Author Contributions

Conceptualization, Z.Z. and D.W.; methodology, Z.Z.; software, Z.Z.; validation, Z.Z., H.Z. and H.W.; formal analysis, Z.Z. and C.X.; investigation, Z.Z.; resources, Z.Z.; data curation, Y.W., Z.C. and D.L.; writing—original draft preparation, Z.Z.; writing—review and editing, S.S. and J.H.; visualization, Z.Z.; supervision, Z.Z.; project administration, X.H.; funding acquisition, X.H. All authors have read and agreed to the published version of the manuscript. (Design and Testing of Discrete Element-based Counter-rotating Excavation Device for Cyperus esculentus).

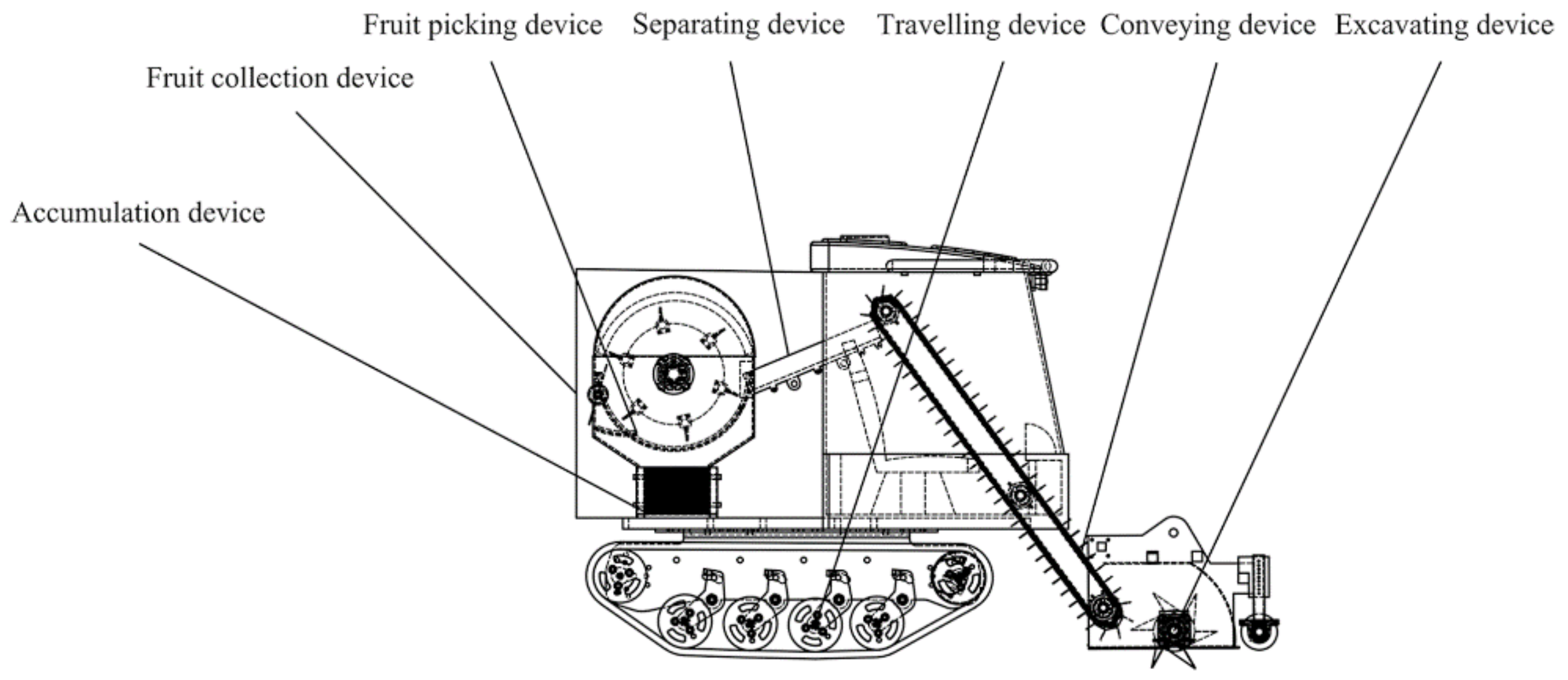

Figure 1.

Overall structure of the Cyperus esculentus combine harvester.

Figure 1.

Overall structure of the Cyperus esculentus combine harvester.

Figure 2.

Structure parameters of counter-rotating excavation device.

Figure 2.

Structure parameters of counter-rotating excavation device.

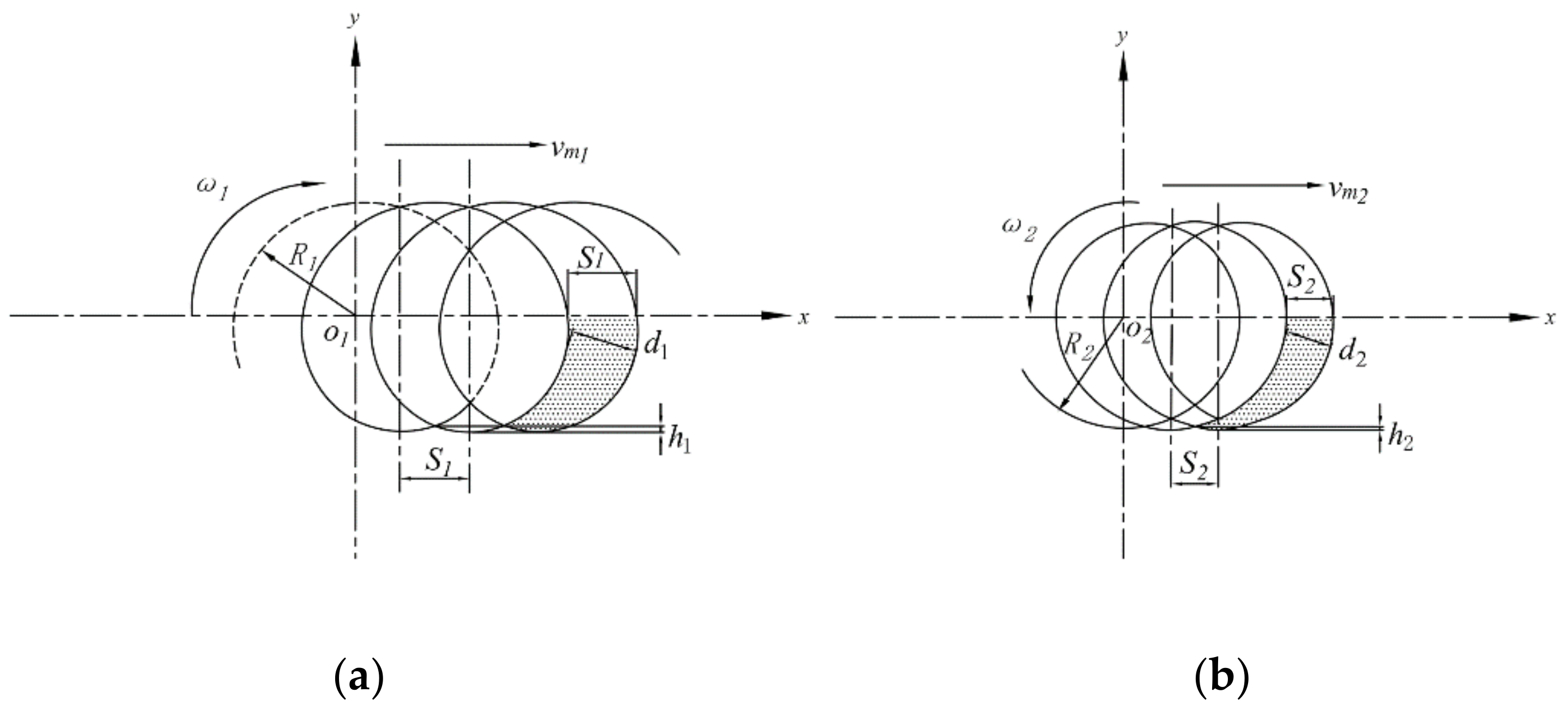

Figure 3.

