Simulations and Experiments of Soil Temperature Distribution after 2.45 GHz Long-Term Microwave Treatment

Abstract

:1. Introduction

2. Materials and Methods

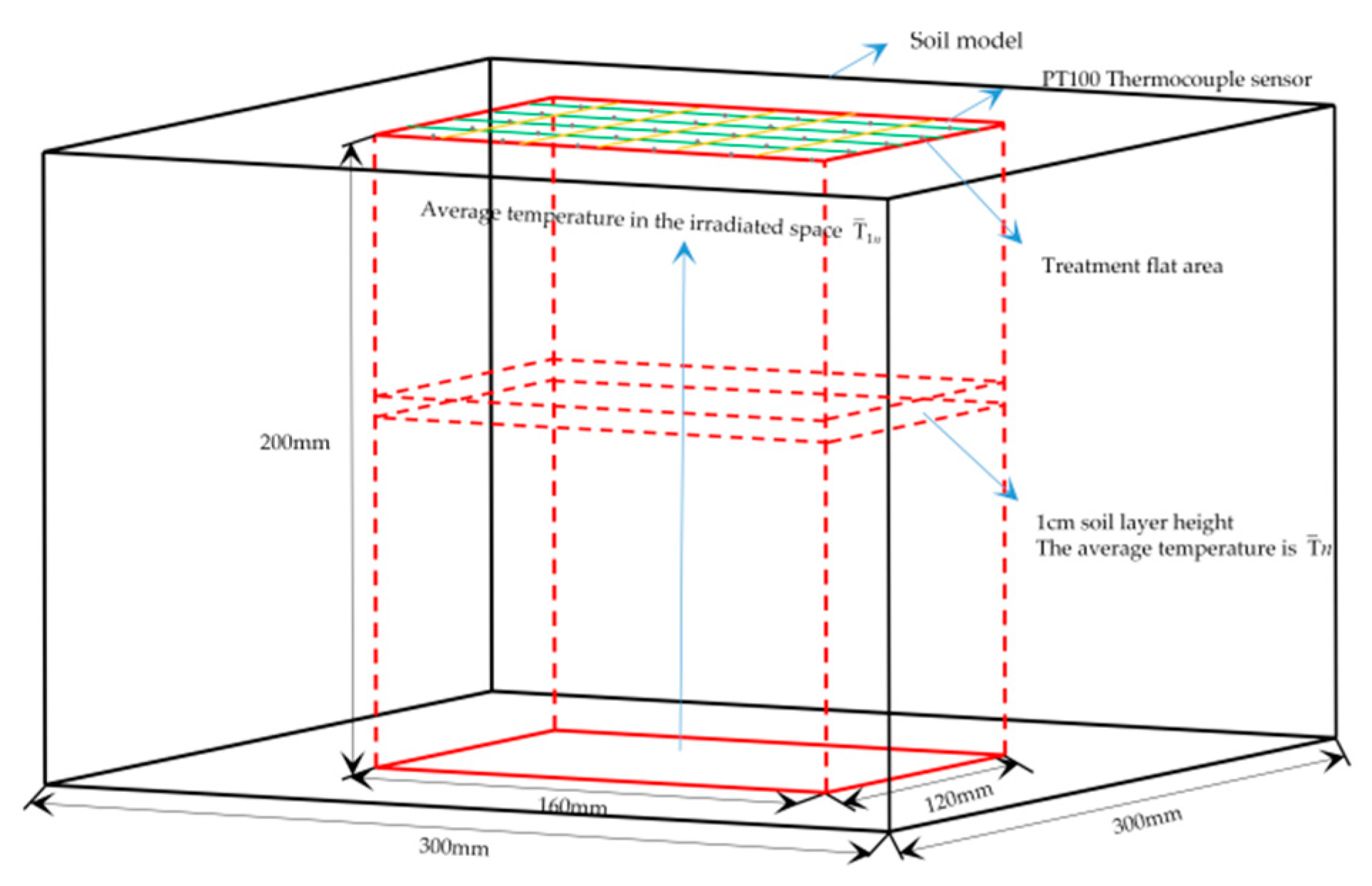

2.1. Simulation Model of the Soil Model Temperature Field under Microwave Action

