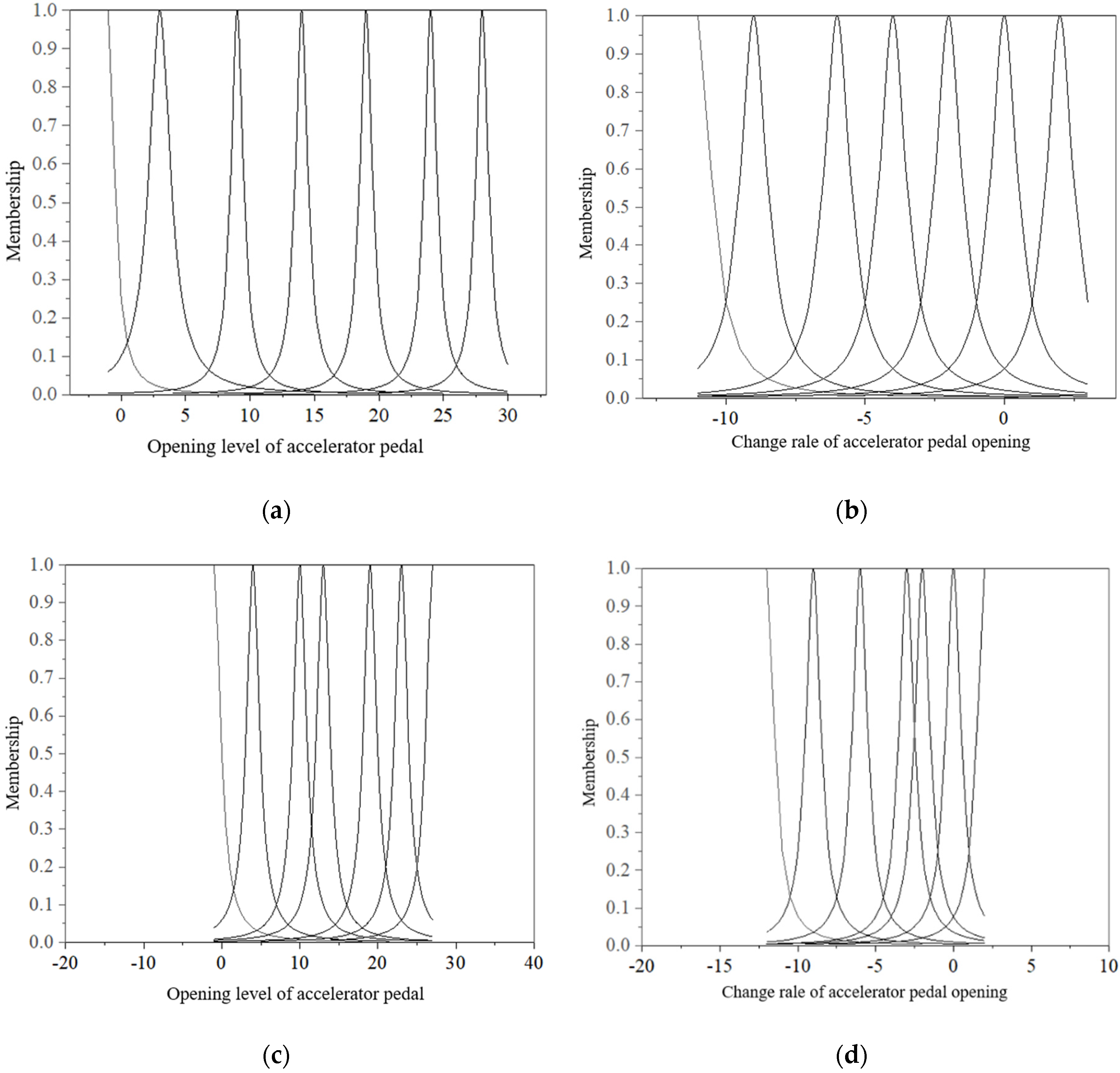

- Traction demand torque fuzzy controller

- (3)

- Accelerated compensation strategy affiliation function

- (4)

- Torque distribution fuzzy controller

3.2. Torque Distribution Algorithm Simulation

- (1)

- PSO algorithm merit verification

- (2)

