Design and Test of Longitudinal Axial Flow Staggered Millet Flexible Threshing Device

Abstract

:1. Introduction

2. Materials and Methods

2.1. Complete Machine Structure

2.2. Working Principle

2.3. Key Component Design

2.3.1. The Design of Threshing Drum

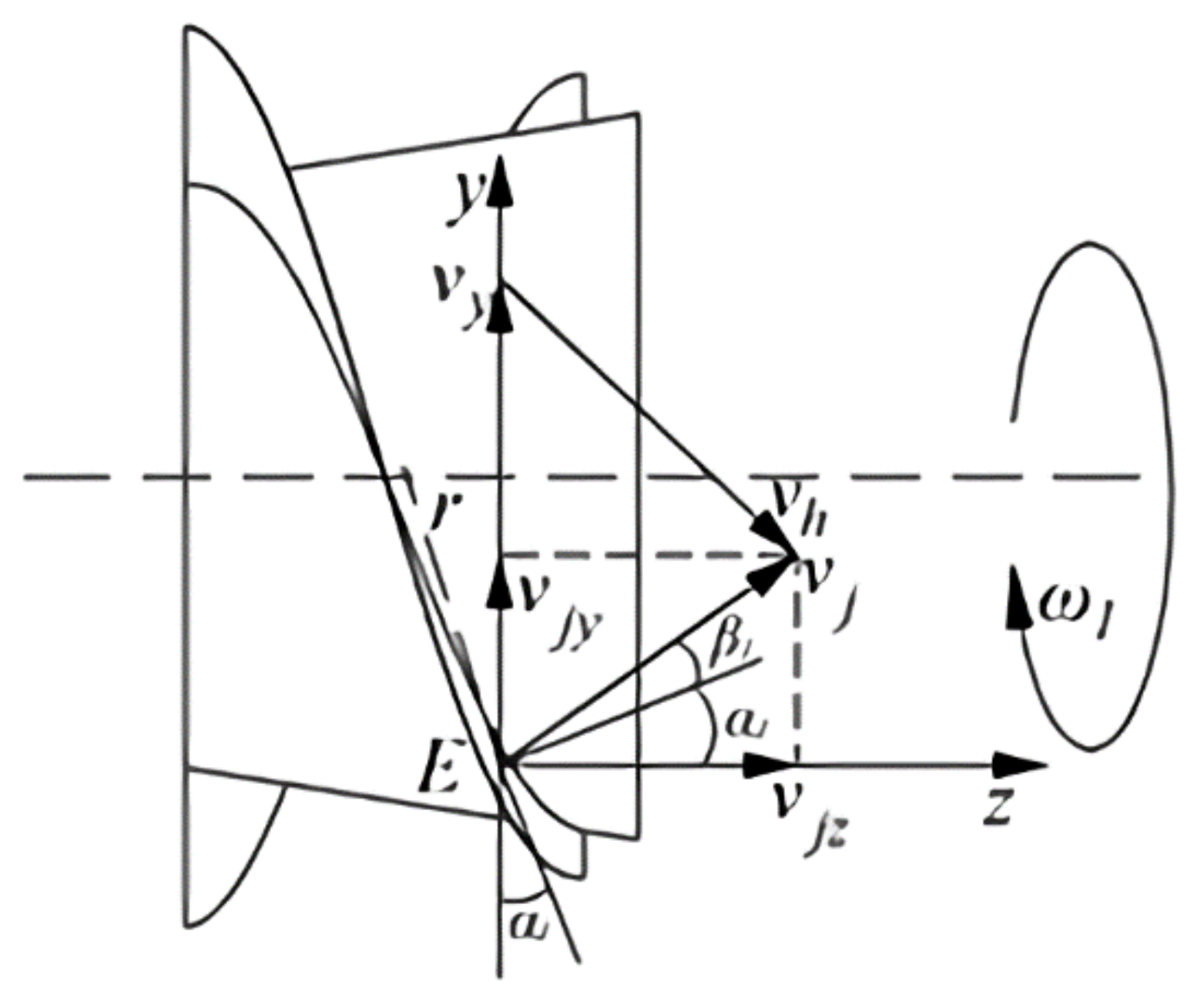

2.3.2. The Design of Conical Spiral Feeding Head

2.3.3. The Design of “Staggered Teeth” Threshing Element

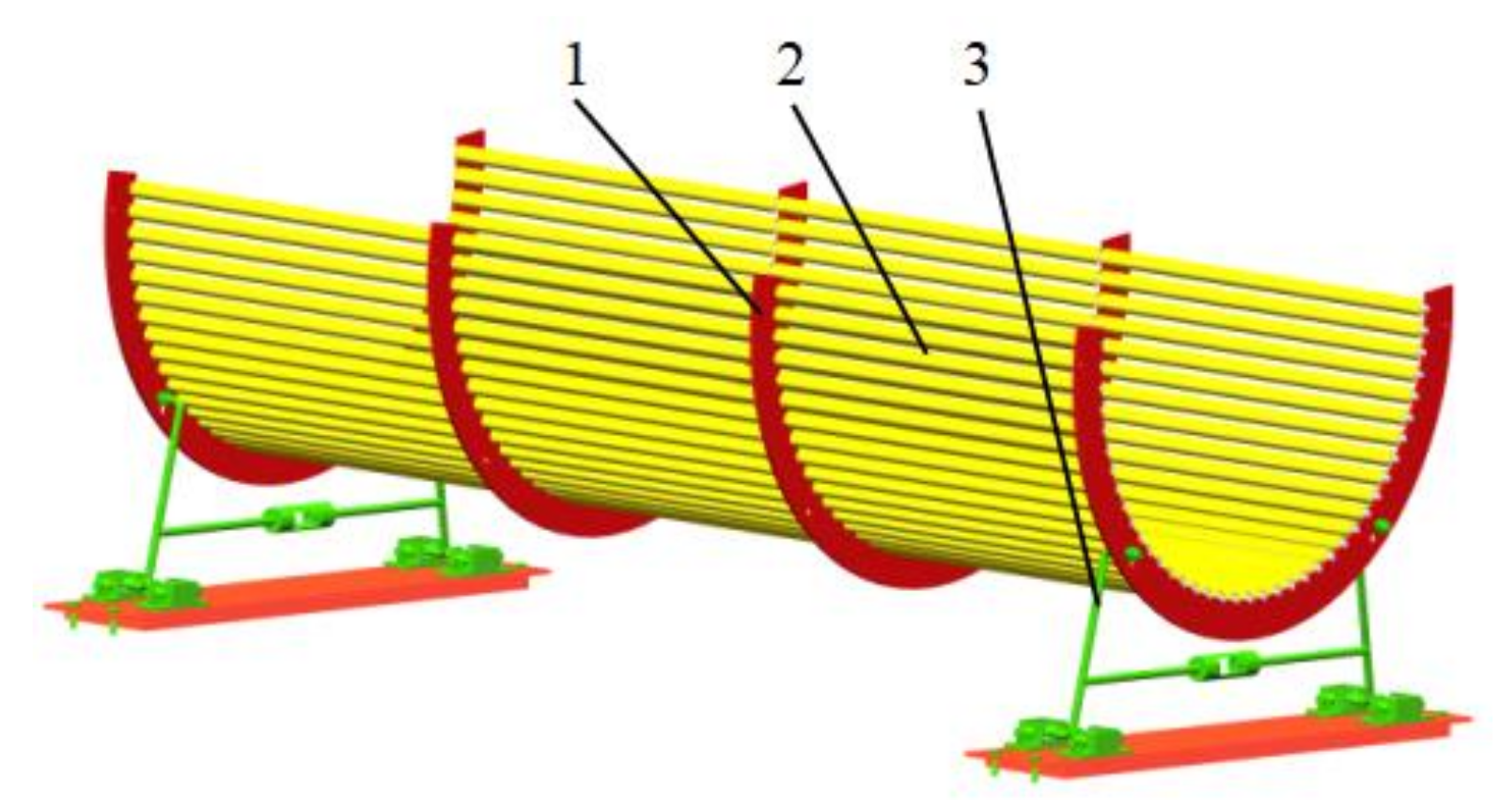

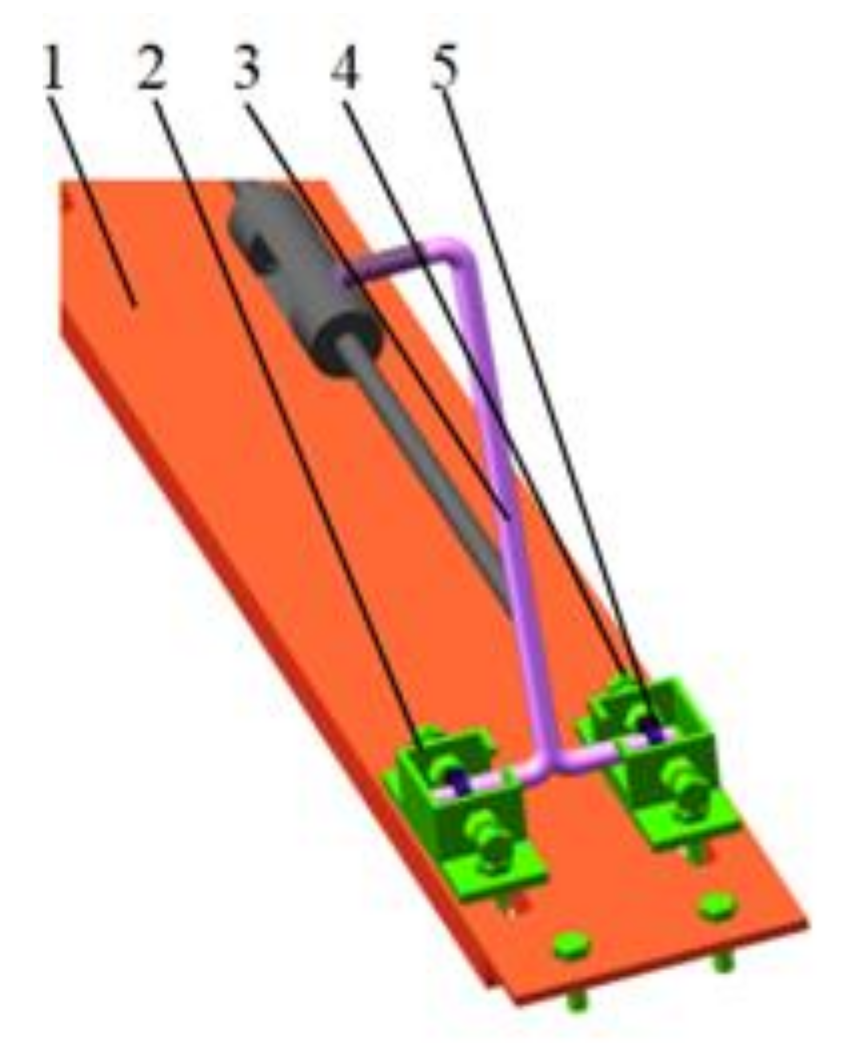

2.3.4. Structural Design of Micro Motion Rotary Tubular Concave Screen

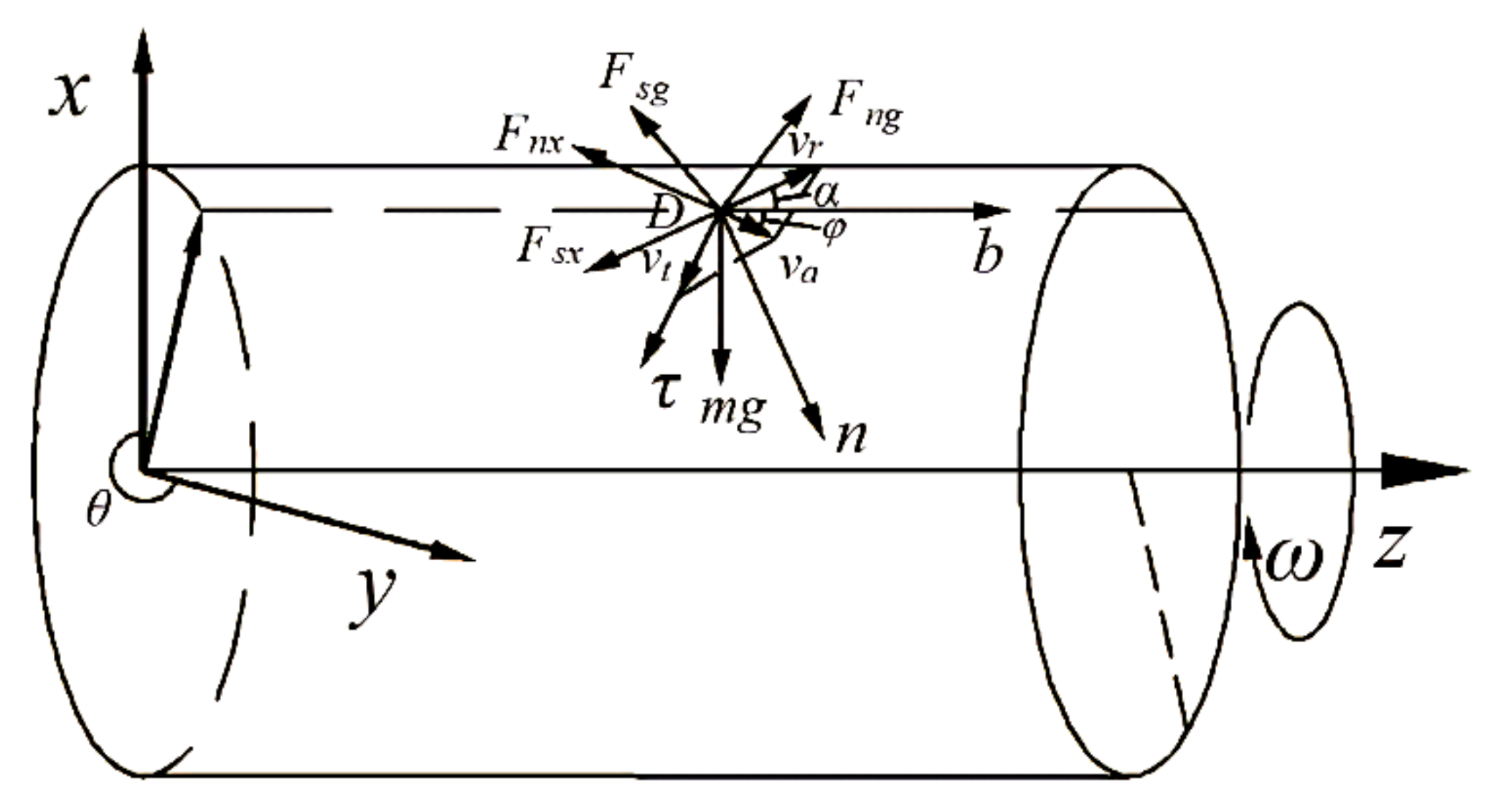