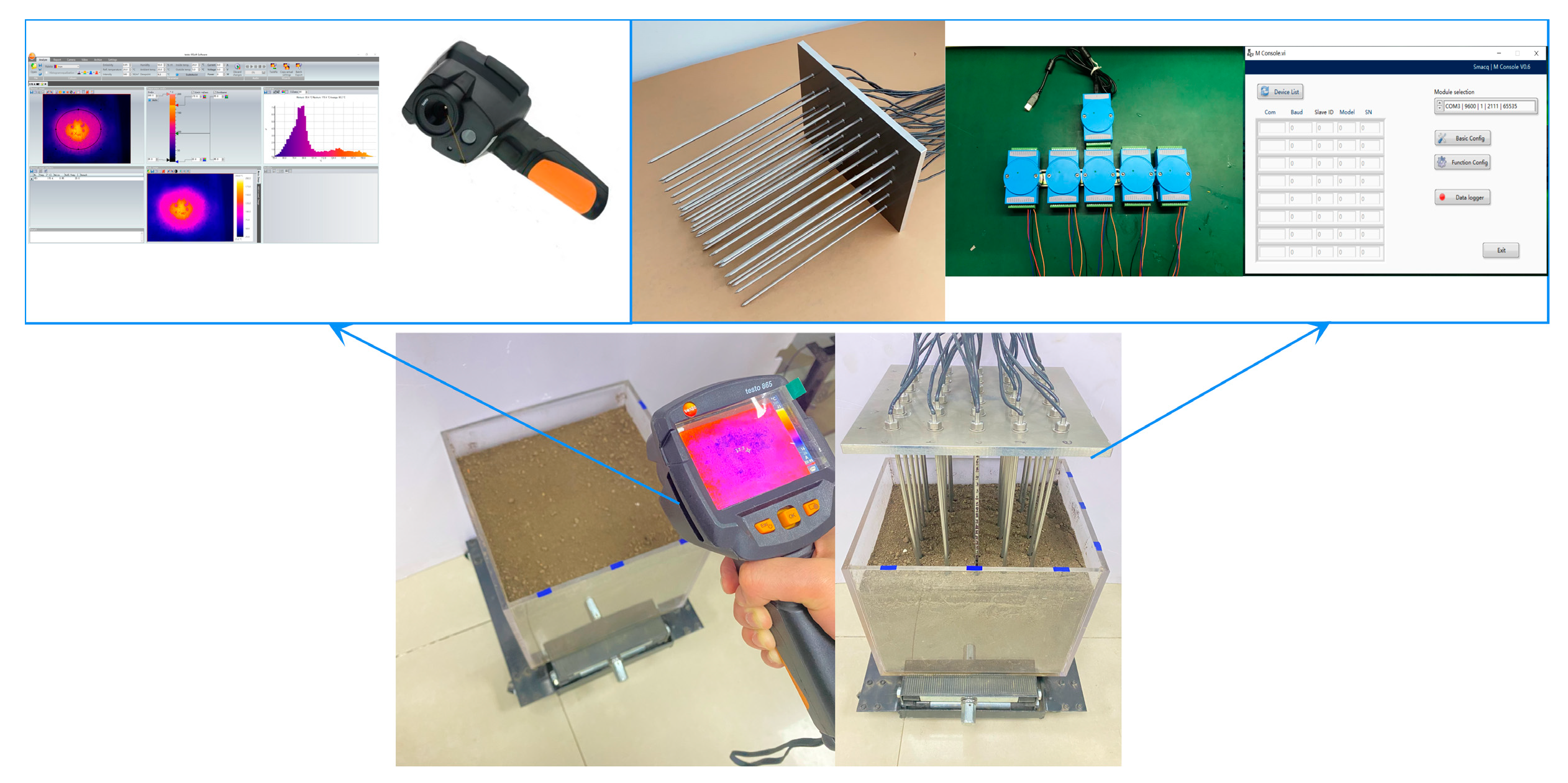

2.2. Microwave Soil Irradiation Test Bench

2.3. Microwave Soil Irradiation Test Method

3. Results and Discussion

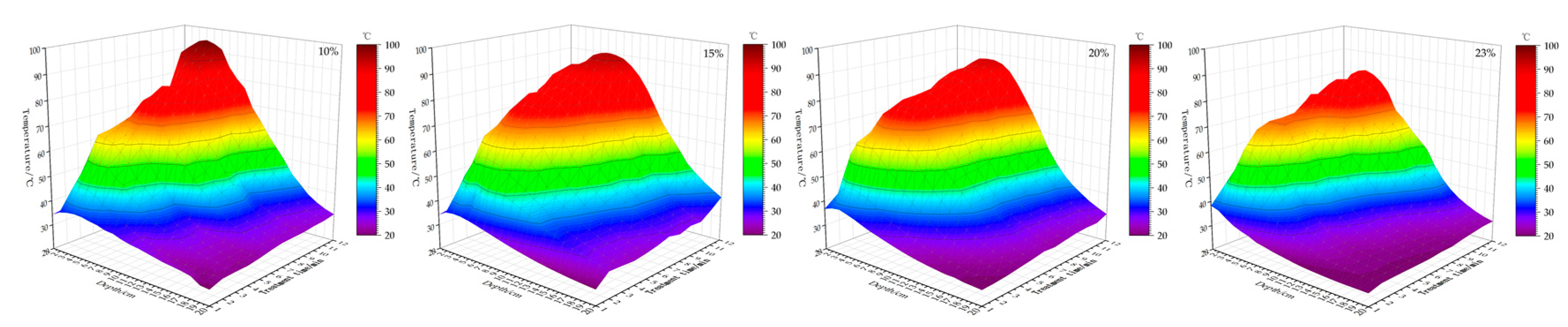

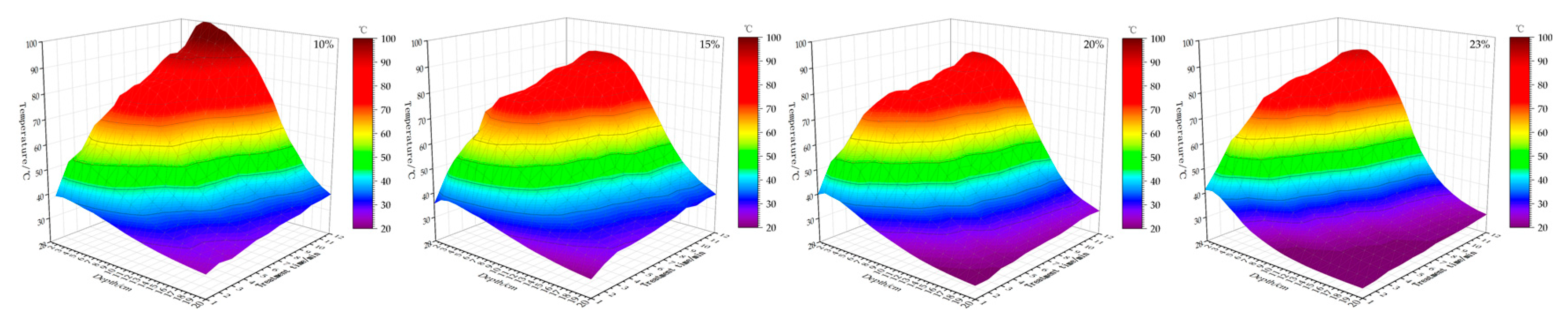

