Abstract

Several feed preservation methods can ensure lower mycotoxin contamination levels enter the food life cycle, and a relatively common wet preservation method of forage plant materials is fermentation. This study aimed to characterize the microbiological state and mycotoxin contamination of fermented silages and haylages (corn, alfalfa, rye, and triticale), their main microbiota, and isolation of bacteria with mycotoxin resistance. Bacteria that remain viable throughout the fermentation process and possess high mycotoxin resistance can have a biotechnological benefit. Lactic acid bacteria, primarily found in corn silage, were Lactiplantibacillus plantarum isolates. Meanwhile, a high percentage of alfalfa silage and haylage was characterized by Lactiplantibacillus pentosus. In rye silage and haylage samples, Pediococci were the typical bacteria. Bacterial isolates were characterized by deoxynivalenol and zearalenon resistance. Some of them were sensitive to aflatoxin B1, while ochratoxin A caused 33–86% growth inhibition of the cultures. The mycotoxin resistant organisms are under further research, aiming for mycotoxin elimination in feed.

1. Introduction

Forages can be fermented in a fermentation process that can be divided into five successive phases [1]. At a pH lower than 4, forages become more stable, and the growth of undesirable microbes can be prevented. When the silo is opened, with the introduction of air, yeasts, molds, and aerobic bacteria begin to function, and toxic molecules (e.g., mycotoxins) can be produced [2,3].

Mycotoxins are low molecular weight organic compounds, secondary metabolites produced by molds that can enter the animal or human body causing serious diseases [4]. These molecules can have acute or chronic carcinogenic, neurotoxic, immunotoxic, hepatotoxic, and nephrotoxic effects. Mycotoxins produced by aerobic filamentous fungi (mainly Alternaria, Fusarium, Aspergillus, and Penicillium species) are often found on plant materials on fields and in storage. Freshly harvested plant materials are usually contaminated with some of the well-known mycotoxins under certain environmental conditions [3,5].

Deoxynivalenol (DON) and zearalenone (ZEA) are Fusarium mycotoxins, which are the main contaminating agents on corn worldwide [6,7]. DON is a potent inhibitor of the eukaryotic protein synthesis in Eukarya, while ZEA is associated with reproductive disorders, as it is known as a myco-oestrogen with hormonal effects on both male and female mammals [6]. Ochratoxin A (OTA) produced by mainly Aspergilli and Penicilli bound to albumin can enter tissues all over the animal body. Others like fumonisins (Fusarium mycotoxins) can be released with milk, urine, or any other exudates. Aflatoxins (AFs), especially AFB1, are carcinogenic compounds, and due to their binding ability to DNA, they also have strong mutagenic effect [8].

In addition to the mycotoxins produced on raw materials, the toxin production also may occur under the wilting or fermentation steps of the plant material. Oxygen in the improperly sealed and pressed plant material supports the viability of molds and allows further mycotoxin production [9,10,11,12].

The composition and size of the microbiome can affect mold growth and the available mycotoxins [9,10]. Biological control of mycotoxin contamination is well-known [13]; however, it is hard to carry out in practice because of the inhomogeneity, the unfavorable conditions for microbial growth, or simply because of the heterogeneity of the contaminating mycotoxins. Bacteria can fulfil some of those functions, as bacterial cells usually adsorb mycotoxins, e.g., AFs on their cell wall components [13]; or can detoxify these contaminants by their enzymes, e.g., ZEA by esterases [14]; or can simply inhibit the outgrowth of molds by different metabolites, e.g., bacteriocins and acid production [1]. However, the overall solution to decrease the mycotoxin content is not known due to the diverse chemical structures of the mycotoxins that should be dealt with [10,13]. Spore-forming bacteria can also be important in mycotoxin decontamination, since the spores can survive harsh conditions, e.g., low pH or bacteriocins [1].

The hypothesis of this study was that bacteria that remain viable throughout the fermentation process can possess high mycotoxin resistance, and we could possibly find some prosperous mycotoxin-eliminating organisms. Therefore, fermented forages of different origins were investigated for the microbiological state and the mycotoxin content. Several bacterial isolates were identified, and their mycotoxin resistance was determined for further biocontrol research.

2. Materials and Methods

2.1. Samples

Twenty-two fermented forages (14 corn, 4 alfalfa, 2 rye, and 2 triticale) were collected at the final stage of the fermentation (after 4–6 weeks) from different Hungarian dairy cattle farms, where the producers collected 10 parallel samples per site, and forage from the freshly opened silos and bales. The samples were combined (minimum of 5 kg) and transferred in sterile velcro bags to the analytical laboratory for further analysis.

