Method Research and Structural Design of Segmented Shrimp Clamping

Abstract

1. Introduction

2. Materials and Methods

2.1. Shrimp Clamping Method

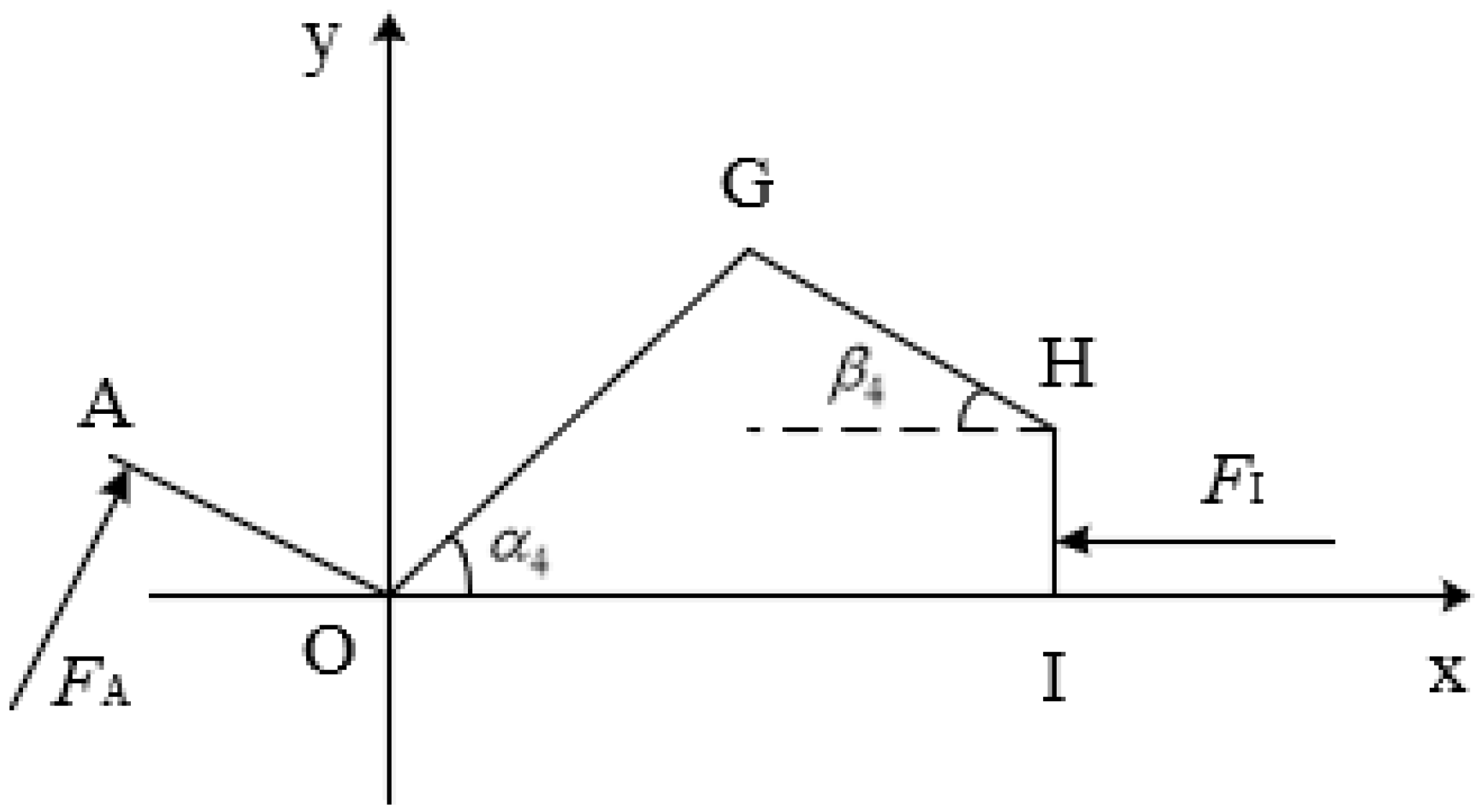

2.1.1. Analysis of Clamping Conditions

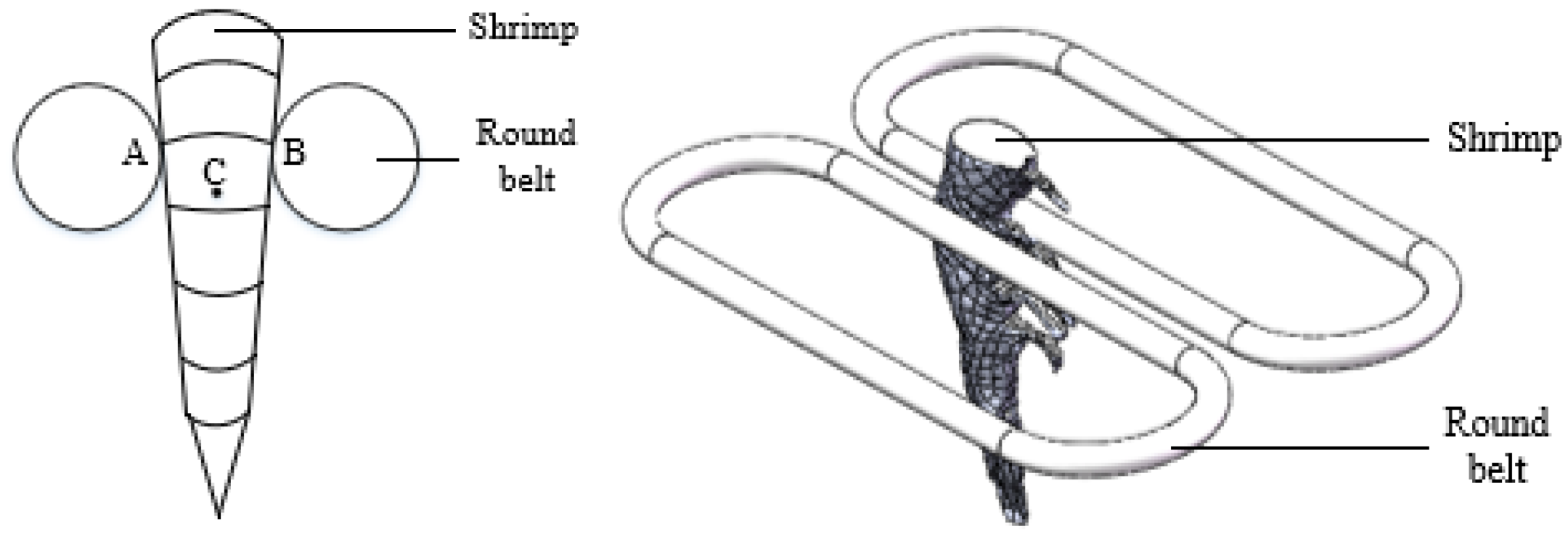

2.1.2. Proposed Segmented Clamping Method

2.1.3. Influence of Segmented Clamping on Peeling

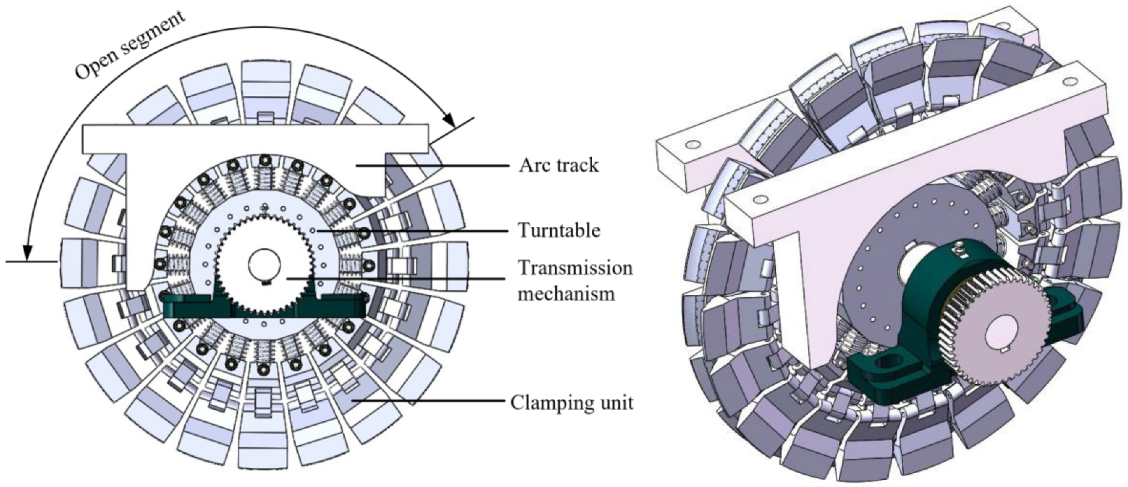

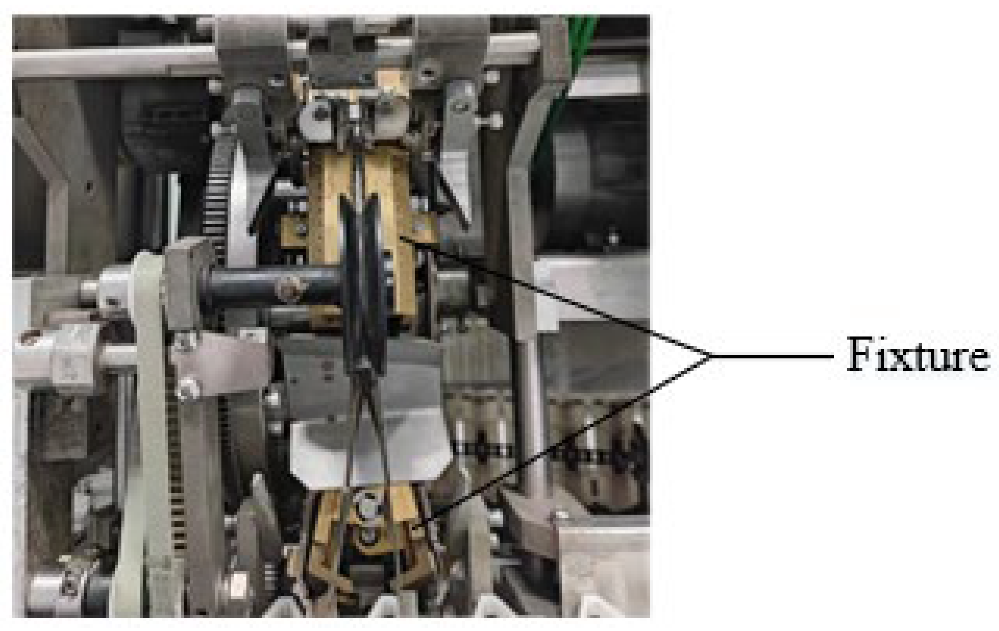

2.2. Design of Segmented Clamping Mechanism

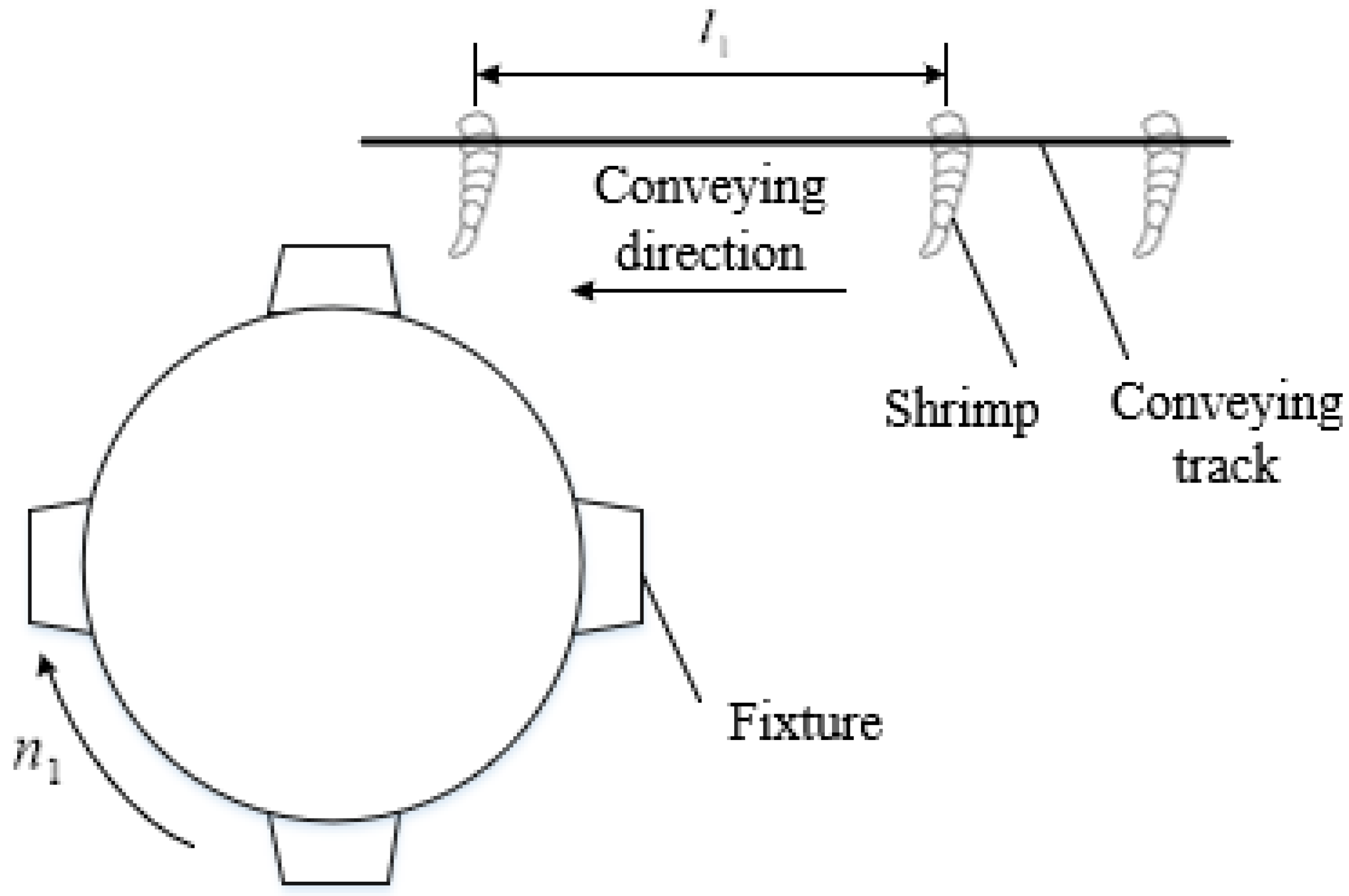

2.2.1. Overall Structure and Working Principle

2.2.2. Design of Clamping Units

