A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations

Abstract

1. Introduction

- Part I. General Aspects of Hydroponics.

2. History and Contributions from Plant Physiology

3. Hydroponic Cultivation Techniques

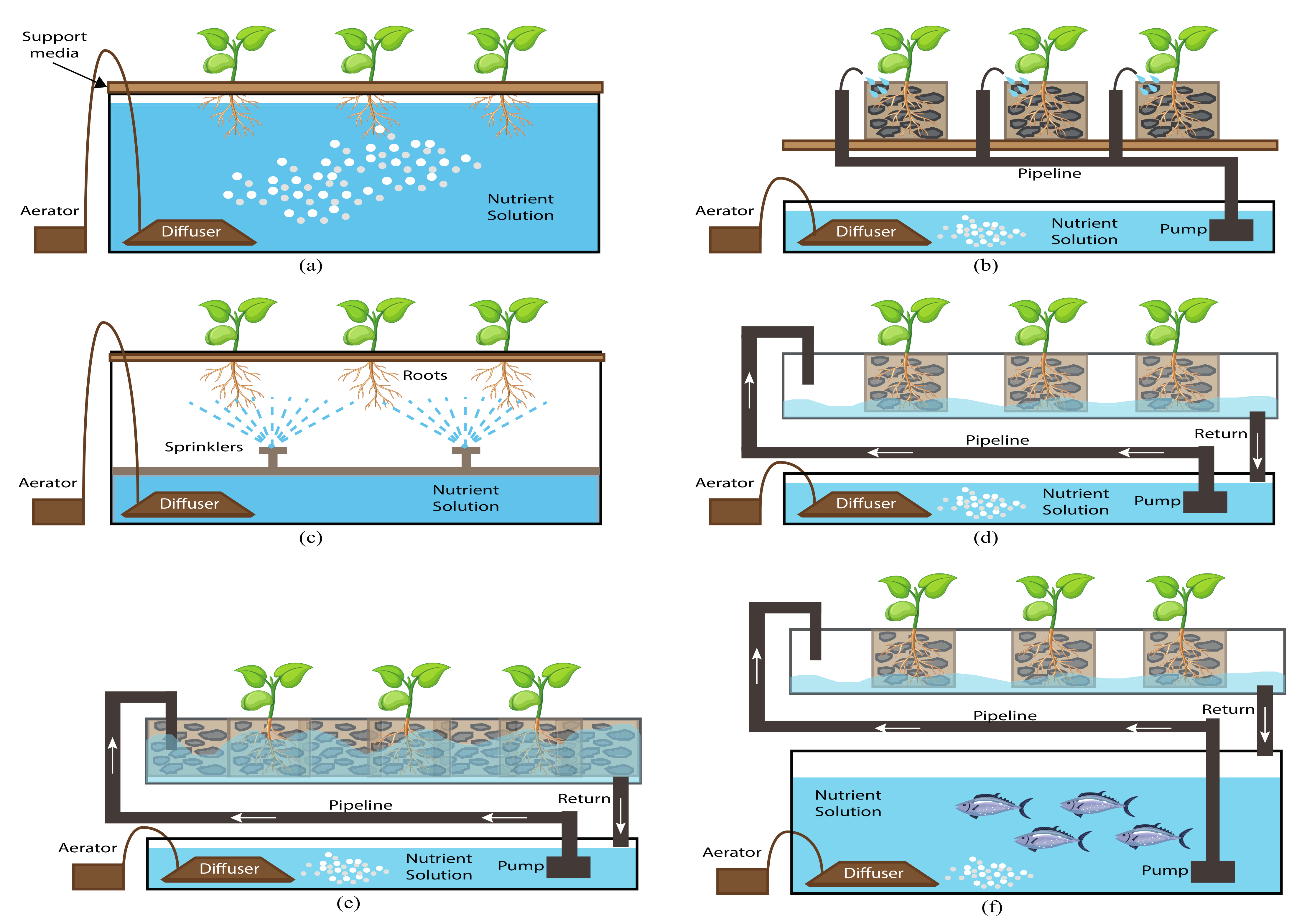

3.1. Floating Root System or Deep Water Culture (DWC)

3.2. Drip Irrigation

3.3. Aeroponics

3.4. Nutrient Film Technique

3.5. Ebb and Flow

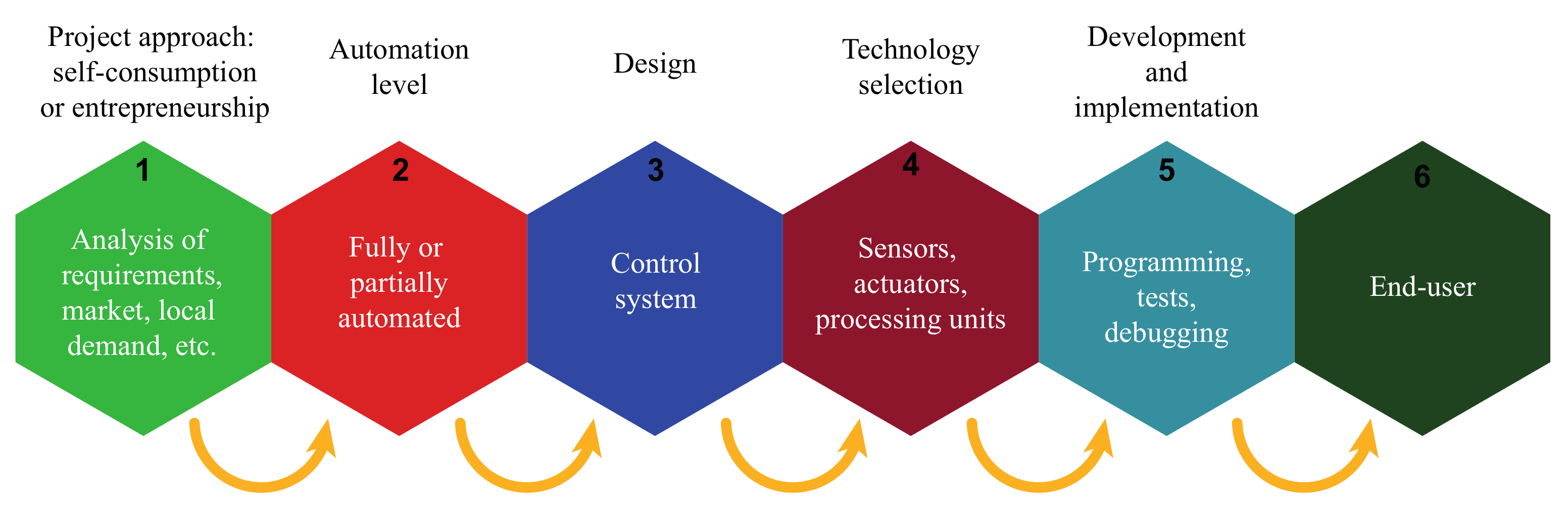

3.6. Aquaponics

4. Advantages and Disadvantages

4.1. Advantages

- Ubiquity and space efficiency. Hydroponics makes it possible to grow food everywhere a controlled environment can be implemented. Indeed, even deep space exploration considers hydroponics as the main source of food for spaceship crews. Furthermore, depending on the type of plant, it is possible to devise vertical arrangements for increased produce output.