Trajectory analysis of positive-rotating and counter-rotating rotation. (a) Trajectory analysis of positive-rotating, where vm1 is machine advance speed of positive rotation, m/s; ω1 is tool shaft rotation speed of positive rotation, rad/s; S1 is soil cutting pitch of positive rotation, mm; d1 is positive-rotating movement of the soil with cutting thickness, mm; h1 is positive-rotating harvesting groove bottom bulge height, mm; R1 is motion radius of gyration of positive rotation, mm. (b) Trajectory analysis of counter-rotating, where vm2 is machine advance speed of counter rotation, m/s; ω2 is tool shaft rotation speed of counter rotation, rad/s; S2 is soil cutting pitch of counter rotation, mm; d2 is counter-rotating movement of the soil to the cutting thickness, mm; h2 is counter-rotating harvesting groove bottom bulge height, mm; R2 is motion radius of gyration of counter rotation, mm.

Figure 3.

Trajectory analysis of positive-rotating and counter-rotating rotation. (a) Trajectory analysis of positive-rotating, where vm1 is machine advance speed of positive rotation, m/s; ω1 is tool shaft rotation speed of positive rotation, rad/s; S1 is soil cutting pitch of positive rotation, mm; d1 is positive-rotating movement of the soil with cutting thickness, mm; h1 is positive-rotating harvesting groove bottom bulge height, mm; R1 is motion radius of gyration of positive rotation, mm. (b) Trajectory analysis of counter-rotating, where vm2 is machine advance speed of counter rotation, m/s; ω2 is tool shaft rotation speed of counter rotation, rad/s; S2 is soil cutting pitch of counter rotation, mm; d2 is counter-rotating movement of the soil to the cutting thickness, mm; h2 is counter-rotating harvesting groove bottom bulge height, mm; R2 is motion radius of gyration of counter rotation, mm.

Figure 4.

Structure of the counter-rotating blade.

Figure 4.

Structure of the counter-rotating blade.

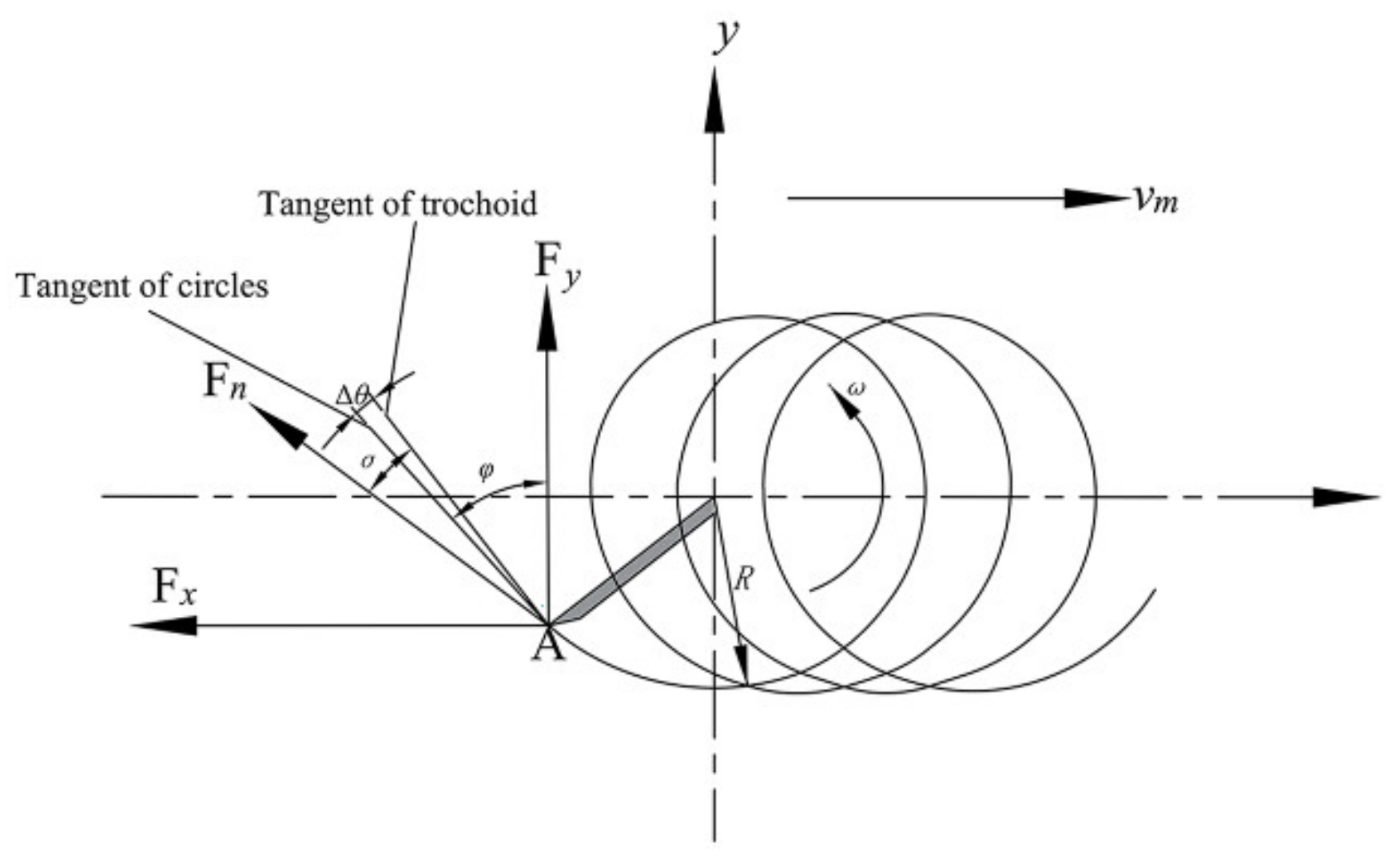

Figure 5.

Schematic diagram of the force of counter-rotating blade, where Fx is the working resistance of the counter-rotating blade in the x direction, N; Fy is the working resistance of the counter-rotating blade in the y direction, N; Fn is the total resistance of the counter-rotating blade, N; ρ is rotary tillage soil cutting-specific resistance; φ is counter-rotating blade rotation angle, °; σ is the angle between Fn and the tangent of trochoidal, °; Δθ is the angle between tangent of circle and tangent of trochoidal, °; R is the motion radius of gyration, mm; and vm is machine advance speed, m/s.

Figure 5.

Schematic diagram of the force of counter-rotating blade, where Fx is the working resistance of the counter-rotating blade in the x direction, N; Fy is the working resistance of the counter-rotating blade in the y direction, N; Fn is the total resistance of the counter-rotating blade, N; ρ is rotary tillage soil cutting-specific resistance; φ is counter-rotating blade rotation angle, °; σ is the angle between Fn and the tangent of trochoidal, °; Δθ is the angle between tangent of circle and tangent of trochoidal, °; R is the motion radius of gyration, mm; and vm is machine advance speed, m/s.

