Abstract

In this study, the effects of tillage depth, forward speed and soil moisture content during the cultivator operation on the draft force, energy requirement, and soil disturbance were investigated using five types of cultivators. The experiments were performed in the factorial design based on the randomized complete block design (RCBD) with three replications in loamy sand soil. Different soil moisture contents (factor A) from 5 to 16% for dry soils and 17 to 35% for wet soils, forward speed of tractor (factor B) at four levels of 1.16, 1.61, 1.97, and 3.82 km/hand working depth (factor C) at two levels of 10 and 20 cm were selected. The analysis of variance results showed that the main effects on the draft force, energy requirement, and soil disturbance were significant. With increasing the forward speed, working depth, and blade width, the draft force, energy requirement, and soil disturbance significantly increased. As the soil moisture content increased, the amount of draft force decreased. The average maximum draft force and energy requirement are related to the crescent cultivator and the lowest ones to the cultivator with a sweep blade. The maximum amounts of draft force and energy requirement at the speed of 3.82 km/h were 296.702 N and 0.03708 MJ in the dry conditions, respectively. The average maximum draft force and energy requirement are related to the crescent cultivator and the lowest ones to the cultivator with a sweep blade. The average maximum draft force and energy requirement in dry soil at 10–20 cm depth were 313.534 N and 0.039204 MJ, respectively, and the lowest values were 189 N and 0.019512 MJ in wet soil at the depth of 0–10 cm, respectively. The highest mean value of the area obtained from the profiles was 254.62 cm2 related to the dry conditions and forward speed of 3.82 km/h, and the lowest mean value of the area obtained in the wet conditions was 199.6 cm2 at the forward speed of 1.16 km/h. The highest average area obtained from the profiles was observed in the dry conditions for C4 as 434.813 cm2 and the lowest one was 57.94 cm2 in the wet conditions for the cultivator with a chisel blade and L-shaped shank. The highest average area created by cultivators at the 10–20 cm depth in the dry conditions was 332.875 cm2 and the lowest one at the 0–10 cm depth in the wet conditions was 123.55 cm2. The results of this study can help the designers and manufacturers of agricultural machinery to effectively design and manufacture the machinery with optimum draft and energy requirements.

1. Introduction

Pests and weeds are two critical barriers to the growth of crops, which considerably reduce the quantity, quality, and economic value of the crop [1,2]. Weed control is one of the costly operations to increase the crop productivity and has a direct effect on the product price [3]. The conventional weed control methods include the prevention methods, agronomic methods, physical and mechanical methods, biological methods, and chemical methods [4,5,6]. Cultivator application is one of the essential and cost-effective mechanical methods for the weed control to promote the plant growth through the weed eradication, soil preparation for rain storage, soil permeability modification, mixing of fertilizers and insecticides with soil, hilling, and increased activity of microorganisms [7,8].

Various research works have been conducted to explore the use of cultivators and effect of cultivator application on the crop yield. The research results show that the cultivator operation enhances the crop yield [9,10,11]. Afzalinia and Niromand-Jahromy [9] studied the performance of furrower, crescent, and rolling cultivators in the sugar beet fields to determine the number of operation times required during the growth period and also the optimum cultivator. The results showed that the sugar grade was higher than the crescent type when used for three times, and the highest amount of weed was observed on the farm when using the furrower for two times. The crop yield in the hand weeding did not differ significantly from that using the cultivator, which indicates the fact that the cultivator can easily be substituted for the hand weeding [9]. Safari [12] introduced a rotary cultivator to control the weeds in the row crops such as chickpeas, beans, and sugar beets. The results of machine evaluation in sugar beet fields showed 87–93% weeding efficiency. The working width of the machine also varied from 30 to 60 cm [12].

The forward speed, shape, and other design parameters of the cultivator blade are among the factors affecting the performance and efficiency of cultivators [13]. Alexandrou and Coffing [14] studied the effect of forward speed on the weed control in four types of cultivators on the corn and soybean farms at two-leaf, five-leaf, and eight-leaf stages of canola which were selected as the weeds. The sweep type was more effective in reducing the number of canola plants between the rows. The rolling cultivator had unacceptable results and was sensitive to speed variations, but at the five-leaf stage of maize, the low speed yielded better results [14]. Perumpral et al. [15] studied the effect of cultivator blade shape and forward speed in combination with two spraying methods in the maize crop zero-till system. The high forward speed caused no problems in the weed control and crop yield, and even in the first two years at the 11.2 km/h forward speed, the higher yield and lower weed were observed compared to the 6.4 km/h forward speed. There was no significant difference between the band and full spraying in terms of yield. The crop yield was higher in the case of using the sweep and flat sweep cultivators compared to the point blade.

Because of the popularity and simplicity of the row crop method in the world, many crops such as potato, corn, cotton, soybean, and sugar beet are planted by the row crop method in the large areas [16]. For this reason, it is necessary to address the problems associated with this type of cultivation by evaluating different cultivators and combining the methods, and even, if necessary, by designing new tools and machines and localizing the equipment. In many parts of the world, including in some parts of Iran like Moghan in Ardabil province, which have heavy soil texture, the rolling and crescent cultivators are used as the weeding tools. In addition to the poor performance in this type of soil texture, the rolling type damages the plant at high forward speeds. The main problems of crescent cultivator work in the cotton and maize fields, which are the main crops of this region, include the difficulty in soil penetration and advancement, high draft force required, lateral vibration, and damage to the main plant, especially at high speeds. One purpose of this study is to investigate the use of alternative cultivators that are designed to meet the requirements of the region, and at the same time, have appropriate field capacity. In this study, the cultivator with the high forward speed was used for the mentioned purpose [17].

Among the design parameters of these tools, the draft force and shear force of soil are among the effective forces for calculating the energy of the tools [18,19]. As one of the forces between tractor and equipment, the draft force plays an essential role in the management of tractor and agricultural equipment. The agricultural machinery engineers choose the most suitable tractor power with the knowledge of draft force and power required in different soils [20]. However, the soil shear forces and horizontal components of soil shear and tension are important because of the direct relationship with the tillage energy requirement and type of tractor used [21]. To calculate the amount of energy requirement during an operation, it is necessary to estimate all the forces affecting the tool from the soil or trailing implement during the operation. The most important factors are: (1) Soil parameters, including soil texture, soil moisture, and soil type and conditions in which the tillage operation is performed. (2) Tool parameters, including type of tiller and its geometrical shape, blade sharpness, and friction properties of tool in contact with soil. (3) Performance parameters, including plowing speed, plowing depth, and other effective factors.

