Numerical Simulation of Multi-Span Greenhouse Structures

Abstract

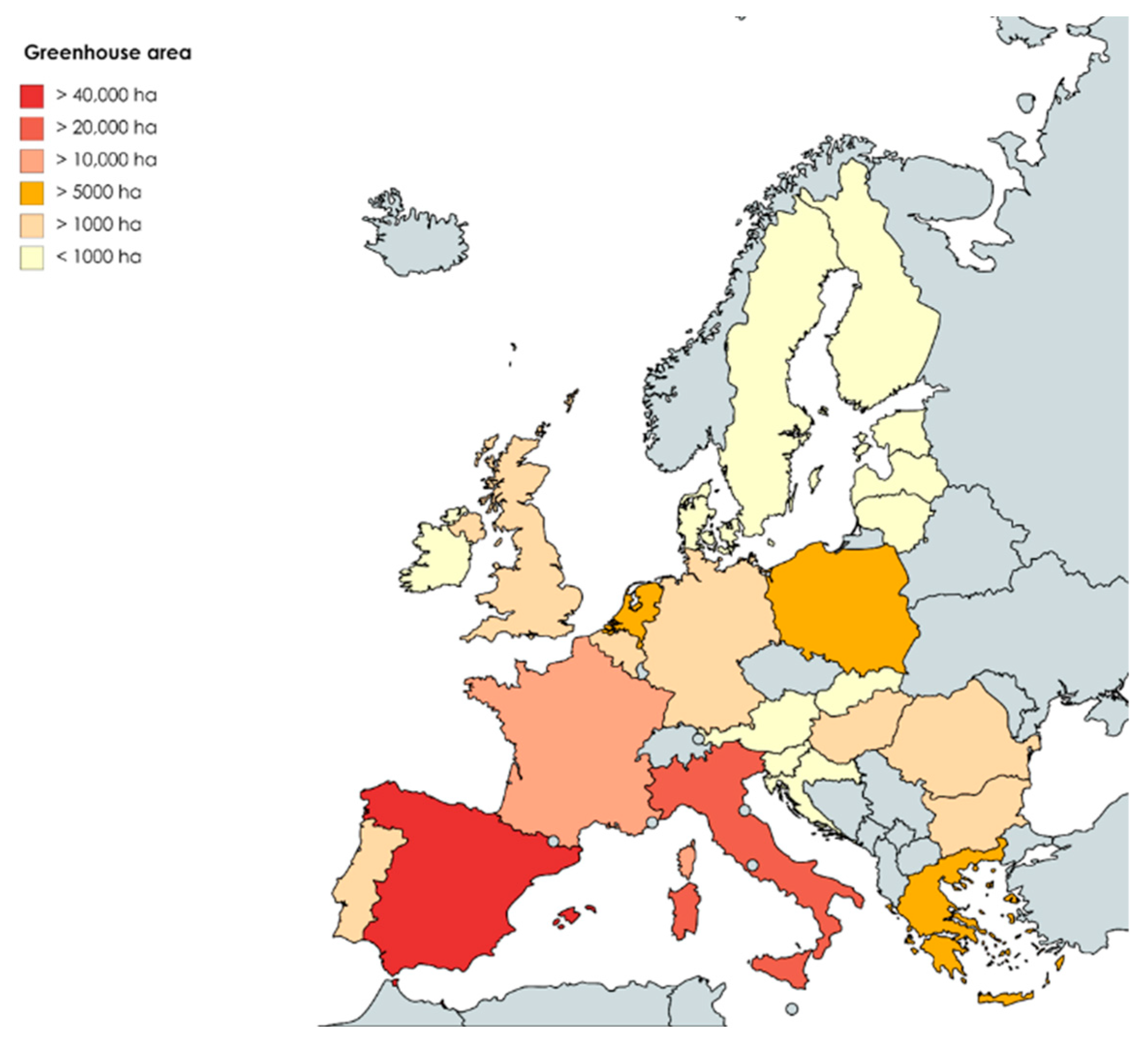

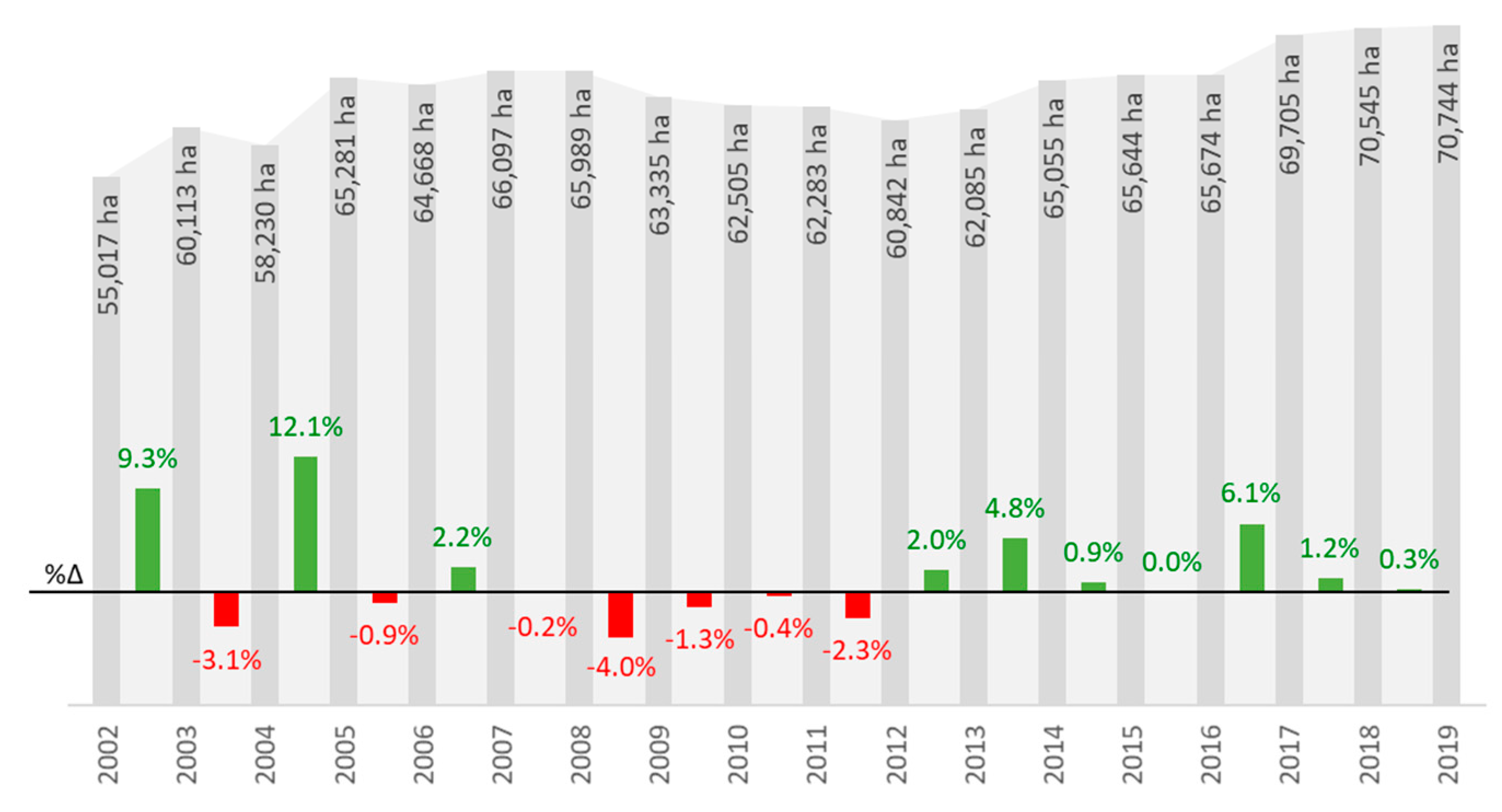

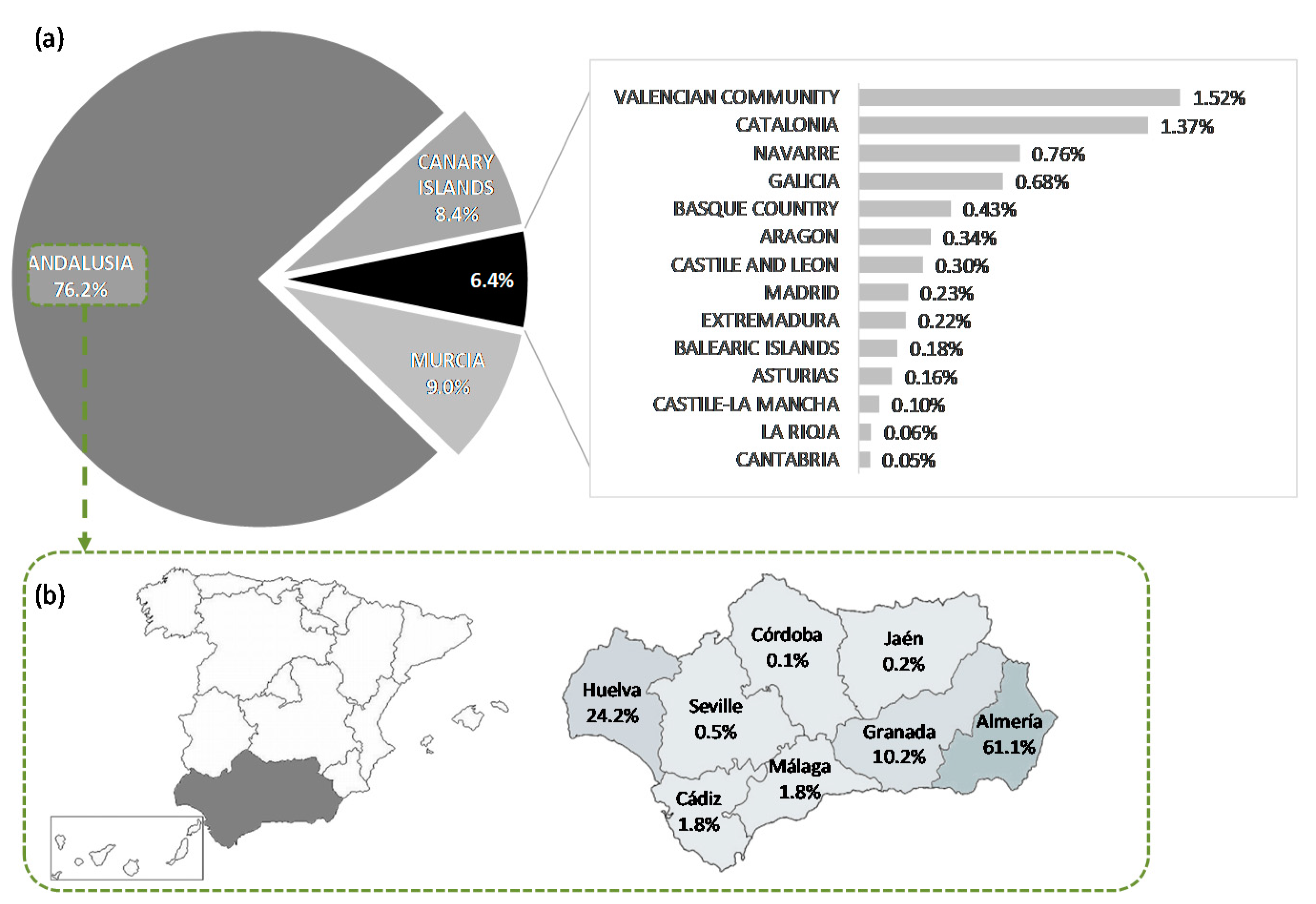

1. Introduction

2. Materials and Methods

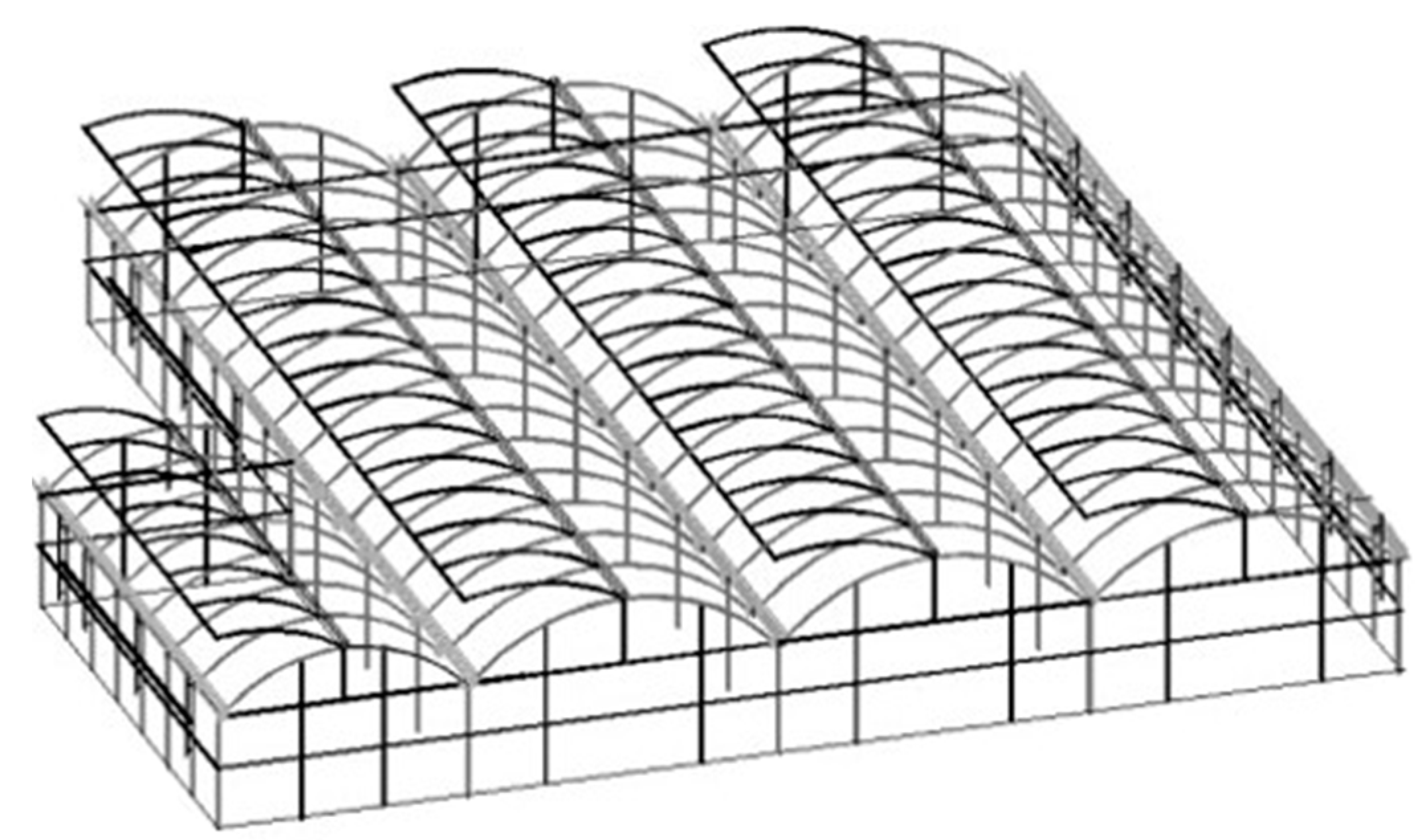

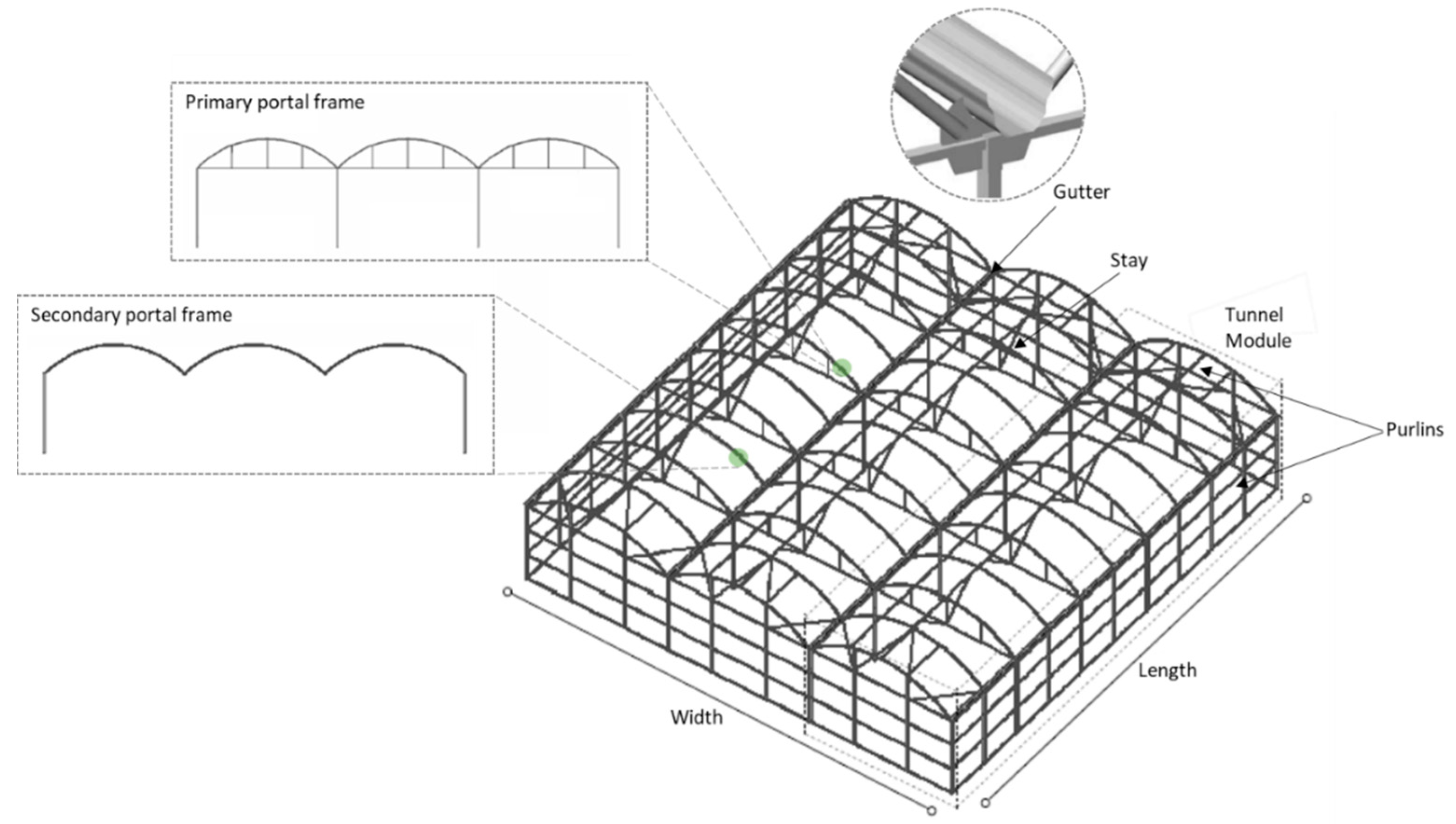

2.1. Greenhouse Structure

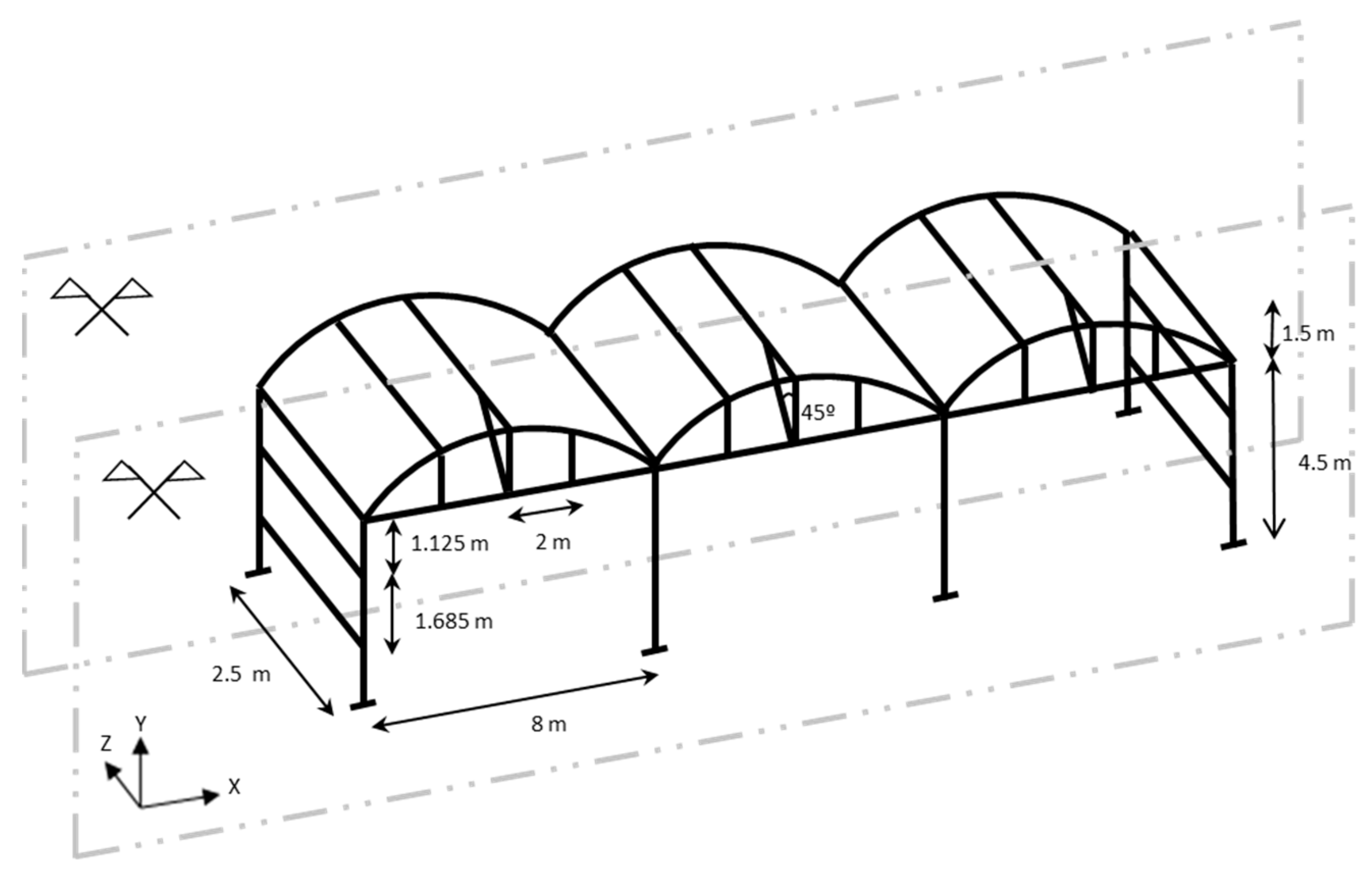

2.1.1. Geometry

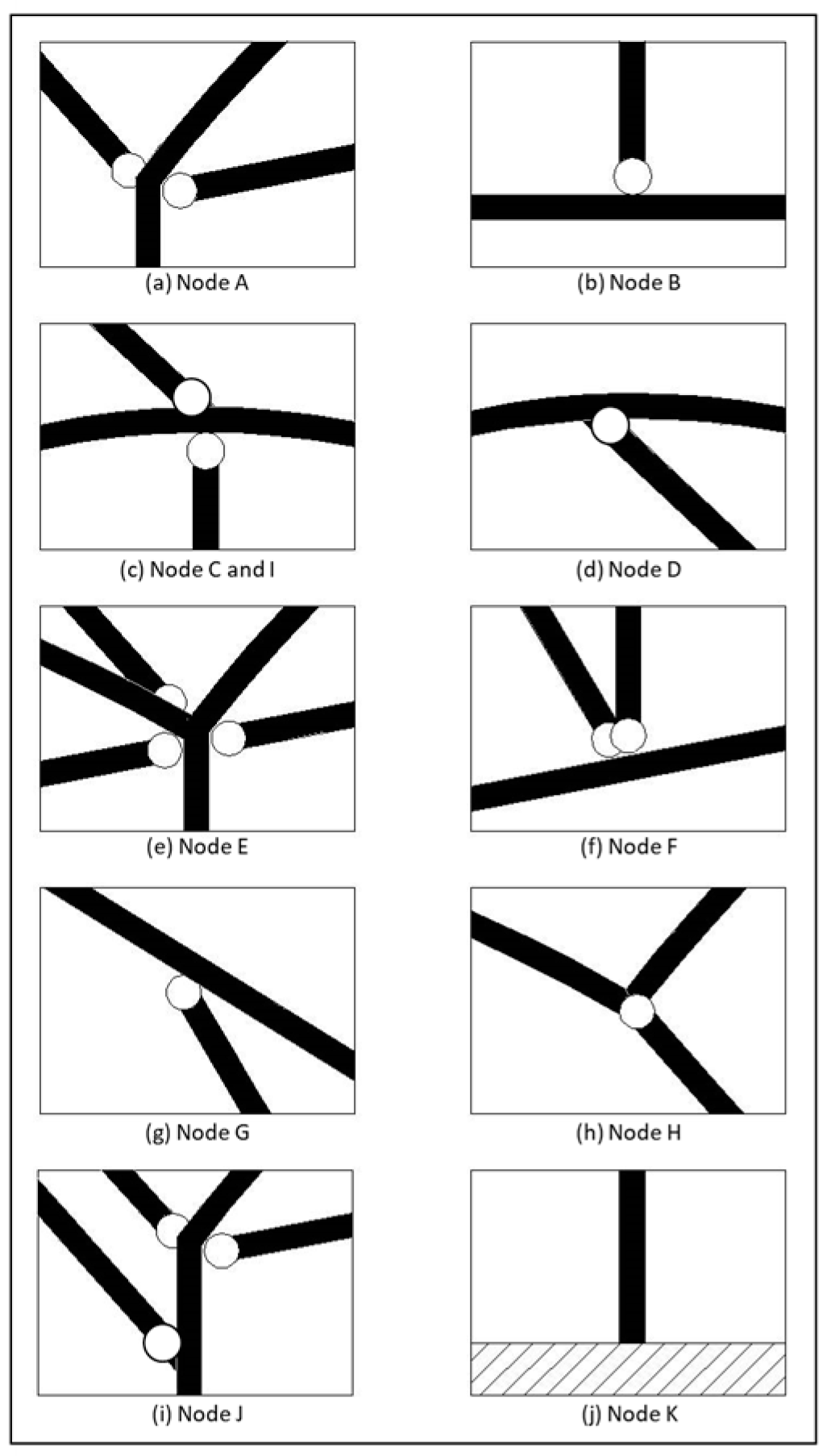

2.1.2. Boundary Conditions

2.1.3. Structural Analysis

2.2. Actions on the Greenhouse Structure

2.2.1. According to the Current Standards

- Permanent loads: Those produced by the self-weight of the structural metal frame and the film cladding system (0.092 kg·m−2 for a 10−4 m film thickness).