- Quantity and quality assurance. In traditional agriculture, crop rotation is necessary to preserve soil fertility; however, hydroponic crops can be repeated as many times as required, increasing the yield per cycle per crop. Also, since nourishment is administered accordingly with the physiological requirements of the plant, produce quality is assured. However, one must bear in mind that in highly automated greenhouses small changes in the operation conditions cause quick crop responses.

- Sustainability. Since the produce is not in contact with the soil and the nourishing solution is recycled, factors like water evaporation, seepage, or pollution are minimized and rinsing water is not needed. Additionally, by having a controlled environment, the optimal growth conditions and protection against plant plagues and diseases is assured, eliminating the need for chemicals and pesticides and saving on important natural resources like soil and water.

- Economics. In some routinary steps, operations in hydroponics are simpler than those required in traditional agriculture. In this sense, conventional practices require many effort-laden preparations before sowing, including the cost of heavy machinery and specialized equipment, which eventually may come through a rental of the same. In other aspects, hydroponics may require more dedication, commonly needing a set of sensors and devices for a precise follow-up of the crop condition.

4.2. Disadvantages

- High initial cost. The initial investment in a hydroponic system is relatively high due to the cost of required raw materials and equipment for the operation.

- Highly trained labor. Large-scale hydroponic operations require personnel with deep knowledge of agriculture, plant physiology, chemistry, and sophisticated control and information systems.

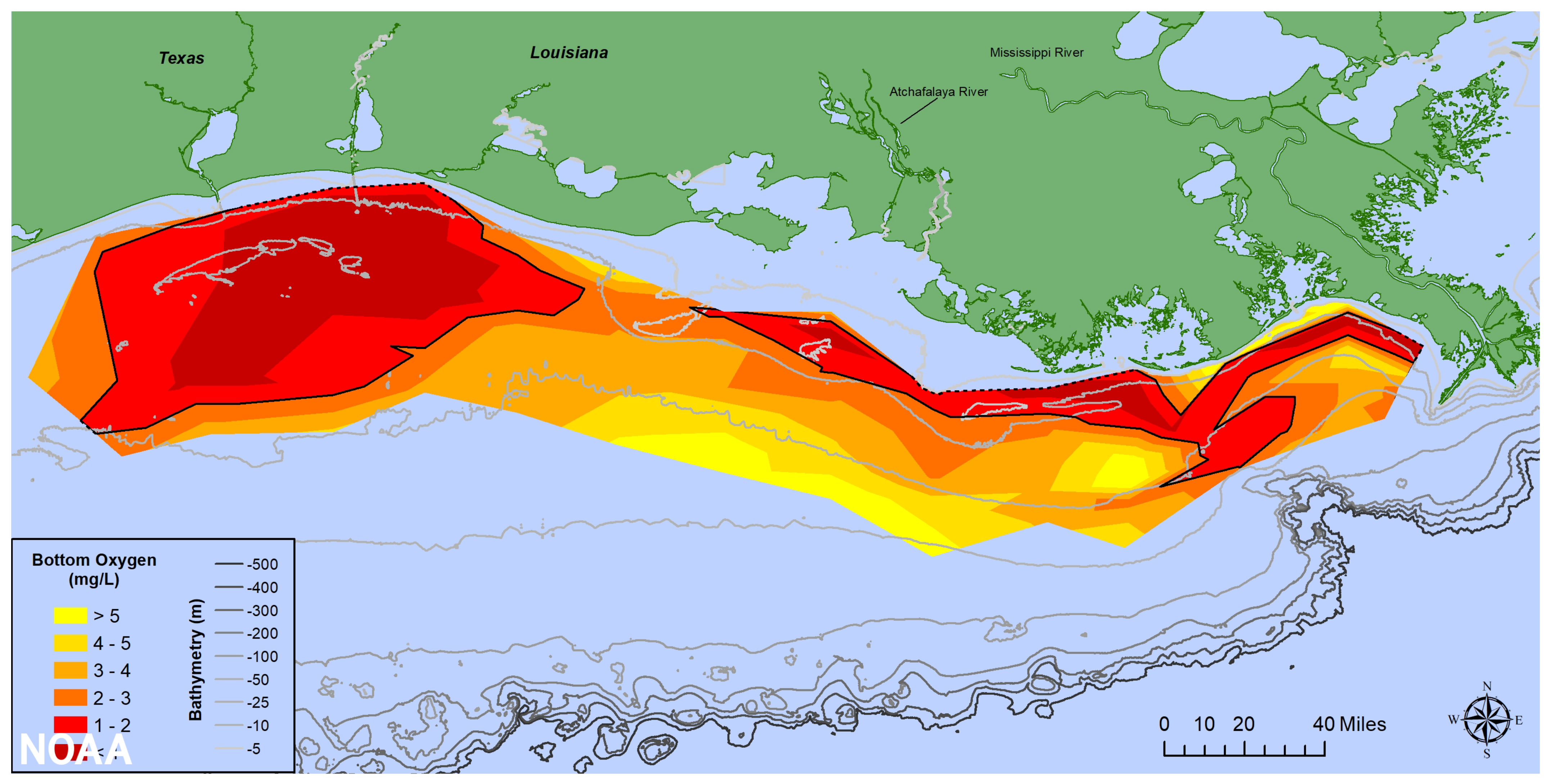

- Environmental pollution. If the residual nutrient solution is not properly disposed of, the discharged solution, enriched with phosphorus and nitrates, can generate excessive growth of algae and other microorganisms in bodies of water and effluents, creating serious environmental problems.

5. Substrates

- Porosity. This property influences nutrient availability for the plant to perform metabolic processes like breathing, transpiration, and photosynthesis.

- Capillarity. Through capillarity, the substrate absorbs nutrients and distributes them to the plant’s root.

- Oxygenation. The structure of the substrate must allow the intake of oxygen by the roots while these are in contact with the nutrient solution.

- Chemically inert. The substrate must consist of materials unable to react with the chemicals in the nutrient solution to avoid any alteration in its composition.

- Biologically inert. Because the nutrient solution circulates among a high root density of several plants, diseases can spread rapidly from one to another if corrective actions are not applied immediately. Therefore, the substrate must not favor any biological activity since micro-organisms may have a detrimental effect on crops, like diseases, malnutrition, and other consequences.

