Abstract

The use of pergola trellis crops has led to a need for irrigation and the spraying of pesticides. Thus, a new integrated micro-nozzle was designed to provide water and pesticides. The structural parameters that affect the irrigation performance were selected based on the working principle of the sprinkler. They included the outlet diameter, refractive surface angle, and the distance from the outlet plane to the refractive surface (cone hole distance). The structural parameters that affect the performance of spraying pesticide included the number of diversion chutes, nozzle diameter, and nozzle outer cone angle. The structural optimization of the water–pesticide integrated sprinkler was determined by a single-factor and a three-factors four-levels orthogonal tests. The indices used to evaluate the performance of the sprinkler were irrigation flow rate, wetted radius, and uniformity coefficient. Those used to evaluate the performance at spraying pesticides included the flow rate of spraying pesticides, spray cone angle, and relative size range of the droplets. The entropy weight and the extreme difference analytical methods were used to process the test data. The main order of the influence of key structural parameters on the irrigation performance was obtained as follows: outlet diameter, refractive surface angle, and cone hole distance. The primary and secondary order of the influence on the performance of spraying pesticide was as follows: the number of diversion chutes, angle of the outer cone of the nozzle, and nozzle diameter. The optimal combination of parameters for this water–pesticide integrated micro sprinkler was obtained as follows: outlet diameter 2.0 mm, refractive surface angle 30°, cone hole distance 1.0 d, nozzle diameter 3.0 mm, two diversion chutes, and nozzle outer cone angle 90°. The performance indices included the irrigation water flow rate 0.284 m3/h, wetted radius 4.26 m, uniformity coefficient 91.07%, flow rate of pesticides spread 0.097 m3/h, spray cone angle 121.25°, and average relative distribution span of droplets 1.18. The results provide an important theoretical basis for the practical application of sprinklers.

1. Introduction

Grape (Vitis vinifera) is one of the top five types of fruit grown in China based on both planting areas and yield. Grapes are primarily planted using either a hedgerow trellis or a pergola trellis. The current method of irrigation for trellised grapes is primarily drip irrigation or micro-spraying [1], and the use of pesticides primarily includes the manual spraying of pesticides or the use of a sprayer. This method of applying pesticides has problems, such as large drift losses, low pesticide utilization, and pollution of the orchard environment [2,3,4]. Integrated water–pesticide technology can combine the functions of irrigation and pesticide application. It can be an effective way to solve the problem of excessive utilization of water and pesticides in the current agricultural production process [5]. Researchers have applied water–pesticide integration technology to drip irrigation. The specific practice is to deliver the desired chemicals to the root on time, on demand, and accurately and evenly with pressurized irrigation water in the pipe, thus reducing diseases of the roots and improving the effective utilization of pesticides [6,7]. Water–pesticide integrated micro-sprinkler technology can act directly on the surface of crop leaves through the scattering and atomization of water flow, so that it can save both irrigation water and the need to spray pesticides on the branches and leaves. [8]. This requires sprinklers to meet the performance standards of both irrigation and spraying pesticides. Currently, the most commonly used micro-sprinklers for fruit trees are centrifugal sprinklers, fan-shaped atomizing sprinklers, and pneumatic electrostatic sprinklers. For example, in 2011, Negeed et al. [9] conducted a study on aerial sprinklers with different pressures and different nozzle diameters for liquid film rupture and then derived the relevant empirical equations. In 2013, Xie Chen et al. [10] tested the atomization characteristics of standard fan nozzles (STs) and antidrift nozzles (IDKs). In 2014, Ouazaa et al. [11] conducted hydraulic performance tests of low-pressure refractive sprinklers by varying the working pressures and nozzle diameters. A low-pressure refractive sprinkler water distribution calculation model was derived by combining the ballistic theory model and the hydraulic performance test data. In 2016, Tsaboula et al. [12] studied the deposition of droplets using a water–pesticide integrated spray under different wind speeds. In 2019, Fengbo Yang et al. [13] produced a rapid prediction model for atomized sprinkler spray width by conducting aerial centrifugal sprinkler atomization performance tests and processing the test results using various mathematical methods. The existing research on micro-sprinklers primarily focuses on the spraying performance of pesticide nozzles, while there is less research on water–pesticide integrated sprinklers that synergistically spray pesticides and irrigate with water in the same micro-sprinkler system. In this study, a water–pesticide integrated sprinkler was invented to meet the two working modes of low-pressure irrigation and the medium-pressure spraying of pesticides in the same system.

The goal of this study was to evaluate the influence of the main structural parameters on the performance of irrigation and spraying pesticides. The optimal combination of parameters for this water–pesticide integrated micro-sprinkler was obtained, which provides an important theoretical basis for the practical application of water–pesticide integrated sprinklers.

