4.2. Variance Analysis

The quadratic polynomial regression model showing the effect of

A (RV),

B (IDTCU), and

C (VT) on CPR was established based on the data in

Table 3. The regression model is shown in Equation (14). The variance analysis of regression equation is shown in

Table 4.

According to the analysis results in

Table 4, the significance levels of the regression model for CPR were all less than 0.05, implying that the significance of the regression analysis model was excellent. The significance level of the lack of fit for the model was greater than 0.05, indicating that the model had good fitting degrees in the range of the experimental parameters. In addition, the coefficient of determination

R2 of the equations was 0.9828, demonstrating that more than 98% of the response values could be explained by the regression models. Therefore, the parameters of the chopping device could be preliminarily predicted by using the regression model of CPR.

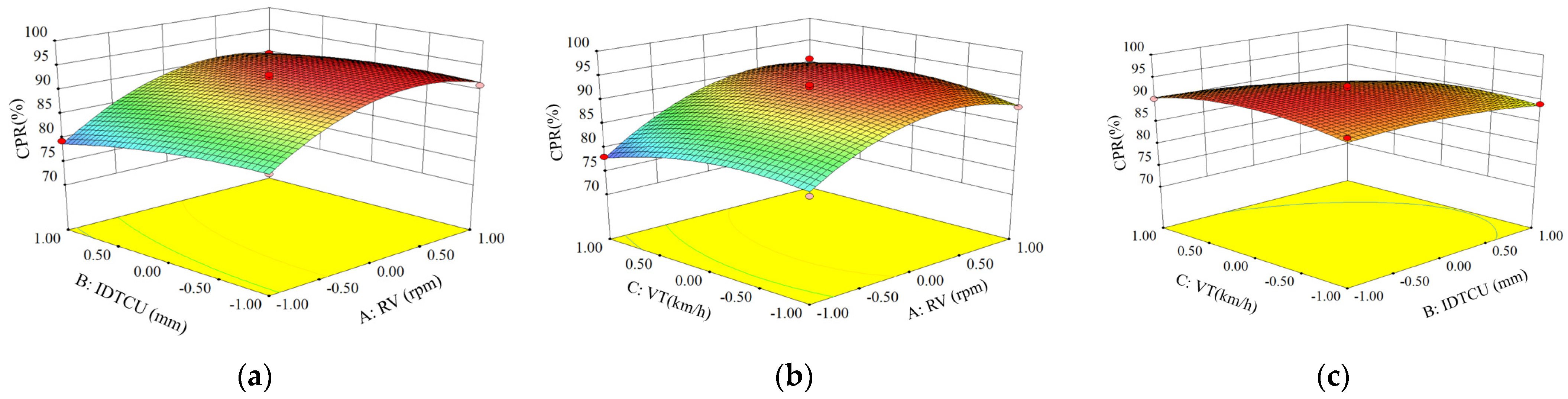

For the main effect, the rotational velocities of the two chopping units (factor

A: RV) had highly significant effects on CPR, while the installation distance of the two chopping units (factor

B: IDTCU) and the velocity of the tractor (factor

C: VT) had a significant effect on CPR. For the interaction effects, the interactive factor

AC had a significant effect on CPR. The interactive factor

AB,

BC had no significant effect on CPR (

Figure 13a,b). For the quadratic factor effect, the quadratic factor

A2 had a highly significant effect on CPR. The quadratic factors

B2 and

C2 had a significant effect on CPR. Consequently, the regression models were optimized so that the insignificant items were removed, while ensuring

p < 0.01 for the model and

p > 0.05 for the lack of fit, as shown in Equation (15).

The contribution value rate (

K) reflects the influence degree of a single parameter on the regression model such that a higher value of

K indicates a greater influence degree.

K is calculated as follows:

where

δ is the evaluation value of the regression term to

F,

F is each

F value of the regression term in the regression equation in

Table 4, and

KXj is the contribution rate of each parameter.

From

Table 4 and Equations (15)–(17), the order of the contribution rate of each parameter on CPR was the rotational velocities of the two chopping units (factor

A: RV) > the installation distance of the two chopping units (factor

B: IDTCU) > the velocity of the tractor (factor

C: VT). The calculation results are shown in

Table 5.