Sustainability Criteria for Choosing Substrates

6. Ideal Crops for Hydroponics

7. Nutrient Solution

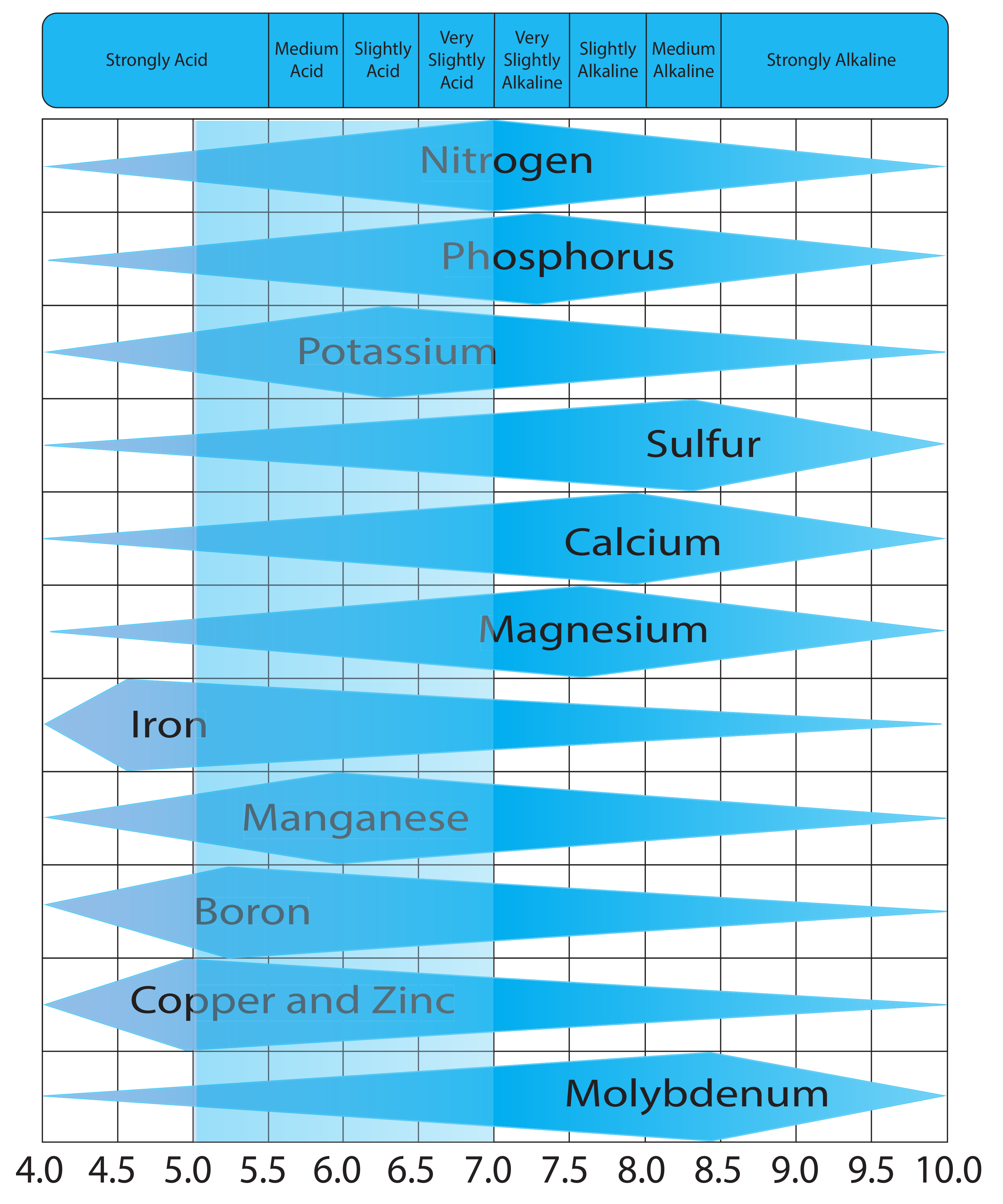

7.1. pH in Hydroponics Nutrient Solutions

7.2. Electrical Conductivity

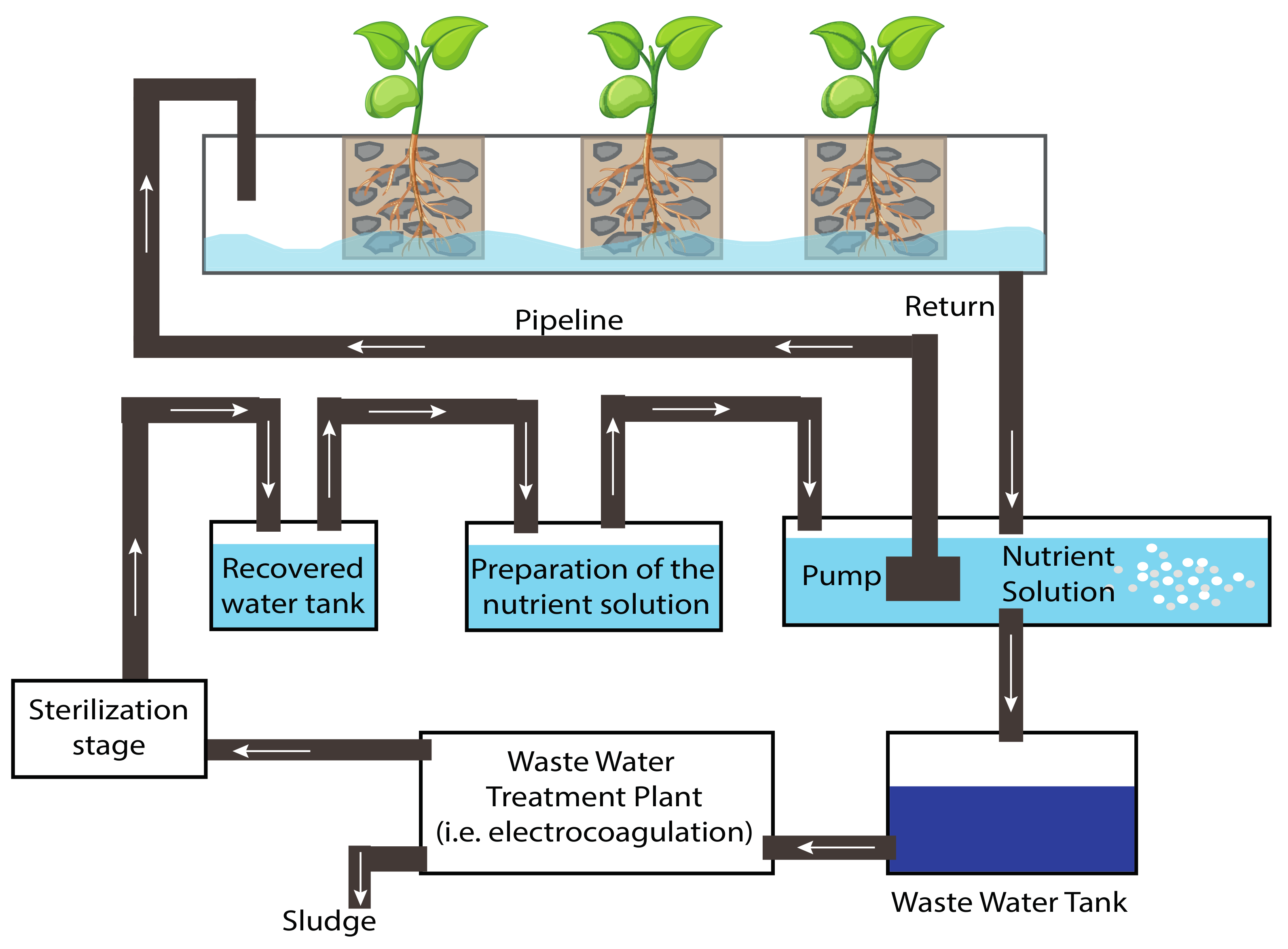

8. Sterilization of Nutrient Solutions

Impact of Residual Nutrient Solutions on the Environment

- Part II. Hydroponics and Technology.

9. Agriculture 4.0

10. Suitable Technology for Small and Medium-Scale Food Production Using Hydroponic

- Sensing. The capacity of a system for event detection, data acquisition, and accurate measurement of changes in the physical parameters of the environment.

- Smart. The capacity of a system to incorporate control and actuation functions that, after the interpretation of input data, supports the decision-making process, following predictive or adaptive logics. Furthermore, the term smart adduces to the ability of several interconnected systems to operate simultaneously.

- Sustainable. This concept applies to the development of technology with a combined social, economic, and environmental perspective.

11. Small and Medium-Scale Hydroponic Production Systems: How to Select the Appropriate Level of Technology?

12. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations for Food and Agriculture Organization (FAO). How to Feed the World in 2050. 2018. Available online: https://www.fao.org/fileadmin/templates/wsfs/docs/expert_paper/How_to_Feed_the_World_in_2050.pdf (accessed on 20 December 2021).

- United Nations. Goal 11: Make Cities Inclusive, Safe, Resilient and Sustainable. 2018. Available online: https://www.un.org/sustainabledevelopment/cities/ (accessed on 20 May 2021).

- World Bank. Urban Population (% of Total Population). 2018. Available online: https://data.worldbank.org/indicator/SP.URB.TOTL.IN.ZS (accessed on 10 September 2021).

- United Nations. World Urbanization Prospects: The 2018 Revision. 2018. Available online: https://population.un.org/wup/Publications/Files/WUP2018-Report.pdf (accessed on 15 January 2022).

- Zárate, M.A. Manual de Hidroponia. 2014. Available online: https://www.gob.mx/cms/uploads/attachment/file/232367/Manual_de_hidroponia.pdf (accessed on 5 April 2020).

- De Clercq, M.; Vats, A.; Biel, A. Agriculture 4.0: The Future of Farming Technology. 2018. Available online: https://www.oliverwyman.com/content/dam/oliver-wyman/v2/publications/2021/apr/agriculture-4-0-the-future-of-farming-technology.pdf (accessed on 20 January 2022).