- Concentrated vertical action: In order to account for the weight of the worker in the maintenance labor, it is considered as a normal force of 0.35 kN. The force is applied to the middle of the secondary portal frame, which is the most unfavorable situation.

- Crop load: Usually, the greenhouse structure supports the weight of the plants and the crop products. The standard establishes this load as a uniformly distributed vertical force applied to the bottom chord of the trussed roof frame. A typical value for tomatoes and cucumbers of 0.15 kN·m−2 was considered in this research work.

- Snow load: According to the Spanish standard UNE 76210 IN [70], the corresponding snow load for Almeria, which is located at an altitude of less than 200 m, should be contemplated as an accidental load (Ak) with a value of 0.19584 kN·m−2, as determined by Equation (1):where μi is the snow load shape coefficient (μi = 0.8 for a curve multi-span greenhouse as defined in the EN standard), ct is the thermal coefficient (ct = 1 due to the lack of heating system as defined in the EN standard) and cn is the correction coefficient for a specified return period (cn = 0.612 for a 10-year lifespan as defined in the EN standard).Ak = μi × ct × cn × 0.4

- Wind loads: According to EN 13031-1 [53], Eurocode 1-4 [57] and UNE 76209 IN [69], greenhouses in which windows could be open and closed must be designed as a structure without openings. In fact, the lack of interior wind loads is the most realistic option for greenhouses that are professionally constructed, as the air leakage, which causes loss of heat and carbon dioxide, is completely controlled.