2. Materials and Methods

2.1. Structural Design and Working Principle of a Water–Pesticide Integrated Sprinkler

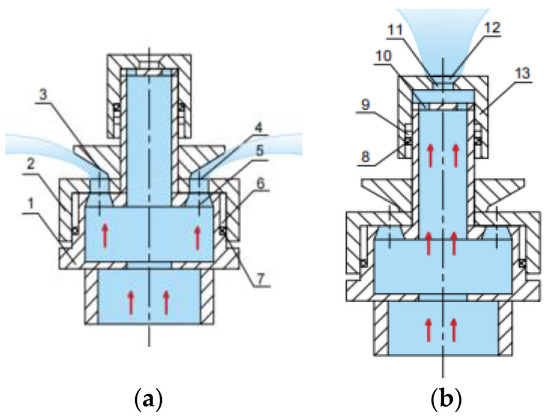

The structural design of the water–pesticide integrated sprinkler is shown in Figure 1. It primarily consists of a sprinkler body, rotating housing, and sprinkler cap. Irrigation mode is a working state of this sprinkler. The irrigation mode requires watering the roots of the plants. The pesticide-spraying mode requires spraying the leaves of the plants.

Figure 1.

Two working models of the sprinkler. 1. Sprinkler body. 2. Rotating shell body. 3. Refractive surface. 4. Outlet nozzle. 5. Diversion hole. 6. First limit slot. 7. First limit pin. 8. Second limit pin. 9. Second limit slot. 10. Diversion chute. 11. Nozzle. 12. Outer cone angle. 13. Nozzle cap. (a) Irrigation water model; (b) Pesticide-spraying model.

The working principle of the sprinkler is as follows: During the irrigation operation under low-pressure conditions (100 kPa~200 kPa), the water outlet on the rotating shell body is aligned with the diversion hole on the sprinkler body. At this time, the water flows through the diversion hole and shoots out from the water outlet. After encountering the obstruction of the refraction surface, it forms a fan-shaped thin water layer and shoots to both sides. Under the action of air resistance, it splits into small water droplets and falls to the ground to complete the irrigation function. During medium- and high-pressure (300 kPa~500 kPa) pesticide spraying operations, the limit pin is inserted on the rotating housing into the second limit slot and rotated clockwise to close the diversion hole, so that the liquid can only flow into the four diversion chutes. The liquid flows into the cavity by rotating through the diversion chute and is sprayed out from the nozzle in a conical mist after producing a vortex motion around the wall in cavity. The atomized droplets are sprayed upward and act on the back of crop leaves to complete the function of spraying pesticides.

According to the working principle of this water–pesticide integrated sprinkler, the main structural parameters that affect the irrigation performance are as follows: outlet diameter, refractive surface angle, and the distance from the outlet plane to the refractive surface (cone hole distance). The main structural parameters that affect the performance of spraying pesticides are as follows: the number of diversion chutes, nozzle diameter, and nozzle outer cone angle. Therefore, this study explores the influence of these structural parameters on the performance of irrigation and spraying pesticides to obtain the optimal structural parameters of the water–pesticide integrated micro-sprinkler.

2.2. Experiment Setup

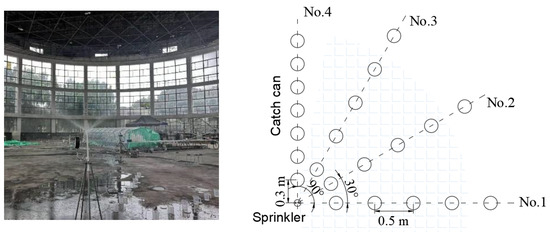

2.2.1. Irrigation Performance

The experiments were carried out in the Sprinkler Irrigation Laboratory of Jiangsu University (Zhenjiang, China). The system of irrigation performance is shown in Figure 2. The test equipment primarily includes a pipeline system, Centrifugal pump(Grundfos: Shanghai; China), pressure gauge (HongQi: Shanghai; China), electromagnetic flowmeter (ShunLaiDa: Shanghai; China), sprinkler, tape measure, and rainfall collector. The catch can diameter is 11 cm; the height is 20 cm; the arrangement was a ray; the included angle was 30°; and the spacing between the catch can was 0.5 m [14].

Figure 2.

Irrigation experiment system diagram.

During the irrigation experiment, three structural parameters, namely the diameter of the water outlet d, the angle of the refraction surface θ, and cone hole distance h, were selected to study the influence of each structure on the performance of sprinkler irrigation. The sprinkler parameters are shown in Table 1. The working pressure was 100 kPa. The duration of spraying is 30 min.

Table 1.

Structural parameters of the irrigation water.

A single-factor controlled variable method was used for the irrigation tests. When the outlet diameter was changed, the other sprinkler structure remained the same; the design refractive surface angle was 30°, and the cone hole distance was h = d. Similarly, the sprinkler refractive surface angle changed; the design outlet diameter was 2.0 mm, and the cone hole distance was h = d. When the sprinkler cone hole distance was changed, the design outlet diameter was 2.0 mm, and the refractive surface angle was 30°.