- Lin, B.B.; Philpott, S.M.; Jha, S. The future of urban agriculture and biodiversity-ecosystem services: Challenges and next steps. Basic Appl. Ecol. 2015, 16, 189–201. [Google Scholar] [CrossRef]

- Armanda, D.T.; Guinée, J.B.; Tukker, A. The second green revolution: Innovative urban agriculture’s contribution to food security and sustainability–A review. Glob. Food Secur. 2019, 22, 13–24. [Google Scholar] [CrossRef]

- GVR. Hydroponics Market Size (2021–2028). 2021. Available online: https://www.grandviewresearch.com/industry-analysis/hydroponics-market/methodology (accessed on 10 October 2021).

- Van Delden, S.H.; SharathKumar, M.; Butturini, M.; Graamans, L.J.A.; Heuvelink, E.; Kacira, M.; Kaiser, E.; Klamer, R.S.; Klerkx, L.; Kootstra, G.; et al. Current status and future challenges in implementing and upscaling vertical farming systems. Nat. Food 2021, 2, 944–956. [Google Scholar] [CrossRef]

- Kremer, M. Population Growth and Technological Change: One Million B.C. to 1990. Q. J. Econ. 1993, 108, 681–716. [Google Scholar] [CrossRef]

- Dimitri, C.; Effland, A. From farming to food systems: The evolution of US agricultural production and policy into the 21st century. Renew. Agric. Food Syst. 2020, 35, 391–406. [Google Scholar] [CrossRef]

- Savvas, D.; Gianquinto, G.; Tuzel, Y.; Gruda, N. Soilless Culture. In FAO Plant Production and Protection Paper No. 217: Good Agricultural Practices for Greenhouse Vegetable Crops; FAO: Rome, Italy, 2013; Volume 217, pp. 303–354. [Google Scholar]

- Torabi, M.; Mokhtarzadeh, A.; Mahlooji, M.; Iran, P. The Role of Hydroponics Technique as a Standard Methodology in Various Aspects of Plant Biology Researches. In Hydroponics—A Standard Methodology for Plant Biological Researches; IntechOpen: London, UK, 2012; p. 22. [Google Scholar] [CrossRef][Green Version]

- Malik, A.; Iqbal, K.; Aziem, S.; Mahato, P.; Negi, A. A Review on The Science of Growing Crops without Soil (Soilless Culture)-A Novel Alternative For Growing Crops. Int. J. Agric. Crop Sci. 2014, 7, 833–842. [Google Scholar]

- Ebel, R.; Fallahi, E.; Griffis, J.L.; Nandwani, D.; Nolan, D.; Penhallegon, R.H.; Rogers, M. Urban Horticulture, from Local Initiatives to Global Success Stories. HortTechnol. Hortte 2020, 30, 4–5. [Google Scholar] [CrossRef]

- Schwarz, M. Soilless Culture Management. In Advanced Series in Agricultural Sciences; Springer: Berlin/Heidelberg, Germany, 1995; Volume 24, p. 197. [Google Scholar] [CrossRef]