2.3.5. Dynamic Analysis of Millet on the Side of Top Cover

3. Results

3.1. Test Materials and Equipment

3.2. Test Purpose

3.3. Test Method

3.4. Analysis of Test Results

3.4.1. Analysis of Variance of Regression Model

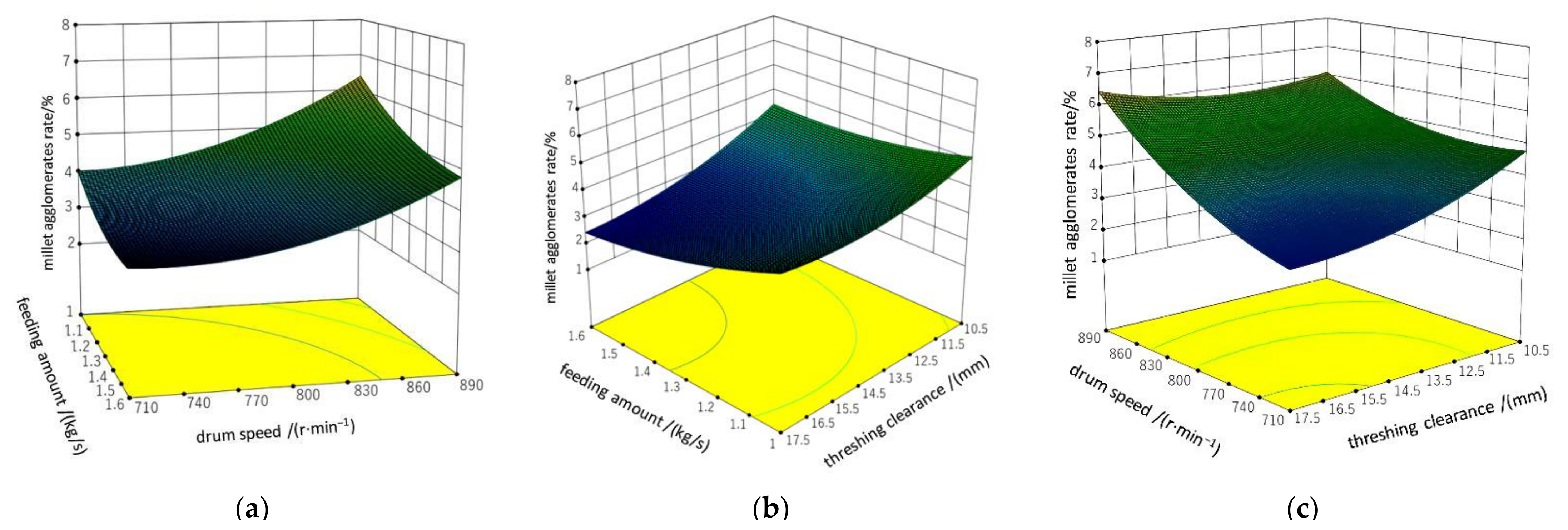

3.4.2. Analysis of the Influence of Various Factors on the Millet Agglomerates Rate

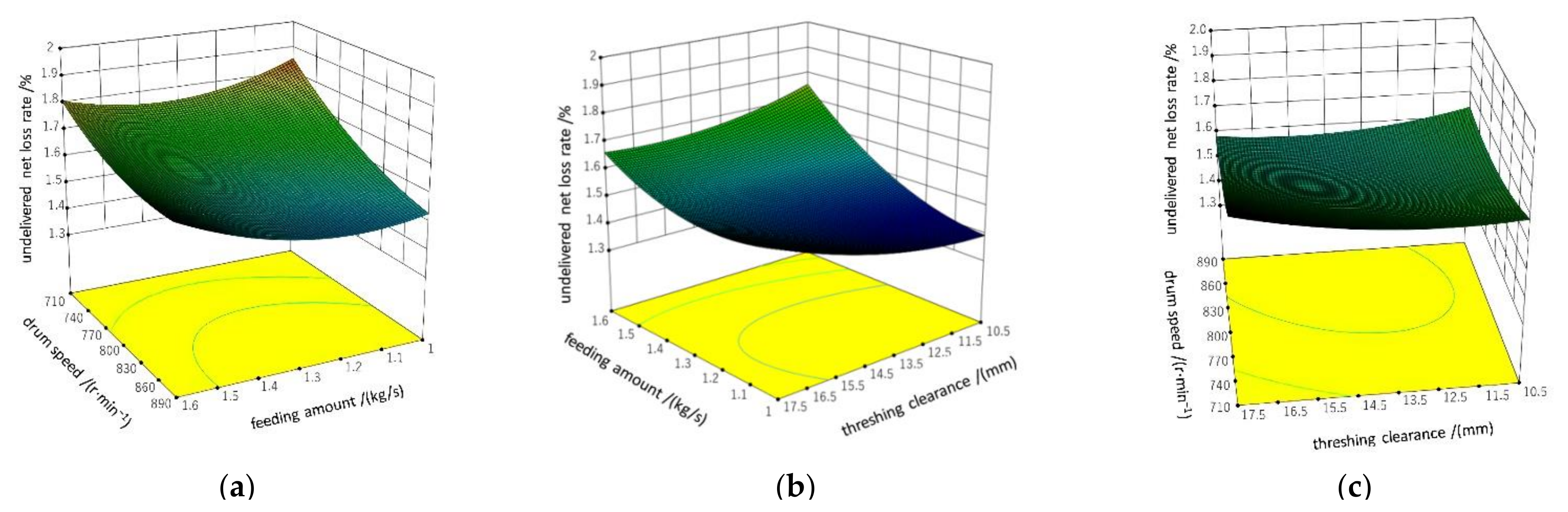

3.4.3. Analysis on the Influence of Various Factors on Undelivered Net Loss Rate

3.4.4. Analysis of Influence of Various Factors on Damage Rate

3.4.5. Parameter Optimization Analysis of Threshing Device

- (1)

- Objective function

- (2)

