1. Introduction

Energy demand is increasing due to population growth and improved living standards. This has resulted in an increase in global pollution and a reduction in fossil energy resources. Natural energy resources should be used effectively to mitigate the above negative effects. Moreover, the share of renewable energy should be of a high proportion [

1,

2,

3]. On the whole, the use of renewable energy may be a viable option. This decision could meet energy requirements and simultaneously reduce harmful emissions, including carbon dioxide emissions [

4,

5].

Modern civilization is currently looking for renewable and environmentally friendly combustible energy resources [

6]. Municipal and industrial waste, agricultural products, and by-products can be valuable energy sources for a sustainable energy future [

7,

8]. Organic raw materials can be used as feedstock for biofuel production.

The use of energy crops (such as maize, sorghum, etc.) as biofuel production feedstock compete with other food crops for arable land. It is possible to cultivate lignocellulosic plants on marginal lands to avoid competition for land. Some grasses (like miscanthus, switchgrass, foxtail millet, etc.) are suitable to be grown on marginal lands [

9,

10]. Lignocellulosic biomass is an alternative feedstock for bioethanol production [

11]. Sorghum biomass (for example, sorghum bicolor) can be used as feedstock for lignocellulosic bioethanol production. Moreover, its average bioethanol yield exceeds yields for other lignocellulosic feedstock [

12].

Biofuels are usually produced from biomass (energy crops, crop residues, animal waste, etc.), and they are viable energy sources. In EU countries, agricultural biomass is the primary energy resource in biofuel production [

1,

13,

14].

Many studies have proven that plants that are grown for energy production reduce carbon dioxide emissions [

1,

2,

13,

15]. The most common biomass for biofuel (bioethanol, biogas, pellets, etc.) production are the following: corn (grain and silage), sugarcane, sugar beet, and sorghum (grain and silage) [

16,

17,

18,

19]. These crops have demonstrated great energy potential as substitutes for fossil fuels and abating greenhouse gas emissions.

Maize is a widespread crop that produces biofuels such as bioethanol and biomethane [

20]. This crop has a relatively high biomass yield [

21,

22]. Moreover, maize is well adapted to monoculture [

23]. However, this has a detrimental effect on soil degradation, lower yield, etc. [

24]. Therefore, biorefineries should be supplied with different feedstock [

22,

25,

26]. Crops must be a source of biomass and ensure the biodiversity of ecosystems [

27,

28]. Sorghum is a relative of maize [

15]. However, unlike maize, this crop has better drought resistance and requires less fertilizer [

29,

30]. These features are gaining importance due to global climate change.

Sorghum is the alternative feedstock for biofuel production. It can be used for direct firing (electricity and heat generation), conversion to bioethanol (fermentation), and biomethane production (anaerobic digestion). Refs [

31,

32,

33,

34] proved that sweet sorghum could be efficiently converted into biogas and ethanol. Bioconversion was significantly improved with pretreatment. Wannasek et al. [

35] highlighted that sorghum could be used as the main crop for biogas production since it has a high specific methane yield. Its methane yield is similar to maize silage.

Sorghum has several advantages compared to other energy crops. This crop is well adapted to drought, high air temperatures, and soil salinity. Wannasek et al. [

35] confirmed (via experimental data) the drought resistance of this crop. Unlike other crops, sorghum has lower requirements for water and fertilizer per unit of biomass [

36]. This is a significant factor, as energy crops must have a positive energy balance. Moreover, sorghum is a fast-growing crop. Therefore, it can be used in crop rotation, and the production of ethanol and biogas from sorghum minimizes competition with other food crops [

37,

38]. These properties of sorghum, combined with progressive agricultural technologies, make this crop a promising feedstock for biofuel production [

39,

40].

The energy efficiency of its cultivation depends on many factors such as cultivar, soil, climate conditions, agricultural practices, and both direct and indirect energy inputs [

39]. Energy balance is a tool to determine the energy efficiency of any renewable resource [

41,

42]. High energy efficiency of biomass production is the basis for a sustainable energy system [

43]. To determine the above efficiency, energy inputs and outputs must be taken into account and analyzed. Energy balance depends on crops and production systems. The energy efficiency of the production process is determined by the energy outputs to energy inputs ratio [

44,

45].

