Machine Learning Model for Nutrient Release from Biopolymers Coated Controlled-Release Fertilizer

Abstract

:1. Introduction

Enzymatic Degradation of Biopolymers

2. Materials & Methods

2.1. Materials & Pre-Treatment

2.2. Preparation of St-PVOH (Starch Based Polyvinyl Alcohol-Cross-Linked Starch) Solution

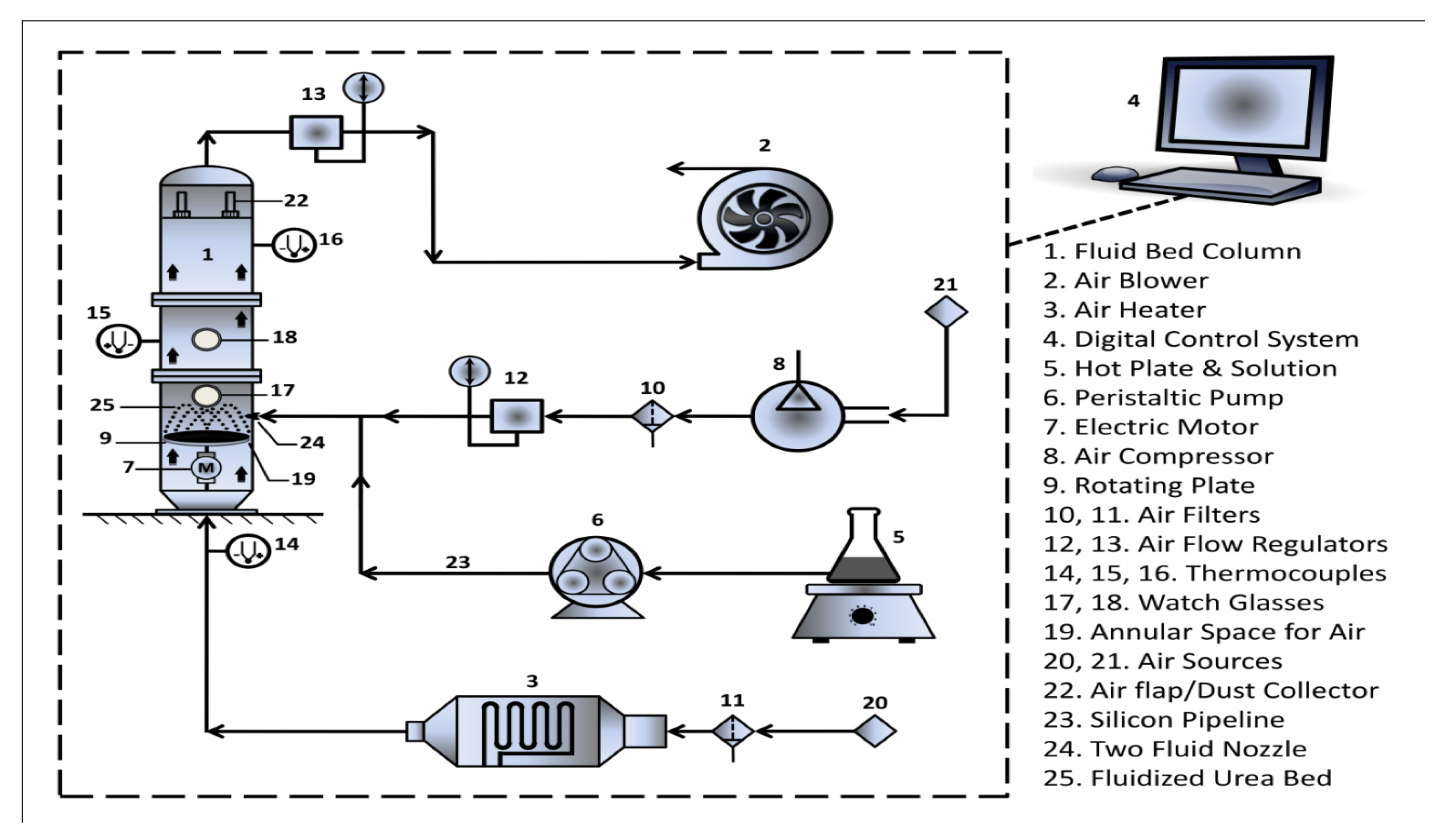

2.3. Preparation of St-PVOH Coated Urea (St-PCU)

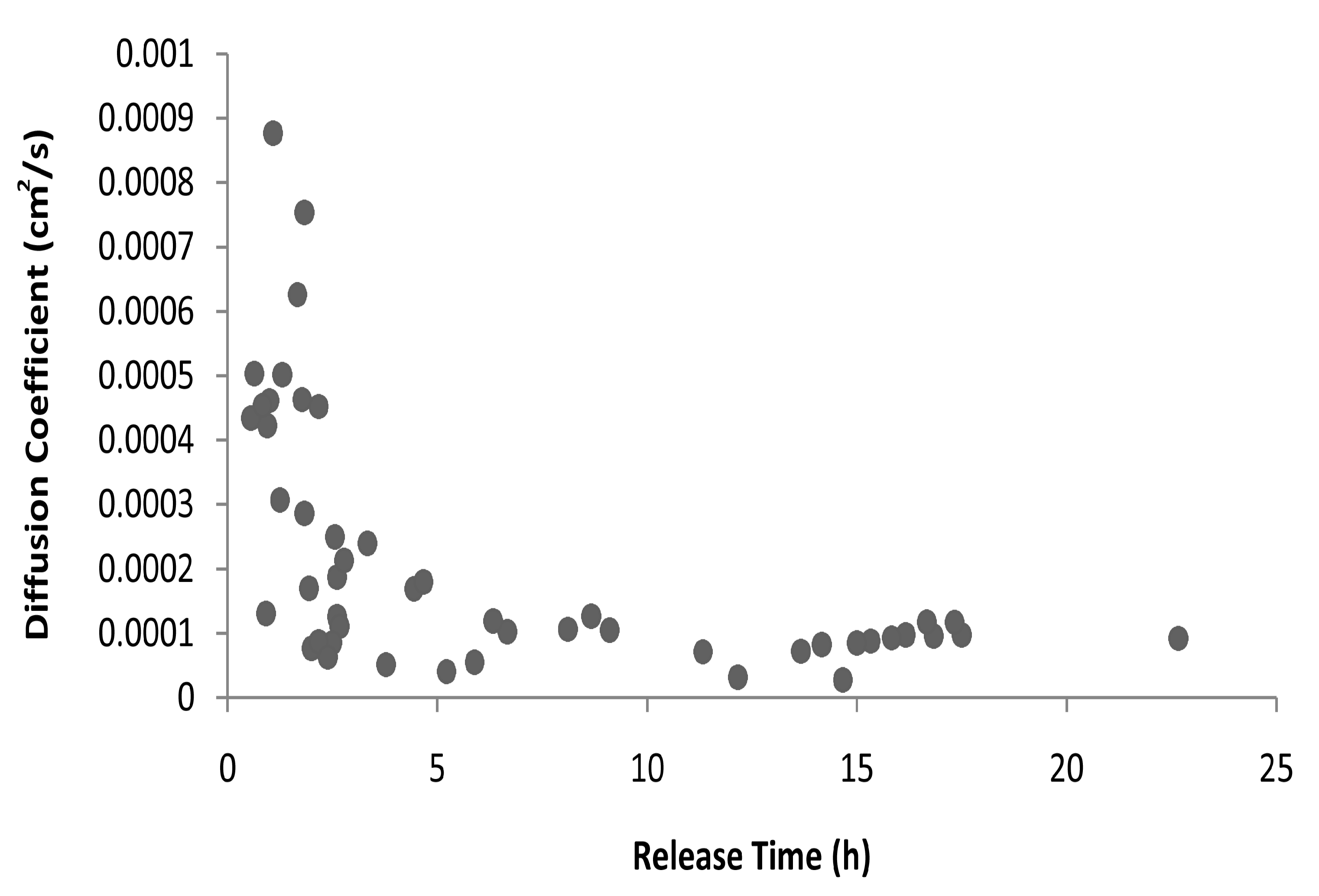

2.4. Controlled Release Characteristics of St-PCU

2.5. Coating Uniformity of St-PCU

