Simulation Parameter Calibration and Experimental Study of a Discrete Element Model of Cotton Precision Seed Metering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Determination of the Intrinsic Parameters of Cotton Seeds

2.1.1. Three-Dimensional Geometric Model and Distribution Law

2.1.2. Density and Moisture Content

2.1.3. Poisson’s Ratio, Elastic Modulus, and Shear Modulus

2.1.4. Establishment of Discrete Element Model of Cotton Seed Based on 3D Scanning

2.2. Exposure Parameter Determination

2.2.1. Contact Model Selection

2.2.2. Collision Recovery Coefficient Determination

2.2.3. Static Friction Factor Determination

2.2.4. Determination of Rolling Friction Factor

3. Results and Discussion

3.1. Stacking Angle and Angle-of-Repose Test

3.2. Determining Significant Influence Parameters

3.3. Steepest Climb Test

3.4. Response Surface Optimization Test and Regression Model Establishment

3.5. Test Results and Discussion

3.5.1. Mathematical Model Establishment and Significance Test

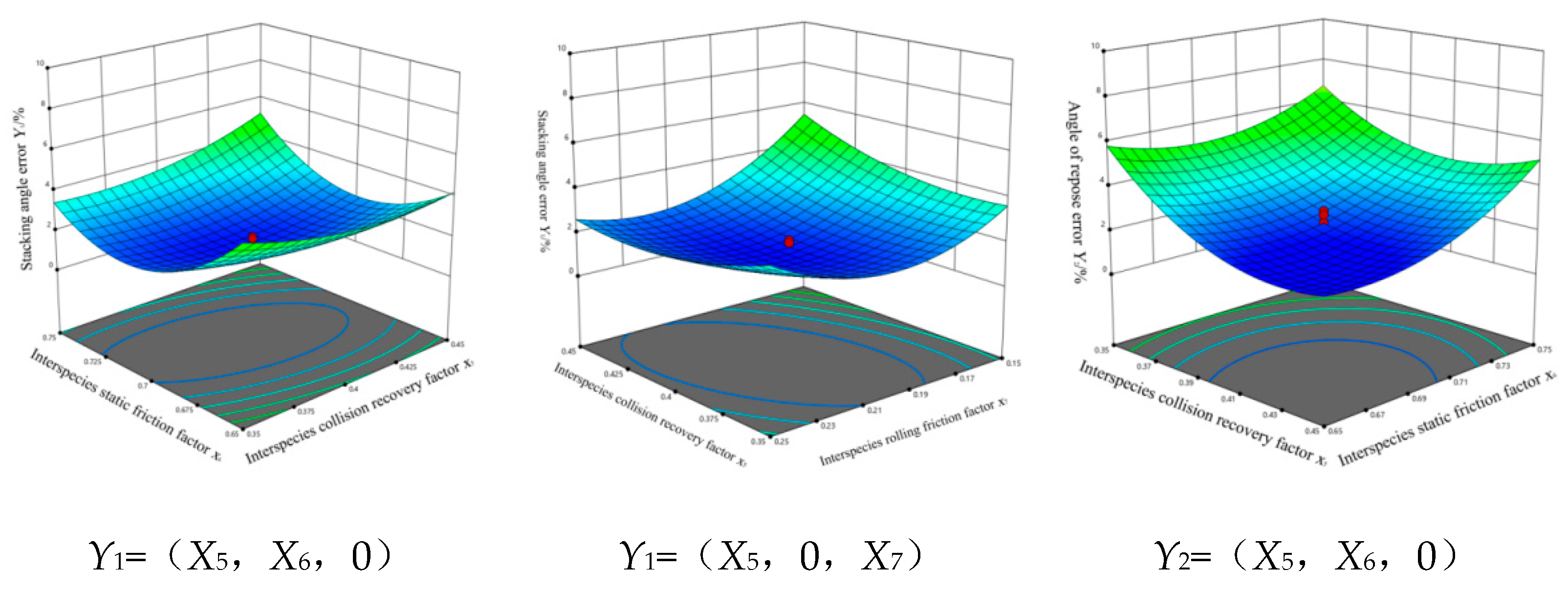

3.5.2. Influence of Various Factors on Test Index and Parameter Optimization

3.6. Verification Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, S.L. Research on the Mechanism and Computer Simulation of the Mechanism of the Mechanical Clamp Type Cotton Precision Metering Device; Shihezi University: Shihezi, China, 2009; (In Chinese with English Abstract). [Google Scholar]