As shown in

Table 3 and

Table 4, when the values of factor

B (IDTCU) and factor

C (VT) are 600 mm (0) and 4 km/h (0), respectively, the CPR increased when the factor

A (RV) increased from 550 (−1) rpm to 680 (0.3) rpm. The maximum value of the CPR could be obtained when factor

A (RV) was around 680 rpm (0.3). The CPR decreased while factor

A (RV) increased when the value of factor

A (RV) was larger than 680 rpm (0.30). However, the decrease rate was slow. When the values of factor

A (RV) and factor

C (VT) are 650 rpm (0) and 4 km/h (0), respectively, the CPR increased when factor

B (IDTCU) increased from 480 mm (−1) to 600 (0) mm. The maximum value of CPR could be obtained when factor

B (IDTCU) was around 540 mm (−0.5). The CPR decreased while factor

A (RV) increased from 540 rpm (−0.5) to 720 (1) mm. When the values of factor

A (RV) and factor

B (IDTCU) are 650 rpm (0) and 600 mm (0), respectively, the CPR increased when factor

C (VT) increased from 3 (−1) km/h to 4 km/h (0). The maximum value of the CPR could be obtained when factor

C (VT) was around 4 km/h (0). The CPR decreased while factor

C (VT) increased from 4 km/h (0) to 5 km/h (1).

In terms of the above significance analysis, the law of influence of the interactive factors

AC on the CPR was studied. The interaction of the rotational velocities of the two chopping units (factor

A: RV) and the velocity of the tractor (factor

C: VT) on the CPR are shown in

Figure 13b. The effect of

AC on CPR is the same regardless of the value of factor

B. The CPR first increased and then decreased with an increase in the rotational velocities of the two chopping units at the same velocity as the tractor. The CPR will decrease when the rotational velocities of the two chopping units exceed a critical value. Besides, the CPR first increased and then decreased with an increase in the velocity of the tractor at the same rotational velocities of the two chopping units. The CPR will increase when the velocity of the tractor is increased within limits. When the velocity of the tractor exceeds the critical value, the CPR will decrease. Therefore, there was an optimal combination of the rotational velocities of the two chopping units and the velocity of the tractor that resulted in the maximum CPR. In summary, the maximum CPR can be obtained when the rotational velocities of the two chopping units are equal to 650 rpm, the installation distance of the two chopping units is equal to 600 mm, and the velocity of the tractor is equal to 4 km/h.

The quadratic polynomial regression model showing the effect of

A (RV),

B (IDTCU), and

A (VT) on SBD (0–50 mm), SBD (50–100 m), and SBD (100–150 mm) was established based on the data in

Table 6. The regression model is shown in Equations (18)–(20). The variance analysis of regression equations is shown in

Table 7.

According to the analysis results in

Table 7, the significance levels of the regression model for SBD (0–50 mm, 50–100 mm) were all less than 0.05, and the lack of fit for the model was greater than 0.05. Therefore, there was a significant relationship between three factors (

A: RV,

B: IDTCU, and

C: VT) and SBD (0–50 mm, 50–100 mm). In addition, the coefficient of determination

R2 of the equations were 0.9443 (0–50 mm) and 0.9365 (50–100 mm), demonstrating that more than 94% and 93% of the response values could be explained by the regression models. Therefore, the structural parameters and working parameters of the chopping device could be predicted and analyzed using the regression model of CPR. However, the significance levels of the regression model for SBD (100–150 mm) were all more than 0.05, implying that there was an insignificant relationship between three factors (

A: RV,

B: IDTCU, and

C: VT) and SBD (100–150 mm). For the main effect, the rotational velocities of the two chopping units (factor

A: RV) and the velocity of the tractor (factor

C: VT) had significant effects on SBD (0–50 mm, 50–100 mm). For the quadratic factor effect, the quadratic factor

A2 had a significant effect on SBD (0–50 mm, 50–100 mm).

