A Practical Hybrid Control Approach for a Greenhouse Microclimate: A Hardware-in-the-Loop Implementation

Abstract

1. Introduction

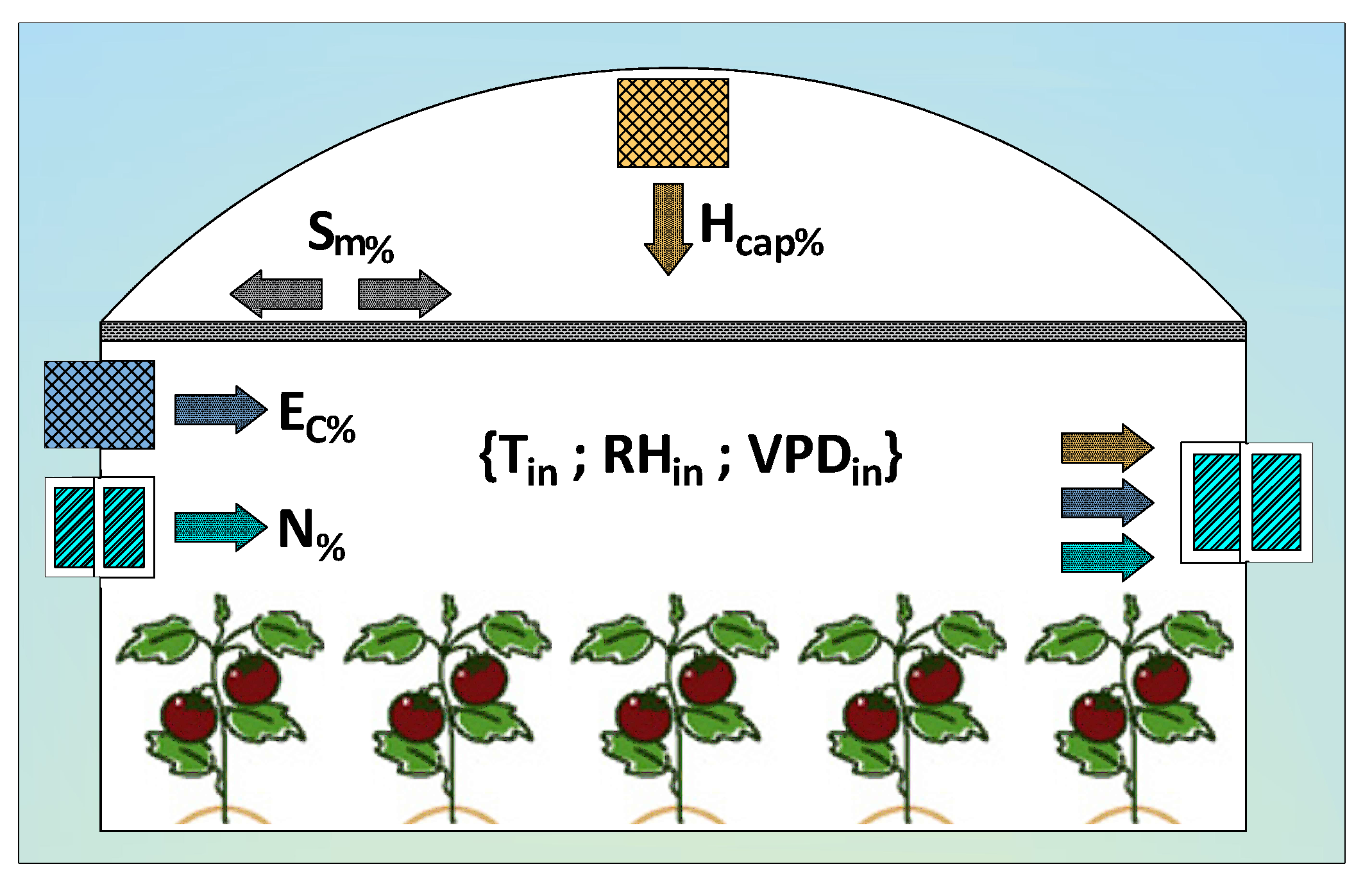

2. Mathematical Model

2.1. Greenhouse Climatic Dynamic Model

2.2. Analysis of Units for Humidity

2.2.1. Change from Absolute to Relative Humidity Units

2.2.2. Change from Relative to Absolute Humidity Units

2.3. Vapor Pressure Deficit (VPD)

2.4. Identification and Normalization of Interest Variables for the Control System

2.4.1. Normalization of the Manipulated Variables

2.4.2. Summary of Variables of the Greenhouse Mathematical Model

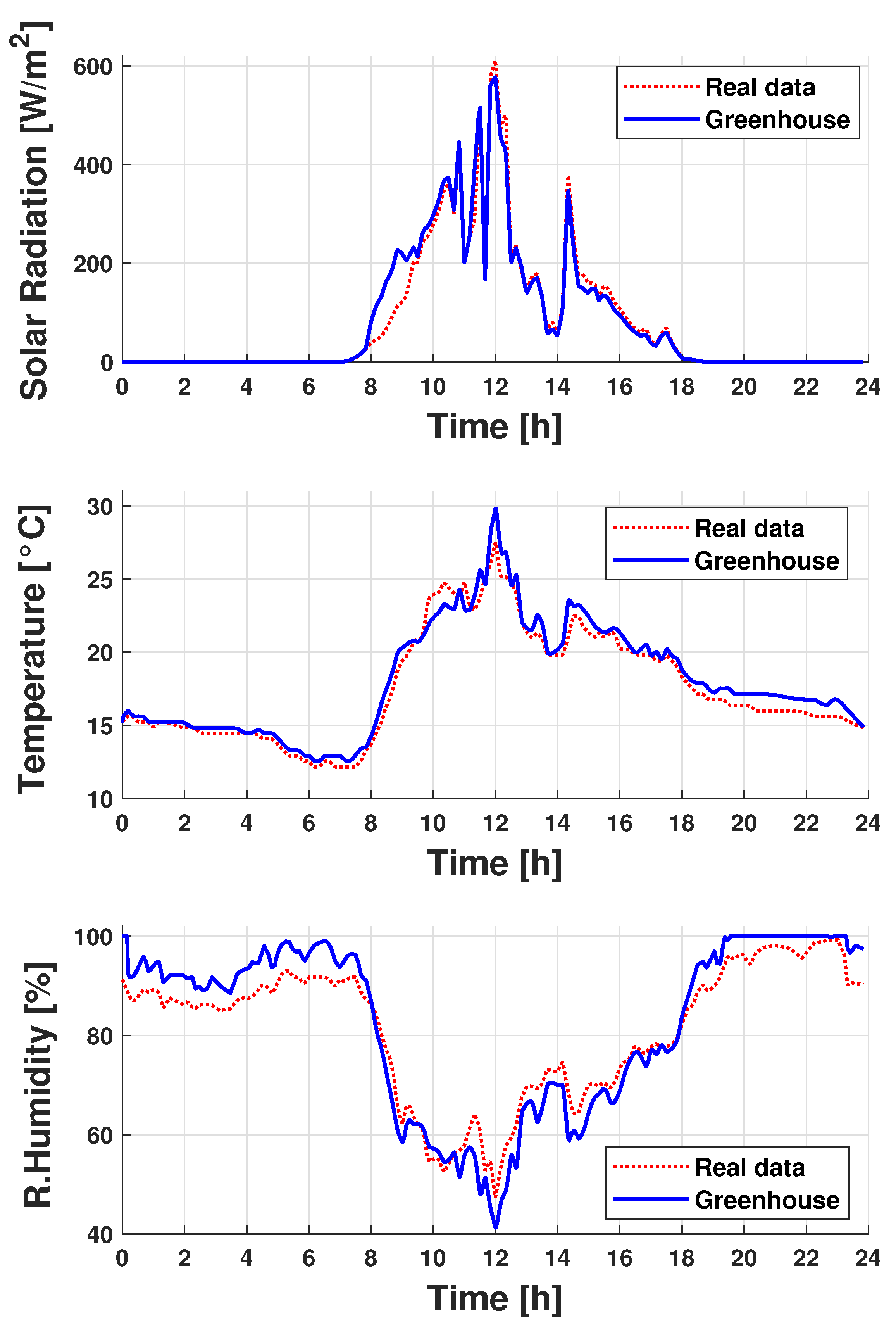

3. Open Loop Greenhouse Model Validation

3.1. Considerations for Validation

- As the greenhouse model had more physical data than those known from the real greenhouse (in Santa Rosa, Mérida-Venezuela), it was necessary to assume some values to the simulation could be carried out:

- −

- Ventilation of 50% throughout the day, then .

- −