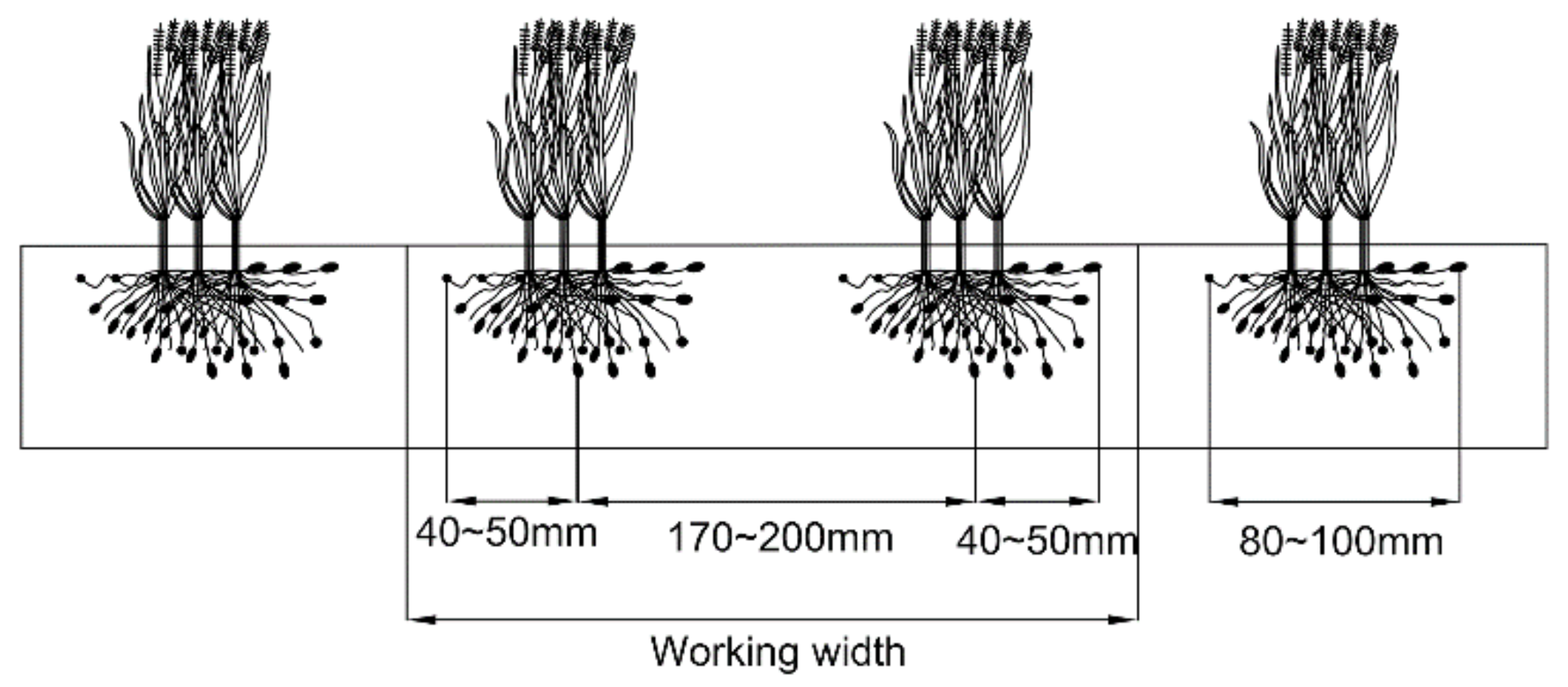

Figure 6.

Cyperus esculentus planting pattern.

Figure 6.

Cyperus esculentus planting pattern.

Figure 7.

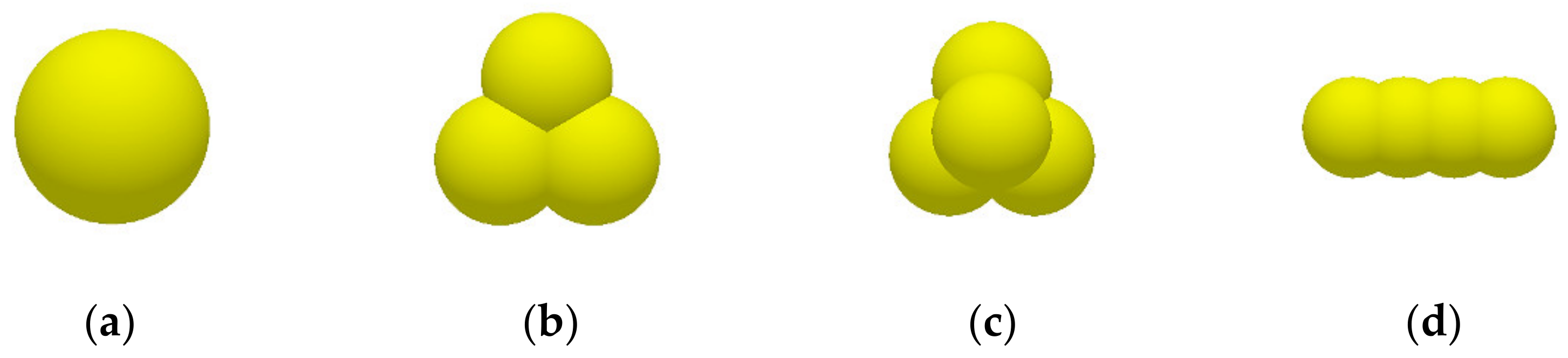

Soil discrete element model. (a) Single grain spherical model; (b) three-grain flake model; (c) four-grain block model; (d) four-grain rod model.

Figure 7.

Soil discrete element model. (a) Single grain spherical model; (b) three-grain flake model; (c) four-grain block model; (d) four-grain rod model.

Figure 8.