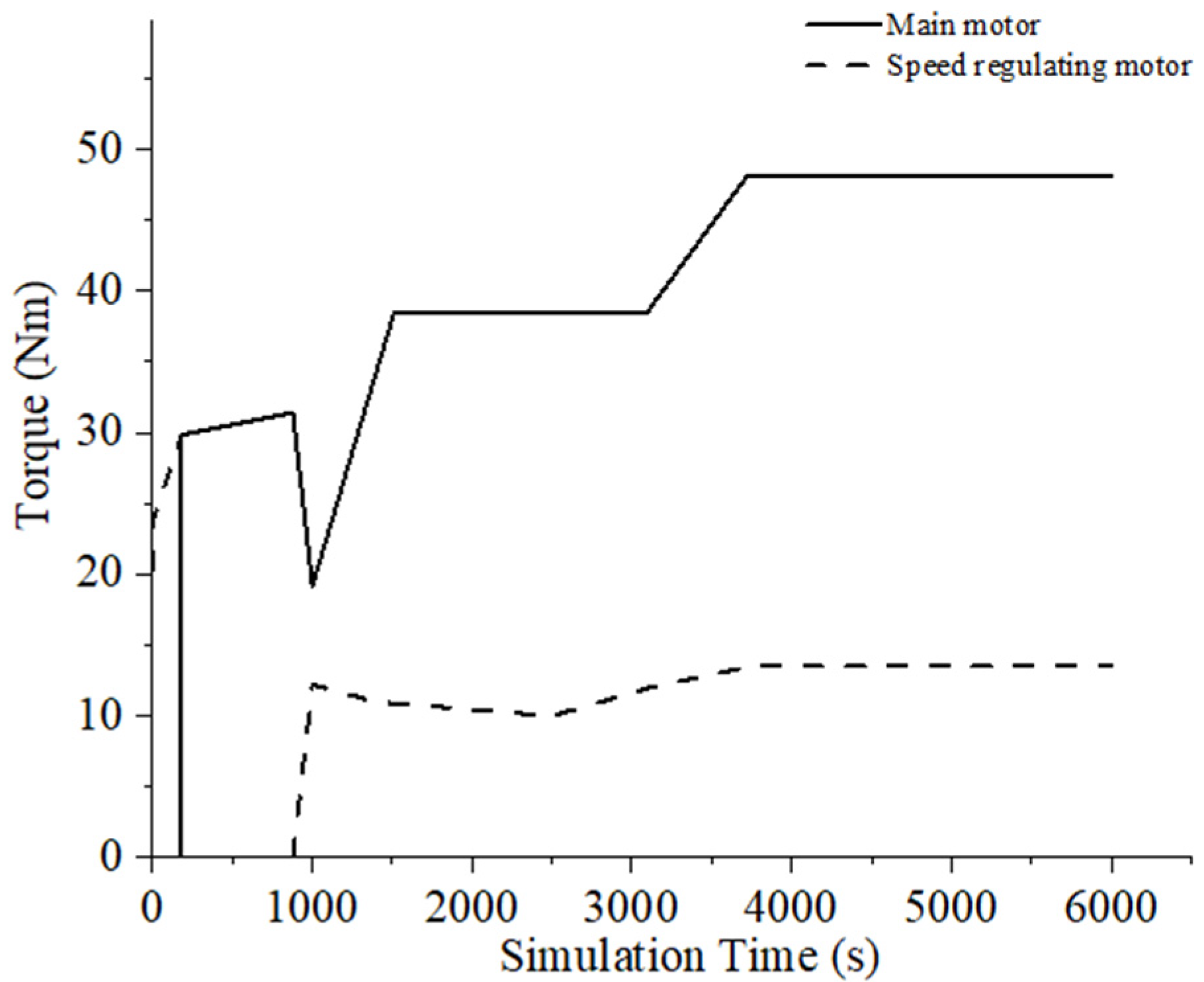

- Torque distribution simulation

3.3. Performance Test of Motor Torque Distribution

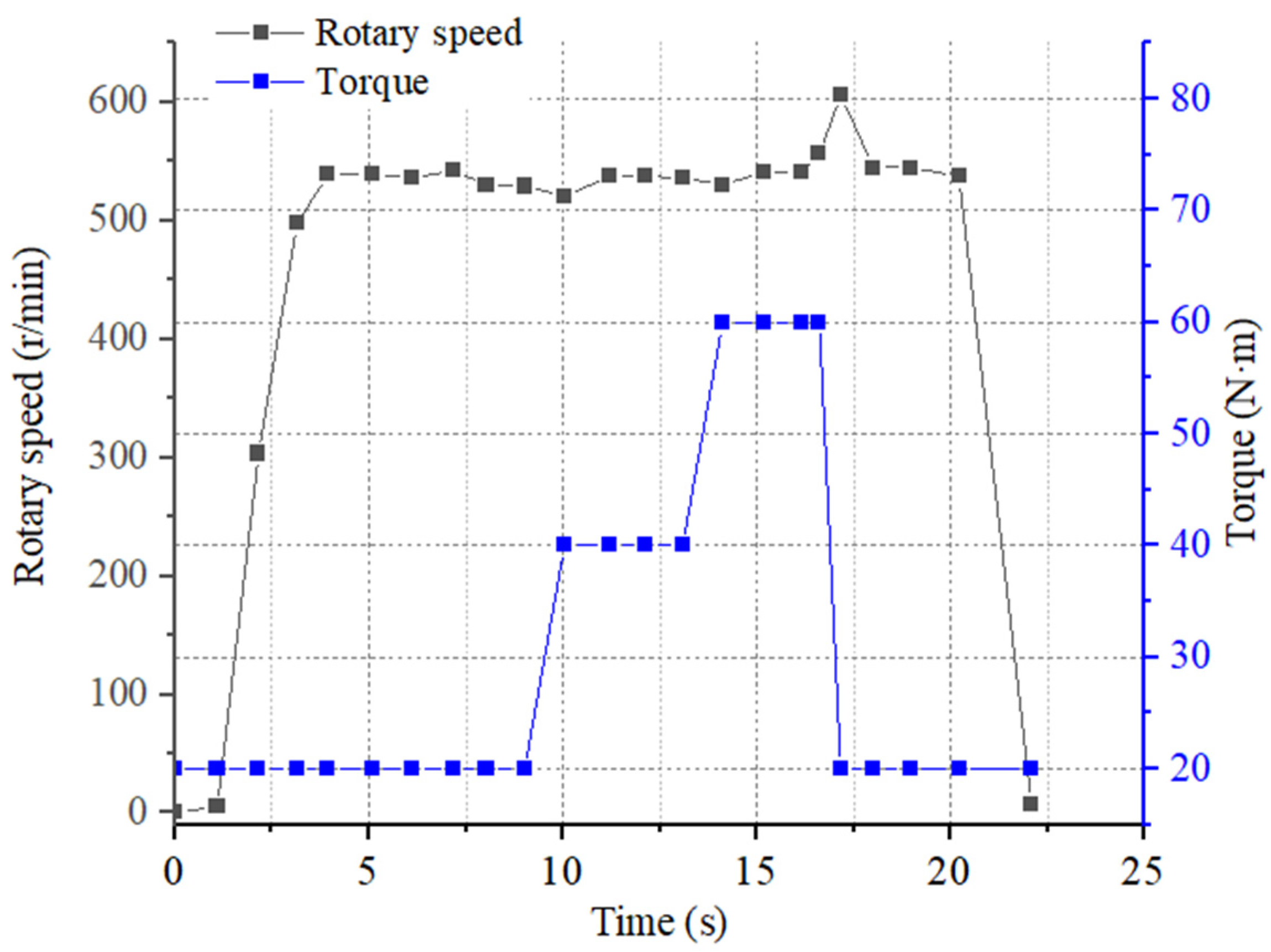

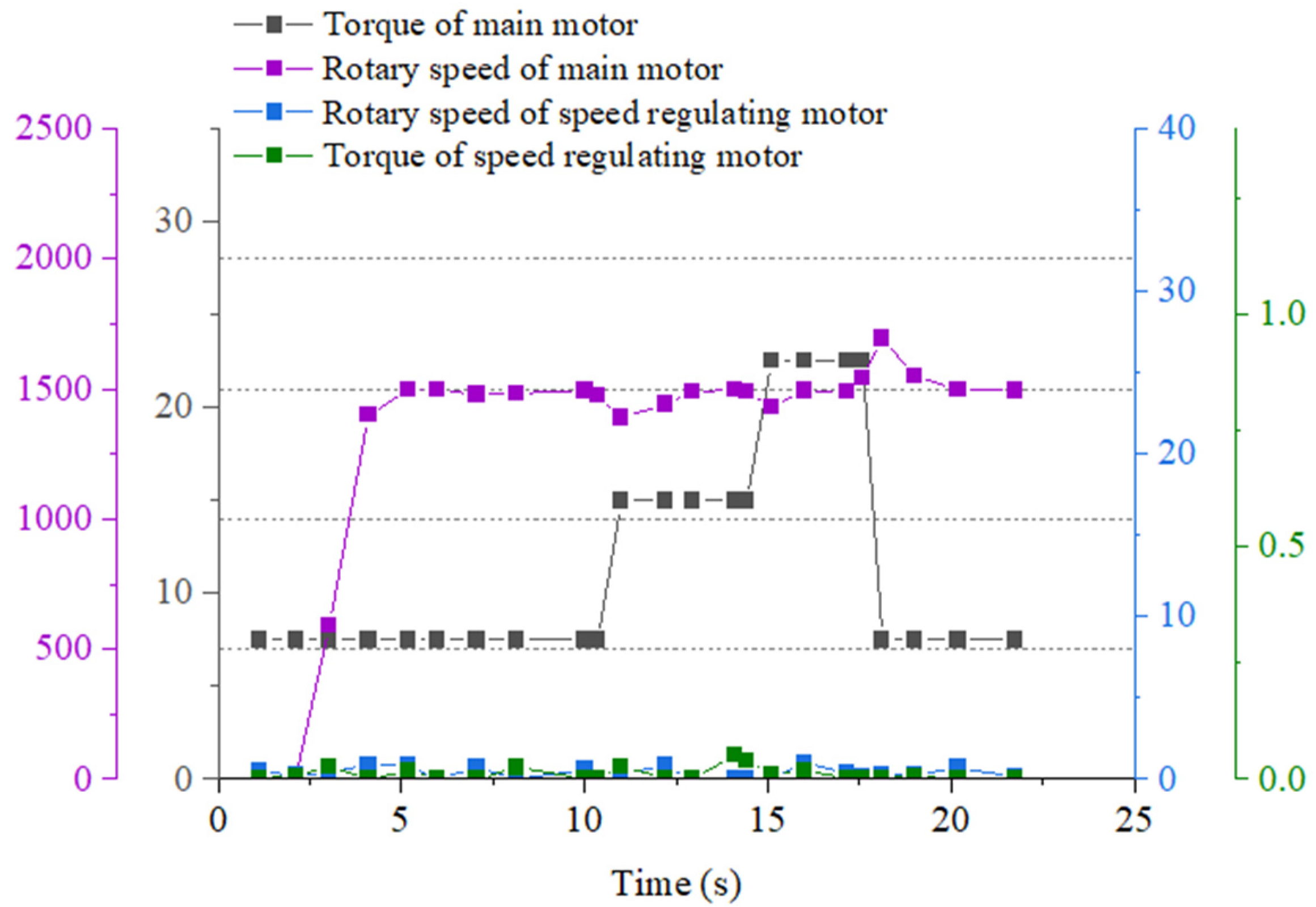

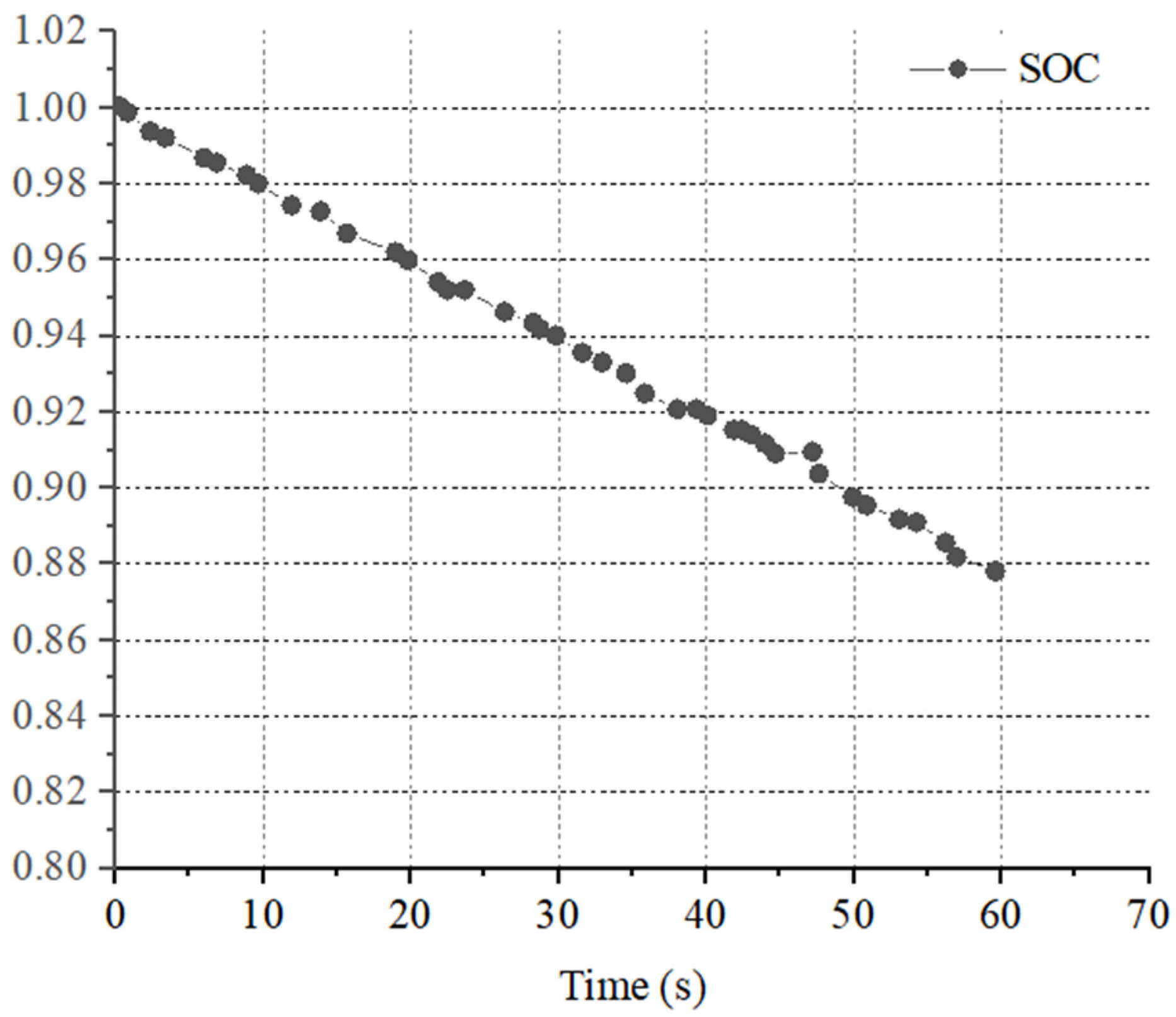

3.3.1. In Situ PTO Operation

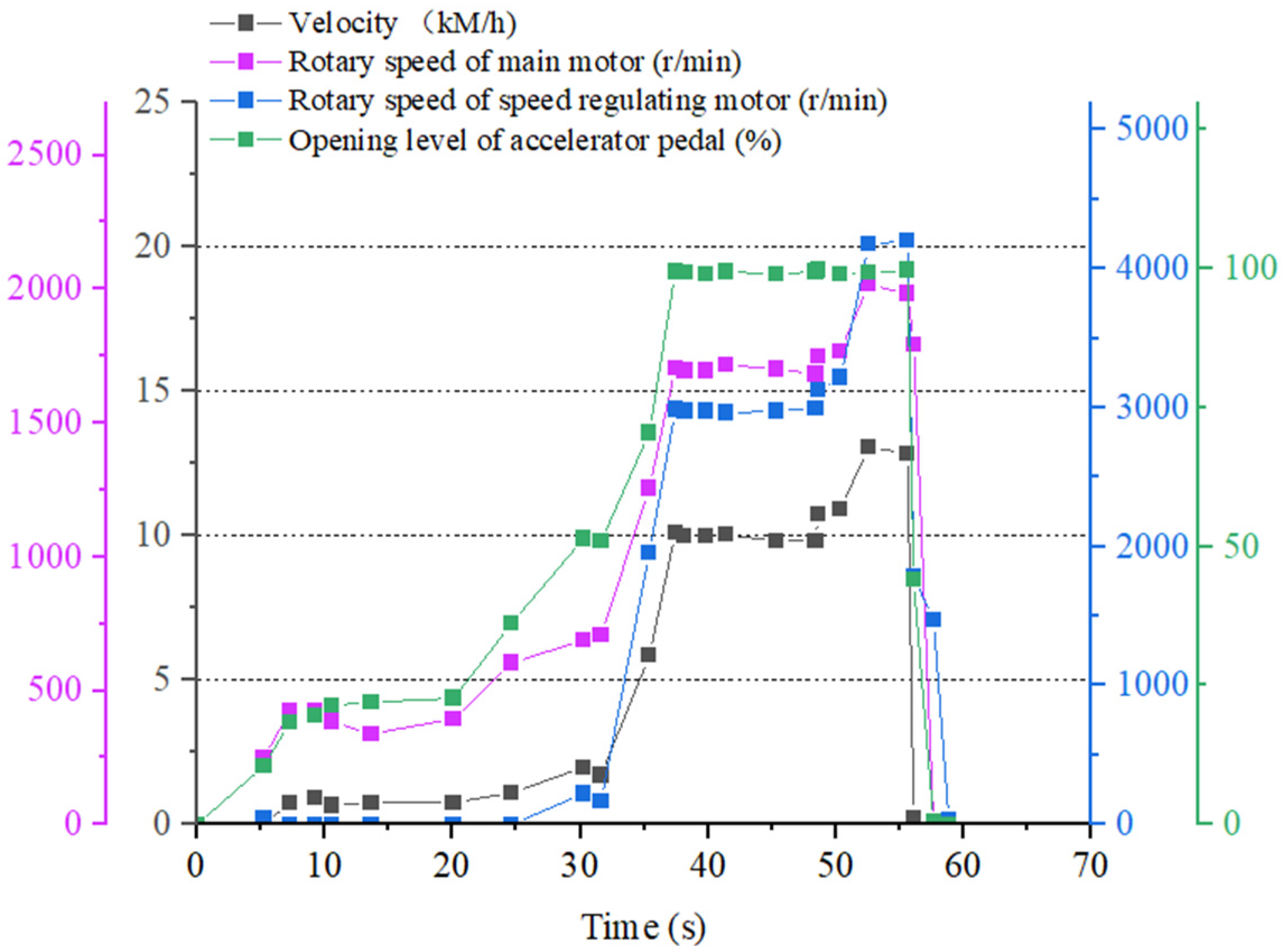

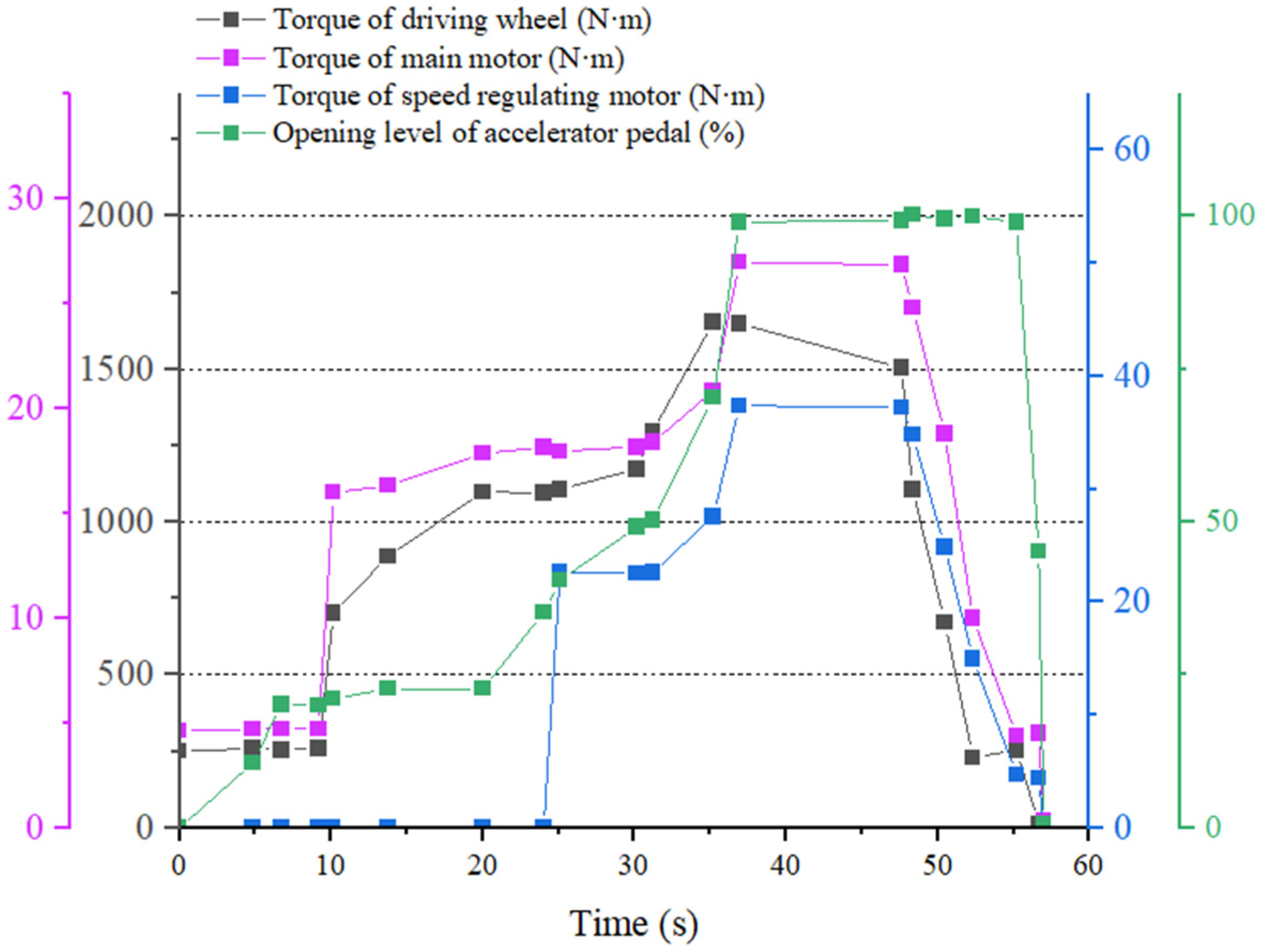

3.3.2. Plowing Operations

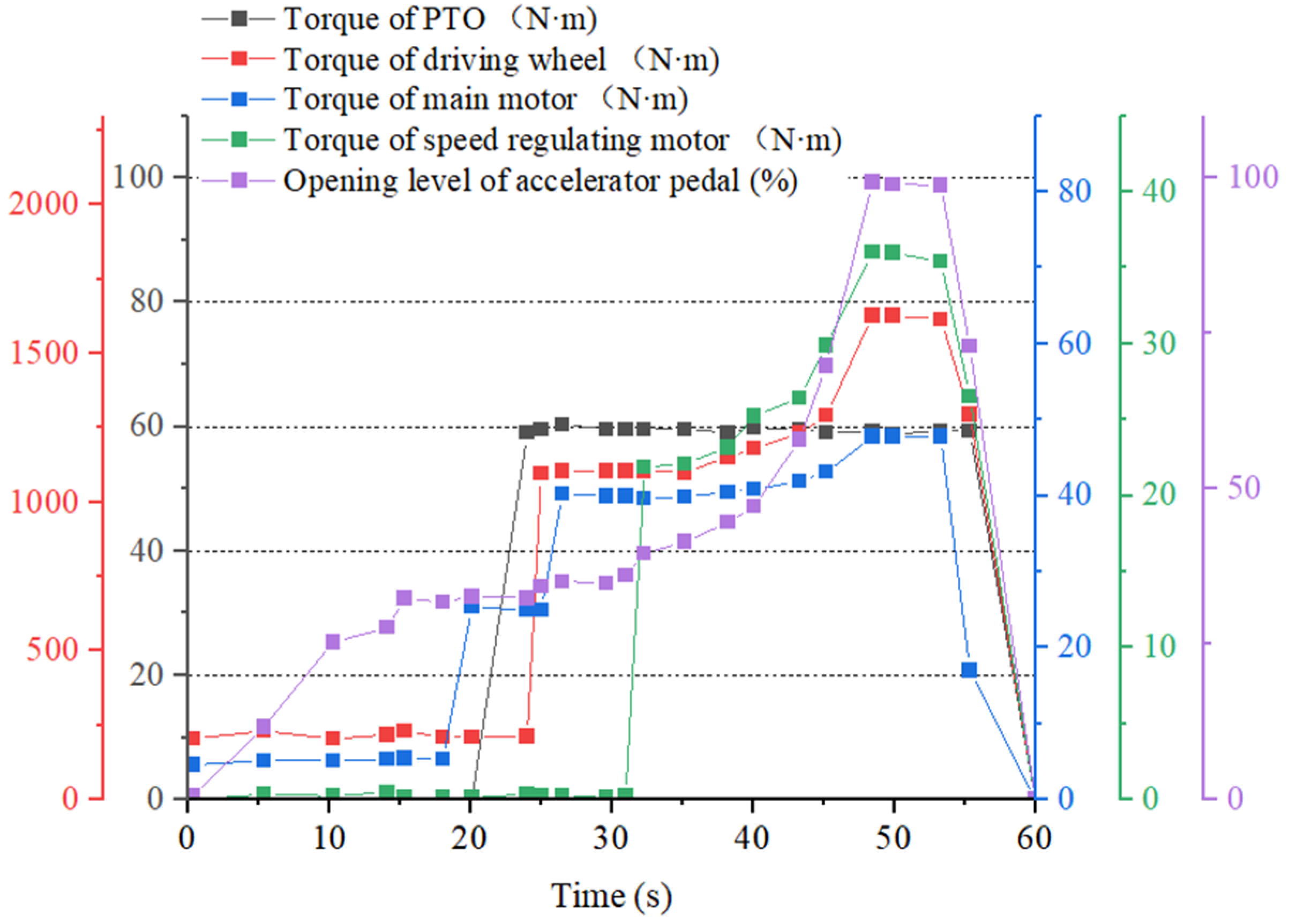

3.3.3. Rototilling Operation

4. Conclusions

- (1)

- The demand torque during the operation of the tractor is divided into two parts, basic and compensating, and a simulation model for the calculation of torque is established separately.