In this regard, the objectives of this research are as follows:

- To compare the draft force and energy requirement of five types of cultivators with different blades.

- To compare the soil disturbance and its pattern in several cultivators.

2. Materials and Methods

2.1. Equipment Used for Experiments

In this research, the tractive power required for the field tests was provided by a 55 kW rear-axle MF-285 Massey Ferguson tractor (ITMCO, Tabriz, Iran). The tractor was equipped with the precision measuring systems to collect the draft force, forward speed, and dynamic load data applied to the front wheels during the tillage operation. The tools included a three-point hitch dynamometer, a fifth wheel speed sensor, a dynamic load measuring sensor (strain gauges mounted on the front axle of the tractor), a laptop computer, and a data collection system (DT800 data logger, Omni instruments Ltd., Dundee, Scotland, UK). The following sections describe the structure and operation of some of the mentioned equipment.

2.2. Draft Force and Actual Tractor Speed Measurement System

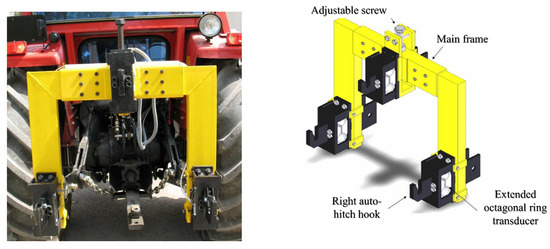

The dynamometer used in this study was a three-point adjustable hitch dynamometer designed and constructed by Abbaspour-Gilandeh et al. [22] (Figure 1). The total draft force required to pull the tillage tool into the soil (Ftotal) is calculated by Equation (1):

where FRX, FLX, and FTX are the horizontal forces applied to the right lower, left lower, and upper hitch pins, respectively.

Figure 1.

Adjustable three-point hitch dynamometer.

Also, to obtain the energy requirement for the tillage operation, Equation (2) was used:

where E is the energy requirement (MJ), t is the time required to perform the tillage operation within the test plot (h), and EPTO is the equivalent power consumption of the tractor power take-off for the tillage operation (kW).

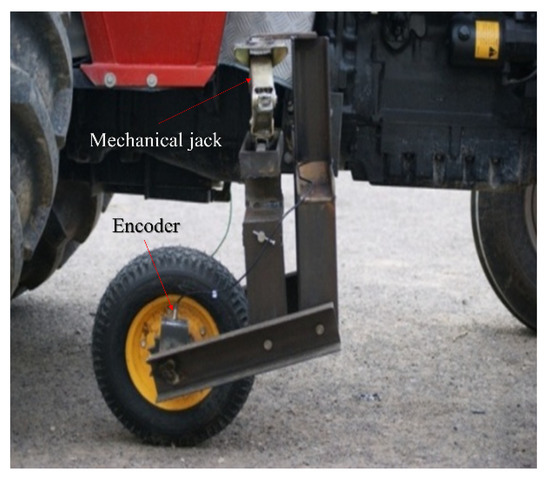

In this research, a fifth wheel consisting of a 39 cm diameter rubber wheel (Figure 2), a mechanical jack for height control, an induced proximity sensor (PR12-2 DN Model, Autonix Co., Busan, Republic of Korea) for rotation counting, and a pulse meter for rotation measurement were used to measure the forward speed of the tractor.

Figure 2.

Adjustable fifth wheel to measure forward speed of tractor.

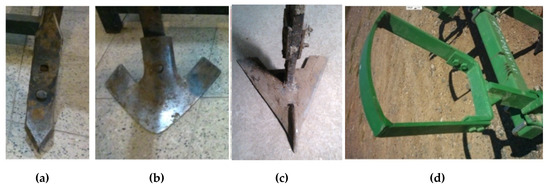

In the field experiments, to compare the draft force and energy requirement of conventional cultivators, five types of single-tine cultivators with different blades were used including C-shaped spring tine cultivator with sweep blade (C1), cultivator with C-shaped spring tine and chisel blade (C2), high-speed cultivator (C3), crescent cultivator (C4), and cultivator with L-shaped rigid tine and chisel blade (C5) (Table 1, Figure 3). The sweep blades (C1) are usually available in different sizes. The low-width sweeps are used for the seedbed preparation and the wide types are mainly used to eliminate weeds and to perform relatively well in the presence of residues. The sweep blade width was 30 cm. C2 and C5 are the most common types of cultivator blades which are generally used for the deeper secondary tillage in hard soils, and are also used in the relatively low-residue soils. The chisel type blade width used in this study was 8 cm. The heavy texture of the soil makes the penetration of blades into soil difficult. Also, the extensive cultivation of row crops forces farmers to do the weeding more quickly in less time, which leads agricultural engineers to design and build a flat-sweep cultivar, namely high-speed cultivator (C3). The width of this type of blade was 40 cm.

Table 1.

Cultivators used in the experiments.

Figure 3.

(a) Chisel blade (b) sweep blade, (c) high-speed cultivator blade, and (d) crescent cultivator blade.

In order to measure the soil cone index values in the test plots, a cone penetrometer was mounted behind the tractor [23]. The penetrometer was mounted to the three-point hitch of tractor which was equipped with multiple penetration rods that could measure the soil cone index values at various points and depths (Figure 4). The main part of the penetrometer is a cone-shaped end-tool with the cross-section of 133 mm2 and the 30° point angle which is added to the end of a 95 cm long rod. The rod attached to the cone tip is pushed into the soil using the hydraulic force generated by the hydraulic jack.

Figure 4.

Soil cone index measurement system: (1) hydraulic jack, (2) load cell, (3) rode, and (4) cone.

A soil profile meter of 75 cm long and 60 cm wide with parallel vertical bars of 5 cm spacing was used to investigate the soil disturbance caused by the cultivators during the tests.