Sweet sorghum as an energy and fodder crop is of great practical interest for agriculture in general and especially for arid regions of Ukraine. Sorghum provides high yields in conditions of heat and drought. The positive properties of this crop include the fact that it is undemanding to the quality of soils [

22,

39].

The implementation of energy-saving sorghum production technology is important. This is a valuable crop for drought prone regions, which is typical for southern Ukraine. Moreover, sorghum is superior to corn in yield [

46].

Ukraine has fertile soil and low population density. This makes Ukraine a large exporter of agricultural products [

47,

48]. Therefore, the country has great potential for developing bioenergy.

Many scientists have studied sorghum as a bioenergy crop. Morozova et al. [

49] assessed methane yields from energy crops, including sweet sorghum. The impact of mean daily temperature and precipitation on sorghum yield was studied by Kiesel and Lewandowski [

50], Zegada-Lizarazu et al. [

51], Kotrla and Prčík [

52], etc. An evaluation of different production systems was carried out by López-Sandin et al. [

53]. Jankowski et al. [

54] studied the energy balance of sorghum production in Poland. Energy input and output of sorghum growth as a bioenergy crop was evaluated by Ren et al. [

55]. Sorghum as a feedstock for biofuel production studied by many researchers [

56].

Sorghum is currently a rare crop in Ukraine. In 2019, its (grain sorghum) gross harvest was 192 thousand tons and its yield was 4.08 t/ha [

46]. Sweet sorghum is produced in limited quantities.

Soil and climate conditions in the South of Ukraine are quite different compared to Western European countries, China, Mexico, etc. Ukraine is located in Eastern Europe. Its area is 603 thousand square kilometers. Farmers cultivate around 26 million hectares of arable land from around 41 million hectares of agricultural land.

