Abstract

The main reason for the massive loss of rapeseed in mechanized harvesting is the mismatch between the harvester requirements and the pod shatter resistance and plant branching characteristics. Low pod resistance, entanglement caused by excessive branches, and inconsistent pod maturity are primary mismatch problems. However, studies on rape characteristics by integrating agricultural machinery and agronomy are limited. A total of 15 varieties were planted for research from 2016 to 2018. In this paper, the Two-Degree-of-Freedom (2-DOF) collision method was adopted to evaluate the pod shatter resistance taken from the field, and the plant agronomic characteristics and their correlation were investigated. In 2020, a screened variety of C6009 with higher shatter resistance and suitable plant features for mechanized harvesting was planted in large areas and harvested by machines for verification. The test results demonstrated that the compact plant varieties with high branches might be more favorable for yield and shatter resistance. The field harvest loss of the screened variety was significantly less than that of the control group. It provides a reliable reference for agronomic experts in terms of rape variety improvement and agricultural machinery experts regarding the optimization of rape harvesters.

1. Introduction

Rapeseed (Brassica napus L.) is an essential raw material in edible and industrial applications [,,]. A long-plagued problem of rape production is the enormous loss in mechanized harvesting [,,,]. The main causes for this problem are that the rape pod is fragile and that the plant is multibranched [,].

Fragile pods are more prone to cracking with the effects of reel tine and the vibration collision force of vertical cutters in combine harvesting, leading to massive losses and falling seeds on the ground [,,,,]. A principal reason for the excessive losses is the Brassica napus property of indefinite inflorescence with asynchronous mature pods []. For rapeseed, the multi-branching is the essential reason for the exceeding inconsistency among individuals. Additionally, their frondent and long branches are prone to intertwine with adjacent plants, causing stalks to tangle on the reel casually [,]. This complicates the process of dividing, cutting, and conveying in mechanized harvesting. The branches, leaves, shells, and seeds easily stick and block the screen surface when cleaning, leading to harvesting losses and problems in one large increment [,,]. In consideration of these issues, it is necessary to identify rapeseed varieties with strong pod shatter resistance and suitable branch architectural features that are favorable for reducing the losses caused by direct mechanized harvesting.

Many studies have been conducted to evaluate rape pod shatter resistance. In particular, the ripping method was adopted in a cantilever test to measure the resistance from the bending moment and the energy when the pod cracked []. Subsequently, this method was improved to measure the cracking force of different varieties, and the proportion of pod samples in each force interval was analyzed [,]. Additionally, a three-point bending fracture method was proposed, and the relationship between the pod moisture content and its shatter resistance was explored []. The other principle was to apply the random collision between metal balls and pods to make the pods crack under dynamic conditions [,]. This method has been recognized and expanded by many experts, and they optimized the parameters of the test method and the material treatment [,,]. However, none of these methods can be applied to this field because of excessive interference from humans and environmental factors during the test process, which cannot accurately represent the actual field pod shatter resistance at the harvest. Previous research on rapeseed plant varieties and branching has focused on the regulation of plant branch development, the branch formation mechanism, and hormone control [,,,,]. The relationship among the biomass, the plant morphology, and nitrogen, including its fertilization and utilization efficiency, has been investigated [,,]. The heterosis and combination ability of rape plant varieties characteristics has also drawn great attention []. The leading trend and objective of the current groundwork is still to increase the yield. However, the impediments and losses caused by the plant branch and structure in mechanized cutting have not been considered. Through the selection of germplasm resources in recent years, the preharvest losses caused by pod burst opening have been controlled to a very low level, so the main causes for pod cracking have been left with the external force during mechanical harvesting.

Overall, comprehensive studies on the selection of rape varieties considering the pod shatter resistance and branching structure features on mechanized harvesting are limited. The objectives of this paper are to first, identify rapeseed varieties suitable for mechanical harvesting combined with the evaluation of the pod shatter resistance in the field and the analysis of the plant characteristics and branching structures suitable for the structural feature of harvester, and second, conduct the field comparison test to determine whether these traits are beneficial for harvest. This study provides a more reliable reference for agronomists regarding varieties modification and cultivation patterns and machinery designers regarding harvester upgrading.

2. Materials and Methods

2.1. Test Cultivars

A total of 15 test varieties were used in the study, among which, varieties 15w2133-3, 15w2133-4, 15w2133-5, 15w2130-6, and 15w2130-8 were collected from the Institute of Oil Crops, Chinese Academy of Agricultural Sciences, and n749, C69, C96, C6009, C104, C105, C122, and n741 were collected from Hunan Yahua Academy of Seed Science. All of them are typical rapeseed varieties studied by the research institutes in recent years. In addition, two commercial varieties—ZS11 and NY12—were also planted as the control group []. All varieties are Brassica napus, which are sown in autumn and mature in the summer of the following year.

All the varieties were sown in the experimental field of Jiangsu University (East Longitude 119°52′38″ and North Latitude 32°20′44″) on 19 October 2016 and 25 September 2017. The soil type was loam, and the climate type was subtropical monsoon climate. The planting density in the two years was 16 plants per m2. In 2018, the preliminarily screened varieties of C6009, C122, and n741, with higher shatter resistance pods being planted in the experimental field of Jiangsu University for further investigation. In 2019, the finally screened variety C6009, which was planted by direct seeding in a large area for mechanical combine harvesting experiments of the Yangzhou Academy of Agricultural Sciences at Jiangsu Province (119°32′8″ E, 32°25′38″ N) on 9 October 2019. The variety YY12 studied and popularized by the academy was taken as the control group. C6009 was planted and regulated under the same conditions.