2.2. Microbiological Sample Preparation

Fermented forage samples (100 g) in sterile homogenizing Stomacher bags were suspended in a 1:9 ratio in Buffered Peptone Water (BPW) (Scharlab, Barcelona, Spain) and homogenized with a Stomacher Masticator homogenizer (IUL Instruments, Barcelona, Spain). Decimal dilutions were made of the suspensions and applied as inoculums on specific agar media.

The total microbial count was determined on Plate Count Agar (Scharlab, Barcelona, Spain) medium, applying pour plate method and incubation of the solid media at 30 °C for 3 days under anaerobic and aerobic conditions [15].

Lactic acid bacteria count was determined on De Mann-Rogosa-Sharp (MRS) agar (Scharlab, Barcelona, Spain) plates, applying the diluted samples by surface spreading method, and incubating the plates at 30 °C under anaerobic conditions for 3 days [16].

Mold counts were determined by surface spreading method on Chloramphenicol Glucose Agar (CGA) (Scharlab, Barcelona, Spain) medium incubated at 25 °C for 5 days [17].

All microbial counts were determined in parallel cultures from the results of the inoculations of the subsequent dilutions by weighted mean calculations.

2.3. Dry Weight Determination

Fermented forage samples (corn, alfalfa, rye, and triticale) were dried in three repetitions in a drying cabinet (UN55, Memmert GmbH, Schwabach, Germany) at 60 °C ± 1 °C to weight stability, and were not combined. The weight of each sample was measured before and after drying, and the dry weight mean and standard deviation of the three repetitions were calculated [18].

2.4. Mycotoxin Measurement with HPLC Methods

Wet fermented forages (minimum of 4 kg) were dried in a drying cabinet (LABORMIM Ltd., Budapest, Hungary) at 60 °C ± 1 °C to weight stability. After reaching the weight stability, the samples were homogenized with Retsch SM 100 cutting mill.

All HPLC measurements were done on Dionex Ultimate 3000 (Thermo Scientific, Waltham, MA, USA) HPLC equipment. For all measurements, Biopure Aflatoxin Mix 1, deoxynivalenol, zearalenone, or ochratoxin A mycotoxin calibrant solutions were purchased as standards from Romer Labs (Tulln, Austria) and applied in suitable dilutions. The sample preparations were done by the VICAM methods (Waters) with some modifications.

For deoxynivalenol (DON) measurement, 12.5 g dried samples were homogenized with 2.5 g of polyethylene glycol (VWR, Debrecen, Hungary) and 50 mL of distilled water at high-speed mixing. After filtration, 1 mL of the extract was loaded onto the DON immunoaffinity column (VICAM DONtest HPLC Columns, Weber Consulting Ltd., Göd, Hungary). The column was washed sequentially with distilled water (5 mL) and methanol (5 mL) to elute the toxin from the column. The methanol was evaporated from the samples on Rotadest (Büchi). Phenomenex (Torrance, CA, USA) RP-C18 column (125 × 4 mm, 5 µm) was used with DAD detector in UV 218 nm with acetonitrile: water (10:90) eluent.

For HPLC determination of aflatoxin (AF) and ochratoxin A (OTA), 25 g dried samples were homogenized with 2.5 g sodium chloride (VWR) and 50 mL of 80% methanol (HPLC, Sigma-Aldrich, St. Louis, MO, USA) at high-speed mixing. The extract was diluted in a 1:4 ratio with 40 mL of distilled water. The diluted extract was filtered and 10 mL of it was loaded onto the aflatoxin immunoaffinity column (VICAM AflaTest WB HPLC Columns, Weber Consulting Ltd., Göd, Hungary) or ochratoxin immunoaffinity column (VICAM OchraTest WB HPLC Column, Weber Consulting Ltd., Göd, Hungary). The column was washed with 10 mL of distilled water, and the toxin was eluted with methanol (5 mL).

For OTA detection, Phenomenex (Torrrance, CA, USA) RP-C18 column (150 × 4.6 mm, 5 µm) was used with fluorescens detector, ex360 nm, em440 nm, with acetonitrile: 0.012 M Na-phosphate pH 7.5 (60:40) eluent.

For aflatoxin detection, Phenomenex (Torrance, CA, USA) RP-C18 column (150 × 4.6 mm, 5 µm) was used with Romer UV derivatization unit (Romer Labs Ltd., Tulln, Austria) and a fluorescence detector ex360 nm, em440 nm, with methanol: water (45:55) eluent.

For HPLC determination of zearalenone (ZEA), 20 g dried samples were homogenized with 2 g sodium chloride (VWR, Debrecen, Hungary) and 50 mL of 90% acetonitrile (HPLC, Sigma-Aldrich Ltd., Budapest, Hungary) at high-speed mixing. The extract was diluted in a 1:4 ratio with 40 mL of distilled water. The diluted extract was filtered, and 10 mL of it was loaded onto the zearalenone immunoaffinity column (VICAM ZearalaTest WB HPLC Column, Weber Consulting Ltd., Göd, Hungary). The column was washed with 10 mL of distilled water, and the toxin was eluted with methanol (5 mL).

