Experimental Study on Water Distribution and Droplet Kinetic Energy Intensity from Non-Circular Nozzles with Different Aspect Ratios

Abstract

1. Introduction

2. Materials and Methods

2.1. Non-Circular Nozzle Design

2.2. Experimental Equipment

2.3. Test Method

2.4. Data Processing

2.4.1. Coefficient of Variation

2.4.2. Kinetic Energy of Droplets per Unit Volume

2.4.3. Kinetic Energy Intensity

3. Results and Analysis

3.1. Water Discrete Degree Analysis

3.2. Radial Water Application Profiles

3.3. Water Distribution Uniformity Coefficient for Combined Sprinkler Irrigation

3.4. Kinetic Energy Intensity Distribution of Single Nozzles

3.5. Droplet Diameter Distribution

3.5.1. Radial Distribution of Droplet Diameter under Different Pressures

3.5.2. Radial Distribution of Droplet Diameter under Different Aspect Ratios

3.6. Droplet Velocity Distribution

3.6.1. Droplet Velocity Distribution of Nozzles with Different Shapes

3.6.2. Droplet Velocity Distribution under Different Aspect Ratios

3.7. Kinetic Energy per Unit Volume Radial Profiles

3.8. Uniformity Coefficient of Kinetic Energy Intensity Distribution of Combined Sprinkler

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J. Study on the atomizing condition of non-circular nozzles. J. Hydraul. Eng. 1991, 3, 28–32+64. [Google Scholar]

- Chen, C.; Yuan, S.; Li, H.; Wang, C. Effect of Non-circle Nozzle on Hydraulic Performance of Impact Variable-rate Sprinkler. Trans. Chin. Soc. Agric. Mach. 2011, 42, 111–115. [Google Scholar]

- Bao, Y.; Liu, J.; Liu, X.; Tian, K.; Zhang, Q. Experimental study on the effects of pressure on water distribution model of low-pressure sprinkler. J. Drain. Irrig. Mach. Eng. 2016, 34, 81–85. [Google Scholar]

- Yan, H.J.; Bai, G.; He, J.Q.; Lin, G. Influence of Droplet Kinetic Energy Flux Density from Fixed Spray-Plate Sprinklers on Soil Infiltration, Runoff and Sediment Yield. Biosyst. Eng. 2011, 110, 213–221. [Google Scholar] [CrossRef]

- Shi, Y.; Zhu, X.; Hu, G.; Zhang, A.; Li, J. Influence of different working conditions on water distribution in sprinkler irrigation. J. Drain. Irrig. Mach. Eng. 2021, 39, 318–324. [Google Scholar]

- Liu, H.; Kang, Y. Effects of Droplets Kinetic Energy on Soil Infiltration Rate and Surface Runoff under Sprinkler Irrigation. J. Irrig. Drain. 2002, 21, 71–74+79. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Xiang, Q.; Chen, C. Experimental study on breakup length and range of free jet of non-circle jet nozzle. J. Irrig. Drain. 2014, 33, 149–153. [Google Scholar] [CrossRef]

- William, E. Hart Sprinkler Distribution Analysis With a Digital Computer. Trans. ASAE 1963, 6, 0206–0208. [Google Scholar] [CrossRef]

- Yuan, S.; Li, H.; Wang, X. Status, problems, trends and suggestions for water-saving irrigation equipment in China. J. Drain. Irrig. Mach. Eng. 2015, 33, 78–92. [Google Scholar]

- Bubenzer, G.D.; Jones, B.A., Jr. Drop Size and Impact Velocity Effects on the Detachment of Soils Under Simulated Rainfall. Trans. ASAE 1971, 14, 0625–0628. [Google Scholar] [CrossRef]

- Mohammed, D.; Kohl, R.A. Infiltration Response to Kinetic Energy. Trans. ASAE 1987, 30, 0108–0111. [Google Scholar] [CrossRef]

- Christiansen, J.E. Irrigation by Sprinkling; University of California: Berkeley, CA, USA, 1942; Volume 4. [Google Scholar]

- Abd El-Wahed, M.H.; Medici, M.; Lorenzini, G. Harvesting Water in a Center Pivot Irrigation System: Evaluation of Distribution Uniformity with Varying Operating Parameters. J. Eng. Thermophys. 2015, 24, 143–151. [Google Scholar] [CrossRef]

- Li, Y.; Liu, J. Prospects for development of water-saving irrigation equipment and technology in China. J. Drain. Irrig. Mach. Eng. 2020, 38, 738–742. [Google Scholar]

