Experimental Study of Disc Fertilizer Spreader Performance

Abstract

1. Introduction

2. Materials and Methods

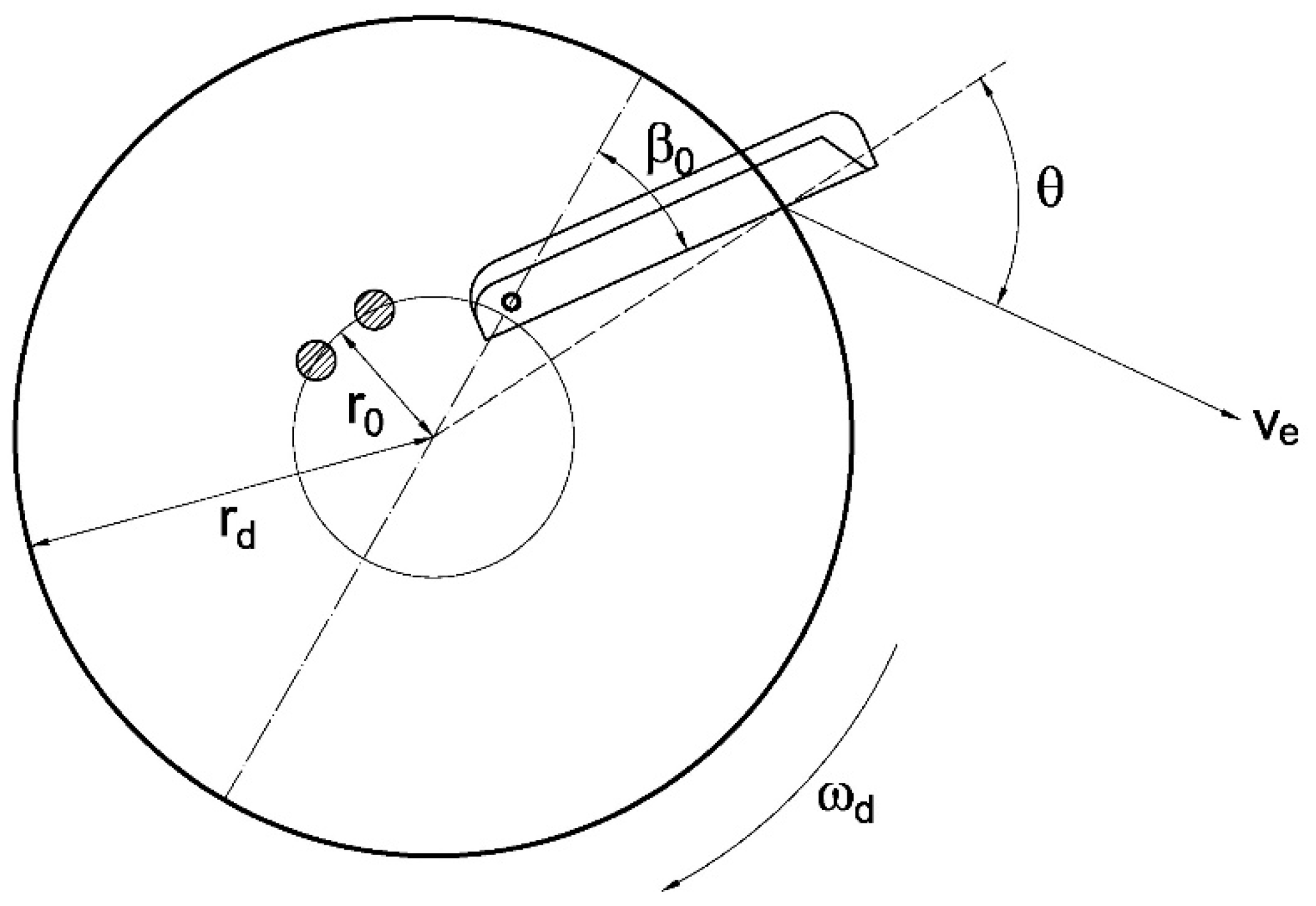

2.1. Theoretical Considerations

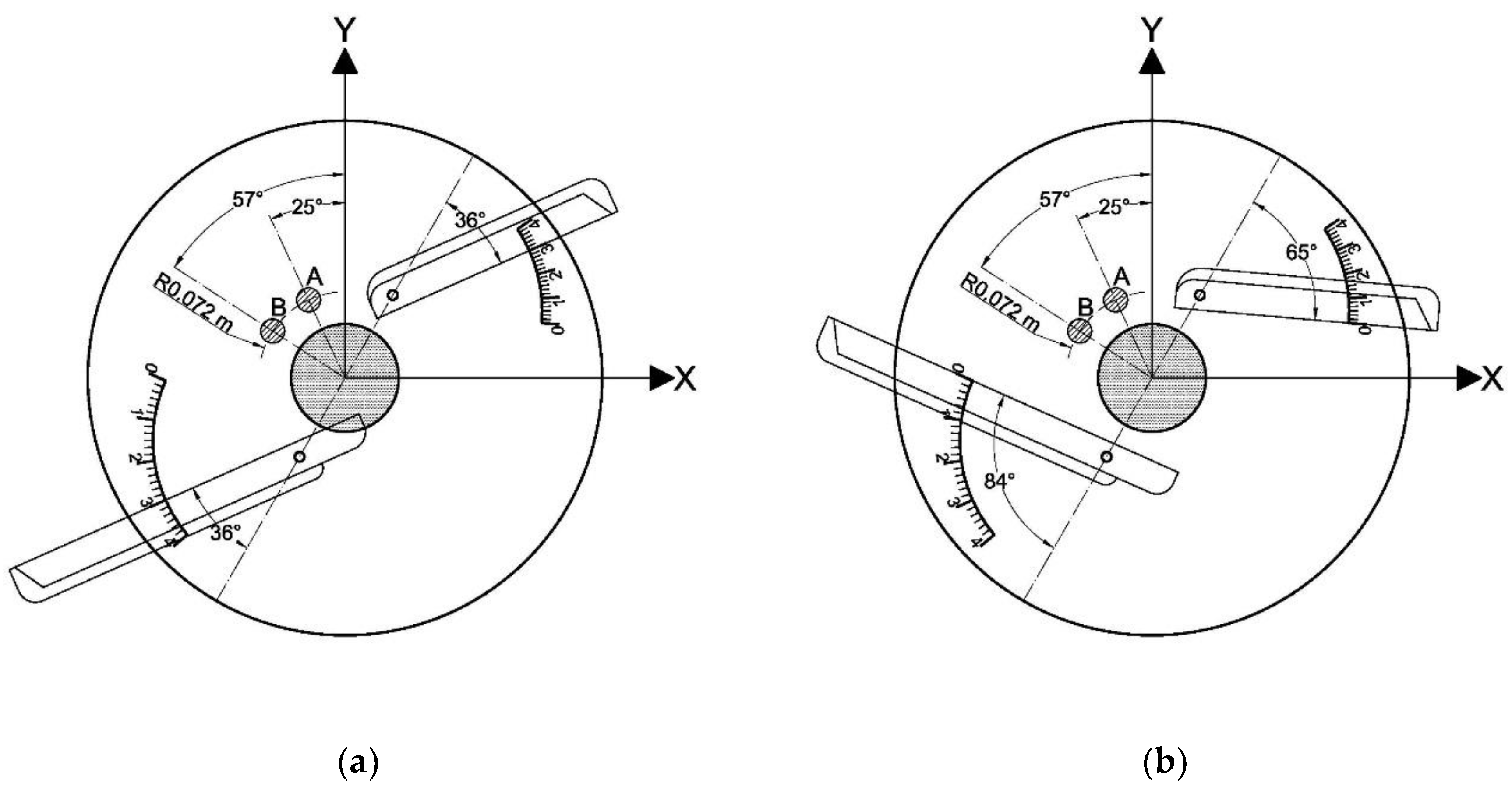

2.2. Esperimental Tests

- n: number of testing field rows;

- m: number of testing field columns;

- : mass of fertilizer collected by tray at row i column j of testing field, kg;

- : distance between center of tray at row i column j of the testing field and center of disc, m.