2.2. Experiments for Pod Shatter Resistance

2.2.1. Materials

All the test pods were collected from the experimental field. In the process of mechanized combine harvesting, too much moisture of pods will cause difficulty in threshing and separation as well as excessive cleaning load, and consequently increase the harvest loss. Generally, the moisture content of pods should not exceed 20% during mechanized harvest. At the late stage of plant maturity in the field, the moisture content of pods in the middle of main inflorescence was tested every day. When the pod moisture content reached ~15%, 60 intact pods of each variety without any pest and disease at the same maturity in the middle of the main inflorescence were cut for tests in May 2017 and 2018.

The previous methods for testing the shatter resistance were all conducted indoors. For comparison, this paper also tested the pod indoor referring to previous material treatment. Approximately 40 days after the main inflorescence blooming, five plants with approximately the same growth were selected, and the main inflorescence was cut and placed in a room with a temperature of 25 °C and a humidity of 50% for 25 days to ensure that the pod moisture was consistent (water-balanced). Then, 60 intact pods of about the same size of each variety without ant pest and disease were cut for testing.

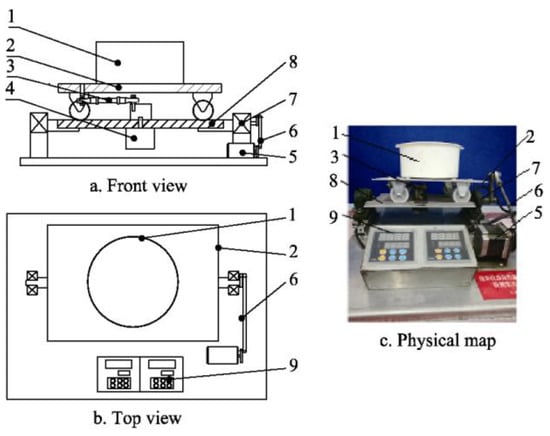

2.2.2. Two-Degree-of-Freedom Collision Method (2-DOF Method)

The Two-Degree-of-Freedom Collision tester was specially designed for field pod shatter resistance by our team. It has two motion mechanisms of crank-rocker and crank-slider, as shown in Figure 1 []. The crank-rocker mechanism is driven by motor 1: the crank-rocker drives the upper and lower plates to swing left and right. The second mechanism is crank-slider: motor 2 drives the upper plate and the material box to make a reciprocating linear motion along the slideway of the lower plate. Twelve steel balls of 13 mm diameter were placed in the material box in advance. When testing, 20 prepared pods were put in the box. The collision stops automatically every minute, and the broken rape pods are removed and counted every stop. The pod shatter resistance index (SRI) was calculated as Formula (1), and the average value was calculated based on three replications []:

where xi is the number of pods broken in the ith collision; n1 is the total number of pods; n2 is the number of collision minutes with an upper limit of 10.

Figure 1.

Structure and physical diagram of the 2-degree-of-freedom collision tester. (a) Front view of the tester; (b) Top view of the tester; (c) Physical map of the tester. 1. Material box, 2. Upper plate, 3. Crank slide mechanism, 4. Motor 2, 5. Motor 1, 6. Crank rocker mechanism, 7. Bearing, 8. Lower plate, and 9. Controller.

2.3. Rape Agronomic Traits and Plant Geometry Investigation

Agronomic traits and plant geometry are closely related to mechanical harvesting. To better understand various plant varieties, we measured detailed plant traits. A band tape was used to measure plant height (PH), lowest branch height (LBH), branch length (BL; the average length of all primary branches), maximum diameter of the pod layer (MDPL), and pod layer thickness (PLT). The unit is centimeters, to one decimal place. The main stem diameter (MSD; 20 cm above the ground) was measured with a vernier caliper. The unit is millimeters, and the measurement accuracy is two decimal places. The branching angle (BA) and stem lodging angle (SLA) were measured with a protractor. In addition, the thousand-seed weight (TSW) and yield per plant (YPP) were also weighed. The unit is g, to two decimal places. The primary branching number (PBN) and the number of seeds per pod (NSPP) were also counted. Generally, the lowest branch height and the length of the main stem with branches are closely related to the plant height, which means that the lowest branch height will increase with the rise of plant height. For statistics on the structures of different plant varieties, length of the main stem with branches (LMB, length of the lowest branch and highest branch), length of branches with pods (LBP) and relative branch height (ratio of branch height to plant height, i.e., LBH/PH) were gauged. In May 2017 and 2018, the maturity period of rape, 15 plants of each variety were randomly selected to measure the above traits.

Moreover, in order to explore the shape of the pod layer in detail and analyze its effects on harvest loss, the pod layer of the variety C6009, C122, and n741with high shatter resistance and yield screened out in the first two years was drawn in 2019. The lowest point of the main stem was regarded as the coordinate origin and the main inflorescence as the coordinate-axis Y to establish a rectangular coordinate system. Then, the distances between the apex and end position of each inflorescence from the X-axis and Y-axis were measured, correspondingly. Consequently, the starting and ending point coordinates of each inflorescence were obtained. Ultimately, a graph was drawn to connect the coordinates, and the structure of the pod layer of each variety was obtained.