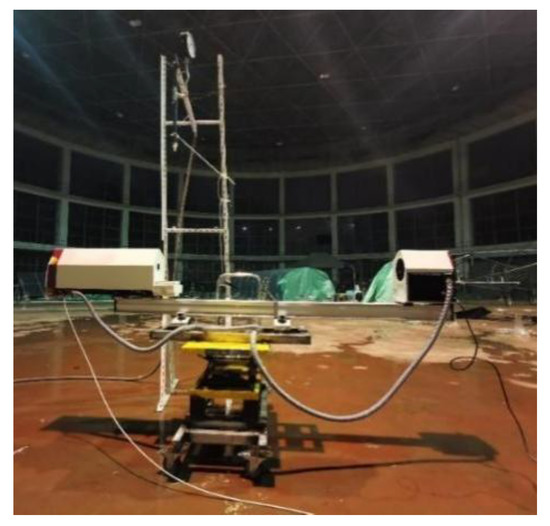

2.2.2. Spraying Pesticide Performance

The test system of the spraying pesticide performance test is shown in Figure 3. A WQ HELOS KR VARIO laser particle size meter (Sympatec Instruments, Pulverhaus: Clausthal-Zellerfeld, Germany) was used to measure the particle size of the sprayed droplets, and its range of measurement was 0.1~3500 μm. The test area was designed to be 1200 mm. The test sprinkler was installed at 1.2 m above the ground.

Figure 3.

Spraying pesticide experiment system diagram.

The spray cone angle of the sprinkler was photographed using a Canon EOS800D camera(Canon: Tokyo, Japan). The test was taken after the sprinkler operation had stablized. After grayscale processing by Adobe Photoshop (San Jose, CA, USA), each spray cone angle was read and averaged for multiple shots. Nozzle diameter D was selected for the test of spraying pesticide; the number of diversion chutes was n, and the nozzle outer cone angle α had three structural parameters. The influence of each structure on the performance law of pesticide application by the sprinkler was analyzed. The research showed that there was only a small difference in the mixture of water and pesticide when the droplet particle size, spray liquid film fragmentation form and other characteristics and the characteristics of the size of pure water droplets were analyzed [15,16]. Therefore, water was chosen to be the test medium. The structural parameters for spraying pesticide are shown in Table 2. The working pressure was 300 kPa.

Table 2.

Structure parameters of the spraying pesticides.

A single-factor controlled variable method was used to test the spraying of pesticides. When the nozzle diameter was changed, there were four diversion chutes, and the outer cone angle of the nozzle was 90°. When the number of diversion chutes was changed, the nozzle diameter was 3.0 mm, and the nozzle outer cone angle was 90°. When the outer cone angle of the nozzle was changed, the nozzle diameter was 3.0 mm, and there were four diversion chutes.

3. Results and Discussion

3.1. Influence of Different Structural Parameters on Irrigation Performance

3.1.1. Flow Rate and Wetted Radius

Table 3 shows the effects of different outlet diameters, refractive surface angles, and cone hole distances on the rate of irrigation flow and the wetted radius of the sprinkler obtained from the test. Among them, the wetting radius is the average of the four measurement directions.

Table 3.

The influence of key structures on the irrigation flow rate and wetted radius.

As shown in Table 3, the irrigation flow rate and the wetted radius increased as the diameter of the water outlet of the sprinkler increased. Under the same flow rate, a larger wetting radius of the nozzle resulted in larger spacing of the nozzle arrangement. This approach is highly advantageous because it reduces costs and improves adaptability. An angle of 30° for the refraction surface resulted in the largest wetted radius. The wetted radius also gradually increased as the cone distance increased. Properly increasing the cone hole distance helped to improve the wetted radius of the sprinkler.

3.1.2. Application Rate

The application rate can be varied in different soil structures. Grapes are mostly planted in sandy loam soil, and a relatively large application rate can be used in sandy loam soil.

The average application rate is the average of the application rate at all points in the control area. Assuming that the area represented by each point is the same size, the calculation formula is as follows [8]:

where: is average application rate, mm/h; n is the number of points in the same area; ρi is the point application rate.

Figure 4 shows the effects of different outlet diameters, refracting surface angles, and cone hole distances on the average application rate.

Figure 4.

The influence of key structures on the average application rate of sprinkler irrigation.

As shown in Figure 4, the diameter of water outlet significantly affected the average application rate. An increase in the diameter of the water outlet resulted in an approximately linear increase in the intensity of average sprinkler application. The average sprinkler application rate increased with the increase in the angle of the refraction surface. When the cone hole distance was increased, the average sprinkler application rate first increased and then decreased. A cone hole distance of 1.5 mm produced the most intense average sprinkler application.

3.1.3. Uniformity Coefficient

The uniformity coefficient usually uses the Christianson calculation method to describe the ratio of the absolute value of the water depth and the average water depth deviation at each measuring point to the total water depth average value. For this water–pesticide integrated sprinkler irrigation system, the uniformity coefficient should not be lower than 75%. It is calculated as follows [8]:

where: Cu is the uniformity coefficient of sprinkler irrigation, %; hi is the recipitation depth of i-th measurement point, mm; is the average water depth in the entire spraying area, mm; n is the number of measurement points.