- By evaluating the coefficient of variance of film thickness

- By evaluating the coefficient of variance of size distribution

- By evaluating the change in coating mass deposited on the surface of granules

2.6. Coefficient of Variance of Coating Thickness

2.7. Coating Mass Variance of St-PCU

2.8. Coefficient of Variance of Size Distribution of St-PCU

2.9. Experimental Design & Process Optimization

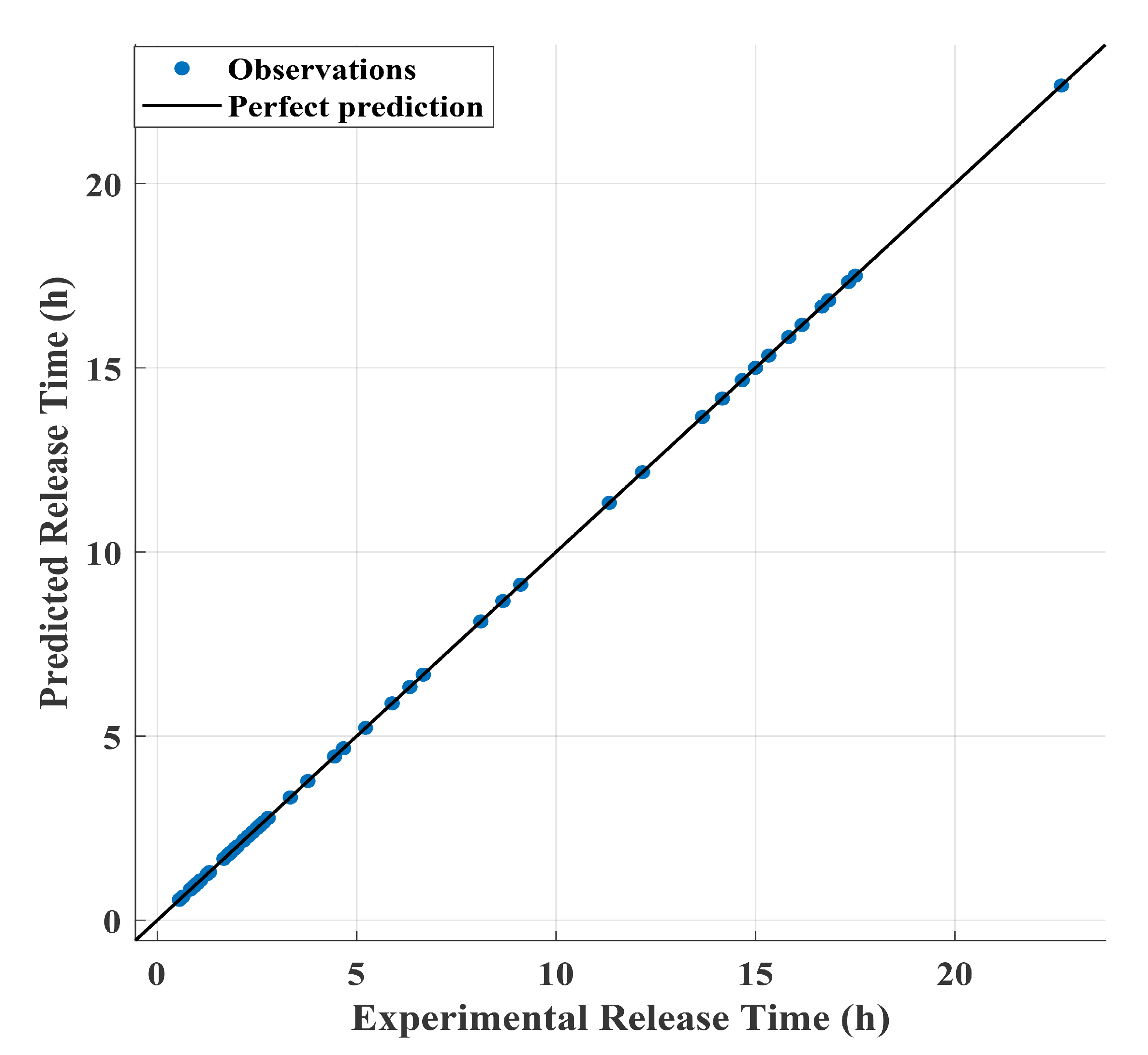

3. Gaussian Process Regression (GPR) Based Machine Learning

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| GPR | Gaussian Process Regression |

| CRF | Controlled Release Fertilizer |

| SRF | Slow Release Fertilizer |

References

- United Nations. World Population Prospects; Technical Report; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Trenkel, M.E. Slow- and Controlled-Release and Stabilized Fertilizers: An Option for Enhancing Nutrient Use Efficiency in Agriculture; International Fertilizer Industry Association: Paris, France, 2010. [Google Scholar]