2.4. Field Mechanical Harvesting

The mechanized combine harvesting tests were conducted in Yangzhou Academy of Agricultural Sciences on 22 May 2020. A combine harvester (DR50E11, World Group, Zhen jiang, China) with a 2 m cutting width was applied in this experiment, and the sampling method was used to measure the header loss. Before harvesting, a groove was dug between two rows of rapeseed for placing a sampling trough. The groove depth should have been equal to the height of trough. After the harvester passed, pods and seeds hit by the reel dropped into the tough, then the cleaned rapeseeds were collected and weighed after removing the soil, stalks, and peels artificially. For the specific operation method and device refer to method in [].The harvester header loss rate (Sg) was calculated as follows:

where Wt is the total yield of rapeseed in the harvesting test area, g.m−2; Wi is the quality of the rapeseed that was collected in the ith sampling trough, g; L is the length of the harvesting area, m; B is the slot width of the sample trough, m; and n is the number of sampling troughs.

3. Results

3.1. Pod Shatter Resistance of Different Varieties

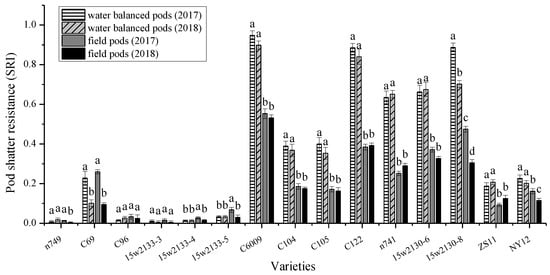

The average SRI results of the field pods and indoor water-balanced pods in 2016 to 2017 and 2017 to 2018 were contrasted as shown in Figure 2. After indoor water-balancing, the moisture contents of various pod varieties were between 13.15% and 14.67%. For rape pods in the field, the moisture content was tracked on a daily basis to keep the moisture content of pods in the field at about 15%, ensuring which was not different from the laboratorial level. The moisture contents varied slightly from variety to variety due to the uncontrollable maturity in the field. After testing, the moisture contents of different varieties ranged from 13.54% to 17.89%, nearly at the same level or slightly higher than those of the water-balanced pods.

Figure 2.

Pod shatter resistance index (SRI) values of the main inflorescence pods of two types (indoor water-balanced pods and field pods) according to the 2-degree-of-freedom collision method in 2016–2018. Lowercase letters indicate that the SRIs differ significantly within one variety based on Fisher’s protected LSD (p = 0.05).

In 2017, the range of SRI of the field pods was 0.013–0.553, and the range of the corresponding water-balanced pods was from 0.008 to 0.948. In 2018, the SRI ranges of the field pods and water-balanced pods were 0.003–0.532 and 0.018–0.898, respectively, and the results for the two types of pods differed significantly (p < 0.05). Except for C69 and 15w2130-8, there were no significant differences in the cracking resistance of the same variety between the two years. The crack resistance of the C69 field pods in 2017 was not significantly different from that of the water-balanced pods. However, the moisture content of the field pods in the experiment was 17.89%, significantly higher than that of the water-balanced pods. The effect of the moisture content on the cracking resistance was not excluded. In addition, for the varieties with higher cracking resistance, the resistance of the field pods is significantly less than their water-balanced counterparts, although the water content is approximately at the same level. By contrast, for varieties with low cracking resistance, such as n749, C96, and 15w2133-33, there is no significant difference in the cracking resistance between the two types of pods. This shows that the field test is necessary for reflecting the real characteristics of the mechanical harvesting pod. The top five varieties of C6009, C122, 15w2130-8, 15w2130-6, and n741 with better shatter resistance were screened preliminarily.

3.2. Rape Plant Agronomic Traits

The statistical agronomic characteristics of the rape plant are presented in Table 1. The plant type with the largest proportion is the upper-branch rape plant, whose branches are concentrated on the middle and upper parts, with well-developed main inflorescences. Varieties with special plant characteristics are 15w2133-5 and n741. Variety 15w2133-5 is the lower-branch type that branches from the bottom; therefore, its lowest branch height (LBH) is minimum, and its overall shape is cylindrical. Variety n741 is a mutant material with two to three shoot meristems and multiple main inflorescences. Lodging is a very unfavorable feature for harvesting. Most varieties investigated were erect except for 15w2130-6, 15w2130-8, C122, and 15w2133-4, which exhibited root lodging with stem inclination, the 15w2133-4, which had the maximum average stem lodging angle (SLA) with 33.2°, and the followed 15w2130-6 with 31.4°. Generally speaking, varieties with excessive plant height and scattered plant shapes are susceptible to lodging. The correlations among the important agronomic traits of rapeseed plants were also analyzed. Mechanized harvesting loss is closely related to the length of the main stem with branches (LMB), branching angle (BA), and SLA. LMB represents the concentration of branches, and BA denotes the dispersion of plant varieties. With the increase of branches and branch angle, the entanglement between plants will become more severe, aggravating harvest loss. In the correlation analysis, as a mutant of unconventional plant type, n741 missed some characteristic parameters, which were not included in the data analysis. Unfortunately, in 2017, the cultivated rapeseed was attacked by birds, and the yield was affected, so no statistics were collected.

