The Eco-Efficiency of Castor Supply Chain: A Greek Case Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Sites

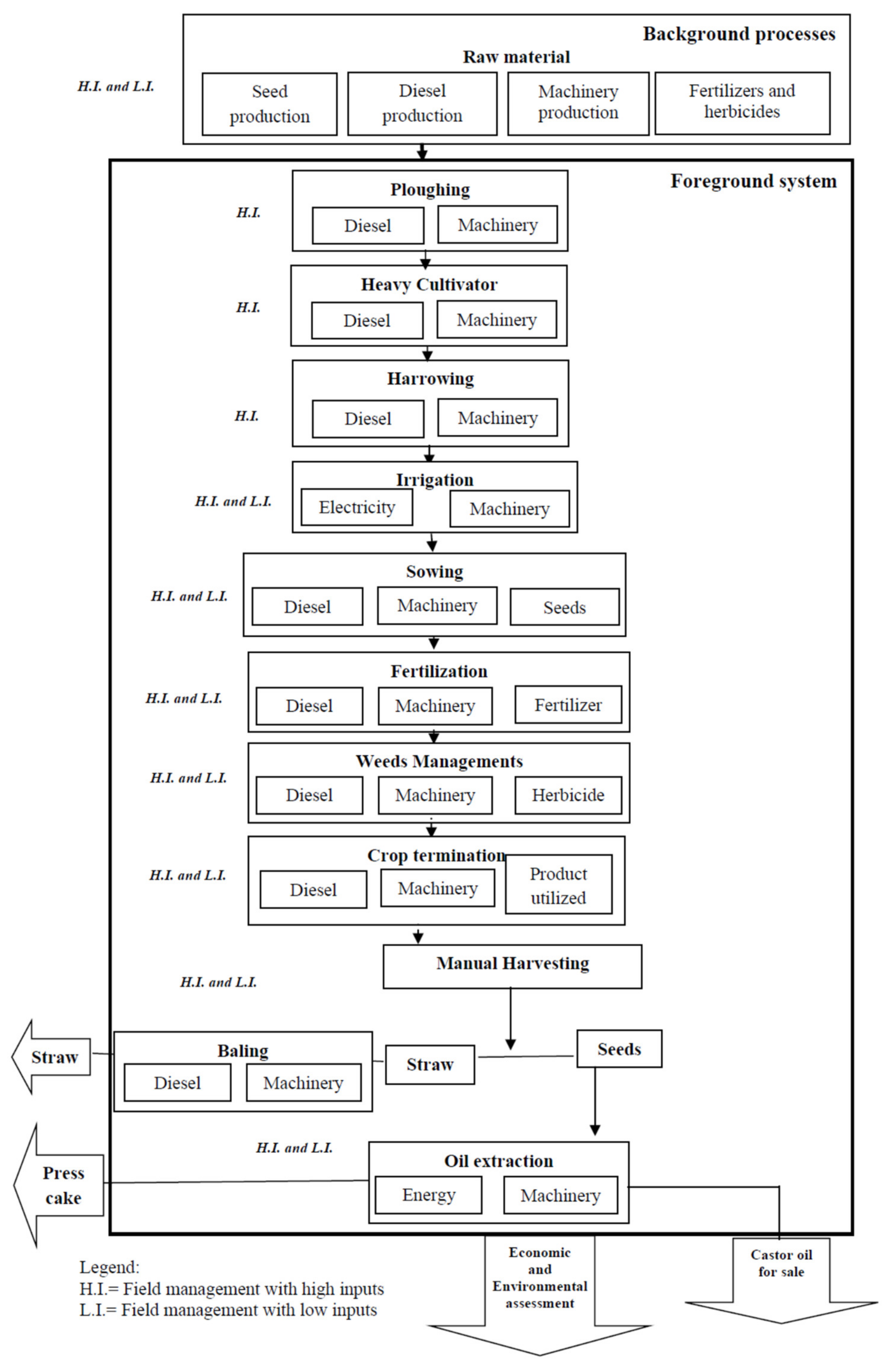

2.2. Life Cycle Assessment: The Steps

2.3. Life Cycle Costing

3. Results and Discussions

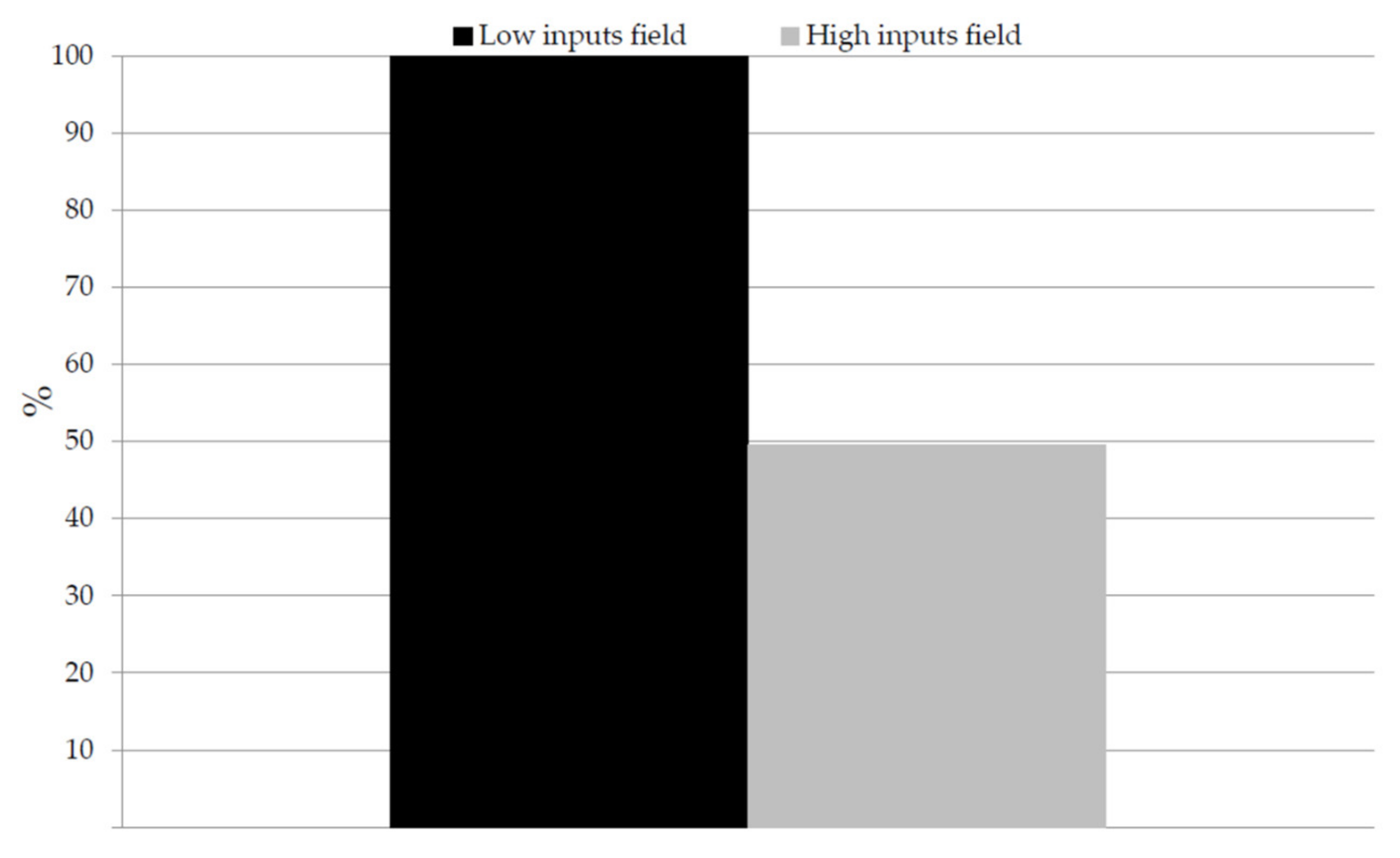

3.1. LCA

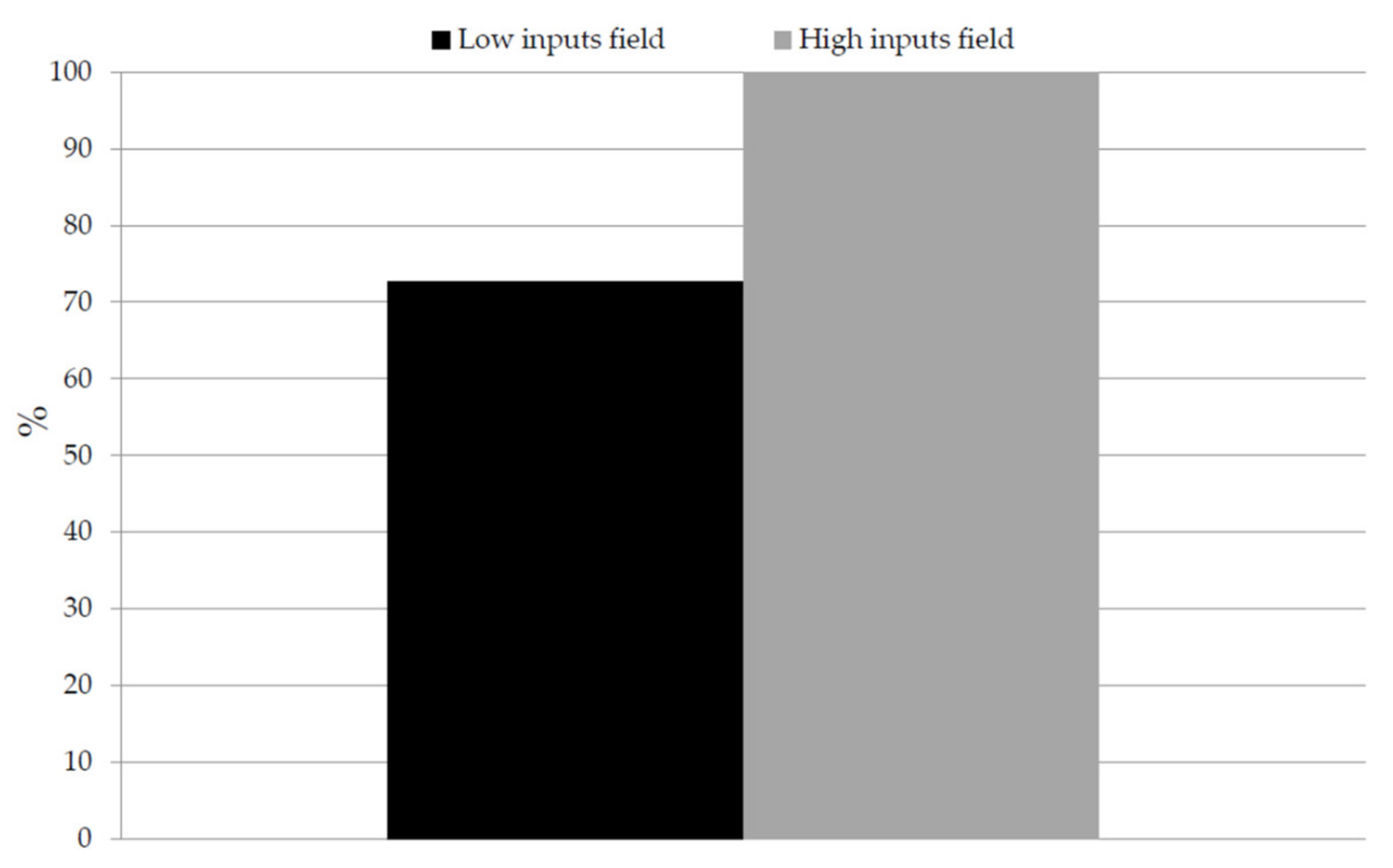

3.2. Economic Assessment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Doering, O.; Sorensen, A. The land that shapes and sus. In How to Feed World; Island Press: Washington, DC, USA, 2018; pp. 46–58. [Google Scholar]

- IEA. World Energy Outlook—Executive Summary. 2018; IEA: Paris, France, 2018. [Google Scholar]

- Pari, L.; Suardi, A.; Stefanoni, W.; Latterini, F.; Palmieri, N. Environmental and economic assessment of castor oil supply chain: A case study. Sustainability 2020, 12, 6339. [Google Scholar] [CrossRef]

- Searle, S.; Christensen, A. Decarbonization potential of electrofuels in the European Union. Retrieved Int. Counc. Clean Transp. 2018. Available online: https//www.theicct.org/publications/decarbonization-potential-electrofuels-eu (accessed on 1 December 2021).