- Salimi, M.; Motamedi, E.; Motesharezedeh, B.; Hosseini, H.M.; Alikhani, H.A. Starch-g-poly(acrylic acid-co-acrylamide) composites reinforced with natural char nanoparticles toward environmentally benign slow-release urea fertilizers. J. Environ. Chem. Eng. 2020, 8, 103765. [Google Scholar] [CrossRef]

- Majeed, Z.; Ramli, N.K.; Mansor, N.; Man, Z. A comprehensive review on biodegradable polymers and their blends used in controlled-release fertilizer processes. Rev. Chem. Eng. 2015, 31, 69–95. [Google Scholar] [CrossRef]

- Phang, S.W.; Sin, L.T.; Bee, S.T.; Tee, T.T. Release kinetic model of nitrogen released encapsulated in starch-alginate controlled released urea: Diffusion and its decay release. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2020; p. 040006. [Google Scholar] [CrossRef]

- Fertahi, S.; Bertrand, I.; Ilsouk, M.; Oukarroum, A.; Amjoud, M.; Zeroual, Y.; Barakat, A. Impact of Plasticizers on Lignin–Carrageenan Formulation Properties and on Phosphorus Release from a Coated Triple Superphosphate Fertilizer. Ind. Eng. Chem. Res. 2020, 59, 14172–14179. [Google Scholar] [CrossRef]

- Naz, M.Y.; Sulaiman, S.A. Slow release coating remedy for nitrogen loss from conventional urea: A review. J. Control. Release 2016, 225, 109–120. [Google Scholar] [CrossRef] [PubMed]

- Majeed, Z.; Mansor, N.; Man, Z.; Wahid, S.A. Lignin reinforcement of urea-crosslinked starch films for reduction of starch biodegradability to improve slow nitrogen release properties under natural aerobic soil condition. e-Polymers 2016, 16, 159–170. [Google Scholar] [CrossRef]

- Spiridon, I.; Popescu, M.C.; Bodârlău, R.; Vasile, C. Enzymatic degradation of some nanocomposites of poly(vinyl alcohol) with starch. Polym. Degrad. Stab. 2008, 93, 1884–1890. [Google Scholar] [CrossRef]

- Weng, Y.X.; Wang, L.; Zhang, M.; Wang, X.L.; Wang, Y.Z. Biodegradation behavior of P(3HB,4HB)/PLA blends in real soil environments. Polym. Test. 2013, 32, 60–70. [Google Scholar] [CrossRef]

- Shogren, R.; Doane, W.; Garlotta, D.; Lawton, J.; Willett, J. Biodegradation of starch/polylactic acid/poly(hydroxyester-ether) composite bars in soil. Polym. Degrad. Stab. 2003, 79, 405–411. [Google Scholar] [CrossRef]

- Tomasik, P.; Horton, D. Enzymatic Conversions of Starch, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2012; Volum 68, pp. 59–436. [Google Scholar] [CrossRef]

- Tzafriri, A.R. Mathematical modeling of diffusion-mediated release from bulk degrading matrices. J. Control. Release 2000, 63, 69–79. [Google Scholar] [CrossRef]

- Watanabe, M.; Kawai, F.; Shibata, M.; Yokoyama, S.; Sudate, Y. Computational method for analysis of polyethylene biodegradation. J. Comput. Appl. Math 2003, 161, 133–144. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, M.; Kawai, F. Simulation for microbial depolymerization processes of polyethylene glycol. WIT Trans. Inf. Commun. Technol. 2014, 53, 97–107. [Google Scholar] [CrossRef]

- Watanabe, M.; Kawai, F. Solutions of inverse problems for biodegradation of xenobiotic polymers. In AIP Conference Procedings; AIP Publishing LLC: Melville, NY, USA, 2016; p. 050019. [Google Scholar] [CrossRef]

- Takahashi, S.; Ono, S.I. Nitrogen release from polyolefin-coated urea with attention to individual weights. Nutr. Cycl. Agroecosystems 1996, 46, 153–156. [Google Scholar] [CrossRef]