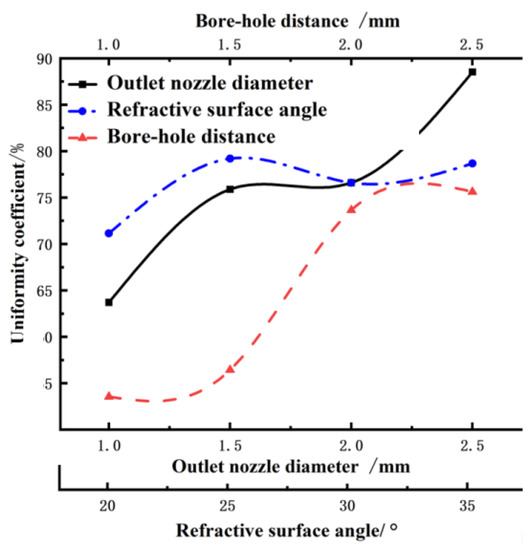

Figure 5 shows the effects of different outlet diameters, refractive surface angles, and cone hole distances on the uniformity coefficient.

Figure 5.

The influence of key structures on the uniformity coefficient.

As shown in Figure 5, the sprinkler uniformity coefficient increased as the outlet diameter increased. The maximum uniformity coefficient was 88.53% when the outlet diameter was 2.5 mm. The uniformity coefficient of sprinkler fluctuated with the increase in refractive surface angle, and the maximum uniformity coefficient was 78.20% when the refractive surface angle was 25°. The uniformity coefficient of the sprinkler increased with the increase in cone hole distance, and the range of variation was 54.42~78.82%. The range of values of the cone hole distance was 1.0~2.5 mm, and the uniformity coefficient was greater than 75%.

This analysis showed that the uniformity coefficient gradually increased as the outlet diameter, sprinkler irrigation water flow rate, wetted radius, and application rate increased. A larger diameter of the water outlet helped to improve the performance of the sprinkler when irrigating. As the refractive surface angle increased, the sprinkler irrigation water flow rate and sprinkler application rate tended to increase, while the sprinkler wetted radius and uniformity coefficient fluctuated. The sprinkler hydraulic performed more effectively when the angle of refractive surface was 30°; its wetted radius was the largest; the average sprinkler application rate was smaller, and the uniformity coefficient was higher. Sprinklers with a larger cone hole distance, such as h = 1.0~1.25 d, had a larger wetted radius, smaller sprinkler intensity, higher uniformity coefficient, and better irrigation performance.

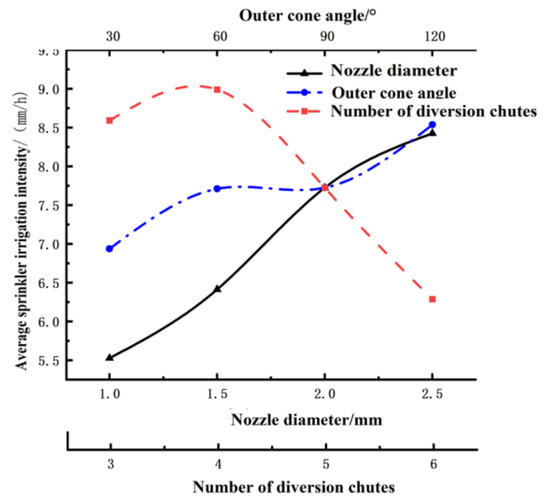

3.2. Influence of Different Structural Parameters on Spraying Pesticide Performance

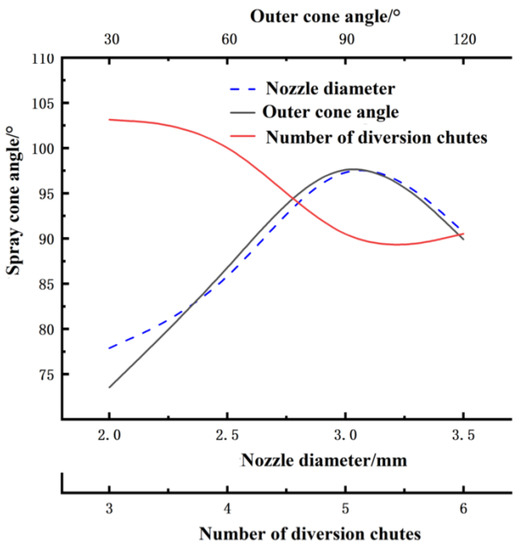

3.2.1. Spray Cone Angle

The spray cone angle is an important parameter that is used to evaluate the quality of sprinklers that spray pesticides [17]. Under the same flow rate, a larger spray cone angle helps improve the performance of spraying pesticides and droplet coverage area of the sprinkler and reduce the system cost. Figure 6 shows the effect of different nozzle diameters, the number of diversion chutes, and the outer cone angle on the spray cone angle.