- Zafeiriou, E.; Karelakis, C. Income volatility of energy crops: The case of rapeseed. J. Clean. Prod. 2016, 122, 113–120. [Google Scholar] [CrossRef]

- Bello, E.I.; Makanju, A. Production, characterization and evaluation of castor oil biodiesel as alternative fuel for diesel engines. J. Emerg. Trends Eng. Appl. Sci. 2011, 2, 525–530. [Google Scholar]

- Anjani, K. Castor genetic resources: A primary gene pool for exploitation. Ind. Crops Prod. 2012, 35, 1–14. [Google Scholar] [CrossRef]

- Falasca, S.L.; Ulberich, A.C.; Ulberich, E. Developing an agro-climatic zoning model to determine potential production areas for castor bean (Ricinus communis L.). Ind. Crops Prod. 2012, 40, 185–191. [Google Scholar] [CrossRef]

- Anjani, K.A.K. A re-evaluation of castor (Ricinus communis L.) as a crop plant. CAB Rev. Perspect. Agric. Veter-Sci. Nutr. Nat. Resour. 2014, 9, 1–21. [Google Scholar] [CrossRef]

- Gómez, J.J.M.; Saadaoui, E.; Cervantes, E. Seed shape of castor bean (Ricinus communis L.) grown in different regions of Tunisia. J. Agric. Ecol. Res. Int. 2016, 8, 1–11. [Google Scholar] [CrossRef]

- MAGIC. Available online: https://magic-h2020.eu/ (accessed on 1 December 2021).

- Campbell, D.N.; Rowland, D.L.; Schnell, R.W.; Ferrell, J.A.; Wilkie, A.C. Developing a castor (Ricinus communis L.) production system in Florida, US: Evaluating crop phenology and response to management. Ind. Crops Prod. 2014, 53, 217–227. [Google Scholar] [CrossRef]

- Mensah, M.B.; Awudza, J.A.M.; O’Brien, P. Castor oil: A suitable green source of capping agent for nanoparticle syntheses and facile surface functionalization. R. Soc. Open Sci. 2018, 5, 180824. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Severino, L.S.; Auld, D.L.; Baldanzi, M.; Cândido, M.J.D.; Chen, G.; Crosby, W.; Tan, D.; He, X.; Lakshmamma, P.; Lavanya, C.; et al. A review on the challenges for increased production of castor. Agron. J. 2012, 104, 853–880. [Google Scholar] [CrossRef] [Green Version]

- Pari, L.; Latterini, F.; Stefanoni, W. Herbaceous oil crops, a review on mechanical harvesting state of the art. Agriculture 2020, 10, 309. [Google Scholar] [CrossRef]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Karampinis, E.; Kougioumtzis, M.A.; Grammelis, P.; Pari, L. Machine Performance and Hog Fuel Quality Evaluation in Olive Tree Pruning Harvesting Conducted Using a Towed Shredder on Flat and Hilly Fields. Energies 2020, 13, 1713. [Google Scholar] [CrossRef] [Green Version]

- Stefanoni, W.; Latterini, F.; Ruiz, J.P.; Bergonzoli, S.; Palmieri, N.; Pari, L. Assessing the camelina (Camelina sativa (L.) Crantz) seed harvesting using a combine harvester: A case-study on the assessment of work performance and seed loss. Sustainability 2021, 13, 195. [Google Scholar] [CrossRef]

- Pari, L.; Suardi, A.; Stefanoni, W.; Latterini, F.; Palmieri, N. Economic and Environmental Assessment of Two Different Rain Water Harvesting Systems for Agriculture. Sustainability 2021, 13, 3871. [Google Scholar] [CrossRef]