- Asao, T.; Asaduzzaman, M.; Mondal, M.F.; Tokura, M.; Adachi, F.; Ueno, M.; Kawaguchi, M.; Yano, S.; Ban, T. Impact of reduced potassium nitrate concentrations in nutrient solution on the growth, yield and fruit quality of melon in hydroponics. Sci. Hortic. 2013, 164, 221–231. [Google Scholar] [CrossRef]

- Baron, D.; Ferreira, G.; Boaro, C.; Domingos, R.; Amaro, A.; Mischan, M. The Effect of the Ionic Strength of Nutrient Solution on Gas Exchange, Ionic Concentration and Leaf Biomass of Annona emarginata (Schltdl.) H. Rainer Variety ‘Terra-Fria’ Seedlings. J. Plant Nutr. 2015, 38, 1944–1960. [Google Scholar] [CrossRef]

- Bufalo, J.; Rodrigues, T.M.; de Almeida, L.F.R.; dos Santos Tozin, L.R.; Marques, M.O.M.; Boaro, C.S.F. PEG-induced osmotic stress in Mentha x piperita L.: Structural features and metabolic responses. Plant Physiol. Biochem. 2016, 105, 174–184. [Google Scholar] [CrossRef][Green Version]

- Gruda, N.; Gianquinto, G.P.; Tuzel, Y.; Savvas, D. Culture: Soil-less. In Encyclopedia of Soil Science, 3rd ed.; Lal, R., Ed.; CRC Press-Taylor & Francis Group: Boca Raton, FL, USA, 2017; Volume i–iii, pp. 533–537. [Google Scholar] [CrossRef]

- Olle, M.; Ngouajio, M.; Siomos, A. Vegetable quality and productivity as influenced by growing medium: A review. Zemdirbyste-Agriculture 2012, 99, 399–408. [Google Scholar]

- Vinci, G.; Rapa, M. Hydroponic cultivation: Life cycle assessment of substrate choice. Br. Food J. 2019, 121, 1801–1812. [Google Scholar] [CrossRef]

- Othman, Y.; Bataineh, K.; Al-Ajlouni, M.; Alsmairat, N.; Ayad, J.; Shiyab, S.; Al-Qarallah, B.; St Hilaire, R. Soilless Culture: Management of growing substrate, water, nutrient, salinity, microorganism and product quality. Fresenius Environ. Bull. 2019, 28, 3249–3260. [Google Scholar]

- Gruda, N.S. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef]

- Savvas, D.; Gruda, N. Application of soilless culture technologies in the modern greenhouse industry—A review. Eur. J. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Gizas, G.; Savvas, D. Particle Size and Hydraulic Properties of Pumice Affect Growth and Yield of Greenhouse Crops in Soilless Culture. HortScience 2007, 42, 1274–1280. [Google Scholar] [CrossRef]

- Rogers, M.A. Organic Vegetable Crop Production in Controlled Environments Using Soilless Media. Horttechnology 2017, 27, 166–170. [Google Scholar] [CrossRef]

- Ramazzotti, S.; Gianquinto, G.; Pardossi, A.; Muñoz, P.; Savvas, D. Good Agricultural Practices for Greenhouse Vegetable Crops; FAO: Rome, Italy, 2013. [Google Scholar]

- Bosques, J.H. Curso Basico de Hidroponia; lulu.com Edit: CA, USA, 2010. [Google Scholar]

- Lu, N.; Shimamura, S. Protocols, Issues and Potential Improvements of Current Cultivation Systems. In Smart Plant Factory: The Next Generation Indoor Vertical Farms; Kozai, T., Ed.; Springer: Singapore, 2018; pp. 31–49. [Google Scholar] [CrossRef]

- Khaidem, T.; Thounaojam, T.; Jha, S. Influence of soil pH on nutrient availability: A Review. Int. J. Emerg. Technol. Innov. Res. 2018, 5, 707–713. [Google Scholar]

- Dunn, B.; Singh, H. Electrical Conductivity and pH Guide for Hydroponics; Technical Report; Oklahoma State University: Stillwater, OK, USA, 2016. [Google Scholar] [CrossRef]

- Sonneveld, C.; Voogt, W. Nutrient Management in Substrate Systems. In Plant Nutrition of Greenhouse Crops; Springer: Dordrecht, The Netherlands, 2009; pp. 277–312. [Google Scholar] [CrossRef]

- Raviv, M.; Krasnovsky, A.; Medina, S.; Reuveni, R. Assessment of various control strategies for recirculation of greenhouse effluents under semi-arid conditions. J. Hortic. Sci. Biotechnol. 1998, 73, 485–491. [Google Scholar] [CrossRef]

- Savvas, D.; Passam, H. Hydroponic Production of Vegetables and Ornamentals; Embryo Publications: Athens, Greece, 2002; p. 463. [Google Scholar]

- Ehret, D.; Alsanius, B.; Wohanka, W.; Menzies, J.; Utkhede, R. Disinfection of recirculating nutrient solutions in greenhouse horticulture. Agronomie 2001, 21, 323–339. [Google Scholar] [CrossRef]

- Alsanius, B.W.; Wohanka, W. Chapter 5-Root Zone Microbiology of Soilless Cropping Systems. In Soilless Culture, 2nd ed.; Raviv, M., Lieth, J.H., Bar-Tal, A., Eds.; Elsevier: Boston, MA, USA, 2019; pp. 149–194. [Google Scholar] [CrossRef]

- Gagnon, V.; Maltais-Landry, G.; Puigagut, J.; Chazarenc, F.; Brisson, J. Treatment of Hydroponics Wastewater Using Constructed Wetlands in Winter Conditions. Water Air Soil Pollut. 2010, 212, 483–490. [Google Scholar] [CrossRef]

- Hu, X.; Li, Q.; Huang, W.J.; Chen, B.; Cai, W.J.; Rabalais, N.; Turner, R. Effects of eutrophication and benthic respiration on water column carbonate chemistry in a traditional hypoxic zone in the Northern Gulf of Mexico. Mar. Chem. 2017, 194, 33–42. [Google Scholar] [CrossRef]

- Montesano, F.F.; van Iersel, M.W.; Boari, F.; Cantore, V.; D’Amato, G.; Parente, A. Sensor-based irrigation management of soilless basil using a new smart irrigation system: Effects of set-point on plant physiological responses and crop performance. Agric. Water Manag. 2018, 203, 20–29. [Google Scholar] [CrossRef]

- Liu, W.; Li, F.; Li, Y. Development and Future Trends of Internet of Things. In Cyber Security Intelligence and Analitics; Xu, Z., Choo, K.K.R., Dehghantanha, A., Parizi, R., Hammoudeh, M., Eds.; Springer International Publishing AG: Cham, Switzerland, 2020; Volume 928, pp. 648–656. [Google Scholar] [CrossRef]