- Mao, S.C.; Li, Y.B.; Dong, H.Z.; Bie, S.; Lin, Y.Z.; Dong, H. Chinese Cotton Cultivation; Shanghai Scientific & Technical Publishers: Shanghai, China, 2013; (In Chinese with English Abstract). [Google Scholar]

- National Bureau of Statistics of People’s Republic of China. China Statistical Yearbook; China Statistics Press: Beijing, China, 2019; (In Chinese with English Abstract).

- Liu, L.H.; Yang, R.B.; Shang, S.Q.; Lian, Z.G.; Cui, G.P.; Yang, H.G.; Xu, P.X. Design and Experiment of 2MBJ-2 Subsoiling Tillage Fertilizer Coated Cotton Planter. J. Agric. Mech. Res. 2017, 4, 134–138, (In Chinese with English Abstract). [Google Scholar]

- Liu, L.H. Design and Experiment Research of High Density Compound Cotton Planter; Qingdao Agricultural University: Qingdao, China, 2017; (In Chinese with English Abstract). [Google Scholar]

- Kang, S.W.; Ni, X.D.; Qi, Q.Z.; Han, S.M. Design and experiment of a suction drum type cotton precision seed metering device. J. Agric. Mech. Res. 2020, 6, 136–141, (In Chinese with English Abstract). [Google Scholar]

- Liu, H.X.; Wang, F.L.; Yang, G.L. Study on a new type vertical composite disc soybean precision seed metering device. Trans. Chin. Soc. Agric. Eng. 2007, 10, 112–116, (In Chinese with English Abstract). [Google Scholar]

- Liu, H.X.; Guo, L.F.; Fu, L.L.; Tang, S.F. Study on multi size seed metering device for vertical plate soybean precision planter. Int. J. Agric. Biol. Eng. 2015, 8, 1–8. [Google Scholar]

- Ess, D.R.; Hawkins, S.E.; Young, J.C.; Christmas, E.P. Evaluation of the performance of abelt metering system for soybeans planted with a grain drill. Appl. Eng. Agric. 2005, 6, 965–969. [Google Scholar] [CrossRef]

- Hu, M.J.; Xia, J.F.; Zheng, K.; Du, J.; Liu, Z.Y.; Zhou, M.K. Design and Experiment of Inside-filling Pneumatic High Speed Precision Seed-metering Device for Cotton. Trans. Chin. Soc. Agric. Mach. 2021, 8, 73–85, (In Chinese with English Abstract). [Google Scholar]

- Ni, X.D.; Xu, G.J.; Wang, Q.; Peng, X.R.; Wang, J.; Hu, B. Design and Experiment of Pneumatic Cylinder Array Precision Seed-metering Device for Cotton. Trans. Chin. Soc. Agric. Mach. 2017, 12, 58–67, (In Chinese with English Abstract). [Google Scholar]

- Zhou, Y.; Hu, M.J.; Xia, J.F.; Zhang, G.Z.; Xu, Z.Y.; Feng, C.C.; Tang, N.R.; Liu, D.Z. Design and experiment of inside-filling adjustable precision seed-metering device with combined hole for cotton. Trans. Chin. Soc. Agric. Eng. 2018, 18, 59–67, (In Chinese with English Abstract). [Google Scholar]

- Zhang, X.J.; Chen, Y.; Shi, Z.L.; Jin, W.; Zhang, H.T.; Fu, H.; Wang, D.J. Design and experiment of double-storage turntable cotton vertical disc hole seeding and metering device. Trans. Chin. Soc. Agric. Eng. 2021, 19, 27–36, (In Chinese with English Abstract). [Google Scholar]

