Design and Experiment of Symmetrical Spiral Row-Sorting of the Straw Device Based on Kinematics Analysis

Abstract

:1. Introduction

2. Methods and Materials

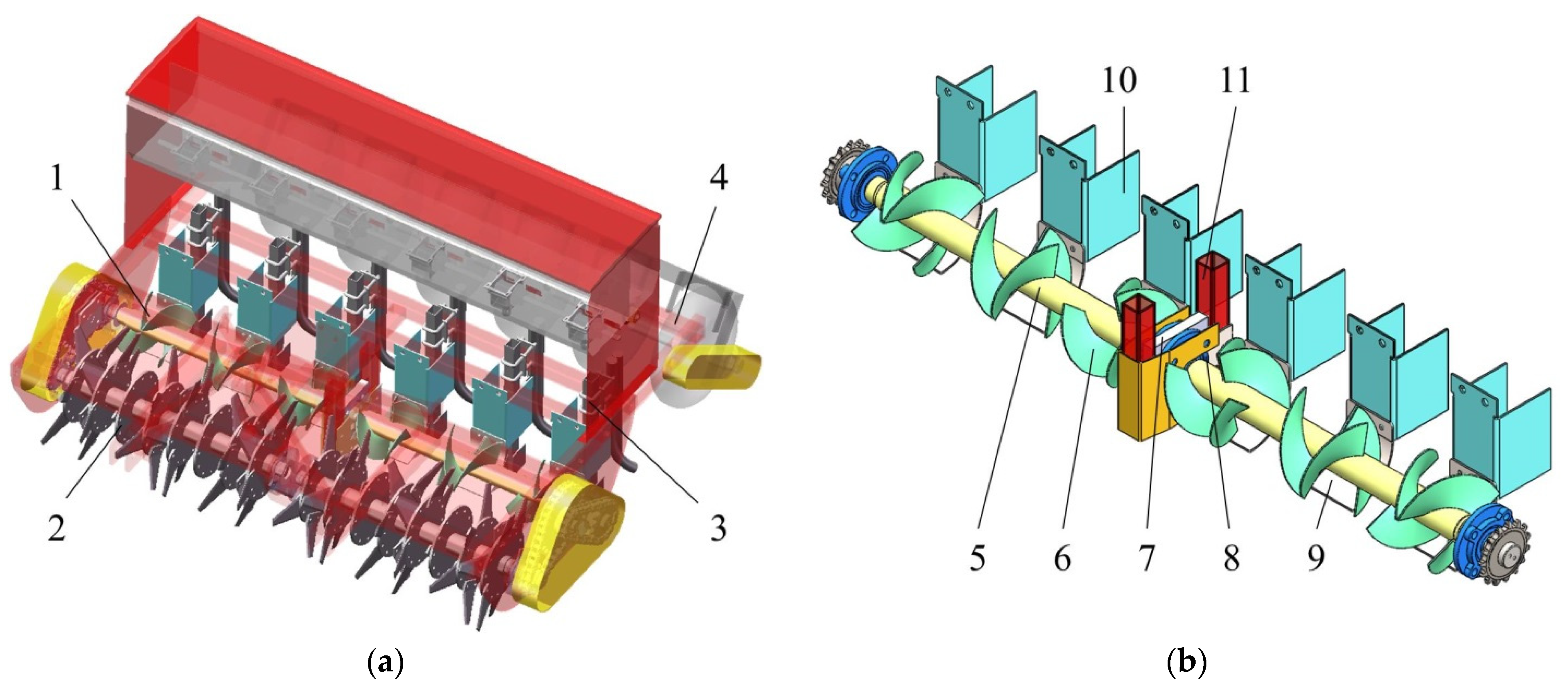

2.1. Machine Structure and Working Principle of the SSRSD

2.1.1. Structure of the SSRSD

2.1.2. Working Principle

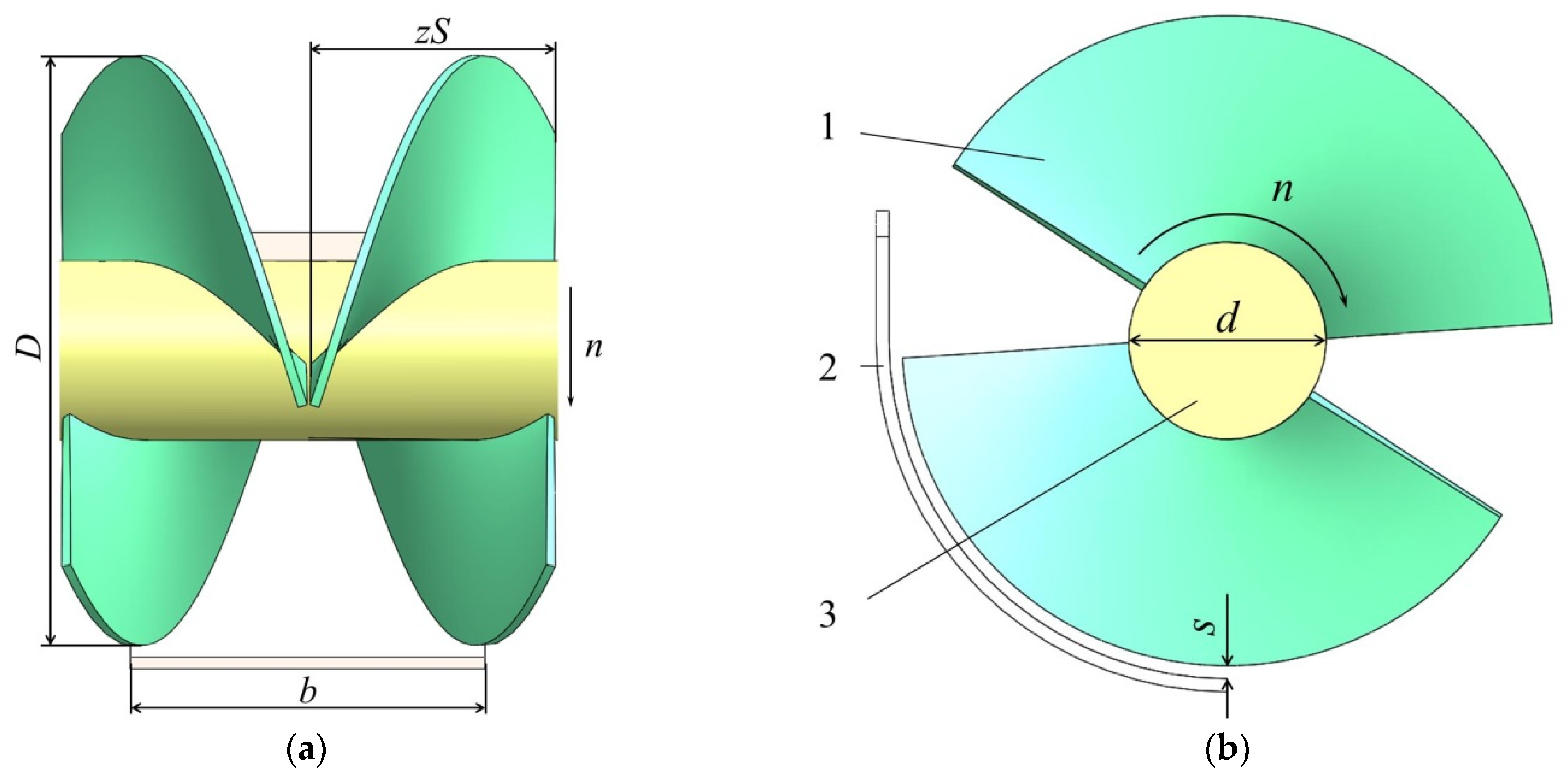