- Wu, P.; Zhu, D.; Lv, H.; Zhang, L. Hydraulics problems in farmland irrigation. J. Drain. Irrig. Mach. Eng. 2012, 30, 726–732. [Google Scholar]

- Tu, Q.; Li, H.; Wang, X.; Li, Y.; Jiang, Y. Comparison and selection of small-scale irrigation machines with multiple sprinklers based on grey relational analysis. J. Jiangsu Univ. 2014, 35, 656–662. [Google Scholar]

- Xu, H.; Gong, S.; Jia, R.; Liu, X. Study on droplet size distribution of ZY sprinkler head. J. Hydraul. Eng. 2010, 41, 1416–1422. [Google Scholar] [CrossRef]

- Gong, X.; Zhu, D.; Zhang, L.; Zhang, Y.; Ge, M.; Yang, W. Drop Size Distribution of Fixed Spray-plate Sprinklers with Two-dimensional Video Disdrometer. Trans. Chin. Soc. Agric. Mach. 2014, 45, 128–133+148. [Google Scholar]

- Lorenzini, G. Water droplet dynamics and evaporation in an irrigation spray. Trans. ASABE 2006, 49, 545–549. [Google Scholar] [CrossRef]

- Ouazaa, S.; Burguete, J.; Paniagua, M.P.; Salvador, R.; Zapata, N. Simulating Water Distribution Patterns for Fixed Spray Plate Sprinkler Using the Ballistic Theory. Span. J. Agric. Res. 2014, 12, 850. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, X.; Liu, J.; Yuan, S.; Bao, Y. Droplet kinetic energy distribution regulation of complete fluidic sprinkler. Trans. Chin. Soc. Agric. Eng. 2015, 31, 26–31. [Google Scholar]

- Li, J.; Ma, F. Effect of nozzle shape on the spraydrop kinetic energy from sprinklers. J. Irrig. Drain. 1997, 16, 3–8. [Google Scholar]

- Chen, D. Shape and structure of special nozzle. Water Sav. Irrig. 1982, 3, 37. [Google Scholar]

- Li, Y.; Liu, J.; Guo, Z.; Liu, X.; Lou, Y. Research and development of hydraulic performance of energy-saving special-shaped nozzle. J. Irrig. Drain. 1990, 2, 43–50. [Google Scholar] [CrossRef]

- Wei, Y.; Yuan, S.; Li, H.; Xiang, Q.; Chen, C. Hydraulic Performance Experiment of the Variable-rate Sprinkler with Non-circle Nozzle. Trans. Chin. Soc. Agric. Mach. 2011, 42, 70–74. [Google Scholar]

- Li, D.; Lu, X.; Zhao, X. Experimental Study on Low Pressure Jet Characteristic of the Non-circle Jet Nozzle. Light Ind. Mach. 2006, 24, 18–20. [Google Scholar]

- Zhou, X.; Li, H.; Jiang, Y. Study on water distribution uniformity of non-circular nozzles at low pressure. J. Drain. Irrig. Mach. Eng. 2017, 35, 448–453. [Google Scholar]

- Jiang, Y.; Li, H.; Hua, L.; Zhang, D.; Issaka, Z. Experimental Study on Jet Breakup Morphologies and Jet Characteristic Parameters of Non-Circular Nozzles under Low-Intermediate Pressures. Appl. Eng. Agric. 2019, 35, 617–632. [Google Scholar] [CrossRef]

- Liu, X. Droplets Distribution Characteristic Study on Complete Fluidic Sprinkler. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2016. [Google Scholar]

- Zhu, X.; Shi, Y.; Hu, G.; Liu, J. Dynamic Simulation and Test of Water Distribution of Fluidic Sprinkler. J. Irrig. Drain. 2020, 39, 74–83. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, G.; Liu, J.; Jiang, J.; Tian, K. Droplets distribution research of impact sprinkler based on Laser Precipitation Monitor. J. Drain. Irrig. Mach. Eng. 2015, 33, 908–914. [Google Scholar]

- Liu, J.; Yuan, S.; Li, H.; Zhu, X. Analysis and Experiment on Influencing Factors of Range and Spraying Uniformity for Complete Fluidic Sprinkler. Trans. Chin. Soc. Agric. Mach. 2008, 39, 51–54. [Google Scholar]