3.1. Simulation Results of Microwave-Irradiated Soil

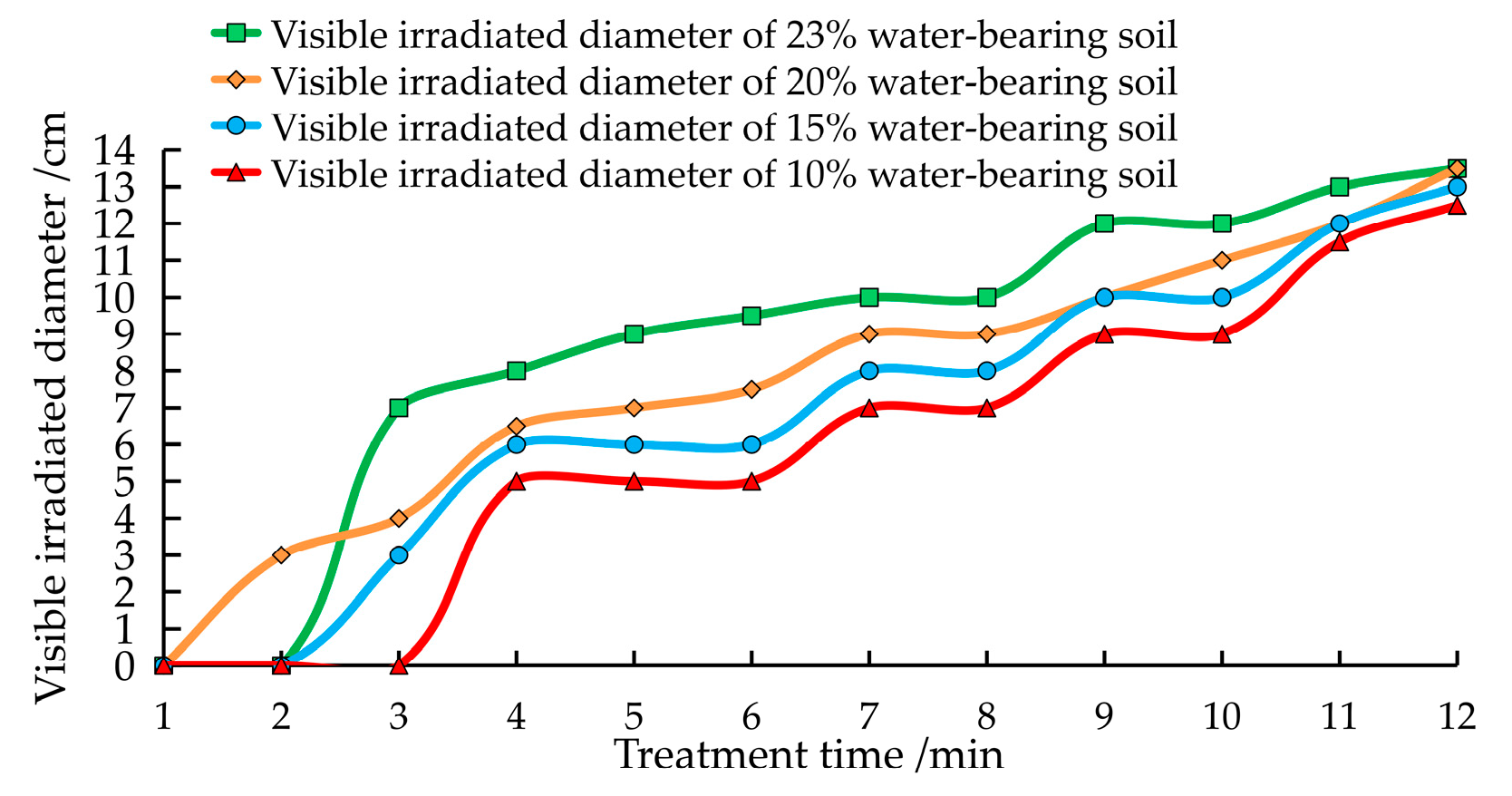

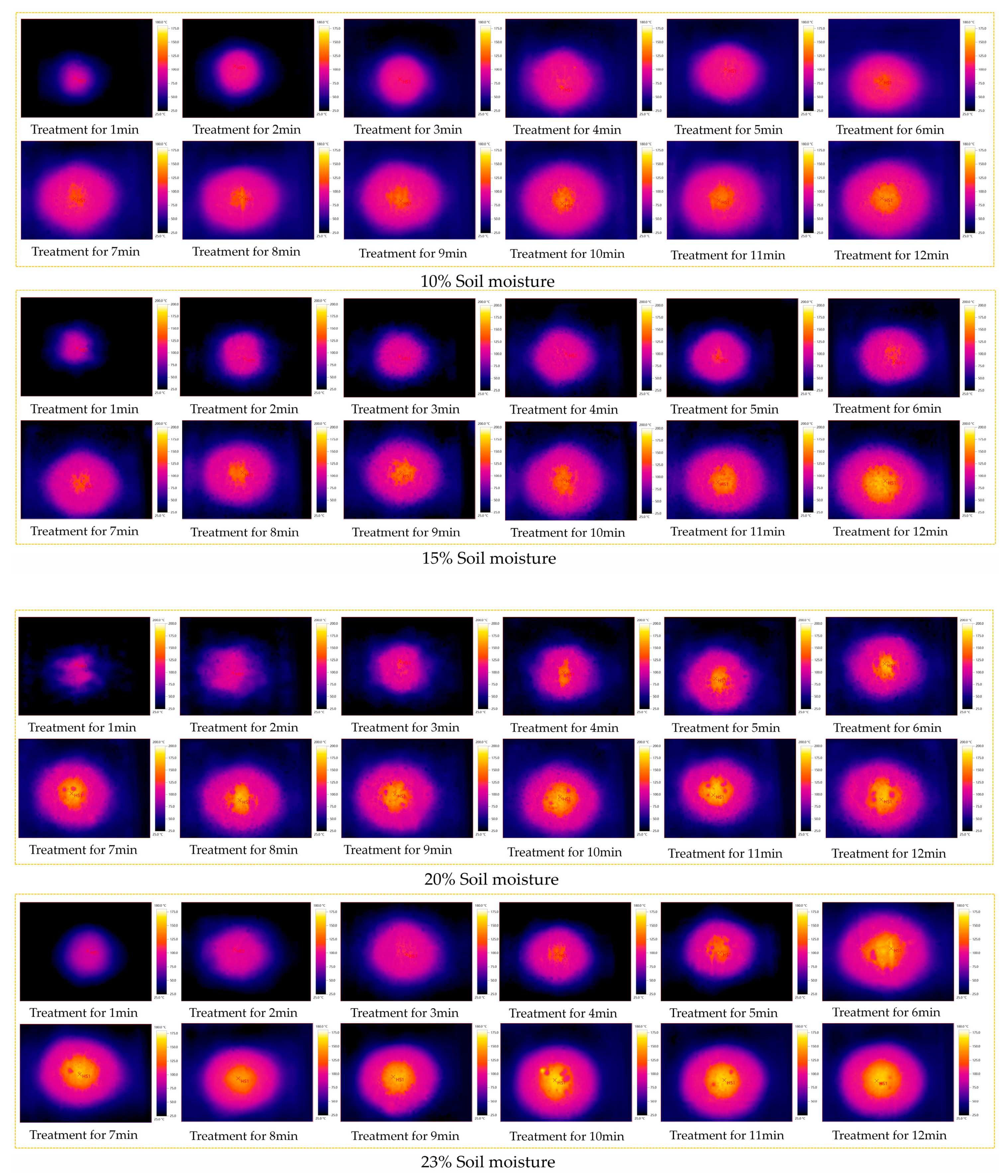

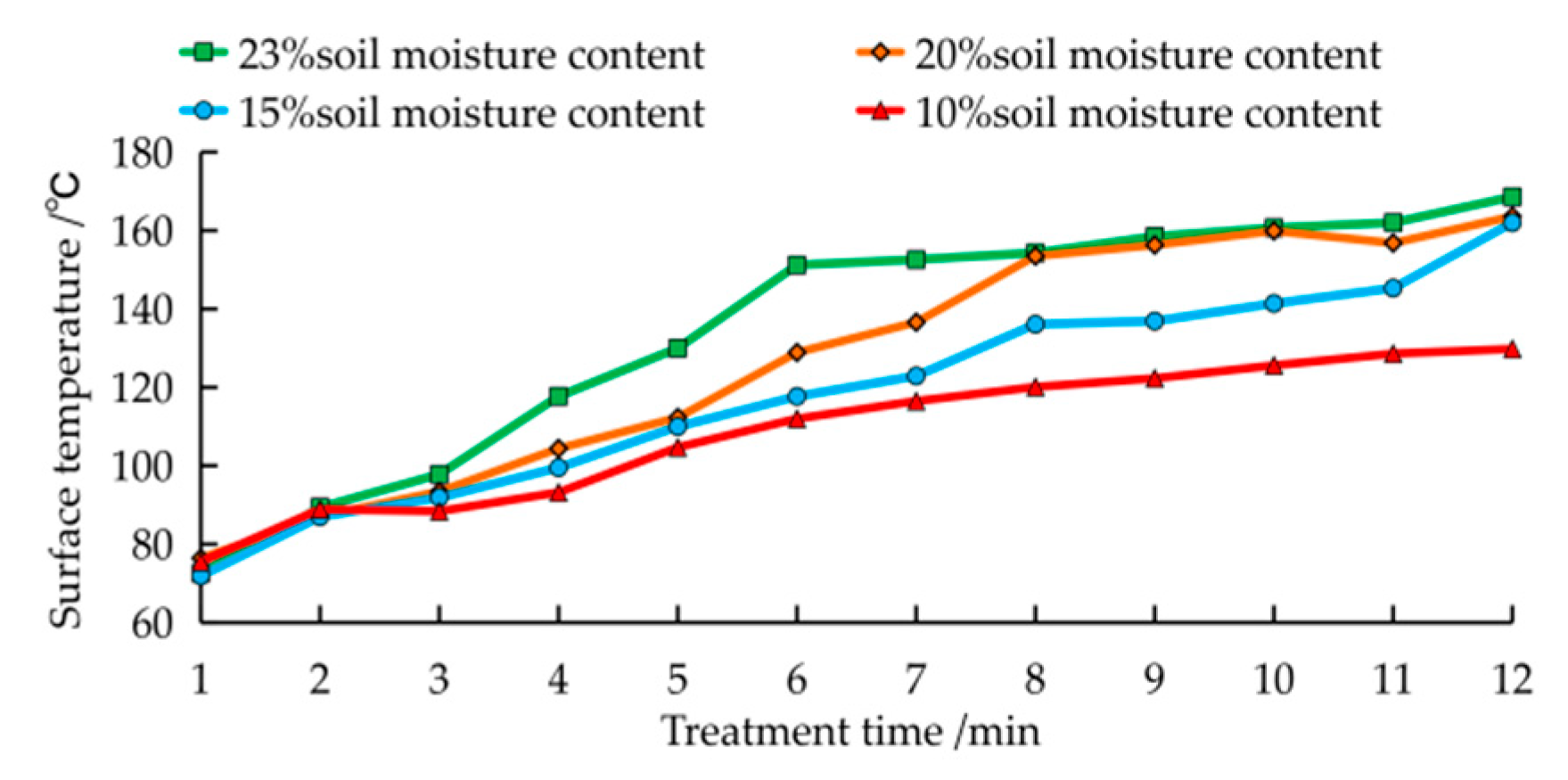

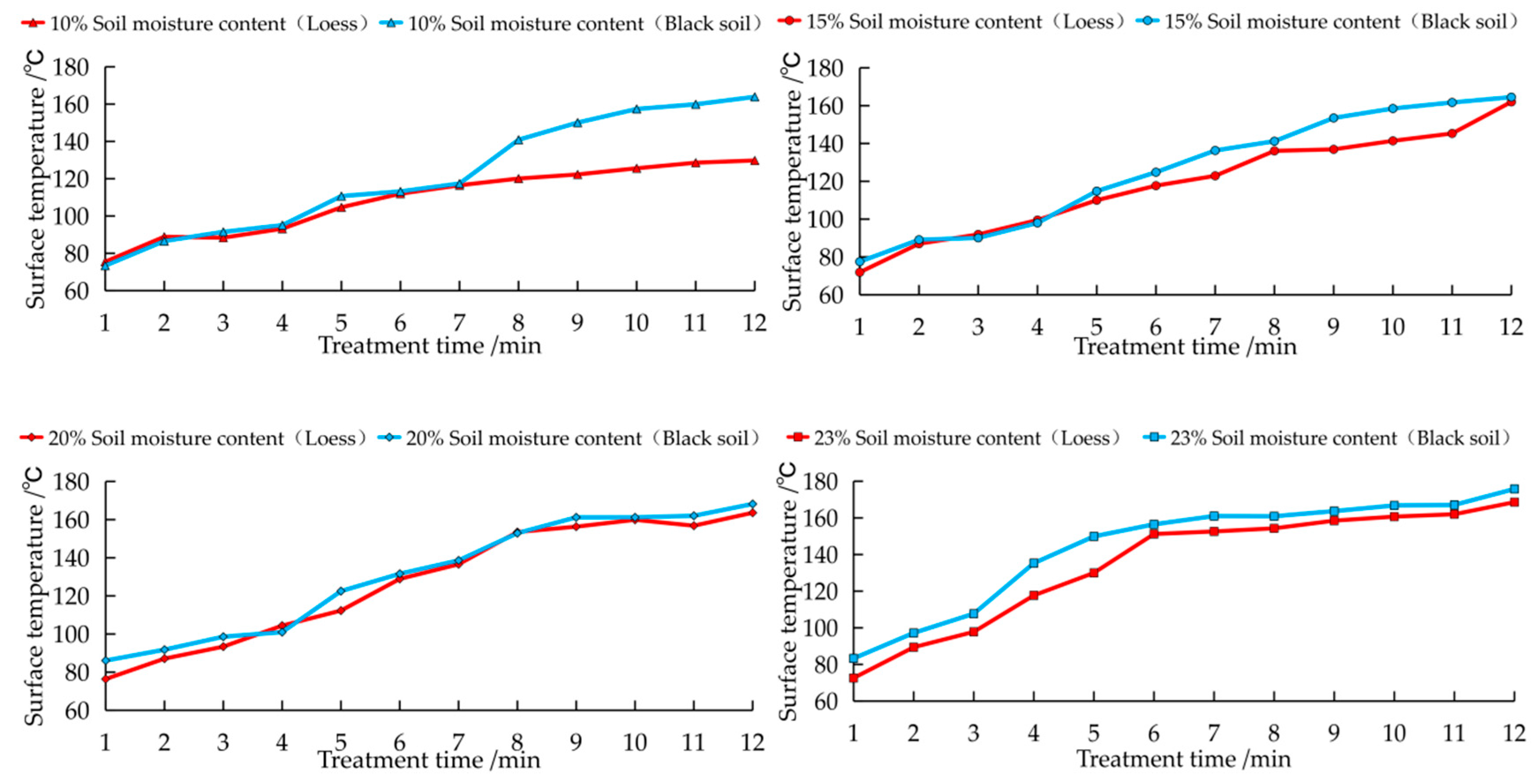

3.2. Results of Microwave-Irradiated Soil Surface Test