- Constraints

3.5. Verification Test

4. Conclusions

- (1)

- Aiming at the existing problems of millet threshing, a longitudinal axial flow staggered flexible threshing device for millet was designed. Compared with traditional threshing devices such as peg-tooth axial flow threshing and separating unit, bar threshing device, and 5GJT-400 millet thresher, it has the following advantages: the threshing element material of the drum adopts wear-resistant rubber, and the threshing process is gentler. The concave screen is a micro rotating circular tube concave screen. The concave screen screening unit can rotate, and the concave screen support device can micro move. The whole system uses the grinding principle to thresh. The device can meet the requirements of low millet agglomerates rate, low undelivered net loss rate, and low damage rate.

- (2)

- The key structural parameters of the threshing drum and flexible micro motion concave were designed and analyzed, and the dynamic analysis of grain located on the side of top cover at any time was carried out by using the principle of d’Alembert. The results showed that the effect of the threshing element of the drum and screening unit of the concave screen on grain and the gravity of grain, the friction characteristics between grains, the structural parameters of the threshing element and screening unit, and the motion track of grain in the separation space acceleration are related.

- (3)

- Through the analysis of the test results, it was found that the primary and secondary relationships of each factor on the millet agglomerates rate and damage rate were drum speed, feeding amount, and threshing clearance. The primary and secondary relationships of the influence of various factors on the undelivered net loss rate of non-threshing were feeding amount, drum speed, and threshing clearance.