- Li, J.J.; Zhang, H.P.; Bi, X.S.; Wang, J.; Hu, B.; Li, S.Z. Simulation analysis and test on the filling performance of rotary type-hole precision seed-metering device for cotton. Trans. Chin. Soc. Agric. Eng. 2020, 5, 38–49, (In Chinese with English Abstract). [Google Scholar]

- Ma, W.P.; You, Y.; Wang, D.C.; Ni, S.J.; Xun, X.L. Parameter Calibration of Alfalfa Seed Discrete Element Model Based on RSM and NSGA-Ⅱ. Trans. Chin. Soc. Agric. Mach. 2020, 8, 136–144, (In Chinese with English Abstract). [Google Scholar]

- Shi, L.R.; Sun, W.; Zhao, W.Y.; Yang, X.P.; Feng, B. Parameter determination and validation of discrete element model of seed potato mechanical seeding. Trans. Chin. Soc. Agric. Eng. 2018, 6, 35–42, (In Chinese with English Abstract). [Google Scholar]

- Rackl, M.; Hanley, K.J. A methodical calibration procedure for discrete element models. Powder Technol. 2017, 307, 73–83, (In Chinese with English Abstract). [Google Scholar] [CrossRef] [Green Version]

- Coetzee, C.J. Review Calibration of the discrete element method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Liu, R.; Li, Y.J.; Liu, Z.J.; Liu, L.J.; Lv, H.T. Analysis and Calibration of Discrete Element Parameters of Coated Maize Seed. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–8, (In Chinese with English Abstract). [Google Scholar]

- Liu, W.Z.; He, J.; Li, H.W.; Li, X.Q.; Zheng, K.; Wei, Z.C. Calibration of Simulation Parameters for Potato Minituber Based on EDEM. Trans. Chin. Soc. Agric. Mach. 2018, 5, 125–135, 142, (In Chinese with English Abstract). [Google Scholar]

- Wang, Y.X.; Liang, Z.J.; Zhang, D.X.; Cui, T.; Shi, S.; Li, K.H.; Yang, L. Calibration method of contact characteristic parameters for corn seeds based on EDEM. Trans. Chin. Soc. Agric. Eng. 2016, 22, 36–42, (In Chinese with English Abstract). [Google Scholar]

- Liu, F.Y.; Zhang, J.; Li, B.; Chen, J. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap. Trans. Chin. Soc. Agric. Eng. 2016, 12, 247–253, (In Chinese with English Abstract). [Google Scholar]

- Lu, F.; Ma, X.; Tan, S.Y.; Chen, L.T.; Zeng, L.C.; An, B. Simulative Calibration and Experiment on Main Contact Parameters of Discrete Elements for Rice Bud Seeds. Trans. Chin. Soc. Agric. Mach. 2018, 2, 93–99, (In Chinese with English Abstract). [Google Scholar]

- Hao, J.J.; Wei, W.B.; Huang, P.C.; Qin, J.H.; Zhao, J.G. Calibration and experimental verification of discrete element parameters of oil sunflower seeds. Trans. Chin. Soc. Agric. Eng. 2021, 12, 36–44, (In Chinese with English Abstract). [Google Scholar]

- Yu, Q.X.; Liu, Y.; Chen, X.B.; Sun, K.; Lai, Q.H. Calibration and Experiment of Simulation Parameters for Panax notoginseng seeds based on DEM. Trans. Chin. Soc. Agric. Eng. 2020, 2, 123–132, (In Chinese with English Abstract). [Google Scholar]

- Hou, Z.F.; Dai, N.Z.; Chen, Z.; Chou, Y.; Zhang, X.W. Measurement and calibration of physical property parameters for Agropyron seeds in a discrete element simulation. Trans. Chin. Soc. Agric. Eng. 2020, 24, 46–54, (In Chinese with English Abstract). [Google Scholar]

- Ma, Y.H. Agricultural Materials Science; Chemical Industry Press: Beijing, China, 2015; (In Chinese with English Abstract). [Google Scholar]

- Khodabakhshian, R. Poisson’s ratio of pumpkin seeds and their kernels as a function of variety, size, moisture content and loading rate. Agric. Eng. Int. CIGR J. 2012, 3, 203–209. [Google Scholar]