- Zaidel, E. Models of Controlled Release of Fertilisers; Research Thesis; Agricultural Engineering Technion-IIT: Haifa, Israel, 1996. [Google Scholar]

- Shaviv, A.; Raban, S.; Zaidel, E. Modeling controlled nutrient release from a population of polymer coated fertilizers: Statistically based model for diffusion release. Environ. Sci. Technol. 2003, 37, 2257–2261. [Google Scholar] [CrossRef]

- Shaviv, A.; Raban, S.; Zaidel, E. Modeling controlled nutrient release from polymer coated fertilizers: Diffusion release from single granules. Environ. Sci. Technol. 2003, 37, 2251–2256. [Google Scholar] [CrossRef]

- Basu, S.; Kumar, N. Mathematical model and computer simulation for release of nutrients from coated fertilizer granules. Math. Comput. Simul. 2008, 79, 634–646. [Google Scholar] [CrossRef]

- Basu, S.K.; Kumar, N.; Srivastava, J.P. Modeling NPK release from spherically coated fertilizer granules. Simul. Model. Pract. Theory 2010, 18, 820–835. [Google Scholar] [CrossRef]

- Al-Zahrani, S.M. Controlled-release of fertilizers: Modelling and simulation. Int. J. Eng. Sci. 1999, 37, 1299–1307. [Google Scholar] [CrossRef]

- Irfan, S.A.; Razali, R.; Shaari, K.Z.K.; Mansor, N. Modelling and simulations of controlled release fertilizer. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2016; p. 080025. [Google Scholar] [CrossRef]

- Irfan, S.; Razali, R.; KuShaari, K.; Mansor, N. Reaction-Multi Diffusion Model for Nutrient Release and Autocatalytic Degradation of PLA-Coated Controlled-Release Fertilizer. Polymers 2017, 9, 111. [Google Scholar] [CrossRef] [Green Version]

- Irfan, S.A.; Razali, R.; KuShaari, K.; Mansor, N.; Azeem, B.; Ford Versypt, A.N. A review of mathematical modeling and simulation of controlled-release fertilizers. J. Control. Release 2018, 271, 45–54. [Google Scholar] [CrossRef]

- Jarrell, W.M.; Pettygrove, G.S.; Boersma, L. Characterization of the thickness and uniformity of the coatings of sulfur-coated urea. Soil Sci. Soc. Am. J. 1979, 43, 602. [Google Scholar] [CrossRef]

- Du, C.; Tang, D.; Zhou, J.; Wang, H.; Shaviv, A. Prediction of nitrate release from polymer-coated fertilizers using an artificial neural network model. Biosyst. Eng. 2008, 99, 478–486. [Google Scholar] [CrossRef]

- Banerjee, A.; Chatterjee, K.; Madras, G. Enzymatic degradation of polymers: A brief review. Mater. Sci. Technol. 2014, 30, 567–573. [Google Scholar] [CrossRef]

- Azhari, R.; Lotan, N. Enzymic hydrolysis of biopolymers via single-scission attack pathways: A unified kinetic model. J. Mater. Sci. Mater. Med. 1991, 2, 9–18. [Google Scholar] [CrossRef]

- Gold, T.; Azhari, R.; Lotan, N. Enzyme-Promoted Degradation of Polymeric Matrices for Controlled Drug Delivery: Analytical Model and Numerical Simulations. In Degradation of Implant Materials; Eliaz, N., Ed.; Springer: New York, NY, USA, 2012; Volume Chapter 8, pp. 173–194. [Google Scholar] [CrossRef]

- LeVeque, R.J. Finite Difference Methods for Ordinary and Partial Differential Equations; SIAM: Philadelphia, PA, USA, 2008; pp. 1–356. [Google Scholar] [CrossRef]

- Bikiaris, D.N.; Papageorgiou, G.Z.; Achilias, D.S.; Dimitris, S. Synthesis and comparative biodegradability studies of three poly (alkylene succinate) s. Polym. Degrad. Stab. 2006, 91, 31–43. [Google Scholar] [CrossRef]

- Azeem, B.; KuShaari, K.; Man, Z.; Irfan, S.; Trinh, T. Tumbling fluidized-bed process parameters affecting quality of biopolymer coating on surface of pristine urea particles. Powder Technol. 2017, 320, 714–725. [Google Scholar] [CrossRef]