Figure 6.

The influence of key structures on the spray cone angle.

As shown in Figure 6, when the nozzle diameter increased, the sprinkler spray cone angle first increased and then decreased. The maximum spray cone angle was 102.36° when the nozzle diameter was 3.0 m. As the number of sprinkler diversion chutes increased, the spray cone angle was first reduced and then increased. The maximum spray cone angle was 103.14° when the diversion chute was 3. The spray cone angle was significantly larger than that of the two diversion chutes when there were three or four diversion chutes.

This is because the liquid rotates into the sprinkler cavity through the diversion chute. Thus, an increase in the number of slots increases the flow rate of the water sprinkler cavity. This resulted in an increase in the sprinkler cavity vortex flow rate, and the radial velocity and tangential velocity of the spray droplets became larger, which reduced the spray cone angle. Therefore, a smaller number of diversion chutes helped to increase the spray cone angle of the sprinkler. The spray cone angle increased with the increase in the outer cone angle and then decreased, and the maximum spray cone angle was 102.36° when the outer cone angle was 90°.

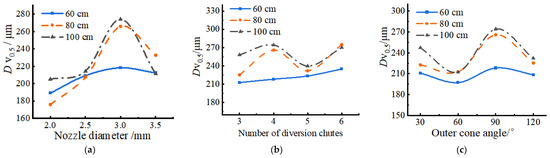

3.2.2. Droplet Size

Droplet size is the main indicator of the quality of sprinkler atomization. Smaller droplets help to improve the pesticide coverage, but they are likely to cause droplet drift, which results in pesticide waste and environmental pollution. Larger droplets have difficulty being absorbed by leaves and pests, but they help to improve the penetration of droplets [18,19,20]. Figure 7 shows the effect of key structures, such as different nozzle diameters, numbers of diversion chutes and outer cone angle, on the droplet particle size at different distances of the sprinkler from the measuring surface. The droplet size is expressed as the droplet volume median diameter (Dv0.5).

Figure 7.

The influence of key structures on droplet size. (a) Nozzle diameter; (b) number of diversion chutes; (c) outer cone angle.

As shown in Figure 7, as the nozzle diameter increased, the particle size distribution curve first increased and then decreased. There was an obvious trend in the change in the droplets of the sprinkler when the laser pa rticle size meter was 60 cm. The increase in droplet size ranged from 27.02% to 44.39% at the 80 cm test distance and from 27.55% to 50.72% at the 100 cm test distance. This indicates that the atomization process of the liquid ejected from the nozzle occurs within a certain axial distance. When the droplets are ejected further than this, their breakup and the particle size distribution will stabilize.

With the increase in the number of diversion chutes, the droplet size at the measurement distance of 80 cm and 100 cm fluctuated, and the change rules were similar. In contrast, the droplet size at a test distance of 60 cm had little change, and grew slowly with the increase in the number of chutes. The droplet size increased with the increase in the test distance. This is because in the spraying process, the collision of droplets has a great influence on the size distribution of the droplets. The farther the nozzle is, the greater the number of large particle droplets.

The droplet size at each measurement distance fluctuated, indicating that the outer cone angle of the nozzle had no significant effect on the droplet size and particle size distribution. Among them, the variation law of particle size between 80 cm and 100 cm measurement distances is particularly similar.

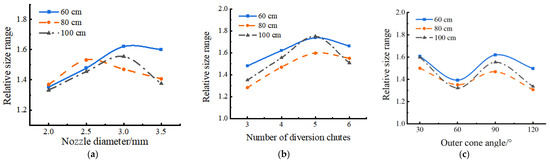

3.2.3. Relative Range of Droplet Sizes

The width of the droplet spectrum reflects the concentration of droplet sizes. As the droplet spectrum narrowed, the distribution of droplet sizes became more concentrated. The droplet relative size range Δs was used to measure the droplet spectrum width of the water–pesticide integrated sprinkler, and the calculation formula is as follows [18]:

where Δs is the relative size range of droplet; Dv0.1 is the droplet diameter of 10% of the droplet volume cumulative distribution, μm; Dv0.9 is the droplet diameter of 90% of the droplet volume cumulative distribution, μm; and Dv0.5 is the droplet volume median diameter, μm.

A larger Δs value represents a larger range of droplet size and poorer uniformity of droplets. A smaller value of Δs indicates a higher droplet consistency and drift controllability. When the value of Δs is 1, it is the ideal state, which indicates that the droplet size is symmetrically distributed. The same principle was used to select the representative value of the middle diameter of the droplet volume. The relative droplet size range of the water–pesticide integrated sprinkler should be selected as the representative value for the droplet relative size range of the grape frame surface and the test plane above and below the frame surface. Figure 8 shows the effect of different nozzle diameters, the number of diversion chutes, and the outer cone angle on the relative range of the droplet sizes at different distances of the sprinkler from the measuring surface.