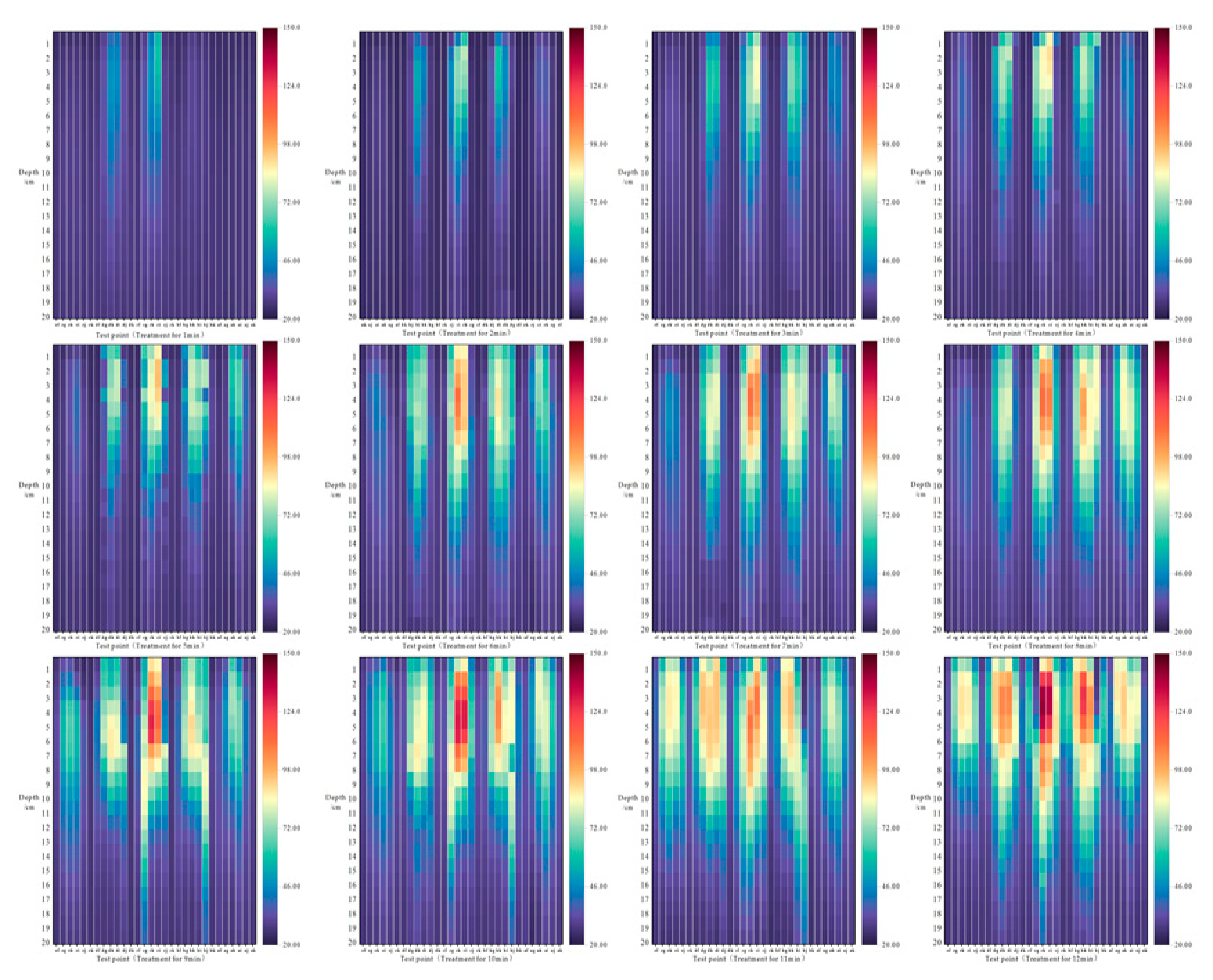

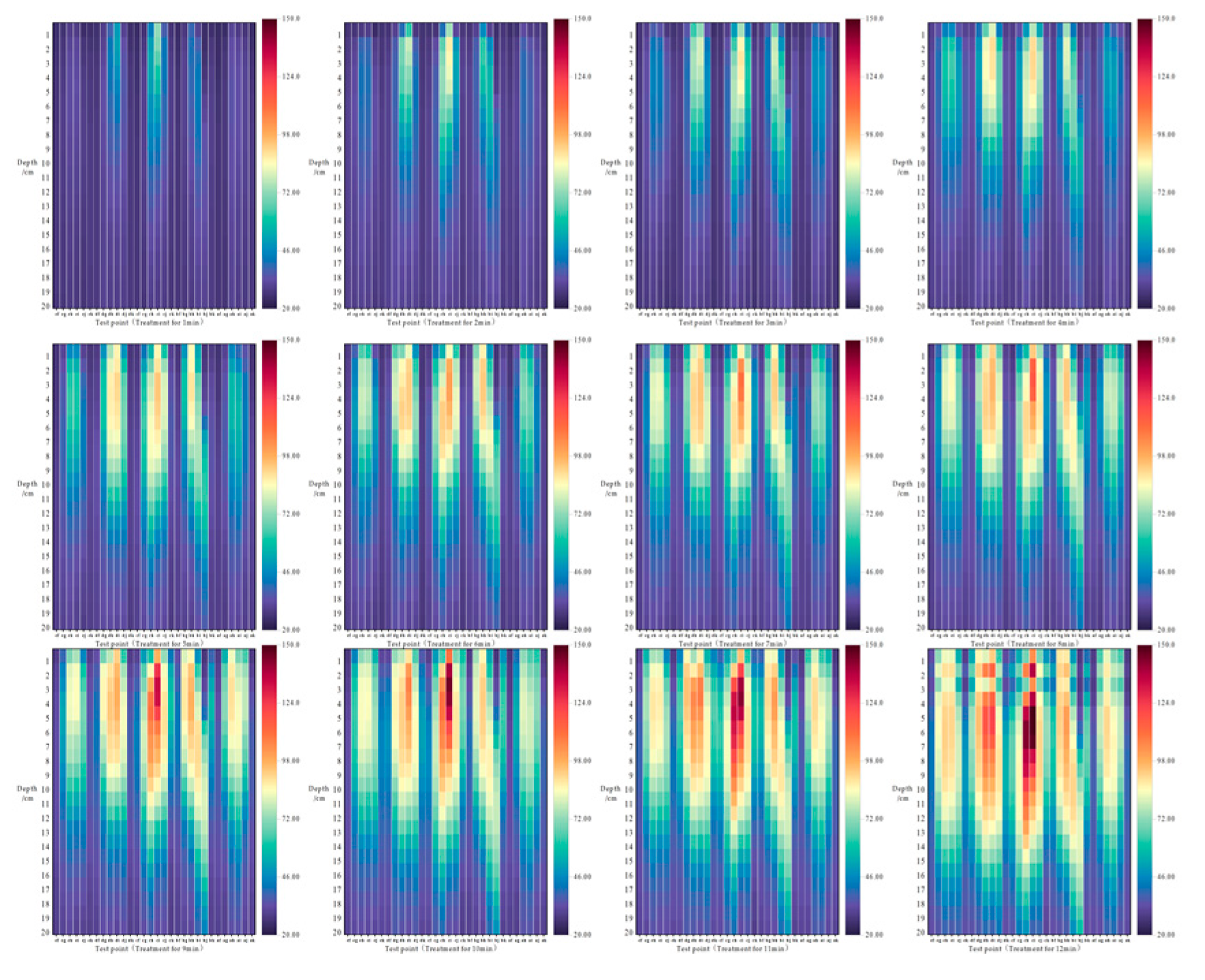

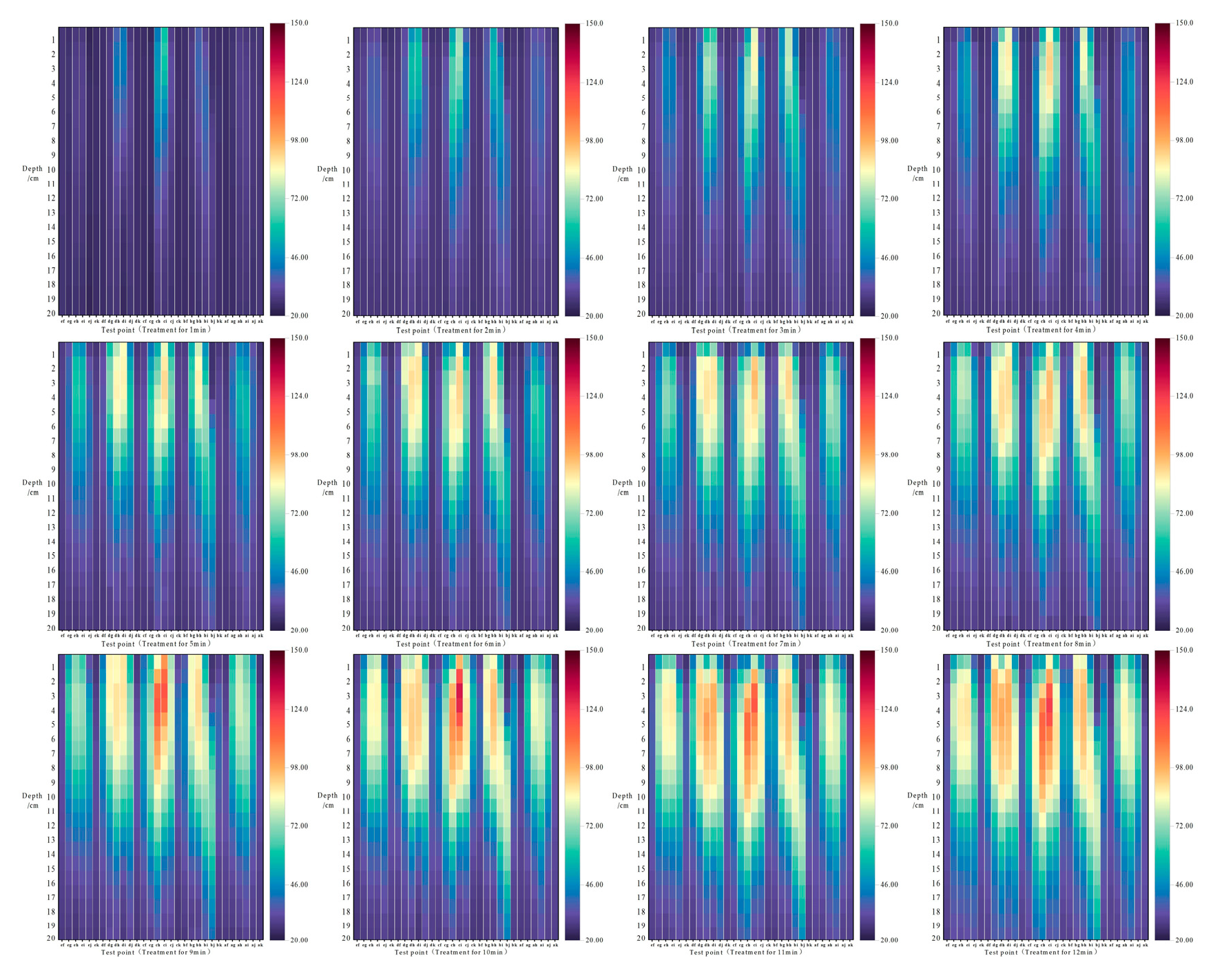

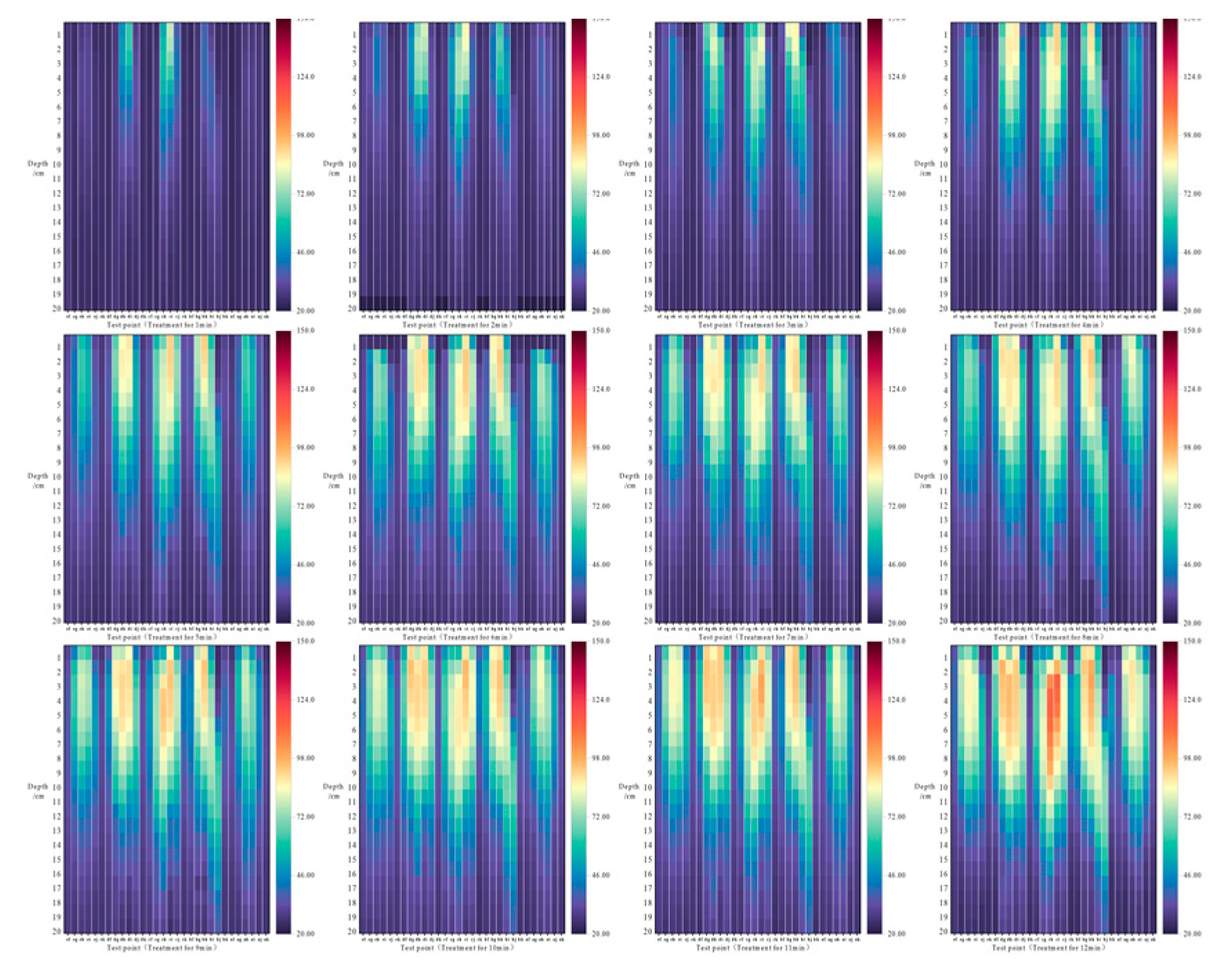

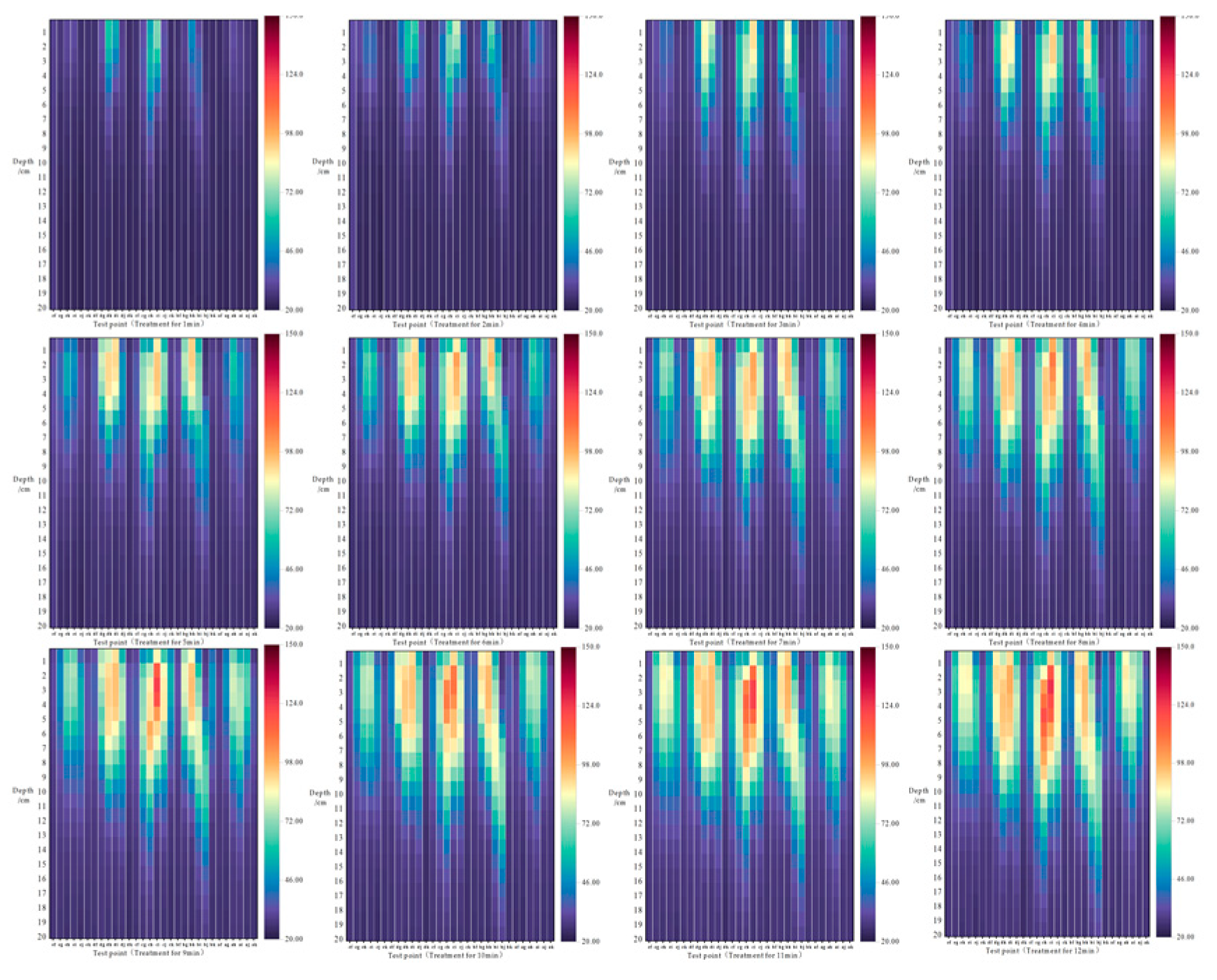

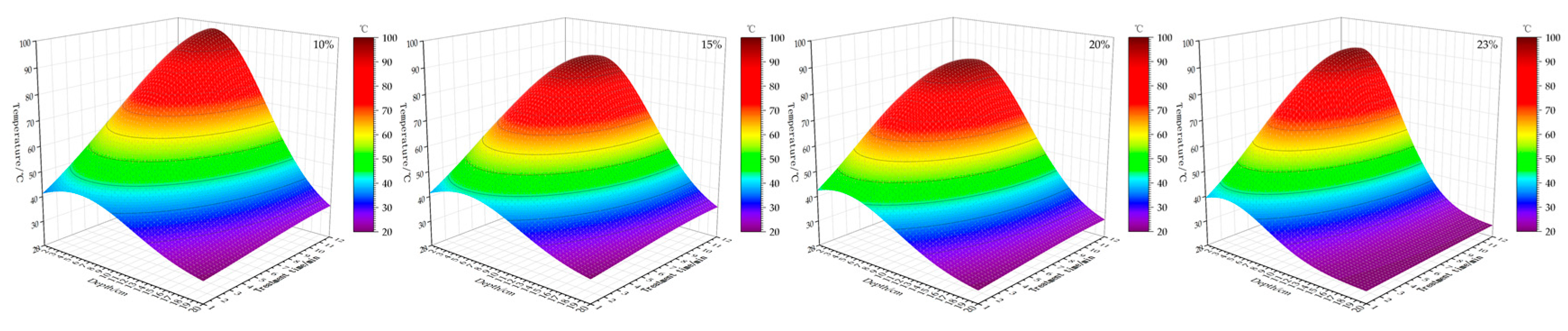

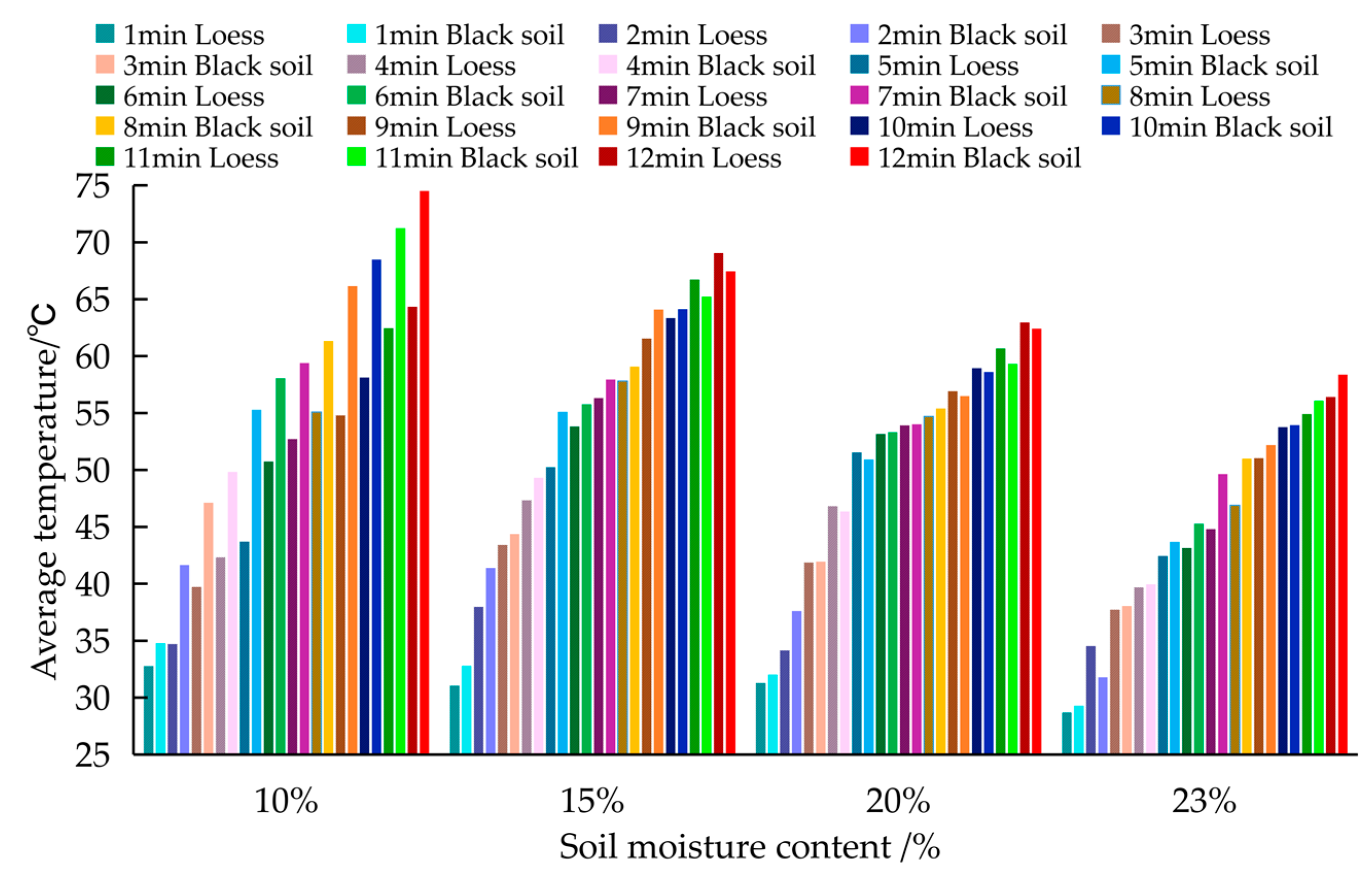