Table 1.

Average value of plant type characters and the correlation between important traits of he tested materials in 2017 and 2018.

According to the results, BA showed a significant positive correlation with the maximum diameter of the pod layer (MDPL) and a significant negative correlation with the number of seeds per pod (NSPP) in two years consecutively. Excessive BA will lead to the scattered plant type and severe branching among plants, which is unsuitable for mechanized harvesting. SLA also displaced a negative correlation with the NSPP and significant positive correlations with MDPL and BA. It revealed that stem lodging may be unfavorable to harvest and may affect the development of pods and reduce the number of seeds in the pods. In addition, the larger the branch angle, the more serious the lodging results, which also indicated that the compact plant type is more conducive to harvesting. The positive correlation between the main stem with branches (LMB) and primary branch number (PBN) also showed that less branching is more conducive to harvesting, yet this is under the premise of not affecting the yield.

In the varieties with highly shatter-resistant pods, the lodging angles (SLA) of 15w2130-6 and 15w2130-8 were too large, while the yields were too small, which is not conducive to production. Although the n741 pod was slightly weaker than that of 15w2130-6, it had the highest yield and stronger lodging resistance, which is beneficial for harvesting. Therefore, C6009, C122, and n741 were preliminarily selected for further investigation.

3.3. Pod Layer Geometry

The pod layer shape of C6009, C122, and NY12 was canopy-type, and that of n741 was almost trapezoidal. The heights of the outer branches were lower and the bottom of the pod layer of C122 and NY12 was arched, whereas C6009 was nearly straight and the pod layer was more concentrated (Figure 3). Compared with NY12, the pod layer height of C122 was nearly the same, and the maximum diameter of the pod layer was similar, but the thickness and area of C122 were smaller. The pod layer height of C6009 was significantly lower than that of NY12, and the diameter, thickness, and area of the pod layer of C6009 were also smaller. Comparatively, n741 had the lowest pod height and the largest pod area. In mechanized combine harvesting, the thickness of the fruit layers of c6009 and c122 that needed to be cut by a vertical cutter was less than 30 cm, while those of NY12 and n741 were similar, namely, approximately 55 cm. Theoretically, the smaller the thickness of the pod layer divided by the vertical cutter, the fewer the pods that are damaged and shattered, the smaller the division cutting area of the combine harvesting header, and the smaller the loss. Therefore, in terms of the pod layer structure, C6009 and C122 are more suitable for mechanical harvesting.

Figure 3.

Comparison of the shapes of the pod layers of C6009, C122, and n741 with the commercial variety NY12. The horizontal axis represents the coordinate of the pod layer, where the value “0” corresponds to the main inflorescence of rape; for n741, zero corresponds to the middle position of the whole pod layer because it had more than one main inflorescence. The vertical axis represents the height of the pod layer above the ground. The dashed line (2) represents the pod layer of adjacent rape plants with a planting space of 30 cm. The pink dash-dotted line corresponds to the vertical cutter and intersects with the pod layer, and the corresponding longitudinal height range of the left dash-dotted line at its intersection is the height of the cutting pod layer of each variety at harvest.

However, C122 is unsuitable for mechanical harvesting due to its lodging phenomenon for two years. In comparison, C6009 is more suitable for harvesting because of its advantages of moderate plant height, few branches, concentrated pod layer, compact plant type, plump seed, higher pod shatter resistance, and the same level yield as commercial varieties.

3.4. Field Mechanical Harvesting

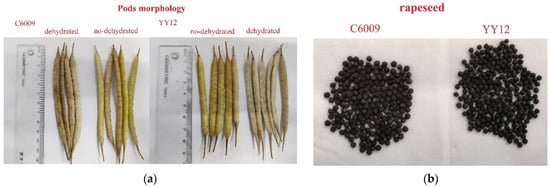

In 2020, variety C6009 was planted in Yangzhou and evaluated for mechanical harvesting, and the results are presented in Table 2. The pod structure of the control variety YY12 is similar to that of NY12 and is the most common canopy structure with an arched bottom edge and the most common mainstream structure in the market. In reference to plant characteristics, C6009 was significantly smaller than YY12 in PH, PBN, LBH, and PLT, and its overall plant type was more concentrated. Moreover, YY12 exhibited the phenomenon of tipping, and the SLA was significantly higher than that of C6009, which was not conducive to mechanized harvesting. For yield-related traits, the yield of C6009 was less than that of YY12 with no significant difference, but the yield values of TSW and NSPP were significantly larger than those of YY12. The morphological comparison of the pods and seeds of C6009 and YY12 is shown in Figure 4. The pods of C6009 were significantly larger than those of YY12, and the seeds of C6009 were bigger and fuller. In recent years, to enhance the threshing separation and cleaning in mechanical harvesting, attempts have been made to spray dehydrating agents on pods to reduce the moisture content. It can be seen from the figure that the color of dehydrated pods is slightly white. In this experiment, half of the plants of the two varieties were dehydrated for comparison with natural plants. However, the pods of YY12 after the dehydration treatment were too poor to resist cracking in mechanical harvest; therefore, only the C6009 test was conducted.

Table 2.