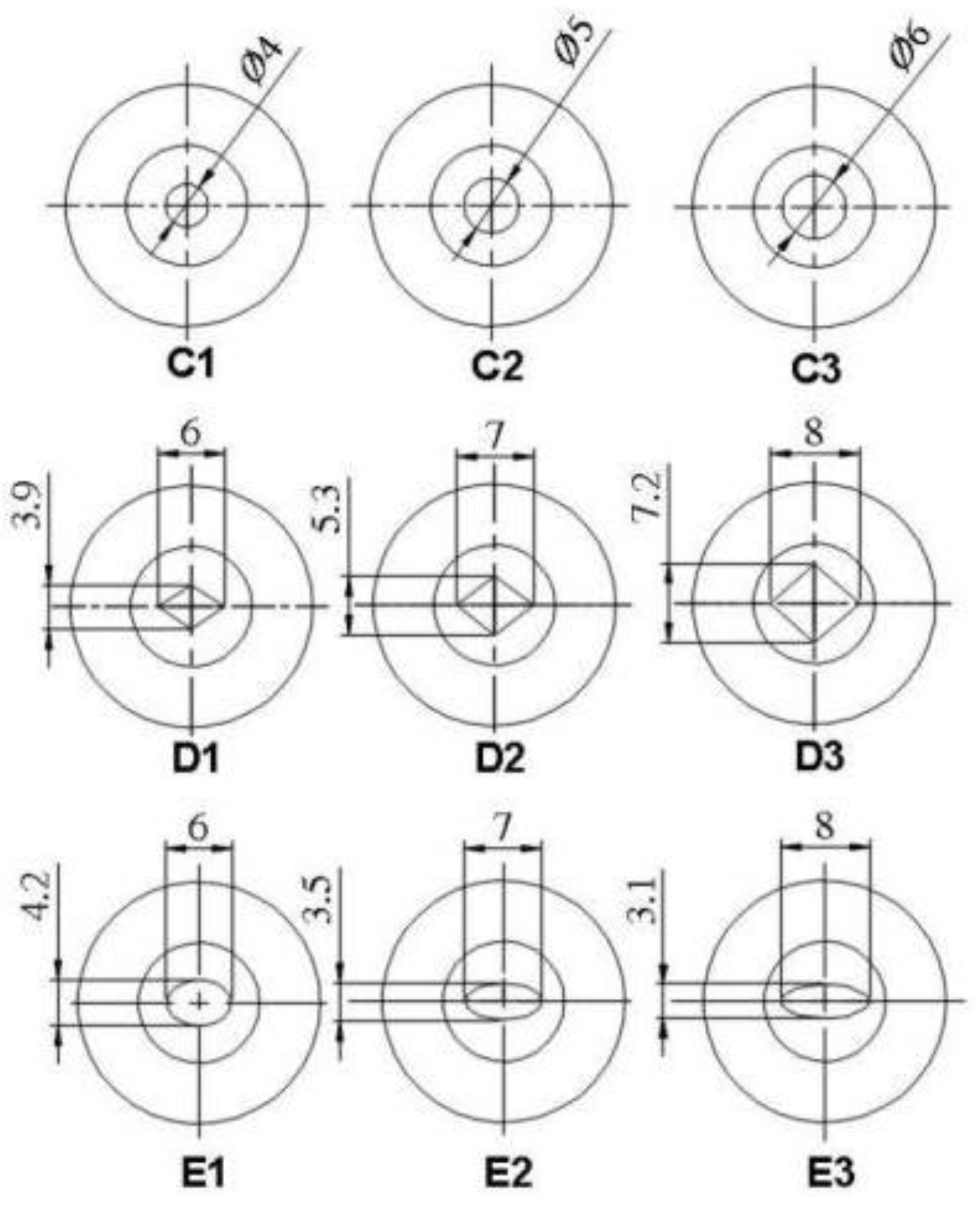

| Inlet Cone Angle | Shape | Number | Outlet Diameter | Long Axis | Minor Axis | Aspect Ratio (L/D) |

|---|---|---|---|---|---|---|

| 45° | Circle | C1 | 4 | / | / | / |

| C2 | 5 | / | / | / | ||

| C3 | 6 | / | / | / | ||

| Diamond | D1 | 4 | 6 | 3.9 | 1.54 | |

| D2 | 5 | 7 | 5.3 | 1.32 | ||

| D3 | 6 | 8 | 7.2 | 1.11 | ||

| Ellipse | E1 | 5 | 6 | 4.2 | 1.43 | |

| E2 | 5 | 7 | 3.5 | 2 | ||

| E3 | 5 | 8 | 3.1 | 2.58 |

| Outlet Diameter | Number | 150 kPa | 200 kPa | 250 kPa | 300 kPa | 350 kPa | 400 kPa |