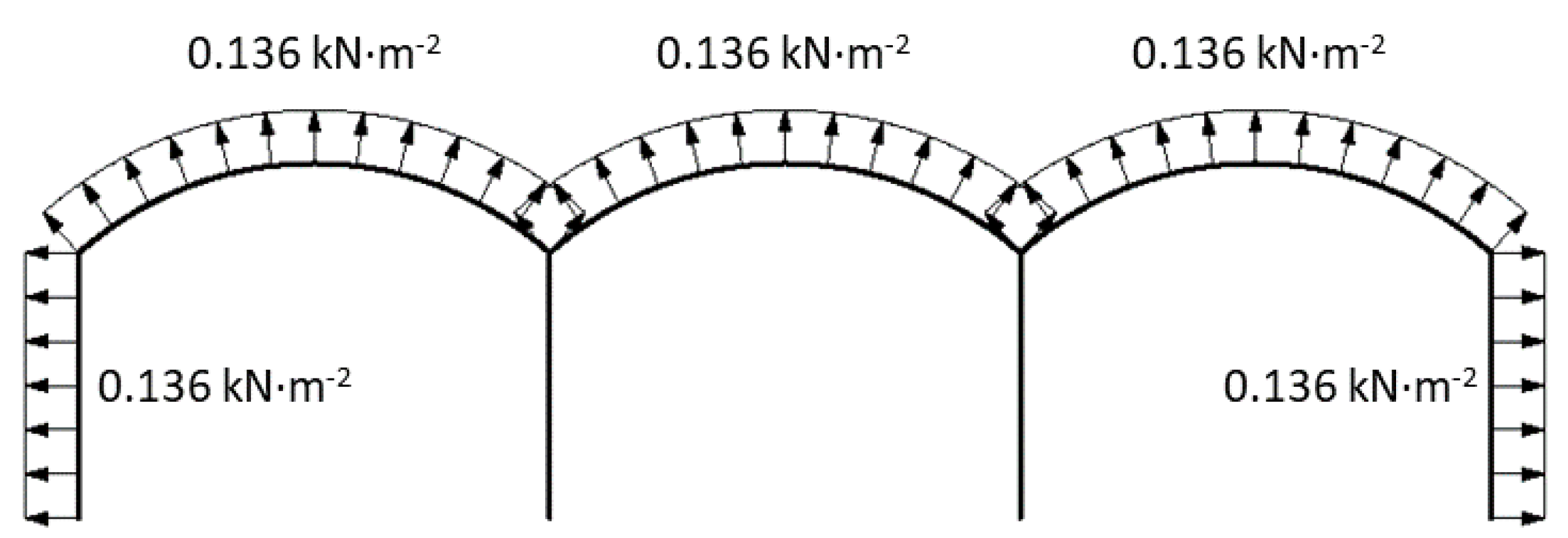

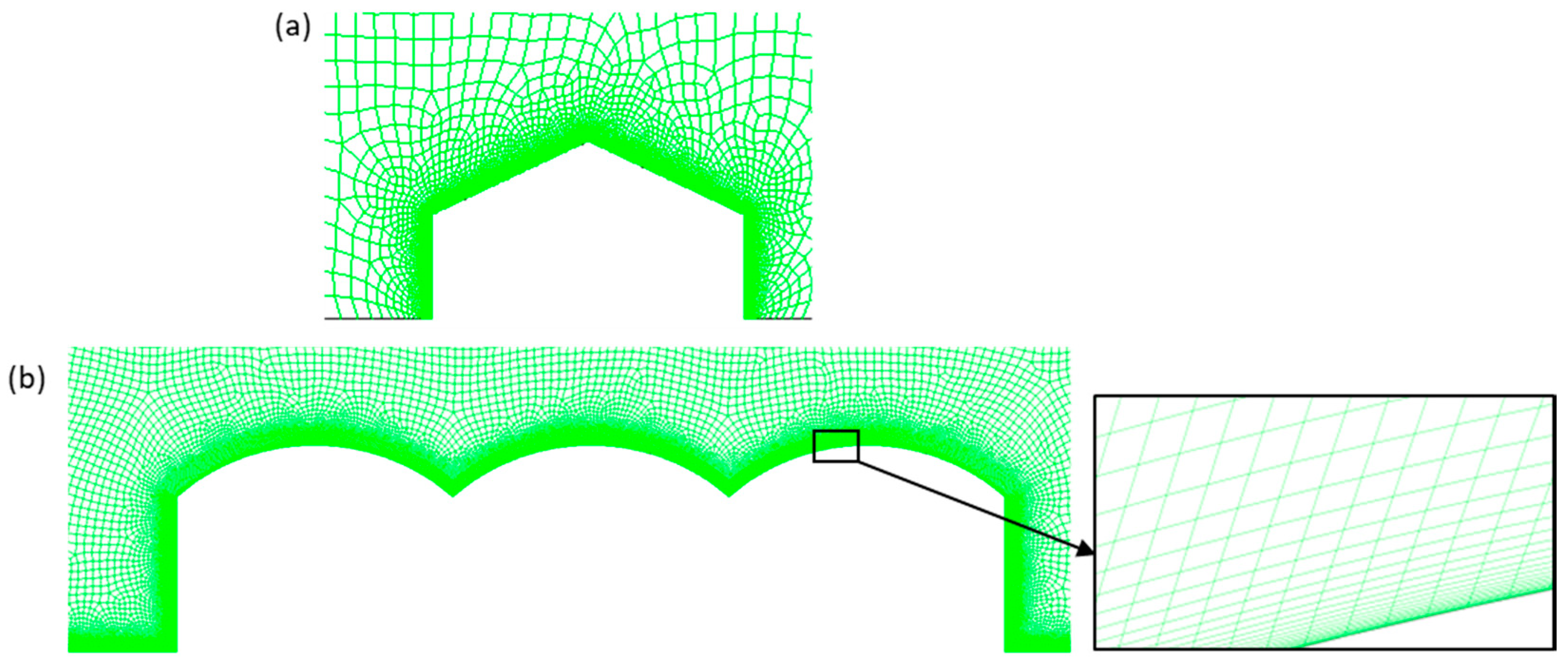

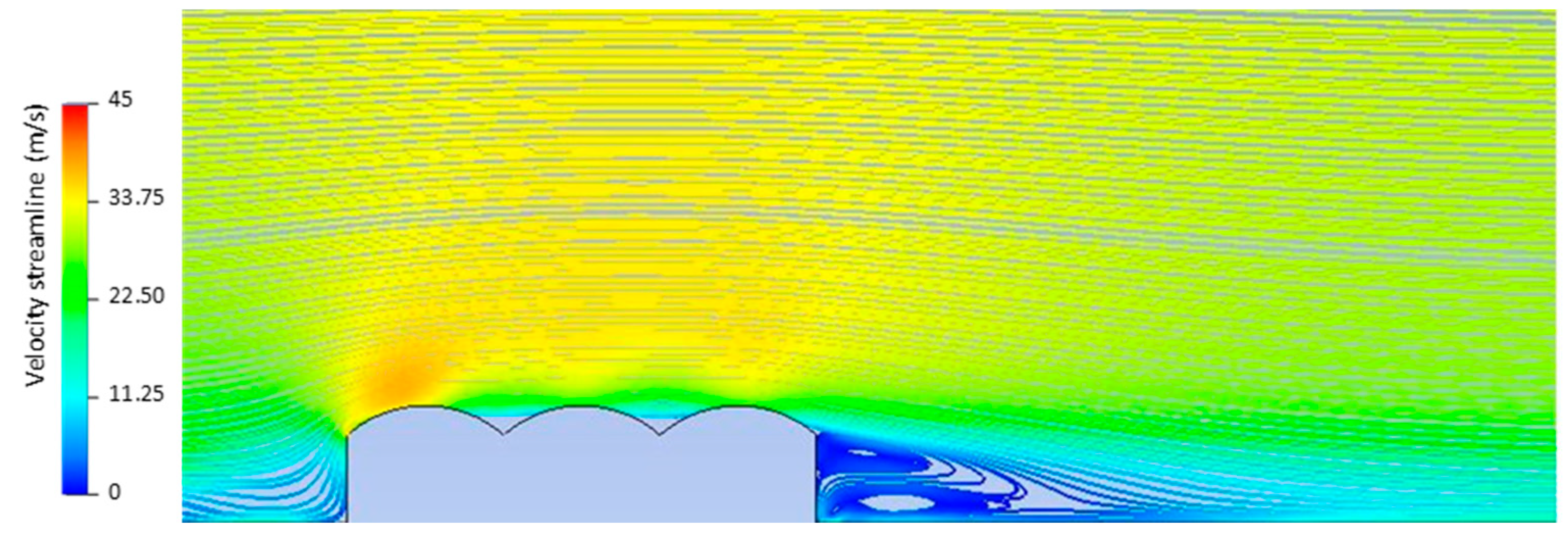

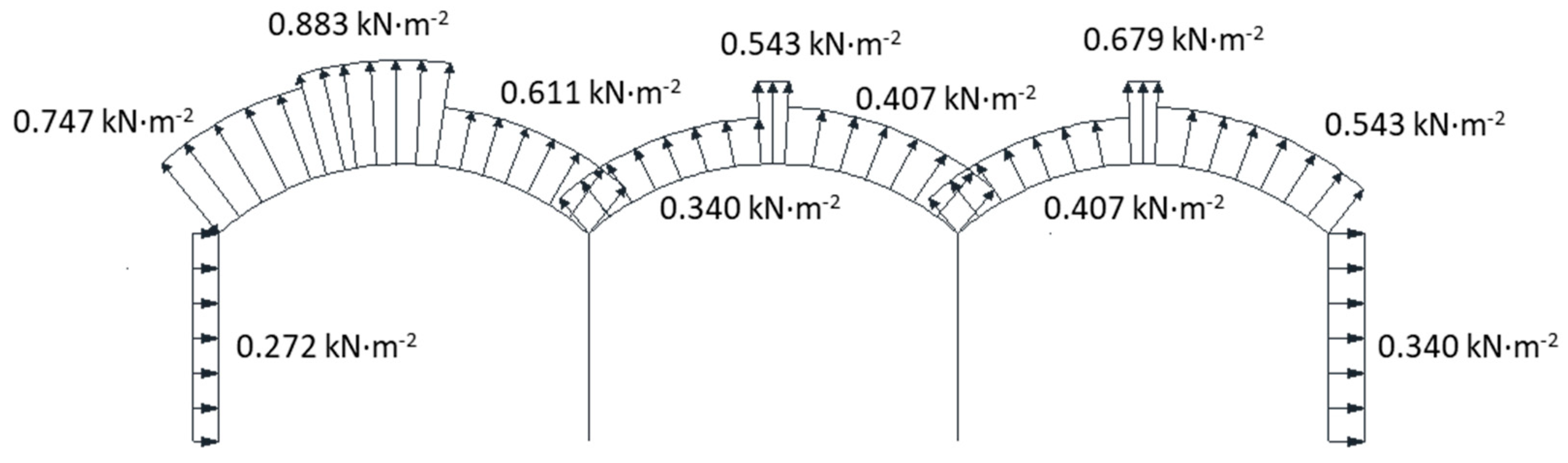

2.2.2. Wind Load Action Simulated Through CFD

2.3. Foundation

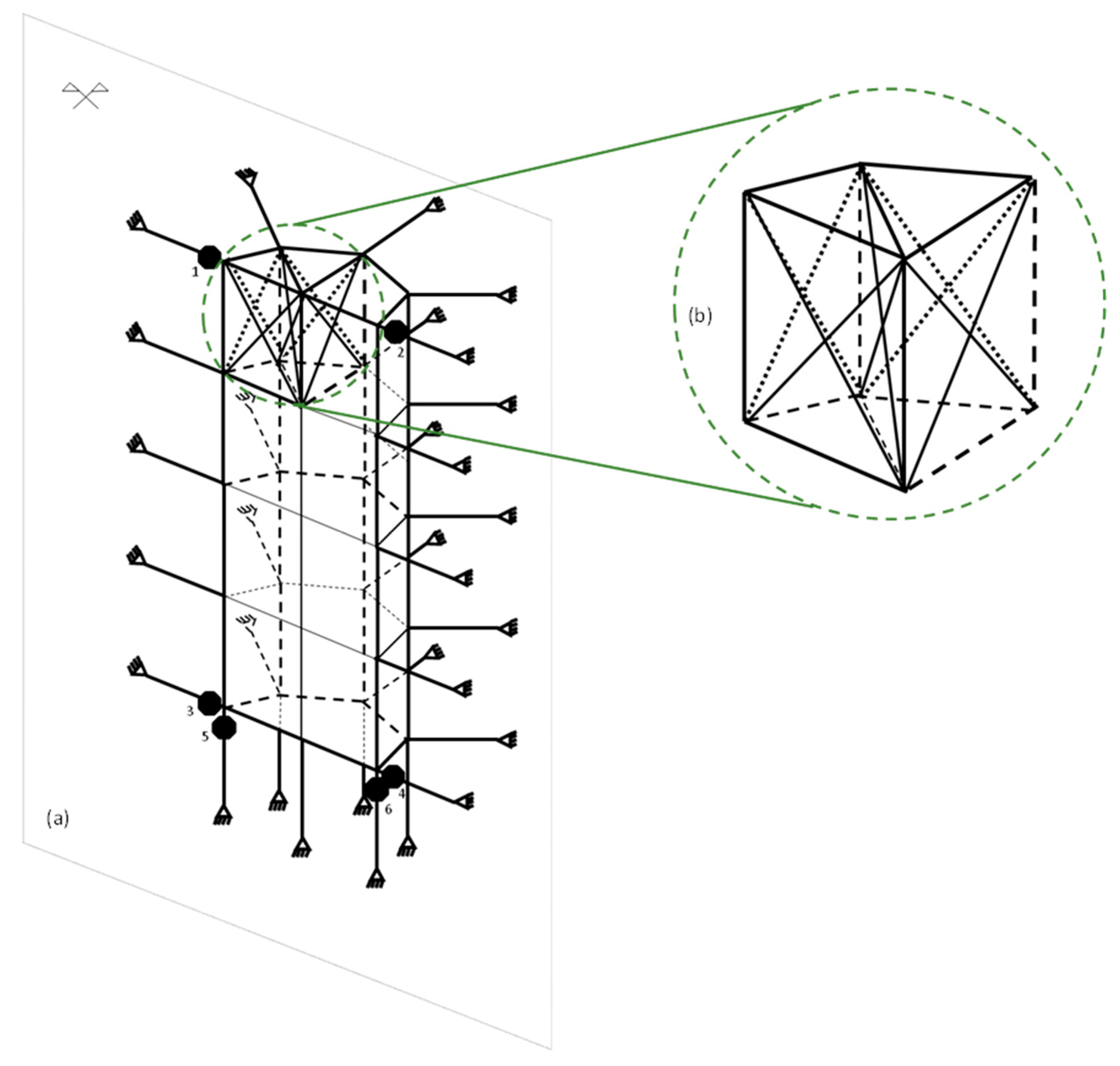