- Shading mesh, an evaporative cooling system, and heating were not used. Thus, , , and .

- −

- The existence of an abundant crop was considered; therefore,

- The reflectance of solar radiation on the ground taken of [15] was ; after several tests, it was adjusted to , which gave better results on validation.

3.2. Model Validation for 5 Days of Data Measured in Santa Rosa, Mérida-Venezuela: From 12 November 2006 to 16 November 2006

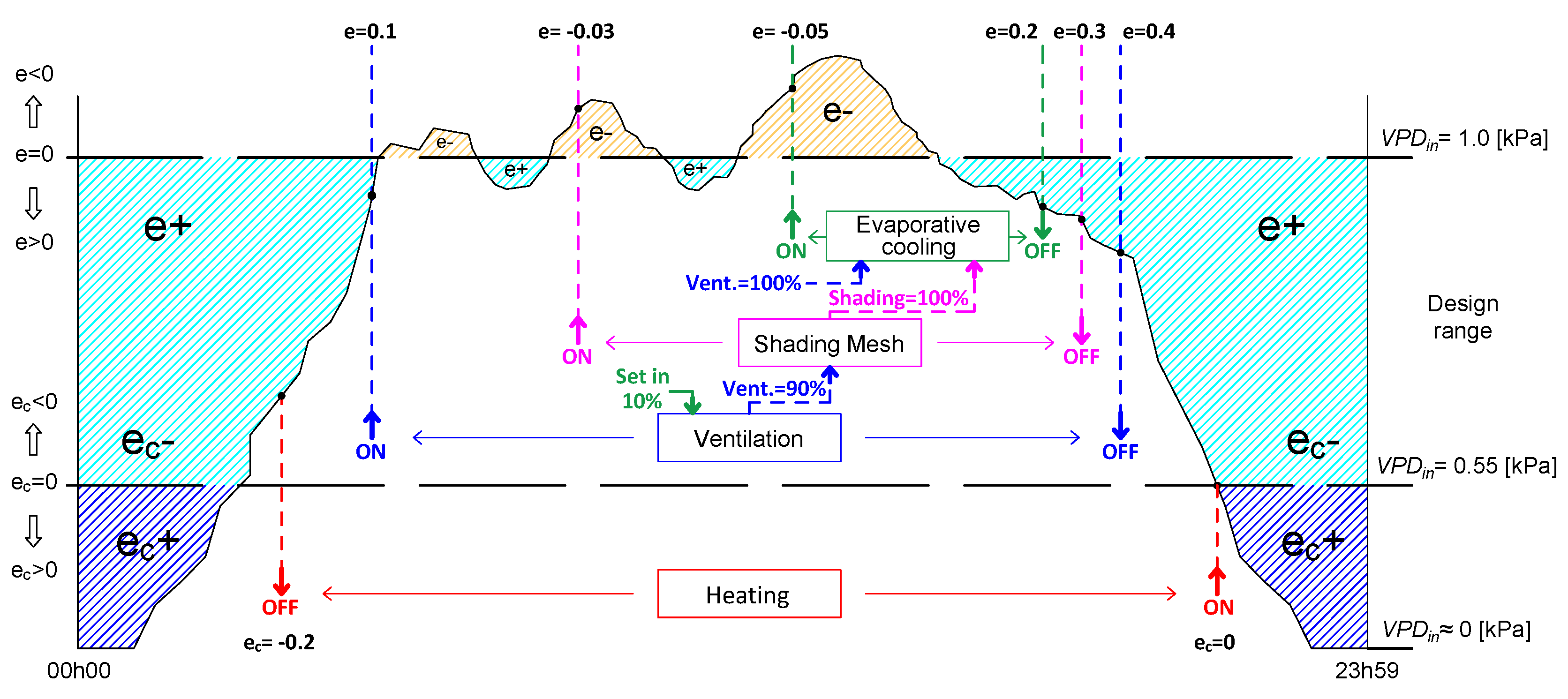

4. Proposed Control Strategy

4.1. Variable to Control

4.2. VPD Controllability Range

- Range 0.75–1.5 (kPa): Optimum nutrient absorption and photosynthesis for most greenhouse crops.

- Range 0.8–1.5 (kPa): Better CO exchange, improvement of the hydraulic potential of the leaves, and regulation of the osmotic pressure. Moreover, photosynthesis and stomata conductance are ideal in this range.

- Range 0.3–1.6 (kPa): Efficiency in water use is ideal, with better gas exchange and conductance in the stomata; it also improves the regulation of foliar abscisic acid.

