Abstract

Cultivating the soil is a necessary measure to ensure the growth of potatoes, and it has a significant impact on potato yield. In this study, a soil cultivator with a textured shovel wing was designed to address the problem that soil cultivators have poor working performance. Based on a combination of discrete element simulation and a digital soil trench verification test, the effects of the structure parameters of the surface textures on the traction resistance and soil fragmentation rate of the soil cultivator with a textured shovel wing were studied. These parameters were optimized to provide a basis for the design of the soil cultivator. The main research results of this paper are as follows. (1) The factors influencing the traction resistance of the soil cultivator were as follows: blade penetration angle > convex hull distance > convex hull diameter. The convex hull diameter was the main factor affecting the soil fragmentation rate. The traction resistance of the soil cultivator with a textured wing was reduced by 9.49%, and the soil fragmentation rate was increased by 10.67%, showing that the quality of soil cultivation was significantly improved. (2) The best parameters for the texture structure of the shovel wing were a blade penetration angle of 26°, a convex hull diameter of 34.4 mm, and a convex hull distance of 28.5 mm. (3) The relative errors between the simulation and the soil trench test for the traction resistance and the soil fragmentation rate were 2.60% and 13.97%, respectively. This study can provide technical support for the design of soil cultivators and is of great significance in improving the quality of soil cultivators.

1. Introduction

Soil cultivation during the potato seedling stage is an important measure to improve the yield and quality of potatoes. The quality of soil cultivation is mainly affected by the structure and parameters of the cultivator device [1,2]. At present, the types of soil cultivators in fields include rotary soil cultivators, wall soil cultivators, and spiral soil cultivators [3]. These devices can be used for potato soil cultivation, but there are problems such as a low soil fragmentation rate and a high traction resistance when working in heavy clay soil.

In recent years, the application of bionic and surface processing technology in research into agricultural soil contact parts has been increasing, and its drag reduction effect has been clearly proven [4,5]. Yang developed a bionic rotary tillage blade based on the polytoed structure of the mole, and the power of the tillage device was reduced by about 20% [6]. Matin simulated the toes of the brown bear to improve the shape of the rotary tillage blade, and the traction resistance of the device was reduced by 14% [7]. Computer simulation can quickly obtain the optimal structural parameters of devices, and is used by scholars as a reliable research method in the design of soil contact parts [8,9]. Liu optimized the design of the potato ridging device based on a simulation model of the contact surface between earthworms and soil [10,11]. Ucgul established a discrete element simulation model of the interaction between the soil contact parts and the soil [12,13].

In summary, the traditional cultivator has a low soil fragmentation rate and a high traction resistance under heavy clay soil conditions, thus decreasing the yield and quality of potatoes and increasing the working costs. In this study, a soil cultivator with a textured shovel wing was designed to address the problem that soil cultivators have poor working performance. The main working parts of the soil cultivator were the shovel chest with a semicircular corrugated structure and a wing plate with a convex hull structure, based on earthworms and rose petals, respectively. Discrete element simulation and a digital soil-bin test were used to study the influence of structural parameters such as blade penetration angle, the diameter of the convex hull, and the effect of the convex hull on the soil fragmentation rate and traction resistance, with the purpose of designing the optimal structure parameters for the textured shovel wing to improve the quality of the soil cultivator.

2. Materials and Methods

2.1. The Device of the Soil Cultivator with Textured Shovel Wing

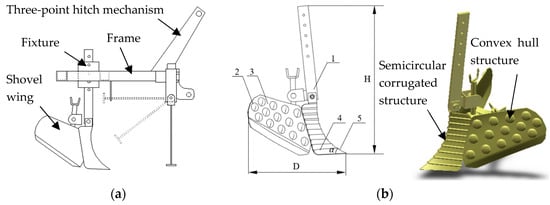

As shown in Figure 1a, the soil cultivator mainly includes the shovel wing, a three-point hitch mechanism, the frame, and the fixture. The shovel wing is the most important working part, playing the role of enabling soil loosening and ridge cultivation. The soil fragmentation rate is used to evaluate the quality of the performance, and the traction resistance of a soil contact part is a common subject of research. Hence, in this study, we designed a textured shovel wing to reduce the traction resistance and increase the soil fragmentation rate, thereby improving the quality of cultivation.