- : m-th result of calculations of the mean fertilizer spread radius for the i-th fertilizer, the j-th angular velocity of disc, the k-th point of fertilizer feed onto the disc and the l-th vane configuration, m;

- μ: general average of the population of fertilizer spread radius measurements, m;

- FT: main effect of the i-th fertilizer;

- DS: main effect of the j-th angular velocity of the disc;

- FP: main effect of the k-th fertilizer feed point on the disc;

- VC: main effect of the l-th vane configuration on the disc;

- Ij: interaction effect of the i-th fertilizer with the j-th angular velocity of the disc;

- ik: interaction effect of the i-th fertilizer with the k-th fertilizer feed point;

- il: interaction effect of the i-th fertilizer with the l-th vane configuration;

- jk: interaction effect of the j-th angular velocity of the disc with the k-th fertilizer feed point;

- jl: interaction effect of the j-th angular velocity of the disc with the l-th vane configuration;

- kl: interaction effect of the k-th fertilizer feed point with the l-th vane configuration;

- : random experimental error, m.

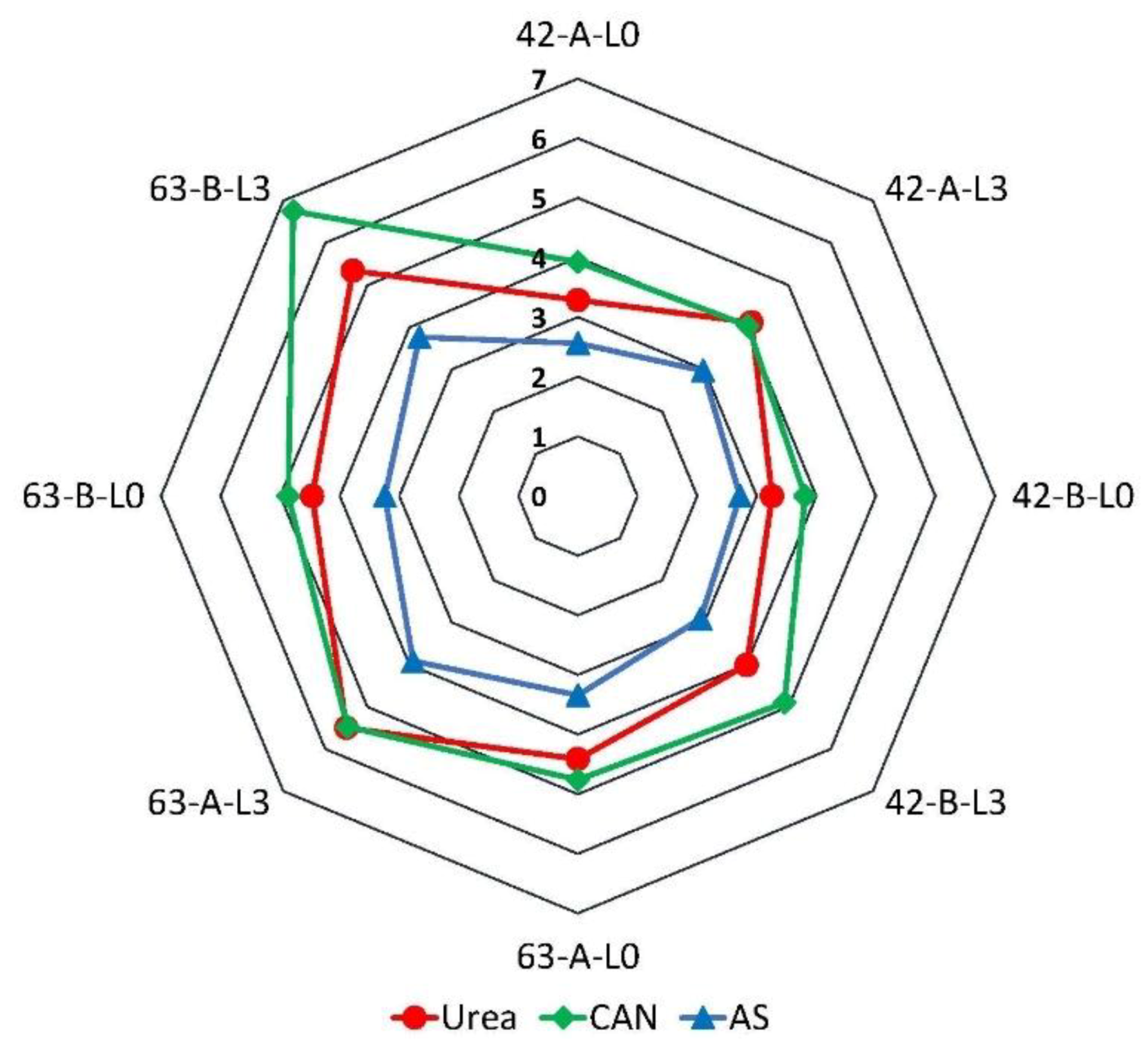

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sobczak, P.; Mazur, J.; Zawiślak, K.; Panasiewicz, M.; Żukiewicz-Sobczak, W.; Królczyk, J.; Lechowski, J. Evaluation of dust concentration during grinding grain in sustainable agriculture. Sustainability 2019, 11, 4572. [Google Scholar] [CrossRef]

- Żukiewicz-Sobczak, W.; Sobczak, P.; Rogóż, A.; Wojtyła-Buciora, P.; Kozak, M.; Zagórski, J. Evaluation of the content of selected elements in herbs cultivated in organic farms in the Lublin region. In Proceedings of the Farm Machinery and Processes Management in Sustainable Agriculture, Lublin, Poland, 22–24 November 2017; pp. 461–464. [Google Scholar] [CrossRef]

- Kachel-Jakubowska, M.; Matwijczuk, A.; Gagoś, M. Analysis of the physicochemical properties of post-manufacturing waste derived from production of methyl esters from rapeseed oil. Int. Agrophys. 2017, 31, 175–182. [Google Scholar] [CrossRef]

- Kachel, M.; Matwijczuk, A.; Sujak, A.; Czernel, G.; Niemczynowicz, A.; Nowicka, A. The influence of copper and silver nanocolloids on the quality of pressed spring rapeseed oil. Agronomy 2019, 9, 643. [Google Scholar] [CrossRef]

- Blicharz-Kania, A.; Pecyna, A.; Krajewska, M.; Andrejko, D.; Szmigielski, M.; Zawiślak, K.; Sobczak, P.; Berbec, A. Chemical properties of tobacco seed oil. Przem. Chem. 2018, 97, 1906–1909. [Google Scholar] [CrossRef]