- (4)

- For millet plants with grain moisture content in the range of 14.9~17.4%, the optimal parameter combination of longitudinal axial flow staggered millet flexible threshing device is as follows: feeding amount of 1.3 kg/s, drum speed of 762 r/min−1 and concave clearance of 15 mm. At this time, the millet agglomerates rate of millet was 2.92%, the undelivered net loss rate of non-threshing was 1.58%, and the damage rate was 0.37%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jia, G.Q.; Diao, X.M. Current Status and Perspectives of Innovation Studies Related to Foxtail Millet Seed Industry in China. Sci. Agric. Sin. 2022, 55, 653–665. [Google Scholar]

- Li, S.G.; Liu, F.; Liu, M.; Cheng, R.H.; Xia, E.J.; Diao, X.M. Current Status and Future Prospective of Foxtail Millet Production and Seed Industry in China. Sci. Agric. Sin. 2021, 54, 459–470. [Google Scholar]

- Li, S.G.; Liu, F.; Liu, M.; Zhao, Y.; Wang, H.J. Current situation, development trend and Countermeasures of millet industry in China. Agric. Mod. Res. 2014, 35, 531–535. [Google Scholar]

- Li, Y.H.; Guo, E.H.; Fan, H.P.; Wang, L.X.; Zhang, A.Y.; Liu, X.; Cheng, L.P. Discussion on the development of millet industry. Mod. Agric. Sci. Technol. 2019, 22, 28–29. [Google Scholar]

- Jia, G.; Liu, X.; Schnable, J.C.; Niu, Z.; Wang, C.; Li, Y.; Wang, S.; Wang, S.; Liu, J.; Guo, E. Microsatellite Variations of Elite Setaria Varieties Released during Last Six Decades in China. PLoS ONE 2015, 10, e0125688. [Google Scholar] [CrossRef] [Green Version]

- Tang, X.H.; Jin, C.Q.; Zhang, G.T.; Guo, Z.; Zhao, N.; Xu, B. Research status of threshing and separation device of combine harvester in China. Res. Agric. Mech. 2022, 44, 1–9. [Google Scholar] [CrossRef]

- Yang, L.Q.; Wang, W.Z.; Zhang, H.M.; Li, L.H.; Wang, M.M.; Hou, M.T. Improved design and bench test of tangential transverse axial flow corn threshing system. Trans. Chin. Soc. Agric. Eng. 2018, 34, 35–43. [Google Scholar]

- Tang, Z.; He, J.Z.; Zhou, Y.P.; Liu, J.B. Threshing parameter test and analysis of multi drum threshing and separation device. Res. Agric. Mech. 2017, 37, 153–157. [Google Scholar]

- Miu, P.I.; Kutzbach, H.-D. Modeling and simulation of grain threshing and separation in axial threshing units: Part II. Application to tangential feeding. Comput. Electron. Agric. 2008, 60, 105–109. [Google Scholar] [CrossRef]

- Gao, Y.E. Brief introduction of grain combine production abroad. Grain Oil Process. Food Mach. 1987, 5, 18–20. [Google Scholar]

- Lu, W.T.; Wang, R.X.; Deng, Z.G. Research status and Prospect of threshing technology for combined harvest of coarse grains. China J. Agric. Chem. 2017, 38, 11–16. [Google Scholar] [CrossRef]

- Wu, H.Y.; Liu, H.X.; Yang, Z.J.; Li, X.H.; Jiao, H.; Wang, C.J.; Zhang, G.J. Analysis on the current situation and development trend of millet production mechanization. Agric. Technol. Equip. 2012, 12, 14–17. [Google Scholar]

- Arnold, R.E. Experiments with rasp bar threshing drum. J. Agric. Eng. Res. 1964, 9, 99–131. [Google Scholar]

- Powar, R.; Aware, V.; Shahare, P. Optimizing operational parameters of finger millet threshing drum using RSM. J. Food Sci. Technol. 2019, 56, 3481–3491. [Google Scholar] [CrossRef] [PubMed]

- Gummert, M.; Kutzbach, H.D.; Muhlbauer, W.; Wacker, P.; Quick, G.R. Performance evaluation of an IRRI axial-flow paddy thresher. Agric. Mech. Asia Afr. Latin Am. 1992, 23, 47–54. [Google Scholar]

- Xu, D.X. Preliminary analysis of longitudinal axial flow drum. J. Luoyang Inst. Agric. Mach. 1980, 1, 115–131. [Google Scholar]

- Wu, X.F. Analysis and Experimental Study on Relevant Mechanical Characteristics of New Millet Thresher; Shanxi Agricultural University: Taigu, China, 2005. [Google Scholar]

- Zhang, D.M.; Yi, S.J.; Tao, G.X.; Mao, X. Development of millet axial threshing and separation test bench. Res. Agric. Mech. 2019, 41, 62–67. [Google Scholar]

- Zong, W.Y.; Liao, Q.X.; Chen, L.; Li, H.T.; Huang, P. The effect of different threshing methods on rapeseed pod at the end of ripening stage. Trans. Chin. Soc. Agric. Eng. 2012, 28, 29–34. [Google Scholar]