Figure 1.

The soil cultivator and textured shovel wing structure. 1. Shovel handle; 2. convex hull; 3. wing plate; 4. semicircular corrugation; 5. shovel chest. (a) Soil cultivator; (b) Shovel wing with textured surface. H is the height of shovel wing, D is the width of shovel wing, α is the soil entry angle of shovel chest.

The shovel wing with a textured surface is shown in Figure 1b, and is mainly composed of a wing plate with a convex hull, a shovel chest with semicircular corrugation, and a shovel handle. These structures were based on the papillae of the rose leaf and the convex ridges of the earthworm. A convex hull and a semicircular corrugated structure were constructed on the wing plate and the shovel chest of the shovel wing, respectively.

When the soil cultivator with the textured shovel wing is working, as the shovel wing moves forward the soil will move back along the semicircular corrugation of the shovel chest to the wing plate, and large clods will be broken up by the action of the convex hull on the surface of the wing plate. The soil cultivator has the same size as the standard cultivator: the height of cultivator H = 550 mm, the width D = 480 mm, and the soil entry angle α = 32° [14].

2.2. The Surface Texture Structure Design of Shovel Wing

The shovel chest has great resistance when cutting the soil, and therefore drag-reducing designs are used for the shovel chest by researchers. In this study, a semicircular corrugated structure was designed for the shovel chest to reduce drag. The soil fragmentation rate is mainly affected by the wing plate, and therefore the convex hull structure wing plate was designed to increase the soil fragmentation rate.

- (1)

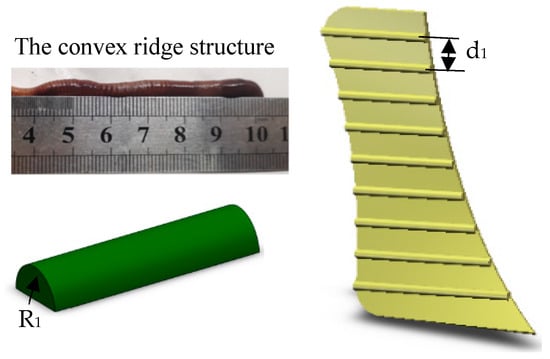

- The semicircular corrugated structure of the shovel chest

The convex ridge structure of the earthworm body surface can enable improved reduction of viscosity and resistance in the soil [15,16]. Measurement shows that the distance between the ribs and grooves of the earthworm is 1.5 mm under static conditions, and the convex ridge structure has been simplified to a semicircular corrugation, with a cross-sectional radius R1 = 3 mm and a distance between corrugations d1 = 15 mm, as shown in Figure 2.

Figure 2.

The semicircular corrugated structure of the shovel chest.

- (2)

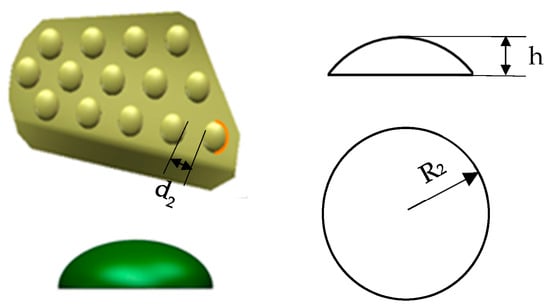

- The convex hull structure of the wing plate

The papillary structure of rose petal surface can increase its capacity for water adhesion, which is also considered to increase the soil fragmentation rate. The convex hull structure was used for the surface of the wing plate, with a diameter R2 = 32 mm, a height h = 9.6 mm, and a distance d2 = 30 mm, as shown in Figure 3.

Figure 3.

The convex hull structure of the wing plate.

The resistance of the textured shovel wing in the horizontal direction of the soil is related to the contact area of the wing plate and the blade penetration angle of the shovel chest. In this paper, the blade penetration angle α (as shown in Figure 1a), the convex hull diameter, the convex hull height–diameter ratio, and the convex hull distance were taken as the main factors in the experimental research.