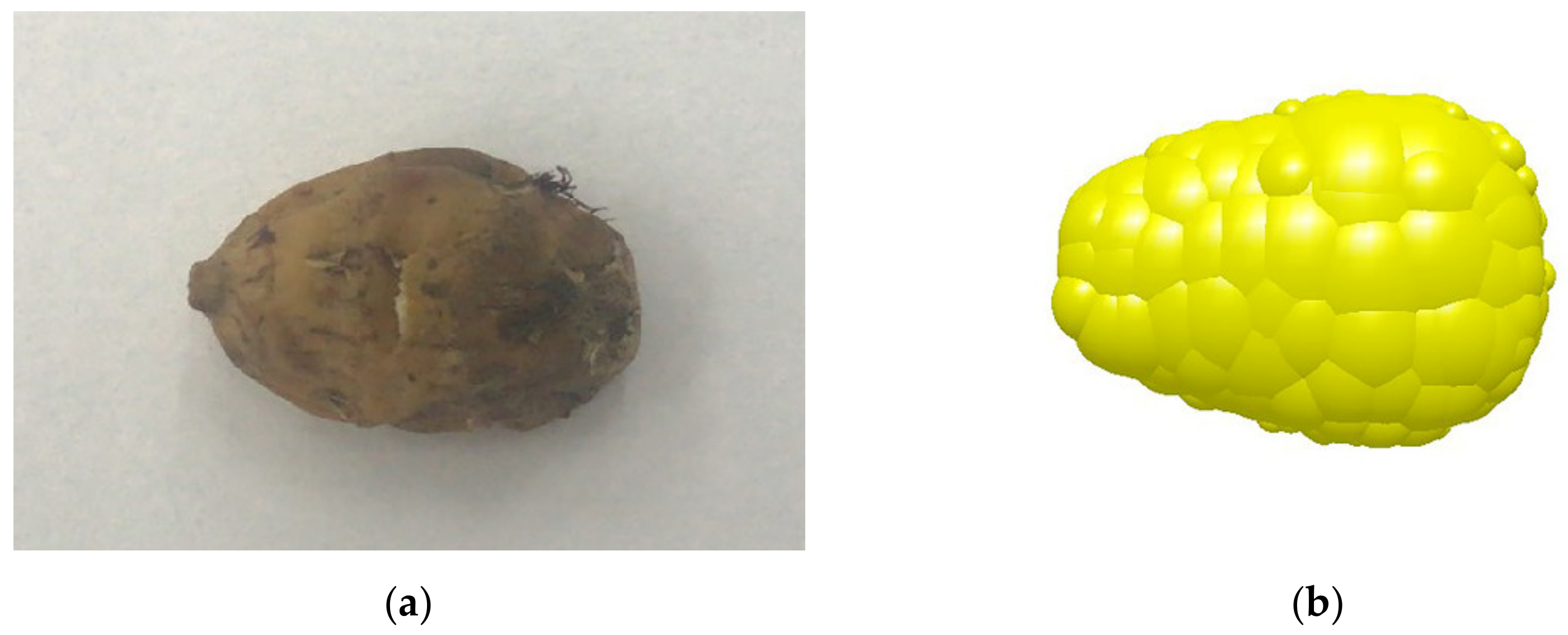

Discrete element model of Cyperus esculentus tuber. (a) Cyperus esculentus tuber model; (b) discrete element modeling of Cyperus esculentus.

Figure 8.

Discrete element model of Cyperus esculentus tuber. (a) Cyperus esculentus tuber model; (b) discrete element modeling of Cyperus esculentus.

Figure 9.

Discrete element model of Cyperus esculentus root system. (a) Cyperus esculentus root system model; (b) discrete element modeling of Cyperus esculentus.

Figure 9.

Discrete element model of Cyperus esculentus root system. (a) Cyperus esculentus root system model; (b) discrete element modeling of Cyperus esculentus.

Figure 10.

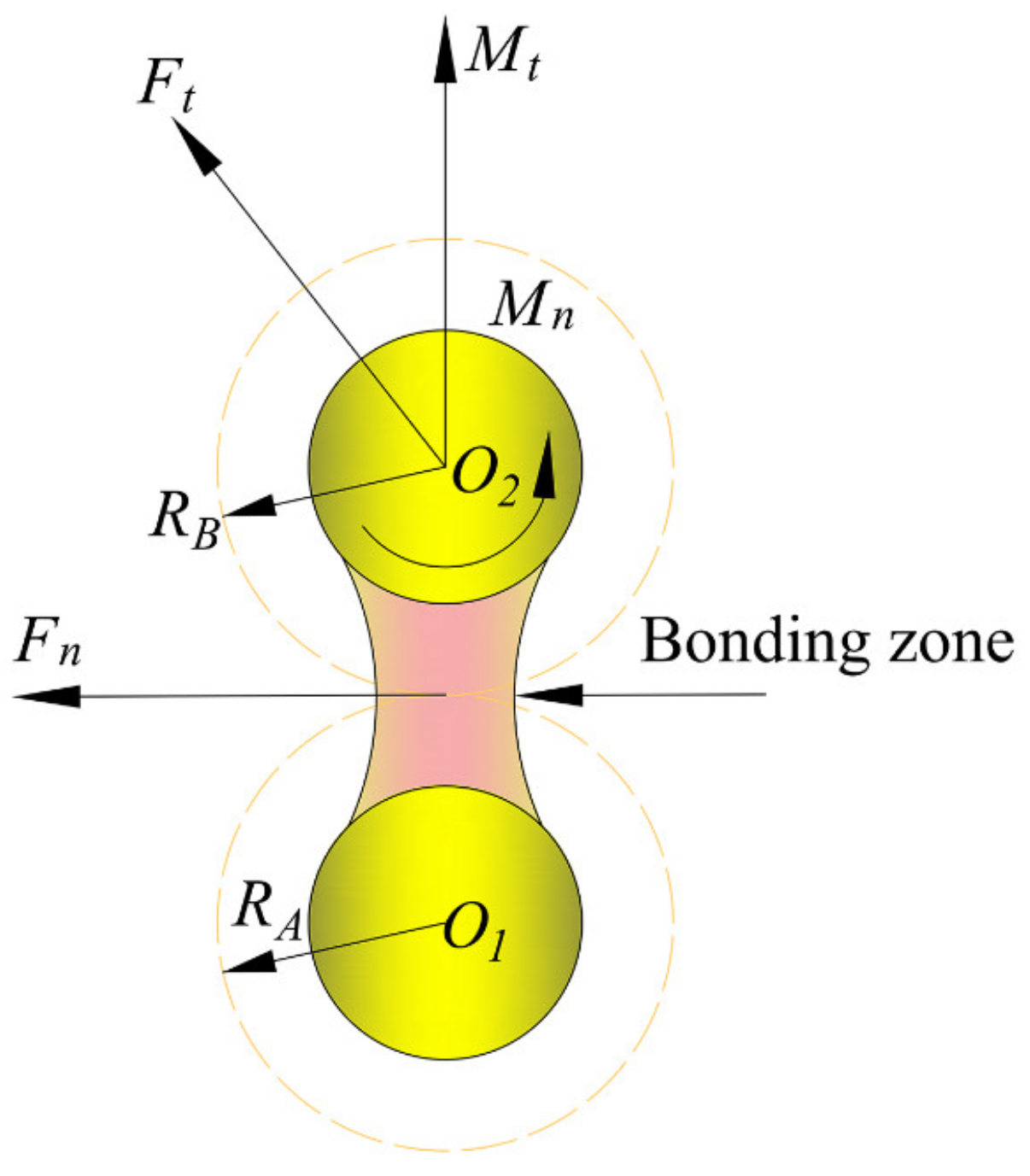

Soil contact particle model, where O1 and O2 is the center of the circle of the soil model; R1 and R2 is the radius of the soil model; Fn is normal contact force, N; Ft is tangential contact force, N; Mn is normal moment, Nm; and Mt is tangential moment, Nm.

Figure 10.

Soil contact particle model, where O1 and O2 is the center of the circle of the soil model; R1 and R2 is the radius of the soil model; Fn is normal contact force, N; Ft is tangential contact force, N; Mn is normal moment, Nm; and Mt is tangential moment, Nm.

Figure 11.