3.3. Test Results of the Internal Temperature of the Soil Irradiated by Microwaves

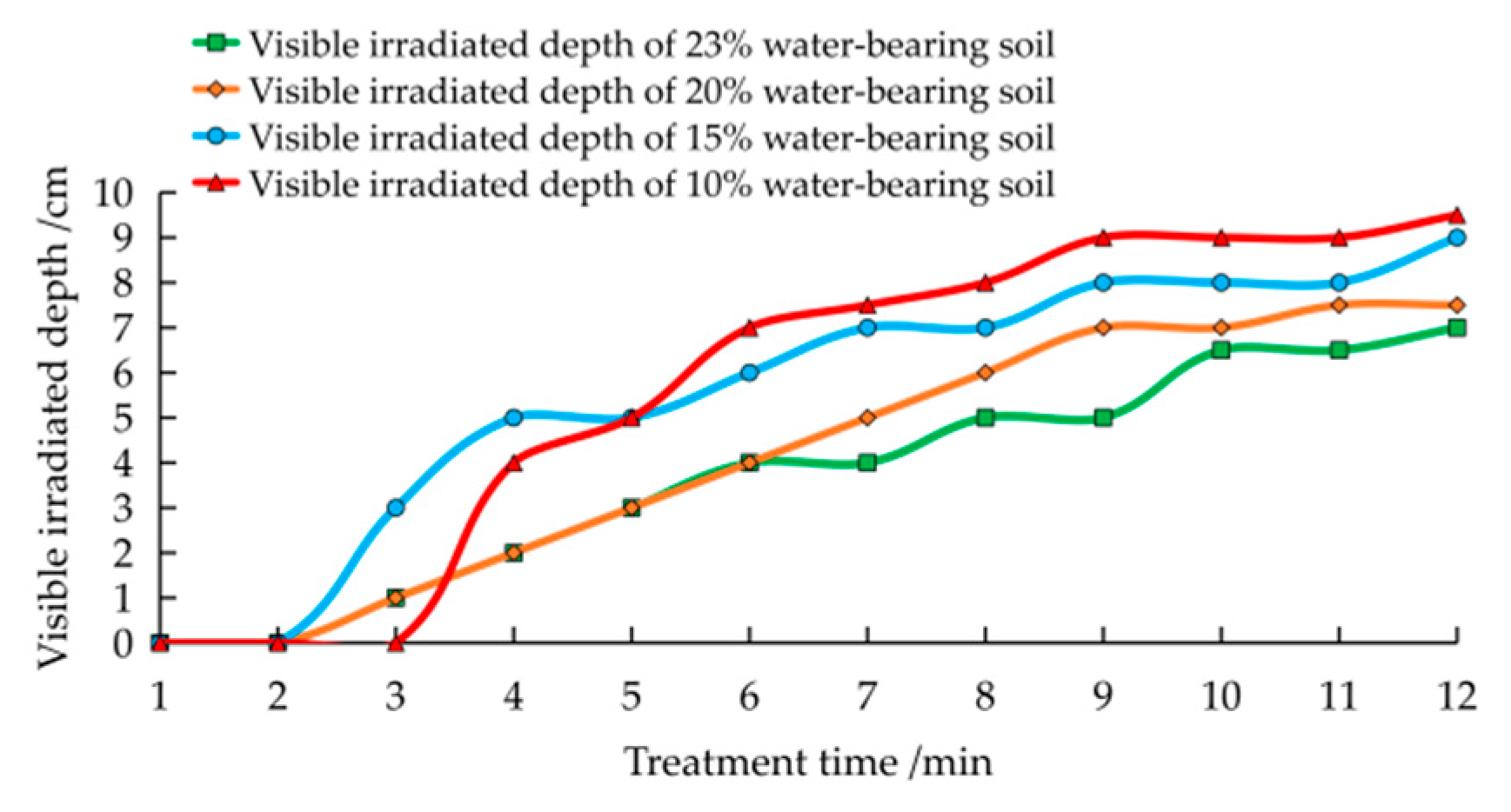

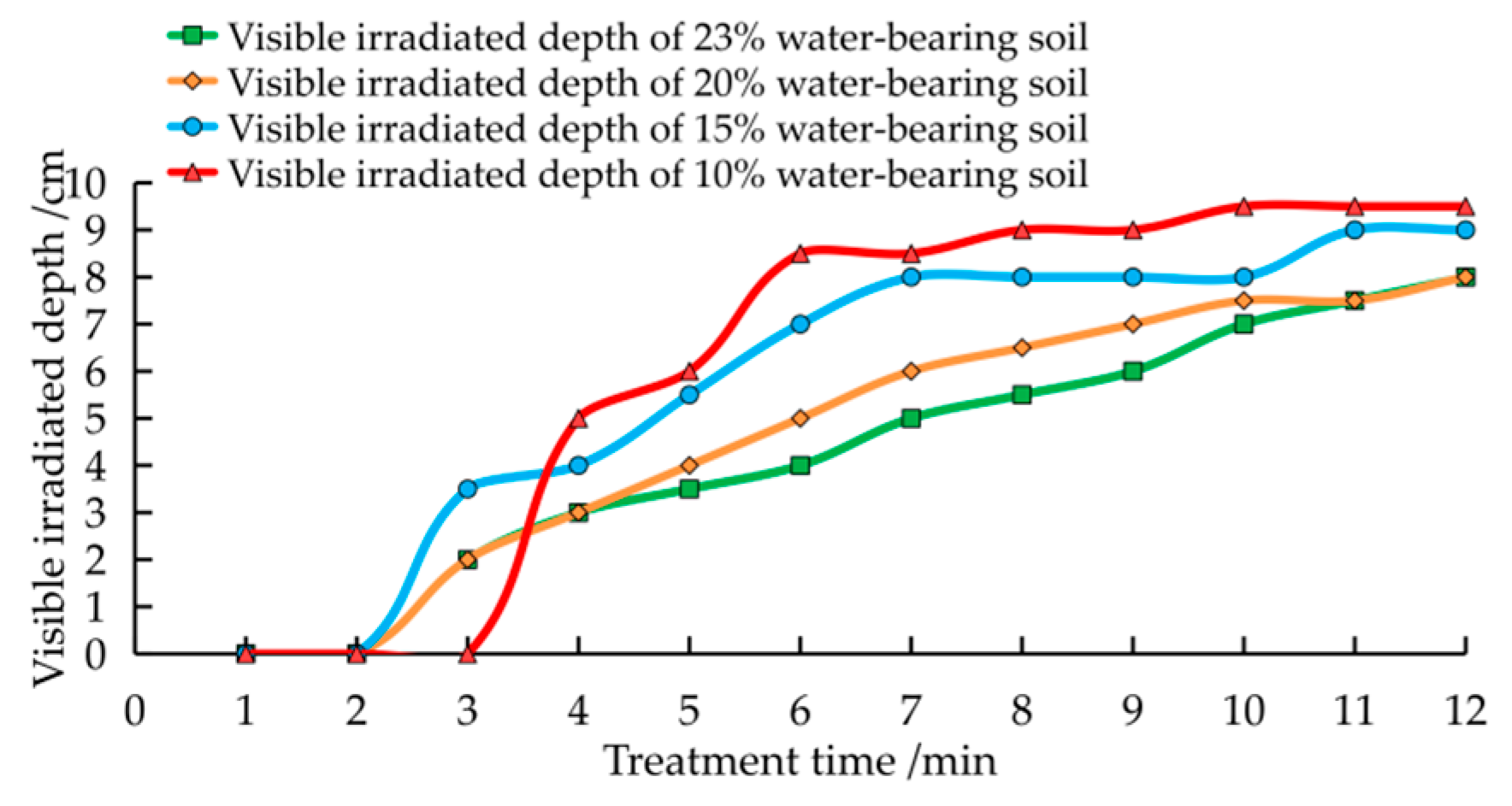

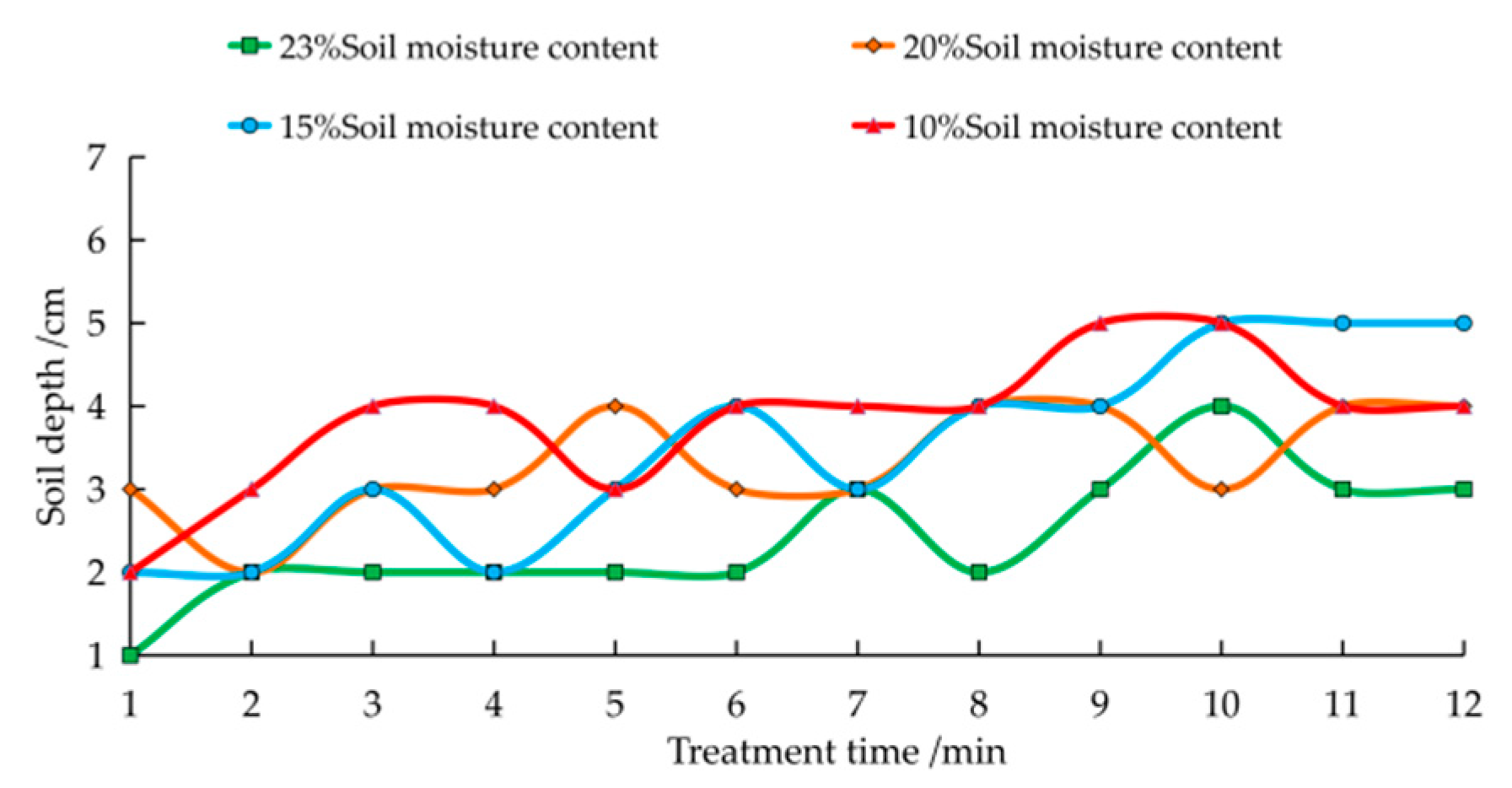

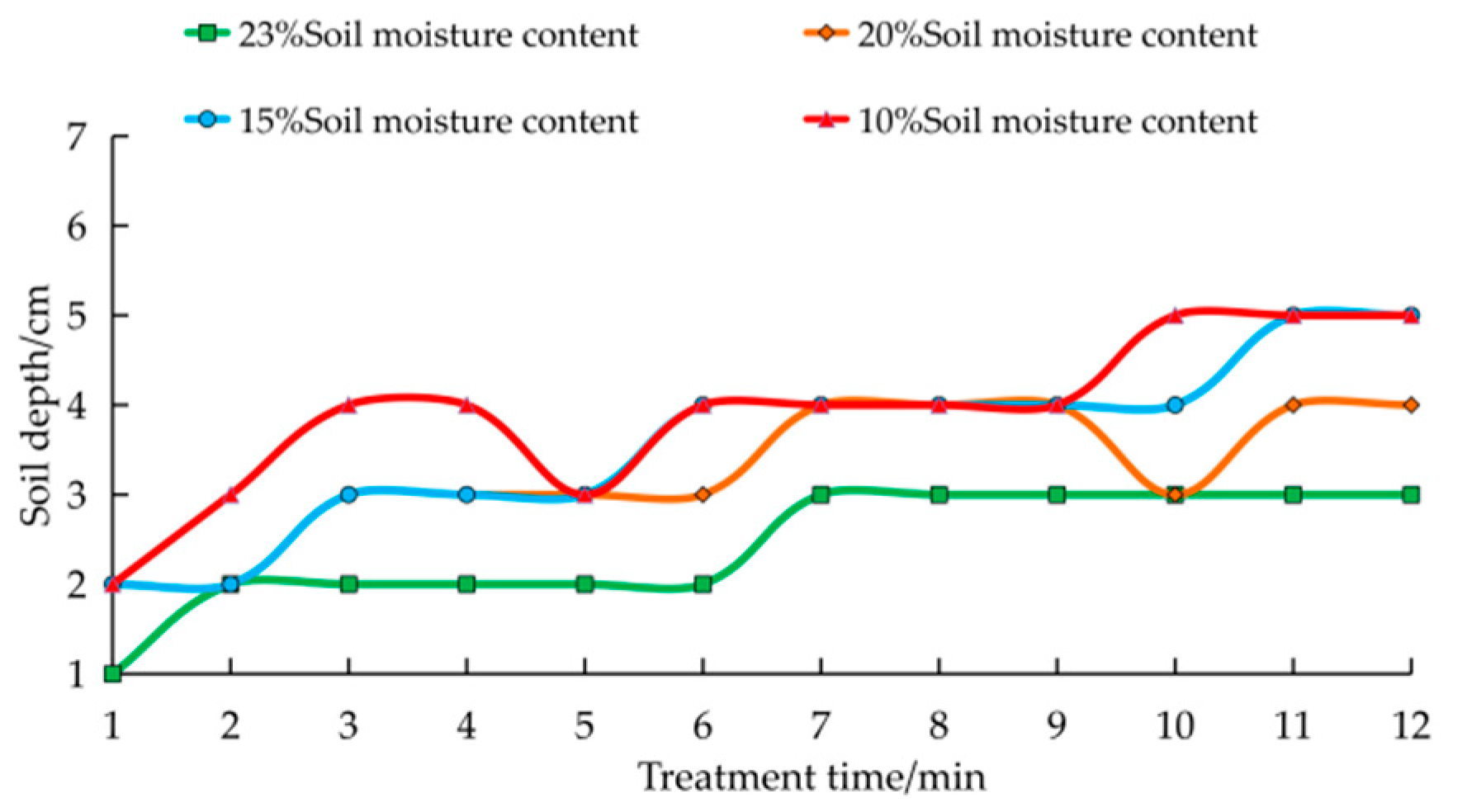