2.2. Determination of Critical Parameters of SSM

2.2.1. Calculation of Maximum Straw Feeding Amounts

2.2.2. Determination of Critical Parameters

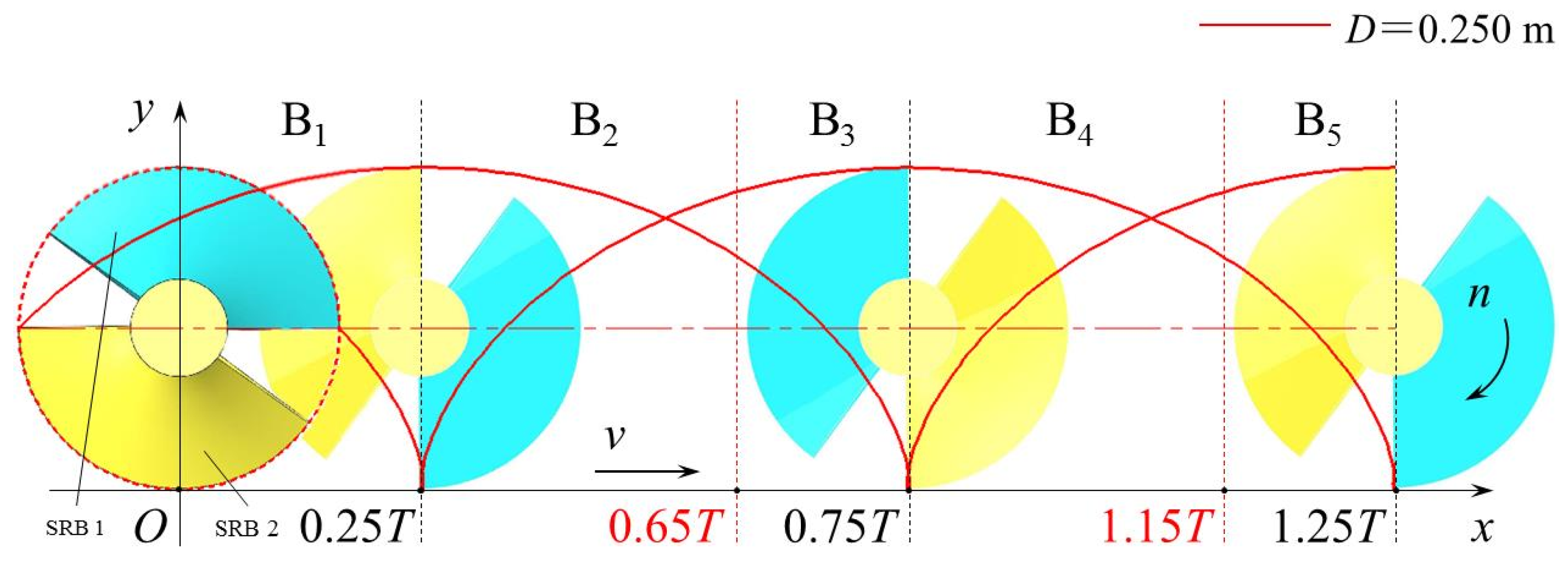

2.3. Kinematic Analysis Method to Determine the Rational and Reasonable Value of Critical Parameters

2.3.1. Kinematic Analysis Methods

2.3.2. Determination of Rational and Reasonable Parameters Value Range