For the detection, Phenomenex (Torrance, CA, USA) RP-C18 column (150 × 4.6 mm, 5 µm) was used with fluorescence detector ex360 nm, em440 nm, and acetonitrile: water: methanol (46:46:8) eluent.

Performance as LOD, linear range, and reproducibility of the applied HPLC methods were determined with the spiking of dried and ground corn silage with different concentrations of the mycotoxins tested (n = 8). For AFB1, OTA, DON, and ZEA, the LOD were 0.01 µg/kg, 0.5 µg/kg, 0.1 mg/kg, and 0.1 mg/kg, respectively. The linear ranges were found up to 300 µg/kg for AFB1 and OTA, while for DON and ZEA, we detected linearity up to 50 mg/kg. Relative standard deviation (RSD%) as an absolute value of the coefficient of variation was calculated and was found under 10% in all cases.

2.5. Identification of Bacteria Isolated from Fermented Forages by MALDI-TOF MS Method

Bacteria isolated from MRS, and Plate Count Agar media were identified by MALDI-TOF MS (Microflex LT Instrument, Bruker Daltonik GmbH, Bremen, Germany). Solitaire colonies were applied and analyzed with the Biotyper 3.0 software (Bruker Daltonik GmbH, Germany). The highest scored bacteria were considered as taxonomically identical to the isolates. Only scores above 1.950 were considered as valid results. All analyses were made parallel on two solitaire colonies of the isolates.

2.6. Toxin Resistance of Isolated Bacterial Cultures

For all resistance studies, Biopure Aflatoxin Mix 1, deoxynivalenol, zearalenone, or ochratoxin A mycotoxin calibrant solutions were purchased as standards from Romer Labs (Tulln, Austria) and applied in suitable dilutions. Bacterial isolates were inoculated into MRS broth (Scharlab) for LAB or Nutrient Broth (Scharlab) for other bacteria and incubated for 16 h at 30 °C, gaining exponential phase cultures. Microtiter plate with MRS broth or Nutrient Broth was inoculated to gain a low-density culture (0.100 < OD630nm < 0.200). Mycotoxins were added at different concentrations to the cultures (AFB1: 24–100 µg/L; OTA: 50–1000 µg/L; DON: 700 µg/L–1000 µg/L; ZEA: 100–500 µg/L). The bacteria were incubated with the mycotoxins for up to 24 h at 30 °C in a microtiter plate reader (Synergy HTX multi-mode reader, BioTech Hungary Ltd., Szigetszentmiklós, Hungary), and optical density was read every hour at 630 nm after intensive shaking (30 s). The growth curve of the untreated control (w/o mycotoxins) cultures was compared to the mycotoxin-treated cultures. All mycotoxins with all isolates were measured in four repetitions. Data analyses were done in Gen5 3.05 software (BioTech Hungary Ltd.) and Windows Excel (Microsoft, Redmond, WA, USA).

2.7. Statistical Analysis

Correlation (Pearson) analysis of all measured microbial counts, mycotoxin contents and water contents were done in Windows Excel Analysis ToolPac (Microsoft). Growth data analyses were done in Gen5 3.05 software (BioTec) and Windows Excel Analysis ToolPac (Microsoft), where significant differences in growth of the mycotoxin-treated and untreated cultures were analyzed by t-probe (at p ≤ 0.05).

3. Results

3.1. Toxicological Characterization of the Fermented Forages

Well-known mycotoxins like aflatoxins (AFs), ochratoxin A (OTA), deoxynivalenol (DON), and zearalenone (ZEA) were measured from the fermented forages. In this way, preharvest and post-silo contaminations by Aspergillus/Penicillium as well as Fusarium could be presumed.

Interestingly, corn silages were decontaminated from most of the mycotoxins as the investigation proved. Mainly DON contamination was detected, and the concentration range was quite wide, from <0.1 mg/kg to 3.254 ± 0.031 mg/kg. Nevertheless, the average contamination by DON in corn silage was 0.901 ± 0.012 mg/kg. Other mycotoxins were also detected, and AFB1 and another less toxic AF metabolite, aflatoxin G2, and in some cases ZEA were also measured in the fermented forages. In alfalfa fermented products, OTA and AF contaminations were characteristic both in silage and haylage samples, and in silage, DON was also detected (Table 1). Triticale haylage samples were characterized by low mycotoxin contents and relatively high LAB counts (2.5–5.3 log10 colony-forming unit, CFU/g) (Table 1 and Table 2).