- Sun, C.L.; Zuo, J.W.; Lu, F.Y.; Geng, L.X. Design and test of combined axial flow drum for oat threshing. Res. Agric. Mech. 2021, 43, 135–141. [Google Scholar]

- Lu, W.T. Experimental study on performance of millet threshing system. Agric. Mach. 2020, 6, 100–103. [Google Scholar]

- Tang, Z.; Li, Y.; Xu, L.; Li, H.; Pang, J. Experiment and evaluating indicators of wheat threshing and separating on test-bed of longitudinal axial-threshing unit. Trans. Chin. Soc. Agric. Eng. 2012, 28, 14–19. [Google Scholar]

- Wang, J.; Li, Z.; Hussain, S.; Lu, Q.; Song, H.; Zheng, D. Design and threshing outputs study of internal and external rotary roller buckwheat thresher. INMATEH-Agric. Eng. 2020, 60, 173–182. [Google Scholar] [CrossRef]

- Lachuga, Y.F.; Bur’yanov, A.; Pakhomov, V.; Chervyakov, I. Adaptation of Threshing Devices to Physical and Mechanical Characteristics of Harvested Crops. Russ. Agric. Sci. 2020, 46, 198–201. [Google Scholar] [CrossRef]

- Samuel, A.A.; Alice, K.A.; Seckley, E.M.; Adetunla, A.O. Development of a Threshing Device for Pearl Millet. Curr. J. Appl. Sci. Technol. 2019, 33, 1–12. [Google Scholar] [CrossRef]

- Fan, C.L.; Cui, T.; Zhang, D.X.; Ynag, L.; Qu, Z.; Li, Y.H. Design and test of low damage combined corn threshing and separation device. Trans. Chin. Soc. Agric. Mach. 2019, 50, 113–123. [Google Scholar]

- Zhalnin, E.V.; Chaplygin, M.E. Dynamics of Fractional Composition of Grain-and-Straw Mass Being Threshedin the Threshing Mechanism of a Combine Harvester. Eng. Technol. Syst. 2022, 32, 249–262. [Google Scholar] [CrossRef]

- Li, Y.M. Design and Analysis of Grain Combine, 1st ed.; China Machine Press: Beijing, China, 2014; pp. 34–40. [Google Scholar]

- Wang, Z.B.; Wang, Z.W.; Zhang, Y.P.; Yan, W.X.; Chi, Y.J.; Liu, C.Q. Design and test of longitudinal axial flow flexible hammer claw corn threshing device. Trans. Chin. Soc. Agric. Mach. 2020, 51, 109–117. [Google Scholar]

- Chen, M.Z.; Xu, G.F.; Wang, C.X.; Diao, P.S.; Zhang, Y.P.; Niu, G.D. Design and test of longitudinal axial flow roller combined corn flexible threshing and separation device. Trans. Chin. Soc. Agric. Mach. 2020, 51, 123–131. [Google Scholar]

- Wang, X.W. Study on Threshing Separation System with Adjustable Threshing Clearance; Hunan Agricultural University: Changsha, China, 2019. [Google Scholar]

- Wang, D.R. Development and application progress of polyurethane elastomer. China Rubber Plast. Technol. Equip. 2021, 47, 24–28. [Google Scholar] [CrossRef]

- Ren, L.Q. Experimental Design and Optimization, 2nd ed.; Science Press: Beijing, China, 2009; pp. 7–35. [Google Scholar]

- Singh, K.; Pardeshi, I.; Kumar, M.; Srinivas, K.; Srivastva, A. Optimisation of machine parameters of a pedal-operated paddy thresher using RSM. Biosyst. Eng. 2008, 100, 591–600. [Google Scholar] [CrossRef]