- Kozak-Kalita, M.; Sobczak, P.; Zawiślak, K.; Mazur, J.; Panasiewicz, M.; Żukiewicz-Sobczak, W. Influence of UV-C radiation on the microbiological purity in selected species of herbs. Health Probl. Civiliz. 2018, 12, 285–290. [Google Scholar] [CrossRef]

- Przywara, A.; Kachel, M.; Koszel, M.; Leszczyński, N.; Kraszkiewicz, A.; Anifantis, A.S. The influence of digestate on the static strength of spring rapeseeds (Brassica napus var. arvensis). Sustainability 2019, 11, 2133. [Google Scholar] [CrossRef]

- Guerrieri, A.S.; Anifantis, A.S.; Santoro, F.; Pascuzzi, S. Study of a large square baler with innovative technological systems that optimize the baling effectiveness. Agriculture 2019, 9, 86. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.; Kachel, M.; Parafiniuk, S.; Zając, G.; Niedziółka, I.; Sprawka, M. Assessment of the possibility of using hemp biomass (Cannabis sativa L.) for energy purposes: A case study. Appl. Sci. Basel 2019, 9, 4437. [Google Scholar] [CrossRef]

- Rajabi Hamedani, S.; Villarini, M.; Colantoni, A.; Carlini, M.; Cecchini, M.; Santoro, F.; Pantaleo, A. Environmental and economic analysis of an anaerobic co-digestion power plant integrated with a compost plant. Energies 2020, 13, 2724. [Google Scholar] [CrossRef]

- Pantaleo, A.; Villarini, M.; Colantoni, A.; Carlini, M.; Santoro, F.; Rajabi Hamedani, S. Techno-economic modeling of biomass pellet routes: Feasibility in Italy. Energies 2020, 13, 1636. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Anifantis, A.S.; Santoro, F. Oscillations analysis of front-mounted beet topper machine for biomass harvesting. Energies 2019, 12, 2774. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Ivanovs, S.; Santoro, F.; Anifantis, A.S.; Ihnatiev, I. Performance assessment of front-mounted beet topper machine for biomass harvesting. Energies 2020, 3, 3524. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Bulgakov, V.; Santoro, F.; Anifantis, A.S.; Ivanovs, S.; Holovach, I. A study on the drift of spray droplets dipped in airflows with different directions. Sustainability 2020, 12, 4644. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Santoro, F.; Manetto, G.; Cerruto, E. Study of the correlation between foliar and patternator deposits in a “Tendone” vineyard. Agric. Eng. Int. CIGR J. 2018, 20, 97–107. [Google Scholar]