2.3. Experimental Method

The textured shovel wing and virtual soil trench digital models were constructed in EDEM, and the basic parameters were selected from related research literature data [17,18,19], as shown in Table 1.

Table 1.

Simulation model of soil contact parameters.

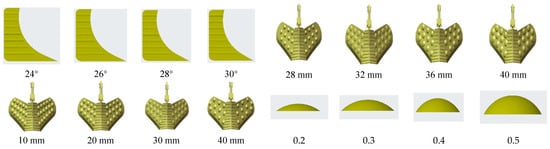

The authors’ previous research results showed that an appropriate contact model between soil particles is the Hertz–Mindlin model, and the bonding key will break when the pressure acting on it is higher than the critical value. As shown in Figure 4, the blade penetration angles were 24°, 26°, 28°, and 30°, the convex hull diameters were 28, 32, 36, and 40 mm, the convex hull distances were 10, 20, 30, and 40 mm, and the convex hull height–diameter ratios were 0.2, 0.3, 0.4, and 0.5.

Figure 4.

The textured shovel wing models with different structural parameters.

In addition to the effect of the structural parameters on the traction resistance and soil fragmentation rate of the soil cultivator, the speed of the device also affects both these indicators [20]. Therefore, the speed, blade penetration angle, convex hull diameter, height–diameter ratio, and distance were selected as the experimental factors in the single-factor simulation test, to analyze and calculate the traction resistance and soil fragmentation rate. Then, on the basis of the single-factor simulation test, the quadratic regression orthogonal rotation combined test was used to obtain the multiple regression model and the best structural parameters for the surface textures.

- (1)

- The traction resistance

When the soil cultivator is working, the shovel wing performs the functions of cutting, applying friction, and lifting to the soil. The cutting resistance of the shovel chest is the main force in the horizontal direction of the soil cultivator, and it is an important component of the tractor’s traction resistance [21]. Therefore, the working resistance was selected as the test index for increasing the traction performance of the soil cultivator.

- (2)

- The soil fragmentation rate

Potato growth requires a loose and finely fragmented soil environment and ensuring this environment is an important way to improve the yield and quality of potatoes. The soil fragmentation rate is often used to characterize the degree of soil fragmentation, and in the EDEM software, the bond fracture coefficient is generally used as a quantitative evaluation index [22]. The calculation formula for the fracture coefficient I is:

where, Nb and Na are the numbers of broken and unbroken soil bonds in the work area, respectively.

According to the Hertz–Mindlin bonding model, the critical stiffness of the soil bonding key is 5 × 107 N/m3, and the critical pressure is 3 × 105 Pa with a radius of 5 mm. Therefore, when the pressure or stiffness acting on the soil particles is higher than the critical value during the solution process, the bonding key is considered to break.

3. Results and Discussion

3.1. The Single-Factor Simulation Test

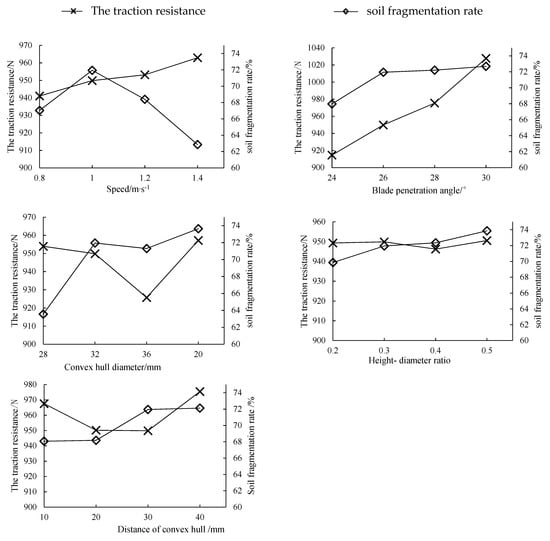

According to the previous analysis, the factors that affected the quality of the soil cultivator with a textured shovel wing mainly included speed, blade penetration angle, convex hull diameter, height–diameter ratio, and distance. The basic working and structural parameters of the single-factor simulation test research were a speed of 1.0 m/s, a blade penetration angle of 26°, a convex hull height–diameter ratio of 0.3, a convex hull distance of 30 mm, and a convex hull diameter of 32 mm. The significance of various factors with regard to the traction resistance and soil fragmentation rate were investigated, providing the basis for the orthogonal experiment to obtain the optimal parameter combination.