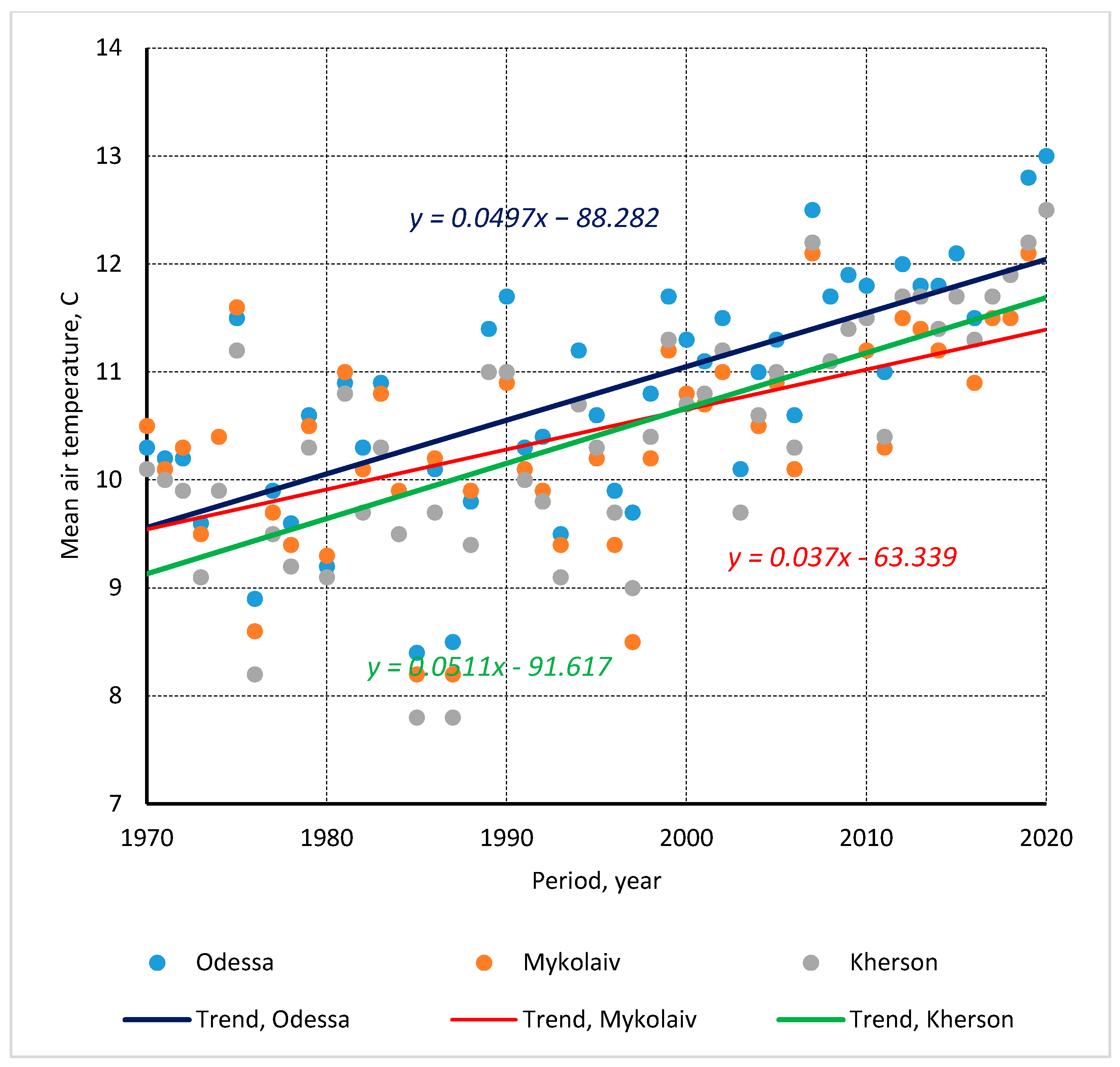

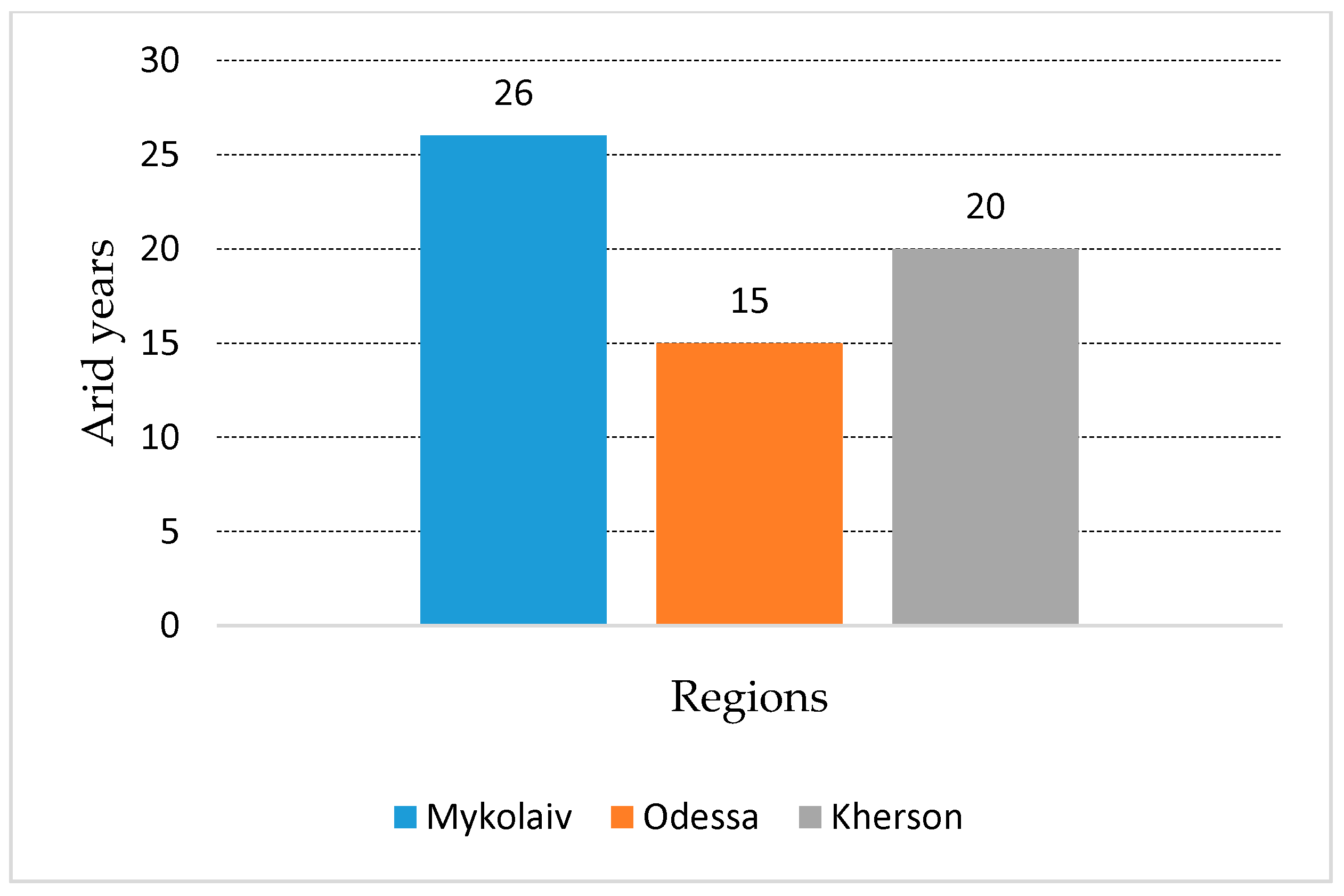

The territory of Ukraine has been divided into five climate zones: Northern, Southern, Western, Eastern, and Central (

Figure 1). The climate zones have similar weather conditions (temperature and precipitation). The boundaries of administrative units (oblasts) are shown within the climate zones [

57,

58,

59].