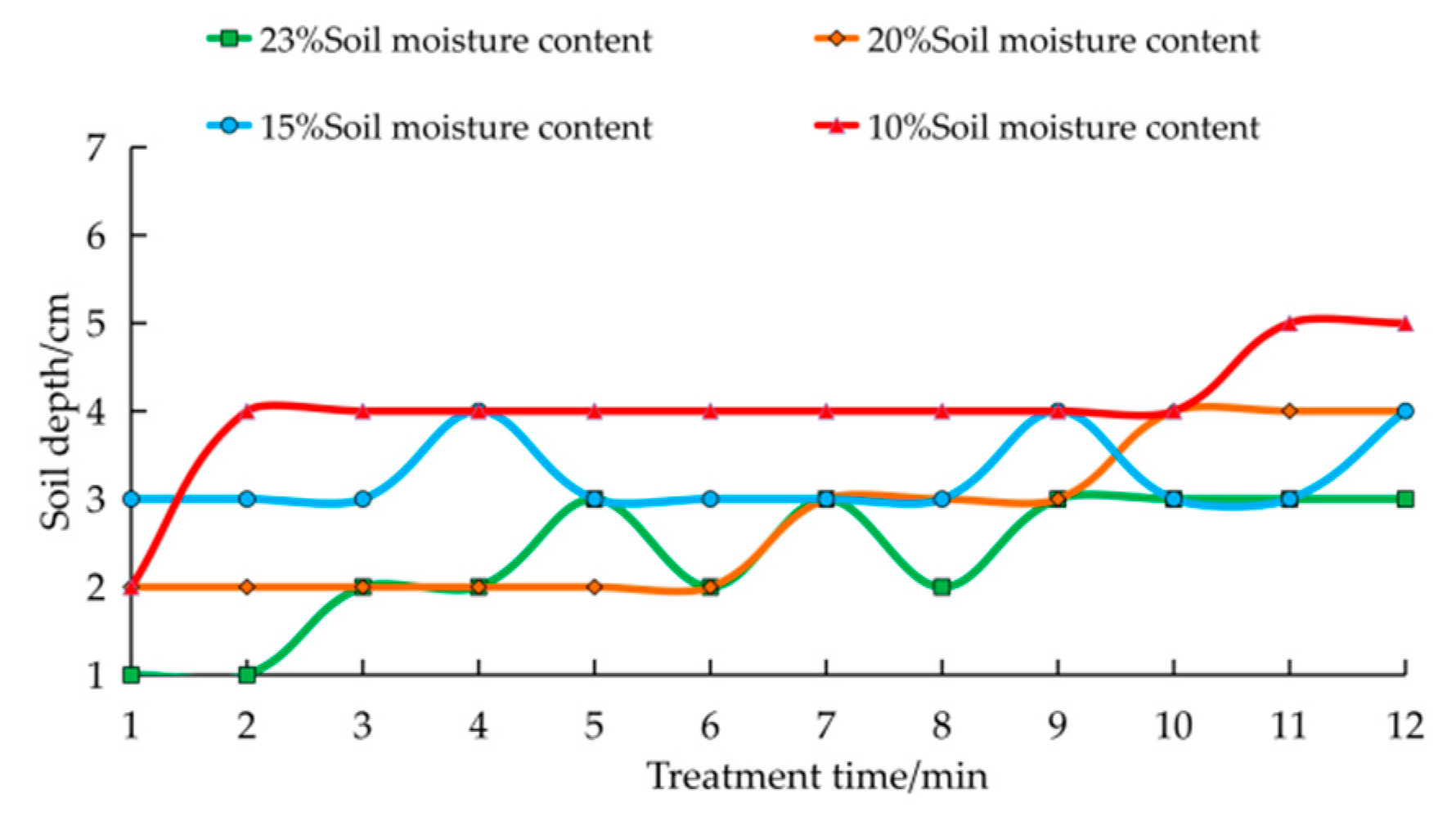

Long-Term Microwave Action Soil Irradiation Depth Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Du, Y. Research on the status and role of facility agriculture in ecological environment construction. New Agric. 2022, 5, 42. [Google Scholar]