- Santoro, F.; Anifantis, A.S.; Ruggiero, G.; Zavadskiy, V.; Pascuzzi, S. Lightning protection systems suitable for stables: a case study. Agriculture 2019, 9, 72. [Google Scholar] [CrossRef]

- Przywara, A. The impact of structural and operational parameters of the centrifugal disc spreader on the spatial distribution of fertilizer. Agric. Agric. Sci. Procedia 2015, 7, 215–222. [Google Scholar] [CrossRef]

- Dintwa, E.; Tijskens, E.; Olieslagers, R.; De Baerdemaeker, J.; Ramon, H. Calibration of a spinning disc spreader simulation model for accurate site-specific fertiliser Application. Biosyst. Eng. 2004, 88, 49–62. [Google Scholar] [CrossRef]

- Anifantis, A.S.; Camposeo, S.; Vivaldi, G.A.; Santoro, F.; Pascuzzi, S. Comparison of UAV photogrammetry and 3D modeling techniques with other currently used methods for estimation of the tree row volume of a super-high-density olive orchard. Agriculture 2019, 9, 233. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Santoro, F.; Anifantis, A.S. Mathematical model of the plane-parallel movement of the self-propelled root-harvesting machine. Sustainability 2018, 10, 3614. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Nadykto, V.; Ivanovs, S. A mathematical model of the plane-parallel movement of an asymmetric machine-and-tractor aggregate. Agriculture 2018, 8, 151. [Google Scholar] [CrossRef]

- Abbou-ou-Cherif, E.M.; Piron, E.; Chateauneuf, A.; Vilette, S. On-the-field simulation of fertilizer spreading: Part 3—Control of disk inclination for uniform application on undulating fields. Comput. Electron. Agric. 2019, 158, 150–158. [Google Scholar] [CrossRef]

- Grift, T.E.; Kweon, G. Development of a Uniformity Controlled Granular Fertilizer Spreader; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006; pp. 1–14. [Google Scholar]

- Koko, J.; Virin, T. Optimization of a fertilizer spreading process. Math. Comput. Simul. 2009, 79, 3099–3109. [Google Scholar] [CrossRef]

- Hofstee, J.W.; Speelman, L.; Scheufler, B. 1.4-Fertilizer Distributors. In CIGR Handbook of Agricultural Engineering; The International Commission of Agricultural Engineering, Stout, B.A., Cheze, B., Eds.; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1999; Volume III, pp. 240–268. [Google Scholar]

- EN 13739-2:2011 European Standard. Agricultural Machinery—Solid Fertilizer Broadcasters and Full Width Distributors—Environmental Protection—Part 2: Test Methods; CEN: Bruxselles, Belgium, 2011. [Google Scholar]

- Kleinman, K.; Horton, N.J. SAS and R. Data Management, Statistical Analysis, and Graphics; CRR Press-Taylor & Francis Group: Boca Raton, FL, USA, 2010. [Google Scholar]

- Hofstee, J.W.; Huisman, W. Handling and spreading of fertilizers: Part 1, Physical properties of fertilizer in relation to particle motion. J. Agric. Eng. Res. 1990, 62, 9–24. [Google Scholar] [CrossRef]

| Property | Fertilizer | ||

|---|---|---|---|

| Urea | CAN | AS | |

| Bulk density (loose), | 758 | 1029 | 1018 |

| Bulk density (sieved), | 789 | 1062 | 1104 |

| Specific density, | 1340 | 1800 | 1780 |

| Mass powdery fraction , % | 10.350 | 0.030 | 52.500 |

| Median diameter , | 0.830 | 2.100 | 0.490 |

| Variation | DoF | Sum of Squares | Mean of Squares | F Function Value | Pr > F |