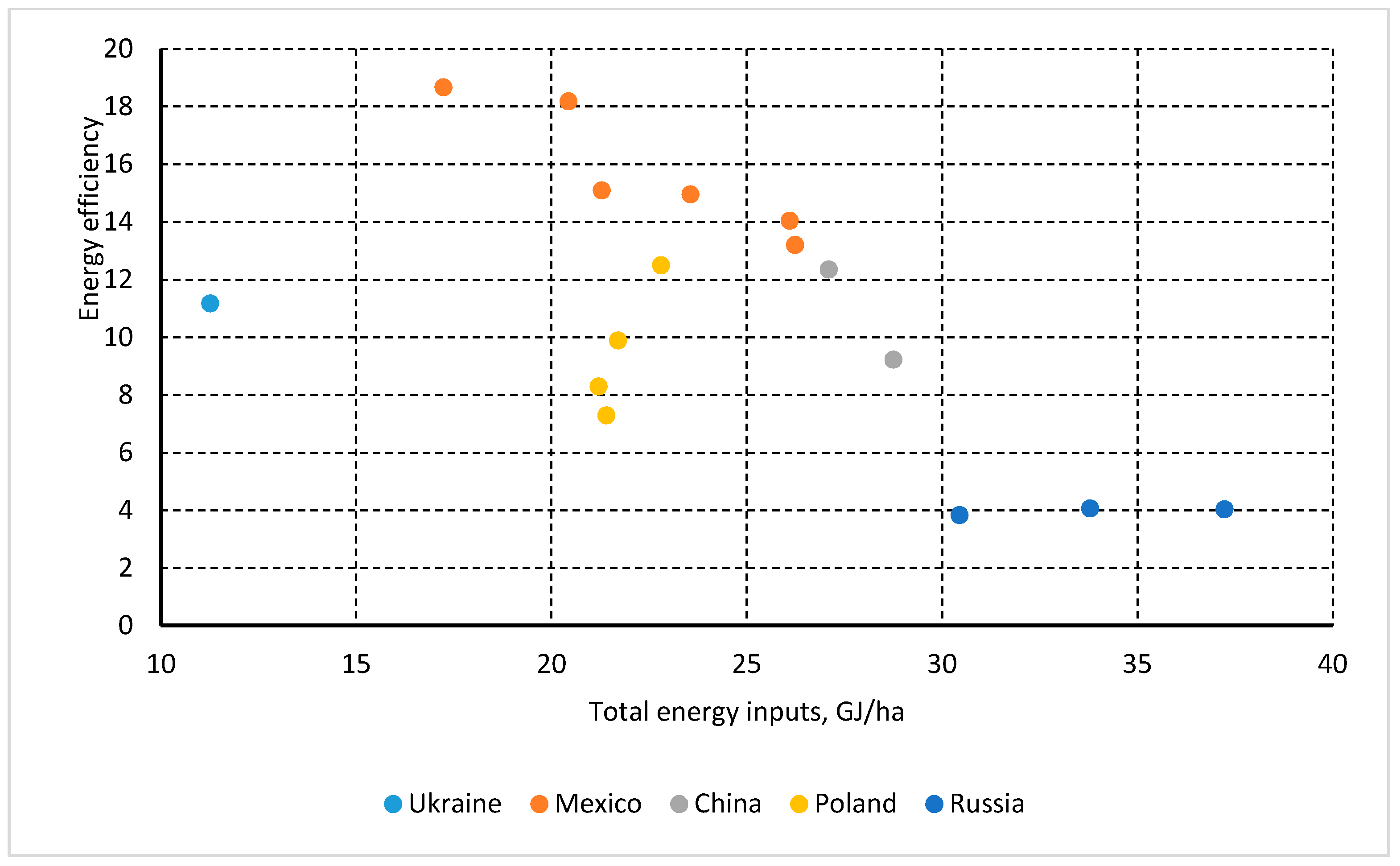

Therefore, their experience cannot be applied to Ukraine. This stipulates for the study of sorghum growing in the specific warm and arid conditions of southern Ukraine. Moreover, little attention has been paid to the energy balance for sweet and grain sorghum.

The purpose of this study is to analyze the energy balance and to determine the energy efficiency ratio of growing sweet and grain sorghum in conditions of warm and droughty climates in the South of Ukraine. To achieve this purpose, the following goals were set up:

To trace changes in precipitation and mean daily temperature;

To carry out an energy analysis of sweet sorghum production;

To reveal the influence of external factors (precipitation, sowing date, plant density) on the energy efficiency of grain sorghum production.

This study is a continuation of the previous author’s study concerning energy analysis of biomass energy systems [

60,

61,

62,

63,

64].