2.4. Field Test Method to Verify the Operating Performance of the SSRSD

2.4.1. Field Test Conditions

2.4.2. Index and Test Method

The Machine’s Passing Capacity

The SRR of the Sowing Belt

3. Results and Discussion

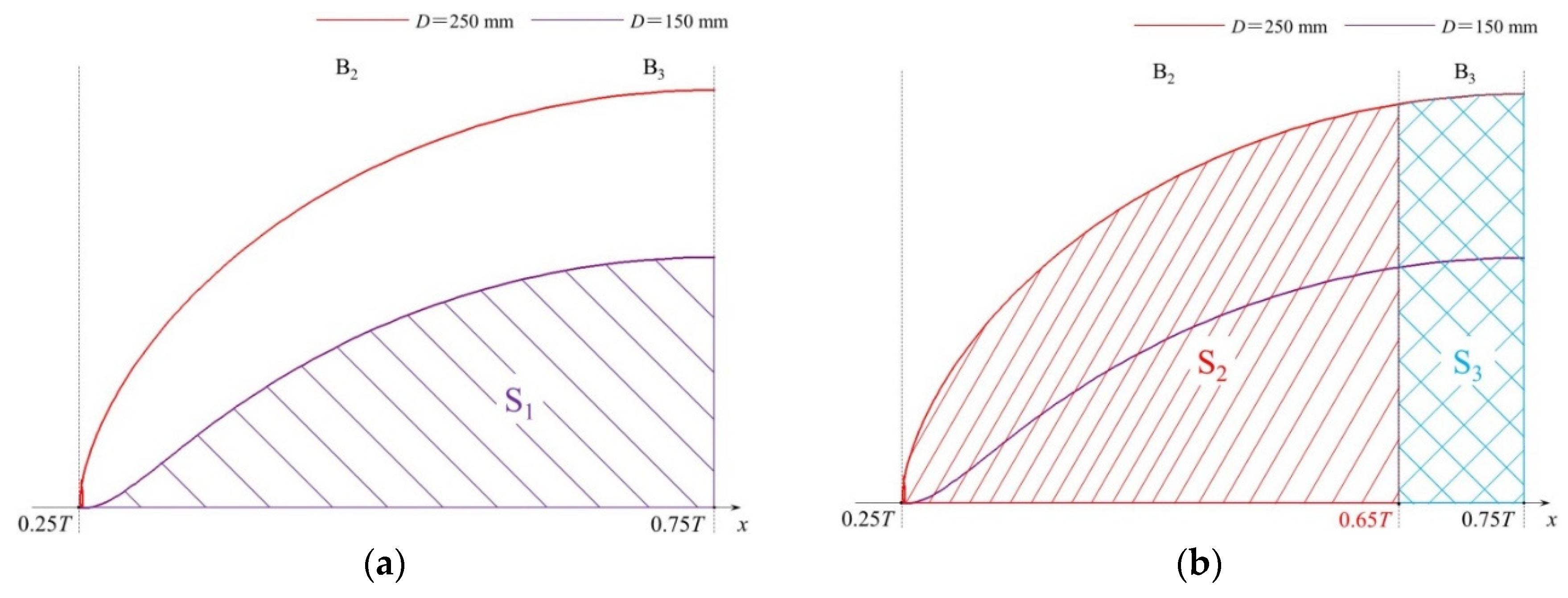

3.1. Determination of the ODRB D

3.1.1. Analysis When the ODRB D = 150 mm