Figure 8.

The influence of key structures on the relative range of droplet sizes. (a) Nozzle diameter; (b) number of diversion chutes; (c) outer cone angle.

As shown in Figure 8, as the nozzle diameter increased, the Δs value first increased and then decreased. The nozzle diameter was 3.0 mm; the Δs maximum was 1.62 when the sprinkler distance from the measuring surface was 60 cm. The minimum Δs was 1.33 when the nozzle diameter was 2.0 mm. The maximum value of Δs was 1.53 when the distance of sprinkler from the measuring surface was 80 cm. The average variation in the value of Δs as the nozzle diameter increased was 16.07% for each test distance.

Different measurement distances indicated that the Δs value was the largest at a distance of 60 cm, and the droplets were more diffuse. The Δs value was the smallest at a distance of 80 cm, and the droplets were highly consistent. As the number of inflow channels increased, the variation pattern of the Δs value of each measurement distance was the same. All of them increased first and then decreased. The peak value of Δs at each measurement distance was 1.75 when there were four diversion chutes. The peak value of Δs at each test distance was 1.28 when there were three diversion chutes. Therefore, the sprinklers with a smaller number of deflector slots have a narrower droplet spectrum width and more uniform droplets.

With the increase in the nozzle outer cone angle, the Δs values of different measurement distances fluctuated, but the pattern of change was consistent. Among them, the outer cone angle was 90°; the Δs value was the largest at 1.62; the outer cone angle was 60°; and the Δs value was the smallest at 1.31.

4. Structural Optimization of the Water–Pesticide Integrated Micro-Sprinkler

4.1. Experiment Setup

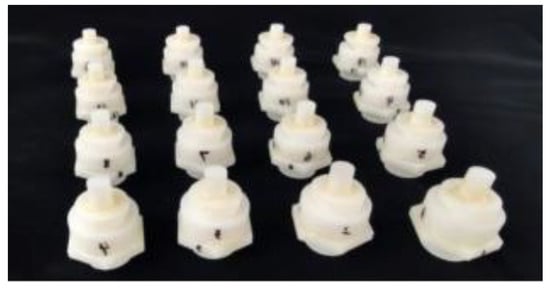

On the basis of the test results in Section 3.1, the L16 (43) orthogonal test table was designed. The test scheme is shown in Table 4, which includes the parameters of nozzle structure 4. The irrigation test sprinkler is shown in Figure 9, and the spray sprinkler is shown in Figure 10. The test working pressure was 100 kPa, and the test method was the same as that in Section 2.2.

Table 4.

Nozzle structural parameters. “d” is Outlet nozzle diameter.

Figure 9.

Sprinklers of the orthogonal experiment for irrigation water.

Figure 10.

Sprinklers of the orthogonal experiment for the spraying pesticide.

4.2. Results and Discussion

4.2.1. Irrigation Experiment Results

The test results of the orthogonal test of irrigation performance are shown in Table 5 where the wetted radius is the mean range of the four measurement directions.

Table 5.

Results of the tests for the performance of irrigation water.

The data in Table 5 indicate that as the sprinkler wetted radius varied from 2.53 to 5.42 m, the uniformity coefficient varied from 63.92 to 93.62%, and the flow rate varied from 0.137 to 0.690 m3/h. Among them, the sprinkler wetted radius and uniformity coefficient were significantly higher compared with the test results in Section 2.1. This indicates that increasing the range of values of outlet diameter and cone hole successfully improved the hydraulic performance of the sprinkler.

4.2.2. Spraying Pesticide Experiment Results

The orthogonal test results of the performance of spraying pesticide are shown in Table 6, where is the average value of the relative size range of droplet measured when the nozzle to laser particle size meter was 60 cm, 80 cm, and 100 cm.

Table 6.

Results of the performance tests of spraying pesticides.

The results in Table 6 show that the maximum spray cone angle was 121.25°, and the minimum value of was 1.06. A comparison of the maximum spray cone angle of 103.14° and the minimum value of 1.35 that appeared in the test results in Section 2.1 indicates that the performance of spraying pesticides was significantly better, indicating that reducing the number of diversion chute range of values indeed helps to improve the performance of the sprinklers that spray pesticides. The factor level of this orthogonal test was taken as a reasonable value.

4.2.3. Optimization of Multiple Indicators

The entropy weight method is highly adaptable and strongly objective. Thus, this method was selected to evaluate the index weight. First, the normalization method was used to standardize the data of the performance indicators, and the test data x1j, x2j, …, xij of each indicator x1, x2, …, xj were mapped to the range of [0, 1] using the following formula:

where xij are the test data of each index, and min (xij) is the minimum value of each index. max (xij) is the maximum value of each index, and Yij is the value after the standardized processing of the test data.

According to the results of normalization, the weight value of each index was calculated, and the formula is as follows:

where ej is the index entropy value; m is the number of factors; and is the indicator weight value.