- (2)

- The optimized demand torque combined with the battery SOC is assigned to both motors using fuzzy rules. The total torque is less than 22.6 N·m, and the speed-controlled motor is driven alone. The total torque increases to 31.4 N·m, and the main motor is driven separately. The total torque is greater than 31.4 N·m, and the two motors are driven together. The simulation results show that the PSO algorithm converges quickly, the adaptation value can be stabilized in about 20 iterations, and the main and the speed control motor can respond quickly and accurately according to the assigned torque, within 1 s.

- (3)

- The bench test results show that the main and speed control motor respond within 3 s of receiving the pedal signal, with good real-time performance. The drive wheel torque of plowing and rotating operation can reach 1600 N·m. The PTO torque of rotating operation can reach 60 N·m. The maximum torque of the output shaft can reach 150 N·m during rotating tillage, with good tillage performance. The battery SOC shows a stable linear decrease during all tillage processes, and the battery’s working state has stability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, X.W.; Liao, J.; Hu, L.; Zang, Y.; Zhou, Z.Y. Improving agricultural mechanization for sustainable agricultural development. Trans. Chin. Soc. Agric. Eng. 2016, 32, 1–11. [Google Scholar]

- Moreda, G.P.; Munoz-García, M.A.; Barreiro, P. High voltage electric~fiction of tractor and agricultural machinery A review. Energy Convers Manag. 2016, 115, 117–131. [Google Scholar] [CrossRef]

- Zhao, C.F.; Si, J.D.; Gong, L.J. Modeling and simulation analysis of electric tractor drive control system. Xinjiang Agric. Mech. 2022, 1, 15–17+37. [Google Scholar]

- Ghobadpour, A.; Mousazadeh, H.; Kelouwani, S.; Zioui, N.; Kandidayeni, M.; Boulon, L. An intelligent energy management strategy for an off-road plug-in hybrid electric tractor based on farm operation recognition. IET Electr. Syst. Transp. 2021, 11, 333–347. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Zhou, J.; Yang, H.X.; Wang, X. Design and testing of a rapid prototyping platform measurement and control system for electric tractors. Trans. Chin. Soc. Agric. Mach. 2022, 2, 412–420. [Google Scholar]