3.1.2. Analysis When the ODRB D = 250 mm

3.1.3. Mechanism Analysis of Motion Trajectory and Determination of ODRB D

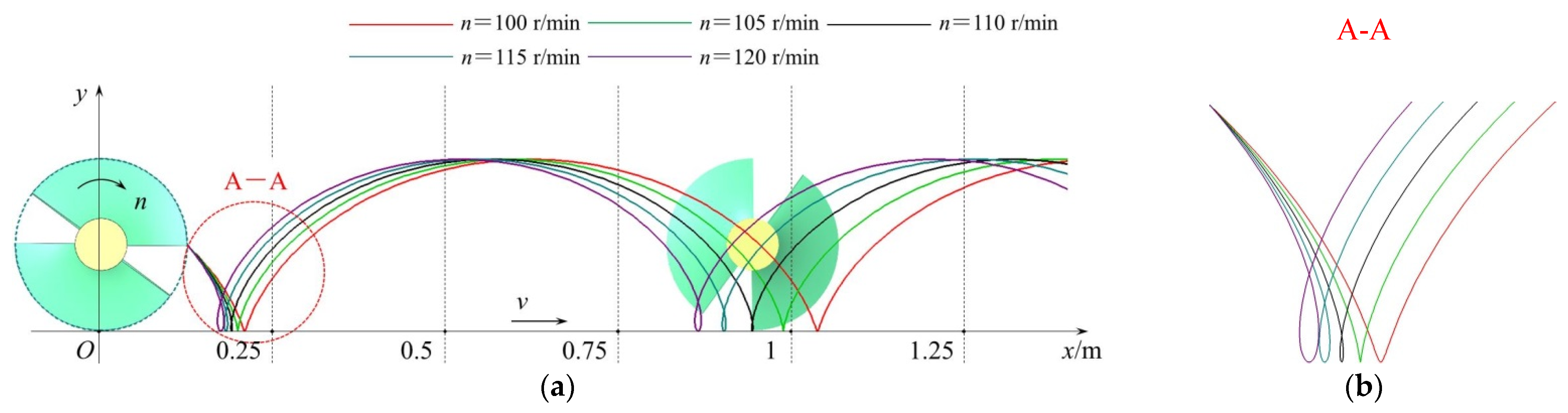

3.2. Determination of the RVSS n

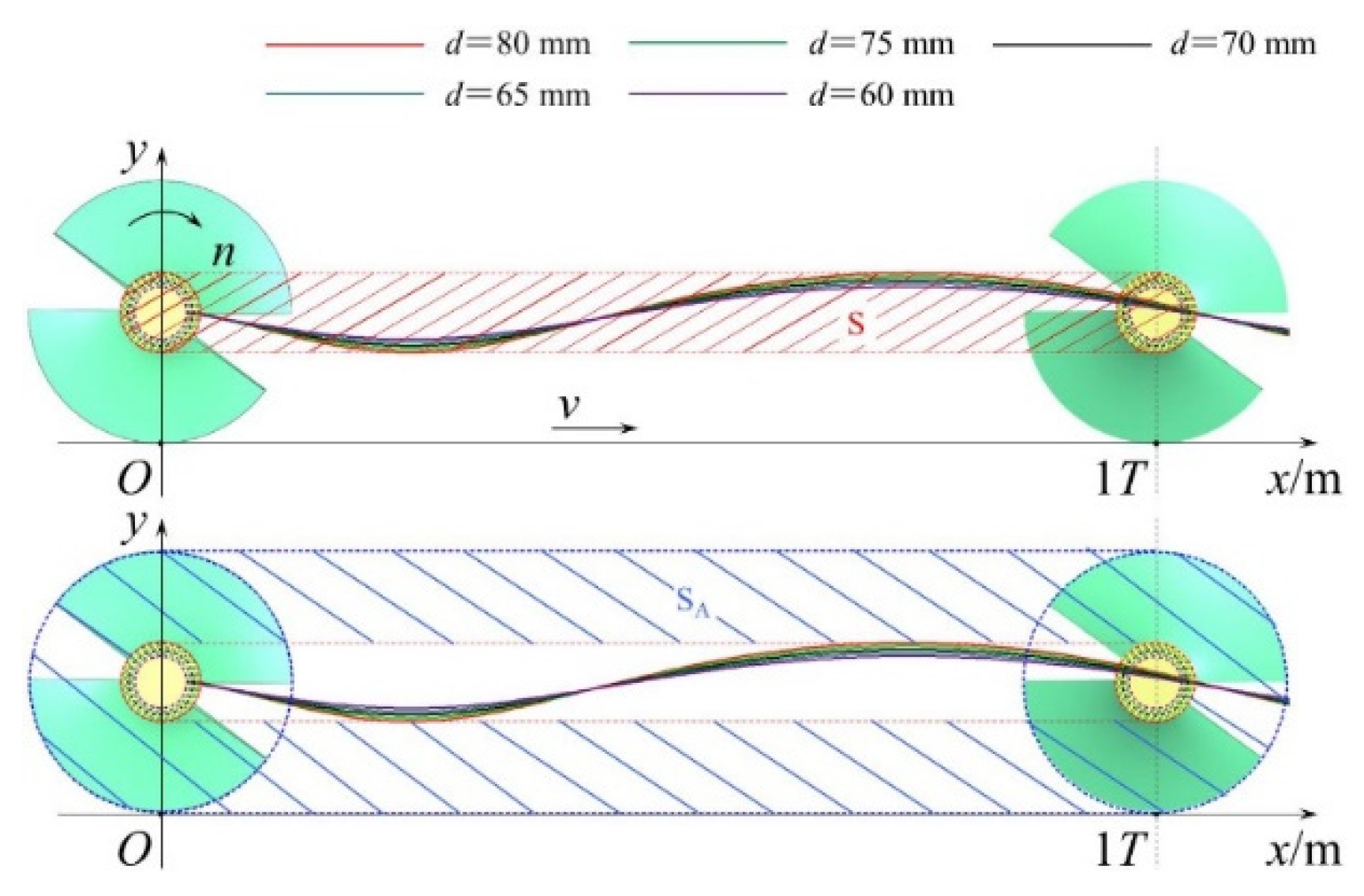

3.3. Determination of the DSS d

3.3.1. Calculation of the Minimum Value of the DSS d

3.3.2. Influence of DSS d change on Ineffective Operation Rate η