Field combine harvest comparison test of screened variety C6009 and control variety YY12 in 2020 in Yangzhou. Different lowercase letters in a column correspond to significantly different values at the level of 0.05.

Figure 4.

Comparison of morphology of the dehydrated and non-dehydrated pods and rapeseeds of C6009 and YY12. (a) Comparison of pods morphology. (b) Comparison of seeds morphology.

According to Table 2, for the non-dehydrated pods, the moisture content of the pods (MCP), SRI, and the moisture content of the seeds (MCS) were significantly higher than those of YY12. With the increase in the harvesting speed, the header loss rate (Sg) will increase due to the stronger impact force on pods from the combine reel and the higher cutting frequency of the vertical cutter. The harvesting speed of C6009 was 2.12 m/s, significantly higher than that of YY12; however, YY12 had a header loss rate of 4.32%, significantly higher than that of C6009, and a lower impurity rate despite no significant difference. For the dehydrated pods of C6009, the pod moisture content was 14.35%, which was similar to those of the water-balanced pods and field pods in the previous experiment; on the other hand, their SRI was significantly lower than that of YY12 without dehydration. In addition, the header loss rate was slightly lower than that of YY12, with no significant difference under similar harvesting speeds. However, the impurity rate and MSC were significantly lower, especially when the impurity was only 0.59%. Overall, the pod layer structure and pod characteristics of YY12 caused much more header loss than the case of C6009, which is more suitable for mechanical harvesting. The higher the moisture content of the pod, the higher the impurity rate.

4. Discussion

4.1. Plant Structure Suitability for Mechanized Harvesting

Theoretically, comprehensive consideration for selecting a suitable rape canopy, pod shatter resistance, rape maturity and harvesting time, and using reasonable working parameters of combine harvesters can minimize harvesting losses. The structure of the rape combine harvester differs from that of the common rice–wheat harvester. Vertical cutters are installed on the left or both sides of the header to cut the intersecting branches and separate the crops.

However, in the process of harvesting, when the pods have low shatter resistance, the transverse impact on the pods under the forced vibration of the vertical cutter and the rotary attack under the rotary motion of the reel will cause the pods to crack and explode quickly, thereby increasing seed loss. In addition, the large difference in pod maturity among the same plant renders makes it difficult for the threshing drum to satisfy the shelling demands of pods that vary in moisture content simultaneously, which often leads to difficult or unclean removal problems, thereby increasing the threshing loss. The ultimate cause of inconsistency in pod maturity is the excessive number of rape branches. Therefore, the main reason for the large loss in rape combine harvesting is the mismatch between the combine harvester and pod resistance and the branching characteristics of the plants.

Considering the harvesting techniques and structural characteristics of the combine harvester, a rape plant suitable for mechanized harvesting should not be too tall because the plant is prone to lodging if too tall and the height adjustment range of the harvester reel is limited, which is also unfavorable for supporting and feeding the crops. In addition, an excessively tall plant usually causes more branches, leaves, stems, and stalks to enter the drum, which renders the contents difficult to separate and clean and causes sticking and blockage of the cleaning screen, thereby increasing the loss rate and the energy consumption.

Therefore, the plant height of mechanized harvesting rape should not exceed 1.6 m. The LBH and LMB have more significant effects on the mechanized harvest. Plants with a higher LBH have fewer branches and can better meet the demand for light energy in the later growth stage of rapeseed. However, they should not be too tall because moving up the center of gravity will result in poor lodging resistance, which is not conducive to harvesting, such as with C122. The smaller LMB indicates that the branches are relatively concentrated, and the interlaced parts of the rape plants are smaller, which is favorable for reducing the division vibration and loss. Moreover, the mature period is more consistent and conducive to threshing. A branch structure with a longer BL and a larger BA typically ends up with severe crossover between adjacent plants, causing significant vibrations of adjacent plants in the process of division and harvesting. Most productive researchers have revealed that the number of branches is an important factor affecting the yield of plants. Therefore, many multibranched varieties were selected to increase the yield []. However, too many branches will cause branch drooping, severe entanglement, and larger differences in pod maturity, leading to severe header loss. A significant positive correlation between the yield and the number of branches was not identified in this study; however, the PBH, NSPP, BA, and SLA did present correlations with the yield. Therefore, to ensure yield, varieties with fewer branches, concentrated branches, and more, NSPP with plump grains can be selected. Studies have found that the larger the TSW of rapeseed, the lower the hull rate and the higher the oil content []. Moreover, the pod shatter resistance may be higher with larger TSW in this study. All the above traits are advantageous for mechanical harvesting.