- Hati, A.J.; Singh, R.R. Smart Indoor Farms: Leveraging Technological Advancements to Power a Sustainable Agricultural Revolution. AgriEngineering 2021, 3, 47. [Google Scholar] [CrossRef]

- Keating, B.A.; Carberry, P.S.; Bindraban, P.S.; Asseng, S.; Meinke, H.; Dixon, J. Eco-efficient Agriculture: Concepts, Challenges, and Opportunities. Crop Sci. 2010, 50, S109–S119. [Google Scholar] [CrossRef]

- Weselek, A.; Ehmann, A.; Zikeli, S.; Lewandowski, I.; Schindele, S.; Högy, P. Agrophotovoltaic systems: Applications, challenges, and opportunities. A review. Agron. Sustain. 2019, 39, 35. [Google Scholar] [CrossRef]

- Pathak, H.S.; Brown, P.; Best, T. A systematic literature review of the factors affecting the precision agriculture adoption process. Precis. Agric. 2019, 20, 1292–1316. [Google Scholar] [CrossRef]

- Avgoustaki, D.D.; Xydis, G. Indoor Vertical Farming in the Urban Nexus Context: Business Growth and Resource Savings. Sustainability 2020, 12, 1965. [Google Scholar] [CrossRef]

- Markets & Markets. Hydroponics Market. 2021. Available online: https://www.marketsandmarkets.com/Market-Reports/hydroponic-market-94055021.html (accessed on 8 January 2022).

- Buehler, D.; Junge, R. Global Trends and Current Status of Commercial Urban Rooftop Farming. Sustainability 2016, 8, 1108. [Google Scholar] [CrossRef]

- Gnauer, C.; Pichler, H.; Schmittner, C.; Tauber, M.; Christl, K.; Knapitsch, J.; Parapatits, M. A recommendation for suitable technologies for an indoor farming framework. Elektrotech. Inftech. 2020, 137, 370–374. [Google Scholar] [CrossRef]

- Gabriel, K. Mycodo Environmental Regulation System. 2018. Available online: https://hackaday.io/project/11997/instructions (accessed on 26 April 2020).

- Aronson, R. Farmbot. 2019. Available online: https://farm.bot/ (accessed on 26 April 2020).

- Mauricio-Moreno, H.; Miranda, J.; Chavarría, D.; Ramírez-Cadena, M.; Molina, A. Design S3-RF (Sustainable x Smart x Sensing-Reference Framework) for the Future Manufacturing Enterprise. IFAC-PapersOnLine 2015, 48, 58–63. [Google Scholar] [CrossRef]

- Miranda, J.; Ponce, P.; Molina, A.; Wright, P. Sensing, smart and sustainable technologies for Agri-Food 4.0. Comput. Ind. 2019, 108, 21–36. [Google Scholar] [CrossRef]

- Tatas, K.; Al-Zoubi, A.; Antoniou, A.; Zolotareva, D. iPONICS: IoT Monitoring and Control for Hydroponics. In Proceedings of the 2021 10th International Conference on Modern Circuits and Systems Technologies (MOCAST), Thessaloniki, Greece, 5–7 July 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Li, J.; Mao, Z.; Cao, Z.; Tei, K.; Honiden, S. Self-adaptive Hydroponics Care System for Human-hydroponics Coexistence. In Proceedings of the 2021 IEEE 3rd Global Conference on Life Sciences and Technologies (LifeTech), Nara, Japan, 9–11 March 2021; pp. 204–206. [Google Scholar] [CrossRef]

- Zamora-Izquierdo, M.A.; Santa, J.; Martinez, J.A.; Martinez, V.; Skarmeta, A.F. Smart farming IoT platform based on edge and cloud computing. Biosyst. Eng. 2019, 177, 4–17. [Google Scholar] [CrossRef]

- Aliac, C.J.G.; Maravillas, E. IOT Hydroponics Management System. In Proceedings of the 2018 IEEE 10th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Baguio City, Philippines, 29 November–2 December 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Atmadja, W.; Liawatimena, S.; Lukas, J.; Nata, E.P.L.; Alexander, I. Hydroponic system design with real time OS based on ARM Cortex-M microcontroller. In Proceedings of the International Conference on Eco Engineering Development 2017 (ICEED 2017), Yogyakarta, Indonesia, 14–15 November 2017; Volume 109. [Google Scholar] [CrossRef]

- Chang, C.L.; Hong, G.F.; Fu, W.L. Design and implementation of a knowledge-based nutrient solution irrigation system for hydroponic applications. Trans. Asabe 2018, 61, 369–379. [Google Scholar] [CrossRef]

- Fernandes, M.B.; Costa, B.A.; Lemos, J.M. Hydroponic Greenhouse Crop Optimization. In Proceedings of the 2018 13th APCA International Conference on Control and Soft Computing (CONTROLO), Ponta Delgada, Portugal, 4–6 June 2018; pp. 270–275. [Google Scholar] [CrossRef]

- Mashumah, S.; Rivai, M.; Irfansyah, A.N. Nutrient Film Technique based Hydroponic System Using Fuzzy Logic Control. In Proceedings of the 2018 International Seminar on Intelligent Technology and Its Applications (ISITIA 2018), Bali, Indonesia, 30–31 August 2018; pp. 387–390. [Google Scholar] [CrossRef]

- Mehra, M.; Saxena, S.; Sankaranarayanan, S.; Tom, R.J.; Veeramanikandan, M. IoT based hydroponics system using Deep Neural Networks. Comput. Electron. Agric. 2018, 155, 473–486. [Google Scholar] [CrossRef]

- Palande, V.; Zaheer, A.; George, K. Fully Automated Hydroponic System for Indoor Plant Growth. In Proceedings of the 2017 International Conference on Identification, Information and Knowledge in the Internet of Things, Shandong, China, 19–21 October 2017; Volume 129, pp. 482–488. [Google Scholar] [CrossRef]

- Sihombing, P.; Karina, N.; Tarigan, J.; Syarif, M. Automated hydroponics nutrition plants systems using arduino uno microcontroller based on android. J. Phys. Conf. Ser. 2018, 978, 012014. [Google Scholar] [CrossRef]

- Tagle, S.; Pena, R.; Oblea, F.; Benoza, H.; Ledesma, N.; Gonzaga, J.; Lim, L.A.G. Development of an Automated Data Acquisition System for Hydroponic Farming. In Proceedings of the 2018 IEEE 10th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Baguio City, Philippines, 29 November–2 December 2018. [Google Scholar] [CrossRef]

- Adhau, S.; Surwase, R.; Kowdiki, K.H. Design of Fully Automated Low Cost Hydroponic System using Labview and AVR Microcontroller. In Proceedings of the 2017 IEEE International Conference on Intelligent Techniques in Control, Optimization and Signal Processing (INCOS), Srivilliputtur, India, 23–25 March 2017. [Google Scholar] [CrossRef]