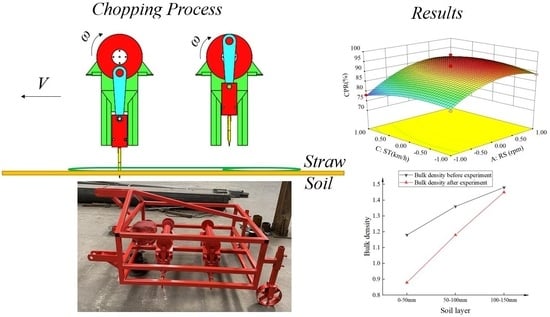

The values of SBD were 1.18 g/cm

3 (0–50 mm), 1.36 g/cm

3 (50–100 mm), and 1.48 g/cm

3 (100–150 mm), respectively, before the field test. As shown in

Table 6 and

Table 7, the values of SBD (0–50 mm and 50–100 mm) were obviously decreased after the device conducted chopping operations. However, the values of SBD (100–150 mm) did not change significantly. Furthermore, the minimum values of SBD (0–50 mm, 50–100 mm) were all obtained when the rotational velocities of the two chopping units were 750 rpm, the installation distance of the two chopping units was 600 mm, and the velocity of the tractor was 3 km/h. There was a positive relationship between factor

A: RV and SBD (0–50 mm, 50–100 mm). Meanwhile, there was a negative relationship between factor

C: VT and SBD (0–50 mm, 50–100 mm).