As shown in Figure 5, the single-factor simulation test results showed the following characteristics. As the speed increased, the traction resistance of the soil cultivator increased linearly, and the soil fragmentation rate first increased and then decreased. The authors believe that the soil fragmentation caused by the cultivator mainly occurs for two reasons. The first is the direct impact and friction of the shovel wing on the soil, and as the speed increases, the impact force will increase, so the soil fragmentation rate will gradually increase. This plays a leading role when the speed is low. However, the soil will be continuously broken in the process of deformation recovery after the cultivator passes, and the soil fragmentation rate is related to the disturbance range of the shovel wing in the soil. As the speed increases, the disturbance range will decrease, so the soil fragmentation rate will gradually decrease. This plays a leading role when the speed is high. In summary, as the speed of the cultivator increased, the soil fragmentation rate first increased and then decreased. When the speed was 1.0 m/s, the soil fragmentation rate reached 72.3%.

Figure 5.

The effect of speed and surface texture structure parameters on the traction resistance and soil fragmentation rate.

With an increase in the blade penetration angle, the traction resistance of the soil cultivator increased linearly, and the soil fragmentation rate increased slowly. The reason for this is that as the blade penetration angle increases, the contact area between the shovel chest and the soil increases; therefore, the frictional resistance increases. However, the larger the blade penetration angle, the more difficult it is for the wing plate surface to pass, and as the height of the soil being lifted increases, the soil moves further during the flip process, and more power is needed to flip the soil to both sides of the shovel wing. As a result, the traction resistance of the soil cultivator continues to increase as the blade penetration angle increases.

As the convex hull diameter increased, the traction resistance of the soil cultivator first decreased and then increased. As the convex hull diameter increases, the proportion of non-smooth surface structure increases, so the traction resistance will gradually decrease, and when the convex hull diameter reaches a critical value, the soil adhesion effect will increase, leading to increased traction resistance. The diameter of the convex hull significantly affected the soil fragmentation rate: as the diameter of the convex hull increased, the soil fragmentation rate increased.

With an increase in the height–diameter ratio, the traction resistance of the soil cultivator and the soil fragmentation rate remained basically unchanged, indicating that the height–diameter ratio has little effect on the traction resistance of the soil cultivator and the soil fragmentation rate.

As the distance of the convex hull increased, the traction resistance of the soil cultivator first decreased and then increased, but the increase was slow. When the convex hull diameter was fixed (32 mm), as the distance of the convex hull increased from 10 mm to 30 mm, the non-smooth surface structure of shovel wing was enhanced, so the soil adhesion effect decreased and the traction resistance gradually decreased. When the distance of the convex hull was higher than 30 mm, the soil adhesion effect decreased, leading to increased traction resistance. Therefore, as the distance of the convex hull diameter increased, the traction resistance of the soil cultivator first decreased and then increased.

In summary, the main factors that affect the quality of the soil cultivator with a textured shovel wing were the blade penetration angle, the diameter, and the distance of the convex hull.

3.2. The Quadratic Regression Orthogonal Rotation Combined Test

Three factors, including the blade penetration angle, the diameter, and the distance of the convex hull were selected, and a three-factor quadratic regression orthogonal rotation combined test was carried out. The test indicators were traction resistance and soil fragmentation rate. Design-Expert 8.0 software was used to design the test factor level coding table, as shown in Table 2 and Table 3. The traction resistance and the soil fragmentation rate calculated from each group of tests were recorded, as shown in Table 3. The results of the analysis of variance are shown in Table 4.

Table 2.

The test factor level coding table.

Table 3.

The test result table.

Table 4.

Analysis of variance table.