3.3.3. The influence of DSS d change on the structural strength τT

3.3.4. Determination of the Value of the DSS d

3.4. Design Results of Main Structural Parameters

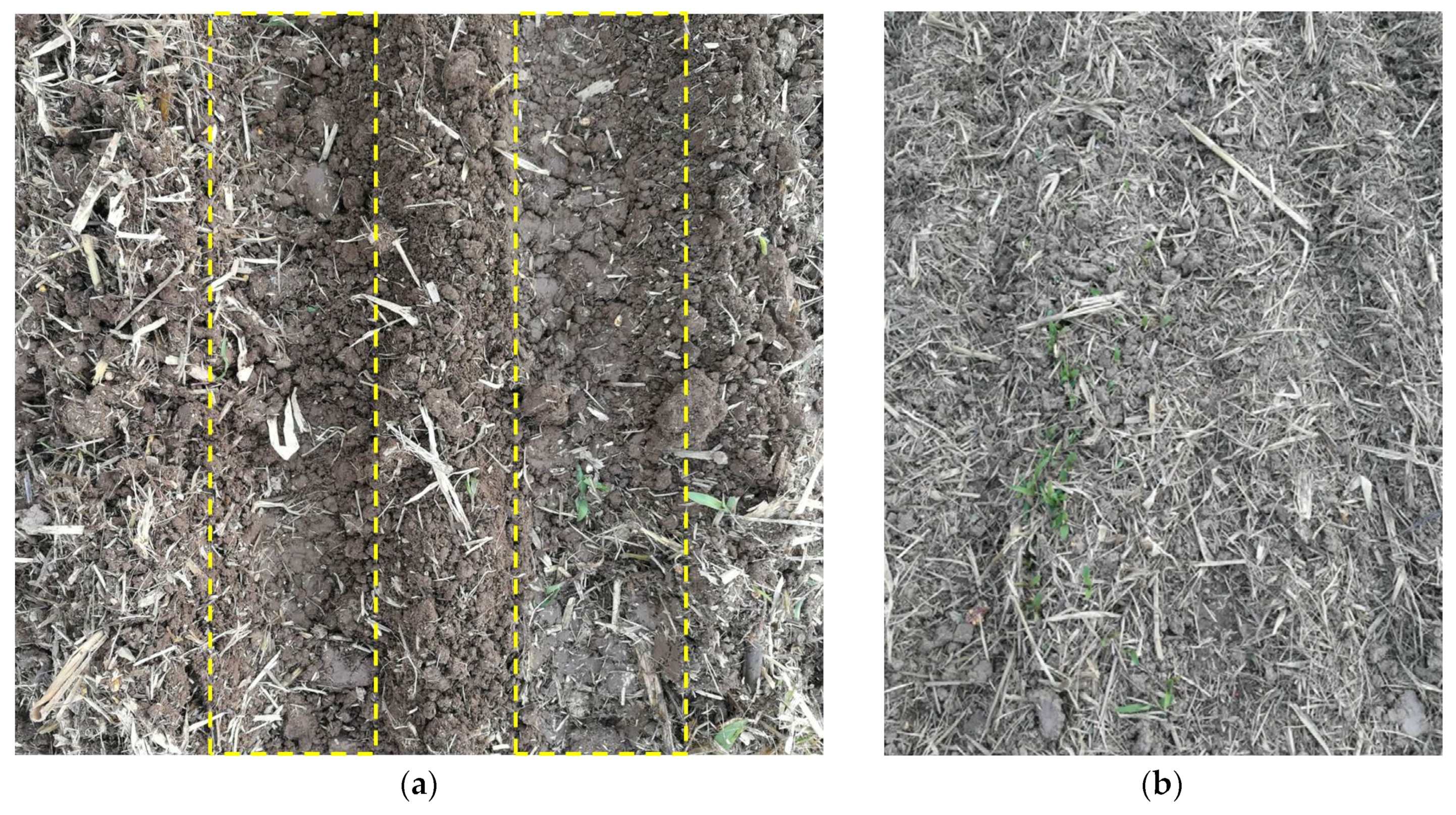

3.5. Field Test Verification

3.5.1. The Machine’s Passing Capacity

3.5.2. The SRR of the Sowing Belt

3.6. Discussion

4. Conclusions

- (1)