2. Materials and Methods

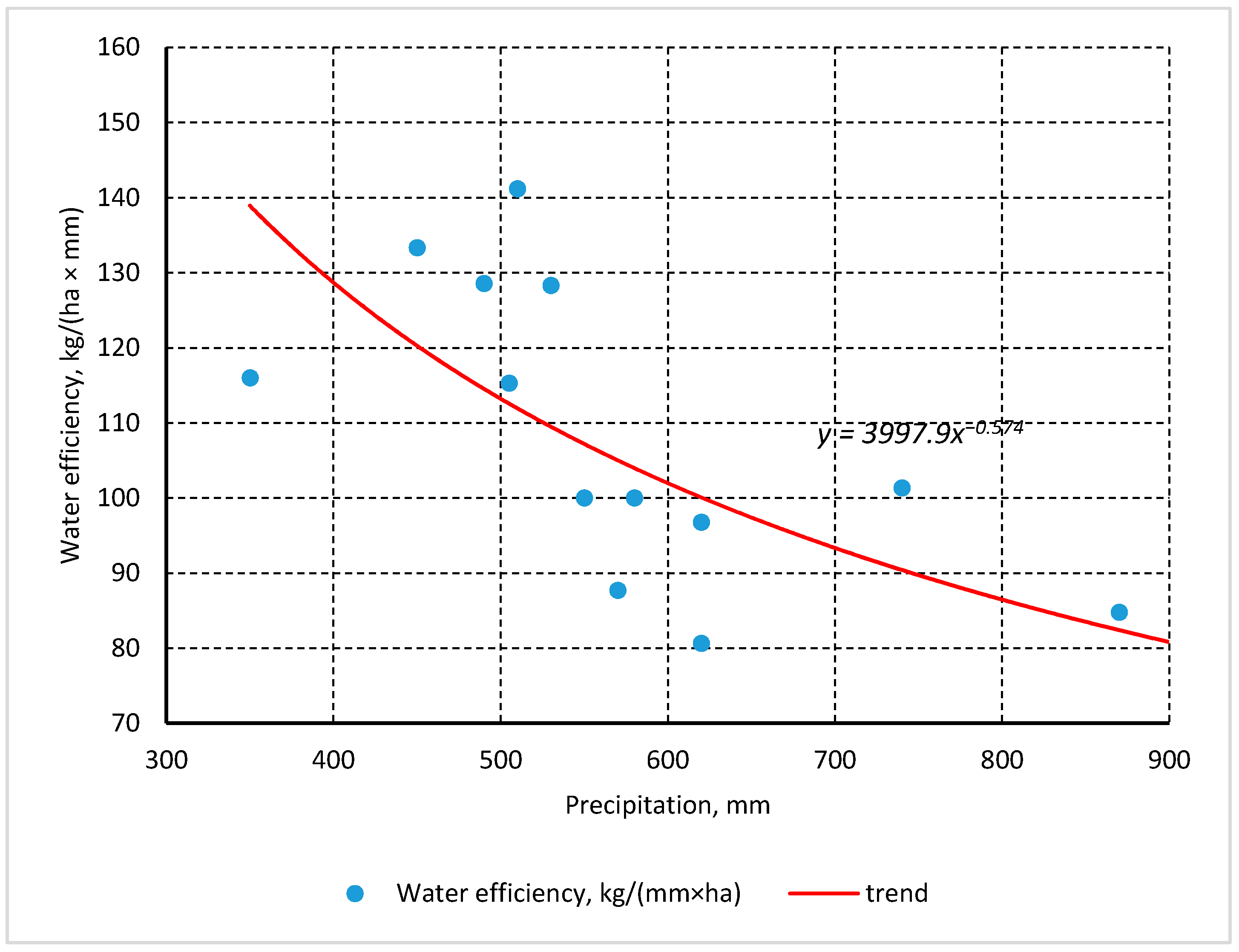

This study focuses on the assessment of the energy efficiency of sorghum production (both silage and grain) and proposes the use of an integrated methodology combining statistical analysis and performing field experiments. This methodology is based on the following steps: the analysis of climate conditions (precipitation and air temperature); the collection of field experiment data; the assessment of the energy inputs and outputs; calculation of energy efficiency ratio; the assessment of water use efficiency; and a correlation-regression analysis of a grain sorghum energy efficiency ratio.

Field experiments were carried out in the Mykolaiv and Kherson regions of Ukraine.

2.1. Field Experiment

Field experiments were performed in the Mykolaiv and Kherson regions. Sweet sorghum was grown in the Mykolaiv region and grain sorghum was grown in the Kherson region (

Figure 2).

The experiments were carried out in 2020 in the Mykolaiv region, Ukraine (46°58′06″ N; 31°42′39″ E). The experimental field had an area of 5 ha. The experiment had a randomized design with three replications. Winter wheat was a preceding crop for sweet sorghum. The pH of the soil was within the range from 6.8 to 7.2. Soil properties were found as follows: soil organic carbon, from 2.9 to 3.2 g·kg

−1; phosphorus, from 31 to 38 mg·kg

−1; and potassium, from 332 to 525 mg·kg

−1. The bulk density of soil was 1400 kg·m

−3. Sweet sorghum was cultivated following a conventional agricultural practice (

Table 1).

Grain sorghum has been studied for three years. The experiments were performed in 2015-2018 in the Kherson region, Ukraine (46°38′03″ N; 32°26′20″ E). The experimental field had an area of 3 ha. Soil properties were found as follows: soil organic carbon, 2.34–2.9 g·kg

−1; phosphorus, 49–65 mg·kg

−1; and potassium, 280–360 mg·kg

−1. The preceding crop was winter wheat too. The production of grain sorghum is presented in

Table 2.

The experiments were carried out for three years on non-irrigated lands. A two-factor field experiment was established by the method of randomized split plots. All studies, observations, and sampling were performed in quadruplicate. The number of variants in the experiment was eight, the total number of plots was thirty-two. In the field experiment, we studied two factors. Factor A is the plant density, thousand units per ha: 100, 140, 180, and 220. Factor B is the sowing dates: early, at a soil temperature of 8-10 °C (the first decade of May) and late, at a soil temperature of 14–16 °C (the third decade of May).

During the three-year experiment, there has been a fluctuation in annual rainfall. Therefore, additionally, we investigated the third factor: how rainfall impacts yield and an energy efficiency ratio.