The results of the analysis of variance show that the blade penetration angle was the most important factor that affected the traction resistance of the soil cultivator with a textured shovel wing, and the effects of the convex hull distance and the diameter were also significant. For the effect on soil fragmentation rate, the convex hull diameter and the blade penetration angle were significant, but the convex hull distance had no significant effect on the soil fragmentation rate. This is consistent with the results of the single-factor experiment. The interaction between the three factors had no significant effect on the indicators.

The order of the influence on the traction resistance of the soil cultivator with a textured shovel wing was as follows: blade penetration angle > convex hull distance > convex hull diameter. The convex hull diameter had a greater effect on the soil fragmentation rate than the blade penetration angle.

Design-Expert 8.0 software was used to calculate the test results, and the quadratic polynomial regression equations of the influence of various factors on the traction resistance (y1) and soil fragmentation rate (y2) were obtained.

y1 = 2999.70 + 23.03A − 197.31B − 2.74C − 0.91AB + 0.09AC + 0.11BC − 0.03A2 + 4.52B2 − 0.03C2

y2 = 987.03 + 8.61A − 77.70B − 0.50C − 0.18AB + 0.01AC + 0.04BC − 0.05A2 + 1.49B2 − 0.02C2

Using the regression equation, the optimal parameter combination for the surface textures can be obtained. Combining the selection range of experimental factors, the optimization goal was to minimize the traction resistance and maximize the soil fragmentation rate. The objective function is shown in Equation (2).

The optimal combination of structural parameters for the surface textures was a convex hull diameter of 34.4 mm, a blade penetration angle of 26°, and a convex hull distance of 28.5 mm. The simulation test of the optimized results showed that the traction resistance of the soil cultivator with a textured shovel wing was 913.20 N, and the soil fragmentation rate was 75.16%.

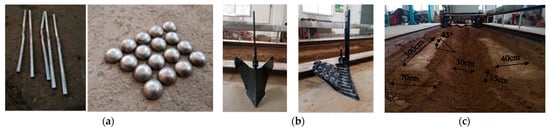

3.3. Soil Trench Verification Test

According to the optimal parameter combination for the surface textures, the soil cultivator with a textured shovel wing was manufactured at the Northwest Agriculture and Forestry University Processing Center, and a soil trench verification test was carried out comparing this with a traditional soil cultivator to verify the accuracy of the simulation research.

Before the test, the soil in the digital soil trough was prepared as shown in Figure 6c, and the ridge shape of the structure was sprinkled and compacted. The average soil moisture content of the 0–20 cm tillage layer in the soil trench was 21.77% (w. b.), the soil compactness was 841 kPa, and the soil bulk density was 1.12 g/cm3, which are values found in clay soil. Figure 6a shows the processed semicircular corrugated structure and the convex hull structure. As shown in Figure 6b, a traditional soil cultivator and a soil cultivator with a textured shovel wing were manufactured.

Figure 6.

Entity processing and soil trench test of soil cultivator. (a) Semicircular corrugated and convex hull structure; (b) the traditional soil cultivator and soil cultivator with textured shovel wing; (c) the standard ridge.

The traditional soil cultivator and the soil cultivator with a textured shovel wing were installed in the soil trench. The depth of the blade penetration was 120 mm and the speed was 1.0 m/s. After the soil cultivator entered the stable working area, sampling was carried out at intervals of 0.3 m (10 locations in total), and the test indicators were measured and recorded. The traction resistance of the soil cultivator was measured using a force sensor installed on the suspension frame of the soil trench. The soil fragmentation rate was calculated with reference to the calculation method in the working quality standard of the rotary tiller. Each test was repeated three times, and the average value was taken as the data point.

Table 5 shows the traction resistance and soil fragmentation rate of the traditional soil cultivator and the soil cultivator with a textured shovel wing. Scholars generally believe that a non-smooth surface on the soil contact parts can effectively reduce the adhesion effect of the soil, thereby reducing the traction resistance. The results show that soil contact parts with surface textures can reduce the traction resistance by about 14–20%. In this study, compared with the traditional soil cultivator, the traction resistance of the soil cultivator with a textured shovel wing was reduced by 9.49%, and the soil fragmentation rate was increased by 10.67%, indicating that the soil cultivator with a textured shovel wing can improve the quality while reducing the resistance.