- Azeem, B.; KuShaari, K.; Man, Z.; Irfan, S.A. Parametric study of tumbling fluidized bed to evaluate nitrogen release characteristics of biopolymer-coated controlled release urea. Chem. Eng. Commun. 2018, 205, 1397–1414. [Google Scholar] [CrossRef]

- Yu, H.; Rezaee, R.; Wang, Z.; Han, T.; Zhang, Y.; Arif, M.; Johnson, L. A new method for TOC estimation in tight shale gas reservoirs. Int. J. Coal Geol. 2017, 179, 269–277. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Sun, Y.; Sun, C.; Liu, Z.; Dong, N. Methods of calculating total organic carbon from well logs and its application on rock’s properties analysis. GeoConvention 2013 Integr. 2013, 41372, 7. [Google Scholar]

- Shen, Y.Z.; Du, C.W.; Zhou, J.M.; Ma, F. Modeling nutrient release from swelling polymer-coated urea. Appl. Eng. Agric. 2015, 31, 247–254. [Google Scholar] [CrossRef]

- Shen, Y.Z.; Du, C.W.; Zhou, J.M.; Ma, F. Release profile predictions of controlled release fertilisers: Least Squares Support Vector Machine. Biosyst. Eng. 2018, 31, 67–74. [Google Scholar] [CrossRef]

| Size Range | % Population |

|---|---|

| 2.5–3.0 mm | 3% |

| 1.5–2.0 mm | 60% |

| Beow 1.0 mm | 37% |

| Sr | Process Variables | Min Value | Max Value |

|---|---|---|---|

| 1 | Atomizing air pressure (Bar) | 0.05 | 0.4 |

| 2 | Fluidizing gas temperature (°C) | 50 | 120 |

| 3 | Spray rate (RPM) | 0.5 | 5.0 |

| 4 | Spray temperature (°C) | 70 | 100 |

| 5 | Coating time (min) | 30 | 150 |

| Rel.Time (RT) | Diff. Coeff | Coat.Mass | CV Siz Dist. (SD) | Surf.Hard. (SH) | CV Coat.Thick. (CT) |