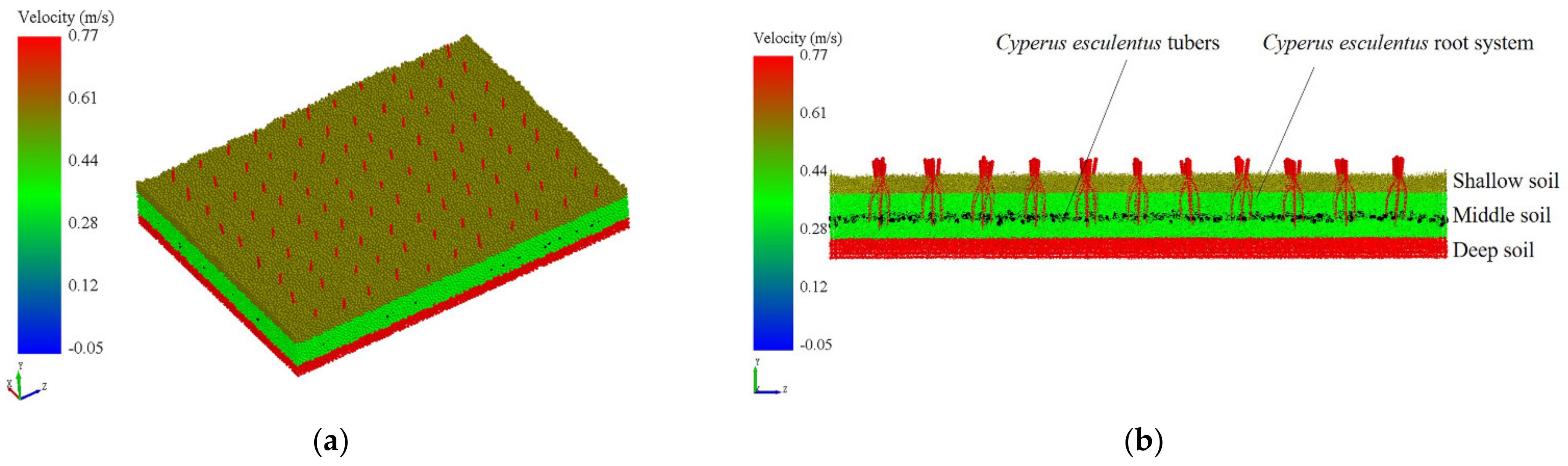

Cyperus esculentus agglomerate. (a) The overall model of Cyperus esculentus agglomerate; (b) the vector model of the Cyperus esculentus agglomerate.

Figure 11.

Cyperus esculentus agglomerate. (a) The overall model of Cyperus esculentus agglomerate; (b) the vector model of the Cyperus esculentus agglomerate.

Figure 12.

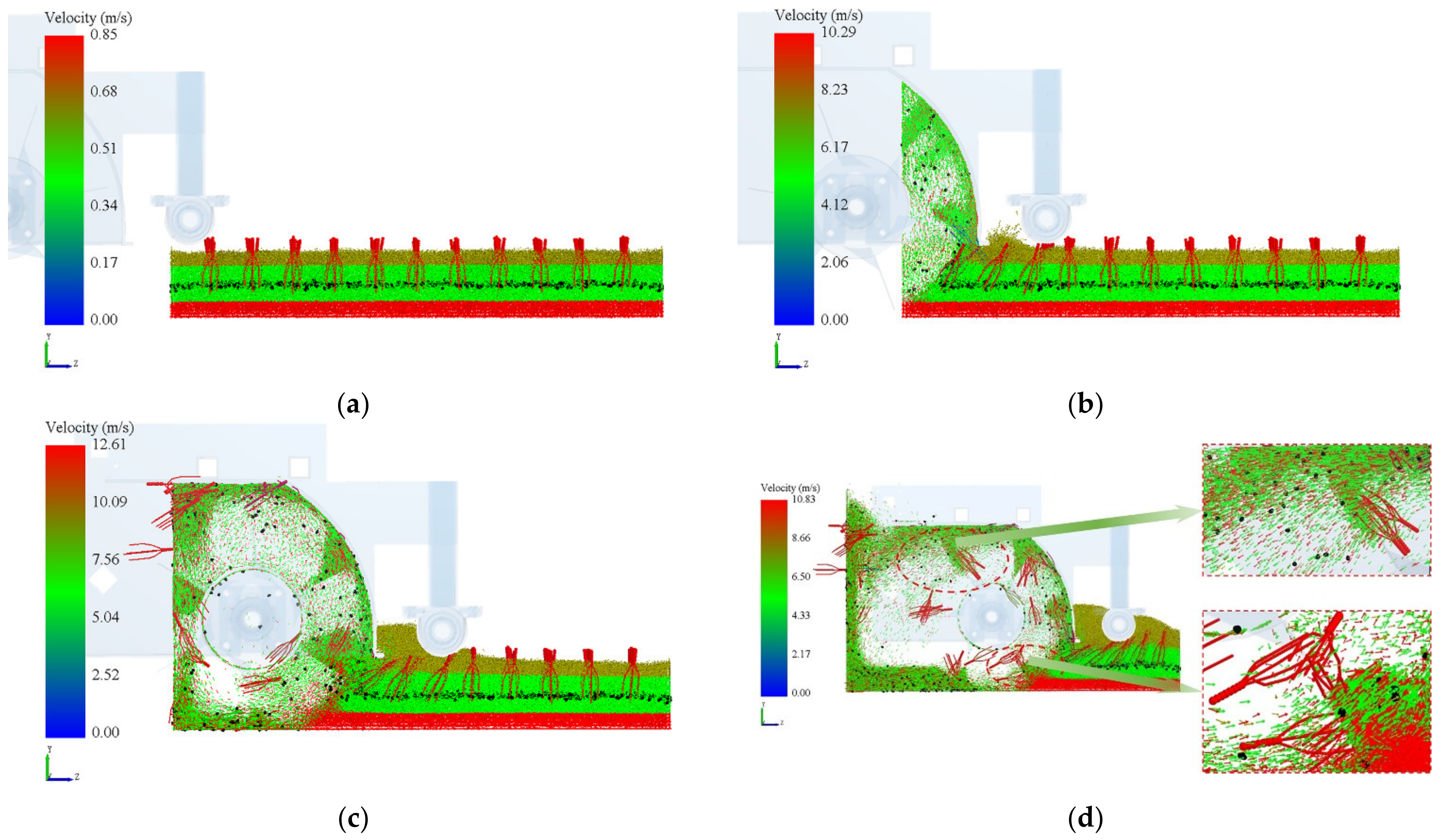

Discrete element simulation test of Cyperus esculentus agglomerate counter-rotation excavation. (a) 1 s; (b) 2 s; (c) 3 s; (d) 4 s.

Figure 12.

Discrete element simulation test of Cyperus esculentus agglomerate counter-rotation excavation. (a) 1 s; (b) 2 s; (c) 3 s; (d) 4 s.

Figure 13.

Field trial conditions measurement. (a) Measurement of planting pattern of Cyperus esculentus; (b) planting depth measurement of Cyperus esculentus.

Figure 13.

Field trial conditions measurement. (a) Measurement of planting pattern of Cyperus esculentus; (b) planting depth measurement of Cyperus esculentus.

Figure 14.

Field trial. (a) The counter-rotating excavation device; (b) the positive-rotating excavation device.

Figure 14.

Field trial. (a) The counter-rotating excavation device; (b) the positive-rotating excavation device.