- Wang, L.; He, X.W.; Hu, C.; Guo, W.S.; Wang, X.F.; Xing, J.F.; Hou, S.L. Measurement of the physical parameters and calibration of discrete element simulation parameter of coated cotton seed. J. China Agric. Univ. 2022, 6, 71–82, (In Chinese with English Abstract). [Google Scholar]

- Zhang, R.; Han, D.L.; Ji, Q.L.; He, Y.; Li, J.Q. Calibration methods of sandy soil parameters in simulation of discrete element method. Trans. Chin. Soc. Agric. Mach. 2017, 3, 49–56, (In Chinese with English Abstract). [Google Scholar]

- Li, S.N.; Lin, X.; Chen, Y.; Ma, L.Z. 3D converse modeling for sphere point cloud. J. Graph. 2013, 34, 49–52, (In Chinese with English Abstract). [Google Scholar]

- Liu, C.L.; Wang, Y.L.; Song, J.N.; Li, Y.N.; Ma, T. Experiment and discrete element model of rice seed based on 3D laser scanning. Trans. Chin. Soc. Agric. Eng. 2016, 15, 294–300, (In Chinese with English Abstract). [Google Scholar]

- Li, Y.X.; Li, F.X.; Xu, X.M.; Sheng, C.P.; Meng, K.P.; Chen, J.; Chang, D.Q. Parameter calibration of wheat flour for discrete element method simulation based on particle scaling. Trans. Chin. Soc. Agric. Eng. 2019, 16, 320–327, (In Chinese with English Abstract). [Google Scholar]

- Huo, X.C. The Experimental Research on Discrete Element Analysis Parameters of the Agaricus Bisporus Seeds and the Seed-metering Device Optimization; Chinese Academy of Agricultural Sciences: Beijing, China, 2019; (In Chinese with English Abstract). [Google Scholar]

- Lu, Y.G.; Wu, N.; Wang, B.; Yu, Z.Y.; Lin, D.C.; Hu, Z.C. Measurement and analysis of peanuts’ restitution coefficient in point-to-plate collision model. J. China Agric. Univ. 2016, 8, 111–118, (In Chinese with English Abstract). [Google Scholar]

- Ge, T.; Jia, Z.H.; Zhou, K.D. A theoretical model for the coefficient of restitution calculation of point impact. Mech. Des. Res. 2007, 23, 14–16, (In Chinese with English Abstract). [Google Scholar]

- Yu, C.C.; Duan, H.B.; Cai, X.K.; Xu, T.; Yao, F.H.; Chen, Z.H.; Yan, F.Y. Discrete element simulation parameters-based measurement of materials for potato minituber. J. Huazhong Agric. Univ. 2021, 1, 210–217, (In Chinese with English Abstract). [Google Scholar]

- Zhang, S.W.; Zhang, R.Y.; Chen, T.Y.; Fu, Q.; Yuan, H.F. Calibration of Simulation Parameters of Mung-been Seeds Using Discrete Element Method and Verification of Seed-metering Test. Trans. Chin. Soc. Agric. Mach. 2022, 3, 71–79, (In Chinese with English Abstract). [Google Scholar]

- Hamzah, M.; Beakawi, A.H.; Omar, S. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397–417. [Google Scholar]

- Tsa, B.; Rf, B.; Er, B. Classification of granular materials via flowability-based clustering with application to bulk feeding. Powder Technol. 2021, 378, 288–302. [Google Scholar]

- Müller, D.; Fimbinger, E.; Brand, C. Algorithm for the determination of the angle of repose in bulk material analysis. Powder Technol. 2021, 383, 598–605. [Google Scholar] [CrossRef]

- Ge, Y.Y. Experiment Design Method and Application of Design-Expert Software; Harbin Institute of Technology Press: Harbin, China, 2015; (In Chinese with English Abstract). [Google Scholar]