2.3.1. Simulation of a Solid Rigid Body by Means of the Winkler Model

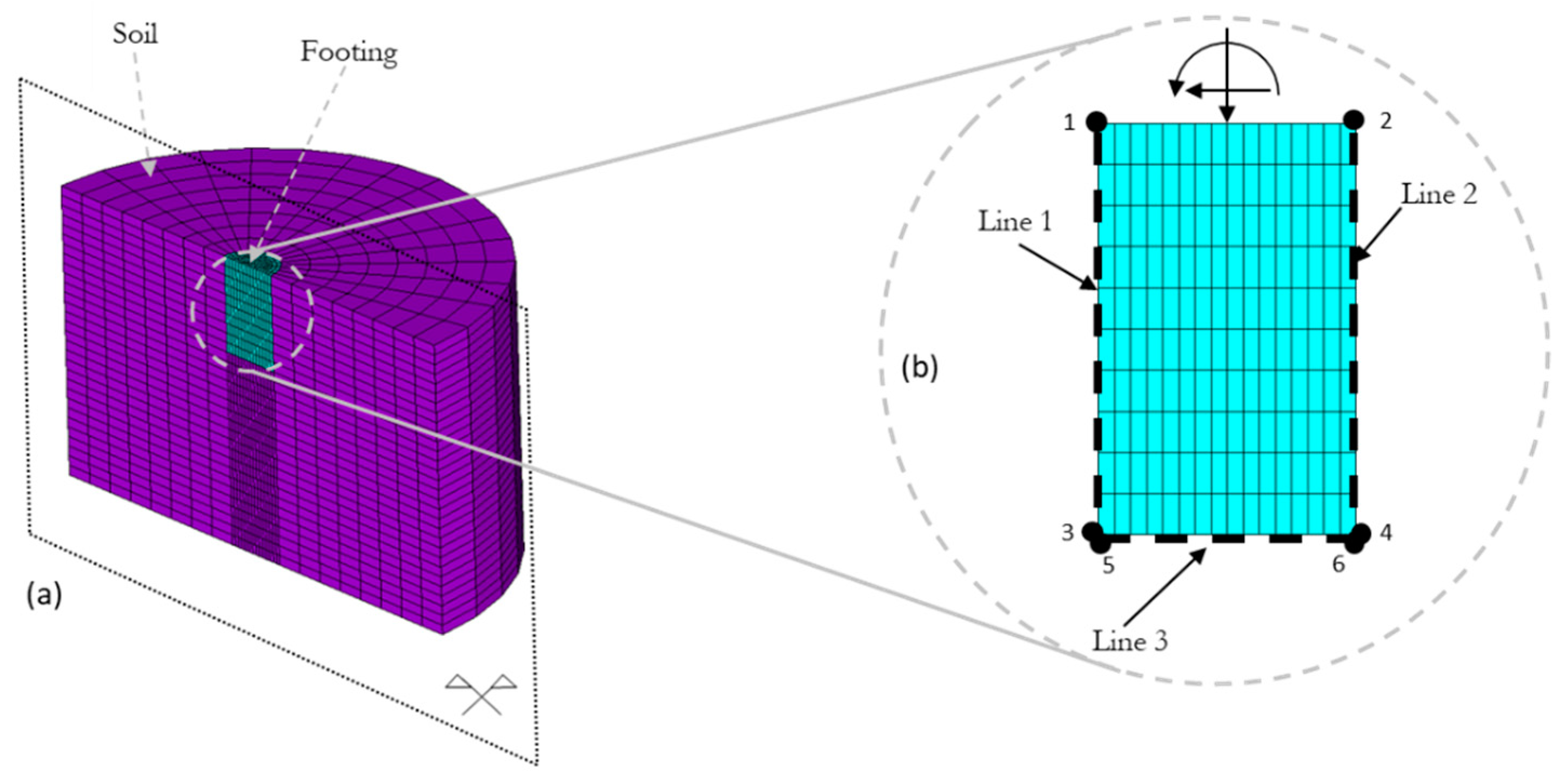

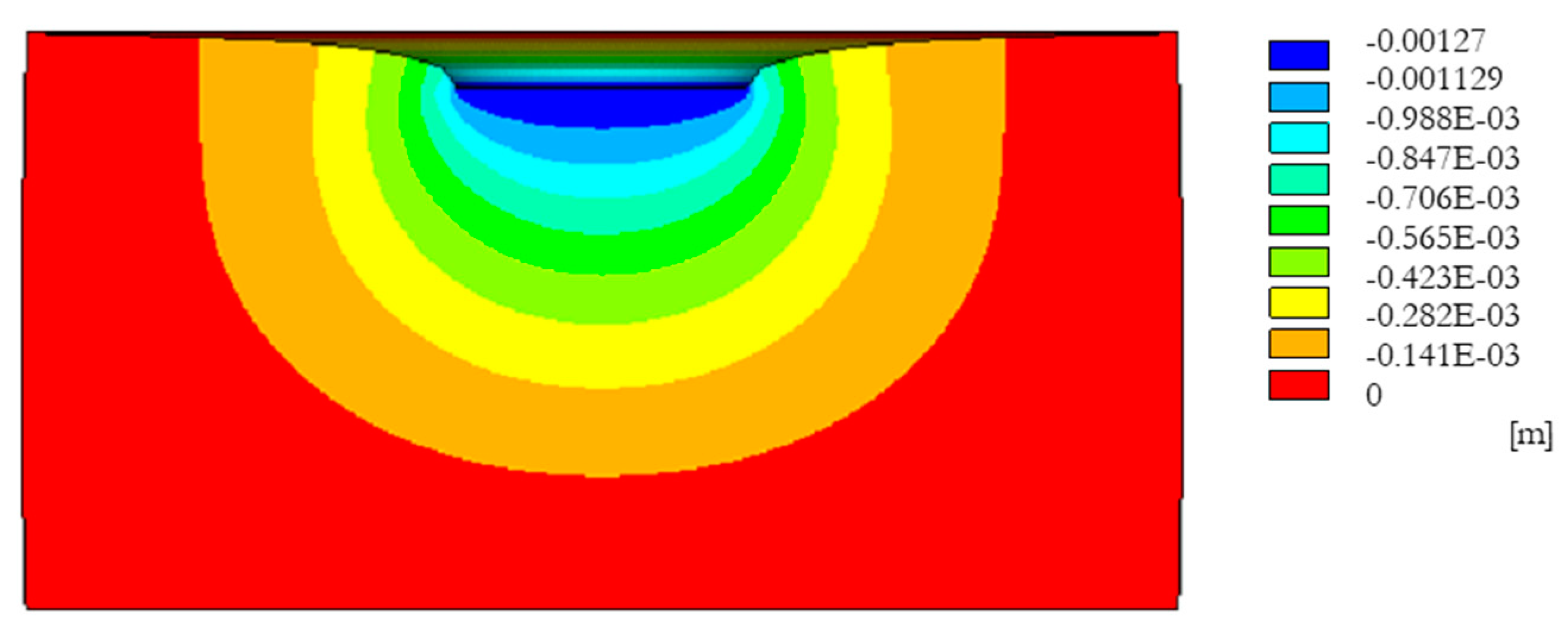

2.3.2. Solid Model with FEM

3. Results and Discussions

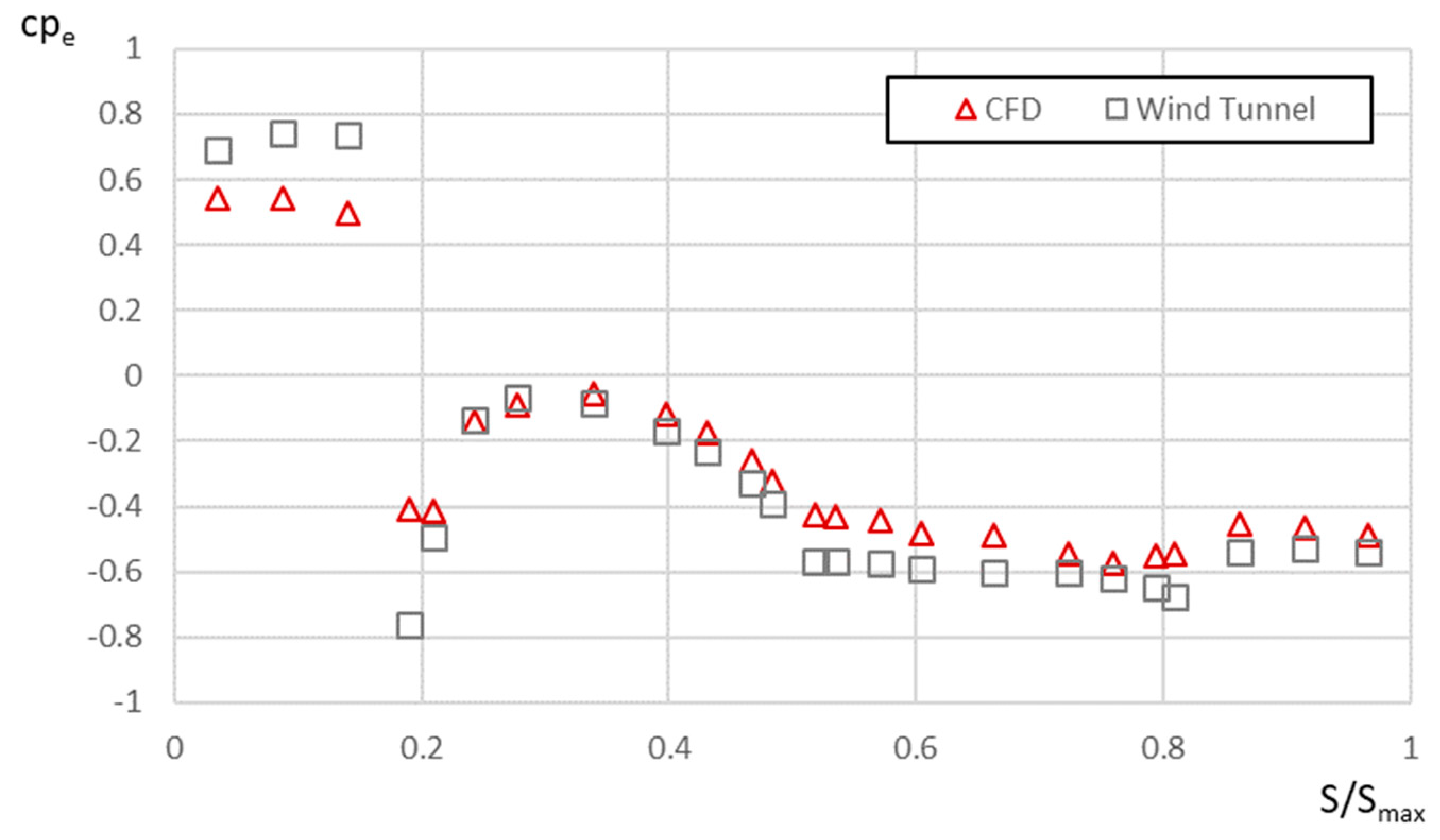

3.1. CFD Simulation for the 0° Wind Loads

3.2. Effects of the External Loads on the Greenhouse Structure