4.3. Control Proposal for the Greenhouse Microclimate

5. Hybrid Controller Design

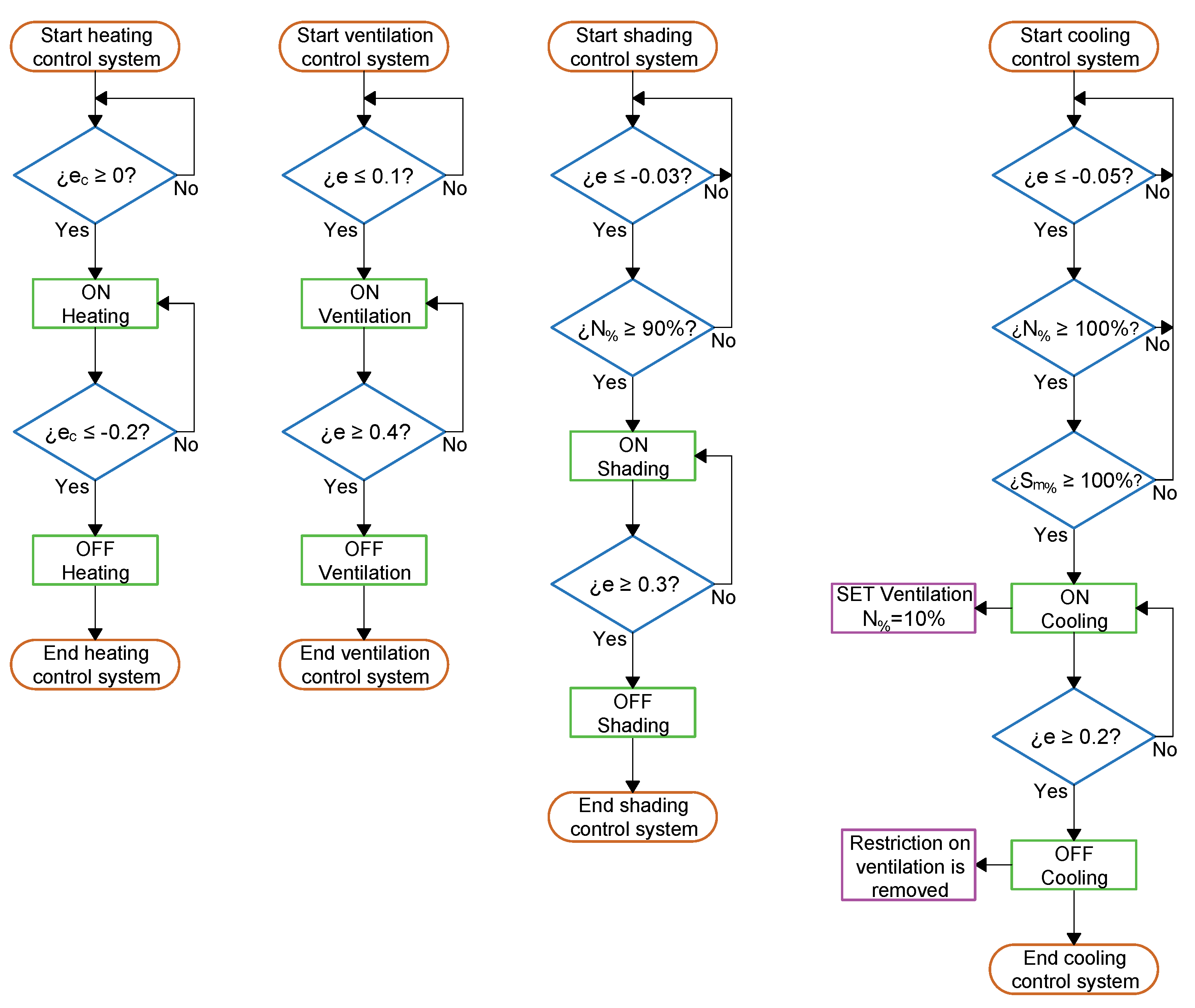

5.1. Design of Enabling and Disabling Each Controller

- e: error of the feedback control loop for cooling that can be positive () or negative ();

- : error of the feedback control loop for heating that can be positive () or negative ();

- : vapor pressure deficit inside the greenhouse, which is the variable controlled by cooling (fogging) or the heating system.