- In this paper, an SSRSD was designed. The high-velocity rotating no-till anti-blocking knife cut and chopped the straw and threw it to the rear SSM during the operation. Based on the spiral shaft rotary, the RB of the SSM pushed the straw that fell into the straw hopper to the non-sowing area on both sides of the sowing belt and played the role of row-sorting the straw. It realizes the cleaning of the seed belt while alleviating the blockage of the machines.

- (2)

- The relationship between the material-bearing capacity limit of the SSM and the SFA (that was, the SMQ) in the actual operation process was theoretically analyzed. The critical parameters of the SSM were determined as the ODRB D, the RVSS n, and the DSS d. The rational and reasonable value range was D∈[150, 250], n∈[100, 120], d∈[60, 80].

- (3)

- Based on the kinematics analysis method, the motion trajectory mechanism of the RB of the SSM was analyzed, and the rational and reasonable values of the critical parameters were determined. Namely, the ODRB was 250 mm, the RVSS was 110 rpm, and the DSS was 76 mm. Based on the values of the above critical parameters, a field test was carried out after the prototype was manufactured. The results show that the no-till planter installed with the SSRSD was 87.98%, and the average SRR of the no-till planter installed without the SSRSD was 72.91%. The SRR was increased by 20.7%, and the cleaning effect of the seed belt was significantly improved, which could simultaneously improve the passing capacity of the machine and the quality of wheat no-till sowing.

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, J.; Li, H.; Chen, H.; Lu, C.; Wang, Q. Research progress of conservation tillage technology and machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–19. [Google Scholar] [CrossRef]

- Wang, Q.; Cao, X.; Wang, C.; Li, H.; He, J.; Lu, C. Research progress of no/minimum tillage corn seeding technology and machine in northeast black soil regions of China. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–15. [Google Scholar]

- Liu, W.; Li, W.; Zheng, K.; Zhao, H. The current research status of conservation tillage technology. J. Agric. Mech. Res. 2017, 39, 7. [Google Scholar] [CrossRef]

- Department of Agricultural Mechanization Management. Ministry of Agriculture. Conservation Tillage in China; China Agricultural Press: Beijing, China, 2008.

- Liu, J.; Cui, Z.; Ma, J.; Wei, J. Problems and countermeasures of wheat corn rotation production mechanization for main crops in huanghuaihai region. J. Agric. Mech. Res. 2016, 38, 259–263. [Google Scholar] [CrossRef]

- Central People’s Net of the People’s Republic of China. Available online: http://www.gov.cn/xinwen/ (accessed on 8 October 2021).

- Li, H.; Liu, H.; Zhou, J.; Wei, G.; Shi, S.; Zhang, X.; Zhang, R.; Zhu, H.; He, T. Development and first results of a no-till pneumatic seeder for maize precise sowing in Huang-Huai-Hai plain of China. Agriculture 2021, 11, 1023. [Google Scholar] [CrossRef]

- Lu, C.; Li, H.; He, J.; Wang, Q.; Sarker, K.K.; Li, W.; Lu, Z.; Rasaily, R.G.; Li, H.; Chen, G. Effects of controlled traffic no-till system on soil chemical properties and crop yield in annual double-cropping area of the north china plain. Soil Res. 2016, 54, 760–766. [Google Scholar] [CrossRef]

- Lu, C.; Zhao, C.; Meng, Z.; Wang, X.; Wu, G.; Gao, N. Straw friction characteristic based on rotary cutting anti-blocking device with slide plate pressing straw. Trans. Chin. Soc. Agric. Eng. 2016, 32, 83–89. [Google Scholar] [CrossRef]

- Lu, C. Study on anti-blocking technology and device of rotary cutting with slide plate pressing straw for no-till planter. Ph.D. Thesis, China Agricultural University, Beijing, China, May 2014. [Google Scholar]

- Lu, C.; He, J.; Li, H.; Wang, Q.; Zhang, X.; Liu, J. Finite element analysis and experiment on anti-blocking device based on support cutting. Trans. Chin. Soc. Agric. Mach. 2013, 44 (Suppl. 1), 61–66. [Google Scholar] [CrossRef]