- Chen, Y.N.; Xie, B.; Du, Y.F.; Mao, E.R. Powertrain parameter matching and optimal design of dual-motor driven electric tractor. Int. J. Agric. Biol. Eng. 2019, 12, 33–41. [Google Scholar] [CrossRef]

- Xie, B.; Wang, S.; Wu, X.H.; Wen, C.K.; Zhang, S.L.; Zhao, X.Y. Design and hardware-in-the-loop test of a coupled drive system for an electric tractor. Biosyst. Eng. 2022, 216, 165–185. [Google Scholar] [CrossRef]

- Wen, C.K.; Zhang, S.L.; Xie, B.; Song, Z.H.; Li, T.H.; Jia, F.; Han, J.G. Design and verification of innovative approach of dual-motor power coupling drive systems for electric tractors. Energy 2022, 247, 123538. [Google Scholar] [CrossRef]

- Li, T.H.; Xie, B.; Li, Z.; Li, J.K. Design and Optimization of a Dual-Input Coupling Powertrain System: A Case Study for Electric Tractors. Appl. Sci. 2020, 10, 1608. [Google Scholar] [CrossRef]

- Liu, M.N.; Li, S.Y.; Xu, L.Y.; Zhao, Y.R. Design and performance analysis of bi-directional coupled electric drive system for tractors. Trans. Chin. Soc. Agric. Mach. 2022, 53, 423–431 + 449. [Google Scholar]

- Kim, W.; Lee, D.H.; Kim, Y.J.; Kim, Y.S.; Park, S.U. Estimation of Axle Torque for an Agricultural Tractor Using an Artificial Neural Network. Sensors 2021, 21, 1989. [Google Scholar] [CrossRef]

- Wan-Soo, K.; Yong-Joo, K.; Seung-Yun, B.; Seung-Min, B.; Yeon-Soo, K.; Seong-Un, P. Development of a Prediction Model for Tractor Axle Torque during Tillage Operation. Appl. Sci. 2020, 10, 4195. [Google Scholar]

- Kim, W.S.; Kim, Y.S.; Kim, Y.J. Development of prediction model for axle torque od agriculture tractors. Trans. Asabe 2020, 63, 1773–1786. [Google Scholar] [CrossRef]

- Yin, D.J.; Wang, J.J.; Du, J.J.; Chen, G.; Hu, J.S. A New Torque Distribution Control for Four-Wheel Independent-Drive Electric Vehicles. Actuators 2021, 10, 122. [Google Scholar] [CrossRef]

- Mao, P.J.; Yin, S.S.; Min, J.J.; Zhang, Y.L.; Zhang, J.R.; Jiang, K. Research progress of electric tractor controller. Agric. Eng. 2017, 1, 11–14. [Google Scholar]

- Zhang, Y.F.; Lu, M.; Xie, Q. Economic-based drive design of greenhouse electric tractor. Xinjiang Agric. Mech. 2017, 5, 21–23 + 37. [Google Scholar]

- Xu, L.-Y.; Zhang, J.-J.; Liu, M.-N. Torque distribution strategy of incremental four-wheel drive electric tractor. J. Henan Univ. Sci. Technol. (Nat. Sci.) 2017, 38, 80–85. [Google Scholar]

- Wu, Z.B.; Xie, B.; Chi, R.J.; Ren, Z.Y.; Du, Y.F.; Li, Z. Drive torque management model for electric tractor field cruising operation. Trans. Chin. Soc. Agric. Eng. 2019, 4, 88–98. [Google Scholar]

- Wu, Z.B.; Xie, B.; Li, Z.; Chi, R.J.; Ren, Z.Y.; Du, Y.F.; Eiji, I.; Muneshi, M.; Takashi, O.; Yasumaru, H. Modeling and verification of driving torque management for electric tractor: Dual-mode driving intention interpretation with torque demand restriction. Biosyst. Eng. 2019, 182, 65–83. [Google Scholar] [CrossRef]

- Roeber, J.B.W.; Pitla, S.K.; Hoy, R.M.; Luck, J.D.; Kocher, M.F. Tractor Power Take-Off Torque Measurement and Data Acquisition System. Appl. Eng. Agric. 2017, 33, 679–686. [Google Scholar] [CrossRef]

- Wang, S.Y.; Hu, Z.C.; Chen, C.; Gao, X.M.; Gu, F.W.; Wu, H.C. Design and bench test automatic row alignment system of traction type sugar beet combine harvester. Trans. Chin. Soc. Agric. Mach. 2020, 4, 103–112 + 163. [Google Scholar]

- Pochi, D.; Grilli, R.; Fornaciari, L.; Betto, M.; Benigni, S.; Fanigliulo, R. Bench Testing of Sensors Utilized for In-Line Monitoring of Lubricants and Hydraulic Fluids Properties. Sensors 2021, 21, 8201. [Google Scholar] [CrossRef] [PubMed]

- Fatih, K.; Celalettin, Y.; Oguz, D.; Mehmet, O.G.; Necmettin, K. Design and development of tractor clutch using combined field and bench tests. Trans. Can. Soc. Mech. Eng. 2018, 42, 136–146. [Google Scholar]

- Huang, Z.J. DSP-based two-wheel drive system with switched reluctance motor for electric tractor. J. Agric. Mech. Res. 2022, 2, 241–245. [Google Scholar]

- Tao, Q.W.; Yan, X.H.; Tong, Y.J.; Yan, Y.X.; Xu, L.Y. Tractor indoor bench test technology status and outlook. Chin. J. Agric. Chem. 2021, 12, 121–128. [Google Scholar]

- Jin, A.J.; Shao, F.X.; Yan, Z.G. Adaptive fuzzy neural network-based vector control of induction motor. Electron. Sci. Technol. 2011. [Google Scholar] [CrossRef]