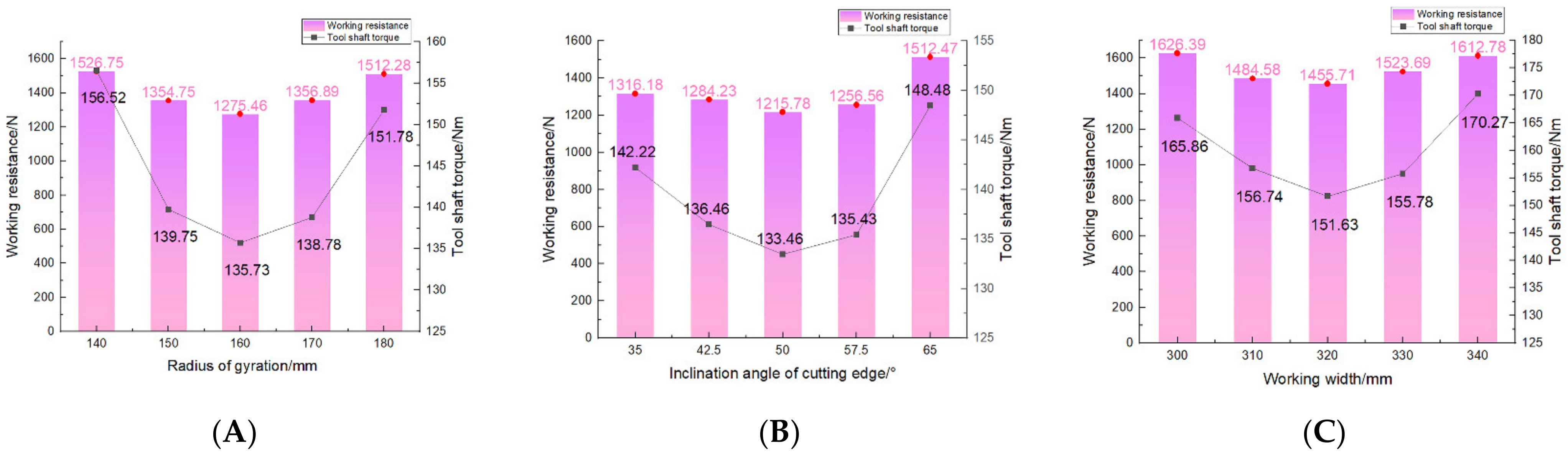

Figure 15.

Results of single-factor test on evaluation indicators. (A) Results of single-factor test on radius of gyration R. (B) Results of single-factor test on inclination angle of cutting edge β. (C) Results of single-factor test on working width L.

Figure 15.

Results of single-factor test on evaluation indicators. (A) Results of single-factor test on radius of gyration R. (B) Results of single-factor test on inclination angle of cutting edge β. (C) Results of single-factor test on working width L.

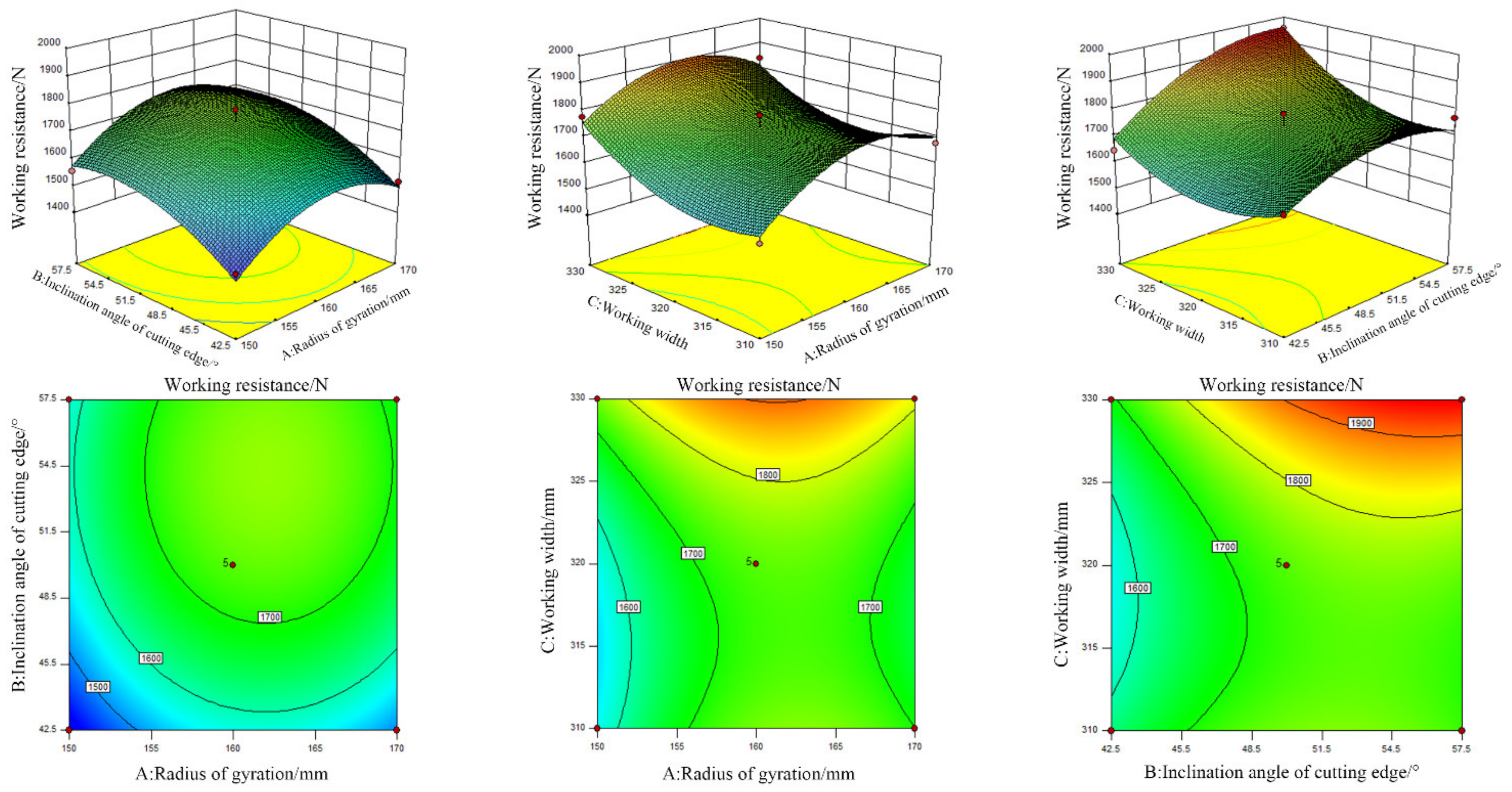

Figure 16.

The relationship between each test factor and the working resistance.

Figure 16.

The relationship between each test factor and the working resistance.

Figure 17.

The response surface of each test factor to working resistance.

Figure 17.

The response surface of each test factor to working resistance.