- Cao, A.; Fang, W.; Li, Y.; Yan, D.; Wang, Q.; Guo, M.; Huang, B.; Song, Z.; Jin, Q. Review of 60 years of soil fumigation and disinfection in my country. J. Plant Prot. 2022, 49, 325–335. [Google Scholar] [CrossRef]

- Liu, Z.; Zhong, H.; Li, Y.; Wen, Q.; Liu, X.; Jian, Y. Characteristics of China’s grain production changes in the past 20 years and its impact on regional grain supply and demand patterns. J. Nat. Resour. 2021, 36, 1413–1425. [Google Scholar] [CrossRef]

- Fang, W.; Cao, A.; Wang, Q.; Yan, D.; Li, Y.; Jin, X.; Zhao, Q.; Qiu, Y.; Zhao, H. A new integrated soil disinfection machine improves the uniformity of dazomet in soil. Sci. Agric. Sin. 2021, 54, 2570–2580. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, D.; Wang, X.; Li, X.; Cao, A. Research advances in soil fumigants. J. Plant Prot. 2017, 44, 529–543. [Google Scholar]

- Wang, X.-N.; Cao, A.-C.; Yan, D.-D.; Wang, Q.; Huang, B.; Zhu, J.-H.; Wang, Q.-X.; Li, Y.; Ouyang, C.-B.; Guo, M.-X.; et al. Evaluation of soil flame disinfestation (SFD) for controlling weeds, nematodes and fungi. J. Integr. Agric. 2020, 19, 164–172. [Google Scholar] [CrossRef]

- Hess, M.C.M.; Buisson, E.; Mesléard, F. Soil compaction enhances the impact of microwave heating on seedling emergence. Flora 2019, 259, 151457. [Google Scholar] [CrossRef]

- Tang, T.; Liu, Y.; Wen, G.; Liu, G.; Wen, J.G.; Liu, L. Simulation for propagation of high-power microwave with repeated monopulses in soil. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 1308–1311. [Google Scholar] [CrossRef]

- Rahi, G.S.; Rich, J.R. Effect of moisture on efficiency of microwaves to control plant-parasitic nematodes in soil. J. Microw. Power Electromagn. Energy 2011, 45, 86–93. [Google Scholar] [CrossRef]

- Sabry, A.; Allam, A.; Abdel-Rahman, A.B.; El-Ansary, D. A novel microwave applicator for sandy soil disinfection. In Proceedings of the 2018 Progress in Electromagnetics Research Symposium (PIERS-Toyama), Toyama, Japan, 1–4 August 2018; IEEE: New York, NY, USA, 2018; pp. 636–641. [Google Scholar]

- Bebawi, F.; Cooper, A.P.; Brodie, G.; Madigan, B.A.; Vitelli, J.; Worsley, K.J.; Davis, K. Effect of microwave radiation on seed mortality of rubber vine (Cryptostegia grandiflora R.Br.), parthenium (Parthenium hysterophorous L.) and bellyache bush (Jatropha gossypiifolia L.). Plant Prot. Q. 2007, 22, 136–142. [Google Scholar]

- Brodie, G.; Pasma, L.; Bennett, H.; Harris, G.; Woodworth, J. Evaluation of microwave soil pasteurization for controlling germination of perennial ryegrass (Lolium perenne) seeds. Plant Prot. Q. 2007, 22, 150–154. [Google Scholar]

- Liu, H.J.; Wang, P.F.; Li, J.P.; Yang, X. Research on weed pre-emergent control using microwave radiation. J. Chin. Agric. Mech. 2019, 40, 59–62. [Google Scholar]

- Sun, L.; Yu, F.; Ge, X. Experimental study on the application of self-propelled fine-rotating soil flame insecticide in facility vegetable production. Jiangsu Agric. Mech. 2020, 4, 4. [Google Scholar]

- Bisceglia, B. Innovative applications in horticulture: Electromagnetic fields treatment of soil and seeds. Acta Hortic. 2017, 1164, 85–92. [Google Scholar] [CrossRef]

- Gai, Z.; Sun, L.; Wei, D.; Wang, C.L.; Yang, G.J.; Lin, Z.Y. Effects of microwave on soil microorganisms and functional diversity of their communities. Henan Agric. Sci. 2007, 3, 5. [Google Scholar]

- O’Brien, M. Microwave—A Fresh Look at Old Technology for Weed Control; The Australian Cottongrower: Toowoomba, Australia, 2017; pp. 26–28. [Google Scholar]

- Wang, Z.; Shi, Y.; Liu, C. Control effect of microwave disinfection on pathogenic microorganisms in soil. Henan Agric. Sci. 2010, 12, 3. [Google Scholar]

- Maddalwar, S.; Nayak, K.K.; Kumar, M.; Singh, L. Plant microbial fuel cell: Opportunities, challenges, and prospects. Bioresour. Technol. 2021, 341, 125772. [Google Scholar] [CrossRef]

- Zhou, Z.; Bu, X.; Wu, Y.; Xue, J.H. Effects of biochar on soil microbial properties. J. Nanjing For. Univ. Nat. Sci. 2016, 40, 8. [Google Scholar]

- Gai, Z.; Zhou, Y.; Wang, B.; Li, D.W.; Guo, X.G.; Wei, X.D. Soil test study of microwave disinfection facility. South. Agric. J. 2007, 38, 174–176. [Google Scholar]

- Wang, C.; Cai, G.; Liu, X.; Wu, M. Prediction of soil thermal conductivity based on Intelligent computing model. Heat Mass Transf. 2022. [Google Scholar] [CrossRef]

- Brodie, G.; Hamilton, S.; Woodworth, J. An assessment of microwave soil pasteurization for killing seeds and weeds. Plant Prot. Q. 2007, 22, 143–149. [Google Scholar]

- Khan, M.J.; Brodie, G.I.; Gupta, D. Microwave: A novel approach to tackle herbicide resistance in no-till farming systems. In Proceedings of the 21st Australasian Weeds Conference, New South Wales, Australia, 9–12 September 2018; Johnson, S., Weston, L., Wu, H.W., Auld, B., Eds.; CABI: Wallingford, UK, 2019; pp. 140–143. [Google Scholar]

- Fanti, A.; Spanu, M.; Lodi, M.B.; Desogus, F.; Mazzarella, G. Nonlinear analysis of soil microwave heating: Application to agricultural soils disinfection. IEEE J. Multiscale Multiphys. Comput. Tech. 2017, 2, 105–114. [Google Scholar] [CrossRef]

- Nelson, S.O. A review and assessment of microwave energy for soil treatment to control pests. Trans. ASAE 1996, 39, 281–289. [Google Scholar] [CrossRef]

- Kim, J.; Mun, S.C.; Ko, H.-U.; Kim, K.-B.; Khondoker, M.A.H.; Zhai, L. Review of microwave assisted manufacturing technologies. Int. J. Precis. Eng. Manuf. 2012, 13, 2263–2272. [Google Scholar] [CrossRef]

- Rahi, G.; Rich, J. Potential of microwaves to control plant-parasitic nematodes in soil. J. Microw. Power Electromagn. Energy 2007, 42, 5–12. [Google Scholar] [CrossRef]

- Li, Y. Plug-in Microwave Soil Sterilization and Insecticide Device. Patent CN2607780, 31 March 2004. [Google Scholar]

- Nelson, S.O.; Kraszewski, A.W. Dielectric properties of materials and measurement techniques. Dry. Technol. 1990, 8, 1123–1142. [Google Scholar] [CrossRef]

- Zhou, M.C. Study on Numerical Simulation of Microwave Heating and Temperature Control. Ph.D Thesis, Southwest University of Science and Technology, Mianyang, China, 2020; pp. 13–14. [Google Scholar]

- Mironov, V.L.; Bobrov, P.P.; Fomin, S.V.; Karavaiskii, A.Y. Generalized refractive mixing dielectric model of moist soils considering ionic relaxation of soil water. Russ. Phys. J. 2013, 56, 319–324. [Google Scholar] [CrossRef]

- Behzadi, M.; Dayyari, S.; Ali Akbarian, H.; Nezamabadi, N. Design and fabrication of a microwave weed killer device for weed control applications. Int. J. Eng. 2019, 32, 947–953. [Google Scholar]

- Jeong, C.H.; Seo, D.G.; Lee, W.S. Improved Heating Uniformity of a 3-kWatt 2.45 GHz Microwave Dryer Using Multiple Multi-Slotted Waveguides. In Proceedings of the 2019 International Applied Computational Electromagnetics Society Symposium (ACES), Miami, FL, USA, 14–19 April 2019; pp. 1–2. [Google Scholar]

- Brodie, G.; Harris, G.; Pasma, L.; Travers, A.; Leyson, D.; Lancaster, C.; Woodworth, J. Microwave soil heating for controlling ryegrass seed germination. Trans. ASABE 2009, 52, 295–302. [Google Scholar] [CrossRef]

- Metaxas, A.C.; Meredith, R.J. Industrial Microwave Heating; IEEE Power Engineering Series 4; Peter Peregrinus Ltd.: London, UK, 1993. [Google Scholar]

- Zhang, F.; Wang, X.; Liang, X.; Kong, X.; Zhang, Q.; Yang, L. Discrimination and analysis of soil classes and subclasses and their survey mapping in the second national soil census. Soil 2014, 46, 761–765. [Google Scholar] [CrossRef]

- Chang, Y. Spatial Distribution Characteristics and Driving Factors of Soil Microorganisms in Long-Term Maize Continuous Cropping in Jilin Province. Ph.D Thesis, Jilin Agricultural University, Jilin, China, 2021; pp. 2–3. [Google Scholar]

- Li, T. Relationship between geochemical process and element background content in Beijing soil. Environ. Sci. 1987, 4, 59–63. [Google Scholar]

- Liu, Z.; Gao, Y.; Liu, Z.; Duan, A. Effects of rainfall characteristics and mulching patterns on soil moisture in wheat fields. Trans. Chin. Soc. Agric. Eng. 2012, 28, 113–120. [Google Scholar]

- Wang, Z.; Liu, Z.; Cao, Z.; Li, Y.; Zhang, Z.; Wang, L. Effects of biochar on water-holding properties of black soil in Northeast China. Chin. J. Agric. Eng. 2019, 35, 147–153. [Google Scholar]

- Wei, H.; Meng, F. Research on soil conductivity measurement based on four-terminal method and time-domain reflectometry. J. Agric. Mach. 2019, 50, 237–242. [Google Scholar]

- Han, C.; Yang, W.; Dou, H.; Wang, X.; Hu, L.; Zhai, C. Design and test of a rapid detection system for soil conductivity in the field. J. Agric. Mach. 2022, 53, 301–310. [Google Scholar]

- Cicatelli, A.; Guarino, F.; Castiglione, S.; Luca, A.D.; Esposito, D.; Grimaldi, M.; Bisceglia, B. Microwave treatment of agricultural soil samples. In Proceedings of the 2015 IEEE 15th Mediterranean Microwave Symposium (MMS), Lecce, Italy, 30 November–2 December 2015; IEEE: New York, NY, USA, 2015; pp. 1–3. [Google Scholar]

- Wang, M.; Xiao, H.; Song, W.D.; Zhu, T.; Zhao., R.; Xiao, S.W. Effects of microwave treatment on root-knot nematodes in greenhouse continuous cropping soils. Chin. J. Agric. Mech. 2013, 2013, 95–99. [Google Scholar]

- Li, Y.; Cao, H.; Xu, F.; Ren, W.; Liu, J.; Zhang, S.; Zhang, F.; Chen, Z. Effects of different forms of soil disinfection on soil physical properties and cucumber growth. Chin. J. Eco-Agric. 2010, 18, 1189–1193. [Google Scholar] [CrossRef]