2.2.3. Determination of Spring Parameters

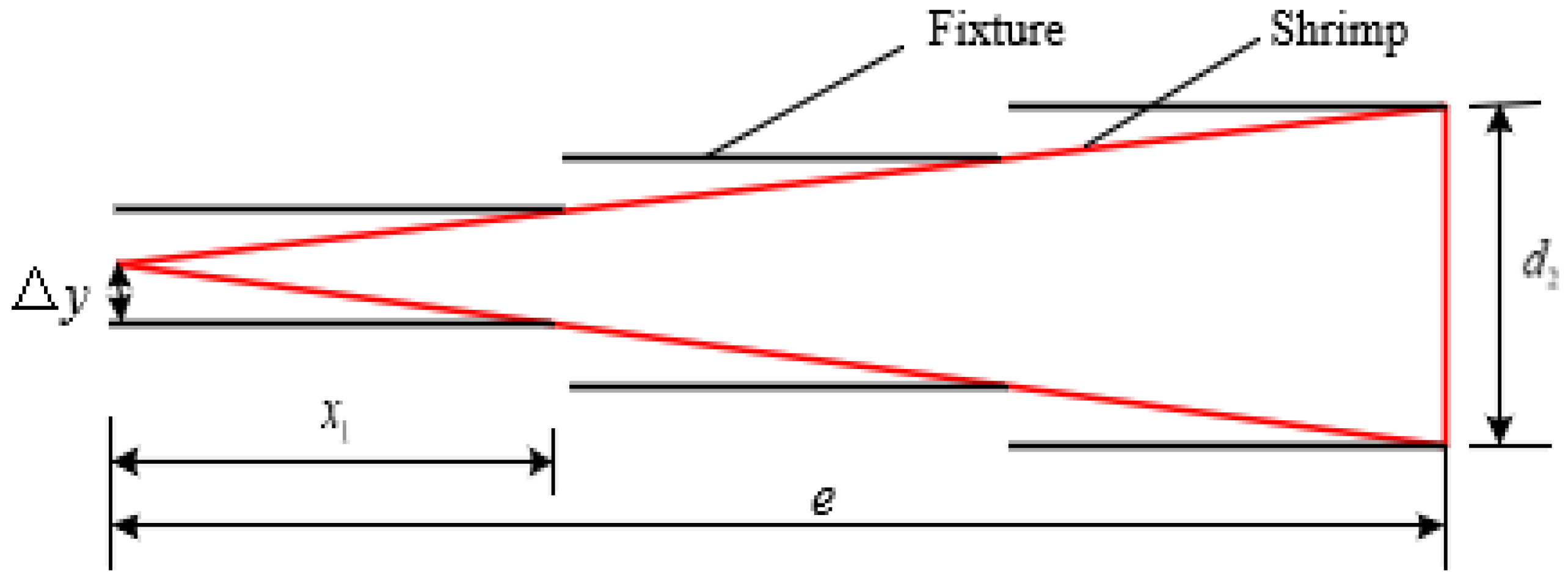

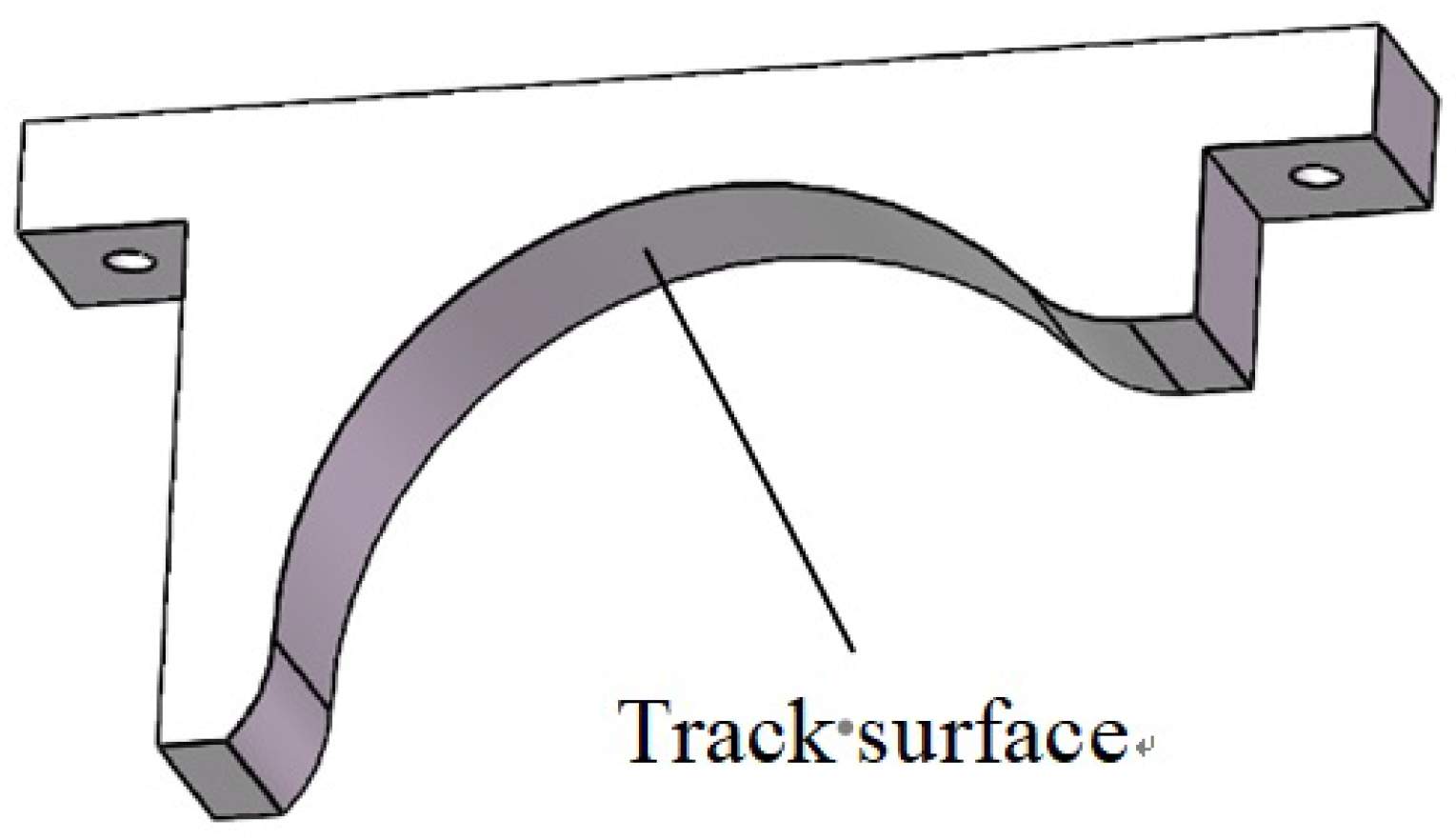

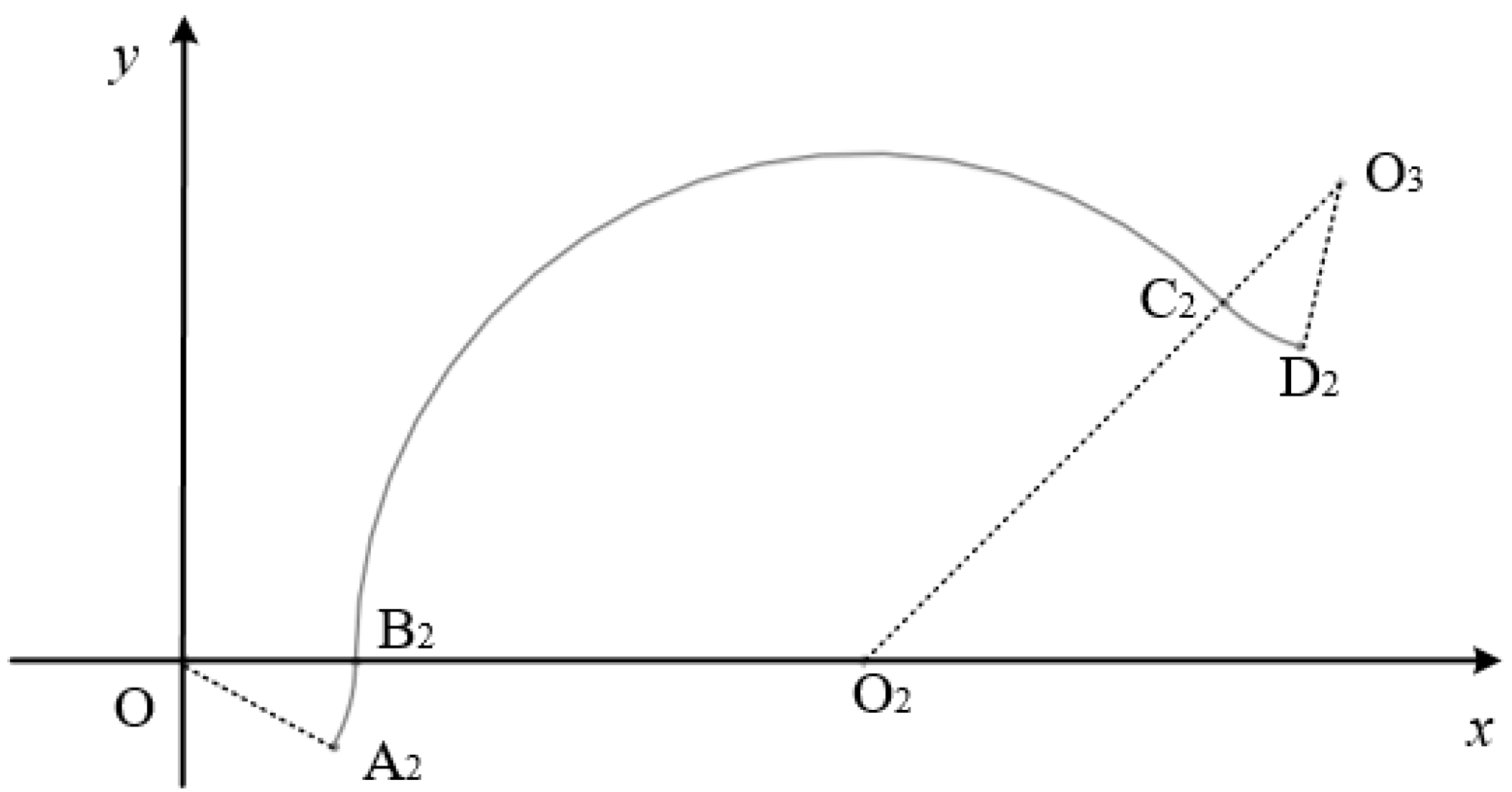

2.2.4. Arc Track Design

2.3. Clamping Mechanism Simulation Model Building

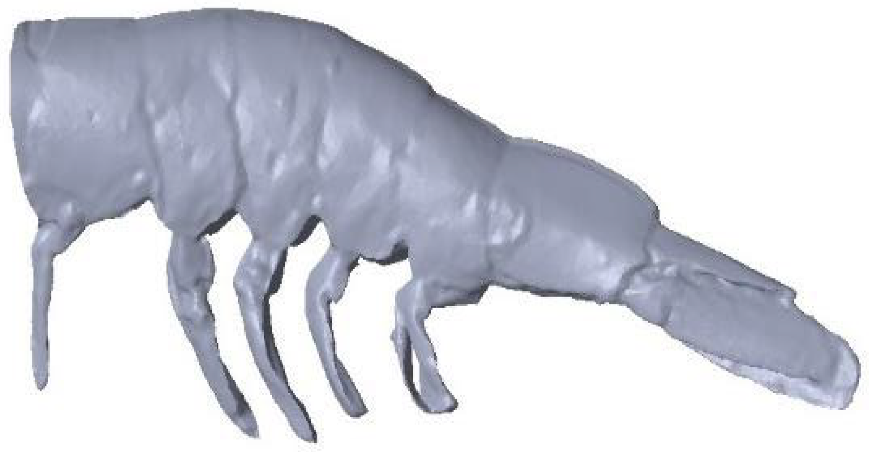

2.3.1. Modeling of Shrimp in 3D

2.3.2. Simulation Model

2.4. Shrimp Clamping Test Arrangement

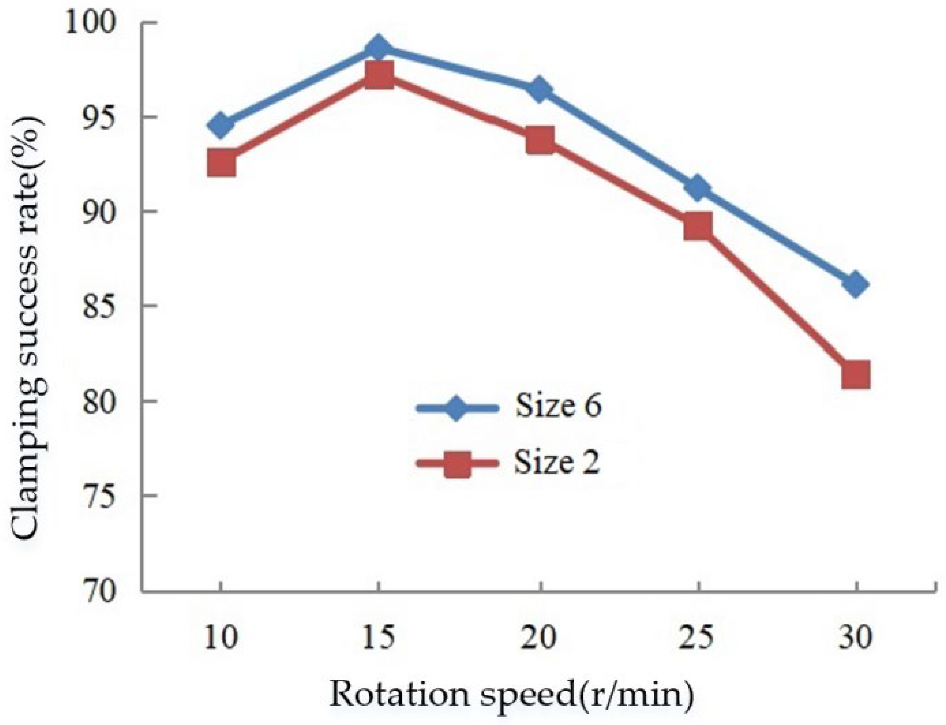

2.4.1. Single Factor Test

2.4.2. Comparison Test

2.4.3. Performance Test

3. Results and Discussion

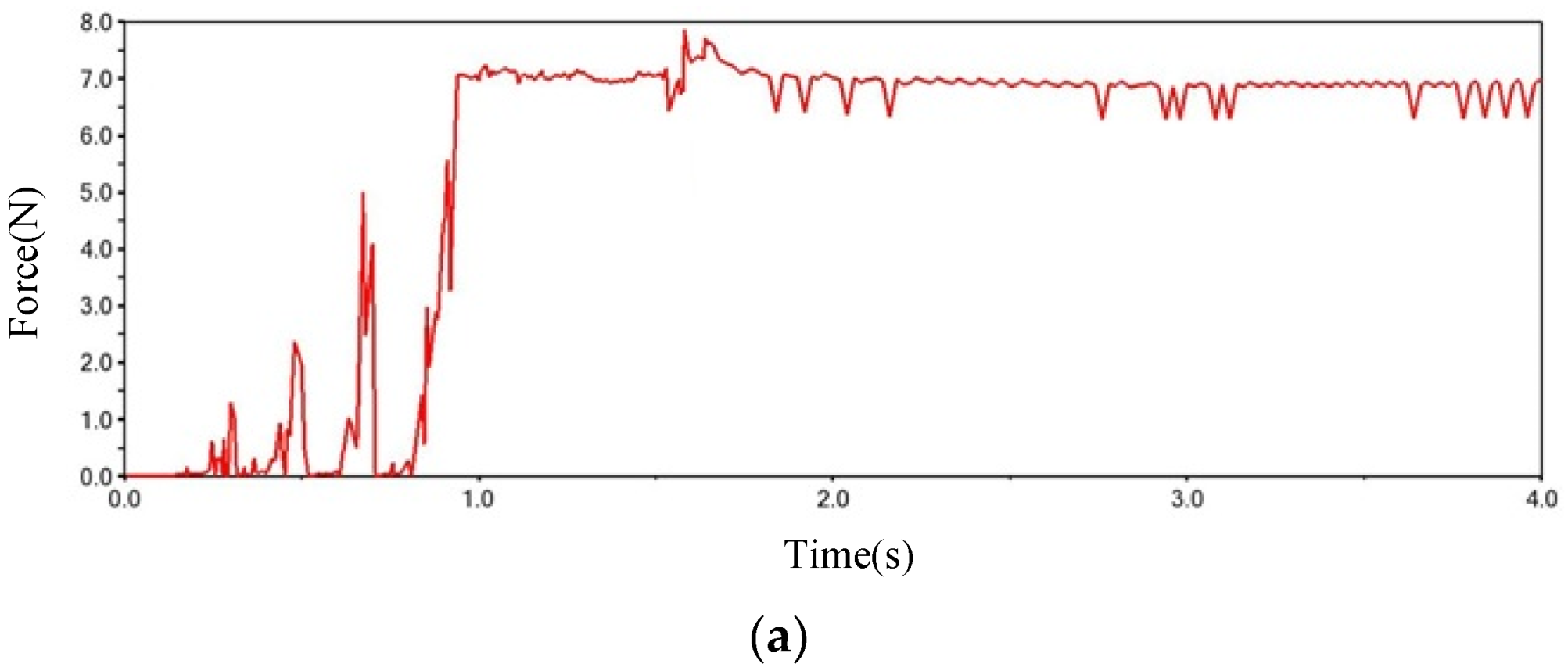

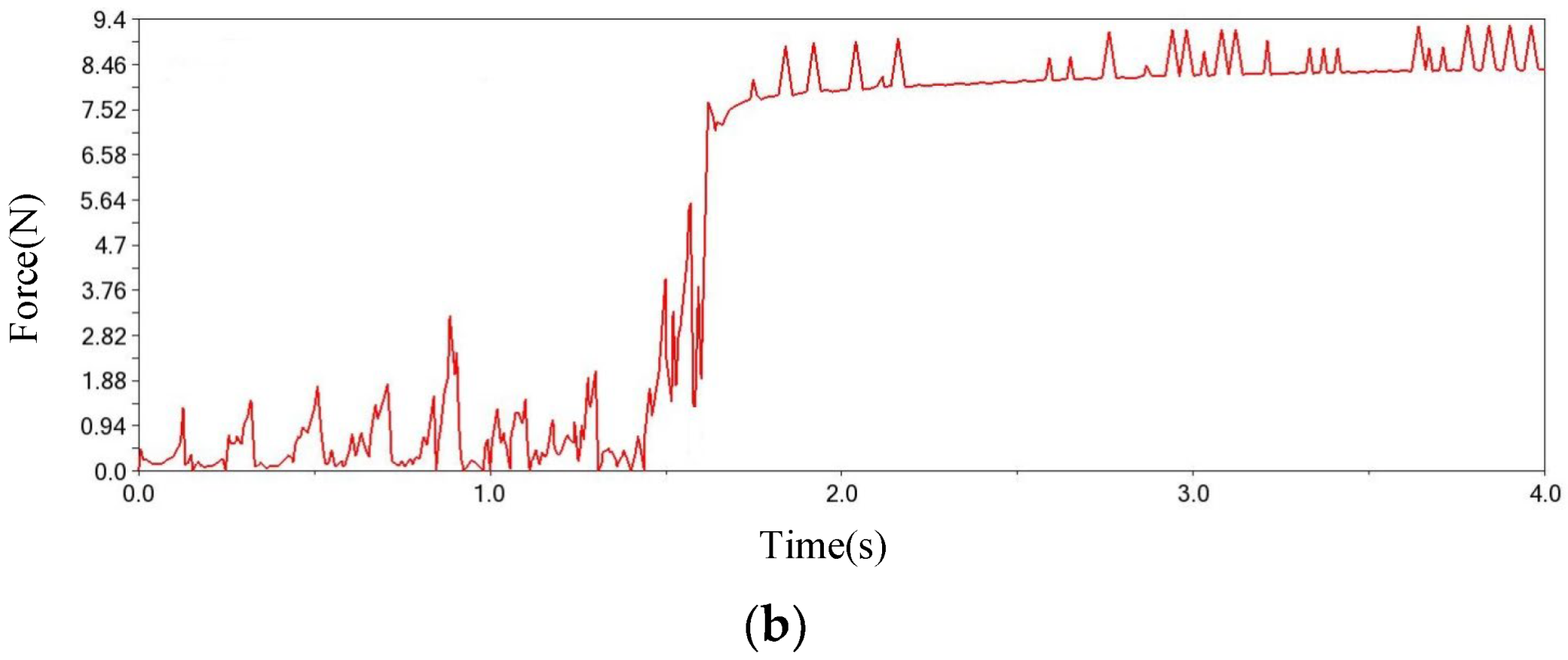