- Wu, Z.B.; Liu, Y.; Zhang, J.; Zhou, F.-T.; He, J.-Q.; Xie, B. Ballast configuration design and parameter optimization of electric tractor power battery. J. Agric. Mach. 2021, 10, 425–433. [Google Scholar]

- Tang, J.; Zheng, S.H.Q.; Wang, Z.C.; Hong, J.H.; Zhang, Y.B. A Particle Swarm Optimization with improved learning and compression factor. Yunnan Hydropower 2022, 6, 77–79. [Google Scholar]

- Qu, L.; Yang, Z.; Yang, N.; Xing, Y. Optimization of milling parameters using improved particle swarm algorithm. Mach. Des. Manuf. 2022, 7, 187–191. [Google Scholar]

- Wang, L.; Zong, J.; Wang, Y.; Fu, L.; Mao, X.; Wang, S. Compilation and bench test of tractor three-point suspension traction load spectrum based on optimal distribution fitting. J. Agric. Eng. 2022, 2, 41–49. [Google Scholar]

- Chen, A.Y.; Chen, S.R.; Shi, A.P.; Xu, L.Y.; Zhang, H.Z. Design of torque distribution strategy for electric tractor with dual motor coupling drive. Agric. Mech. Res. 2021, 11, 1–6. [Google Scholar]

- Chen, A.Y. Central Controller Strategy and Software Design for Electric Tractor with Dual Motor Coupling Drive. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2020. [Google Scholar]

- Wang, Y.; Wang, L.; Zong, J.; Lv, D.; Wang, S. Research on Loading Method of Tractor PTO Based on Dynamic Load Spectrum. Agriculture 2021, 11, 982. [Google Scholar] [CrossRef]

- Huang, T.L.; Chen, S.R.; Shi, A.P.; Li, F.Q.; Pan, C.F. Energy management strategy for dual-motor power divider pure electric tractors. J. Agric. Mech. Res. 2020, 6, 246–250. [Google Scholar]

| 50 | 2 | 2 | 0.5 | 100 |

| Parameters | On Domain | Fuzzy Subsets |

|---|---|---|

| [0, 1] | {very small (TS), small (S), medium (M), large (B), large (TB)} | |

| [0, 1] | {very low (TL), low (L), medium (M), high (H), very high (TH)} | |

| [0, 1] | {very small (TS), small (S), medium (M), large (B), large (TB)} |

| Serial Number | Parameters | On Domain Taking |

|---|---|---|

| 1 | Accelerator pedal change amount L | [0, 1] |

| 2 | Accelerator pedal rate of change ΔL | [0, 1] |

| 3 | Traction torque coefficient ΔTt | [−1, 1] |

| 4 | Input parameters | {0, 0.25, 0.5, 0.75, 1} |

| 5 | Output parameters | {−1, −0.5, 0, 0.5, 1} |

| \ | Fuzzy subset of each variable | {TS, S, M, B, TB} |

| TS | S | M | B | TB | ||

|---|---|---|---|---|---|---|

| TS | TS | TS | TS | TS | TS | |

| S | S | TS | TS | TS | TS | |

| M | B | M | S | S | TS | |

| B | TB | TB | M | M | S | |

| TB | TB | B | M | S | TS | |

| SOC | ||||||

|---|---|---|---|---|---|---|

| TL | L | M | H | TH | ||

| TS | TS | TS | B | TB | TB | |

| S | TS | TS | M | TB | B | |

| M | TS | TS | S | M | M | |

| B | TS | TS | TS | M | S | |

| TB | TS | TS | TS | S | S | |

| Serial Number | Number of Convergence Iterations | Adequate Function Value | ||

|---|---|---|---|---|

| a | 6 | 300 | 20–30 | 79.0 |

| b | 6 | 900 | <20 | 176.0 |

| c | 18 | 500 | <20 | 242.82 |

| d | 18 | 600 | 30–40 | 48.4 |

| Serial Number | Power/kW | Output Shaft Torque/N·m | Rotational Speed/r·min−1 | Battery Carrying Voltage/V | Current/A | Motor Case Temperature/°C | |

|---|---|---|---|---|---|---|---|

| Output Shaft | Electric Motors | ||||||

| 1 | 2.09 | 20 | 1000 | 3612 | 394.0 | 6.5 | 35.4 |

| 2 | 4.18 | 40 | 998 | 3605 | 394.1 | 12.8 | 38.6 |

| 3 | 6.28 | 60 | 1000 | 3612 | 394.3 | 19.1 | 41.2 |

| 4 | 8.38 | 80 | 1000 | 3612 | 394.2 | 26.0 | 43.5 |

| 5 | 10.47 | 100 | 1000 | 3612 | 394.1 | 32.2 | 45.2 |

| 6 | 12.57 | 120 | 1000 | 3612 | 394.2 | 38.0 | 47.6 |

| 7 | 14.66 | 140 | 1000 | 3612 | 394.0 | 46.1 | 50.2 |

| 8 | 15.71 | 150 | 1000 | 3612 | 394.2 | 48.6 | 49.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture 2022, 12, 1373. https://doi.org/10.3390/agriculture12091373

Yu Y, Hao S, Guo S, Tang Z, Chen S. Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture. 2022; 12(9):1373. https://doi.org/10.3390/agriculture12091373

Chicago/Turabian StyleYu, Yao, Shuaihua Hao, Songbao Guo, Zhong Tang, and Shuren Chen. 2022. "Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors" Agriculture 12, no. 9: 1373. https://doi.org/10.3390/agriculture12091373

APA StyleYu, Y., Hao, S., Guo, S., Tang, Z., & Chen, S. (2022). Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture, 12(9), 1373. https://doi.org/10.3390/agriculture12091373