Table 1.

Toxicological characterization of the studied fermented forages. Aflatoxins (AF), ochratoxin A (OTA), deoxynivalenol (DON), and zearalenone (ZEA) were measured by HPLC techniques from dried samples (n = 3, RSD% ≤ 10%) and expressed as mycotoxin contents for dry weights of the fermented forages. The lowest detection limits (LODs) are presented where no mycotoxin could be detected.

Table 2.

Characterization of the microbial composition of the studied fermented forages (n = 3; CV% ≤ 10%). Counts on total plate count agar, MRS agar, and CYG agar were expressed in logarithmic form.

3.2. Microbial Characterization of the Fermented Forages

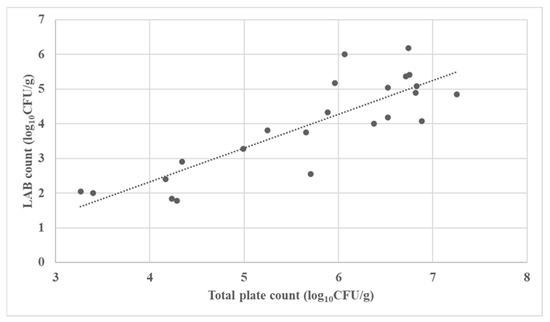

Microbial counts of the fermented forages were very variable, as the logarithmic values of the total plate counts ranged from 3.265 to 7.254 log10 CFU/g. The logarithmic value of the colony counts from the MRS agar medium ranged from 1.778 to 6.167 log10 CFU/g. The total colony counts of the fermented forages were in strong relation to the counts on MRS agar (cultivating mostly lactic acid bacteria) as the correlation coefficient was 0.848, showing a strong positive correlation (Figure 1).

Figure 1.

Correlation of total plate count and LAB counts in the final stage of the fermented forages.

Most of the samples were characterized by low mold counts (1.000 log10 CFU/g), but some samples contained high mold contamination (3.000–6.079 log10 CFU/g) (Table 2). The high mold contamination was in no correlation with high mycotoxin contents in any cases. LAB was found to have only a very weak negative correlation to mycotoxins (AF: −0.360; OTA: −0.336).

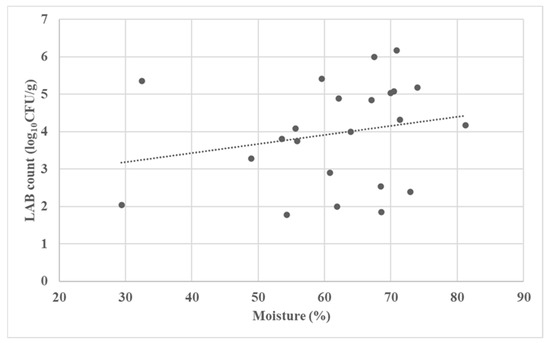

The final total microbial counts were composed mostly of LAB, and their viable cell number did not depend on the final water content of the feed, as the correlation coefficient was only 0.219 between the water content (range 29–81%) of the fermented forages and viable LAB count (Figure 2).

Figure 2.

Correlation of water content and LAB counts in fermented forages.

3.3. Identification of the Isolated Bacteria

Bacteria were isolated from the fermented forages and identified with MALD-TOF MS applying a Bruker MALDI-TOF MS identification software. All score values given by the software were checked, and the bacteria with the highest scores (above 1.950) were taken as real species identifications of the isolates (Table 3). Interestingly, most frequently found LAB was Lactiplantibacillus plantarum in corn silage. A high percentage (78%) of alfalfa silage microbiome was characterized by Lactiplantibacillus pentosus, while Pediococci were the typical bacteria in rye silage and haylage samples. Some of the aerobic spore-forming bacteria (e.g., Lysinibacillus spp., Rummeliibacillus spp., and Bacillus spp.), and an enterobacterium, Klebsiella pneumoniae, were also isolated and characterized from the ensilaged materials.

Table 3.

Identification results of bacterial isolates from fermented forages and their aflatoxin B1 (AFB1) and ochratoxin (OTA) resistance. All identifications of the isolates based on the protein profile of the bacteria were done in two repetitions with the MALDI-TOF MS technique. Identification with a score value below 1.950 was defined as an uncertain identification, and the analysis was repeated. Bacterial growth inhibition was tested with 24 µg/L AFB1 and 1000 µg/L OTA, respectively.