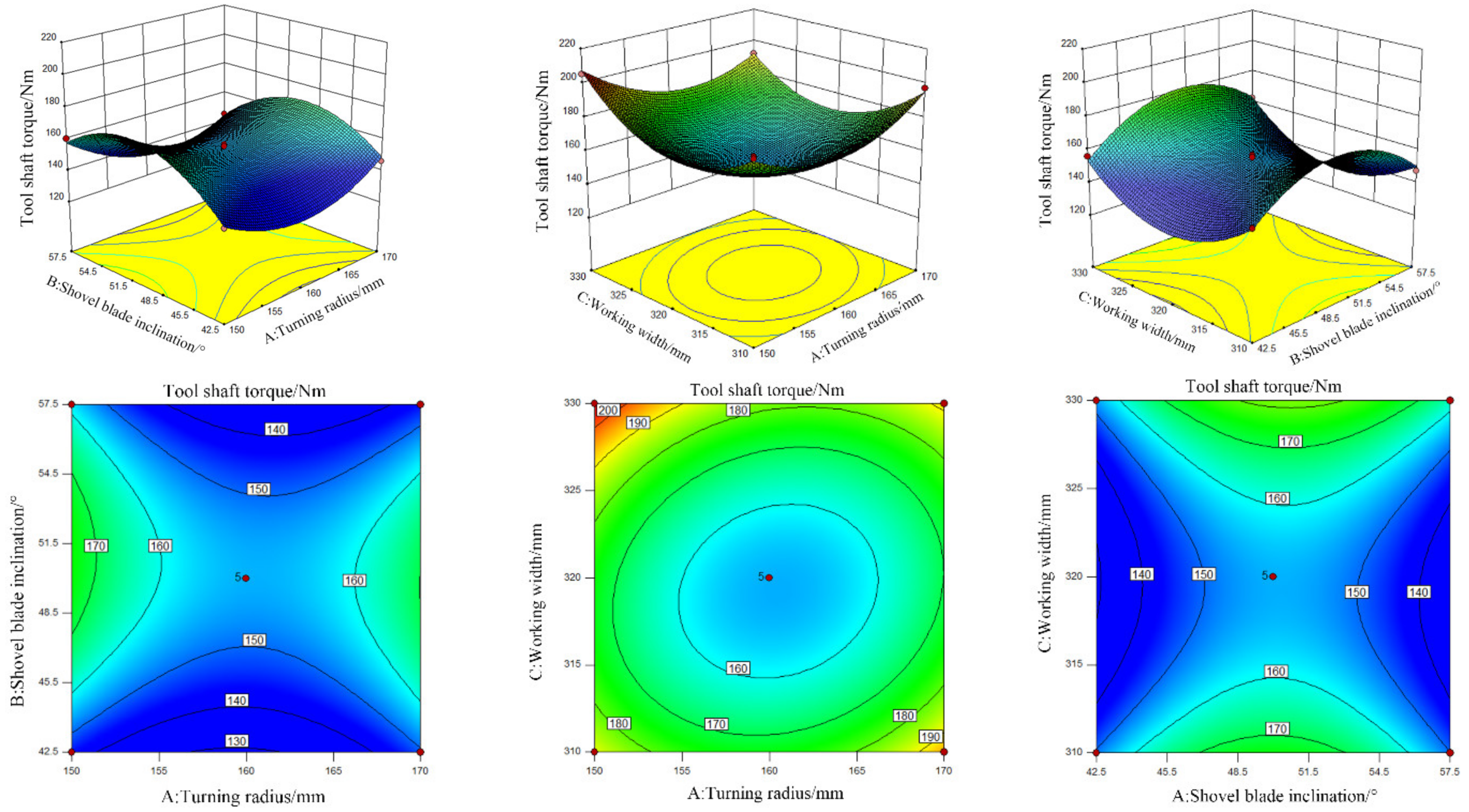

Figure 18.

The relationship between each test factor and the tool shaft torque.

Figure 18.

The relationship between each test factor and the tool shaft torque.

Figure 19.

The response surface of each test factor to tool shaft torque.

Figure 19.

The response surface of each test factor to tool shaft torque.

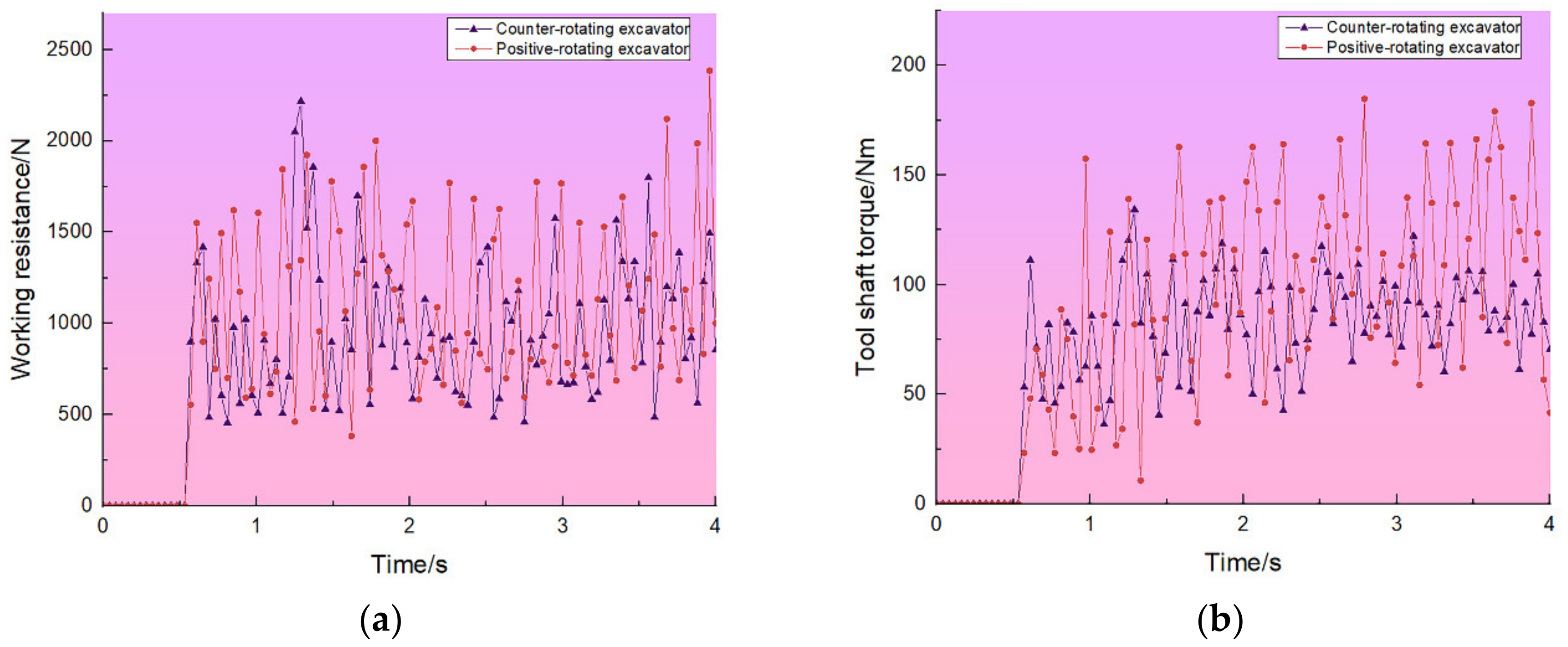

Figure 20.

The response surface of each test factor to tool shaft torque. (a) Results of comparative analysis of working resistance. (b) Results of comparative analysis of tool shaft torque.

Figure 20.

The response surface of each test factor to tool shaft torque. (a) Results of comparative analysis of working resistance. (b) Results of comparative analysis of tool shaft torque.

Table 1.

Discrete element contact parameters.

Table 1.

Discrete element contact parameters.

| Parameters | Values |

|---|

| Working width/(mm) | 1000 |

| Working depth/(mm) | 0~200 |

| Dimension (L × W × H)/(mm) | 1250 × 950 × 800 |

| Matching power/(kW) | 75~100 |

| Operation efficiency/(km·h−1) | 1.1~1.5 |

Table 2.

Discrete element contact parameters.