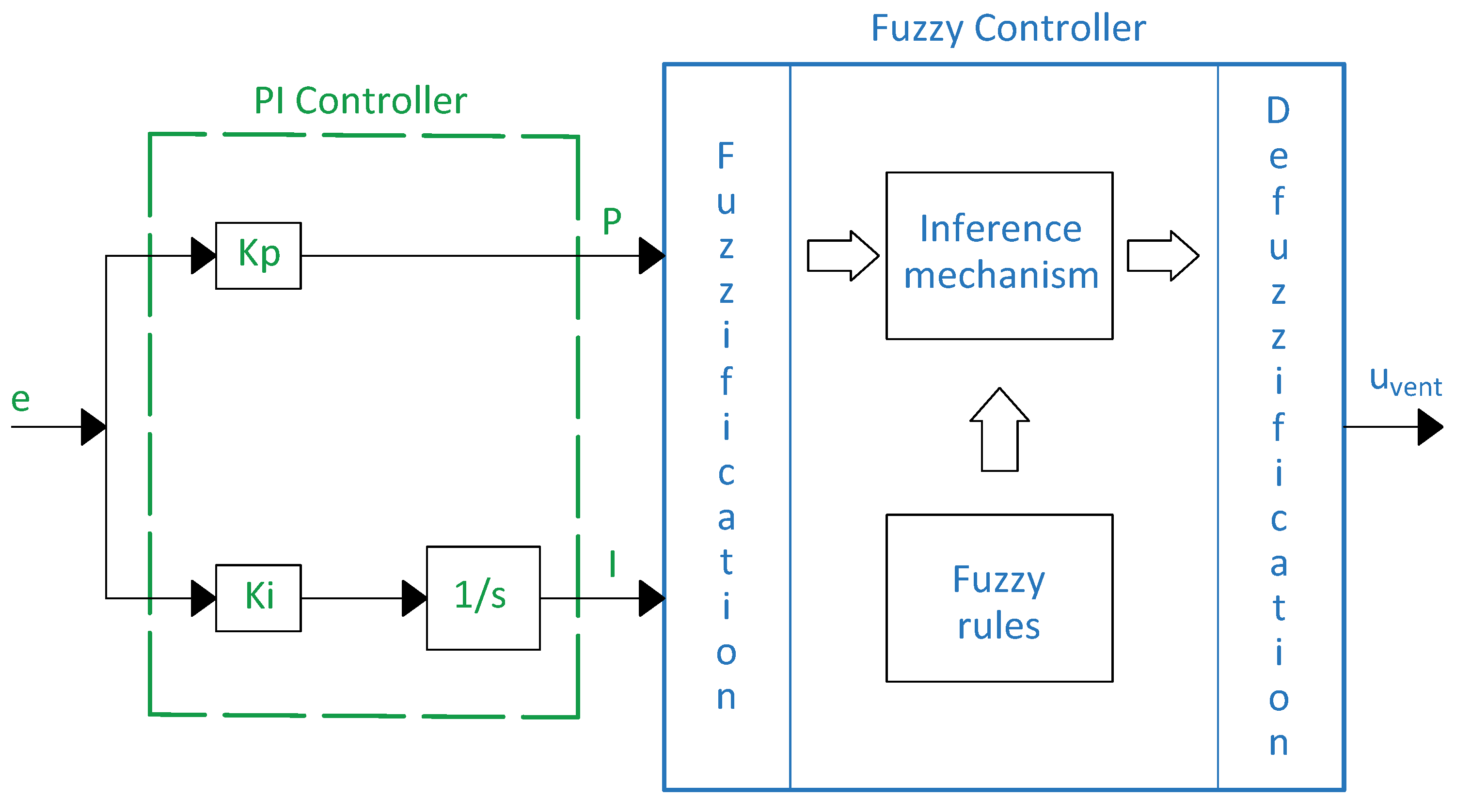

5.2. Design for Ventilation Controller

5.2.1. Reaction Curve to the Greenhouse with the Ventilation System

5.2.2. Design of a PI Controller for the Ventilation System

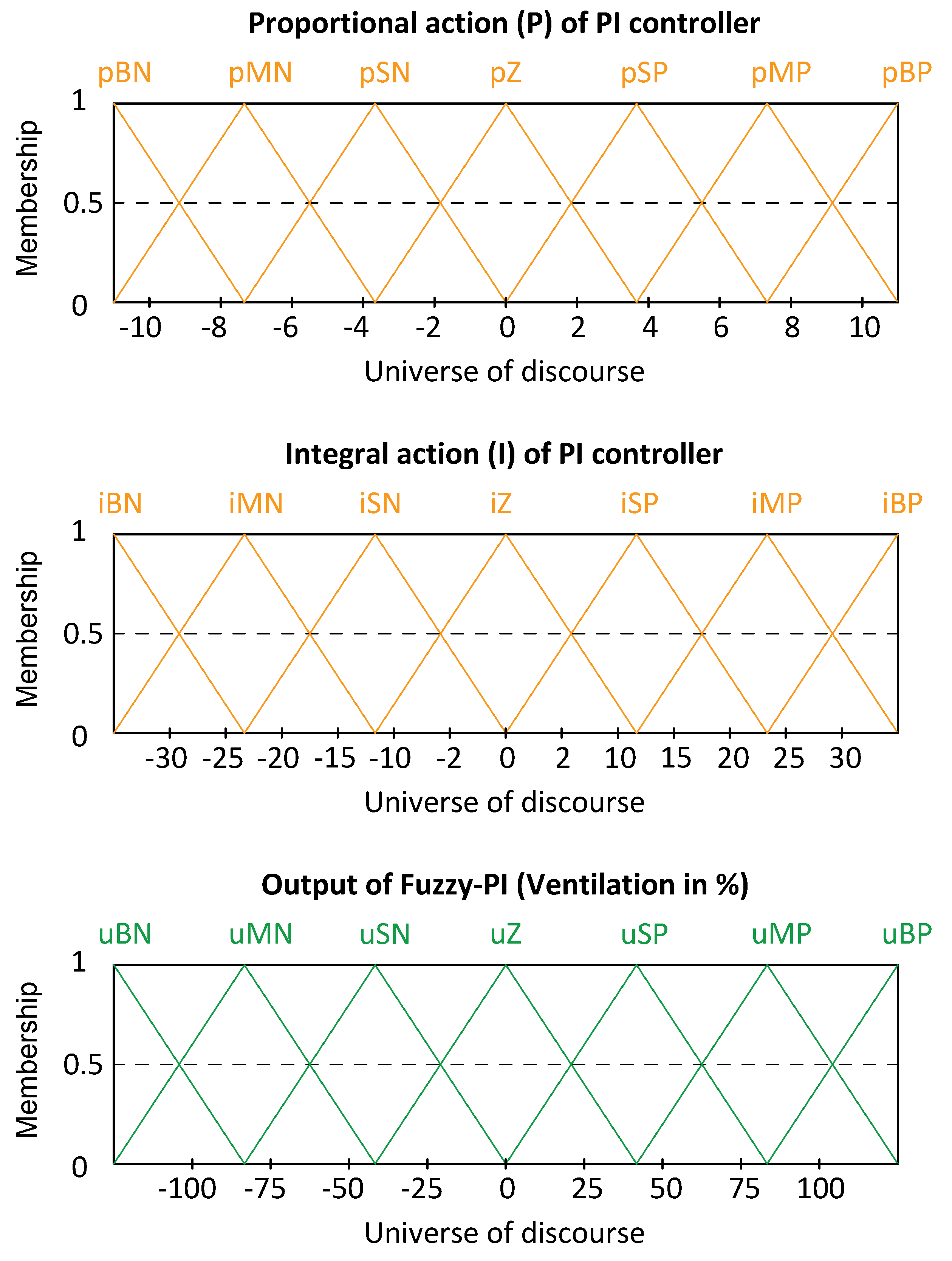

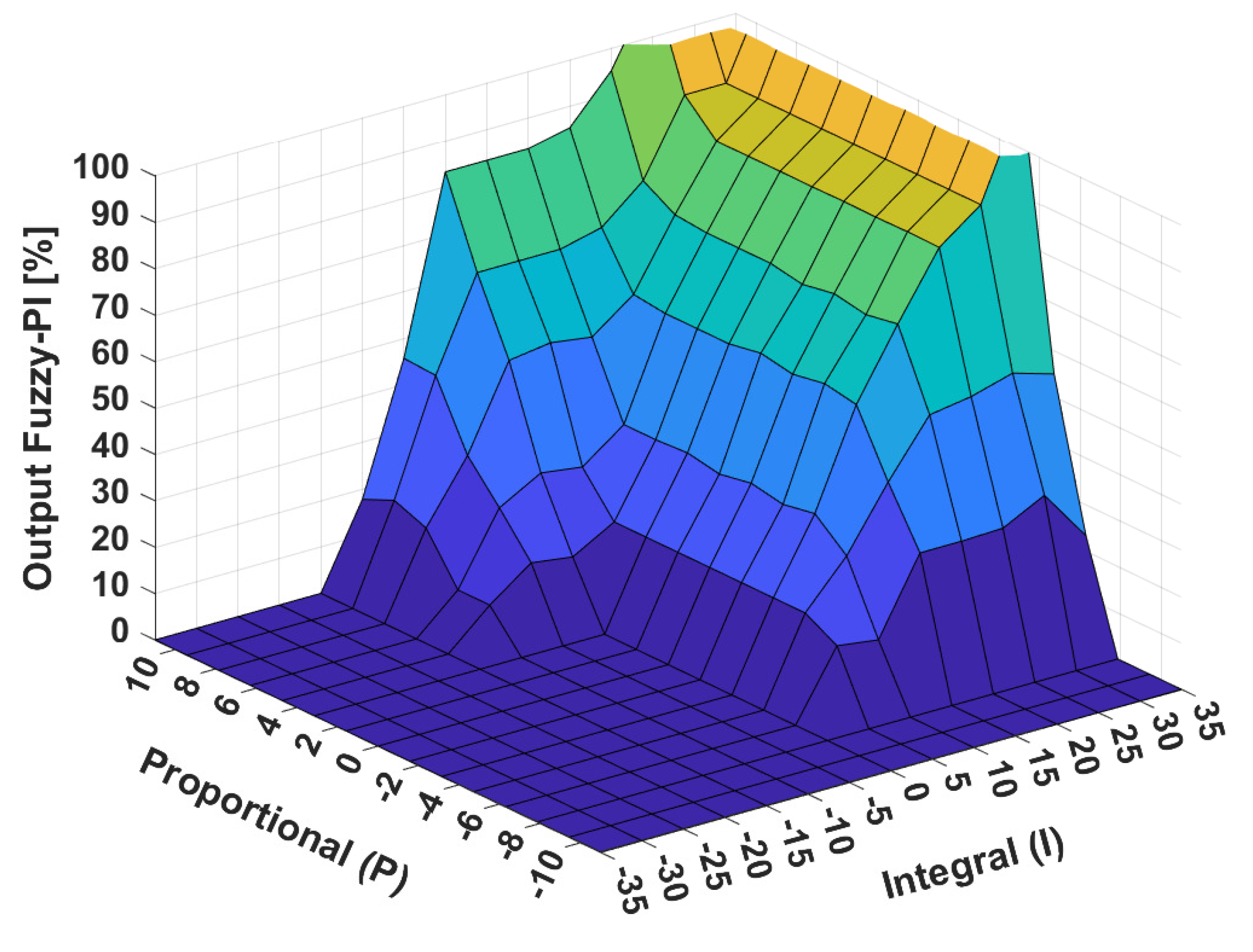

5.2.3. Design of a Fuzzy-PI Controller for the Ventilation System

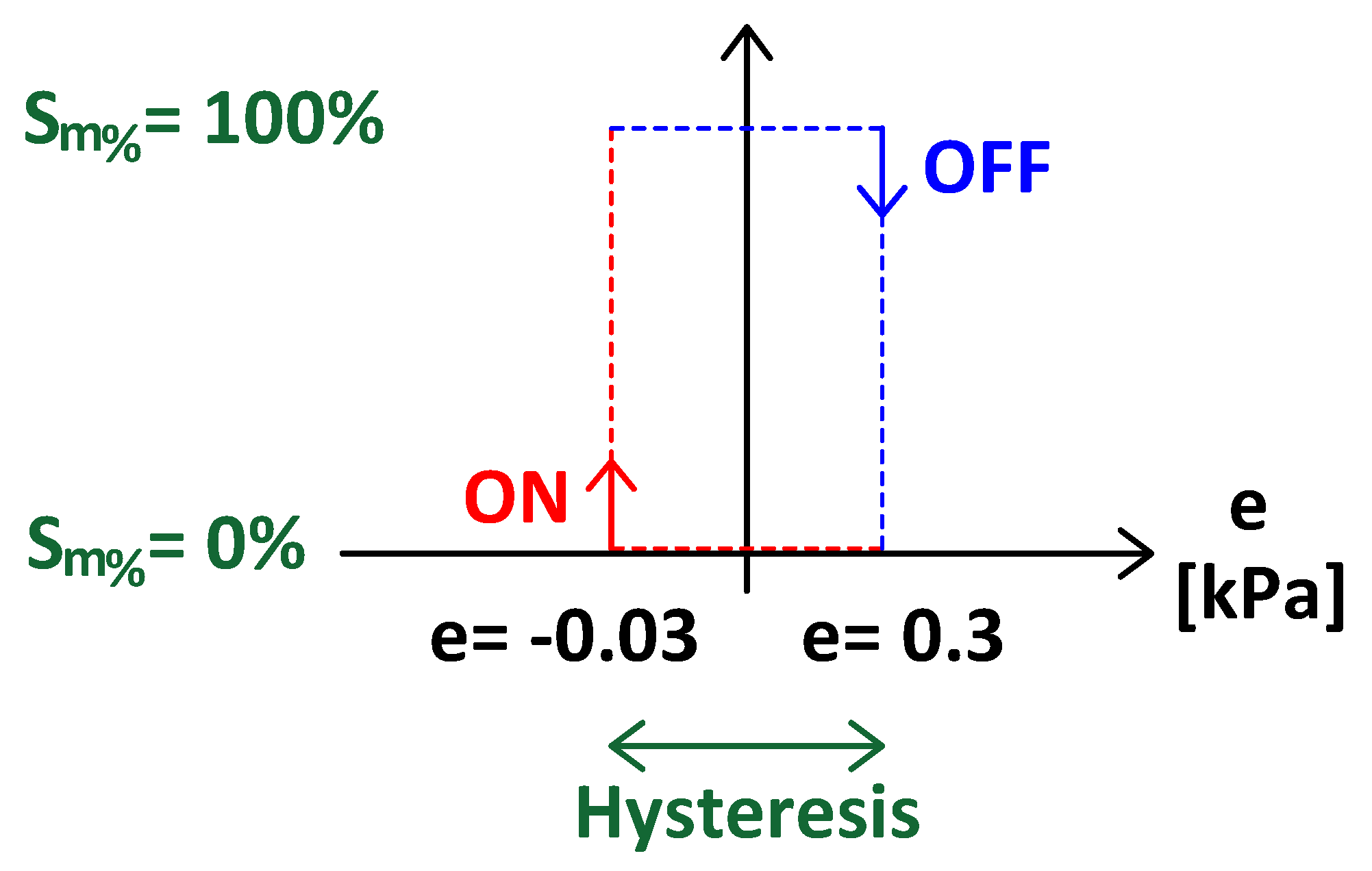

5.3. Design for Shading System Controller

5.4. Design for Evaporative Cooling System Controller

5.4.1. Reaction Curve to the Greenhouse with the Evaporative Cooling System

5.4.2. Design of a PI Controller for the Evaporative Cooling System

5.5. Design for Heating System Controller

5.5.1. Reaction Curve to the Greenhouse with the Heating System

5.5.2. Design of a PI Controller for the Heating System

6. Results and Analysis

6.1. Hardware-in-the-Loop Implementation

6.1.1. Activation and Deactivation of Each Control System

6.1.2. Sampling Time for Digital Controller

6.1.3. Correction Factor for the Time Constants of the Controllers due to the Simulation in the Hardware-in-the-Loop Way