3.4. Mycotoxin Resistance of the Isolated Bacteria

Mycotoxin resistance of pure bacterial cultures was studied to investigate the possibility of bacterial growth inhibition causing significant hindrance of the fermentation procedures. Based on the growth curves of mycotoxin treated and untreated bacterial cultures, it was concluded for the tested mycotoxin concentrations, that the isolated organisms usually showed strong resistance (Table 3). DON (700 µg/L) and ZEA (100 µg/L) did not cause inhibition of the cell growths. However, OTA mycotoxin caused overall inhibition of the bacterial growth, with 33–86% of inhibition at 1000 µg/L concentration. Lower concentrations of the mycotoxin did not cause alternations in the growth of the bacterial cultures, and LAB, spore-forming bacteria, and Klebsiella pneumoniae did not differ.

AFB1 in 24 µg/L concentration caused growth inhibition in some LAB isolates (L. curvatus, L. brevis, L. coryniformis), but only up to 24% (L. brevis). Growth of the isolated spore-forming bacteria (Lysinibacillus spp., Rummeliibacillus spp., and Bacillus spp.) and K. pneumoniae were not affected by up to 100 µg/L AFB1 (Table 3).

4. Discussion

Feed producers hope to eliminate mycotoxins that endanger animal health, while gaining nutrient-rich feed by fermenting plant materials. In contrast to this expectation, the fermented forages contained high concentrations (450–3250 µg/kg) of Fusarium mycotoxin DON in a considerable percentage of samples (41%), mainly in corn silage. The concentration of DON measured recently (e.g., 159.8–203.5 µg/kg, [9] and 100–213 µg/kg, [19]) was much lower than the mean for corn silages in our study (901 µg/kg). DON is one of the most usually detected mycotoxins in silages, and its concentration can be very high [20]. High DON amounts indicated that the microbial community could not eliminate it during ensiling. Besides, Jensen et al. (2019) [21] and Keller et al. (2013) [7] reported DON concentration increase under corn ensiling through biodegradation of DON derivatives to free DON structure. Meanwhile, the other Fusarium mycotoxin, ZEA, was not affected due to the stability of both the compound and its derivatives (α-zearalenol and β-zearalenol) [21]. Other sources mentioned reduction or complete elimination of DON and ZEA through ensilaging [22] by the microbial activities and environmental differences; therefore, it could be concluded that the results are contradictory and need further investigation.

We could assume that ensiling is not favorable for the ephemeral Fusarium species because of the decreasing pH and the anaerobic conditions [20]; therefore, concentrations of stable DON and ZEA Fusarium toxins detected might reflect the fungal contamination before harvesting [23] or wilting of plant materials for haylage. It was also assumed that alfalfa feed products were contaminated by Penicillium and Aspergillus strains, causing OTA and AF contamination of the feeds. The concentration of AFs in fermented forages may increase if the material is exposed to air during the preservation [24]. Considering that the mold counts of the alfalfa samples were not outstanding, the fungal contamination could happen before ensiling. High AF and OTA contaminations were also reported for alfalfa from different countries [5,25]. However, references stated that the incidence and concentration of OTA in silage are usually low relative to Fusarium mycotoxins (DON and ZEA) [26]. In our study, AFB1 and ZEA contaminations were insignificant in the samples. AFG2 with lower toxicity was present, possibly due to bioconversion of AFB1.

At the end of the fermentation, mostly acid tolerating organisms and spores survived [10,11]. The fermented forages contained many beneficial lactic acid bacteria (LAB) essential for the preservation, with antimycotic and antimycotoxic characteristics. Water content decrease by wilting haylage materials and natural drying of the fermented forages [27] did not harshly affect the viable LAB numbers. It was also assumed that a relatively low species number was characteristic of the final stage of the fermentation [28] in rye silage and haylage samples, and it was shown in corn silages as well [10]. There were some initiatives to collect information on final stage of microbiome [29,30] with the same result. While these researchers did not investigate mycotoxin resistance of the composing microbes.

LAB used to be applied as an inoculant in silos. The most common homofermentative species involved are L. plantarum, various Lactiplantibacillus or Pediococcus species, and Enterococcus faecium [31]. Lentilactobacillus buchneri is the heterofermentative species used to improve aerobic stability [32]. P. pentosaceus and L. buchneri increased aerobic stability and prevented the production of AFs (5200 µg/kg versus 0 µg/kg [33]) at ensiling. Inoculated L. buchneri decreased AFs and did not affect DON or ZEA concentrations in corn silages [34]. LAB are also applied as an antibacterial biocontrol to inhibit the growth of pathogenic bacteria. L. plantarum, L. lactis, L. acidophilus, L. plantarum, L. brevis, and L. buchneri are the most common antimicrobial bacteriocin producers [31]. Besides bacteriocins, inhibition of the growth of pathogenic bacteria, yeasts, and molds gained by the synergistic action of the LAB metabolome, where lactic acid, acetic acid, hydrogen peroxide, lactate peroxidase, lysozyme, and reuterin can affect the surrounding microbiome [35] and decrease total plate counts. LAB are also well-known as potent participants in mycotoxin biocontrol [13,36,37]. L. plantarum and L. brevis are well-known as inoculants for ensilaging; however, the aim of their usage usually is in their volatile organic carbon production and not their biocontrol capability [1].