- Fu, J.; Yuan, H.K.; Zhang, D.P.; Chen, Z.; Ren, L.Q. Multi-objective optimization of process parameters of longitudinal axial threshing cylinder for frozen corn using RSM and NSGA-II. Appl. Sci. 2020, 5, 1646. [Google Scholar] [CrossRef] [Green Version]

| 3D Size | Maximum/mm | Minimum/mm | Average/mm | Standard Deviation | Equivalent Diameter/mm | Sphericity/% |

|---|---|---|---|---|---|---|

| Length | 9.67 | 7.79 | 8.52 | 0.43 | 5.56 | 65.26 |

| Width | 5.38 | 3.54 | 4.50 | 0.32 | ||

| Thickness | 5.43 | 3.57 | 4.48 | 0.41 |

| Material | Nature | Value |

|---|---|---|

| Cotton seeds | Poisson’s ratio | 0.22 |

| Shear modulus/Pa | 0.94 × 106 | |

| Density/(kg/m3) | 652.19 | |

| Stainless steel | Poisson’s ratio | 0.3 |

| Shear modulus/Pa | 7 × 1010 | |

| Density/(kg/m3) | 7800 | |

| Nylon | Poisson’s ratio | 0.4 |

| Shear modulus/Pa | 1 × 108 | |

| Density/(kg/m3) | 1500 |

| Test Parameters | Low Level | High Level |

|---|---|---|

| Cotton seed-steel plate collision recovery coefficient X1 | 0.2 | 0.4 |

| Cotton seed-steel plate static friction coefficient X2 | 0.3 | 0.5 |

| Cotton seed-steel plate rolling friction coefficient X3 | 0.1 | 0.3 |

| Cotton Seed Poisson’s Ratio X4 | 0.1 | 0.3 |

| Cotton Seed—Cotton Seed Recovery Factor X5 | 0.3 | 0.5 |

| Cotton Seed—Cotton Seed Static Friction Coefficient X6 | 0.4 | 0.6 |

| Cotton Seed—Cotton Seed Rolling Friction Coefficient X7 | 0.1 | 0.3 |

| Cotton Seed-Nylon Plastic Collision Recovery Coefficient X8 | 0.5 | 0.7 |

| Cotton Seed-Nylon Plastic Coefficient of Static Friction X9 | 0.6 | 0.8 |

| Cotton Seed-Nylon Plastic Coefficient of Rolling Friction X10 | 0.1 | 0.3 |

| X11, X12, X13, X14 | Dummy parameter | |

| No. | Test Parameters | Stacking Angle/° | Angle of Repose/° | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1/X8 | X2/X9 | X3/X10 | X4 | X5 | X6 | X7 | X11 | X12 | X13 | X14 | |||

| 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | 34.78/36.48 | 38.24/40.20 |

| 2 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | 38.96/40.10 | 43.78/45.90 |

| 3 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | 43.64/45.78 | 47.70/50.10 |

| 4 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 39.13/41.12 | 43.19/45.39 |

| 5 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 40.78/42.82 | 45.56/47.90 |

| 6 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | 39.10/40.09 | 41.91/44.08 |

| 7 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | 35.46/36.89 | 38.63/40.06 |

| 8 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 36.88/39.01 | 41.20/44.30 |

| 9 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | 39.50/41.37 | 42.80/44.84 |

| 10 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 39.55/40.53 | 42.51/44.70 |

| 11 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 35.58/38.36 | 40.50/42.59 |

| 12 | 1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 35.11/37.02 | 38.76/40.10 |

| Parameter | Angle of Repose Error | Stacking Angle Error | ||||||

|---|---|---|---|---|---|---|---|---|

| Normalization Effect | Sum of Square | Contribution Rate | Significance Ranking | Normalization Effect | Sum of Square | Contribution Rate | Significance Ranking | |

| X1/X8 | −0.735/ −0.308333 | 1.62067/ 0.285208 | 2.04183/ 0.359257 | 4/ 5 | −0.22333/ −0.0333333 | 0.149633/ 0.00333333 | 0.167211/ 0.00314385 | 6/ 7 |

| X2/X9 | −0.245/ 0.0916667 | 0.180075/ 0.0252083 | 0.22687/ 0.0317532 | 7/ 6 | 0.16/ 0.303333 | 0.0768/ 0.276033 | 0.0858219/ 0.260342 | 7/ 6 |