|---|---|---|---|---|---|

| Model | 14 | 123.82 | 8.84 | 783.26 | <0.0001 |

| Error | 57 | 0.64 | 0.01 | ||

| Total | 71 | 124.46 | |||

| Average mean radius of fertilizer spread = 4.10 m | |||||

| Standard Estimation Error = 0.103 m | |||||

| Coefficient of Variation = 0.0248 | |||||

| FT | 2 | 63.44 | 31.72 | 2809.03 | <0.0001 |

| DS | 1 | 34.24 | 34.24 | 3032.2 | <0.0001 |

| FP | 1 | 0.01 | 0.01 | 0.94 | 0.337 |

| VC | 1 | 15.92 | 15.92 | 1409.65 | <0.0001 |

| FT × DS | 2 | 6.16 | 3.08 | 272.55 | <0.0001 |

| FT × FP | 2 | 0.05 | 0.025 | 2.16 | 0.1241 |

| FT × VC | 2 | 3.02 | 1.51 | 133.76 | <0.0001 |

| DS × FP | 1 | 0.05 | 0.05 | 4.21 | 0.0448 |

| DS × VC | 1 | 0.89 | 0.89 | 79.54 | <0.0001 |

| FP × VC | 1 | 0.05 | 0.05 | 4.12 | 0.0471 |

| Compared Averages for | Average Value | Number of Observations | Mean Square Error | Limit Value (α = 0.05) | Least Significant Difference |

|---|---|---|---|---|---|

| Fertilizer type (FT): Urea | 4.23 | 24 | 0.011 | 3.40 | 0.074 |

| Fertilizer type (FT): CAN | 5.45 | 24 | 0.011 | 3.40 | |

| Fertilizer type (FT): AS | 3.15 | 24 | 0.011 | 3.40 | |

| angular velocity of disc (DS): 42 | 3.59 | 36 | 0.011 | 2.83 | 0.05 |

| angular velocity of disc (DS): 63 | 4.97 | 36 | 0.011 | 2.83 | |

| Fertilizer feed point (FP): A | 4.26 | 36 | 0.011 | 2.83 | 0.05 |

| Fertilizer feed point (FP): B | 4.29 | 36 | 0.011 | 2.83 | |

| Vane configuration (VC): L0 | 3.81 | 36 | 0.011 | 2.83 | 1.86 |

| Vane configuration (VC): L3 | 4.75 | 36 | 0.011 | 2.83 |

| Variation | Parameter | SE | F Function Value | Pr > F | Partial Correlations |

|---|---|---|---|---|---|

| Constant | 0.80798 | 0.47985 | 2.84 | 0.0969 | - |

| VC | −0.03483 | 0.00352 | 98.1 | <0.0001 | 0.12789 |

| DS | 0.00690 | 0.00047 | 211.01 | <0.0001 | 0.31543 |

| SD | 1.65821 | 0.23382 | 50.29 | <0.0001 | 0.00421 |

| DF | −0.04357 | 0.00221 | 389.04 | <0.0001 | 0.85308 |

| Variation | DoF | Sum of Squares | Mean of Squares | F Function Value | Pr > F |

|---|---|---|---|---|---|

| Model | 4 | 113.59512 | 28.39878 | 175.02 | <0.0001 |

| Error | 67 | 10.87144 | 0.16226 | ||

| Total | 71 | 124.46656 | |||

| Coefficient of Variation = 0.0942 | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Przywara, A.; Santoro, F.; Kraszkiewicz, A.; Pecyna, A.; Pascuzzi, S. Experimental Study of Disc Fertilizer Spreader Performance. Agriculture 2020, 10, 467. https://doi.org/10.3390/agriculture10100467

Przywara A, Santoro F, Kraszkiewicz A, Pecyna A, Pascuzzi S. Experimental Study of Disc Fertilizer Spreader Performance. Agriculture. 2020; 10(10):467. https://doi.org/10.3390/agriculture10100467

Chicago/Turabian StylePrzywara, Artur, Francesco Santoro, Artur Kraszkiewicz, Anna Pecyna, and Simone Pascuzzi. 2020. "Experimental Study of Disc Fertilizer Spreader Performance" Agriculture 10, no. 10: 467. https://doi.org/10.3390/agriculture10100467

APA StylePrzywara, A., Santoro, F., Kraszkiewicz, A., Pecyna, A., & Pascuzzi, S. (2020). Experimental Study of Disc Fertilizer Spreader Performance. Agriculture, 10(10), 467. https://doi.org/10.3390/agriculture10100467