The capability of the cells to resist mycotoxins and absorb or degrade the molecules is a well applicable characteristic [13] in food and feed industry. However, significant growth inhibition of LAB can hinder the fermentation and the elimination of mycotoxins as well. OTA and AFB1 were detected to inhibit bacterial growth of the isolates; although, AFB1 showed only moderate concentration in this case, causing low consideration. Meanwhile, non-lactic acid bacteria also can be potent mycotoxin eliminating organisms. In the project, Lysinibacillus spp. and Rummeliibacillus spp. spore-forming Gram-positive aerobe bacteria were isolated, besides Klebsiella pneumoniae Gram-negative bacterium that are not known to have a special role in fermentation processes, as far as we know. None of those bacteria were known for their mycotoxin resistance or elimination, except Lysinibacillus fusiformis [38]; however, it was shown here that, similarly to LAB, they also possess that positive characteristic. Natural contamination or active inoculation applying these bacteria could have an effect on mycotoxin content as, besides absorption, there is a possibility for mycotoxin degradation by enzyme activities similar to Bacillus spp. [13,14]. The role of these organisms in mycotoxin elimination are under further research to explore their potential for biotechnological applications.

5. Conclusions

Based both on the literature and our study, it was assumed that the main Fusarium mycotoxin DON could cause most of the quality problems, especially in corn silages, where occasionally low viable LAB counts can characterize the system. The other problem is OTA contamination, because the bacterial growth inhibitory characteristic of this mycotoxin could hinder the fermentation processes at high concentrations of the toxin.

Relatively low LAB species number was characteristic of the final stage of the fermentations. Isolation and application of bacteria presented at that stage, usually in low counts but with significant antimycotic and/or anti-mycotoxigenic activity, is a new perspective. Here, we identified and characterized also some non-lactic acid bacteria with unknown mycotoxin elimination possibilities. Their activity could hinder fungal growth and mycotoxin contaminations at the aerobic starting conditions of ensilaging or after silo openings. The possible role of these organisms in mycotoxin elimination needs further research to explore their use.

Author Contributions

Conceptualization, I.P., and Z.G.; methodology, T.P., and Z.D.; investigation, C.A., and S.K.; writing—original draft preparation, C.A.; writing—review and editing, T.P.; visualization, C.A.; supervision, I.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded National Research, Development, and Innovation Fund of Hungary project no. 2018-1.2.1-NKP-2018-00002, project no. 2019-2.1.13-TÉT_IN-2020-00056, and project no. TKP2020-IKA-04 (TP).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Acknowledgments

The authors acknowledge Erika Sőrés and Csaba Kiss for technical support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, D.H.; Lee, K.D.; Choi, K.C. Role of LAB in silage fermentation: Effect on nutritional quality and organic acid production—An overview. AIMS Agric. Food 2021, 6, 216–234. [Google Scholar] [CrossRef]

- Lin, C.; Bolsen, K.K.; Brent, B.E.; Fung, D.Y.C. Epiphytic lactic acid bacteria succession during the pre-ensiling and ensiling periods of alfalfa and maize. J. Appl. Bacteriol. 1992, 73, 375–387. [Google Scholar] [CrossRef]

- Adesogan, A.T.; Newman, Y.C. Silage Harvesting, Storing, and Feeding. IFAS Extension, University of Florida, Gainesville. 2014. Available online: http://edis.ifas.ufl.edu/pdf/AG/AG180\AG180-Dz70s07cdf.pdf (accessed on 19 May 2017).

- Weidenbörner, M. Encyclopedia of Food Mycotoxins; Springer: Berlin/Heidelberg, Germany, 2001; p. 173. [Google Scholar]

- Rodrigues, I.; Handl, J.; Binder, E.M. Mycotoxin occurrence in commodities, feeds and feed ingredients sourced in the Middle East and Africa. Food Addit. Contam. Part B 2011, 4, 168–179. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Döll, S.; Danicke, S. The Fusarium toxins deoxynivalenol (DON) and zearalenone (ZON) in animal feeding. J. Prev. Vet. Med. 2011, 102, 132–145. [Google Scholar] [CrossRef] [PubMed]

- Keller, L.A.M.; Gonzáles Pereyra, M.L.; Keller, K.M.; Alonso, V.A.; Oliveira, A.A.; Almeida, T.X.; Barbosa, T.S.; Nunes, L.M.T.; Cavaglieri, L.R.; Rosa, C.A.R. Fungal and mycotoxins contamination in corn silage: Monitoring risk before and after fermentation. J. Stored Prod. Res. 2013, 52, 42–47. [Google Scholar] [CrossRef]