Prior to the tillage operation by cultivators, soil samples were taken from each test plot to measure the soil moisture content. The samples were then transferred to the laboratory to determine the soil moisture content. The samples were weighed in the laboratory with an electronic sensitive scale and then placed in an oven at 105 °C for 24 h. After 24 h and re-weighting of soil samples, the soil moisture content (based on dry weight) was determined.

2.3. Field Experiments

The field experiments were conducted on the educational and research farm of the agricultural faculty of University of Mohaghegh Ardabili with the loamy sand soil. In this study, the factorial test based on the randomized complete block design (RCBD) with three replications was used to measure and determine the factors affecting the amount of draft force, energy and soil disturbance of each cultivator. In the tested soil, different moisture contents (factor A) from 5 to 16% for dry soils and 17 to 35% for wet soils, tractor forward speed (factor B) at four levels, and working depth (factor C) at two levels of 10 and 20 cm within each test plot were selected. Within each plot, the draft force of cultivators with different blades, soil cone index, and soil moisture content were measured.

The cone index values were measured in each test plot after identifying the field and bounding it by wooden nails and applying the moisture conditions. The cone index values in each test plot were measured in three points at the depth of 0–40 cm before tilling with cultivators.

The depth required for the cultivators was adjusted by the lower links of the tractor and the gauge wheels. Then, by selecting the gear and engine rotation of the tractor, the data logging and record of output signals begun from the circuit. The movement of tractor was carried out for 30 m and then returned at the end of the field, and the experiment with the next conditions was performed with the one and a half meters distance from the previous furrow. In each condition, 40 furrows were created inside the soil. The data obtained at the end of each furrow was saved in a separate txt file. In order to apply the moisture conditions, the test plots were irrigated to achieve the desired moisture content.

3. Results and Discussion

The contents of this section include presenting the results related to the research objectives and discussing the results. This section presents the results of the analysis of variance for the data of draft force, energy requirement, soil disturbance, and shape of the profiles obtained under different test conditions.

3.1. Analysis of Variance of Data for Draft Force and Energy Requirement

The results of the analysis of variance for the data related to the draft force and energy of cultivators used in the research are presented in Table 1 and Table 2. The coefficient of variations of draft force and cultivator energy (CV) data is equal to 15.68%. According to the analysis of variance table, it can be seen that the main effects of soil conditions, tools, speeds, and working depths on the amount of draft force and energy requirement of the cultivator were significant (at the probability level of 1%).

Table 2.

Results of analysis of variance of data for draft force measurement.

The results showed that with increasing the soil moisture content, the draft force and energy requirement decreased. The results are consistent with those of researchers e.g., Abbaspour-Gilandeh et al. [24]. The decrease in draft force and energy requirement by increasing the soil moisture content in this experiment can be attributed to the decrease in the soil failure force and the change in the cone index by changing the soil moisture content [24].

The average draft force showed a significant difference at all forward speeds. This difference in the draft force of the equipment and its increase with different forward speeds can be attributed to the greater acceleration resulting from the faster displacement. The acceleration appears for two main reasons: (1) The acceleration forces increase the vertical loads on the surfaces in contact with the soil, thereby increasing the frictional resistance, and (2) the increase in the kinetic energy applied to the soil by the increased forward speed. The results showed that the energy requirement at all different speeds was significantly different. This increase in the amount of energy at different speeds can be justified by the fact that increasing the speed increases the amount of forces that should be overcome.

As mentioned earlier, five different cultivators were used in this study. The average maximum draft force and energy requirement are related to C4 and the lowest ones to the original C1. The higher values in C4 can be attributed to the high contact area of this cultivator with the soil as well as its special shaped tine and lack of flexibility of the blade. The results of the analysis of variance for the effect of tool type on the draft force and energy requirement of the cultivator showed that the effect of all the tools used in the research on the energy requirement of the cultivator was significant. There was no significant difference between C2 and C1.

The results showed that by increasing the tillage depth, the draft force and energy requirement significantly increased. This increase is due to the fact that by increasing the tillage depth, the mechanical strength of the soil increases due to the increased contact surface of blade and soil, and in the studied soils, the soil mechanical strength (cone index) increases with the depth. The results are consistent with those of researchers such as Abbaspour-Gilandeh et al. [24] Ashrafizadeh and Kushwaha [25], and Manuwa and Ademosun [26].

In addition, the dual effects of soil moisture content at speed, soil moisture content at tool, tool at forward speed, soil moisture content at working depth, and tool at working depth on the draft force and energy requirement are also significant (at the probability level of 1%). The effect of forward speed at working depth on the draft force and energy requirement was significant at the 5% probability level. As can be seen in Table 1 and Table 2, all triple effects except the effects of soil moisture content at forward speed at working depth are significant at 1% probability level. The quadratic effect is significant at the 1% level, as seen in the tables. The significant quadratic effect on the draft force of the used cultivators is a remarkable result that warrants the use of advanced modeling systems such as artificial neural networks (ANNs). This result indicates that the quadratic effect of the tool, soil moisture, forward speed, and working depth on the draft force and energy should be considered.

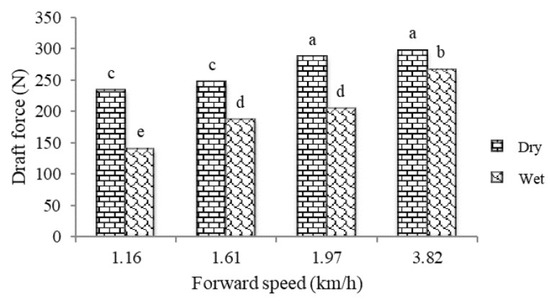

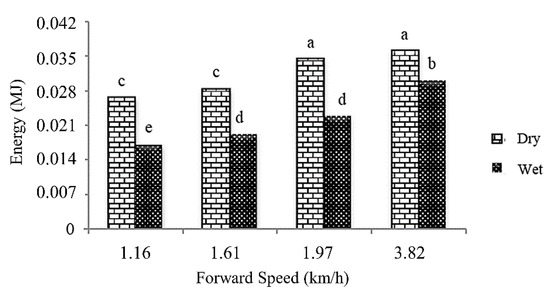

3.1.1. Effect of Forward Speed at Soil Moisture Content on Draft Force and Energy Requirement of Cultivators

As can be seen from Figure 5 and Figure 6, in both dry and wet soil conditions, there was a significant increase in the forward speed and energy requirement with the draft force. There was only no significant relationship between the forward speeds of 1.16 and 1.61 km/h in the dry soil conditions and 1.61 and 1.97 km/h in the wet soil conditions, respectively. The maximum amounts of draft force and energy requirement at the speed of 3.82 km/h were 296.702 N and 0.03708 MJ in the dry conditions, respectively. Horn [27] reported that as the soil moisture content decreases due to the soil drying and hardening, the draft force increases. Therefore, the soil strength increases by increasing the cone index [27].