Table 5.

Comparison of the traditional soil cultivator and soil cultivator with textured shovel wing.

Comparing the simulation results with the soil trench test data, the results show that the relative errors between the simulation results and the experimental data for traction resistance and soil fragmentation rate were 2.60% and 13.97%, respectively. This shows that the accuracy of the simulation results is high, and that this a feasible method for the study of the interaction relationship between the tillage parts and the soil.

Due to the limitation of the length of the soil bench, the maximum speed of the soil cultivator was 1.0 m/s, whereas the field operation speed can generally reach about 1.4 m/s. The simulation results showed that the soil fragmentation rate decreased significantly with an increase in speed, therefore further work should include research into soil cultivators under conditions of high speed (1.2–1.6 m/s). In recent years, this technical problem has attracted more and more scholarly attention, from authors such as Lv Jinqing (2017), Wang Xuezhen (2018), and others.

4. Conclusions

- (1)

- In this study, a semicircular corrugated structure shovel chest and a convex hull structure wing plate were designed, based on earthworms and rose petals, respectively, as prototypes. The results of the soil trench test showed that the traction resistance of the soil cultivator with a textured shovel wing was reduced by 9.49%, the soil fragmentation rate was increased by 10.67%, and the quality of soil cultivation was significantly improved.

- (2)

- The results of the quadratic regression orthogonal rotation combined test showed that the factors influencing the traction resistance of the soil cultivator with a textured shovel wing were as follows: blade penetration angle > convex hull distance > convex hull diameter. The convex hull diameter was the main factor affecting the soil fragmentation rate. The optimal combination of structural parameters for the surface textures were a blade penetration angle of 26°, a convex hull diameter of 34.4 mm, and a convex hull distance of 28.5 mm.

- (3)

- The results of the simulation and the soil trench verification test showed that the relative error between the simulation and the soil trench test for the traction resistance and the soil fragmentation rate were 2.60% and 13.97%, respectively.

Author Contributions

Conceptualization, Z.F.; methodology, M.W. and Z.F.; validation, W.W.; investigation, Y.H. and Z.Z.; resources, Z.F.; writing—original draft preparation, Z.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Key Research and Development Projects of Shaanxi Province (2019NY-169 and 2018ZDCXL-NY-03-06).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on demand from the corresponding author at fuzuoli@nwsuaf.edu.cn.

Acknowledgments

This work was financially supported by the Northwest A&F University. All support and assistance is sincerely appreciated.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jinqing, L.; Zhongen, T.; Ying, Y.; Qinqin, S.; Jiner, W.; Zihui, L.; Xiaoyong, W. The development status, existing problems and development trend of potato machinery. J. Agric. Mech. Res. 2015, 37, 258–263. [Google Scholar]

- Kempenaar, C.; Struik, P.C. The canon of potato science: Haulm killing. Potato Res. 2008, 50, 341–345. [Google Scholar] [CrossRef]

- Matin, M.A.; Fielke, J.M.; Desbiolles, J.M.A. Furrow parameters in rotary strip-tillage: Effect of blade geometry and rotary speed. Biosyst. Eng. 2014, 118, 7–15. [Google Scholar] [CrossRef]

- Zhongchao, G.; Feng, L.; Qiuju, W.; Hui, J.; Jinsong, Z.; Chunyu, Y.; Pan, G. Application and yield increasing effect on potato using special-designed ridging cultivator. Trans. Chin. Soc. Agric. Eng. 2016, 32, 49–54. [Google Scholar]

- Jinqing, L.; Qinqin, S.; Ying, Y. Design and experiment of 1ZL5 potato field cultivator. J. Agric. Mech. Res. 2017, 39, 79–83. [Google Scholar]

- Yuwan, Y.; Jin, T.; Yunhai, M.; Xiaohu, J.; Jinguang, L. Design and experiment of biomimetic rotary tillage blade based on multiple claws characteristics of mole rats. Trans. Chin. Soc. Agric. Eng. 2019, 35, 37–45. [Google Scholar] [CrossRef]