- Zanetti, F.; Chieco, C.; Alexopoulou, E.; Vecchi, A.; Bertazza, G.; Monti, A. Comparison of new castor (Ricinus communis L.) genotypes in the mediterranean area and possible valorization of residual biomass for insect rearing. Ind. Crops Prod. 2017, 107, 581–587. [Google Scholar] [CrossRef]

- Alexopoulou, E.; Papatheohari, Y.; Zanetti, F.; Tsiotas, K.; Papamichael, I.; Christou, M.; Namatov, I.; Monti, A. Comparative studies on several castor (Ricinus communis L.) hybrids: Growth, yields, seed oil and biomass characterization. Ind. Crops Prod. 2015, 75, 8–13. [Google Scholar] [CrossRef]

- Ribeiro, P.R.; de Castro, R.D.; Fernandez, L.G. Chemical constituents of the oilseed crop Ricinus communis and their pharmacological activities: A review. Ind. Crops Prod. 2016, 91, 358–376. [Google Scholar] [CrossRef]

- Giray, G.; Catal, C. Design of a data management reference architecture for sustainable agriculture. Sustainability 2021, 13, 7309. [Google Scholar] [CrossRef]

- Meseguer-sánchez, V.; Gálvez-sánchez, F.J.; Molina-moreno, V. The Main Research Characteristics of the Development of the Concept of the Circular Economy Concept: A Global Analysis and the Future Agenda. Front. Environ. Sci. 2021, 9, 304. [Google Scholar] [CrossRef]

- Palmieri, N.; Suardi, A.; Alfano, V.; Pari, L. Circular economy model: Insights from a case study in south Italy. Sustainability 2020, 12, 3466. [Google Scholar] [CrossRef] [Green Version]

- Palmieri, N.; Forleo, M.B.; Suardi, A.; Coaloa, D.; Pari, L. Rapeseed for energy production: Environmental impacts and cultivation methods. Biomass Bioenergy 2014, 69, 1–11. [Google Scholar] [CrossRef]

- Reinhardt, J.; Hilgert, P.; Von Cossel, M. A Review of Industrial Crop Yield Performances on Unfavorable Soil Types. Agronomy 2021, 11, 2382. [Google Scholar] [CrossRef]

- Forleo, M.B.; Palmieri, N.; Suardi, A.; Coaloa, D.; Pari, L. The eco-efficiency of rapeseed and sunflower cultivation in Italy. Joining environmental and economic assessment. J. Clean. Prod. 2018, 172, 3138–3153. [Google Scholar] [CrossRef]

- Helling, R.K.; Russell, D.A. Use of life cycle assessment to characterize the environmental impacts of polyol production options. Green Chem. 2009, 11, 380–389. [Google Scholar] [CrossRef]

- Amouri, M.; Mohellebi, F.; Zaïd, T.A.; Aziza, M. Sustainability assessment of Ricinus communis biodiesel using LCA Approach. Clean Technol. Environ. Policy 2017, 19, 749–760. [Google Scholar] [CrossRef]

- Palmieri, N.; Suardi, A.; Pari, L. Italian consumers’ willingness to pay for eucalyptus firewood. Sustainability 2020, 12, 2629. [Google Scholar] [CrossRef] [Green Version]

- Palmieri, N.; Suardi, A.; Latterini, F.; Pari, L. The eucalyptus firewood: Understanding consumers’ behaviour and motivations. Agriculture 2020, 10, 512. [Google Scholar] [CrossRef]

- Cosculluela-Martínez, C.; Menéndez-Blanco, J.M. Assessment environmental sustainability and gender equality through crops livestock investment worldwide. Sustainability 2021, 13, 7388. [Google Scholar] [CrossRef]

- Adewale, C.; Reganold, J.P.; Higgins, S.; Evans, R.D.; Carpenter-Boggs, L. Agricultural carbon footprint is farm specific: Case study of two organic farms. J. Clean. Prod. 2019, 229, 795–805. [Google Scholar] [CrossRef]