2.2. Energy Inputs

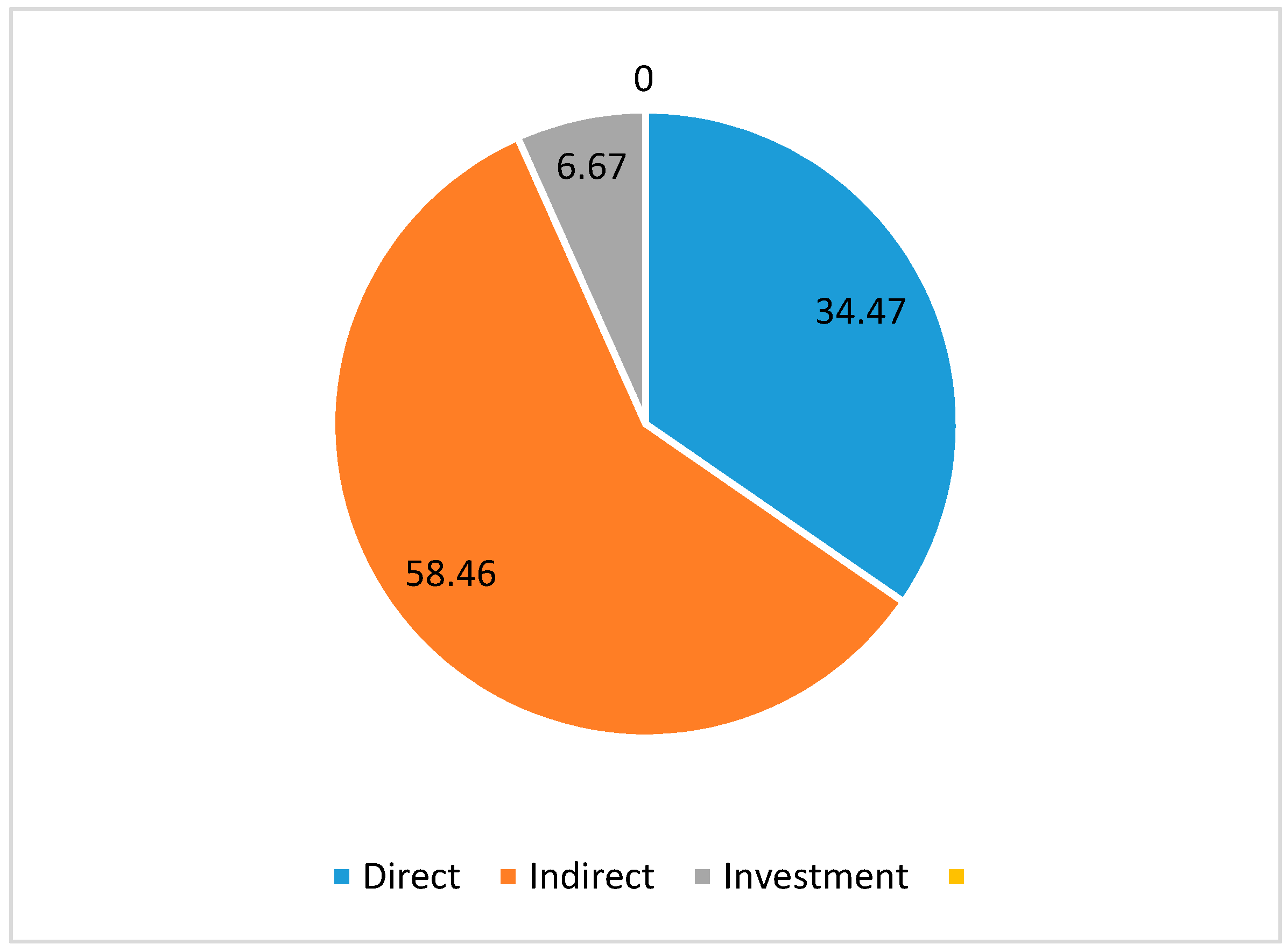

Total energy inputs include direct and indirect energy inputs. The indirect energy inputs are divided into two groups. The first one is the energy used for the production of fertilizers and chemicals such as herbicides, pesticides, fungicides, etc. The second group of indirect inputs is the energy used in the manufacturing of tractors, implements, and other farm machinery.

The total energy inputs are determined by the formula:

where

DEI is the direct energy inputs, MJ/ha;

IDEI1 is the indirect energy inputs (embodied energy of technological materials such as fertilizers, seeds, pesticides, etc.), MJ/ha;

IDEI2 is the indirect energy associated with the manufacturing of farm machinery, MJ/ha; and

IDEI3 is the indirect energy associated with stationary equipment, MJ/ha.

The direct energy inputs are calculated by the following formula:

where

Bi is the liquid or gaseous fuel of

ith type consumed by agricultural machinery, kg/ha;

EEQfi is the energy equivalent of

ith fuel, MJ/kg;

W is the electricity consumption, kWh/ha;

n is the number of fuels; and

EEQe is the energy equivalent of electricity, MJ/kWh.

The Indirect energy inputs of the first group are:

where

EEQCj is the energy equivalent of

jth chemical (or fertilizer), MJ/kg;

MCj is the mass consumption of

jth chemical (or fertilizer), kg/ha; and

m is the number of chemicals used by technological processes.