Figure 5.

Effect of forward speed at the moisture on draft force of cultivators (letters a-e indicate statistical significance).

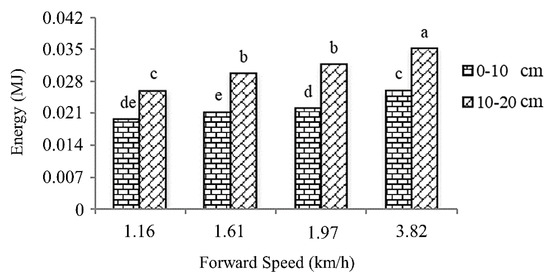

Figure 6.

Effect of forward speed at soil moisture content on energy requirement of cultivators.

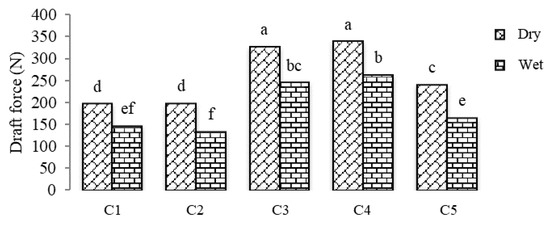

3.1.2. Effect of Tool Type at Soil Moisture Content on Draft Force and Energy Requirement of Cultivators

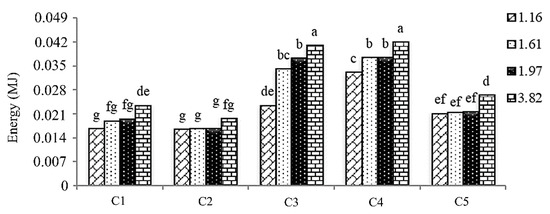

As can be seen from Figure 7 and Figure 8, as the moisture content of the soil increases, the draft force and energy requirement of all the tools significantly change under both the test conditions. There was no significant difference between C4 and C3 and also between C1 and C2. In terms of draft force and energy requirement in both dry and wet conditions, C4 and C3 were in the higher group because of the special geometrical shape and larger contact surface with the soil. The highest average draft force and energy requirement for C4 were obtained in the dry conditions as 339.36 N and 0.042408 MJ, respectively. The lowest values were obtained for C2 as 133.8 N and 0.009216 MJ. The reason for the differences can be attributed to the fact that the soil cohesion-tool and the soil friction-tool are the two main components of soil resistance to the tool movement, and the soil moisture content influences both the factors.

Figure 7.

Effect of tool type at soil moisture content on draft force of cultivators (C1: C-shaped spring tine cultivator with sweep blade, C2: cultivator with C-shaped spring tine and chisel blade, C3: high-speed cultivator, C4: crescent cultivator, and C5: cultivator with L-shaped rigid tine and chisel blade).

Figure 8.

Effect of soil type at soil moisture content on energy requirement of cultivators.

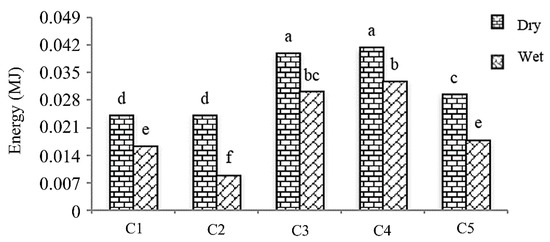

3.1.3. Effect of Tool-Type at Forward Speed on Draft Force and Energy Requirement of Cultivators

From Figure 9 and Figure 10, it can be seen that there is a significant increase in the draft force and energy requirement of all the tested tools with increasing the forward speed. The reason for this significant difference can be attributed to the difference in the soil failure by different tools at different operating speeds. This result is consistent with the findings of researchers such as Al-Janobi and Al-Suhaibani [21] and Grisso et al. [28]. There was no significant effect on the draft force and energy requirement in C4 between the speeds of 1.61 and 1.97 km/h, in C2 between 1.61 and 1.97 km/h, in C1 between the speeds of 1.16 and 1.61 km/h, and in C5 between the speeds of 1.16, 1.61, and 1.97 km/h, respectively. The average maximum draft force and energy requirement at the forward speed of 3.82 km/h for C4 were 344.98 N and 0.043128 MJ, respectively. Because, the highest mean areas of the profile created by the cultivators was related to the crescent cultivator (C4) as is explained in Section 3.2.6.

Figure 9.

Effect of tool type at forward speed on draft force of cultivator.

Figure 10.

Effect of tool type at forward speed on energy requirement of cultivator.

As the forward speed increases, the soil particles gain acceleration as the speed increases. This increase in the soil acceleration energy content, on the one hand, due to the increase in kinetic energy applied to the soil particles as a result of the forward speed and, on the other, due to the increased frictional resistance resulting from the increase in the vertical loads will increase the energy content during the operation (Figure 10).