- Mittal, J.P.; Dhawan, K.C.; Thyagraj, C.R. Energy scenario of castor crop under dryland agriculture of Andhra Pradesh. Energy Convers. Manag. 1991, 32, 425–430. [Google Scholar] [CrossRef]

- Bouyoucos, G.J. Hydrometer method improved for making particle size analyses of soils 1. Agron. J. 1962, 54, 464–465. [Google Scholar] [CrossRef]

- Walkley, A.; Black, I.A. An examination of the Degtjareff method for determining soil organic matter, and a proposed modification of the chromic acid titration method. Soil Sci. 1934, 37, 29–38. [Google Scholar] [CrossRef]

- Chakrabarty, S.; Islam, A.K.M.A.; Yaakob, Z.; Islam, A.K.M.M. Castor (Ricinus communis): An Underutilized Oil Crop in the South East Asia. In Agroecosystems–Very Complex Environmental Systems; IntechOpen: London, UK, 2021; p. 61. [Google Scholar]

- Yassoglou, N.; Tsadilas, C.; Kosmas, C. The soils of Greece; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- ISO (International Organization for Standardization). 14040:2006—Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO (International Organization for Standardization). 14044:2006—Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Ekvall, T.; Azapagic, A.; Finnveden, G.; Rydberg, T.; Weidema, B.P.; Zamagni, A. Attributional and consequential LCA in the ILCD handbook. Int. J. Life Cycle Assess. 2016, 21, 293–296. [Google Scholar] [CrossRef]

- Cellura, M.; Longo, S.; Mistretta, M. Sensitivity analysis to quantify uncertainty in Life Cycle Assessment: The case study of an Italian tile. Renew. Sustain. Energy Rev. 2011, 15, 4697–4705. [Google Scholar] [CrossRef]

- Plassmann, K.; Edwards-Jones, G. Carbon Footprinting and Carbon Labelling of Food Products; Woodhead Publishing Limited: Sawston, UK, 2010. [Google Scholar]

- Brandão, M.; Clift, R.; Basson, L. A life-cycle approach to characterising environmental and economic impacts of multifunctional land-use systems: An integrated assessment in the UK. Sustainability 2010, 2, 3747–3776. [Google Scholar] [CrossRef] [Green Version]

- Dimian, A.C.; Iancu, P.; Plesu, V.; Bonet-Ruiz, A.E.; Bonet-Ruiz, J. Castor oil biorefinery: Conceptual process design, simulation and economic analysis. Chem. Eng. Res. Des. 2019, 141, 198–219. [Google Scholar] [CrossRef]

- Il Sole24ore mercati. Available online: https://mercati.ilsole24ore.com/ (accessed on 1 December 2021).

- Li, S.; Huang, B.; Zhao, F.; Lu, Z.; Wang, X.; Chen, X.; Chen, Y. Environmental impact assessment of agricultural production in Chongming ecological island. Int. J. Life Cycle Assess. 2019, 24, 1937–1947. [Google Scholar] [CrossRef]

- Chatzisymeon, E.; Foteinis, S.; Borthwick, A.G.L. Life cycle assessment of the environmental performance of conventional and organic methods of open field pepper cultivation system. Int. J. Life Cycle Assess. 2017, 22, 896–908. [Google Scholar] [CrossRef] [Green Version]

- Requena, J.F.S.; Guimaraes, A.C.; Alpera, S.Q.; Gangas, E.R.; Hernandez-Navarro, S.; Gracia, L.M.N.; Martin-Gil, J.; Cuesta, H.F. Life Cycle Assessment (LCA) of the biofuel production process from sunflower oil, rapeseed oil and soybean oil. Fuel Process. Technol. 2011, 92, 190–199. [Google Scholar] [CrossRef]

- Cherubini, F.; Bird, N.D.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy-and greenhouse gas-based LCA of biofuel and bioenergy systems: Key issues, ranges and recommendations. Resour. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- Adler, P.R.; Grosso, S.J.D.; Parton, W.J. Life-cycle assessment of net greenhouse-gas flux for bioenergy cropping systems. Ecol. Appl. 2007, 17, 675–691. [Google Scholar] [CrossRef] [PubMed]