The calculation formula of the comprehensive evaluation value F is as follows:

The irrigation performance test results in Table 6 were added to Equations (5)–(8), and the weight values of the nozzle wetted radius, uniformity coefficient, and irrigation flow rate in the irrigation performance test were calculated as ω1 = 0.3746, ω2 = 0.1377, and ω3 = 0.4877, respectively.

The weight value ωj of each index and the result of Yij after the standardization of the test data were brought into Formula (9), and the comprehensive value F of each test scheme was obtained as shown in Table 7. It is apparent from this data that the comprehensive value F of the A2B3C4 sprinkler was the highest, indicating that it is more effective at performing irrigation.

Table 7.

Data processing results of the test for the performance of irrigation water.

The orthogonal test of spraying pesticide performance was optimized with the same multiple indicators, and the test data in Table 7 were substituted into Equations (5)–(8). Smaller flow rates and values were more effective. Therefore, they were substituted into Equation (5). The larger spray cone angle was more effective, so that was substituted into Equation (6). The weight values of sprinkler flow rate, spray cone angle, and average droplet relative distribution span for the spraying pesticide performance test were calculated as ω4 = 0.3434, ω5 = 0.4585, and ω6 = 0.1981. The combined values F for each test scheme that were calculated using Equation (9) are shown in Table 8. They show that the D3E1F3 test had the highest integrated value, indicating that it is more effective at the integrated spraying of pesticides.

Table 8.

Data processing results of the test for the performance of spraying pesticides.

4.2.4. Extreme Analysis

Then, we explored the primary and secondary influence order of each structural factor on the irrigation performance of water–pesticide integrated sprinklers and the degree of influence of each factor level on the evaluation index of sprinklers. The range analytical method was selected to analyze the data processing results. The formula is as follows:

where Rj is the range value of the J factor, which is the result after average treatment of the corresponding comprehensive value of the j factor i level. The comprehensive values F in Table 7 and Table 8 were added to Equation (10), and the results of this calculation are shown in Table 9.

Table 9.

Results of the extreme analysis.

As shown in Table 9, RA > RB > RC. Therefore, the primary and secondary factors that affect the indicators of irrigation performance, such as irrigation water flow rate, wetted radius, and uniformity coefficient of the water–pesticide integrated sprinkler, are in this order: (A) outlet diameter, (B) refractive surface angle, and (C) cone hole distance. The optimal combination of the comprehensive irrigation performance was A2B3C4. The outlet diameter was 2.0 mm; the refractive surface angle was 30°; and the cone hole distance was 1.50 d of the test sprinkler. As shown in Table 9, RE > RF > RD, followed by the water–pesticide integrated sprinkler spray pesticide flow rate, spray cone angle, droplet relative distribution span, and the other performance indicators of the factors, in the order of priority, were: E diversion chutes number, F nozzle outer cone angle, and D nozzle diameter. The optimal combination of integrated spraying pesticide performance for D3E1F was a nozzle diameter of 3.0 mm; the number of diversion chutes was two, and the nozzle outer cone angle was a 90° test sprinkler for the optimal structural parameters.

5. Conclusions

According to the planting characteristics of grapes and the requirements of irrigation and spraying, a water–pesticide integrated sprinkler was developed. The irrigation performance and spraying performance of the water–pesticide integrated nozzle with different structural parameters were tested. The influence law of key structural parameters on the irrigation performance and spraying performance was obtained using a single-factor control variable method and an orthogonal test method. The main conclusions are as follows:

- (1)

- A water–pesticide integrated sprinkler was designed. Adjusting the position of upper limit pin of the nozzle body, changing the inner flow channel structure, and the spraying form of the sprinkler head enabled the functions of irrigation under low-pressure conditions and spraying under medium-to-high-pressure conditions.

- (2)

- The influences of key structural parameters, such as outlet diameter, refraction plane angle, and cone hole distance, on sprinkler performance were revealed, and the influences of key structural parameters, such as nozzle diameter, number of diversion chutes, and external cone angle, on sprinkler spraying performance were also revealed.

- (3)

- The irrigation flow rate, wetted radius, application rate, and spraying uniformity were tested as irrigation performance indices, and the spray cone angle, droplet size, and droplet relative size range were tested as spraying performance indices. The recommended values for the design of key structural parameters to achieve better performance were as follows: the outlet diameter was 2.0 mm; the refractive surface angle was 30°; the cone hole distance was 1.0 d; and the nozzle diameter was 3.0 mm; there were two diversion chutes, and the nozzle outer cone angle was 90°.

Author Contributions

X.W., Conceptualization methodology, validation, formalanalysis, investigation, data curation, writing-originaldraft preparation, visualization. J.L.: Conceptualization, project administration. Q.Z.: methodology, formal analysis, investigation, writing-review and editing, supervision. All authors have read and agreed to the published version of the manuscript.