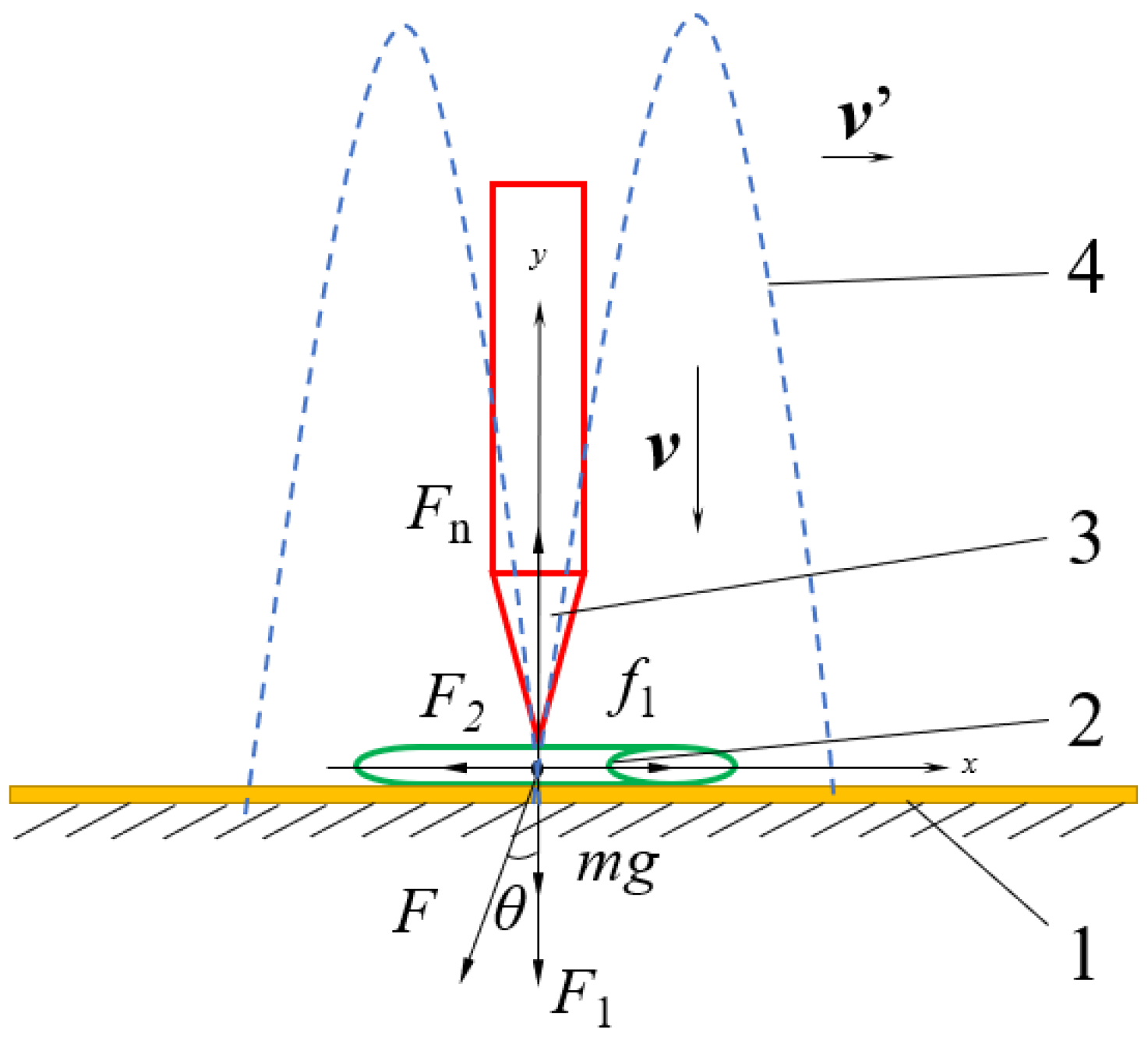

4.3. Effects on CPR and SBD

In the chopping process, under the ground support and chopping by the blades, the pith and rind are compressed; then, the rind is broken. With the high chopping velocity of the blade in the chopping process, the pith and rind are simultaneously chopped under a force, and the maize straw is finally cut off. When the velocity of the blade was increased, the chopping force on the straw from the chopping blade became larger. It makes the straw easier to be cut off, and then the CPR of maize straw is improved [

41]. When the rotational velocities of the two chopping units are increased, the velocity and acceleration of the chopping blades are also increased. However, when the rotational velocities of the two chopping units are too fast, the chopping force will become so large that makes the straw move irregularly. There will be a leakage chopping phenomenon. When the velocity of the tractor is increased, the fluidity of straw will be also increased, which makes the straw be chopped easier. However, when the velocity of the tractor is too high, the chopping blade will drive the straw to move forward, and the straw will be piled up and then the device will be blocked.

In the chopping process, the soil is disturbed by chopping blades. With the high rotational velocity of the blades in the chopping process, the soil was loosed under force, and it finally became fined [

18]. The depth of the chopping blade into the soil was 65.45 mm. Therefore, the soil was loose in the depth of 0 to 66 mm. The soil below 66 mm is not affected by the chopping blades. Therefore, the values of SBD (0–50 mm, 50–100 mm) were decreased sharply while the values of SBD (100–150 mm) did not change significantly. In this study, there was a positive correlation between factors

A: RV and SBD (0–50 mm, 50–100 mm). The reason may be that in the maize straw chopping process when RV was increased, the force and frequency from the chopping blade are also increased. Simultaneously, there was a negative correlation between factors

C: VT and SBD (0–50 mm, 50–100 mm). The reason may be that in the maize straw chopping process when VT was increased, the chopping times to soil is decreased per time.

4.4. Optimization and Verification

The analysis above indicates that the impact of various factors on the experimental index was inconsistent. To obtain the best value of CPR, and let the SBD (0–50 mm, 50–100 mm) decrease over 20% and 10%, respectively, a multi-objective optimization method combined with a restraint condition was used to optimize the regression equation. The restraint condition is given as:

Equation (21) was solved combined with restraint conditions, and the optimal parameter combination was as follows: the rotational velocity of the two chopping units was 610 rpm (−0.40), the installation distance of the two chopping units was 526.8 mm (−0.61), and the velocity of the tractor was 3.96 km/h (−0.04), while the CPR was 93.4%, the SBD values (0–50 mm, 50–100 mm, and 100–150 mm) were 0.90, 1.22, and 1.44, respectively.