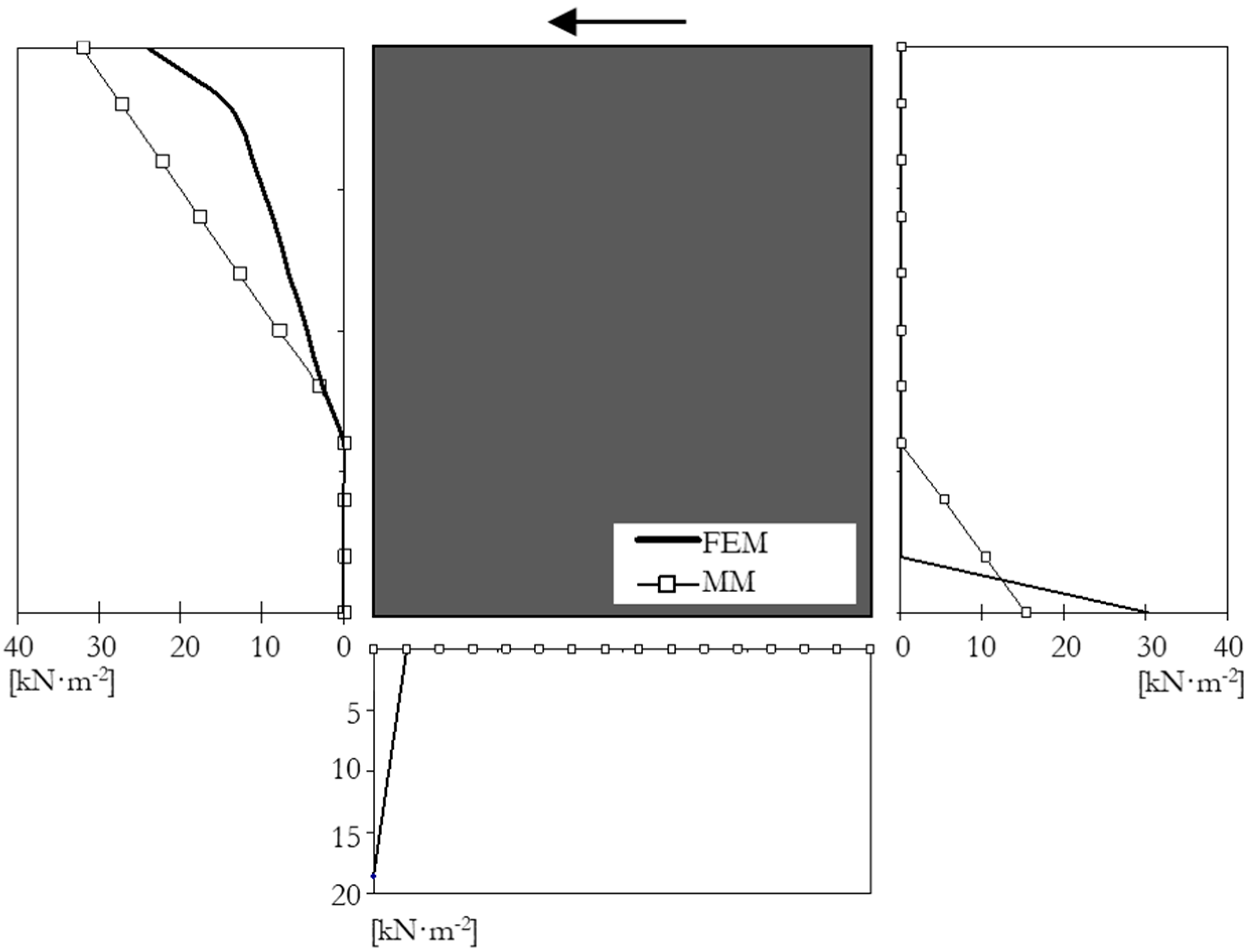

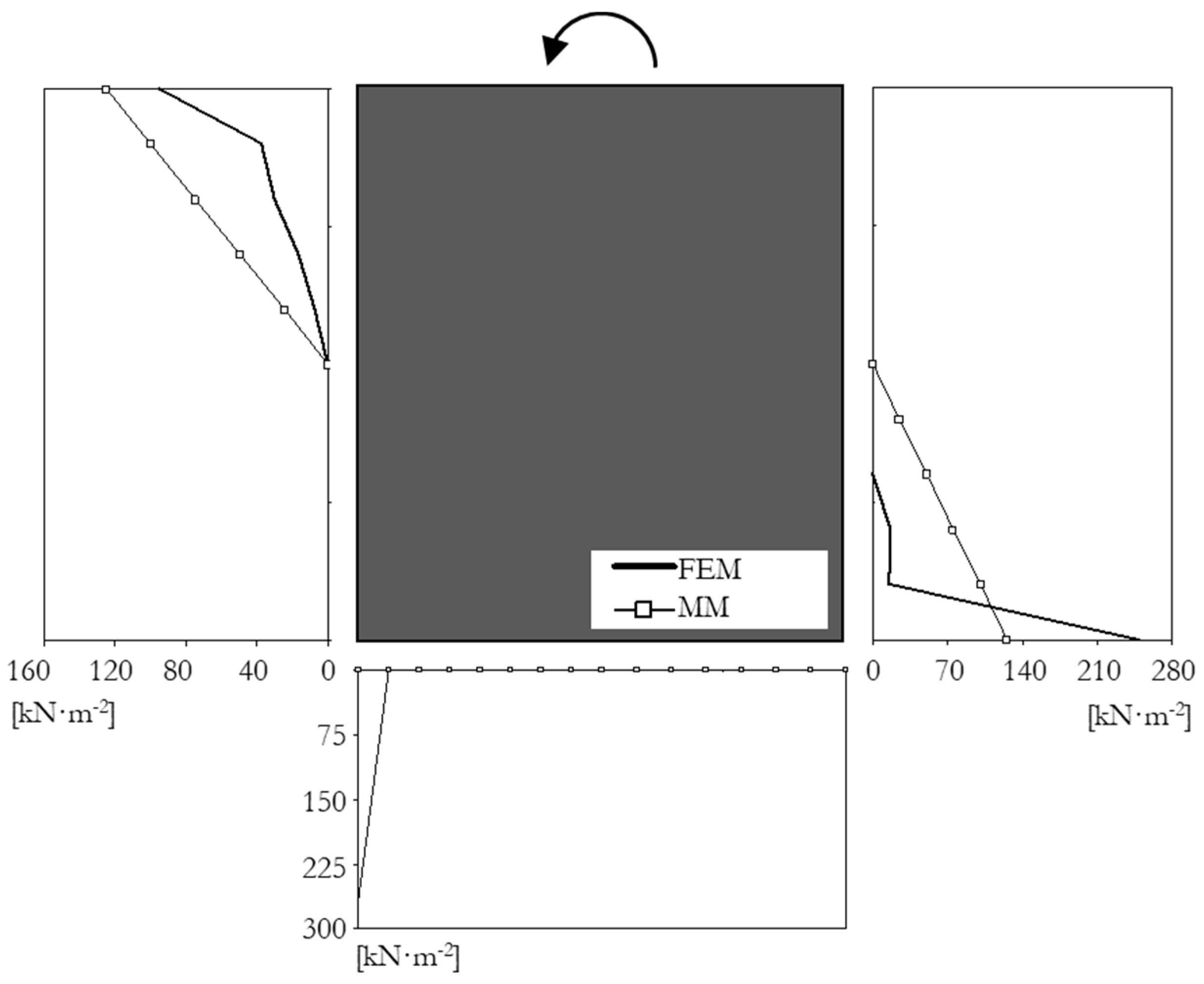

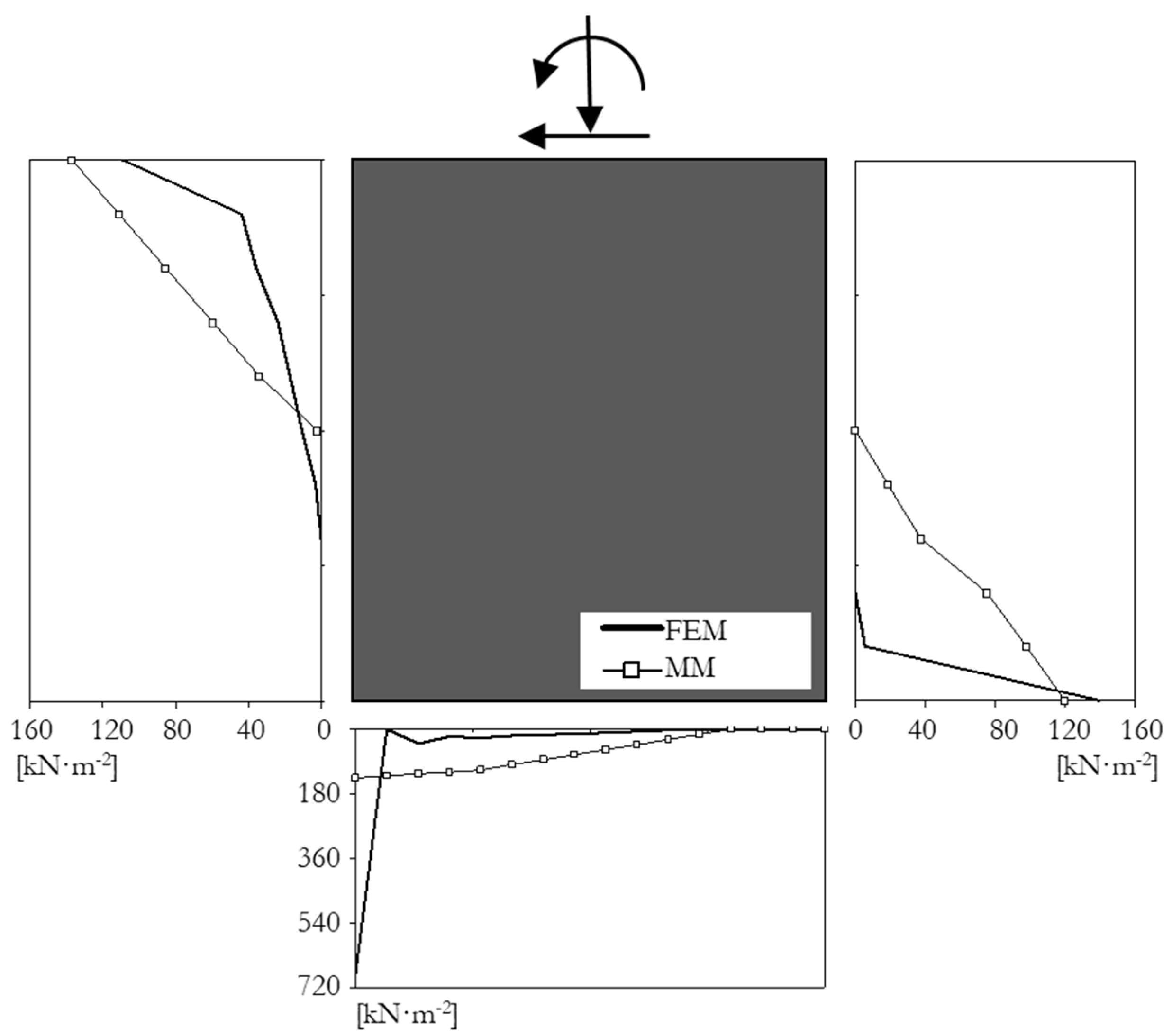

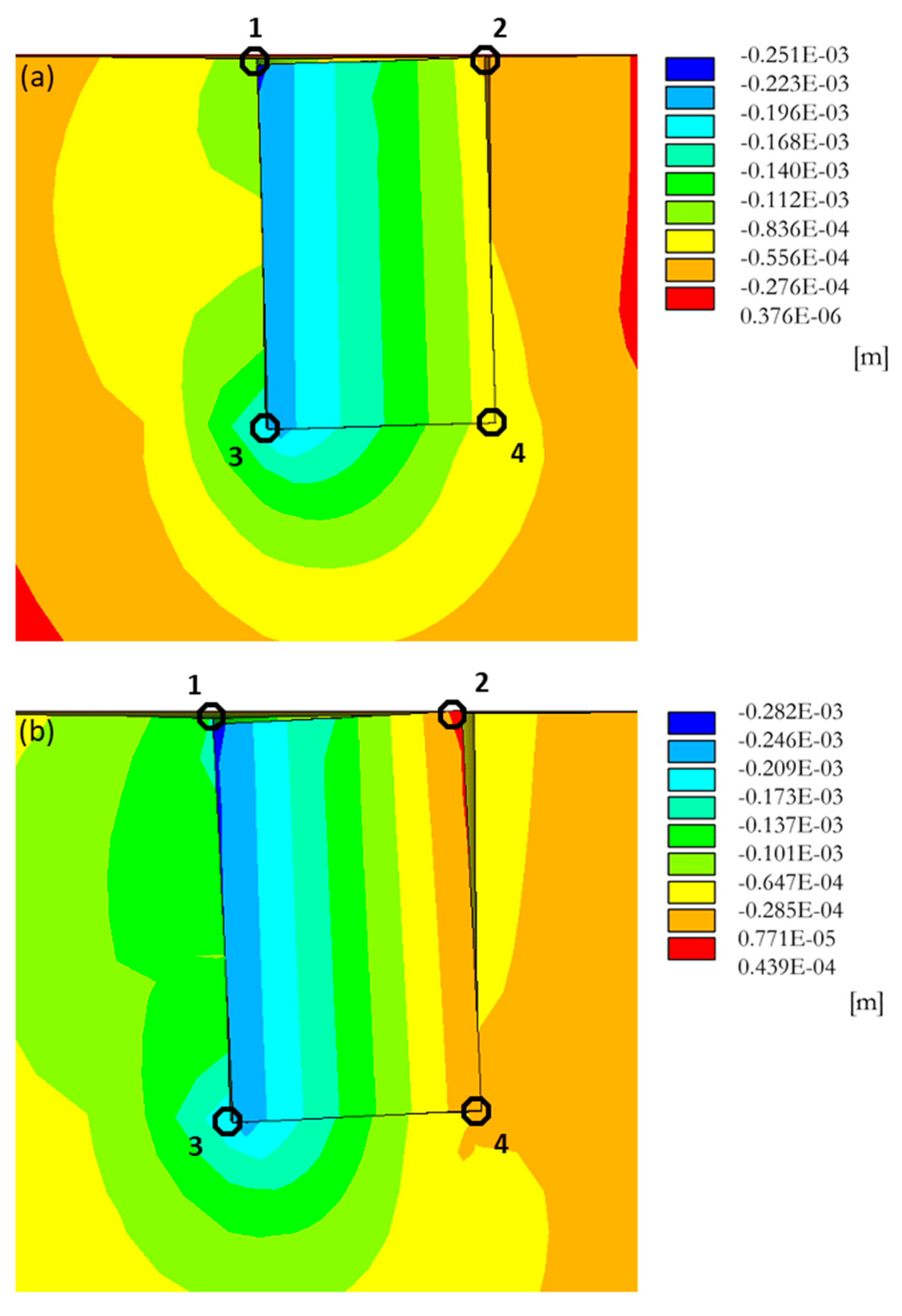

3.3. Concrete Footings

4. Conclusions

- Wind load applied to the structure: Computational fluid dynamics;