- Alipio, M.I.; Dela Cruz, A.E.M.; Doria, J.D.A.; Fruto, R.M.S. A smart hydroponics farming system using exact inference in Bayesian network. In Proceedings of the 2017 IEEE 6th Global Conference on Consumer Electronics (GCCE), Nagoya, Japan, 24–27 October 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Eridani, D.; Wardhani, O.; Widianto, E.D. Designing and Implementing the Arduino-based Nutrition Feeding Automation System of a Prototype Scaled Nutrient Film Technique (NFT) Hydroponics using Total Dissolved Solids (TDS) Sensor. In Proceedings of the 2017 4th International Conference on Information Technology, Computer, and Electrical Engineering (ICITACEE), Semarang, Indonesia, 18–19 October 2017; pp. 170–175. [Google Scholar] [CrossRef]

- Kaewwiset, T.; Yooyativong, T. Electrical Conductivity and pH Adjusting System for Hydroponics by using Linear Regression. In Proceedings of the 2017 14th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Phuket, Thailand, 27–30 June 2017; pp. 761–764. [Google Scholar] [CrossRef]

- Saputra, R.E.; Irawan, B.; Nugraha, Y.E. System design and implementation automation system of expert system on hydroponics nutrients control using forward chaining method. In Proceedings of the 2017 IEEE Asia Pacific Conference on Wireless and Mobile (APWiMob), Bandung, Indonesia, 28–29 November 2017; pp. 41–46. [Google Scholar] [CrossRef]

- Ruengittinun, S.; Phongsamsuan, S.; Sureeratanakorn, P. Applied Internet of Thing for Smart Hydroponic Farming Ecosystem (HFE). In Proceedings of the 2017 10th International Conference on UBI-MEDIA Computing and Workshops (UBI-MEDIA), Pattaya, Thailand, 1–4 August 2017; pp. 462–465. [Google Scholar] [CrossRef]

| Material | Advantages | Disadvantages | Source |

|---|---|---|---|

| Sand | Economically viable, good porosity features, and provides good plant support | High density (around of 1500 kg/m3), low retention of water, susceptible to salt accumulation | [22] |

| Perlite | Low density (around of 90 kg/m3), biologically inert, neutral pH, highly available | Expensive, low water retention capacity | [23] |

| Vermiculite | Low density (around 80 kg/m3), high nutrient holding ability, good water holding ability | Expensive, energy consuming product | [15] |

| Rockwool | Low density (around 80 kg/m3), ease of handling, totally inert, sterile from pathogens, eases nutrition management in plants | Negative impacts on human health when is reused | [24,25] |

| Coconut coir | Low density (around 60 kg/m3), good air content and water holding capacity, pH in ranges of 5–8 | High salt level content, energy consumption during transport | [26] |

| Peat/Peat moss | Inert, high water storage capacity, prevents leaching of nutrients | Negative environmental impacts such as loss of soil organic carbon, relatively expensive | [24] |

| Pumice | Cheap and long-lasting usage, chemically inert, low density | Particle size and hydraulic properties affect the growth and yield of crops | [27] |

| Type | Common Name | Scientific Name | Cultivation Technique |

|---|---|---|---|

| Bulb Vegetables | Garlic | Allium sativum | Drip irrigation |

| Onion | Allium cepa | NFT, Drip irrigation | |

| Pore | Allium porrum | NFT, Drip irrigation | |

| Leafy Vegetables | Lettuce | Lactuca sativa | NFT, DWC |

| Cabbage | Brassica oleracea var. capitata | NFT, DWC | |

| Brussels sprouts | Brassica oleracea var. gemmifera | NFT, DWC | |

| Mustard | Brassica nigra | NFT, DWC | |

| Spinach | Spinacea oleracea | NFT, DWC | |

| Chard | Beta vulgaris var. cicla | NFT, DWC | |

| Water cress | Nasturtium officinale | NFT, DWC | |

| Celery | Apium graveolens | NFT, DWC | |

| Parsley | Petroselinum crispum | NFT, DWC | |

| Coriander | Coriandrum sativum | NFT, DWC, drip irrigation | |

| Purslane | Portulaca oleracea | NFT, DWC | |

| Root Vegetables | Beetroot | Beta vulgaris | Drip irrigation, aeroponics |

| Jicama | Pachyrrhizus erosus | Drip irrigation | |

| Turnip | Brassica rapa | NFT | |

| Radish | Raphanus sativus | Drip irrigation, aeroponics | |

| Yucca | Manihot esculenta | NFT, Drip irrigation | |

| Carrot | Daucus carota | Drip irrigation, aeroponics | |

| Tuber Vegetables | Sweet potato | Ipomoea batatas | Drip irrigation |

| Potato | Solanum tuberosum | Drip irrigation | |

| Stem Vegetables | Swede | Brassica oleracea var. gongyloides | Drip irrigation |