4.2. Variety Screening

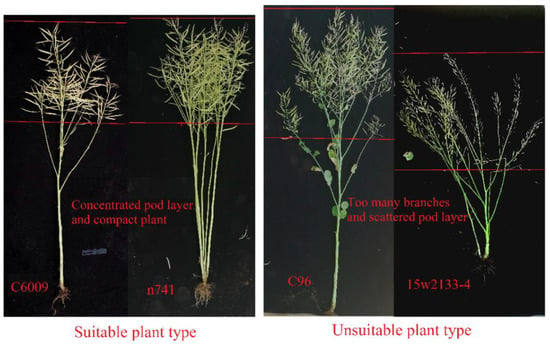

The plant types of the selected representative varieties suitable for mechanical harvesting and those not suitable for mechanical harvesting are illustrated in Figure 5. The mechanized combine harvesting test proved that the harvest loss of C6009 was significantly less than that of commercial varieties; however, its yield was slightly lower than that of the check variety, although with no significant difference. Studies have found that the larger TSW of rapeseed leads to lower shell yield and higher oil content []. TSW of C6009 was significantly larger, and its oil content was potentially higher. We found that although n741 did not possess a conventional rape plant structure, its main inflorescence was not readily observable with a consistent inflorescence height, similar to many rice or wheat plants that are clustered together. Therefore, the entanglement between plants may be insignificant, the yield was higher, and the pod resistance was relatively satisfactory. Theoretically, this plant type is also suitable for mechanized harvesting. However, due to insufficient seed quantity, it is impossible to plant n741 plant in a large area and conduct field harvest tests, leaving the problem of whether the loss is smaller to be determined.

Figure 5.

Comparison of rape plant types and features suitable and unsuitable for mechanized harvesting.

In addition, many researchers have claimed that increasing the planting density could reduce the number of branches and make the pods more consistent in terms of maturity and resistance []. In this study, varieties C6009, C122, and n741 were also planted at a density of 30 plants per m2 in 2019. However, due to the pandemic, the statistical measurement experiment of rape pods was not conducted adequately. It was found that the statistical results of PH, SDMS, PBN, MD, and PLT of high-density plants were significantly smaller than those at a low-density of 16 plants per m2 by the preliminary statistical test. However, the average pod size, pericarp thickness, and pod resistance were relatively higher. This may be due to the increase of the planting density that reduced the shading area between adjacent plants, thereby enhancing the photosynthetic efficiency of the pods and enabling the pods to fully develop []. Studies have shown that increasing the planting density is beneficial for the yield [,]. The lack of management in the field can cause serious diseases and insect pests among rape and miscalculated outputs. Therefore, the effects of the density on plant and pod characteristics require further study. In mechanical harvesting, the unavoidable first contact of the harvester reel usually occurs at the top pods. The selection and breeding of varieties with pod resistance can reduce seed loss. However, in order to reduce the header loss and solve the problem fundamentally, it is necessary to screen suitable harvest varieties and to improve the design of the harvester according to the growth characteristics of rape to minimize the mechanical impact and contact with the pods, by combining agricultural machinery with agronomy.

5. Conclusions

In this paper, two aspects of pod shatter resistance and the features of the plant branching structure were investigated for the screening of rapeseed varieties suitable for mechanical harvesting. The 2-DOF method was adopted to evaluate the field pod shatter resistance for the screening of more reliable varieties. The relative height of the lowest branch (LBH/PH) is an important factor for plant features and has a positive effect on the pod shatter resistance and plant yield, while the branch angle (BA) has a negative effect on the yield. According to the requirements of mechanized harvesting, variety C6009, which has a low plant height, few branches, a concentrated pod layer, a compact plant type, plump seeds, strong resistance, and a desirable field, was selected. Additionally, the combine harvesting comparison test was conducted, which indicated that these characteristics were effective in reducing harvest loss and thus more suitable for mechanical harvesting.

Less branching has been proved to be beneficial to mechanized harvesting. However, the yield of less-branched varieties may be slightly lower than that of commercial counterparts, which is very unfavorable for rape production. In general, increasing yield can be compensated by adjusting the planting density, but the identification of a suitable planting density requires further investigation. Additionally, an unconventional multi-stem rapeseed plant type, a new plant type suitable for harvesting and with a higher yield, was identified. It provides a new direction for breeding that needs to be further evaluated.

Author Contributions

Conceptualization, Y.L. and Y.Q.; methodology, Y.Q.; software, Y.Q.; validation, Z.M.; investigation, Y.Q. and L.X.; resources, Z.M.; data curation, Y.Q. and L.X.; writing—original draft preparation, Y.Q.; writing—review and editing, Y.L.; supervision, Z.M.; project administration, Y.L.; funding acquisition, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of PR China, grant number 31671590.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Ethical review and approval were waived for this study, due to the studies not involving humans or animals.

Data Availability Statement

We choose to exclude this statement because the study did not report any data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Delgado, M.; Felix, M.; Bengoechea, C. Development of bioplastic materials: From rapeseed oil industry by products to added-value biodegradable biocomposite materials. Ind. Crops Prod. 2018, 125, 401–407. [Google Scholar] [CrossRef]

- Szubert, K. Synthesis of organofunctional silane from rapeseed oil and its application as a coating material. Cellulose 2018, 25, 6269–6278. [Google Scholar] [CrossRef]

- Shim, Y.Y.; Falk, K.; Ratanapariyanuch, K.; Reaney, M.J.T. Food and fuel from Canadian oilseed grains: Biorefinery production may optimize both resources. Eur. J. Lipid Sci. Technol. 2017, 119, 1438–7697. [Google Scholar] [CrossRef]

- Kuai, J.; Sun, Y.Y.; Zuo, Q.S.; Liao, Q.X.; Leng, S.H.; Cheng, Y.G.; Cao, S. Optimization of plant density and row spacing for mechanical harvest in winter rapeseed (Brassica napus L.). Acta Agron. Sin. 2016, 42, 898–908. [Google Scholar] [CrossRef]