Funding

Postgraduate Research Practice lnnovation of Jiangsu Province (SJCX22_1868), Key R&D Projects of Zhenjiang City (NY2020013), Key R&D Projects of Jiangsu Province (BE2021341), Project of Faculty of Agricultural Equipment of Jiangsu University (NZXB20210101).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jalini, M. Investigation on the effect of drip irrigation methods and different levels of water on yield and water use efficiency of grape. J. Agric. Eng. Res. 2006, 7, 28. [Google Scholar]

- Zheng, Y.J.; Chen, B.T.; Lyu, H.T.; Kang, F.; Jiang, S.J. Research progress of orchard plant protection mechanization technology and equipment in China. Trans. Chin. Soc. Agric. Eng. 2020, 36, 110–124. [Google Scholar] [CrossRef]

- Baolong, Y. Development of 3WZG-500 self-propelled grape sprayer. Trans. Chin. Soc. Agric. Mach. 2018, 8, 102–104. [Google Scholar]

- Michael, C.; Gil, E.; Gallart, M.; Stavrinides, M.C. Evaluation of the effects of spray technology and volume rate on the control of grape berry moth in mountain viticulture. Agriculture 2021, 11, 178. [Google Scholar] [CrossRef]

- Zhou, R.; Zhang, H.; Zhou, H.; Zheng, J.; Hu, H. Interaction effects of spray parameters on pesticide spray droplet drift. J. Drain. Irrig. Mach. Eng. 2019, 37, 612–617+638. [Google Scholar] [CrossRef]

- Watson, T.T.; Desaeger, J.A. Evaluation of non-fumigant chemical and biological nematicides for strawberry production in Florida. Crop Prot. 2019, 117, 100–107. [Google Scholar] [CrossRef]

- Mao, L.G.; Wang, Q.X.; Yan, D.D.; Liu, P.F.; Shen, J.; Fang, W.S.; Hu, X.M.; Yuan, L.I.; Ouyang, C.B.; Guo, M.X.; et al. Application of the combination of 1, 3-dichloropropene and dimethyl disulfide by soil injection or chemigation: Effects against soilborne pests in cucumber in China. J. Integr. Agric. 2016, 15, 145–152. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, J.; Yuan, S.; Li, Y.; Li, H. Structure design and hydraulic performance test of water and pesticide integrated sprinkler. J. Drain. Irrig. Mach. Eng. 2021, 1–7. [Google Scholar]

- Negeed, E.S.R.; Hidaka, S.; Kohno, M.; Takata, Y. Experimental and analytical investigation of liquid sheet break up characteristics. Int. J. Heat Fluid Flow 2011, 32, 95–106. [Google Scholar] [CrossRef]

- Xie, C.; He, X.; Song, J.; Herbst, A. Comparative study on atomization process of two types of fan fog heads. Trans. Chin. Soc. Agric. Eng. 2013, 29, 25–30. [Google Scholar] [CrossRef]

- Ouazaa, S.; Burguete, J.; Paniagua, M.P.; Salvador, R.; Zapata, N. Simulating water distribution patterns for fixed spray plate sprinkler using the ballistic theory. Span. J. Agric. Res. 2014, 12, 850–863. [Google Scholar] [CrossRef]

- Tsaboula, A.; Papadakis, E.N.; Vryzas, Z.; Kotopoulou, A.; Kintzikoglou, K.; Papadopoulou-Mourkidou, E. Environmental and human risk hierarchy of pesticides: A prioritization method, based on monitoring, hazard assessment and environmental fate. Environ. Int. 2016, 91, 78–93. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Xue, X.; Cai, C.; Zhou, Q.; Sun, Z. Study on atomization performance test and influence factors of aviation special centrifugal nozzle. Trans. Chin. Soc. Agric. Mach. 2019, 50, 96–104. [Google Scholar] [CrossRef]

- GB/T 27612.3-2011; Agricultural Irrigation Equipment-Sprinkler-Part 3: Water Distribution Characteristics and Test Methods. Standardization Administration of China: Beijing, China, 2011.

- Xiao, L.; Liu, M.; Cai, J. Study on droplet characteristics of different biopesticides sprayed by nozzles. Trans. Chin. Soc. Agric. Mach. 2018, 49, 100–106. [Google Scholar]

- Jin, X.; Dong, X.; Yang, X.J. Design and experiment of target spray system of 3WGZ-500 spray machine. Trans. Chin. Soc. Agric. Mach. 2016, 47, 21–27. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, D. Experimental study on optimization of outlet cone angle of liquid-pack atomizing nozzle. Therm. Power Eng. 2013, 28, 57–60+110. [Google Scholar]

- Dai, F.; Yuan, H. Standardization of Plant Protection Machinery and Spraying Technology; China Agricultural Science and Technology Press: Beijing, China, 2002. [Google Scholar]

- Fu, Z.; Qi, L.; Wang, X. Optimization of Pesticide Spraying Technology; China Agricultural Science and Technology Press: Beijing, China, 2002. [Google Scholar]

- He, X. Plant Protection Drone and Pesticide Application Technology; Northwestern Polytechnical University Press: Xi’an, China, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).