| Asparagus | Asparagus officinalis | NFT, DWC | |

| Inflorescent Vegetables | Artichoke | Cynara scolymus | Drip irrigation |

| Broccoli | Brassica oleracea var. Italica | Drip irrigation, NFT | |

| Cauliflower | Brassica oleracea var. botrytis | Drip irrigation, NFT | |

| Huauzontle | Chenopodium sp. | NFT, DWC | |

| Fruit Vegetables | Zucchini | Cucurbita pepo | Drip irrigation, NFT |

| Cucumber | Cucumis sativus | Drip irrigation, NFT | |

| Cantaloupe | Cucumis melo | Drip irrigation, NFT | |

| Watermelon | Citrullus vulgaris | Drip irrigation | |

| Green bean | Phaseolus vulgaris | Drip irrigation | |

| Squash | Sechium edule | Drip irrigation | |

| Chile | Capsicum annuum | Drip irrigation | |

| Eggplant | Solanum melongena | Drip irrigation | |

| Tomato | Solanum licopersicum | Drip irrigation, NFT | |

| Tomato | Physalis ixocarpa | Drip irrigation, NFT | |

| Pulse Vegetables | Pea | Pisum sativum | Drip irrigation |

| Bean | Vicia faba | Drip irrigation | |

| Sweet Corn | Zea mays | Drip irrigation |

| Nutrient | Symbol | Forms Absorbed |

|---|---|---|

| Nitrogen | N | |

| Phosphorus | P | |

| Potassium | K | |

| Calcium | Ca | |

| Magnesium | Mg | |

| Sulfur | S | |

| Iron | Fe | |

| Manganese | Mn | |

| Zinc | Zn | |

| Copper | Cu | |

| Molybdenum | Mo | |

| Boron | B |

| Crops | pH | EC (mS/cm) |

|---|---|---|

| Asparagus | 6–6.8 | 1.4–1.8 |

| African Violet | 6–7 | 1.2–1.5 |

| Basil | 5.5–6 | 1–1.6 |

| Bean | 6 | 2–4 |

| Banana | 5.5–6.5 | 1.8–2.2 |

| Broccoli | 6–6.8 | 2.8–3.5 |

| Cabbage | 6.5–7 | 2.5–3 |

| Celery | 6.5 | 1.8–2.4 |

| Carnation | 6 | 2–3.5 |

| Courgettes | 6 | 1.8–2.4 |

| Cucumber | 5–5.5 | 1.7–2 |

| Eggplant | 6 | 2.5–3.5 |

| Ficus | 5.5–6 | 1.6–2.4 |

| Leek | 6.5–7 | 1.4–1.8 |

| Lettuce | 6–7 | 1.2–1.8 |

| Marrow | 6 | 1.8–2.4 |

| Okra | 6.5 | 2–2.4 |

| Pak Choi | 7 | 1.5–2 |

| Peppers | 5.5–6 | 0.8–1.8 |

| Parsley | 6–6.5 | 1.8–2.2 |

| Rhubarb | 5.5–6 | 1.6–2 |

| Rose | 5.5–6 | 1.5–2.5 |

| Spinach | 6–7 | 1.8–2.3 |

| Strawberry | 6 | 1.8–2.2 |

| Sage | 5.5–6.5 | 1–1.6 |

| Tomato | 6–6.5 | 2–4 |

| Method | Advantages | Disadvantages |

|---|---|---|

| Filtration | ||

| -Sand Filters | Low cost | High space requirements |

| Easy to operate | Effectiveness varies with pathogen | |

| Frequent clogging and seeping | ||

| -Membrane | Highly effective | High initial investment |

| Expensive maintenance | ||

| Heat treatment | ||

| -Pasteurization | Highly effective | High capital costs |

| Precipitates are not generated | High maintenance costs | |

| Radiation | ||

| -UV Radiation | High efficiency (without turbidity) | Low efficiency in the presence of turbidity |

| Low space requirement | Precipitation of Mn and Fe | |

| Relatively expensive equipment | ||

| Chemical treatment | ||

| -Ozone | Highly effective | High capital costs |

| High maintenance costs | ||

| Efficiency drops with high organic matter | ||

| -Hydrogen peroxide | Useful for cleaning irrigation systems | Interaction with some micronutrients |

| Harmful for plant roots when the dose is greater than 0.05% | ||

| -Chlorine | Low cost technique | Its effectiveness depends on many factors: temperature, pH, organic load, ammonium content, etc. |

| Toxic residues can be generated due to the interaction with organic and inorganic elements of the nutrient solution |

| ID | Year | Contribution/Author | I | DU | IoT | S | SM |

|---|---|---|---|---|---|---|---|

| 1 | 2021 | Design and implementation of an intelligent, low-cost IoT-based control and monitoring system for hydroponics greenhouses [55] | X | X | X | ||

| 2 | 2021 | IoT-based self-adaptive hydroponics care system that controls the hydroponic cultivation environment [56] | X | X | X | ||

| 3 | 2019 | Development of a methodology for the implementation of sustainable technology [54] | X | X | X | X | |

| 4 | 2019 | Development of an IoT application for task management in a hydroponic greenhouse [57]. | X | X | X | ||

| 5 | 2018 | Integrated Internet of Things (IoT)-based system for monitoring and managing a hydroponic crop [58]. | X | X | X | X | |

| 6 | 2018 | Development of an automated system for nutrient dosing, pH regulation, conductivity, light intensity, and temperature and humidity monitoring using an ARM Cortex-M4 microcontroller [59]. | X | X | |||

| 7 | 2018 | Development of a microelectronic system for mixing nutrient solutions in hydroponic crops using fuzzy logic [60]. | X | X | |||

| 8 | 2018 | Modeling of a prototype greenhouse for the control of temperature, humidity, luminosity and nutrient management [61]. | X | X | |||

| 9 | 2018 | Conductivity adjustment of the nutrient solution in an NFT type hydroponic system using fuzzy logic [62]. | X | X | |||

| 10 | 2018 | Development of an intelligent hydroponic system based on IoT using deep neural networks in a Raspberry Pi3 and Tensor Flow [63]. | X | X | X | X | |

| 11 | 2018 | Development of a system of monitoring and control of variables for hydroponic crops based on the Internet of Things [64]. | X | X | X | ||

| 12 | 2018 | Development of a nutrient flow control tool in a hydroponic system using Arduino, with remote monitoring and operation using a smartphone [65]. | X | X | X | ||

| 13 | 2018 | Development of an automated data acquisition system for monitoring and control of a hydroponic crop implemented in the Arduino platform [66]. | X | X | |||

| 14 | 2017 | Low cost control system for hydroponic greenhouses using an AVR microcontroller and an interface developed in LabView [67]. | X | X | |||

| 15 | 2017 | Development of an intelligent hydroponic system using exact inference through a Bayes-type neural network [68]. | X | X | |||

| 16 | 2017 | Design and implementation of an automatic system for the dosage of nutrients in an NFT type hydroponic system using Arduino [69]. | X | X | |||

| 17 | 2017 | Conductivity and pH adjustment of the nutrient solution used in hydroponic cultures using a linear regression model programmed in a microcontroller [70]. | X | X | |||

| 18 | 2017 | Design of an embedded system for the dosage of nutrients in a hydroponic system using artificial intelligence [71]. | X | X | |||

| 19 | 2017 | Development of a remote control system based on IoT for the management of a hydroponic system [72]. | X | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations. Agriculture 2022, 12, 646. https://doi.org/10.3390/agriculture12050646

Velazquez-Gonzalez RS, Garcia-Garcia AL, Ventura-Zapata E, Barceinas-Sanchez JDO, Sosa-Savedra JC. A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations. Agriculture. 2022; 12(5):646. https://doi.org/10.3390/agriculture12050646

Chicago/Turabian StyleVelazquez-Gonzalez, Roberto S., Adrian L. Garcia-Garcia, Elsa Ventura-Zapata, Jose Dolores Oscar Barceinas-Sanchez, and Julio C. Sosa-Savedra. 2022. "A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations" Agriculture 12, no. 5: 646. https://doi.org/10.3390/agriculture12050646

APA StyleVelazquez-Gonzalez, R. S., Garcia-Garcia, A. L., Ventura-Zapata, E., Barceinas-Sanchez, J. D. O., & Sosa-Savedra, J. C. (2022). A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations. Agriculture, 12(5), 646. https://doi.org/10.3390/agriculture12050646