| Parameter | Numerical Value |

|---|---|

| Average plant length/mm | 1089 |

| Average length of spike head of millet/mm | 185 |

| Number of grain yards on the head of millet spike/piece | 90~110 |

| Average diameter of millet agglomerates/mm | 8.4 |

| Average grain diameter/mm | 1.48 |

| Plant moisture content/% | 26.8~28.7 |

| Grain moisture content/% | 14.9~17.4 |

| Mass of 1000 grains/g | 2.98 |

| Code | Factor | ||

|---|---|---|---|

| A/(kg·s−1) | B/(r·min−1) | C/(mm) | |

| 1.682 | 1.8 | 950 | 20 |

| 1 | 1.6 | 890 | 17.5 |

| 0 | 1.3 | 800 | 14 |

| −1 | 1 | 710 | 10.5 |

| −1.682 | 0.8 | 650 | 8 |

| Serial Number | A | B | C | y1/% | y2/% | y3/% |

|---|---|---|---|---|---|---|

| 1 | −1 | −1 | −1 | 5.65 | 1.8 | 0.62 |

| 2 | 1 | −1 | −1 | 5.1 | 0.71 | 0.32 |

| 3 | −1 | 1 | −1 | 5.98 | 1.42 | 0.9 |

| 4 | 1 | 1 | −1 | 6.02 | 1.75 | 1.31 |

| 5 | −1 | −1 | 1 | 1.05 | 0.82 | 0.20 |

| 6 | 1 | −1 | 1 | 2.533 | 1.8 | 0.42 |

| 7 | −1 | 1 | 1 | 7.02 | 1.55 | 0.63 |

| 8 | 1 | 1 | 1 | 4.6 | 1.65 | 1.05 |

| 9 | −1.682 | 0 | 0 | 6.1 | 0.46 | 1.52 |

| 10 | 1.682 | 0 | 0 | 2.51 | 0.75 | 1.91 |

| 11 | 0 | −1.682 | 0 | 2.40 | 1.75 | 0.35 |

| 12 | 0 | 1.682 | 0 | 7.6 | 1.52 | 1.04 |

| 13 | 0 | 0 | −1.682 | 5.5 | 1.54 | 0.55 |

| 14 | 0 | 0 | 1.682 | 5.5 | 1.54 | 0.10 |

| 15 | 0 | 0 | 0 | 3.02 | 1.54 | 0.49 |

| 16 | 0 | 0 | 0 | 3.49 | 1.61 | 0.48 |

| 17 | 0 | 0 | 0 | 3.2 | 1.42 | 0.48 |

| 18 | 0 | 0 | 0 | 4.4 | 1.48 | 0.31 |

| 19 | 0 | 0 | 0 | 4.85 | 1.58 | 0.39 |

| 20 | 0 | 0 | 0 | 3.12 | 0.51 | 1.42 |

| 21 | 0 | 0 | 0 | 3.58 | 1.49 | 0.58 |

| 22 | 0 | 0 | 0 | 2.95 | 1.51 | 0.63 |

| 23 | 0 | 0 | 0 | 3.3 | 1.57 | 0.53 |

| Index | Source of Variation | SS | df | MS | F | p |

|---|---|---|---|---|---|---|

| y1 | Regression | 44.06 | 9 | 4.9 | 8.8 | 0.0003 |

| Surplus | 7.23 | 13 | 0.56 | |||

| Misfit | 3.8 | 5 | 0.76 | 1.78 | 0.2242 | |

| Error | 3.43 | 8 | 0.43 | |||

| Total | 51.29 | 22 | ||||

| y2 | Regression | 0.44 | 9 | 0.049 | 12.31 | <0.0001 |

| Surplus | 0.051 | 13 | 0.0039 | |||

| Misfit | 0.014 | 5 | 0.0029 | 0.63 | 0.6861 | |

| Error | 0.037 | 8 | 0.0046 | |||

| Total | 0.49 | 22 | ||||

| y3 | Regression | 1.36 | 9 | 0.15 | 12.03 | <0.0001 |

| Surplus | 0.16 | 13 | 0.013 | |||

| Misfit | 0.092 | 5 | 0.018 | 2.04 | 0.1762 | |

| Error | 0.072 | 8 | 0.0090 | |||

| Total | 1.53 | 22 |

| Test Serial Number | Index | ||

|---|---|---|---|

| y1/% | y2/% | y3/% | |

| Estimate | 2.92 | 1.58 | 0.37 |

| Test 1 | 2.89 | 1.57 | 0.39 |

| Test 2 | 2.91 | 1.59 | 0.41 |

| Test 3 | 2.93 | 1.61 | 0.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhang, W.; Wang, W.; Huang, Y. Design and Test of Longitudinal Axial Flow Staggered Millet Flexible Threshing Device. Agriculture 2022, 12, 1179. https://doi.org/10.3390/agriculture12081179

Li X, Zhang W, Wang W, Huang Y. Design and Test of Longitudinal Axial Flow Staggered Millet Flexible Threshing Device. Agriculture. 2022; 12(8):1179. https://doi.org/10.3390/agriculture12081179

Chicago/Turabian StyleLi, Xinping, Wantong Zhang, Wenzhe Wang, and Yu Huang. 2022. "Design and Test of Longitudinal Axial Flow Staggered Millet Flexible Threshing Device" Agriculture 12, no. 8: 1179. https://doi.org/10.3390/agriculture12081179

APA StyleLi, X., Zhang, W., Wang, W., & Huang, Y. (2022). Design and Test of Longitudinal Axial Flow Staggered Millet Flexible Threshing Device. Agriculture, 12(8), 1179. https://doi.org/10.3390/agriculture12081179