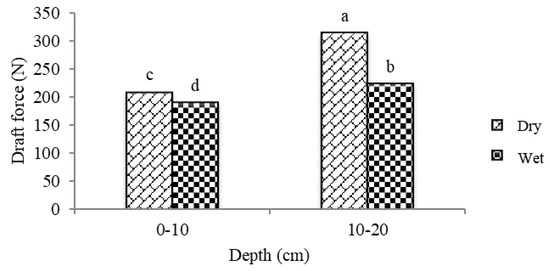

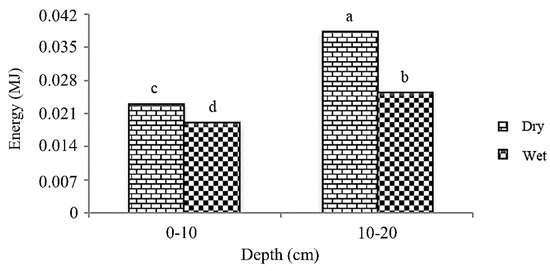

3.1.4. Effect of Soil Moisture Content at Working Depth on Draft Force and Energy Requirement of Cultivators

Figure 11 shows that by increasing the tillage depth in both soil moisture contents, the draft force and energy requirement significantly increased. Also, by increasing the moisture content at all depths, the amount of draft force is significantly reduced. The reason for these results is that as the depth increases, the mechanical strength increases, and as the soil moisture content increases to a certain degree, the mechanical strength of the soil is reduced and therefore, less failure force is required (Figure 12). Also, the effect of soil moisture content on draft force and consequently energy requirement, could be due to the effect of soil moisture content on area of profiles created by cultivators which is investigated in Section 3.2.2. This result is consistent with the findings of researchers such as Khalilian et al. [29] and Summer et al. [30]. The average maximum draft force and energy requirement in dry soil at the 10–20 cm depth were 313.534 N and 0.039204 MJ, respectively, and the lowest values were 189 N and 0.019512 MJ in wet soil at the depth of 0 to 10 cm, respectively.

Figure 11.

Effect of soil moisture content at working depth on draft force of cultivators.

Figure 12.

Effect of soil moisture content at working depth on energy requirement of cultivators.

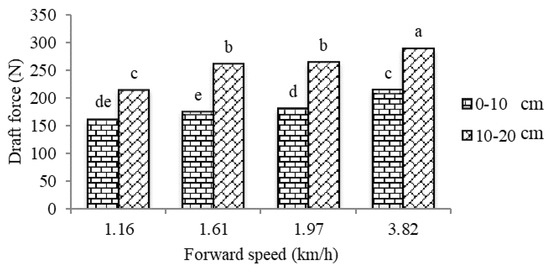

3.1.5. Effect of Working Depth at Forward Speed on Draft Force and Energy Requirement of Cultivators

Figure 13 and Figure 14 show that at all forward speeds, the average draft force and energy requirement for the tillage significantly increase with increasing the tillage depth. However, no significant effect was observed for the depth of 10–20 cm between the speeds of 1.61 and 1.97 km/h. The highest average draft force was obtained at 10–20 cm and 3.82 km/h as 288.5065 N. Also, the lowest average draft force was obtained at the 0–10 cm depth and speed of 1.16 km/h as 160.979 N. The highest and lowest mean values were obtained at the speeds of 3.82 and 1.16 km/h with the values of 0.036072 and 0.020124 MJ, respectively.

Figure 13.

Effect of working depth at forward speed on draft force of cultivators.

Figure 14.

Effect of working depth at forward speed on energy requirement of cultivators.

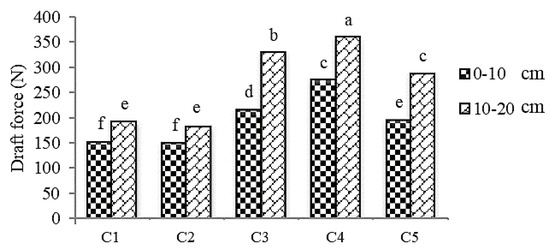

3.1.6. Effect of Tool Type at Tillage Depth on Draft Force and Energy Requirement of Cultivators

From Figure 15 and Figure 16, it is found that by increasing the working depth, the draft force and energy requirement of all the tools significantly increase. At the working depths of 0–10 and 10–20, no significant effect was observed between C2 and C1. The highest average draft force was obtained at the depth of 10–20 as 358.592 N. The lowest average draft force was obtained at the depth of 0–10 as 149.42 N. C4 with an average energy requirement of 0.01244 kWh had the highest amount of energy, and C2 with the average energy of 0.014976 MJ had the lowest amount of energy. Perumpral et al. [15] compared the actual values of tensile strength of narrow tools with the current models and showed that in all the tools, as the working depth increases, the draft force and energy requirement increase, and thus, they justified this factor that as the depth increases, the draft force and energy consumed during the operation will increase because of the increase in the failure level as well as increased volume of the disturbed soil.

Figure 15.

Effect of tool type at working depth on draft force of cultivators.

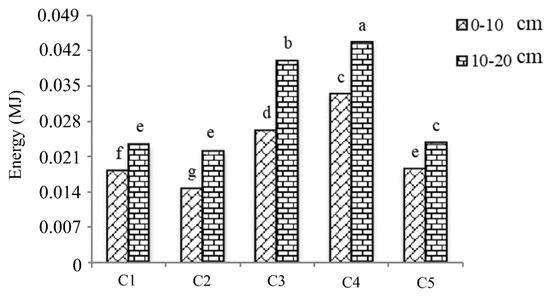

Figure 16.

Effect of tool type at working depth on energy requirement of cultivators.

3.2. Results of Analysis of Variance of Data on Profiles and Disturbance Level

The results of the analysis of variance for the data related to the area of profiles created by the cultivators used in the research are presented in Table 3. The coefficient of variations of the data for the area of profiles created by the cultivators (CV) is 6.42%. According to the analysis of variance table, it is observed that the main effects of soil conditions, tool type, forward speed, and working depth on the area of profiles created by the cultivators were significant (1% probability level), while the dual effects of soil moisture content at tool type, soil moisture content at working depth, and tool type at working depth on the area of profiles created by the cultivators are also significant (1% probability level). The effect of soil moisture content at tool speed and forward speed on the area of profiles created by the cultivators was significant at the 5% probability level. Also, as can be seen in Table 3, all of the triple effects were significant at the 1% probability level, except for the forward speed at the tool type and working depth at the 5% level. The quadruple effect, as shown in Table 3, is significant at the 5% probability level.

Table 3.

Results of analysis of variance of data for the area of profiles created by the cultivators.

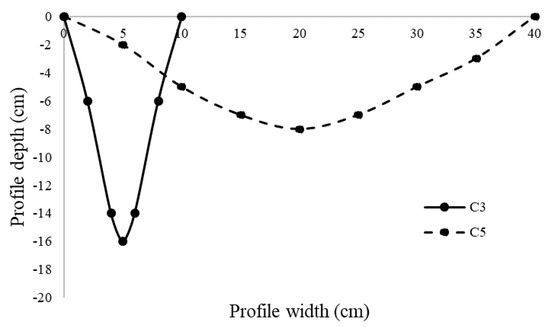

The results of the analysis of variance for measurement of disturbance level of profiles created by the cultivators used in the research are presented in Table 4. Figure 17 illustrates some of the diagrams obtained for the shape of profiles. According to the diagrams, the depth and width, or in other words, the full shape of the disturbance profile can be observed after the operation.