|---|---|---|---|---|---|---|---|

| 5 mm | C2 | 1.067 | 1.234 | 1.385 | 1.516 | 1.636 | 1.747 |

| D2 | 1.036 | 1.198 | 1.347 | 1.476 | 1.601 | 1.709 | |

| Difference | 0.031 | 0.036 | 0.038 | 0.04 | 0.035 | 0.038 | |

| Error | 2.91% | 2.92% | 2.74% | 2.64% | 2.14% | 2.18% | |

| E1 | 1.035 | 1.207 | 1.353 | 1.485 | 1.604 | 1.715 | |

| Difference | 0.032 | 0.027 | 0.032 | 0.031 | 0.032 | 0.032 | |

| Error | 3.00% | 2.19% | 2.31% | 2.04% | 1.96% | 1.83% | |

| E2 | 1.075 | 1.261 | 1.411 | 1.554 | 1.673 | 1.79 | |

| Difference | 0.008 | 0.027 | 0.026 | 0.038 | 0.037 | 0.043 | |

| Error | 0.75% | 2.19% | 1.88% | 2.51% | 2.26% | 2.46% | |

| E3 | 1.064 | 1.237 | 1.386 | 1.523 | 1.642 | 1.755 | |

| Difference | 0.003 | 0.003 | 0.001 | 0.007 | 0.006 | 0.008 | |

| Error | 0.28% | 0.24% | 0.07% | 0.46% | 0.37% | 0.46% | |

| 4 mm | C1 | 0.693 | 0.81 | 0.898 | 0.981 | 1.067 | 1.142 |

| D1 | 0.675 | 0.78 | 0.88 | 0.975 | 1.052 | 1.131 | |

| Difference | 0.018 | 0.03 | 0.018 | 0.006 | 0.015 | 0.011 | |

| Error | 2.60% | 3.70% | 2.00% | 0.61% | 1.41% | 0.96% | |

| 6 mm | C3 | 1.461 | 1.694 | 1.895 | 2.079 | 2.247 | 2.401 |

| D3 | 1.487 | 1.726 | 1.926 | 2.118 | 2.288 | 2.453 | |

| Difference | 0.026 | 0.032 | 0.031 | 0.039 | 0.041 | 0.052 | |

| Error | 1.78% | 1.89% | 1.64% | 1.88% | 1.82% | 2.17% |

| Nozzle Shape (Outlet Diameter 5 mm, Inlet Cone Angle 45°) | Working Pressure (kPa) | ||||