- Lu, C.; Li, H.; He, J.; Zhu, H.; Xu, D. Floated support anti-blocking device of wheat no-till seeder. Trans. Chin. Soc. Agric. Eng. 2013, 44, 52–55+153. [Google Scholar] [CrossRef]

- Yuan, P.; Li, H.; Jiang, G.; He, J.; Lu, C.; Huang, S. Design and experiment of straw cleaning device for wide narrow maize no-tillage sowing strip in drip irrigation area. Trans. Chin. Soc. Agric. Mach. 2021, 52, 43–52. [Google Scholar] [CrossRef]

- Yu, C.; Wang, Q.; Li, H.; He, J.; Lu, C. Design and experiment of spiral-split sowing strip cleaning device. Trans. Chin. Soc. Agric. Eng. 2020, 51 (Suppl. 2), 212–219. [Google Scholar]

- Liu, J.; Wang, H.; Wang, Q.; Li, S.; Li, H.; He, J. Design and experiment of strip cleaning device of no and minimum-tillage corn planter. Trans. Chin. Soc. Agric. Mach. 2018, 49 (Suppl. 1), 132–140. [Google Scholar] [CrossRef]

- Zhao, H. Study on Driven Seedbed-Cleaning and Anti-Blocking Device of Residue Inter-Row Side-Throwing for Minimum till Wheat Seeding; China Agricultural University: Beijing, China, 2019. [Google Scholar]

- Zheng, Z. Study on Corn Straw Pickup-Chopping and Ditch-Burying Returning Field Machine; China Agricultural University: Beijing, China, 2017. [Google Scholar]

- He, J.; Li, H.; Wang, Q.; Gao, H.; Li, W.; Zhang, X.; McGiffen, M. The adoption of conservation tillage in China. Ann. N. Y. Acad. Sci. 2010, 1195, E96–E106. [Google Scholar] [CrossRef]

- He, J.; Zhang, Z.; Li, H.; Wang, Q. Development of small/medium size no-till and minimum-till seeders in Asia: A review. Int. J. Agric. Biol. Eng. 2014, 7, 1–12. [Google Scholar] [CrossRef]

- Cao, X.; Wang, Q.; Li, H.; He, J.; Lu, C. Design and experiment of active rotating collective straw-cleaner. Trans. Chin. Soc. Agric. Eng. 2021, 37, 26–34. [Google Scholar] [CrossRef]

- Cao, X.; Wang, Q.; Li, H.; He, J.; Lu, C. Combined row cleaners research with side cutter and stubble clean disk of corn no-till seeder. Trans. Chin. Soc. Agric. Mach. 2021, 52, 9. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, H.; Zhu, L.; Li, M.; Zhao, J. Design and experiment of star-toothed concave disk row cleaners for no-till planter. Trans. Chin. Soc. Agric. Mach. 2019, 50, 68–77. [Google Scholar]

- Wang, Q. Research on Key Technologies of Inter-Row Clean-Tillage and Its Strip-Till Machine; Jilin University: Changchun, China, 2019. [Google Scholar]

- Lin, J.; Li, B.; Li, H. Design and experiment of Archimedes spiral type stubble breaking ditching device and stubble breaking anti blocking device. Trans. Chin. Soc. Agric. Eng. 2015, 31, 10–19. [Google Scholar] [CrossRef]

- Lin, J.; Li, B.; Li, B.; Niu, J.; Qian, W. Parameter optimization and experiment on archimedes spiral type of gap cutting disc. Trans. Chin. Soc. Agric. Mach. 2014, 45, 118–124. [Google Scholar] [CrossRef]

- Li, Y.; Lu, C.; Li, H.; He, J.; Wang, Q.; Huang, S.; Gao, Z.; Yuan, P.; Wei, X.; Zhan, H. Design and Experiment of Spiral Discharge Anti-Blocking and Row-Sorting Device of Wheat No-Till Planter. Agriculture 2022, 12, 468. [Google Scholar] [CrossRef]

- Ni, H.; Lu, F.; Luo, X.; Tian, H.; Wang, J.; Guan, Y.; Chen, S.; Luo, X.; Zeng, E. Assessment of sampling designs to measure riverine fluxes from the pearl river delta, china to the south china sea. Environ. Monit. Assess. 2008, 143, 291–301. [Google Scholar] [CrossRef]

- China Academy of Agricultural Mechanization. Agricultural Machinery Design Manual; China Agricultural Science and Technology Press: Beijing, China, 2007; Volume 2. [Google Scholar]

- Yuan, Q.; Xu, L.; Niu, C.; Ma, S.; Yan, C.; Zhao, S.; Liu, F.; Wang, K. Development of soil-fertilizer mixing layered backfiller for organic fertilizer deep applicator in orchard. Trans. Chin. Soc. Agric. Eng. 2021, 37, 11–19. [Google Scholar] [CrossRef]

- Transportation Machinery Design and Selection Manual Committee. Transport Machinery Design and Selection Manual, the Next Volume; Chemical Industry Press: Shanghai, China, 1999. [Google Scholar]