- Brodie, G.; Ryan, C.; Lancaster, C. Microwave technologies as part of an integrated weed management strategy: A review. Int. J. Agron. 2012, 2012, 636905. [Google Scholar] [CrossRef]

- Vidotto, F.; De Palo, F.; Ferrero, A. Effect of short-duration high temperatures on weed seed germination. Ann. Appl. Biol. 2013, 163, 454–465. [Google Scholar] [CrossRef] [Green Version]

- Ma, S.; Jin, H.; Zhao, Y.; Hu, H.; Hu, X. Establishment of microwave heating soil simulation model and its weeding and disinfection effect. J. Northwest A&F Univ.(Nat. Sci. Ed.) 2022, 8, 1–9. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Gracia-López, C. Thermal effects of microwave energy in agricultural soil radiation. Int. J. Infrared Millim. Waves 2004, 25, 1109–1122. [Google Scholar] [CrossRef]

- Cao, D.; Dai, W.; Qiang, S.; Song, X. Effects of different soil and water depths on the emergence of 15 weedy rice populations in China. Jiangsu Agric. J. 2011, 27, 750–755. [Google Scholar]

- Joines, W.T. Microwave System and Method for Controlling the Sterilization and Infestation of Crop Soils. Patent US20090232602A1, 19 April 2012. [Google Scholar]

- Sun, X.; Zhai, C.; Yang, S.; Ma, H.; Zhao, C. Simulations and experiments of the soil temperature distribution after 2.45-GHz short-time term microwave treatment. Agriculture 2021, 11, 933. [Google Scholar] [CrossRef]

- Paolanti, M.; Pollini, R.; Frontoni, E.; Mancini, A.; Leo, R.D.; Zingaretti, P.; Bisceglia, B. Exposure protocol setup for agro food treatment. Method and system for developing an application for heating in reverberation chamber. In Proceedings of the 2015 IEEE 15th Mediterranean Microwave Symposium (MMS), Lecce, Italy, 30 November–2 December 2015; IEEE: New York, NY, USA, 2015; pp. 1–4. [Google Scholar]

- Hoekstra, P.; Delaney, A. Dielectric properties of soils at UHF and microwave frequencies. J. Geophys. Res. (1896–1977) 1974, 79, 1699–1708. [Google Scholar] [CrossRef]

- Janney, M.A.; Kimrey, H.D. Diffusion controlled processes in microwave-fired oxide ceramics. In Proceedings of the MRS Symposium; Snyder, W.B., Sutton, W.H., Eds.; Microwave Processing of Materials: Washington, DC, USA, 1991; pp. 215–227. [Google Scholar]

- Davis, F.S.; Wayland, J.R.; Merkle, M.G. Ultrahigh-frequency electromagnetic fields for weed control: Phytotoxicity and selectivity. Science 1971, 173, 535–537. [Google Scholar] [CrossRef]

- Olsen, R.G. A Theoretical investigation of microwave irradiation of seeds in soil. J. Microw. Power 1975, 10, 281–296. [Google Scholar] [CrossRef]

- Giovannini, C.; Lucchesi, S.; Giachetti, M. Effects of heating on some chemical parameters related to soil fertility and plant growth. Soil Sci. 1990, 149, 334–350. [Google Scholar] [CrossRef]

- Lin, Z.; Sui, L.; Zheng, X.; Li, B.; Zou, L.; Liu, C. Influence of microwave foam drying on the dielectric properties of raspberry fruit powder. Food Mach. 2014, 30, 10–14+309. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Gracia-López, C.; Plaza-Gonzalez, P.J. Determination of dielectric properties of agricultural soil. Biosyst. Eng. 2005, 91, 119–125. [Google Scholar] [CrossRef]

| Simulation Parameters | Value (Unit) | Simulation Parameters | Value (Unit) |

|---|---|---|---|

| Soil domain length (L1) | 30 [cm] | Conductivity | 0 (S/m) |

| Soil domain width (L2) | 30 [cm] | Dielectric loss factor (ε″) | 0 |

| Soil domain height (H) | 20 [cm] | Air relative permittivity | 1 |

| Waveguide to soil distance (gap) | 5 [cm] | Meshing maximum element size | C_const/frequency/4 |

| Incident frequency (frequency) | 2.45 [GHz] | Meshing minimum element size | 0.1 |

| Transmit power (power) | 2000 [W] | Meshing maximum element growth rate | 1.5 |

| pml thickness (t_pml) | 5 [cm] | Curvature factor | 0.6 |

| Relative permeability (μr) | 1 | Narrow area resolution | 0.5 |

| Soil thermal conductivity (k_iso) | 0.6 [m·k] | Soil moisture content (M) | 0.11 |

| Soil constant pressure heat capacity (Cp) | 900 [J/(kg·k)] | Density (ρ) | 1220 [kg/m3] |

| The mass fraction of water in the soil | Re (eps) | The mass fraction of water in the soil | Im (eps) |

| 0.021 | 2.99297 | 0.021 | 0 |

| 0.168 | 6.23886 | 0.168 | 0.76203 |

| 0.19 | 9.63988 | 0.19 | 1.10192 |

| 0.248 | 17.146 | 0.248 | 1.89194 |

| 0.292 | 23.63777 | 0.292 | 3.62815 |

| 0.335 | 26.90753 | 0.335 | 5.08877 |

| Equipment (Material) | Specification (Model) | Quantity | Manufacturer | Microwave Soil Irradiation Test Bench |

|---|---|---|---|---|

| Magnetron | 2 M 362 | 1 | LG, Seoul, Korea |  |

| Waveguide | 30 × 12.5 × 4.5 cm | 1 | MEGMEET Electric Co., Ltd., Shenzhen, China | |

| Microwave frequency conversion power supply | WepeX-1000B | 1 | MEGMEET Electric Co., Ltd., Shenzhen, China | |

| Microwave controller | WepeX-C1 | 1 | MEGMEET Electric Co., Ltd., Shenzhen, China | |

| Power display meter | D69-2049 | 1 | Elecall Electric Co., Ltd., Shenzhen, China | |

| Fixture | 100 × 60 × 60 cm | 1 | Self-made | |

| Acrylic box | 30 × 30 × 30 cm | 1 | Hualian Acrylic Factory, Xiamen, Fujian, China, | |

| Soil | 2.25 × 10−2 m3 | - | Self-collection | |

| Movable lift platform | 46 × 32 × 20 cm | 1 | Karlon Hardware Store, Jiaxing, Zhejiang, China | |

| Infrared thermal imager | Testo 865 | 1 | Testo AG, Germany | |

| Temperature sensor | PT100 | 30 | Senxtee Electric Co., Ltd., Hangzhou, China | |

| Signal acquisition module | DS18B20 | 4 | Senxtee Electric Co., Ltd., Hangzhou, China |

| Equation | ||||||||

| Parameters | z0 | A | xc | ω1 | yc | ω2 | R2 | |

| Soil moisture content of loess/% | 10 | 27.77206 ± 0.58904 | 64.3469 ± 1.34936 | 4.74245 ± 0.09999 | 5.43662 ± 0.13654 | 12.54015 ± 0.40527 | 6.44588 ± 0.28604 | 0.96782 |

| 15 | 26.44759 ± 1.05091 | 63.44349 ± 1.24698 | 5.58985 ± 0.11612 | 6.35822 ± 0.19674 | 11.65806 ± 0.33563 | 6.38847 ± 0.29611 | 0.9564 | |

| 20 | 26.0145 ± 0.80595 | 61.09687 ± 0.91617 | 4.97283 ± 0.1123 | 5.66393 ± 0.16698 | 10.56247 ± 0.23881 | 5.94615 ± 0.23518 | 0.9573 | |

| 23 | 24.0885 ± 0.73671 | 58.92115 ± 1.56181 | 2.66982 ± 0.26274 | 6.49518 ± 0.27156 | 12.56472 ± 0.56986 | 7.22563 ± 0.42097 | 0.95647 | |

| Soil moisture content of black soil/% | 10 | 26.55192 ± 1.07152 | 70.99927 ± 1.45919 | 5.65879 ± 0.10169 | 6.58442 ± 0.17942 | 12.39321 ± 0.38395 | 6.99546 ± 0.31257 | 0.96756 |

| 15 | 27.32122 ± 1.15636 | 59.66404 ± 1.12672 | 5.6307 ± 0.11883 | 6.55357 ± 0.21495 | 10.85128 ± 0.26614 | 6.36138 ± 0.2773 | 0.95385 | |

| 20 | 23.54104 ± 0.97546 | 61.01984 ± 1.00369 | 4.22685 ± 0.15539 | 6.68197 ± 0.22432 | 10.81245 ± 0.27616 | 6.73701 ± 0.27937 | 0.96293 | |

| 23 | 24.40695 ± 0.62829 | 64.38545 ± 1.04298 | 3.59239 ± 0.14632 | 5.19025 ± 0.16753 | 11.13109 ± 0.33009 | 6.19061 ± 0.28187 | 0.95807 | |

| Soil Moisture Content | X (Irradiation Time) | Y (Soil Depth) | Z () | |

|---|---|---|---|---|

| Loess | 10% | 12.54015 | 4.74245 | 92.11896 |

| 15% | 11.65806 | 5.58985 | 89.89108 | |

| 20% | 10.56247 | 4.97283 | 87.11137 | |

| 23% | 12.56472 | 2.66982 | 83.00965 | |

| Black soil | 10% | 12.39321 | 5.65879 | 97.55119 |

| 15% | 10.85128 | 5.6307 | 86.98526 | |

| 20% | 10.81245 | 4.22685 | 84.56088 | |

| 23% | 11.13109 | 3.59239 | 88.79240 |

| Surface Fitting Equation (Loess) | Surface Fitting Equation (Black Soil) | |||

|---|---|---|---|---|

| Parameters | z0 | −15.8487 ± 31.86192 | z0 | −15.77101 ± 22.18914 |

| A | 84.52756 ± 32.70872 | B | 90.89622 ± 23.03721 | |

| xc | 14.4657 ± 1.64587 | C | −0.6273 ± 2.0709 | |

| ω1 | 13.48069 ± 4.55263 | D | 6.97897 ± 1.22299 | |

| yc | 0.15286 ± 0.00208 | E | 0.33741 ± 0.03576 | |

| ω2 | 0.14603 ± 0.03564 | F | −0.11324 ± 0.02257 | |

| R2 | 0.97199 | R2 | 0.98244 | |

| 1 < x < 12, 0.1 < y < 0.23 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Zhao, C.; Yang, S.; Ma, H.; Zhai, C. Simulations and Experiments of Soil Temperature Distribution after 2.45 GHz Long-Term Microwave Treatment. Agriculture 2022, 12, 909. https://doi.org/10.3390/agriculture12070909

Sun X, Zhao C, Yang S, Ma H, Zhai C. Simulations and Experiments of Soil Temperature Distribution after 2.45 GHz Long-Term Microwave Treatment. Agriculture. 2022; 12(7):909. https://doi.org/10.3390/agriculture12070909

Chicago/Turabian StyleSun, Xiaohe, Chunjiang Zhao, Shuo Yang, Haolin Ma, and Changyuan Zhai. 2022. "Simulations and Experiments of Soil Temperature Distribution after 2.45 GHz Long-Term Microwave Treatment" Agriculture 12, no. 7: 909. https://doi.org/10.3390/agriculture12070909

APA StyleSun, X., Zhao, C., Yang, S., Ma, H., & Zhai, C. (2022). Simulations and Experiments of Soil Temperature Distribution after 2.45 GHz Long-Term Microwave Treatment. Agriculture, 12(7), 909. https://doi.org/10.3390/agriculture12070909