|---|---|---|---|---|---|

| 100 | 150 | 200 | 250 | 300 | |

| Circle C2 | 1.11 | 0.79 | 0.59 | / | / |

| Diamond D2 | 0.30 | 0.37 | 0.36 | 0.34 | 0.35 |

| Ellipse E1 | 0.40 | 0.47 | 0.44 | 0.26 | 0.37 |

| Nozzle Number | Working Pressure (kPa) | ||||

|---|---|---|---|---|---|

| 100 | 150 | 200 | 250 | 300 | |

| D1 (L/D = 1.54) | 0.82 | 0.54 | 0.46 | 0.37 | 0.36 |

| D2 (L/D = 1.32) | 0.30 | 0.37 | 0.36 | 0.34 | 0.35 |

| D3 (L/D = 1.11) | 0.68 | 0.49 | 0.43 | / | / |

| Nozzle Number | Working Pressure (kPa) | ||||

|---|---|---|---|---|---|

| 100 | 150 | 200 | 250 | 300 | |

| E1 (L/D = 1.43) | 0.40 | 0.47 | 0.44 | 0.26 | 0.37 |

| E2 (L/D = 2.00) | 0.76 | 0.50 | 0.58 | 0.48 | 0.43 |

| E3 (L/D = 2.58) | 0.55 | 0.47 | 0.48 | 0.43 | 0.42 |

| Shape | Number | Pressure (kPa) | 1.0 R | 1.1 R | 1.2 R | 1.3 R | 1.4 R |

|---|---|---|---|---|---|---|---|

| Circle | C2 | 100 | 54.55 | 37.87 | 25.76 | 29.37 | 19.61 |

| 150 | 58.59 | 58.25 | 50.11 | 37.32 | 26.49 | ||

| 200 | 65.26 | 61.75 | 56.92 | 46.71 | 36.15 | ||

| Diamond | D1 | 100 | 47.34 | 45.92 | 27.04 | 20.42 | 27.61 |

| 150 | 63.17 | 59.24 | 47.61 | 45.23 | 46.36 | ||

| 200 | 67.43 | 64.32 | 56.31 | 51.70 | 53.51 | ||

| D2 | 100 | 68.47 | 60.32 | 65.95 | 54.83 | 47.44 | |

| 150 | 69.56 | 70.84 | 63.44 | 55.59 | 54.77 | ||

| 200 | 71.89 | 72.28 | 66.68 | 63.15 | 62.21 | ||

| D3 | 100 | 66.64 | 52.13 | 46.88 | 46.12 | 33.98 | |

| 150 | 66.19 | 62.70 | 60.19 | 48.71 | 41.50 | ||

| 200 | 69.26 | 68.37 | 62.37 | 59.29 | 59.84 | ||

| Ellipse | E1 | 100 | 67.92 | 60.02 | 61.47 | 43.52 | 38.02 |

| 150 | 66.62 | 64.65 | 63.00 | 53.30 | 45.88 | ||

| 200 | 68.43 | 65.36 | 58.76 | 53.86 | 54.38 | ||

| E2 | 100 | 56.98 | 44.87 | 49.03 | 37.15 | 26.24 | |

| 150 | 66.05 | 57.09 | 62.24 | 50.34 | 38.82 | ||

| 200 | 64.27 | 59.30 | 49.05 | 46.60 | 45.33 | ||

| E3 | 100 | 62.46 | 62.12 | 52.83 | 38.58 | 43.59 | |

| 150 | 66.04 | 67.15 | 60.13 | 51.79 | 52.57 | ||

| 200 | 68.51 | 68.72 | 60.87 | 59.05 | 56.46 |

| Shape | Number | Pressure (kPa) | 1.0 R | 1.1 R | 1.2 R | 1.3 R |

|---|---|---|---|---|---|---|

| Circle | C2 | 100 | 40.07 | 29.60 | 18.53 | 18.53 |

| 150 | 49.85 | 45.61 | 22.77 | 10.37 | ||

| 200 | 55.93 | 51.15 | 30.90 | 22.51 | ||

| Diamond | D1 | 100 | 49.32 | 42.63 | 11.27 | 11.27 |

| 150 | 51.78 | 46.68 | 19.08 | 19.08 | ||

| 200 | 63.52 | 45.24 | 45.48 | 49.98 | ||

| D2 | 100 | 63.62 | 67.59 | 67.59 | 40.31 | |

| 150 | 56.34 | 52.41 | 34.58 | 34.58 | ||

| 200 | 65.36 | 59.13 | 49.19 | 54.15 | ||

| D3 | 100 | 52.32 | 53.37 | 53.37 | 18.18 | |

| 150 | 57.12 | 53.72 | 36.09 | 28.76 | ||

| 200 | 59.39 | 59.51 | 39.88 | 39.60 | ||

| Ellipse | E1 | 100 | 55.65 | 48.67 | 48.67 | 29.94 |

| 150 | 57.02 | 49.22 | 32.61 | 32.61 | ||

| 200 | 57.02 | 51.99 | 33.90 | 33.90 | ||

| E2 | 100 | 49.20 | 38.37 | 38.37 | 20.99 | |

| 150 | 55.02 | 53.66 | 28.17 | 28.17 | ||

| 200 | 51.84 | 45.69 | 21.36 | 21.36 | ||

| E3 | 100 | 52.81 | 41.12 | 41.12 | 35.87 | |

| 150 | 51.82 | 39.31 | 39.31 | 35.47 | ||

| 200 | 57.78 | 49.95 | 49.95 | 39.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Jiang, Y.; Liu, J.; Li, H.; Li, H. Experimental Study on Water Distribution and Droplet Kinetic Energy Intensity from Non-Circular Nozzles with Different Aspect Ratios. Agriculture 2022, 12, 2133. https://doi.org/10.3390/agriculture12122133

Wang Z, Jiang Y, Liu J, Li H, Li H. Experimental Study on Water Distribution and Droplet Kinetic Energy Intensity from Non-Circular Nozzles with Different Aspect Ratios. Agriculture. 2022; 12(12):2133. https://doi.org/10.3390/agriculture12122133

Chicago/Turabian StyleWang, Zixin, Yue Jiang, Jialing Liu, Hong Li, and Hao Li. 2022. "Experimental Study on Water Distribution and Droplet Kinetic Energy Intensity from Non-Circular Nozzles with Different Aspect Ratios" Agriculture 12, no. 12: 2133. https://doi.org/10.3390/agriculture12122133

APA StyleWang, Z., Jiang, Y., Liu, J., Li, H., & Li, H. (2022). Experimental Study on Water Distribution and Droplet Kinetic Energy Intensity from Non-Circular Nozzles with Different Aspect Ratios. Agriculture, 12(12), 2133. https://doi.org/10.3390/agriculture12122133