3.1. Simulation Results and Discussion

3.2. Test Results and Discussion

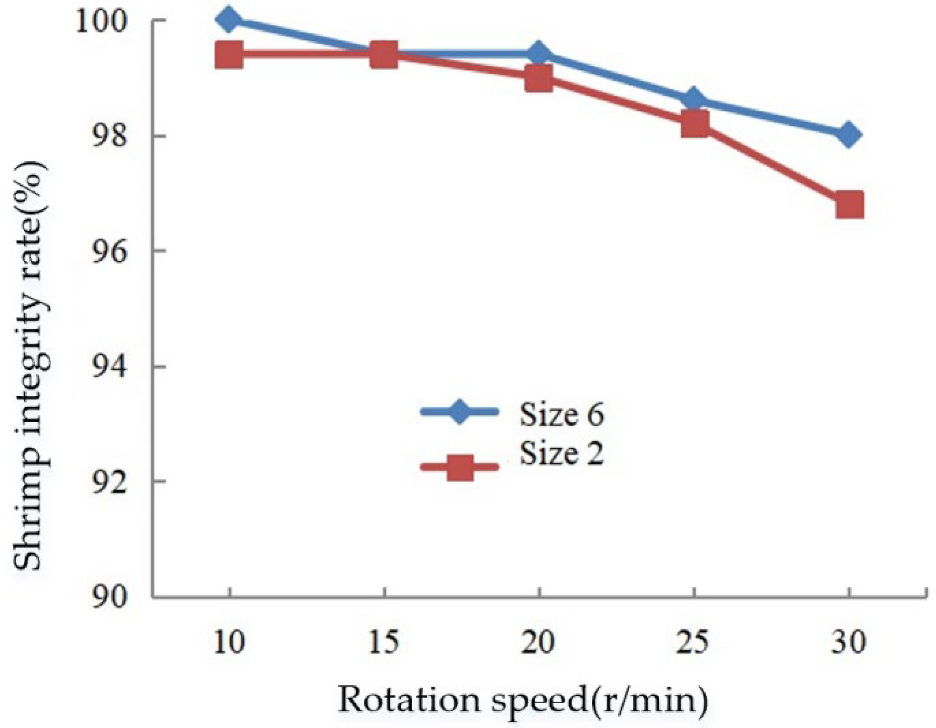

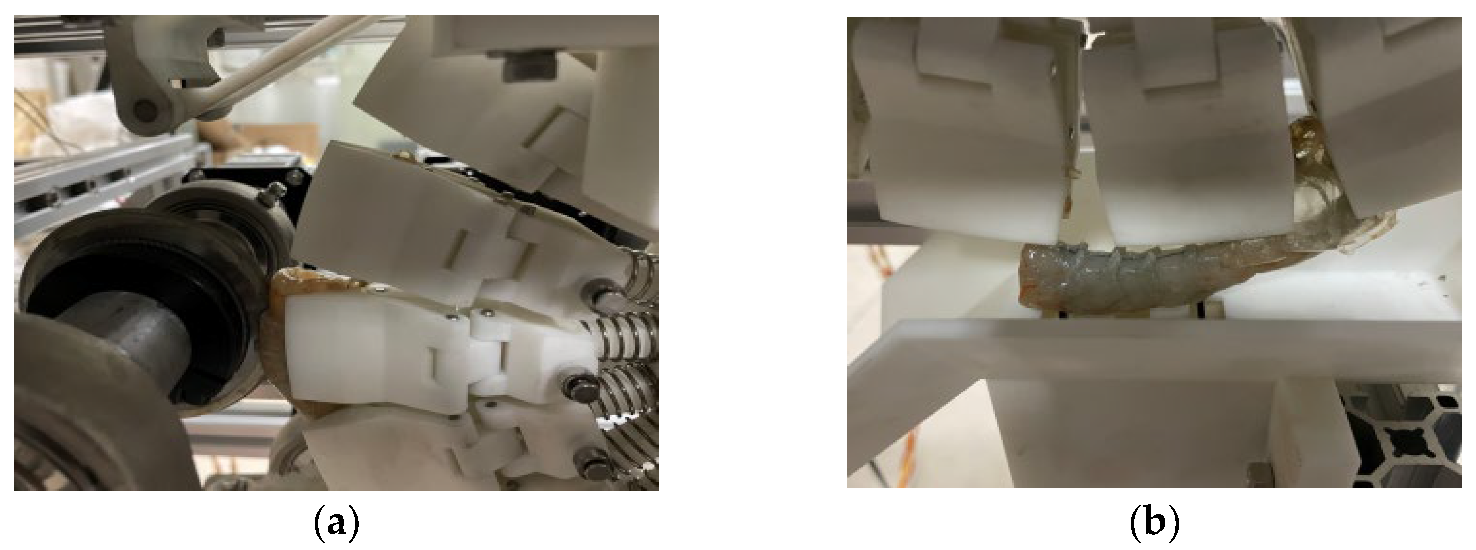

3.2.1. Single Factor Test Results and Analysis

3.2.2. Comparative Test Results and Analysis

3.2.3. Performance Test Results and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Che, B.; Sun, C.; Zhang, H.Q.; Chen, T.G.; Jin, H.T. Cost-benefit analysis of different culture modes of Penaeus vannamei in China. Chin. Fish. Econ. 2018, 36, 70–76. [Google Scholar]