- Buckling failure mode of the structure: Finite element method;

- Foundations: Matrix model and finite element method based on a solid-elastic contact model.

- The wind loads affecting a multi-span greenhouse, such as the ones defined in this research paper, were numerically simulated by means of CFD. In this regard, a greenhouse composed of three tunnels was proven to be of interest from a scientific point of view, since such a geometry allowed to capture differences among the arches on the wind loads, as well as the effects of the loads on the buckling mode of the structure.

- For the columns on the greenhouse structure, the consideration of the 0°-direction wind load led to similar results to those of the corresponding wind action stated in EN 13031-1 [53]. Nonetheless, significant discrepancies were detected for cpe values on the arches of the first and third tunnel.

- Conversely to the EN 13031-1 [53], the CFD wind loads resulted in suction effects on the initial windward zone of the first tunnel of a multi-span greenhouse. In this regard, the consideration of both pressure and suction effects for this region (0–55°) seems appropriate to analyze multi-tunnel greenhouses with this type of loads, which have been also supported by the Eurocode 1-4 [57] regulations and the results found in the literature.

- Regarding the third tunnel, the EN standard [53] establishes the cpe as the 60% value of those in the second tunnel. However, the CFD simulation did not registered the mentioned behavior but exhibited cpe values closer to those in the second arch.

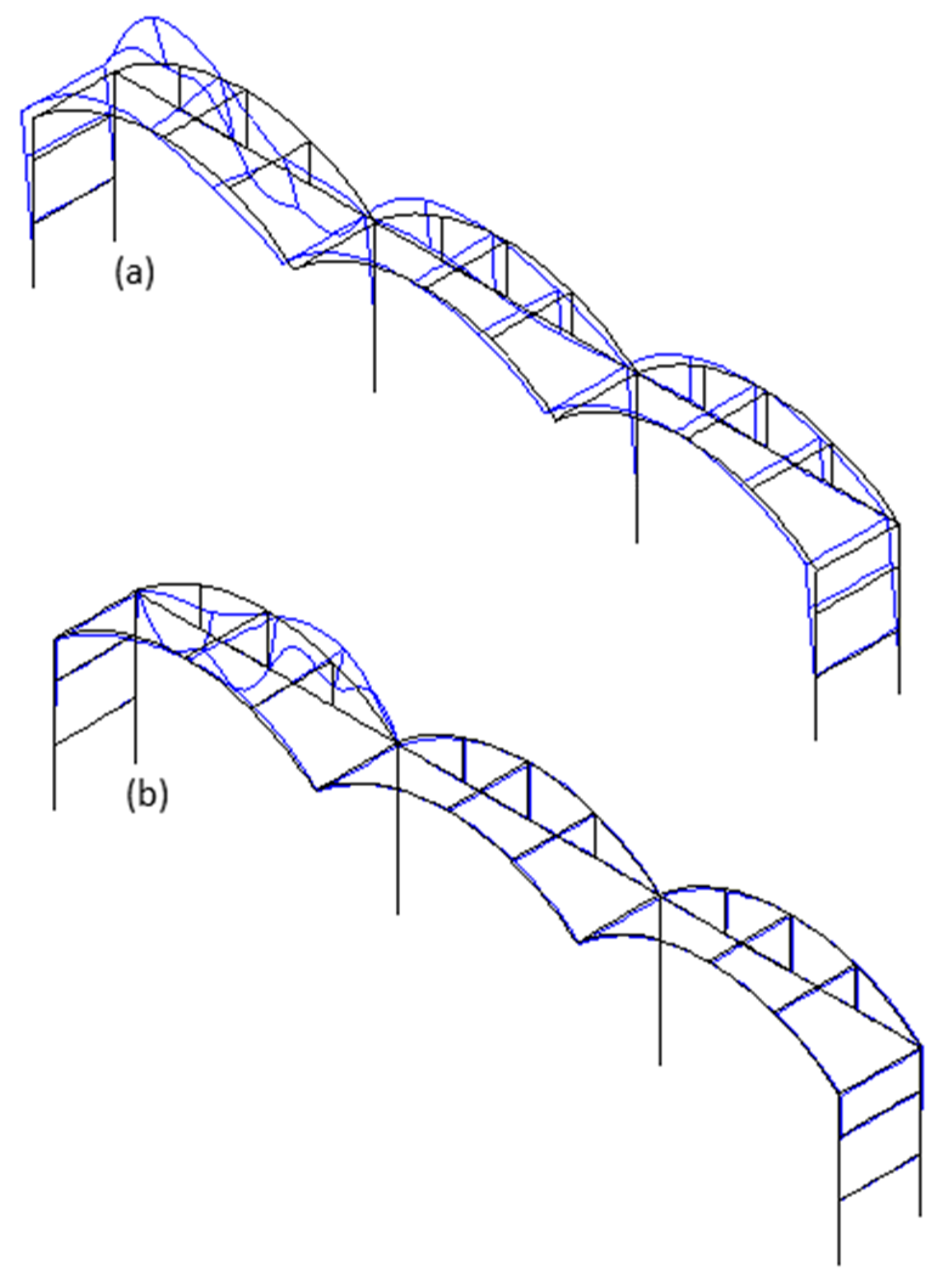

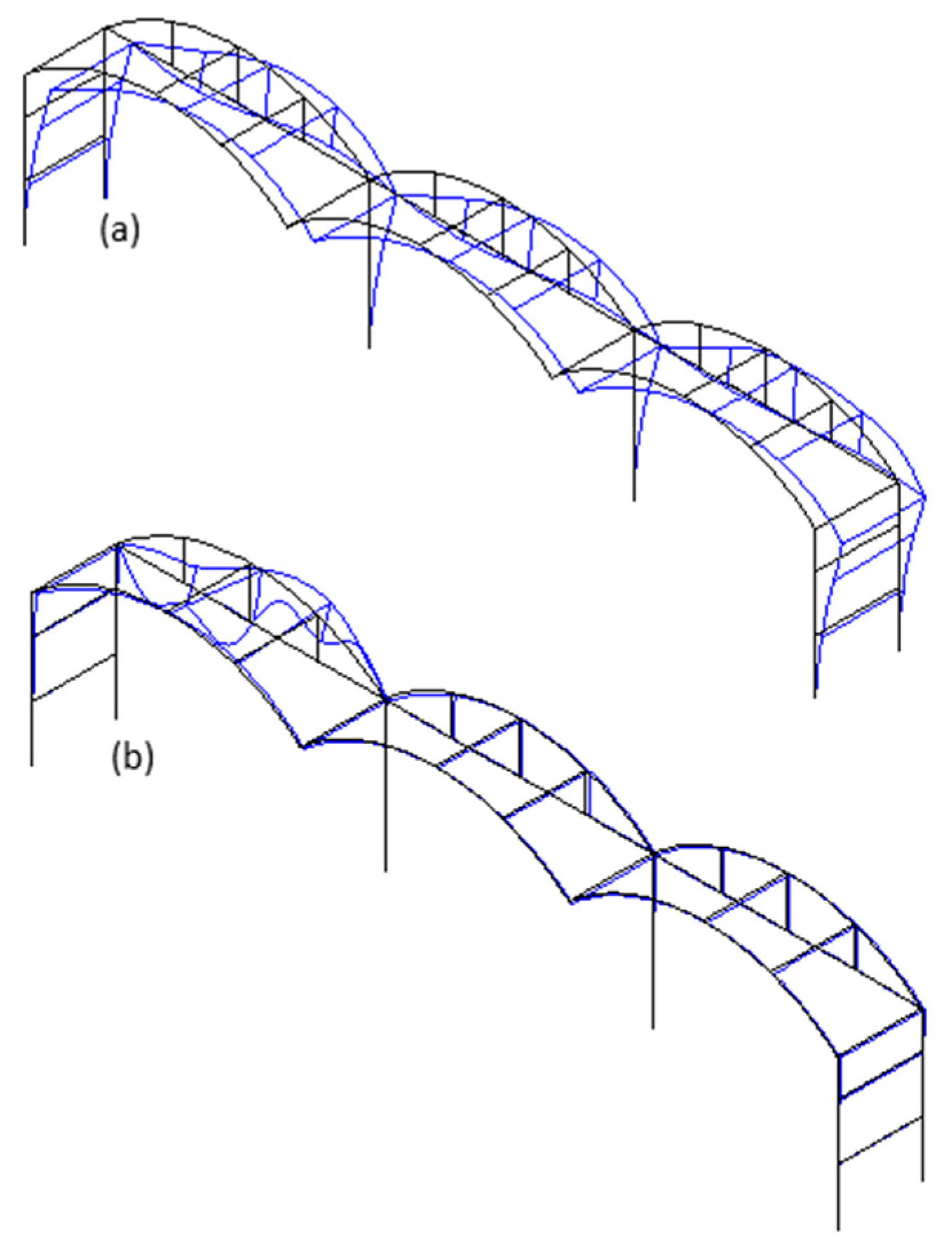

- The CFD wind load values were also employed in the structural assessment of the structure. Due to the increase in the compression axial applied to the arches and the lower chord of the windward tunnel, decreases of the λcr ranging from 31.59% to 56.90% were registered for those combinations of actions in which the 0°-CFD wind loads were involved.

- In this regard, the application of the CFD wind loads would affect the stresses and strain of the structure, but also to the calculation method required to verify the stability of the arches. Since the λcr for those load combinations did not exceed the 3.6 requirement established in EN 13031-1 [53], a second-order analysis should be performed instead of the first-order analysis required for the load combinations that only include the actions established in EN 13031-1 [53].