6.1.4. Conversion of Designed Controllers from a Continuous System to a Discrete One

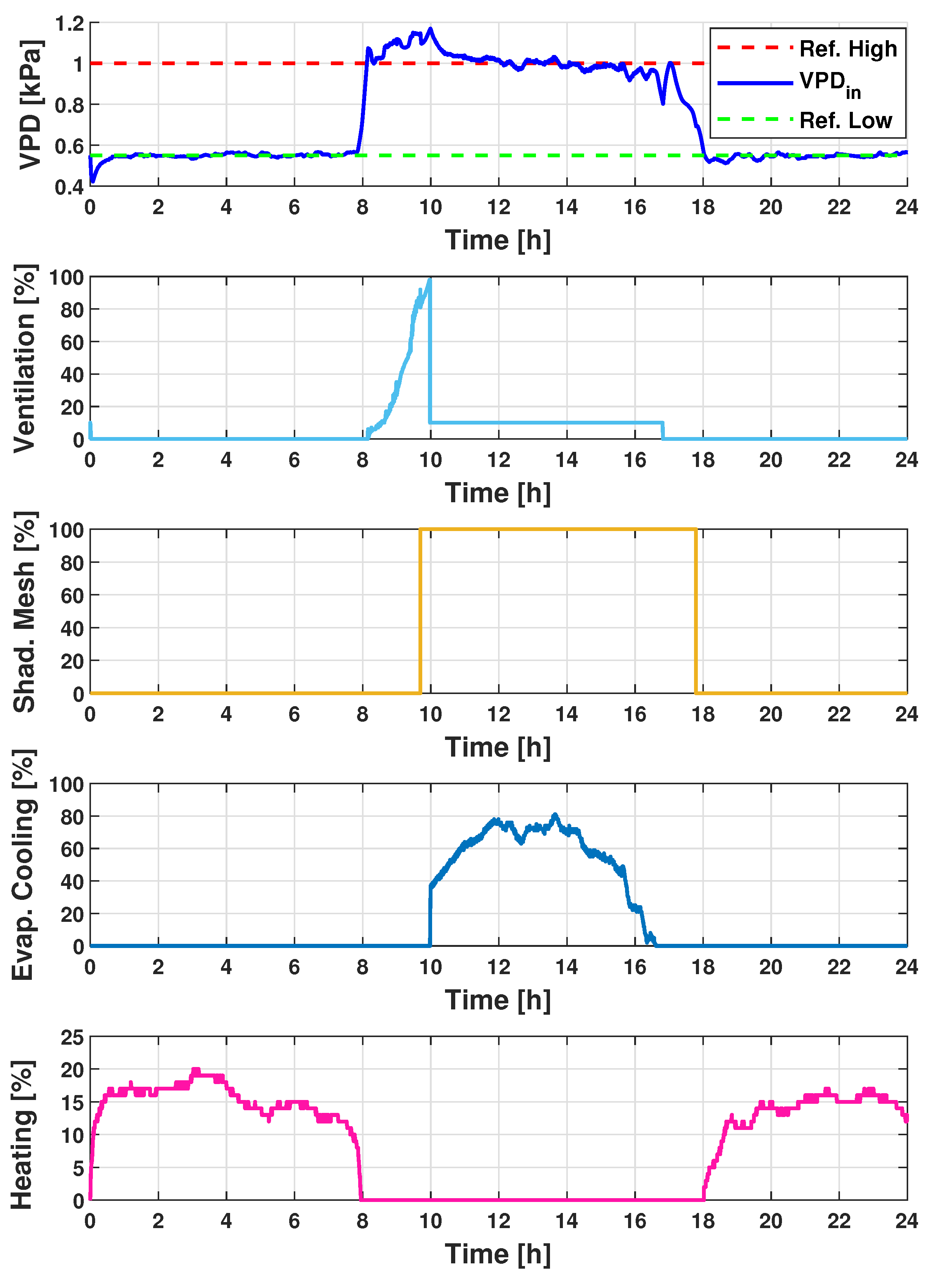

6.2. Operation Tests to the Hybrid Control System Submitted to Real Disturbances

6.2.1. First Operation Test to the Hybrid Control System Submitted to Real Disturbances of Day: 16 November 2006

6.2.2. Second Operation Test to the Hybrid Control System Submitted to Real Disturbances on 13 November 2006

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Albright, L.D.; Arvanitis, K.; Drysdale, A. Environmental control for plants on earth and in space. IEEE Control Syst. Mag. 2001, 21, 28–47. [Google Scholar]

- Giraldo, S.A.C.; Flesch, R.C.; Normey-Rico, J.E. Multivariable greenhouse control using the filtered smith predictor. J. Control Autom. Electr. Syst. 2016, 27, 349–358. [Google Scholar] [CrossRef]

- Liu, Z.; Jiao, X.; Zhu, C.; Katul, G.G.; Ma, J.; Guo, W. Micro-climatic and crop responses to micro-sprinkler irrigation. Agric. Water Manag. 2021, 243, 106498. [Google Scholar] [CrossRef]

- Bersani, C.; Fossa, M.; Priarone, A.; Sacile, R.; Zero, E. Model Predictive Control versus Traditional Relay Control in a High Energy Efficiency Greenhouse. Energies 2021, 14, 3353. [Google Scholar] [CrossRef]

- Moreno, J.; Berenguel, M.; Rodríguez, F.; Baños, A. Robust control of greenhouse climate exploiting measurable disturbances. In Proceedings of the 15th Triennial World Congress, Barcelona, Spain, 28–30 September 2002; Volume 35, pp. 271–276. [Google Scholar]

- Berenguel, M.; Yebra, L.J.; Rodríguez, F. Adaptive control strategies for greenhouse temperature control. In Proceedings of the 2003 European Control Conference (ECC), Cambridge, UK, 1–4 September 2003; IEEE: Piscatway, NJ, USA, 2003; pp. 2747–2752. [Google Scholar]

- Su, Y.; Yu, Q.; Zeng, L. Parameter self-tuning pid control for greenhouse climate control problem. IEEE Access 2020, 8, 186157–186171. [Google Scholar] [CrossRef]

- Nugroho, A.P.; Okayasu, T.; Fushihara, H.; Hirano, O.; Mitsuoka, M.; Inoue, E. Development of intelligent control system for greenhouse. In Proceedings of the Joint Simposium of Asian Federation of Information Technology in Agriculture (AFITA) and World Congress of Computers in Agriculture and Natural Resource (WCCA), Torino, Italy, 19–21 October 2012. [Google Scholar]