- Teng, Y.; Bi, G.D.; Yu, A.M.; Wang, C.L. Overview processing utilization and industrial development of Litopenaeus vannamei. J. Food Saf. Qual. 2021, 12, 5727–5733. [Google Scholar]

- Hao, S.X.; Deng, J.C.; Li, L.H.; Shi, H.; Yang, X.Q.; Huang, H.; Wei, Y.; Qi, B. Nutritional components and safety analysis of shrimp muscle and processing by-products. Sci. Technol. Food Ind. 2012, 33, 337–339+365. [Google Scholar]

- Li, Z.Y. The Influential Factors and Countermeasures for Guangdong Province building the Penaeus vannamei Boone Aquaculture Insurance; Jimei University: Xiamen, China, 2015. [Google Scholar]

- Zhao, L.T.; Xi, M.J.; Wang, W.; Chu, X.; Zhao, X.; Yuan, Y. A review of technology development process of a typical shrimp peeling machine. J. Adv. Mech. Des. Syst. Manuf. 2015, 9, 1–9. [Google Scholar] [CrossRef][Green Version]

- Ye, K.; Ma, J.Y.; Gong, L.; Zhang, L.; Zhao, X.; Xiao, B. Roller-type Shrimp Sheller Shelling Technology and Optimal Shelling Rate Test of Penaeus vannamei. Mod. Agric. Equip. 2020, 41, 73–77. [Google Scholar]

- Yi, J.G.; Ma, J.Y.; Wang, Z.H.; Zhang, X.H.; Yang, S.H. Status and Development of Shrimp Processing Equipment. Mod. Agric. Equip. 2020, 41, 2–11. [Google Scholar]