The indirect energy inputs of the second group are determined by manufacturing energy requirements for farm machinery such as tractors, combine harvesters, cultivators, etc. They depend on the following factors: a certain machinery mass, utilization lifetime, productivity, etc. The indirect energy inputs of the second group can be calculated by the formula:

where

EEQMj is the energy equivalent of

kth machinery, MJ/kg;

OMk is the operation mass of

kth machinery, kg;

ULTk is the utilization lifetime of

kth machinery, h;

FCk is the operation field capacity of

kth machinery, ha/h; and

l is the number of farm machinery used for a certain crop growing.

Energy inputs of stationary technological operations are determined by their energy consumption. They are equal to:

where

IDEI3 is the energy equivalent of production facilities, MJ/m

2;

F is the area of production premises, m

2;

a is the depreciation, %;

T is the utilization time of the facilities per year, hours; and

Wha is the productivity of stationary equipment per hour.

The capacity of stationary equipment is usually measured in tons per hour. Its productivity (in hectares per hour) is determined as follows:

where

RP is the application rate of the material (for example, seed treatment before sowing), or crop yield (when processing products), t/ha; and

Wm is the equipment capacity, t/h.

2.3. Energy Output and Energy Efficiency

Energy output flow (

EOF) of sweet sorghum production is the energy generated by a product. It is calculated as the production of calorific values of silage and a yield:

where

LHVsi is the specific calorific value of silage, MJ/kg; and

Ysi is the yield of silage, kg/ha.

For grain sorghum, the energy output flow is generated by a product (grain) and by-product (straw):

where

LHVs is the lower heating value of straw, MJ/kg;

Ys is the yield of straw, kg/ha;

LHVg is the lower heating value of grain, MJ/kg; and

Yg is the yield of grain, kg/ha.

The energy efficiency ratio of technology is the ratio of the total energy outputs to the total energy inputs:

2.4. Measurement of Yield

Sorghum grain and silage yields were measured at harvest time. The yields were determined by the method of mechanized harvesting. Under this method, harvesting was carried out from a selective plot of the field, which is most typical. The yield is determined by the following formula:

where

MN is the mass of grain or silage from a plot, t;

L is the length of a plot, m; and

B is the combine header width, m.

The width is equal to a reaper width of a combine-harvester. A Claas Jaguar 830 was used to harvest sorghum silage. Sorghum grain was harvested by a Sampo 500.

2.5. Data Analysis

The results of the experiment were processed to determine energy indicators such as energy inputs, energy outputs, and energy efficiency ratio.

To study the relationship between random quantitative variables, a correlation-regression analysis was used. The correlation quantifies the strength of the linear relationship and regression expresses this relationship by an equation. This method was used to study the influence of external factors (precipitation, sowing date, and plant density) on a grain sorghum energy efficiency ratio. The built-in functions of MS Excel were used.

5. Conclusions

The analysis showed the following climate change in the south of Ukraine: an increase in average annual air temperature (17% for the past 50 years) and a decrease in precipitations (12% for the past 50 years). Sorghum is a promising crop for the production of biofuels (pellets, bioethanol, and biogas) due to its high yield and its resistance to arid climates.

The yield potential and energy balance of sweet sorghum were revealed in the South of Ukraine. Despite little annual precipitation (less than 400 mm), the yield of 40.6 t/ha was got. This value exceeded the national average yield of maize silage in Ukraine (25.91 t/ha in 2019). Therefore, sweet sorghum can complement other energy crops to be used in biorefinery. Moreover, this crop has a short growing period (5 months) and can be applied in rotation with other crops.

Production of sweet sorghum silage is a promising alternative to maize silage due to its high energy efficiency ratio, the value of which in the South of Ukraine may exceed 10. Due to fertile soil and an energy-saving technology (no ploughing), the energy efficiency ratio of 11.18 has been achieved. The maximum value of this indicator in some countries reaches 18.

Grain sorghum has a lower value of the energy efficiency ratio compared to sweet sorghum silage. Correlation regression analysis showed that the sowing period has the greatest influence. Early sowing provides a significant increase in energy efficiency. The optimal plant density is 140,000 seeds per hectare.

The field experiment has proven that sweet sorghum can be cultivated with a high energy efficiency ratio in Southern Ukraine. Further studies will reveal the dependence of an energy efficiency ratio on several factors such as plant density, terms of sowing, annual precipitation, cultivars, etc. It is planned that these studies will continue for the next three years.