- Syam, R.; Piarah, W.H.; Jaelani, B. Controlling smart green house using fuzzy logic method. Int. J. Smart Mater. Mechatron. 2016, 2, 116–120. [Google Scholar] [CrossRef]

- Belhaj Salah, L.; Fourati, F. A greenhouse modeling and control using deep neural networks. Appl. Artif. Intell. 2021, 35, 1905–1929. [Google Scholar] [CrossRef]

- Oliveira, P.M.; Solteiro Pires, E.; Boaventura-Cunha, J.; Pinho, T.M. Review of nature and biologically inspired metaheuristics for greenhouse environment control. Trans. Inst. Meas. Control 2020, 42, 2338–2358. [Google Scholar] [CrossRef]

- Andaluz, G.M.; Leica, P.; Herrera, M.; Morales, L.; Camacho, O. Hybrid Controller based on Null Space and Consensus Algorithms for Mobile Robot Formation. Emerg. Sci. J. 2022, 6, 429–447. [Google Scholar] [CrossRef]

- Espín, J.; Estrada, S.; Benítez, D.; Camacho, O. A hybrid sliding mode controller approach for level control in the nuclear power plant steam generators. Alex. Eng. J. 2022, 20, 1651. [Google Scholar] [CrossRef]

- Obando, C.; Chávez, D.; Leica, P.; Camacho, O. Sliding Mode Controller Based on a Hybrid Surface for Tracking Improvement of Non-Linear Processes. IFAC-PapersOnLine 2020, 53, 11747–11752. [Google Scholar] [CrossRef]

- Fitz-Rodríguez, E.; Kubota, C.; Giacomelli, G.A.; Tignor, M.E.; Wilson, S.B.; McMahon, M. Dynamic modeling and simulation of greenhouse environments under several scenarios: A web-based application. Comput. Electron. Agric. 2010, 70, 105–116. [Google Scholar] [CrossRef]

- Briceño Medina, L.Y.; Jaimez Arellano, R.E.; Espinoza Briceño, W.E. Influencia de la condición climática de diferentes localidades en el microclima del invernadero: Región Andina y Central de Venezuela. Interciencia 2010, 35, 380–387. [Google Scholar]

- Mihalič, F.; Truntič, M.; Hren, A. Hardware-in-the-Loop Simulations: A Historical Overview of Engineering Challenges. Electronics 2022, 11, 2462. [Google Scholar] [CrossRef]

- Fernández, M.; Gyenge, J. Técnicas de medición en ecofisiología vegetal. In Conceptos y Procedimientos; Ediciones Instituto Nacional de Tecnología Agropecuaria (INTA): Buenos Aires, Argentina, 2010. [Google Scholar]

- Cardoso, G.; Puzhi, M.; Zhinín, S. Simulación de los procesos psicrométricos. Rev. Fac. Cienc. Químicas 2016, 15, 25–39. [Google Scholar]

- de Medeiros-Junior, R.; de Lima, M.; de Medeiros, M. Discussion about Models for Estimation of Relative Humidity-Case Study of the Brazilian Coast versus Influence in Concrete Durability Discusión Acerca de Modelos para la Estimación de la Humedad Relativa-Estudio de Caso de la Costa Brasileña Frente; Technological Institute of Aeronautics—ITA: Sao Paulo, Brazil, 2014. [Google Scholar]

- Shamshiri, R.R.; Jones, J.W.; Thorp, K.R.; Ahmad, D.; Man, H.C.; Taheri, S. Review of optimum temperature, humidity, and vapour pressure deficit for microclimate evaluation and control in greenhouse cultivation of tomato: A review. Int. Agrophys. 2018, 32, 287–302. [Google Scholar] [CrossRef]

- Escobedo-Sánchez, M.; Conejo-Flores, R.; Durón-Torres, S.; García, J. Radiación fotosintéticamente activa evaluada en la ciudad de Zacatecas. Rev. Energ. Quím. Fís. 2020, 7, 1–11. [Google Scholar] [CrossRef]

- Gutiérrez Hernández, J.O. Control del dÉficit de presión de Vapor (dpvc) en Cultivos de Invernadero con Sistemas de Nebulización. Ph.D. Thesis, Universidad Autónoma Chapingo, Texcoco, Mexico, 2020. [Google Scholar]

- Zhang, D.; Du, Q.; Zhang, Z.; Jiao, X.; Song, X.; Li, J. Vapour pressure deficit control in relation to water transport and water productivity in greenhouse tomato production during summer. Sci. Rep. 2017, 7, 43461. [Google Scholar] [CrossRef] [PubMed]

- Akpenpuun, T.D.; Na, W.H.; Ogunlowo, Q.O.; Rabiu, A.; Adesanya, M.A.; Addae, K.S.; Kim, H.T.; Lee, H.W. Effect of Greenhouse Cladding Materials and Thermal Screen Configuration on Heating Energy and Strawberry (Fragaria ananassa var. “Seolhyang”) Yield in Winter. Agronomy 2021, 11, 2498. [Google Scholar] [CrossRef]

- Smith, C.A.; Corripio, A.B. Principles and Practices of Automatic Process Control; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Skogestad, S.; Grimholt, C. The SIMC Method for smooth PID controller tuning. In PID Control in the Third Millennium; Springer: London, UK, 2012; pp. 147–175. [Google Scholar]

- O’Dwyer, A. Handbook of PI and PID Controller Tuning Rules; World Scientific: Singapore, 2009. [Google Scholar]

- Giraldo, S.A.C.; Gómez, D.S.H.; Blandón, J.H.G. Control y monitoreo de temperatura para un horno de curado de prendas índigo utilizando lógica difusa y controles pi. Rev. Politéc. 2013, 9, 69–81. [Google Scholar]

- Camacho, O.; Rosales, A.; Rivas, F. Control de Procesos; EPN Editorial: Valencia, Spain, 2020. [Google Scholar]

- Jacquot, R.G. Modern Digital Control Systems; Routledge: London, UK, 2019. [Google Scholar]