- El-Zawahri, M.; Moubasher, A.; Morad, M.; El-Kady, I. Mutagenic effect of aflatoxin B₁. Ann. Nutr. Aliment. 1977, 31, 859–866. [Google Scholar]

- Richard, E.; Heutte, N.; Sage, L.; Pottier, D.; Bouchart, V.; Lebailly, P.; Garon, D. Toxigenic fungi and mycotoxins in mature corn silage. Food Chem. Toxicol. 2007, 45, 2420–2425. [Google Scholar] [CrossRef] [PubMed]

- Gallo, A.; Ghilardelli, F.; Atzori, A.S.; Zara, S.; Novak, B.; Faas, J.; Fancello, F. Co-occurrence of regulated and emerging mycotoxins in corn silage: Relationships with fermentation quality and bacterial communities. Toxins 2021, 13, 232. [Google Scholar] [CrossRef]

- Zachariasova, M.; Dzuman, Z.; Veprikova, Z.; Hajkova, K.; Jiru, M.; Vaclavikova, M.; Zachariasova, A.; Pospichalova, M.; Florian, M.; Hajslova, J. Occurrence of multiple mycotoxins in European feedingstuffs, assessment of dietary intake by farm animals. Anim. Feed Sci. Technol. 2014, 193, 124–140. [Google Scholar] [CrossRef]

- Panasiuk, L.; Jedziniak, P.; Pietruszka, K.; Piatkowska, M.; Bocian, L. Frequency and levels of regulated and emerging mycotoxins in silage in Poland. Mycotoxin Res. 2019, 35, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Peles, F.; Sipos, P.; Kovács, S.; Győri, Z.; Pócsi, I.; Pusztahelyi, T. Biological control and mitigation of aflatoxin contamination in commodities. Toxins 2021, 13, 104. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Yu, M.; Dong, F.; Shi, J.; Xu, J. Esterase activity inspired selection and characterization of zearalenone degrading bacteria Bacillus pumilus ES-21. Food Control 2017, 77, 57–64. [Google Scholar] [CrossRef]

- ISO 4833-1 (2014); Microbiology of the Food Chain. Horizontal Method for the Enumeration of Microorganisms. Part 1: Colony count at 30 Degrees C by the Pour Plate Technique. International Standard Organization: Geneva, Switzerland, 2014.

- ISO 15214 (1998); Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Mesophilic Lactic Acid Bacteria—Colony-Count Technique at 30 °C. International Standard Organization: Geneva, Switzerland, 1998.

- ISO 7954 (1999); Microbiology. General Guidance for Enumeration of Yeasts and Moulds. Colony Count Technique at 25 °C. International Standard Organization: Geneva, Switzerland, 1999.

- ISO 6496 (1999); Animal Feeding Stuffs—Determination of Moisture and Other Volatile Matter Content. International Standard Organization: Geneva, Switzerland, 1999.

- Garon, D.; Richard, E.; Sage, L.; Bouchart, V.; Pottier, D.; Lebailly, P. Mycoflora and multimycotoxin detection in corn silage: Experimental study. J. Agric. Food Chem. 2006, 54, 3479–3484. [Google Scholar] [CrossRef]

- Ogunade, I.M.; Martinez-Tuppia, C.; Queiroz, O.C.M.; Jiang, Y.; Drouin, P.; Wu, F.; Vyas, D.; Adesogan, A.T. Silage review: Mycotoxins in silage: Occurrence, effects, prevention, and mitigation. J. Dairy Sci. 2018, 101, 4034–4059. [Google Scholar] [CrossRef] [PubMed]

- Jensen, T.; de Boevre, M.; Preußke, N.; de Saeger, S.; Birr, T.; Verreet, J.; Sönnichsen, F. Evaluation of high-resolution mass spectrometry for the quantitative analysis of mycotoxins in complex feed matrices. Toxins 2019, 11, 531. [Google Scholar] [CrossRef] [Green Version]

- Boudra, H.; Morgavi, D.P. Reduction in fusarium toxin levels in corn silage with low dry matter and storage time. J. Agric. Food Chem. 2008, 56, 4523–4528. [Google Scholar] [CrossRef]

- Driehuis, F.; Spanjer, M.C.; Scholten, J.M.; Te Giffel, M.C. Occurrence of mycotoxins in maize, grass and wheat silage for dairy cattle in the Netherlands. Food Addit. Contam. Part B Surveill. 2008, 1, 41–50. [Google Scholar] [CrossRef]