- Pari, L.; Assirelli, A.; Suardi, A.; Civitarese, V.; Del Giudice, A.; Costa, C.; Santangelo, E. The harvest of oilseed rape (Brassica napus L.): The effective yield losses at on-farm scale in the Italian area. Biomass Bioenerg. 2012, 46, 453–458. [Google Scholar] [CrossRef]

- Gulden, R.H.; Cavalieri, A.; Syrovy, L.D.; Shirtliffe, S.J. Pod drop in brassica napus is linked to weight-adjusted pod-retention resistance. Field Crops Res. 2017, 205, 34–44. [Google Scholar] [CrossRef]

- Gulden, R.H.; Shirtliffe, S.J.; Thomas, A.G. Harvest losses of canola (Brassica napus) cause large seedbank inputs. Weed Sci. 2003, 51, 83–86. [Google Scholar] [CrossRef]

- Squires, T.M.; Gruwel, M.L.H.; Zhou, R.; Sokhansanj, S.; Abrams, S.R.; Cutler, A.J. Dehydration and dehiscence in siliques of Brassica napus and Brassica rapa. Can. J. Bot. 2003, 81, 248–254. [Google Scholar] [CrossRef]

- Luo, H.F.; Tang, C.Z.; Guan, C.Y.; Wu, M.L.; Xie, F.P.; Zhou, Y. Plant characteristic research on field rape based on mechanized harvesting adaptability. Trans. CSAE 2010, 26, 61–66. [Google Scholar]

- Bruce, D.M.; Farrent, J.W.; Morgan, C.L.; Child, R.D. Determining the oilseed rape pod strength needed to reduce seed loss due to pod shatter. Biosyst. Eng. 2002, 81, 179–184. [Google Scholar] [CrossRef]

- Cavalieri, A.; Lewis, D.W.; Gulden, R.H. Pod drop and pod shatter are not closely related in canola. Crop Sci. 2014, 54, 1184–1188. [Google Scholar] [CrossRef]

- Cavalieri, A.; Harker, K.N.; Hall, L.M.; Willenborg, C.J.; Haile, T.A.; Shirtliffe, S.J.; Gulden, R.H. Evaluation of the causes of on-farm harvest losses in canola in the northern Great Plains. Crop Sci. 2016, 56, 1–11. [Google Scholar] [CrossRef]

- Gao, Z.P.; Xu, L.Z.; Li, Y.M.; Wang, Y.D.; Sun, P.P. Vibration measure and analysis of crawler-type rice and wheat combine harvester in field harvesting condition. Trans. CSAE 2017, 33, 48–55. [Google Scholar] [CrossRef]

- Morgan, C.L.; Bruce, D.M.; Child, R.; Ladbrooke, Z.L.; Arthur, A.E. Genetic variation for pod shatter resistance among lines of oilseed rape developed from synthetic B. napus. Field Crops Res. 1998, 58, 153–165. [Google Scholar] [CrossRef]

- Xu, L.Z.; Li, Y.M.; Ma, C.X. Design of Main Working Parts of 4LYB1-2.0 Rape Combine Harvester. Trans. CSAE 2008, 08, 54–57. [Google Scholar]

- Price, J.S.; Hobson, R.N.; Neale, M.A.; Bruce, D.M. Seed losses in commercial harvesting of oilseed rape. J. Agric. Eng. Res. 1996, 65, 183–191. [Google Scholar] [CrossRef]

- Liu, J.; Wang, W.X.; Mei, D.S.; Wang, H.; Fu, L.; Liu, D.M.; Li, Y.C.; Hu, Q. Characterizing variation of branch angle and genome-wide association mapping in rapeseed (Brassica napus L.). Front. Plant. Sci. 2016, 7, 21. [Google Scholar] [CrossRef]

- Kadkol, G.P.; Macmillan, R.H.; Burrow, R.P.; Halloran, G.M. Evaluation of Brassica genotypes for resistance to shatter: I. Development of a laboratory test. Euphytica 1984, 33, 63–73. [Google Scholar] [CrossRef]

- Tan, X.L.; Zhang, J.F.; Yang, L. Quantitive determination of the strength of rapeseed pod dehiscence. Trans. CSAE 2006, 22, 40–43. [Google Scholar]

- Pu, H.M.; Long, W.H.; Gao, J.Q.; Hu, M.L. Silique shatter resistance and correlation analysis in Brassica napus. Chin. J. Oil Crop Sci. 2013, 35, 469–475. [Google Scholar]

- Li, Y.M.; Zhu, J.Q.; Xu, L.Z. Experiment on strength of rapeseed pod dehiscence based on impending fracturing method. Trans. CSAE 2012, 28, 111–115. [Google Scholar] [CrossRef]

- Summers, J.E.; Bruce, D.M.; Vancanneyt, G.; Redig, P.; Werner, C.P.; Morgan, C. Pod shatter resistance in the resynthesized brassica napus line dk142. J. Agric. Sci. 2003, 140, 43–52. [Google Scholar] [CrossRef]

- Peng, P.F.; Li, Y.C.; Hu, Q. Screen of varieties suitable for machine harvesting from new breeding hybrids or lines in Brassica napus. Acta Agric. Boreali Sin. 2009, 24, 223–226. [Google Scholar] [CrossRef]