- Chen, G.; Lu, C.; He, J.; Wang, C.; Wang, X.; Wang, Q. Design and experiment of straw pickup-crushed and deep buried device under strip-tillage. Trans. Chin. Soc. Agric. Mach. 2021, 52, 16–27. [Google Scholar]

- Li, T.; Huang, S.; Niu, Z.; Hou, J.; Wu, Y.; Li, Y. Optimization and experiment of planting perpendicularity of planetary wheel garlic planter. Trans. Chin. Soc. Agric. Eng. 2020, 36, 37–45. [Google Scholar]

- Li, B. Agricultural Mechanics; China Agricultural Press: Beijing, China, 2003. [Google Scholar]

- Pu, L.; Chen, G.; Wu, L. Mechanical Design, 9th ed.; Higher Education Press: Beijing, China, 2013. [Google Scholar]

- General Purpose Agricultural Machinery. Available online: https://www.nongjitong.com/product/33800.html (accessed on 1 January 2022).

- Durczak, K.; Selech, J.; Ekielski, A.; Żelaziński, T.; Waleński, M.; Witaszek, K. Using the Kaplan–Meier Estimator to Assess the Reliability of Agricultural Machinery. Agronomy 2022, 12, 1364. [Google Scholar] [CrossRef]

| Factors | |||

|---|---|---|---|

| ODRB/mm | RVSS/rpm | DSS/mm | |

| Level | 150 | 100 | 60 |

| 175 | 105 | 65 | |

| 200 | 110 | 70 | |

| 225 | 115 | 75 | |

| 250 | 120 | 80 | |

| Items | Parameters | Values |

|---|---|---|

| The straw of the field | Average length/mm | 138 |

| Length range/mm | 65–220 | |

| Average diameter/mm | 4.32 | |

| Diameter range/mm | 1–12 | |

| Covering thickness/mm | 47 | |

| SMQ/(kg/m2) | 1.66 | |

| Moisture content/% | 78.23 | |

| 0–100 mm soil layer | Firmness/kPa | 507 |

| Moisture content/% | 25.39 | |

| Bulk density/(g/cm3) | 1.41 | |

| Temperature/℃ | 16.2 |

| d = 60 mm | d = 65 mm | d = 70 mm | d = 75 mm | d = 80 mm | |

|---|---|---|---|---|---|

| S/mm2 | 25,560 | 27,940 | 30,370 | 32,830 | 35,330 |

| SA/mm2 | 118,200 | 115,900 | 113,400 | 111,000 | 108,500 |

| η/% | 21.62 | 24.11 | 26.78 | 29.58 | 32.56 |

| d = 60 mm | d = 65 mm | d = 70 mm | d = 75 mm | d = 80 mm | |

|---|---|---|---|---|---|

| τT/MPa | 30.15 | 23.71 | 18.98 | 15.43 | 12.72 |

| Parameters | Values |

|---|---|

| Dimensions (length × width × height)/mm | 2000 × 440 × 425 |

| h−1 | 3~5 |

| ODRB D/mm | 250 |

| Pitch S/mm | 250 |

| RVSS n/rpm | 110 |

| DSS d/mm | 76 |

| Turns of RB | 0.4 |

| Width of the straw hopper b/mm | 150 |

| Gap between RB and the straw hopper s/mm | 2 |

| Parameters | The SRR of Sowing Belt Installed with SSARD/% | The SRR of Sowing Belt Installed without SSARD/% |

|---|---|---|

| Average | 87.98 | 72.91 |

| Variation | 4.38 | 9.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Lu, C.; Li, H.; Wang, Z.; Gao, Z.; Wei, X.; He, D. Design and Experiment of Symmetrical Spiral Row-Sorting of the Straw Device Based on Kinematics Analysis. Agriculture 2022, 12, 896. https://doi.org/10.3390/agriculture12070896

Li Y, Lu C, Li H, Wang Z, Gao Z, Wei X, He D. Design and Experiment of Symmetrical Spiral Row-Sorting of the Straw Device Based on Kinematics Analysis. Agriculture. 2022; 12(7):896. https://doi.org/10.3390/agriculture12070896

Chicago/Turabian StyleLi, Yunxiang, Caiyun Lu, Hongwen Li, Zhinan Wang, Zhen Gao, Xuyang Wei, and Dong He. 2022. "Design and Experiment of Symmetrical Spiral Row-Sorting of the Straw Device Based on Kinematics Analysis" Agriculture 12, no. 7: 896. https://doi.org/10.3390/agriculture12070896

APA StyleLi, Y., Lu, C., Li, H., Wang, Z., Gao, Z., Wei, X., & He, D. (2022). Design and Experiment of Symmetrical Spiral Row-Sorting of the Straw Device Based on Kinematics Analysis. Agriculture, 12(7), 896. https://doi.org/10.3390/agriculture12070896