|---|---|---|---|---|---|

| 1.833 | 7.54 | 26.184 | 8.08 | 58.9 | 12.185 |

| 1.667 | 6.26 | 23.803 | 7.84 | 48.9 | 18.56 |

| 2.278 | 7.78 | 32.531 | 6.11 | 62.78 | 29.629 |

| 9.111 | 1.05 | 130.127 | 4.88 | 58.1 | 12.156 |

| 5.222 | 4.0710 | 74.584 | 6.47 | 68.95 | 14.285 |

| 5.889 | 5.513 | 84.105 | 10.26 | 70.7 | 16.571 |

| 2.611 | 1.260 | 37.292 | 6.873 | 81.8 | 16.123 |

| 17.5 | 9.768 | 249.9 | 3.88 | 89.2 | 13.317 |

| 1.944 | 1.704 | 27.771 | 8.824 | 54.25 | 14.907 |

| 0.943 | 4.22 | 13.489 | 7.194 | 60.1 | 34.585 |

| 0.917 | 1.30 | 13.092 | 9.957 | 53.7 | 27.167 |

| 2.666 | 1.111 | 38.085 | 8.807 | 55.7 | 17.85 |

| 2 | 7.7015 | 28.564 | 6.62 | 80.5 | 18.69 |

| 2.611 | 1.877 | 37.292 | 5.338 | 68.5 | 34.521 |

| 6.666 | 1.025 | 95.215 | 5.852 | 89.36 | 21.712 |

| 2.556 | 2.49 | 36.49 | 3.41 | 59.9 | 14.167 |

| 1.833 | 2.86 | 26.18 | 6.296 | 68.4 | 22.372 |

| 2.5 | 8.571 | 35.70 | 6.32 | 72.08 | 18.713 |

| 16.167 | 9.76 | 230.89 | 4.077 | 82.6 | 13.095 |

| 13.667 | 7.23 | 195.19 | 5.53 | 88.75 | 13.882 |

| 2.778 | 2.13 | 39.673 | 7.527 | 69.12 | 32.088 |

| 17.33 | 1.17 | 247.55 | 3.782 | 81.02 | 13.48 |

| 2.166 | 8.70 | 30.945 | 5.264 | 76.2 | 27.491 |

| 15.333 | 8.83 | 218.994 | 6.24 | 76.3 | 12.794 |

| 2.388 | 6.330 | 34.119 | 7.49 | 56.6 | 24.087 |

| 22.667 | 9.24 | 323.73 | 2.854 | 101.23 | 11.590 |

| 4.444 | 1.6 | 63.475 | 6.41 | 56.5 | 14.51 |

| 16.83 | 9.63 | 240.417 | 4.227 | 78.3 | 12.92 |

| 1 | 4.619 | 14.282 | 5.66 | 73.2 | 27.12 |

| 11.333 | 7.171 | 161.86 | 4.846 | 79.5 | 13.92 |

| 3.778 | 5.16 | 53.9 | 7.58 | 65.23 | 16.256 |

| 2.166 | 4.526 | 30.945 | 11.862 | 60.25 | 12.9 |

| 6.33 | 1.19 | 90.45 | 6.31 | 84.36 | 22.85 |

| 14.667 | 2.77 | 209.47 | 7.24 | 84.85 | 13.682 |

| 0.55 | 4.350 | 7.934 | 8.361 | 49.63 | 31.152 |

| 0.639 | 5.039 | 9.125 | 9.845 | 58.98 | 23.51 |

| 16.667 | 1.176 | 238.0 | 4.1 | 93.26 | 12.683 |

| 8.6669 | 1.26 | 123.779 | 5.21 | 87.21 | 21.251 |

| 12.167 | 3.21 | 173.767 | 6.92 | 85.6 | 12.39 |

| 0.83 | 4.54 | 11.9 | 9.2 | 53.6 | 19.9 |

| 4.6 | 1.8 | 66.6 | 4.8 | 71.25 | 20.875 |

| 1.083 | 8.7 | 15.472 | 7.2 | 56.3 | 29.659 |

| 15.833 | 9.3 | 226.13 | 5.0 | 85.2 | 13.333 |

| 15 | 8.5 | 214.233 | 7.92 | 88.69 | 12.583 |

| 3.33 | 2.40 | 47.60 | 6.0 | 90.9 | 22.035 |

| 1.306 | 5.02 | 18.641 | 8.66 | 48.63 | 32.45 |

| 8.11 | 1.0 | 115.845 | 6.875 | 69.31 | 26.48 |

| 1.778 | 4.634 | 25.39 | 12.581 | 47.21 | 12.895 |

| 1.25 | 3.0 | 17.8 | 9.27 | 61.58 | 23.1 |

| 14.167 | 8.2 | 202.33 | 6.07 | 77.6 | 13.5 |

| Sr | Kernel Function | RMSE | |

|---|---|---|---|

| 1 | Rational Quadratic GPR | 0.003 | 1 |

| 2 | Squared Exponential GPR | 0.003 | 1 |

| 3 | Matern/GPR | 0.003 | 0.98 |

| 4 | Exponential GPR | 0.98 | 0.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irfan, S.A.; Azeem, B.; Irshad, K.; Algarni, S.; KuShaari, K.; Islam, S.; Abdelmohimen, M.A.H. Machine Learning Model for Nutrient Release from Biopolymers Coated Controlled-Release Fertilizer. Agriculture 2020, 10, 538. https://doi.org/10.3390/agriculture10110538

Irfan SA, Azeem B, Irshad K, Algarni S, KuShaari K, Islam S, Abdelmohimen MAH. Machine Learning Model for Nutrient Release from Biopolymers Coated Controlled-Release Fertilizer. Agriculture. 2020; 10(11):538. https://doi.org/10.3390/agriculture10110538

Chicago/Turabian StyleIrfan, Sayed Ameenuddin, Babar Azeem, Kashif Irshad, Salem Algarni, KuZilati KuShaari, Saiful Islam, and Mostafa A. H. Abdelmohimen. 2020. "Machine Learning Model for Nutrient Release from Biopolymers Coated Controlled-Release Fertilizer" Agriculture 10, no. 11: 538. https://doi.org/10.3390/agriculture10110538

APA StyleIrfan, S. A., Azeem, B., Irshad, K., Algarni, S., KuShaari, K., Islam, S., & Abdelmohimen, M. A. H. (2020). Machine Learning Model for Nutrient Release from Biopolymers Coated Controlled-Release Fertilizer. Agriculture, 10(11), 538. https://doi.org/10.3390/agriculture10110538