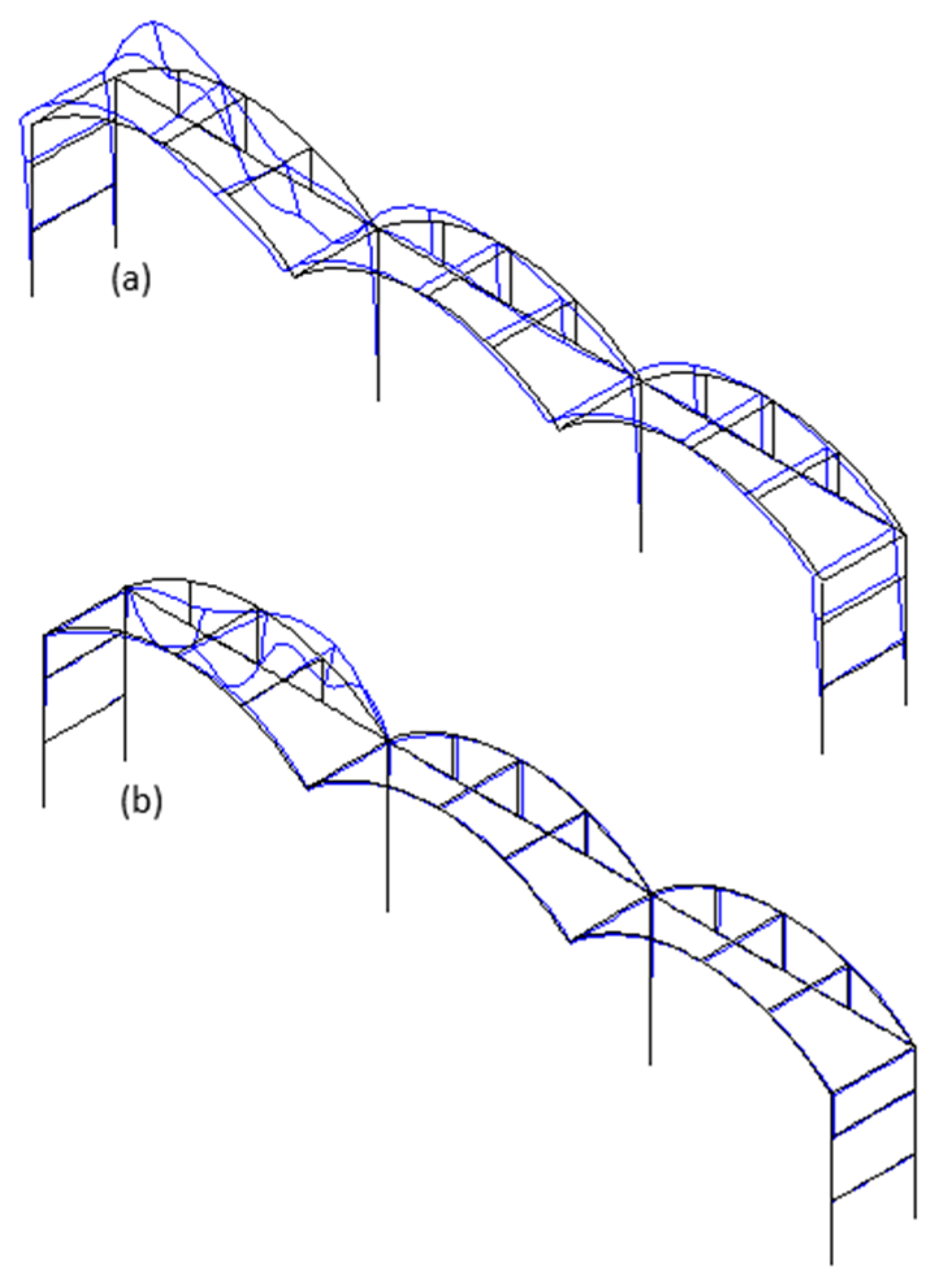

- The reported declines in the λcr due to the consideration of the CFD wind loads were responsible for global buckling modes, which were certainly closer to a typical local buckling shape. A comparison between the influence of the wind loads according to EN 13031-1 [53] and the CFD simulation was carried out for several load combinations in order to evaluate the differences in the resulting failure modes. For those combinations in which the lateral wind load was not of influence, the failure mode was described as general buckling and characterized by the generalized displacement of the top of the columns.

- Finally, a simple calculation approach (i.e., similar to the typical matrix structural analysis calculation procedure followed by any commercial structural software) was proposed for the determination of a non-superficial greenhouse foundation. Cylindrical concrete footings were simulated based on a large rigid block supported on the sides and bottom based on the Winkler model.

Author Contributions

Funding

Conflicts of Interest

References

- Eurostat European Statistics. Statistical Office of the European Communities. Available online: https://ec.europa.eu/eurostat/data/database (accessed on 9 July 2020).

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2019; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2018; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2017; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2016; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2015; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2014; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2013; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2012; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2011; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2010; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2009; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2008; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2007; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2006; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2005; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2004; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2003; p. 17. (In Spanish)

- Encuesta Sobre Superficies y Rendimientos Cultivos (ESYRCE); Spanish Ministry of Agriculture, Fisheries and Food Survey on Crops Surfaces and Yields: Madrid, Spain, 2002; p. 17. (In Spanish)

- Casas, J.J.; Bonachela, S.; Moyano, F.J.; Fenoy, E.; Hernández, J. Chapter 3—Agricultural Practices in the Mediterranean: A Case Study in Southern Spain. In The Mediterranean Diet; Preedy, V.R., Watson, R.R., Eds.; Academic Press: San Diego, CA, USA, 2015; pp. 23–36. ISBN 978-0-12-407849-9. [Google Scholar]

- Von Elsner, B.; Briassoulis, D.; Waaijenberg, D.; Mistriotis, A.; von Zabeltitz, C.; Gratraud, J.; Russo, G.; Suay-Cortes, R. Review of Structural and Functional Characteristics of Greenhouses in European Union Countries, Part II: Typical Designs. J. Agric. Eng. Res. 2000, 75, 111–126. [Google Scholar] [CrossRef]

- Von Elsner, B.; Briassoulis, D.; Waaijenberg, D.; Mistriotis, A.; von Zabeltitz, C.; Gratraud, J.; Russo, G.; Suay-Cortes, R. Review of Structural and Functional Characteristics of Greenhouses in European Union Countries: Part I, Design Requirements. J. Agric. Eng. Res. 2000, 75, 1–16. [Google Scholar] [CrossRef]

- Soriano, T.; Montero, J.I.; Sánchez-Guerrero, M.C.; Medrano, E.; Antón, A.; Hernández, J.; Morales, M.I.; Castilla, N. A Study of Direct Solar Radiation Transmission in Asymmetrical Multi-span Greenhouses using Scale Models and Simulation Models. Biosyst. Eng. 2004, 88, 243–253. [Google Scholar] [CrossRef]

- Iribarne, L.; Ayala, R.; Torres, J.A. A DPS-based system modelling method for 3D-structures simulation in manufacturing processes. Simul. Model. Pract. Theory 2009, 17, 935–954. [Google Scholar] [CrossRef]

- Chen, J.; Xu, F.; Tan, D.; Shen, Z.; Zhang, L.; Ai, Q. A control method for agricultural greenhouses heating based on computational fluid dynamics and energy prediction model. Appl. Energy 2015, 141, 106–118. [Google Scholar] [CrossRef]

- D’Arpa, S.; Colangelo, G.; Starace, G.; Petrosillo, I.; Bruno, D.E.; Uricchio, V.; Zurlini, G. Heating requirements in greenhouse farming in southern Italy: Evaluation of ground-source heat pump utilization compared to traditional heating systems. Energy Effic. 2016, 9, 1065–1085. [Google Scholar] [CrossRef]

- Dhiman, M.; Sethi, V.P.; Singh, B.; Sharma, A. CFD analysis of greenhouse heating using flue gas and hot water heat sink pipe networks. Comput. Electron. Agric. 2019, 163, 104853. [Google Scholar] [CrossRef]

- Gourdo, L.; Fatnassi, H.; Bouharroud, R.; Ezzaeri, K.; Bazgaou, A.; Wifaya, A.; Demrati, H.; Bekkaoui, A.; Aharoune, A.; Poncet, C.; et al. Heating canarian greenhouse with a passive solar water-sleeve system: Effect on microclimate and tomato crop yield. Sol. Energy 2019, 188, 1349–1359. [Google Scholar] [CrossRef]

- Bournet, P.-E.; Boulard, T. Effect of ventilator configuration on the distributed climate of greenhouses: A review of experimental and CFD studies. Comput. Electron. Agric. 2010, 74, 195–217. [Google Scholar] [CrossRef]

- Espinoza, K.; López, A.; Valera, D.L.; Molina-Aiz, F.D.; Torres, J.A.; Peña, A. Effects of ventilator configuration on the flow pattern of a naturally-ventilated three-span Mediterranean greenhouse. Biosyst. Eng. 2017, 164, 13–30. [Google Scholar] [CrossRef]

- Hong, S.-W.; Exadaktylos, V.; Lee, I.-B.; Amon, T.; Youssef, A.; Norton, T.; Berckmans, D. Validation of an open source CFD code to simulate natural ventilation for agricultural buildings. Comput. Electron. Agric. 2017, 138, 80–91. [Google Scholar] [CrossRef]

- McCartney, L.; Lefsrud, M.G. Field trials of the Natural Ventilation Augmented Cooling (NVAC) greenhouse. Biosyst. Eng. 2018, 174, 159–172. [Google Scholar] [CrossRef]

- Briassoulis, D.; Dougka, G.; Dimakogianni, D.; Vayas, I. Analysis of the collapse of a greenhouse with vaulted roof. Biosyst. Eng. 2016, 151, 495–509. [Google Scholar] [CrossRef]

- Bronkhorst, A.J.; Geurts, C.P.W.; van Bentum, C.A.; van der Knaap, L.P.M.; Pertermann, I. Wind Loads for Stability Design of Large Multi-Span Duo-Pitch Greenhouses. Front. Built Environ. 2017, 3. [Google Scholar] [CrossRef]

- Callejón, A.; Carreño, A.; Pérez, J.; Vázquez, J.; Galera, L. Structural improvements in multispan greenhouses for verification the European standard UNE-EN 13031-1. In Proceedings of the XXXIII CIOSTA-CIGR, V Conference: Technology and Management to Ensure Sustainable Agricultura, Agro-Systems, Forestry and Safety, Reggio Calabria, Italy, 17–19 June 2009; pp. 17–19. [Google Scholar]

- Carreño-Ortega, A.; Vázquez-Cabrera, J.; Pérez-Alonso, J.; Callejón-Ferre, A.J.; Sánchez, E. Análisis estructural 3D de los invernaderos multitúnel del sudeste de España. Parte 2: Elementos horizontales. In Proceedings of the VI Congreso Ibérico de AgroIngeniería, Evora, Portugal, 7–9 June 2011; p. 10. (In Spanish). [Google Scholar]

- Castellano, S.; Candura, A.; Scarascia-Mugnozza, G. Greenhouse structures SLS analysis: Experimental results and normative aspects. Acta Hortic. 2005, 701–708. [Google Scholar] [CrossRef]

- Emekli, N.Y.; Kendirli, B.; Kurunc, A. Structural analysis and functional characteristics of greenhouses in the Mediterranean region of Turkey. Afr. J. Biotechnol. 2010, 9, 3131–3139. [Google Scholar]

- Ha, T.; Kim, J.; Cho, B.-H.; Kim, D.-J.; Jung, J.-E.; Shin, S.-H.; Kim, H. Finite element model updating of multi-span greenhouses based on ambient vibration measurements. Biosyst. Eng. 2017, 161, 145–156. [Google Scholar] [CrossRef]

- Hur, D.-J.; Kwon, S. Fatigue Analysis of Greenhouse Structure under Wind Load and Self-Weight. Appl. Sci. 2017, 7, 1274. [Google Scholar] [CrossRef]

- Iribarne, L.; Torres, J.A.; Peña, A. Using computer modeling techniques to design tunnel greenhouse structures. Comput. Ind. 2007, 58, 403–415. [Google Scholar] [CrossRef]

- Kendirli, B. Structural analysis of greenhouses: A case study in Turkey. Build. Environ. 2006, 41, 864–871. [Google Scholar] [CrossRef]

- Kim, R.; Hong, S.; Lee, I.; Kwon, K. Evaluation of wind pressure acting on multi-span greenhouses using CFD technique, Part 2: Application of the CFD model. Biosyst. Eng. 2017, 164, 257–280. [Google Scholar] [CrossRef]

- Kim, R.; Lee, I.; Kwon, K. Evaluation of wind pressure acting on multi-span greenhouses using CFD technique, Part 1: Development of the CFD model. Biosyst. Eng. 2017, 164, 235–256. [Google Scholar] [CrossRef]

- Maraveas, C.; Tsavdaridis, K.D. Strengthening Techniques for Greenhouses. AgriEngineering 2020, 2, 3. [Google Scholar] [CrossRef]

- Nayak, A.; Ramana Rao, K.V. Estimation of wind load on a greenhouse and evaluation of its structural stability. Int. J. Agric. Eng. 2014, 7, 461–466. [Google Scholar] [CrossRef]

- Ren, J.; Wang, J.; Guo, S.; Li, X.; Zheng, K.; Zhao, Z. Finite element analysis of the static properties and stability of a large-span plastic greenhouse. Comput. Electron. Agric. 2019, 165, 104957. [Google Scholar] [CrossRef]

- Vázquez-Cabrera, J.; Carreño-Ortega, A.; Pérez-Alonso, J.; Callejón-Ferre, A.J.; Sánchez-Espinosa, E. Análisis estructural 3D de los invernaderos multitúnel del sudeste de España. Parte 1: Elementos verticales. In Proceedings of the VI Congreso Ibérico de AgroIngeniería, Evora, Portugal, 7–9 June 2011; p. 10. (In Spanish). [Google Scholar]

- Maraveas, C. Wind Pressure Coefficients on Greenhouse Structures. Agriculture 2020, 10, 149. [Google Scholar] [CrossRef]

- Peña, A.; Pérez, F.; Valera, D.L.; Ayuso, J.; Pérez, J. Assessment of response of greenhouse foundations to traction, and their simulation using finite elements. Inf. Construcción 2002, 53. [Google Scholar] [CrossRef][Green Version]

- Briassoulis, D.; Waaijenberg, D.; Gratraud, J.; von Elsner, B. Mechanical Properties of Covering Materials for Greenhouses Part 2: Quality Assessment. J. Agric. Eng. Res. 1997, 67, 171–217. [Google Scholar] [CrossRef]

- Grafiadellis, M. Greenhouse structures in Mediterranean regions: Problems and trends. In Protected Cultivation in the Mediterranean Region; Choukr-Allah, R., Ed.; Cahiers Options Méditerranéennes; CIHEAN: Paris, France, 1999. [Google Scholar]

- EN 13031-1 Greenhouses—Design and Construction—Part 1: Commercial Production Greenhouses; CEN: Belgium, Brussels, 2001.

- Kwon, K.; Kim, D.; Kim, R.; Ha, T.; Lee, I. Evaluation of wind pressure coefficients of single-span greenhouses built on reclaimed coastal land using a large-sized wind tunnel. Biosyst. Eng. 2016, 141, 58–81. [Google Scholar] [CrossRef]

- Mistriotis, A.; Briassoulis, D. Numerical estimation of the internal and external aerodynamic coefficients of a tunnel greenhouse structure with openings. Comput. Electron. Agric. 2002, 34, 191–205. [Google Scholar] [CrossRef]

- Robertson, A.P.; Roux, P.; Gratraud, J.; Scarascia, G.; Castellano, S.; Dufresne de Virel, M.; Palier, P. Wind pressures on permeably and impermeably-clad structures. J. Wind Eng. Ind. Aerodyn. 2002, 90, 461–474. [Google Scholar] [CrossRef]

- EN 1991-1-4+A1 Eurocode 1: Actions on Structures—Part 4: Wind Actions; CEN: Brussels, Belgium, 2010.