| X3/X10 | −0.358333/ −0.081667 | 0.385208/ 0.0200083 | 0.485311/ 0.0252031 | 6/ 7 | −0.626667/ −0.85 | 1.17813/ 2.1675 | 1.31653/ 2.04429 | 5/ 4 |

| X4 | −0.711667/ −1.035 | 1.51941/ 3.21367 | 1.91425/ 4.04805 | 5/ 4 | −0.753333/ −0.74 | 1.70253/ 1.6428 | 1.90253/ 1.54942 | 4/ 5 |

| X5 | 2.785/ 3.255 | 23.2687/ 31.7851 | 29.3154/ 40.0375 | 2/ 1 | 3.71333/ 3.88 | 41.3665/ 45.1632 | 46.2259/ 42.5959 | 1/ 1 |

| X6 | 2.855/ 2.705 | 24.4531/ 21.9511 | 30.8076/ 27.6503 | 1/ 2 | 2.30667/ 2.77667 | 15.9621/ 23.1296 | 17.837/ 21.8149 | 3/ 2 |

| X7 | 2.635/ 2.185 | 20.8297/ 14.3227 | 26.2426/ 18.0413 | 3/ 3 | 2.61/ 2.56667 | 20.4363/ 19.7633 | 22.837/ 18.6399 | 2/ 3 |

| No. | X5 | X6 | X7 | Y1 | Y2 |

|---|---|---|---|---|---|

| 1 | 0.30 | 0.60 | 0.10 | 26.49 | 24.03 |

| 2 | 0.35 | 0.65 | 0.15 | 10.70 | 8.84 |

| 3 | 0.40 | 0.70 | 0.20 | 4.22 | 2.62 |

| 4 | 0.45 | 0.75 | 0.25 | 13.33 | 9.81 |

| 5 | 0.50 | 0.80 | 0.30 | 24.92 | 28.85 |

| Level | Interspecies Collision Coefficient of Restitution X5 | Interspecies Static Friction Factor X6 | Interspecies Rolling Friction Factor X7 |

|---|---|---|---|

| −1.682 | 0.32 | 0.62 | 0.12 |

| −1 | 0.35 | 0.65 | 0.15 |

| 0 | 0.40 | 0.70 | 0.20 |

| 1 | 0.45 | 0.75 | 0.25 |

| 1.682 | 0.48 | 0.78 | 0.28 |

| No. | Interspecies Collision Coefficient of Restitution X5 | Interspecies Static Friction Factor X6 | Interspecies Rolling Friction Factor X7 | Stacking Angle Error Y1/% | Angle of Repose Error Y2/% |

|---|---|---|---|---|---|

| 1 | 0.000 | −1.682 | 0.000 | 8.03 | 4.05 |

| 2 | −1.000 | −1.000 | −1.000 | 7.39 | 7.41 |

| 3 | 0.000 | 0.000 | 0.000 | 1.86 | 2.17 |

| 4 | 0.000 | 0.000 | −1.682 | 7.08 | 7.58 |

| 5 | 0.000 | 0.000 | 0.000 | 1.41 | 2.72 |

| 6 | 1.000 | 1.000 | −1.000 | 8.42 | 7.23 |

| 7 | 0.000 | 1.682 | 0.000 | 7.71 | 6.95 |

| 8 | −1.000 | 1.000 | 1.000 | 5.32 | 8.27 |

| 9 | 1.000 | −1.000 | 1.000 | 4.7 | 2.7 |

| 10 | 1.000 | −1.000 | −1.000 | 7.57 | 4.06 |

| 11 | −1.682 | 0.000 | 0.000 | 3.23 | 8.95 |

| 12 | 0.000 | 0.000 | 0.000 | 1.36 | 2.02 |

| 13 | 0.000 | 0.000 | 0.000 | 1.76 | 1.91 |

| 14 | 0.000 | 0.000 | 0.000 | 1.53 | 2.35 |

| 15 | −1.000 | 1.000 | −1.000 | 4.58 | 7.93 |

| 16 | 0.000 | 0.000 | 1.682 | 4.85 | 4.63 |

| 17 | 1.000 | 1.000 | 1.000 | 5.43 | 6.31 |

| 18 | 0.000 | 0.000 | 0.000 | 1.52 | 2.9 |

| 19 | −1.000 | −1.000 | 1.000 | 6.5 | 6.57 |

| 20 | 1.682 | 0.000 | 0.000 | 3.42 | 4.04 |

| Source | Stacking Angle Error | Angle of Repose Error | ||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Square | Degree of Freedom | F | p | Sum of Square | Degree of Freedom | F | p | |