- Ouyang, J.; Shen, J.; Zheng, X.W.; Huang, Y.X.; Xu, H. Research and application status and development tendency of aquatic products processing equipment. Fish. Mod. 2017, 44, 73–78. [Google Scholar]

- Jonsson, G. Shrimp Tray with Visual and Tactile Shrimp Sensing Means. U.S. Patent US5435775A, 25 June 1995. [Google Scholar]

- Jonsson, G. Method of Cleaning Shrimp. U.S. Patent US2784450A, 12 March 1957. [Google Scholar]

- Jonsson, G. Shrimp Cleaning Machine. U.S. Patent US2850761A, 9 September 1958. [Google Scholar]

- Zhang, X.H.; Wang, L.G.; Wang, Z.H.; Yi, J.G.; Yang, S.H.; Wang, W. A Belt Type Prawn Back Opening Device. China Patent CN105767115B, 15 December 2017. [Google Scholar]

- Zhang, X.H.; Wang, L.G.; Yi, J.G.; Wang, Z.H.; Wang, J. Design and experiment of shrimp backside cutting machine formed by belt clamping and conveying. Trans. Chin. Soc. Agric. Eng. 2017, 33, 284–291. [Google Scholar]

- Jonsson, G. Shrimp Processing Machine and Method. U.S. Patent US3566437A, 2 March 1971. [Google Scholar]

- Jonsson, G. Machine for Cleaning Shrimp. U.S. Patent US3214789A, 2 November 1965. [Google Scholar]

- Keith, J.T.; Betts, E.D.; Dancy, M.J.; Pershinske, J.E. Semi-Automatic Shrimp Peeling Machine. U.S. Patent US5522764A, 4 July 1996. [Google Scholar]