- Malça, J.; Coelho, A.; Freire, F. Environmental life-cycle assessment of rapeseed-based biodiesel: Alternative cultivation systems and locations. Appl. Energy 2014, 114, 837–844. [Google Scholar] [CrossRef]

| Phases | Product and By-Products | Allocation |

|---|---|---|

| Agricultural phases | Husks with seed | 95.84% |

| Straw | 4.16% | |

| Total | 100.00% | |

| Oil extraction phase | Castor oil | 99.93% |

| Castor mill | 0.07% | |

| Total | 100.00% | |

| Agricultural Operation | Plough. | Heavy Cultivator | Harr. | Irrigation | Sow. | Fert. | Weeds Manag | Crop Termination | Manual Harv. | Baling | Oil Extrac. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tractor power (kW) | - | - | - | 23 | 56.4 | 56.4 | 56.4 | 56.4 | - | 82.1 | 3.00 |

| Tractor weight (kg) | - | - | - | 120 | 3100 | 3100 | 3100 | 3100 | - | 4500 | 1900 |

| Fuel or electricity consumption (l ha−1) | - | - | - | 4366 kWh | 1.32 | 1.32 | 9.46 | 1.18 | - | 3.5 | - |

| Lubricant consumption (l ha−1) | - | - | - | - | 0.05 | 0.06 | 0.04 | 0.04 | - | 0.07 | - |

| Lifetime (h ha−1) | - | - | - | 12,000 | 12,000 | 12,000 | 12,000 | 12,000 | - | 16,000 | - |

| Machineries used (type) | - | - | - | - | Monosem NX2*(4rows) | Centrifugal spread 12 m | Boom type sprayer (10 m) | Boom type sprayer (10 m) | - | Forklift and Platform 2 ton | - |

| Machineries power (kW) | - | - | - | - | 30.4 | 12.4 | 10.2 | 10.2 | - | - | - |

| Weight Machineries (kg) | - | - | - | - | 1350 | 165 | 130 | 130 | - | 1550 | - |

| Lifetime (h) | - | - | - | - | 2000 | 1200 | 1500 | 1500 | - | 3000 | - |

| Product utilized (type) | - | - | - | Water | Seeds | 13-46-0 (N-P-K) | Glyphosate 36EC | Diquat | - | - | - |

| Quantity (kg ha−1) | - | - | - | 5,100,000 | 19.3 | 270 | 5.00 | 5.00 | - | - | - |

| Agricultural Operation | Plough. | Heavy Cultivator | Harr. | Irrigation | Sow. | Fert. | Weeds Manag | Crop Termination | Manual Harv. | Baling | Oil Extrac |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tractor power (kW) | 82.1 | 82.1 | 82.1 | 23 | 56.4 | 56.4 | 56.4 | 56.4 | - | 82.1 | 3.00 |

| Tractor weight (kg) | 4500 | 4500 | 4500 | 120 | 3100 | 3100 | 3100 | 3100 | - | 4500 | 1900 |

| Fuel or electricity consumption (l ha−1) | 49.2 | 49.2 | 49.2 | 4366 kWh | 1.32 | 1.32 | 9.46 | 1.18 | - | 3.5 | - |

| Lubricant consumption (l ha−1) | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.06 | 0.04 | 0.04 | - | 0.07 | - |

| Lifetime (h ha−1) | 16,000 | 16,000 | 16,000 | 12,000 | 12,000 | 12,000 | 12,000 | 12,000 | - | 16,000 | - |

| Machineries used (type) | Moaldboard plough | Tine cultivator (heavy type) | Tandem disk harrow | - | Gasperdo (4 rows) | Centrifugal spread 12 m | Boom type sprayer (10 m) | Boom type sprayer (10 m) | - | Forkift and Platform 2 ton | - |

| Machineries power (kW) | 59.9 | 59.1 | 46.0 | - | 14.1 | 12.4 | 10.2 | 10.2 | - | - | - |

| Weight machineries (kg) | 850 | 450 | 1050 | - | 740 | 165 | 130 | 130 | - | 5500 | - |