- Cavallarin, L.; Tabacco, E.; Antoniazzi, S.; Borreani, G. Aflatoxin accumulation in whole crop maize silage as a result of aerobic exposure. J. Sci. Food Agric. 2011, 91, 2419–2425. [Google Scholar] [CrossRef]

- Huerta-Treviño, A.; Dávila-Aviña, J.E.; Sánchez, E.; Heredia, N.; García, S. Occurrence of mycotoxins in alfalfa (Medicago sativa L.), sorghum [Sorghum bicolor (L.) Moench], and grass (Cenchrus ciliaris L.) retailed in the state of Nuevo León, México. Agrociencia 2016, 50, 825–836. [Google Scholar]

- Kosicki, R.; Błajet-Kosicka, A.; Grajewski, A.; Twaruzek, M. Multiannual mycotoxin survey in feed materials and feeding stuffs. Anim. Feed Sci. Technol. 2016, 215, 165–180. [Google Scholar] [CrossRef]

- Borreani, G.; Tabacco, E.; Schmidt, R.J.; Holmes, B.J.; Muck, R.E. Silage review: Factors affecting dry matter and quality losses in silages. J. Dairy Sci. 2018, 101, 3952–3979. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Porto, M.C.W.; Kuniyoshi, T.M.; Azevedo, P.O.S.; Vitolo, M.; Oliveira, R.P.S. Pediococcus spp.: An important genus of lactic acid bacteria and pediocin producers. Biotechnol. Adv. 2017, 35, 361–374. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Q.S.; Yang, P.; Wu, A.B.; Zuo, D.Y.; He, W.J.; Guo, M.W.; Huang, T.; Li, H.P.; Liao, Y.C. Variation in the microbiome, trichothecenes, and aflatoxins in stored wheat grains in Wuhan, China. Toxins 2018, 10, 171. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guan, H.; Shuai, Y.; Ran, Q.; Yan, Y.; Wang, X.; Li, D.; Cai, Y.; Zhang, X. The microbiome and metabolome of Napier grass silages prepared with screened lactic acid bacteria during ensiling and aerobic exposure. Anim. Feed Sci. Technol. 2020, 269, 114673. [Google Scholar] [CrossRef]

- Fabiszewska, A.U.; Zielińska, K.J.; Wróbel, B. Trends in designing microbial silage quality by biotechnological methods using lactic acid bacteria inoculants: A minireview. World J. Microbiol. Biotechnol. 2019, 35, 76. [Google Scholar] [CrossRef] [Green Version]

- Zielińska, K.J.; Fabiszewska, A.U.; Stefańska, I. Different aspects of Lactobacillus inoculants on the improvement of quality and safety of alfalfa silage. Chil. J. Agric. Res. 2015, 75, 298–306. [Google Scholar] [CrossRef] [Green Version]

- Queiroz, O.C.M.; Kim, S.C.; Adesogan, A.T. Effect of treatment with a mixture of bacteria and fibrolytic enzymes on the quality and safety of corn silage infested with different levels of rust. J. Dairy Sci. 2012, 95, 5285–5291. [Google Scholar] [CrossRef] [Green Version]

- Iglesias, C.; Bach, A.; Devant, M.; Adelantado, C.; Calvo, M.A. The effect of Lactobacillus buchneri inoculation on corn silages conservation. In Proceedings of the XI Jornadas sobre Producción Animal, Gobierno de Aragón, Servicio de Investigación Agroalimentaria, Zaragoza, Spain, 11–12 May 2005; pp. 611–613. [Google Scholar]

- Schnürer, J.; Magnusson, J. Antifungal lactic acid bacteria as biopreservatives. Trends Food Sci. Technol. 2005, 16, 70–78. [Google Scholar] [CrossRef]

- Dogi, C.A.; Fochesato, A.; Armando, R.; Pribull, B.; de Souza, M.M.; da Silva Coelho, I.; Araújo de Melo, D.; Dalcero, A.; Cavaglieri, L. Selection of lactic acid bacteria to promote an efficient silage fermentation capable of inhibiting the activity of Aspergillus parasiticus and Fusarium gramineraum and mycotoxin production. J. Appl. Microbiol. 2013, 114, 1650–1660. [Google Scholar] [CrossRef]

- Ragoubi, C.; Quintieri, L.; Greco, D.; Mehrez, A.; Maatouk, I.; D’Ascanio, V.; Landoulsi, A.; Avantaggiato, G. Mycotoxin removal by Lactobacillus spp. and their application in animal liquid feed. Toxins 2021, 13, 185. [Google Scholar] [CrossRef]

- Adebo, O.A.; Njobeh, P.B.; Mavumengwana, V. Degradation and detoxification of AFB1 by Staphylocococcus warneri, Sporosarcina sp. and Lysinibacillus fusiformis. Food Control 2016, 68, 92–96. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).