Table 4.

Results of variance analysis for measurement of disturbance level of profiles.

Figure 17.

Cross-section view of the profile obtained from C3 and C5.

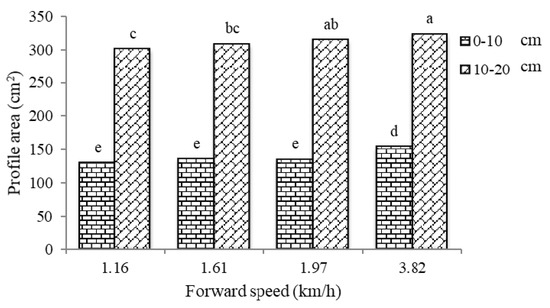

3.2.1. Effect of Forward Speed at Moisture Content on Area of Profiles Created by Cultivators

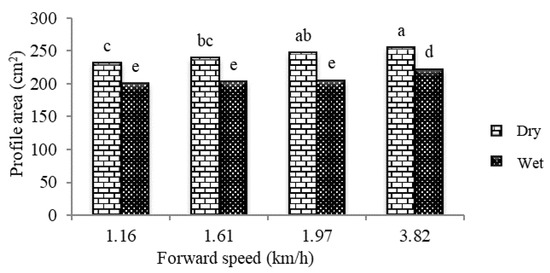

As can be seen from Figure 18, the profile area increases in both dry and wet conditions by increasing the forward speed. The highest mean value of the area obtained from the profiles was 254.62 cm2 related to the dry conditions and forward speed of 3.82 km/h, and the lowest mean value of the area obtained for the wet conditions was 199.6 cm2 and forward speed of 1.16 km/h. As reported by Manuwa and Ademosun [26], when the soil moisture content decreases, the soil particles and masses are bonded with a higher cohesion force, and thus, more force is required for the failure. Also, reducing the soil moisture content increased the maximum soil shear width and maximum soil throw width, which also increased the force and energy consumed during the operation.

Figure 18.

Effect of forward speed at soil moisture content on area of profiles created by cultivators.

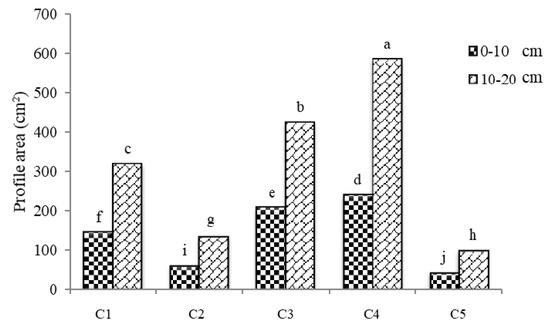

3.2.2. Effect of Tool Type at Soil Moisture Content on Area of Profiles Created by Cultivators

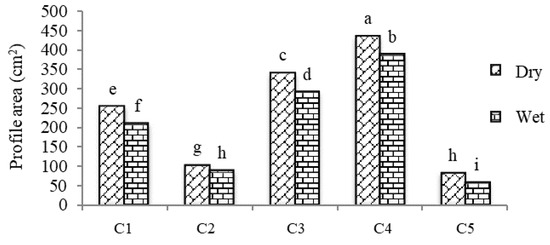

Figure 19 shows that there was a significant increase in the profile area as the moisture content decreases. In this case, it can be noted that in the wet conditions, the components have a ductile form and tend to be less fractured and scattered than the dry soil. This is due to the moisture and cohesion between the soil particles. The highest average area obtained from the profiles was 434.813 cm2 in the dry conditions and C4 and the lowest one in the wet conditions and the cultivator with a chisel blade and L-shaped shank as 57.94 cm2.

Figure 19.

Effect of tool type at moisture content on area of created profiles.

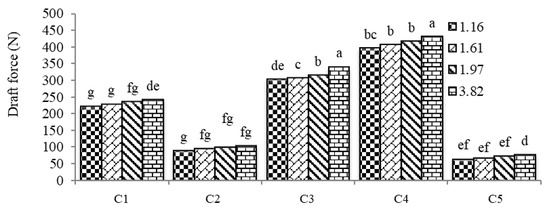

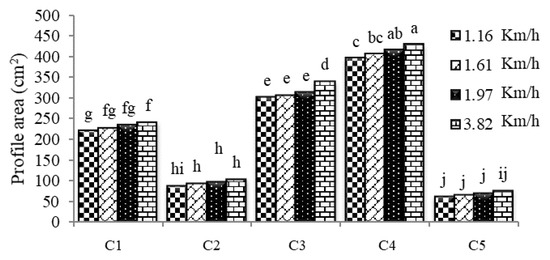

3.2.3. Effect of Tool Type at Forward Speed on Area of Profiles

According to Figure 20, it can be stated that in all the tools, increasing the forward speed increases the area of profiles created by the cultivators. However, the increase in the blade width was another factor affecting the created area of profiles, as C4 and C3 were placed in the higher group in terms of profile area created by the equipment because of the higher blade width and special geometric shape. The highest mean soil disturbance and obtained profile area were 429 cm2 related to C4 with the forward speed of 3.82 km/h. The lowest mean soil disturbance and profile area also belonged to C5 at the forward speed of 1.16 km/h as 63.125 cm2.

Figure 20.

Effect of tool type at forward speed on area of created profiles.

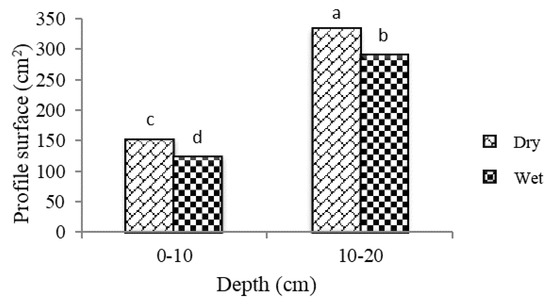

3.2.4. Effect of Moisture Content at Working Depth on Area of Created Profiles

According to Figure 21, the highest average area created by the cultivators at 10–20 cm depth in the dry conditions was 332.875 cm2 and the lowest one at 0–10 cm depth in the wet conditions was 123.55 cm2.