- Fernández Sierra, C.; Pérez-Parra, J.J. Caracterización de los Invernaderos de la Provincia de Almería; Cajamar Editorial: Almería, Spain, 2004. (In Spanish) [Google Scholar]

- Kravanja, S.; Turkalj, G.; Šilih, S.; Žula, T. Optimal design of single-story steel building structures based on parametric MINLP optimization. J. Constr. Steel Res. 2013, 81, 86–103. [Google Scholar] [CrossRef]

- Kravanja, S.; Žula, T. Cost optimization of industrial steel building structures. Adv. Eng. Softw. 2010, 41, 442–450. [Google Scholar] [CrossRef]

- McKinstray, R.; Lim, J.B.P.; Tanyimboh, T.T.; Phan, D.T.; Sha, W. Comparison of optimal designs of steel portal frames including topological asymmetry considering rolled, fabricated and tapered sections. Eng. Struct. 2016, 111, 505–524. [Google Scholar] [CrossRef]

- McKinstray, R.; Lim, J.B.P.; Tanyimboh, T.T.; Phan, D.T.; Sha, W. Optimal design of long-span steel portal frames using fabricated beams. J. Constr. Steel Res. 2015, 104, 104–114. [Google Scholar] [CrossRef]

- Villar-García, J.R.; Vidal-López, P.; Rodríguez-Robles, D.; Guaita, M. Cost optimisation of glued laminated timber roof structures using genetic algorithms. Biosyst. Eng. 2019, 187, 258–277. [Google Scholar] [CrossRef]

- ANSYS® Academic Research; ANSYS Inc.: Canonsburg, PA, USA, 2018.

- Roux, P.; Motro, R. Etude du comportement global d’arcs monotubulaires: Pathologie des serres tunnels sous l’effet de la neige. Rev. Constr. Métallique 1993, 1, 23–39. (In French) [Google Scholar]

- Roux, P.; Robertson, A.; Motro, R. The design of slender monotubular steel arches. Struct. Eng. 1997, 75, 143–151. [Google Scholar]

- Roux, P.; Lezeau, S.; Motro, R. Evaluation de la résistance d’un arceau de serre tunnel: Incidence du modèle de comportement des tubes. Rev. Constr. Métallique 1995, 4, 53–62. (In French) [Google Scholar]

- Simões da Silva, L.; Simões, R.; Gervásio, H. Design of Steel Structures. Eurocode 3: Design of Steel Structures. Part. 1-1—General Rules and Rules for Buildings; Eurocode Design Manuals; ECCS—European Convention for Constructional Steelwork: Brussels, Belgium, 2016. [Google Scholar]

- UNE 76209. In Wind Actions in Greenhouses for Comercial Production; AENOR: Madrid, Spain, 2002.

- UNE 76210. In Snow Actions in Greenhouses for Comercial Production; AENOR: Madrid, Spain, 2006.

- Vidal-López, P. Study of the Natural Ventilation and Transpiration in Greenhouses with CFD; INRA: Sophia Antipolis, France, 2009. [Google Scholar]

- Vidal-López, P.; Martínez-Alvarez, V.; Gallego-Elvira, B.; Martín-Górriz, B. Determination of synthetic wind functions for estimating open water evaporation with Computational Fluid Dynamics. Hydrol. Process. 2012, 26, 3945–3952. [Google Scholar] [CrossRef]

- Boulard, T.; Roy, J.C.; Fatnassi, H.; Kichah, A.; Lee, I.-B. Computer fluid dynamics prediction of climate and fungal spore transfer in a rose greenhouse. Comput. Electron. Agric. 2010, 74, 280–292. [Google Scholar] [CrossRef]

- Fatnassi, H.; Boulard, T.; Bouirden, L. Simulation of climatic conditions in full-scale greenhouse fitted with insect-proof screens. Agric. For. Meteorol. 2003, 118, 97–111. [Google Scholar] [CrossRef]

- Nebbali, R.; Roy, J.C.; Boulard, T. Dynamic simulation of the distributed radiative and convective climate within a cropped greenhouse. Renew. Energy 2012, 43, 111–129. [Google Scholar] [CrossRef]

- Ould Khaoua, S.A.; Bournet, P.E.; Migeon, C.; Boulard, T.; Chassériaux, G. Analysis of Greenhouse Ventilation Efficiency based on Computational Fluid Dynamics. Biosyst. Eng. 2006, 95, 83–98. [Google Scholar] [CrossRef]

- Xing, F.; Mohotti, D.; Chauhan, K. Study on localised wind pressure development in gable roof buildings having different roof pitches with experiments, RANS and LES simulation models. Build. Environ. 2018, 143, 240–257. [Google Scholar] [CrossRef]

- Ansys Fluent; ANSYS: Canonsburg, PA, USA, 2012.

- Matlab; MathWorks: Natick, MA, USA, 2019.

- Gerolymos, N.; Gazetas, G. Winkler model for lateral response of rigid caisson foundations in linear soil. Soil Dyn. Earthq. Eng. 2006, 26, 347–361. [Google Scholar] [CrossRef]

- Gerolymos, N.; Gazetas, G. Development of Winkler model for static and dynamic response of caisson foundations with soil and interface nonlinearities. Soil Dyn. Earthq. Eng. 2006, 26, 363–376. [Google Scholar] [CrossRef]

- Karapiperis, K.; Gerolymos, N. Combined loading of caisson foundations in cohesive soil: Finite element versus Winkler modeling. Comput. Geotech. 2014, 56, 100–120. [Google Scholar] [CrossRef]

- Fernández-García, M.S. Optimización de Estructuras de Invernadero Por Algoritmos Genéticos. Ph.D. Thesis, Universidad de Extremadura, Badajoz, Spain, 2014. (In Spanish). [Google Scholar]

- Vidal, P.; Gallego, E.; Guaita, M.; Ayuga, F. Finite element analysis under different boundary conditions of the filling of cylindrical steel silos having an eccentric hopper. J. Constr. Steel Res. 2008, 64, 480–492. [Google Scholar] [CrossRef]

- Vidal, P.; Gallego, E.; Guaita, M.; Ayuga, F. Simulation of the filling pressures of cylindrical steel silos with concentric and eccentric hoppers using 3-dimensional finite element models. Trans. ASABE 2006, 49, 1881–1895. [Google Scholar] [CrossRef]

- Blackmore, P.A.; Tsokri, E. Wind loads on curved roofs. J. Wind Eng. Ind. Aerodyn. 2006, 94, 833–844. [Google Scholar] [CrossRef]

- Lin, S. Simulation of osmotic pressure acting on planes of dam foundation and structure in FEM. J. Yangtze River Sci. Res. Inst. 1993, 10, 50–53. [Google Scholar]

- Yamin, M.M.; Ashteyat, A.M.; Al-Mohd, I.; Mahmoud, E. Numerical study of contact stresses under foundations resting on cohesionless soil: Effects of foundation rigidity and applied stress level. KSCE J. Civ. Eng. 2017, 21, 1107–1114. [Google Scholar] [CrossRef]

| Wind Direction | Part of the Greenhouse | Angle (°) | External Pressure Coefficient (cpe) | Load (kN·m−2) |

|---|---|---|---|---|

| 0° | First tunnel | 0–55 | 0.30 | 0.204 |

| 55–70 | −1.00 | −0.679 | ||

| 70–115 | −1.00 | −0.679 | ||

| 115–gutter | −0.40 | −0.271 | ||

| Second tunnel | 0–80 | −0.20 | −0.136 | |

| 80–100 | −0.90 | −0.612 | ||

| 100–gutter | −0.30 | −0.204 | ||

| Third tunnel | 0–80 | −0.12 | −0.082 | |

| 80–100 | −0.54 | −0.367 | ||

| 100–gutter | −0.18 | −0.122 | ||

| Left wall | - | 0.60 | 0.408 | |

| Right wall | - | −0.50 | −0.369 | |

| 90° | All | - | −0.20 | −0.136 |

| Load Combination | |||||

|---|---|---|---|---|---|

| 1 | 1.2 · Permanent load | + | 1.2 · 0° wind load | + | 1.2 · 1 · crop load |

| 2 | 1 · Permanent load | + | 1.2 · 0° wind load | + | 1.2 · 1 · crop load |

| 3 | 1.2 · Permanent load | + | 1.2 · 90° wind load | + | 1.2 · 1 · crop load |

| 4 | 1 · Permanent load | + | 1.2 · 90° wind load | + | 1.2 · 1 · crop load |

| 5 | 1.2 · Permanent load | + | 1.2 · 1 · crop load | ||

| 6 | 1 · Permanent load | + | 1.2 · 1 · crop load | ||

| 7 | 1.2 · Permanent load | + | 1.2 · 0.6 · 0° wind load | + | 1.2 · 1 · crop load |

| 8 | 1 · Permanent load | + | 1.2 · 0.6 · 0° wind load | + | 1.2 · 1 · crop load |

| 9 | 1.2 · Permanent load | + | 1.2 · 0.6 · 90° wind load | + | 1.2 · 1 · crop load |

| 10 | 1 · Permanent load | + | 1.2 · 0.6 · 90° wind load | + | 1.2 · 1 · crop load |

| 11 | 1.2 · Permanent load | + | 1.2 · 0° wind load | ||

| 12 | 1 · Permanent load | + | 1.2 · 0° wind load | ||

| 13 | 1.2 · Permanent load | + | 1.2 · 90° wind load | ||

| 14 | 1 · Permanent load | + | 1.2 · 90° wind load | ||

| 15 | 1.2 · Permanent load | + | 1.2 · 1 · crop load | + | 1.2 · concentrated vertical action |

| 16 | 1 · Permanent load | + | 1.2 · 1 · crop load | + | 1.2 · concentrated vertical action |

| 17 | 1.2 · Permanent load | ||||

| 18 | 1 · Permanent load | ||||

| 19 | 1.2 · Permanent load | + | 1.2 · 1 · crop load | + | 0.8 · accidental snow load |

| 20 | 1 · Permanent load | + | 1.2 · 1 · crop load | + | 0.8 · accidental snow load |

| Wind Direction | Part of the Greenhouse | Angle (°) | External Pressure Coefficient (cpe) | Load (kN·m−2) |

|---|---|---|---|---|

| 0° | First tunnel | 0–55 | −1.20 | −0.747 |

| 55–70 | −1.30 | −0.883 | ||

| 70–115 | −1.30 | −0.883 | ||

| 115–gutter | −0.90 | −0.611 | ||

| Second tunnel | 0–80 | −0.50 | −0.340 | |

| 80–100 | −0.80 | −0.543 | ||

| 100–gutter | −0.60 | −0.407 | ||

| Third tunnel | 0–80 | −0.60 | −0.407 | |

| 80–100 | −1.00 | −0.679 | ||

| 100–gutter | −0.80 | −0.543 | ||

| Left wall | - | 0.40 | 0.272 | |

| Right wall | - | −0.50 | −0.340 |

| Load Combination | λcr | Buckling Mode Shape |

|---|---|---|

| 1 | 8.12 | First arch, up-down displacement |

| 1CFD | 3.5 | First arch, down-up displacement |

| 2 | 7.94 | First arch, up-down displacement |

| 2CFD | 3.46 | First arch, down-up displacement |

| 3 | 18.6 | General |

| 4 | 20.1 | General |

| 5 | 6.34 | General |

| 6 | 6.56 | General |

| 7 | 11.87 | General |

| 7CFD | 8.12 | First arch, down-up displacement |

| 8 | 12.52 | General |

| 8CFD | 7.91 | First arch, down-up displacement |

| 9 | 10.83 | General |

| 10 | 11.46 | General |

| 11 | 4.63 | First arch, down-up displacement |

| 11CFD | 2.59 | First arch, down-up displacement |

| 12 | 4.56 | First arch, down-up displacement |

| 12CFD | 2.56 | First arch, down-up displacement |

| 13 | 26.88 | Almost local, central arch |

| 14 | 26.14 | Almost local, first arch |

| 15 | 5.8 | General |

| 16 | 5.99 | General |

| 17 | 30.55 | General |

| 18 | 36.66 | General |

| 19 | 3.79 | General |

| 20 | 3.86 | General |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-García, M.S.; Vidal-López, P.; Rodríguez-Robles, D.; Villar-García, J.R.; Agujetas, R. Numerical Simulation of Multi-Span Greenhouse Structures. Agriculture 2020, 10, 499. https://doi.org/10.3390/agriculture10110499

Fernández-García MS, Vidal-López P, Rodríguez-Robles D, Villar-García JR, Agujetas R. Numerical Simulation of Multi-Span Greenhouse Structures. Agriculture. 2020; 10(11):499. https://doi.org/10.3390/agriculture10110499

Chicago/Turabian StyleFernández-García, María S., Pablo Vidal-López, Desirée Rodríguez-Robles, José R. Villar-García, and Rafael Agujetas. 2020. "Numerical Simulation of Multi-Span Greenhouse Structures" Agriculture 10, no. 11: 499. https://doi.org/10.3390/agriculture10110499

APA StyleFernández-García, M. S., Vidal-López, P., Rodríguez-Robles, D., Villar-García, J. R., & Agujetas, R. (2020). Numerical Simulation of Multi-Span Greenhouse Structures. Agriculture, 10(11), 499. https://doi.org/10.3390/agriculture10110499