Table 2.

Discrete element contact parameters.

| Contact Model | Restitution Coefficient | Static Friction Coefficient | Rolling Friction Coefficient |

|---|

| Soil–soil | 0.43 | 0.55 | 0.15 |

| Soil–excavation device | 0.21 | 0.52 | 0.13 |

| Soil–tuber | 0.13 | 0.46 | 0.01 |

| Soil–root system | 0.14 | 0.42 | 0.01 |

| Root system–root system | 0.53 | 0.62 | 0.58 |

| Root system–excavation device | 0.40 | 0.53 | 0.01 |

| Root system–tuber | 0.21 | 0.42 | 0.10 |

| Tuber–tuber | 0.36 | 0.25 | 0.032 |

| Tuber–excavation device | 0.72 | 0.56 | 0.16 |

Table 3.

Discrete element contact parameters.

Table 3.

Discrete element contact parameters.

| Contact Model | Density (Kg/m3) | Poisson’s Ratio | Modulus of Shear (Pa) |

|---|

| Soil | 1456 | 0.38 | 2.5 × 106 |

| Tuber | 2860 | 0.43 | 1.56 × 107 |

| Root system | 1070 | 0.56 | 0.93 × 105 |

Table 4.

Soil parameter information.

Table 4.

Soil parameter information.

| Soil Depth/mm | Soil Moisture Content/% | Soil Density/g/cm3 | Soil Firmness/Kpa |

|---|

| 0~50 | 10.23 | 1.57 | 364 |

| 50~150 | 13.65 | 1.63 | 517 |

| 150~200 | 15.78 | 1.75 | 756 |

Table 5.

Test factor codes.

Table 5.

Test factor codes.

| Test Factor | Symbol | Test Level |

|---|

| −1 | 0 | 1 |

|---|

| Radius of gyration (mm) | A | 150 | 160 | 170 |

| Inclination angle of cutting edge (°) | B | 42.5 | 50 | 47.5 |

| Working width (mm) | C | 310 | 320 | 330 |

Table 6.

Results of multi-factor test.

Table 6.

Results of multi-factor test.

| No. | Test Factors | Evaluation Indicator |

|---|

| Radius of Gyration | Inclination Angle of Cutting Edge | Working Width | Working Resistance y1/N | Tool Shaft Torque y2/Nm |

|---|

| 1 | −1 | −1 | 0 | 1424.93 | 157.24 |

| 2 | 1 | −1 | 0 | 1515.38 | 160.57 |

| 3 | −1 | 1 | 0 | 1556.51 | 156.45 |

| 4 | 1 | 1 | 0 | 1659.62 | 191.75 |

| 5 | −1 | 0 | −1 | 1536.25 | 143.64 |

| 6 | 1 | 0 | −1 | 1677.88 | 151.58 |

| 7 | −1 | 0 | 1 | 1775.68 | 153.38 |

| 8 | 1 | 0 | 1 | 1839.75 | 205.38 |

| 9 | 0 | −1 | −1 | 1630.54 | 147.36 |

| 10 | 0 | 1 | −1 | 1766.16 | 162.58 |

| 11 | 0 | −1 | 1 | 1645.77 | 188.85 |

| 12 | 0 | 1 | 1 | 1956.57 | 197.32 |

| 13 | 0 | 0 | 0 | 1718.27 | 145.23 |

| 14 | 0 | 0 | 0 | 1732.73 | 146.32 |

| 15 | 0 | 0 | 0 | 1714.71 | 153.45 |

| 16 | 0 | 0 | 0 | 1734.53 | 152.56 |

| 17 | 0 | 0 | 0 | 1781.73 | 155.75 |

Table 7.

Working resistance analysis of variance.

Table 7.

Working resistance analysis of variance.

| Source | Sum of Squares | Freedom | Mean Square | F | p-Value |

|---|

| Model | 2.58 × 105 | 9 | 28,609.83 | 17.70 | <0.01 ** |

| A | 19,926.27 | 1 | 19,926.27 | 12.33 | <0.01 ** |

| B | 65,204.19 | 1 | 65,204.19 | 40.35 | <0.01 ** |

| C | 46,047.02 | 1 | 46,047.02 | 28.49 | <0.01 ** |

| AB | 40.06 | 1 | 40.06 | 0.025 | 0.8793 |

| AC | 1503.89 | 1 | 1503.89 | 0.93 | 0.3668 |

| BC | 7672.01 | 1 | 7672.01 | 4.75 | 0.0658 |

| A2 | 60,457.14 | 1 | 60,457.14 | 37.41 | <0.01 ** |

| B2 | 25,261.58 | 1 | 25,261.58 | 15.63 | <0.01 ** |

| C2 | 34,732.05 | 1 | 34,732.05 | 21.49 | <0.01 ** |

| Residual | 11,312.66 | 7 | 1616.09 | - | - |

| Lack of Fit | 8441.73 | 3 | 2813.91 | 3.92 | 0.1100 |

| Pure Error | 2870.93 | 4 | 717.73 | - | - |

Table 8.

Tool shaft torque analysis of variance.

Table 8.

Tool shaft torque analysis of variance.

| Source | Sum of Squares | Freedom | Mean Square | F | p-Value |

|---|

| Model | 6182.96 | 9 | 687.00 | 84.52 | <0.01 ** |

| A | 39.69 | 1 | 39.69 | 4.88 | 0.0628 |

| B | 39.38 | 1 | 39.38 | 4.85 | 0.0636 |

| C | 120.51 | 1 | 120.51 | 14.83 | <0.01 ** |

| AB | 81.18 | 1 | 81.18 | 9.99 | <0.01 ** |

| AC | 122.10 | 1 | 122.10 | 15.02 | 0.0129 * |

| BC | 26.78 | 1 | 26.78 | 3.29 | 0.2819 * |

| A2 | 1348.83 | 1 | 1348.83 | 165.95 | <0.01 ** |

| B2 | 2312.27 | 1 | 2312.27 | 284.49 | <0.01 ** |

| C2 | 2315.53 | 1 | 2315.53 | 284.89 | <0.01 ** |

| Residual | 56.89 | 7 | 8.13 | - | - |

| Lack of Fit | 41.71 | 3 | 13.90 | 3.66 | 0.1211 |

| Pure Error | 15.19 | 4 | 3.80 | - | - |

Table 9.

Field trial results.

Table 9.

Field trial results.

| No. | Counter-Rotating Excavation | Positive- Rotating Excavation |

|---|

| Fruit Burial rate/% | Damage Rate/% | Fruit Burial Rate/% | Damage Rate/% |

|---|

| 1 | 1.43 | 1.25 | 1.55 | 1.32 |

| 2 | 1.23 | 1.38 | 1.42 | 1.48 |

| 3 | 1.35 | 1.32 | 1.58 | 1.41 |

| 4 | 1.31 | 1.41 | 1.49 | 1.52 |

| 5 | 1.52 | 1.53 | 1.65 | 1.61 |

| Average value | 1.37 | 1.38 | 1.54 | 1.47 |

Table 10.

The results of field trial results discussion.

Table 10.

The results of field trial results discussion.

| Type of Excavation Device | Fruit Burial Rate/% | Working Resistance/N |

|---|

| Counter-rotating excavation | 1.37 | 836.65 |

| Optimised-Rotary tillage | 1.75 | 928.36 |

| Normal-Rotary excavation | 2.07 | 1015.52 |