| Model | 120.34 | 9 | 122.98 | <0.0001 | 109.30 | 9 | 55.78 | <0.0001 |

| x5 | 0.5536 | 1 | 5.09 | 0.0477 | 24.09 | 1 | 110.65 | <0.0001 |

| x6 | 0.5940 | 1 | 5.46 | 0.0415 | 14.10 | 1 | 64.77 | <0.0001 |

| x7 | 6.83 | 1 | 62.85 | <0.0001 | 4.39 | 1 | 20.16 | 0.0012 |

| x5x6 | 3.74 | 1 | 34.40 | 0.0002 | 2.60 | 1 | 11.94 | 0.0062 |

| x5x7 | 4.22 | 1 | 38.81 | <0.0001 | 0.3960 | 1 | 1.82 | 0.2072 |

| x6x7 | 0.2485 | 1 | 2.29 | 0.1615 | 0.3280 | 1 | 1.51 | 0.2477 |

| x52 | 6.53 | 1 | 60.04 | <0.0001 | 31.50 | 1 | 144.69 | <0.0001 |

| x62 | 74.91 | 1 | 688.99 | <0.0001 | 18.29 | 1 | 84.02 | <0.0001 |

| x72 | 37.19 | 1 | 342.05 | <0.0001 | 25.90 | 1 | 118.96 | <0.0001 |

| Residual | 1.09 | 10 | 2.18 | 10 | ||||

| Lack of fit | 0.8934 | 5 | 4.61 | 0.0595 | 1.40 | 5 | 1.81 | 0.2649 |

| Pure error | 0.1939 | 5 | 0.7742 | 5 | ||||

| Total | 121.43 | 19 | 114.48 | 19 | ||||

| Test No. | Stacking Angle/° | Angle of Repose/° |

|---|---|---|

| 1 | 30.01 | 35.02 |

| 2 | 29.56 | 35.55 |

| 3 | 29.89 | 35.26 |

| Average | 29.82 | 35.28 |

| Relative error | 2.50 | 1.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, S.; Yuan, Y.; Niu, K.; Zhou, L.; Zhao, B.; Wei, L.; Liu, L.; Xiong, S.; Shi, Z.; Ma, Y.; et al. Simulation Parameter Calibration and Experimental Study of a Discrete Element Model of Cotton Precision Seed Metering. Agriculture 2022, 12, 870. https://doi.org/10.3390/agriculture12060870

Bai S, Yuan Y, Niu K, Zhou L, Zhao B, Wei L, Liu L, Xiong S, Shi Z, Ma Y, et al. Simulation Parameter Calibration and Experimental Study of a Discrete Element Model of Cotton Precision Seed Metering. Agriculture. 2022; 12(6):870. https://doi.org/10.3390/agriculture12060870

Chicago/Turabian StyleBai, Shenghe, Yanwei Yuan, Kang Niu, Liming Zhou, Bo Zhao, Liguo Wei, Lijing Liu, Shi Xiong, Zenglu Shi, Yihua Ma, and et al. 2022. "Simulation Parameter Calibration and Experimental Study of a Discrete Element Model of Cotton Precision Seed Metering" Agriculture 12, no. 6: 870. https://doi.org/10.3390/agriculture12060870

APA StyleBai, S., Yuan, Y., Niu, K., Zhou, L., Zhao, B., Wei, L., Liu, L., Xiong, S., Shi, Z., Ma, Y., Zheng, Y., & Xing, G. (2022). Simulation Parameter Calibration and Experimental Study of a Discrete Element Model of Cotton Precision Seed Metering. Agriculture, 12(6), 870. https://doi.org/10.3390/agriculture12060870