| Lifetime (h) | 2000 | 2000 | 2000 | - | 2000 | 1200 | 1500 | 1500 | - | 3000 | - |

| Product utilized (type) | - | - | - | Water | Seeds | 11-15-15 (N-P-K) | Glyphosate 36EC | Diquat | - | - | - |

| Quantity (kg ha−1) | - | - | - | 6,800,000 | 19.3 | 515 | 5.00 | 5.00 | - | - | - |

| Fields Management | ||

|---|---|---|

| Costs (EUR/Year) | Low Inputs | High Inputs |

| Ploughing | - | 70.00 |

| Heavy Cultivator | - | 60.00 |

| Harrowing | - | 40.00 |

| Irrigation | 200.00 | 200.00 |

| Sowing | 30.00 | 30.00 |

| Fertilization | 20.00 | 20.00 |

| Weeds Management | 40.00 | 30.00 |

| Crop termination | 35.00 | 20.00 |

| Manual harvesting | 150.00 | 150.00 |

| Baling | 90.00 | 90.00 |

| Oil extraction | 100.00 | 100.00 |

| Revenues (EUR/year) | ||

| Castor oil for sales | 782.46 | 2178.00 |

| Fields Management | ||

|---|---|---|

| Costs (EUR/Year) | Low Inputs | High Inputs |

| Ploughing | - | 19.02 |

| Heavy Cultivator | - | 16.30 |

| Harrowing | - | 10.87 |

| Irrigation | 151.28 | 54.35 |

| Sowing | 22.69 | 8.15 |

| Fertilization | 15.03 | 5.43 |

| Weeds Management | 15.12 | 8.15 |

| Crop termination | 26.47 | 5.43 |

| Manual harvesting | 113.46 | 40.76 |

| Baling | 68.07 | 24.46 |

| Oil extraction | 80.58 | 27.17 |

| Total costs (EUR/Mg) | 492.70 | 220.09 |

| Revenues (EUR/Mg) | ||

| Castor oil for sales (EUR/Mg) | 591.88 | 591.88 |

| Total revenues (EUR/Mg) | 591.88 | 591.88 |

| Gross margin (EUR/Mg) | 99.18 | 371.79 |

| Units | Low Inputs | High Inputs | |

|---|---|---|---|

| Gross Margin | (EUR/FU) | 99.18 | 371.79 |

| GWP | (kg CO2 eq/1Mg) | 667 | 326 |

| Total eco-efficiency | (EUR/kg CO2 eq) | 0.14 | 1.14 |

| Sensitivity analysis | |||

| Gross Margin | (EUR/FU) | 99.18 | 371.79 |

| GWP | (kg CO2 eq/1Ha) | 878 | 1210 |

| Gross Margin/GWP ratio per 1 Ha | (EUR/kg CO2 eq) | 0.11 | 0.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pari, L.; Alexopoulou, E.; Stefanoni, W.; Latterini, F.; Cavalaris, C.; Palmieri, N. The Eco-Efficiency of Castor Supply Chain: A Greek Case Study. Agriculture 2022, 12, 206. https://doi.org/10.3390/agriculture12020206

Pari L, Alexopoulou E, Stefanoni W, Latterini F, Cavalaris C, Palmieri N. The Eco-Efficiency of Castor Supply Chain: A Greek Case Study. Agriculture. 2022; 12(2):206. https://doi.org/10.3390/agriculture12020206

Chicago/Turabian StylePari, Luigi, Efthymia Alexopoulou, Walter Stefanoni, Francesco Latterini, Chris Cavalaris, and Nadia Palmieri. 2022. "The Eco-Efficiency of Castor Supply Chain: A Greek Case Study" Agriculture 12, no. 2: 206. https://doi.org/10.3390/agriculture12020206

APA StylePari, L., Alexopoulou, E., Stefanoni, W., Latterini, F., Cavalaris, C., & Palmieri, N. (2022). The Eco-Efficiency of Castor Supply Chain: A Greek Case Study. Agriculture, 12(2), 206. https://doi.org/10.3390/agriculture12020206