- Keith, J.T. Shrimp Processing Machine and Method of Processing Shrimp. U.S. Patent US06485363B2, 26 November 2002. [Google Scholar]

- Betts, E.D. Shrimp Processing Machine Having Improved Cutting Structure. U.S. Patent US4414709A, 15 November 1983. [Google Scholar]

- Keith, J.T.; Betts, E.D.; Dancy, M.J. Semi-Automatic Shrimp Peeling Machine. U.S. Patent US5366405A, 22 November 1994. [Google Scholar]

- Zhang, J.J.; Zhang, L.Q.; Zhao, X.H.; Luo, Q.J.; Huang, P.S. Research and design of shrimp shelling equipment. Mod. Agric. Equip. 2011, 7, 50–52. [Google Scholar]

- Liu, J. A Study of the Dynamic of Slider-crank Mechanism. J. Shanghai Dianji Univ. 2006, 9, 24–28. [Google Scholar]

- Liu, S.L.; Hu, P.H. Akinetic characteristic analysis of slider- crank mechanism and simulation realization. Mach. Des. Manuf. 2008, 5, 79–80. [Google Scholar]

- Zhou, L.; Chen, P. Research on development of reverse engineering. Comput. Eng. Des. 2004, 1658–1660+1666. [Google Scholar]

- Gong, W.F.; Huang, M.F. Application and Research of Reverse Engineering Technology. Mach. Des. Manuf. 2013, 110–112. [Google Scholar]

- Xiong, S.; Zhao, B.; Hu, X.L.; Li, J.; Zhou, L.M.; Fang, X.F. Design and Experiment on Prawn Single Separation Device. Trans. Chin. Soc. Agric. Mach. 2020, 51, 357–365. [Google Scholar]

- Liu, R.; Liu, Z.J.; Liu, L.J.; Li, Y.H. Design and Experiment of Corn High Speed Air Suction Seed Metering Device with Disturbance Assisted Seed-Filling. Trans. Chin. Soc. Agric. Mach. 2022, 53, 50–59. [Google Scholar]

- Zhang, X.J.; Zhang, Y.H.; Shi, Z.L.; Ma, S.T.; Huang, S.; Cheng, J.P. Optimization and Experiment of Oil Sunflower Combined Harvester Cleaning Device. Trans. Chin. Soc. Agric. Mach. 2022, 53, 103–113. [Google Scholar]

- Zhang, X.H.; Zhao, Q.L.; Wang, Z.H.; Yi, J.G.; Wang, J. Parameter optimization experiment of adjustable five rollers shrimp peeling machine. Trans. Chin. Soc. Agric. Eng. 2016, 32, 247–254. [Google Scholar]

- Li, L.L.; He, X.K.; Song, J.L.; Liu, Y.; Wang, Z.C.; Li, J.Y.; Jia, X.M.; Liu, Z.X. Comparative experiment on profile variable rate spray and conventional air assisted spray in orchards. Trans. Chin. Soc. Agric. Eng. 2017, 33, 56–63. [Google Scholar]

- Zhang, J.X.; Zhang, L.; Liu, X.F.; Jiang, Y.X.; Wang, J.K. Mechanical analysis and contrast experiment on collecting residual plastic film with different side-film shovels. Trans. Chin. Soc. Agric. Eng. 2017, 33, 10–15. [Google Scholar]

- Yi, J.J.; Ding, G.W.; Hu, H.; Dong, P.; Li, Y.; Liao, X.J.; Zhang, Y. Comparison of shucking techniques for white shrimp and its effect on quality of peeled shrimp. Trans. Chin. Soc. Agric. Eng. 2012, 28, 287–292. [Google Scholar]

- Du, Y.F.; Mao, E.R.; Song, Z.H.; Zhu, Z.X.; Gao, J.M. Simulation on Corn Plants in Harvesting Process Based on ADAMS. Trans. Chin. Soc. Agric. Mach. 2012, 43, 106–111. [Google Scholar]

- Wang, S.Y.; Hu, Z.C.; Peng, B.L.; Wu, H.C.; Gu, F.W.; Wang, H.O. Simulation of Auto-follow Row Detection Mechanism in Beet Harvester Based on ADAMS. Trans. Chin. Soc. Agric. Mach. 2013, 44, 62–67. [Google Scholar]

| Shrimp Specifications | Test Index | Segmented Clamping Mechanism | Turntable Fixture Clamping Mechanism | ||

|---|---|---|---|---|---|

| Equal Interval Feeding | Unequally Spaced Feeding | Equal Interval Feeding | Unequally Spaced Feeding | ||

| No. 2 | Clamping success rate/% | 97.2 | 97.2 | 99.4 | 75 |

| Shrimp integrity rate/% | 98.8 | 99.4 | 98.8 | 93.3 | |

| No. 6 | Clamping success rate/% | 98.3 | 97.7 | 98.8 | 78.9 |

| Shrimp integrity rate/% | 99.4 | 99.4 | 99.4 | 95.6 | |

| Shrimp Specifications | Peeling Success Rate (%) | Processing Capacity (pcs/h) |

|---|---|---|

| No. 2 | 92.5 | 2520 |

| 93.1 | 2490 | |

| 92.2 | 2560 | |

| No. 6 | 91.5 | 2420 |

| 91.3 | 2460 | |

| 92.0 | 2460 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, S.; Luo, Q.; Li, J.; Feng, Y.; Gan, L.; Bai, S.; Fang, X. Method Research and Structural Design of Segmented Shrimp Clamping. Agriculture 2022, 12, 2118. https://doi.org/10.3390/agriculture12122118

Xiong S, Luo Q, Li J, Feng Y, Gan L, Bai S, Fang X. Method Research and Structural Design of Segmented Shrimp Clamping. Agriculture. 2022; 12(12):2118. https://doi.org/10.3390/agriculture12122118

Chicago/Turabian StyleXiong, Shi, Qiaojun Luo, Junlue Li, Yunyun Feng, Ling Gan, Shenghe Bai, and Xianfa Fang. 2022. "Method Research and Structural Design of Segmented Shrimp Clamping" Agriculture 12, no. 12: 2118. https://doi.org/10.3390/agriculture12122118

APA StyleXiong, S., Luo, Q., Li, J., Feng, Y., Gan, L., Bai, S., & Fang, X. (2022). Method Research and Structural Design of Segmented Shrimp Clamping. Agriculture, 12(12), 2118. https://doi.org/10.3390/agriculture12122118