Figure 21.

Effect of moisture content at working depth on area of created profiles.

3.2.5. Effect of Depth at Forward Speed on Area of Profiles Created by Cultivators

Figure 22 shows that at both 0–10 and 10–20 cm working depths, the increased forward speed significantly increased the area of profiles created by the cultivators. This effect was not observed between the speeds of 1.16, 1.61, and 1.97 km/h. The highest average area created by the cultivators at the depth of 10–20 cm and speed of 3.82 km/h was 322.85 cm2 and the lowest one at the depth of 0–10 cm and speed of 1.16 km/h was 129.45 cm2.

Figure 22.

Effect of working depth at forward speed on area of created profiles.

3.2.6. Effect of Tool at Depth on Area of Profiles Created by Cultivators

As can be seen in Figure 23, all the tools and equipment used in the research showed a significant increase in the cross-sectional area of the profiles with increasing the working depth. However, some of the used tools had a greater effect on increasing the area of profiles with the increased depth because of the greater shape and contact surface when working with soil. The highest and lowest mean areas of the profile created by the cultivators were related to C4 at the 10–20 cm depth as 584 cm2 and C5 at the 0–10 cm depth as 41.563 cm2.

Figure 23.

Effect of tool at depth on area of profiles created by cultivators.

4. Conclusions

-In this study, the effects of tillage depth, forward speed, and soil moisture content on the draft force, energy requirement, soil disturbance, and area of the soil profiles were investigated using five types of cultivators.

-The parameters of forward speed, tillage depth, soil moisture content, and type of tool are the main factors affecting the draft force, energy requirement, soil disturbance, and area of the profiles created by the cultivators, where their main effects on the draft force of cultivators are significant (at the probability level of 1%).

-The average maximum draft force and energy requirement are related to the crescent cultivator (C4) and the lowest ones to the cultivator with a sweep blade (C1).

-The maximum amounts of draft force and energy requirement at the speed of 3.82 km/h were 296.702 N and 0.037080 MJ in the dry conditions, respectively.

-The highest average draft force and energy requirement for the crescent cultivator (C4) were obtained in the dry conditions as 339.36 N and 0.042408 MJ, respectively. The lowest values were obtained for the cultivator with a chisel blade of spring tine type (C2) as 133.8 N and 0.009216 MJ.

-The average maximum draft force and energy requirement at the forward speed of 3.82 km/h for the crescent cultivator (C4) were 344.98 N and 0.043128 MJ, respectively.

-The average maximum draft force and energy requirement in the dry soil at the 10–20 cm depth were 313.534 N and 0.039204 MJ, respectively, and the lowest values were 189 N and 0.019512 MJ in the wet soil at the depth of 0–10 cm, respectively.

-The highest mean value of the area obtained from the profiles was 254.62 cm2 related to the dry conditions and forward speed of 3.82 km/h, and the lowest mean value of the area obtained in the wet conditions was 199.6 cm2 at the forward speed of 1.16 km/h.

-The highest average area obtained from the profiles was 434.813 cm2 in the dry conditions and the crescent cultivator (C4) and the lowest one was 57.94 cm2 in wet conditions and the cultivator with a chisel blade and L-shaped shank.

-The highest average area created by the cultivators at 10–20 cm depth in dry conditions was 332.875 cm2 and the lowest one at 0–10 cm depth in wet conditions was 123.55 cm2.

-At both 0–10 and 10–20 cm working depths, the increased forward speed significantly increased the area of profiles created by the cultivators. This effect was not observed between the speeds of 1.16, 1.61, and 1.97 km/h.

-All the tools and equipment used in the research showed a significant increase in the cross-sectional area of the profiles with increasing the working depth. However, the highest and lowest mean areas of the profile created by the cultivators were related to the crescent cultivator (C4) at the 10–20 cm depth as 584 cm2 and the chisel blade (C5) at the 0–10 cm depth as 41.563 cm2.

-The significant quadruple effect on the draft force of cultivators is a remarkable result that warrants the use of advanced modeling systems such as ANNs. The results of this section show that the effect of four factors, namely tool type, moisture, speed, and depth, on the draft force and energy requirement should be considered.

-The results of this study can be utilized for the effective design and manufacture of the cultivators with the optimum draft and energy requirements and controlled soil disturbance for the protection of plants from the mechanical damages.

Author Contributions

Conceptualization, Y.A.-G. and M.F.; methodology, Y.A.-G., M.F.; software, Y.A.-G., M.F., and A.R.; validation, Y.A.-G., and J.L.H.-H.; formal analysis, M.F., Y.A.-G., and A.R.; investigation, Y.A.-G. and M.F.; resources, Y.A.-G. and M.F.; data curation, M.F.; writing—original draft preparation, M.F. and A.R.; writing—review and editing, Y.A.-G., J.L.H.-H., A.F.P., and I.H.-M; visualization, Y.A.-G., A.R.; supervision, Y.A.-G.; project administration, Y.A.-G.; funding acquisition, Y.A.-G., J.L.H.-H., A.F.P., and I.H.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financially supported by University of Mohaghegh Ardabili.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Sabzi, S.; Abbaspour-Gilandeh, Y.; García-Mateos, G. A fast and accurate expert system for weed identification in potato crops using metaheuristic algorithms. Comput. Ind. 2018, 98, 80–89. [Google Scholar] [CrossRef]

- Sabzi, S.; Abbaspour-Gilandeh, Y.; Javadikia, H. The use of soft computing to classification of some weeds based on video processing. Appl. Soft Comput. 2017, 56, 107–123. [Google Scholar] [CrossRef]

- Kurstjens, D.A. Precise tillage systems for enhanced non-chemical weed management. Soil Tillage Res. 2007, 97, 293–305. [Google Scholar] [CrossRef]

- Antralina, M.; Istina, I.N.; Yuwariah, Y.; Simarmata, T. Effect of difference weed control methods to yield of lowland rice in the SOBARI. Procedia Food Sci. 2015, 3, e9. [Google Scholar] [CrossRef]