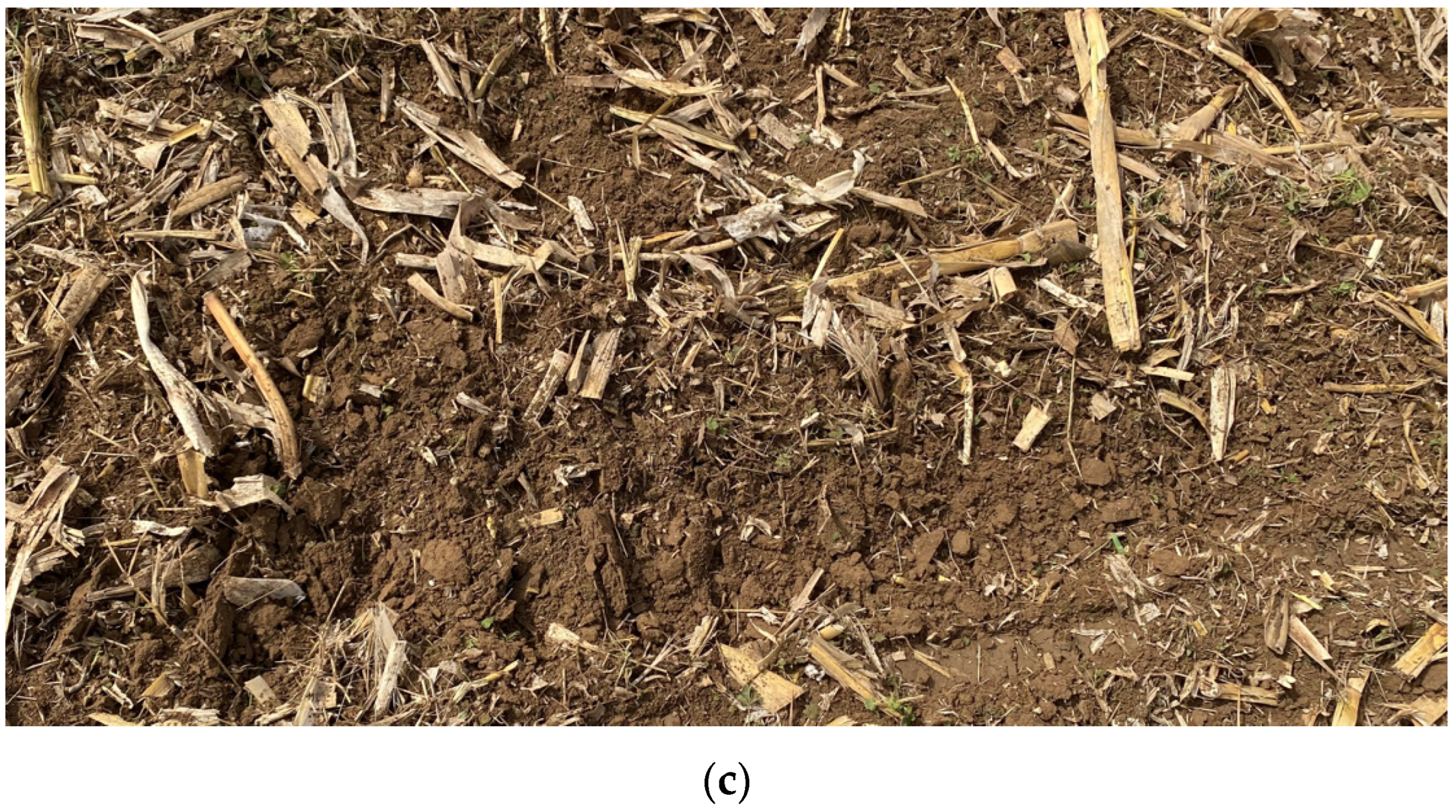

The field validation experiments were conducted to verify the reliability of the optimization results (

Figure 14). The site selection and data collection were the same as described in

Section 3. The rotational velocities of the two chopping units were both 610 rpm, the installation distance of the two chopping units was 550 mm, and the velocity of the tractor was 4 km/h; these were selected as test factors. The results showed that the CPR was 92.0% and the difference was less than 5%. The SBD values (0–50 mm, 50–100 mm, and 100–150 mm) were 0.88, 1.18, and 1.45, respectively. In 0–50 mm and 50–100 mm soil layers, the bulk density was decreased 25.42% and 13.24%, respectively (

Figure 15). Thus, the results of the study are considered acceptable.