- Matin, M.A.; Fielke, J.M.; Desbiolles JM, A. Strip-tillage using rotating straight blades: Effect of cutting edge geometry on furrow parameters. Soil Tillage Res. 2016, 155, 329–340. [Google Scholar] [CrossRef]

- Yang, N. Simulation Research on Potato Ridge and Double Row Ridge Construction Based on DEM-MBD Coupling Technology. Ph.D. Thesis, Lanzhou University of Technology, Lanzhou, China, 2018. [Google Scholar]

- Zhao, J. Simulation and Experimental Research on Working Resistance of Potato Digging Shovel Based on Discrete Element Method. Ph.D. Thesis, Shenyang Agricultural University, Shenyang, China, 2017. [Google Scholar]

- Guomin, L.; Meng, Z.; Jianqiao, L. Inerfacial Dynamics Simulation between Soil and Earthworm Surface. J. Jilin Univ. (Eng. Technol. Ed.) 2010, 40, 1609–1613. [Google Scholar]

- Ucgul, M.; Fielke, J.M.; Saunders, C. Defining the effect of sweep tillage tool cutting edge geometry on tillage forces using 3D discrete element modelling. Inf. Process. Agric. 2015, 2, 130–141. [Google Scholar] [CrossRef] [Green Version]

- Zhang, R.; Li, J. Simulation on mechanical behavior of cohesive soil by Distinct Element Method. J. Terramechan. 2006, 43, 303–316. [Google Scholar] [CrossRef]

- Zhang, R.; Zhou, G.; Chen, G.; Li, J. Research on the Nonlinear Mechanical Model of Cohesive Soil Based on Distinct Element Method. J. Comput. Theor. Nanosci. 2011, 4, 1500–1508. [Google Scholar] [CrossRef]

- Wang, M. Design and Experimental Research of Potato Bionic Soil Apparatus. Ph.D. Thesis, Northwest A&F University, Yangling, China, 2019. [Google Scholar]

- Ren, L.Q.; Deng, S.Q.; Wang, J.C.; Han, Z. Design principles of the non-smooth surface of bionic plow moldboard. J. Bionic. Eng. 2004, 1, 9–19. [Google Scholar] [CrossRef]

- Yunhai, M.; Shengsheng, M.; Honglei, J.; Tucheng, L.; Jie, P.; Zhihui, G. Measurement and analysis on reducing adhesion and resistance of bionic ripple opener. Trans. Chin. Soc. Agric. Eng. 2014, 30, 36–41. [Google Scholar]

- Zhijun, Z.; Shengjie, M.; Honglei, J.; Tucheng, L.; Jie, P.; Yunhai, M. Design and Test of Crushing Bionic Soil Covering Device of Soybean Seeder. Trans. Chin. Soc. Agric. Mach. 2018, 49, 34–40. [Google Scholar]

- Barrios, G.K.P.; de Carvalho, R.M.; Kwade, A.; Tavares, L.M. Contact parameter estimation for DEM simulation of iron ore pellet handling. Powder Technol. 2013, 248, 84–93. [Google Scholar] [CrossRef]

- Jiandong, J.; Jie, G.; Yingdi, Z.; Hoogmoed, W.; Libin, Z. Numerical simulation on resistance reduction of soil vibratory tillage using ALE equation. Trans. Chin. Soc. Agric. Eng. 2012, 28, 33–38. [Google Scholar]

- Gao, X. Research on the Influencing Factors and Cultivation Effects of Subsoiled Soil Structure between Rows. Ph.D. Thesis, Northwest A&F University, Yangling, China, 2018. [Google Scholar]

- Liyan, W.; Zhibin, J.; Yuqiu, S.; Xin, M.; Liu, C.; Kong, A.; Ren, W. Design and Experiment on Testing System for Operation Resistance of Soil Engaging Parts. J. Shenyang Agric. Univ. 2016, 47, 589–596. [Google Scholar]

- Xuezhen, W.; Bin, Y.; Xijie, G. Simulation and experiment on soil disturbance behavior of subsoil shovel with different wing shovel installation height. Trans. Chin. Soc. Agric. Mach. 2018, 49, 124–136. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).