- Åström, K.J.; Wittenmark, B. Computer-Controlled Systems: Theory and Design; Courier Corporation: Chelmsford, MA, USA, 2013. [Google Scholar]

| Variable | Unit | Range | |

|---|---|---|---|

| Manipulated variables | % | 0–100 | |

| % | 0–100 | ||

| % | 0–100 | ||

| % | 0–100 | ||

| Controlled variables | C | - | |

| % | - | ||

| kPa | - | ||

| Disturbance variables | W · m | - | |

| C | - | ||

| % | - |

| Symbol | Value | Unit | Description |

|---|---|---|---|

| 162 | m | Area of the greenhouse floor surface | |

| 372.6 | m | Area of the glazing surface | |

| 1010 | Specific heat of moist air | ||

| H | 5.375 | m | Average greenhouse height |

| 1926 | m | Height above sea level | |

| k | 6.2 | Heat transmission coefficient of glazing | |

| L | Latent heat of vaporization of water | ||

| 1 | − | Number of heaters | |

| w | 2.3 | − | Ratio of glazing surface to floor surface |

| 1.2 | Specific mass of air | ||

| 0.4 | − | Reflectance of ground solar radiation | |

| 0.87 | − | Transmittance of the glazing material | |

| 75,000 | W | Single heater capacity |

| Radiation | Temperature | R. Humidity | ||||

|---|---|---|---|---|---|---|

| Day | RMSE | RMSE (C) | RMSE (%) | |||

| 12 November 2006 | 67.37 | 0.97 | 1.15 | 0.94 | 6.22 | 0.93 |

| 13 November 2006 | 69.20 | 0.96 | 1.38 | 0.93 | 6.31 | 0.92 |

| 14 November 2006 | 76.07 | 0.96 | 1.52 | 0.93 | 6.03 | 0.95 |

| 15 November 2006 | 62.20 | 0.97 | 1.12 | 0.93 | 5.81 | 0.92 |

| 16 November 2006 | 48.21 | 0.97 | 0.82 | 0.95 | 4.82 | 0.92 |

| Average: | 64.61 | 0.97 | 1.20 | 0.94 | 5.84 | 0.93 |

| (kPa) | (C) | (%) | Effects on the Crop | How to Correct |

|---|---|---|---|---|

| High | High | Low | Plants transpire too much. | Ventilation. |

| (>1 kPa) | They become dehydrated, so they close their stomata for self-protection, causing burns or withering on the leaves. | Shading mesh, increase irrigation, evaporative cooling system. | ||

| Optimum | Ok | Ok | Optimal growth. | No need. |

| Low | Low | High | Generates adequately. | |

| (<0.55 kPa) | Environment for pest growth. | Heating system. |

| Manipulated Variables | |||

|---|---|---|---|

| Variable | Value | Units | Description |

| 0 | % | Ventilation factor | |

| 0 | % | Shading mesh factor | |

| 0 | % | Evaporative cooling factor | |

| 0 | % | Heating factor | |

| Controlled Variables | |||

| Variable | Value | Units | Description |

| 20 | C | Air temperature inside the greenhouse | |

| 57.232 | % | Relative humidity inside the greenhouse | |

| 1.0 | kPa | Vapor pressure deficit inside the greenhouse | |

| Disturbance Variables | |||

| Variable | Value | Units | Description |

| 200 | W/m | Global radiation outside the greenhouse | |

| 14.254 | C | Air temperature outside the greenhouse | |

| 81.006 | % | Relative humidity outside the greenhouse | |

| Proportional (Input 1) | Integral (Input 2) | Output | Description |

|---|---|---|---|

| pBN | iBN | uBN | Big negative |

| pMN | iMN | uMN | Medium negative |

| pSN | iSN | uSN | Small negative |

| pZ | iZ | uZ | Zero |

| pSP | iSP | uSP | Small positive |

| pMP | iMP | uMP | Medium positive |

| pBP | iBP | uBP | Big positive |

| iBN | iMN | iSN | iZ | iSP | iMP | iBP | |

|---|---|---|---|---|---|---|---|

| pBN | uZ | uZ | uZ | uZ | uZ | uZ | uZ |

| pMN | uZ | uZ | uZ | uZ | uZ | uZ | uZ |

| pSN | uZ | uZ | uZ | uZ | uSP | uMP | uBP |

| pZ | uZ | uZ | uZ | uZ | uSP | uMP | uBP |

| pSP | uZ | uZ | uZ | uZ | uSP | uMP | uBP |

| pMP | uZ | uZ | uZ | uSP | uSP | uMP | uBP |

| pBP | uZ | uZ | uZ | uMP | uMP | uBP | uBP |

| Manipulated Variables | |||

|---|---|---|---|

| Variable | Value | Units | Description |

| 10 | % | Ventilation factor | |

| 100 | % | Shading mesh factor | |

| 0 | % | Evaporative cooling factor | |

| 0 | % | Heating factor | |

| Controlled Variables | |||

| Variable | Value | Units | Description |

| 20 | C | Air temperature inside the greenhouse | |

| 57.195 | % | Relative humidity inside the greenhouse | |

| 1.0 | kPa | Vapor pressure deficit inside the greenhouse | |

| Disturbance Variables | |||

| Variable | Value | Units | Description |

| 700 | W/m | Global radiation outside the greenhouse | |

| 13.730 | C | Air temperature outside the greenhouse | |

| 84.728 | % | Relative humidity outside the greenhouse | |

| Manipulated Variables | |||

|---|---|---|---|

| Variable | Value | Units | Description |

| 0 | % | Ventilation factor | |

| 0 | % | Shading mesh factor | |

| 0 | % | Evaporative cooling factor | |

| 0 | % | Heating factor | |

| Controlled Variables | |||

| Variable | Value | Units | Description |

| 18 | C | Air temperature inside the greenhouse | |

| 73.347 | % | Relative humidity inside the greenhouse | |

| 0.55 | kPa | Vapor pressure deficit inside the greenhouse | |

| Disturbance Variables | |||

| Variable | Value | Units | Description |

| 50 | W/m | Global radiation outside the greenhouse | |

| 16.566 | C | Air temperature outside the greenhouse | |

| 79.993 | % | Relative humidity outside the greenhouse | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cevallos, G.; Herrera, M.; Jaimez, R.; Aboukheir, H.; Camacho, O. A Practical Hybrid Control Approach for a Greenhouse Microclimate: A Hardware-in-the-Loop Implementation. Agriculture 2022, 12, 1916. https://doi.org/10.3390/agriculture12111916

Cevallos G, Herrera M, Jaimez R, Aboukheir H, Camacho O. A Practical Hybrid Control Approach for a Greenhouse Microclimate: A Hardware-in-the-Loop Implementation. Agriculture. 2022; 12(11):1916. https://doi.org/10.3390/agriculture12111916

Chicago/Turabian StyleCevallos, Gustavo, Marco Herrera, Ramon Jaimez, Hanna Aboukheir, and Oscar Camacho. 2022. "A Practical Hybrid Control Approach for a Greenhouse Microclimate: A Hardware-in-the-Loop Implementation" Agriculture 12, no. 11: 1916. https://doi.org/10.3390/agriculture12111916

APA StyleCevallos, G., Herrera, M., Jaimez, R., Aboukheir, H., & Camacho, O. (2022). A Practical Hybrid Control Approach for a Greenhouse Microclimate: A Hardware-in-the-Loop Implementation. Agriculture, 12(11), 1916. https://doi.org/10.3390/agriculture12111916