- Peng, P.F.; Li, Y.C.; Mei, D.S.; Liu, D.M.; Fu, L.; Wang, H.; Sang, S.F.; Chen, Y.F.; Hu, Q. Optimization and experiment of assessment method for pod shatter resistance in Brassica napus L. Trans. CSAE 2013, 29, 19–25. [Google Scholar] [CrossRef]

- Stirnberg, P.; Chatfield, S.P.; Leyser, H.M. AXR1 acts after lateral bud formation to inhibit lateral bud growth in Arabidopsis. Plant. Physiol. 1999, 121, 839–847. [Google Scholar] [CrossRef]

- Stirnberg, P.; Sande, K.V.C.; Leyser, H.M. MAX1 and MAX2 control shoot lateral branching in Arabidopsis. Development 2002, 129, 1131–1141. [Google Scholar] [CrossRef]

- Shimizu-Sato, S.; Tanaka, M.; Mori, H. Auxin-cytokinin interactions in the control of shoot branching. Plant Mol. Biol. 2009, 69, 429–435. [Google Scholar] [CrossRef]

- Dun, E.A.; Brewer, P.B.; Beveridge, C.A. Strigolactones: Discovery of the elusive shoot branching hormone. Trends Plant. Sci. 2009, 14, 364–372. [Google Scholar] [CrossRef]

- Gomez-Roldan, V.; Fermas, S.; Brewer, P.B.; Puech-Pagès, V.; Dun, E.A.; Pillot, J.P.; Letisse, F.; Matusova, R.; Danoun, S.; Portais, J.C. Strigolactone inhibition of shoot branching. Nature 2008, 455, 189–194. [Google Scholar] [CrossRef]

- Miersch, S.; Gertz, A.; Breuer, F.; Schierholt, A.; Becker, H.C. Influence of the semi-dwarf growth type on nitrogen use efficiency in winter oilseed rape. Crop Sci. 2016, 56, 2952–2961. [Google Scholar] [CrossRef]

- Zhang, W.X.; Cao, H.X.; Zhu, Y.; Liu, Y.; Zhang, W.Y.; Chen, Y.L.; Fu, K.Y. Morphological Structure Model of Leaf Space Based on Biomass at Pre-Over-wintering Stage in Rapeseed (Brassica napus L.). Plant Acta Agron. Sin. 2015, 41, 318–328. [Google Scholar] [CrossRef]

- Pinet, A.; Mathieu, A.; Jullien, A. Floral bud damage compensation by branching and biomass allocation in genotypes of brassica napus with different architecture and branching potential. Front. Plant. Sci. 2015, 6, 70. [Google Scholar] [CrossRef]

- Wolko, J.; Dobrzycka, A.; Bocianowski, J.; Bartkowiak-Broda, I. Estimation of heterosis for yield-related traits for single cross and three-way cross hybrids of oilseed rape (Brassica napus L.). Euphytica 2019, 215, 10. [Google Scholar] [CrossRef]

- Huang, W.; Chang, H.B.; Li, J.; Xu, H.Y. Comprehensive evaluation of 31 rapeseed cultivars in Hubei Province. Jiangsu Agric. Sci. 2019, 47, 84–88. [Google Scholar] [CrossRef]

- Qing, Y.R.; Li, Y.M.; Xu, L.Z.; Ma, Z.; Yang, Y. Technology of 2-DOF collision testing for rape pod shatter resistance. Trans. CSAE 2019, 35, 33–40. [Google Scholar] [CrossRef]

- Qing, Y.; Li, Y.; Yang, Y.; Xu, L.; Ma, Z. Development and experiments on reel with improved tine trajectory for harvesting oilseed rape. BIOS Eng. 2021, 206, 19–31. [Google Scholar] [CrossRef]

- Yang, J.C.; Liu, J.J.; An, Z.Y.; Yang, Q.L.; Qu, G.; Li, H.Y.; Hu, X.Z. The breeding and efficient cultivation techniques of a new rape variety Yuyou No.4 with excellent traits of high and stable yield. Breed 2018, 37, 113–115. [Google Scholar] [CrossRef]

- Cheng, Q.; Xiao, G.; Chang, T.; Zhang, Z.Q.; Guan, C.Y.; Wang, G.H.; Xiong, X.H. The physiological and biochemical characteristics of different 1000-grain weight rapeseed. Mol. Plant. Breed. 2019, 10, 12–13. [Google Scholar] [CrossRef]

- Kuai, J.; Wang, J.J.; Zuo, Q.S.; Chen, H.L.; Gao, J.Q.; Fu, Y.D. Effects and mechanism of higher plant density on directly-sown rapeseed in the Yangtze river basin of China. Sci. Agric. Sin. 2018, 51, 4625–4632. [Google Scholar] [CrossRef]

- Zhao, X.G.; Zhang, Y.W.; Chen, W.J.; Zhang, Y.L.; Wang, Z.Y.; Zhao, X.Z.; Hou, J.L.; Wang, L.P.; Zhang, X. Differences in photosynthetic physiological characteristics of Brassica napus under different planting densities. Southwest China J. Agric. Sci. 2019, 32, 1531–1536. [Google Scholar] [CrossRef]

- Zhao, J.X.; Dai, X.L.; Ren, T.B. Study on direct seeding density of Brassica napus. Agric. Sci. Technol. 2017, 18, 1860–1866. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).