- Barré, K.; Le Viol, I.; Julliard, R.; Kerbiriou, C. Weed control method drives conservation tillage efficiency on farmland breeding birds. Agric. Ecosyst. Environ. 2018, 256, 74–81. [Google Scholar] [CrossRef]

- Pannacci, E.; Tei, F. Effects of mechanical and chemical methods on weed control, weed seed rain and crop yield in maize, sunflower and soyabean. Crop Prot. 2014, 64, 51–59. [Google Scholar] [CrossRef]

- Albertsson, J.; Verwijst, T.; Rosenqvist, H.; Hansson, D.; Bertholdsson, N.; Åhman, I. Effects of mechanical weed control or cover crop on the growth and economic viability of two short-rotation willow cultivars. Biomass Bioenergy 2016, 91, 296–305. [Google Scholar] [CrossRef]

- Okamoto, H.; Hata, S.; Kataoka, T.; Terawaki, M. Automatic weeding cultivator using crop-row detector. IFAC Proc. Vol. 2001, 34, 117–122. [Google Scholar] [CrossRef]

- Afzalinia, S.; Niromand-Jahromy, M. Comparison of Yield of Cultivars in Sugar Beet Fields; Institute of Agricultural Engineering and Engineering Research: Karaj, Iran, 1999. [Google Scholar]

- Selles, F.; McConkey, B.; Campbell, C. Distribution and forms of P under cultivator-and zero-tillage for continuous-and fallow-wheat cropping systems in the semi-arid Canadian prairies. Soil Tillage Res. 1999, 51, 47–59. [Google Scholar] [CrossRef]

- Wasaya, A.; Tahir, M.; Ali, H.; Hussain, M.; Yasir, T.A.; Sher, A.; Ijaz, M. Influence of varying tillage systems and nitrogen application on crop allometry, chlorophyll contents, biomass production and net returns of maize (Zea mays L.). Soil Tillage Res. 2017, 170, 18–26. [Google Scholar] [CrossRef]

- Safari, M. Design, Manufacture and Evaluation of Rotary Cultivator; Institute of Agricultural Engineering and Engineering Research: Karaj, Iran, 2008. [Google Scholar]

- Beeny, J.M.; Greig, D. The efficiency of a rotary cultivator. J. Agric. Eng. Res. 1965, 10, 5–9. [Google Scholar] [CrossRef]

- Alexandrou, A.; Coffing, G. An assessment of the performance of mechanical weeding control mechanisms used in north central Ohio for maize and soybean crops. In Proceedings of the 2001 ASAE Annual Meeting, Sacramento, CA, USA, 29 July–1 August 2001; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2001. [Google Scholar]

- Perumpral, J.; Grisso, R.; Desai, C. A soil-tool model based on limit equilibrium analysis. Trans. ASAE 1983, 26, 991–0995. [Google Scholar] [CrossRef]

- Arnhold, S.; Lindner, S.; Lee, B.; Martin, E.; Kettering, J.; Nguyen, T.T.; Koellner, T.; Ok, Y.S.; Huwe, B. Conventional and organic farming: Soil erosion and conservation potential for row crop cultivation. Geoderma 2014, 219, 89–105. [Google Scholar] [CrossRef]

- Abbaspour, Y.; Bavafa, M. Design and Construction of a High Speed Inter-Row Cultivator. Appl. Mech. Mater. 2012, 110, 4914–4918. [Google Scholar]

- Aday, S.; Ramadhan, M. Comparison between the draft force requirements and the disturbed area of a single tine, parallel double tines and partially swerved double tines subsoilers. Soil Tillage Res. 2019, 191, 238–244. [Google Scholar] [CrossRef]

- Ahmadi, I. Development and evaluation of a draft force calculator for moldboard plow using the laws of classical mechanics. Soil Tillage Res. 2016, 161, 129–134. [Google Scholar] [CrossRef]

- Al-Janobi, A. A data-acquisition system to monitor performance of fully mounted implements. J. Agric. Eng. Res. 2000, 75, 167–175. [Google Scholar] [CrossRef]

- Al-Janobi, A.; Al-Suhaibani, S. Draft of primary tillage implements in sandy loam soil. Appl. Eng. Agric. 1998, 14, 343–348. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Haghighat-Shishvan, S. Extended octagonal ring transducers for measurement of tractor-implement forces. Instrum. Exp. Tech. 2011, 54, 136–140. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Ahani, M.; Askari Asli-Ardeh, E.; Rasooli-Sharabiani, V.; Sofalian, O. Design, fabrication and evaluation of a tractor-mounted soil cone penetrometer with multiple probes. J. Agric. Eng. Res. 2010, 11, 19–34. [Google Scholar]

- Abbaspour-Gilandeh, Y.; Khalilian, A.; Reza, A.; Alireza, K.; Sadati, S. Energy savings with variable-depth tillage. In Proceedings of the 27th Southern Conservation Tillage Systems Conference, Florence, SC, USA, 27–29 June 2005; pp. 84–91. [Google Scholar]

- Ashrafizadeh, S.; Kushwaha, R. Development of a Tillage energy model using a simple tool. In Proceedings of the CSBE/SCGAB National Technical Conference, Edmonton, AB, Canada, 16–19 July 2006; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006; pp. 1–14. [Google Scholar]

- Manuwa, S.; Ademosun, O. Draught and Soil Disturbance of Model Tillage Tines under Varying Soil Parameters. Agric. Eng. Int. CIGR J. 2007, 9, 1–18. [Google Scholar]

- Horn, R. Mechanical properties of structured unsaturated soils. Soil Technol. 1993, 6, 47–75. [Google Scholar]

- Grisso, R.; Yasin, M.; Kocher, M. Tillage implement forces operating in silty clay loam. Trans. ASAE 1996, 39, 1977–1982. [Google Scholar] [CrossRef]

- Khalilian, A.; Garner, T.; Musen, H.; Dodd, R.; Hale, S. Energy for conservation tillage in Coastal Plain soils. Trans. ASAE 1988, 31, 1333–1337. [Google Scholar] [CrossRef]

- Summers, J.; Khalilian, A.; Batchelder, D. Draft relationships for primary tillage in Oklahoma soils. Trans. ASAE 1986, 29, 37–0039. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).