The Effects of Liquid Disinfection and Heat Sterilization Processes on Implant Drill Roughness: Energy Dispersion X-ray Microanalysis and Infrared Thermography

Abstract

1. Introduction

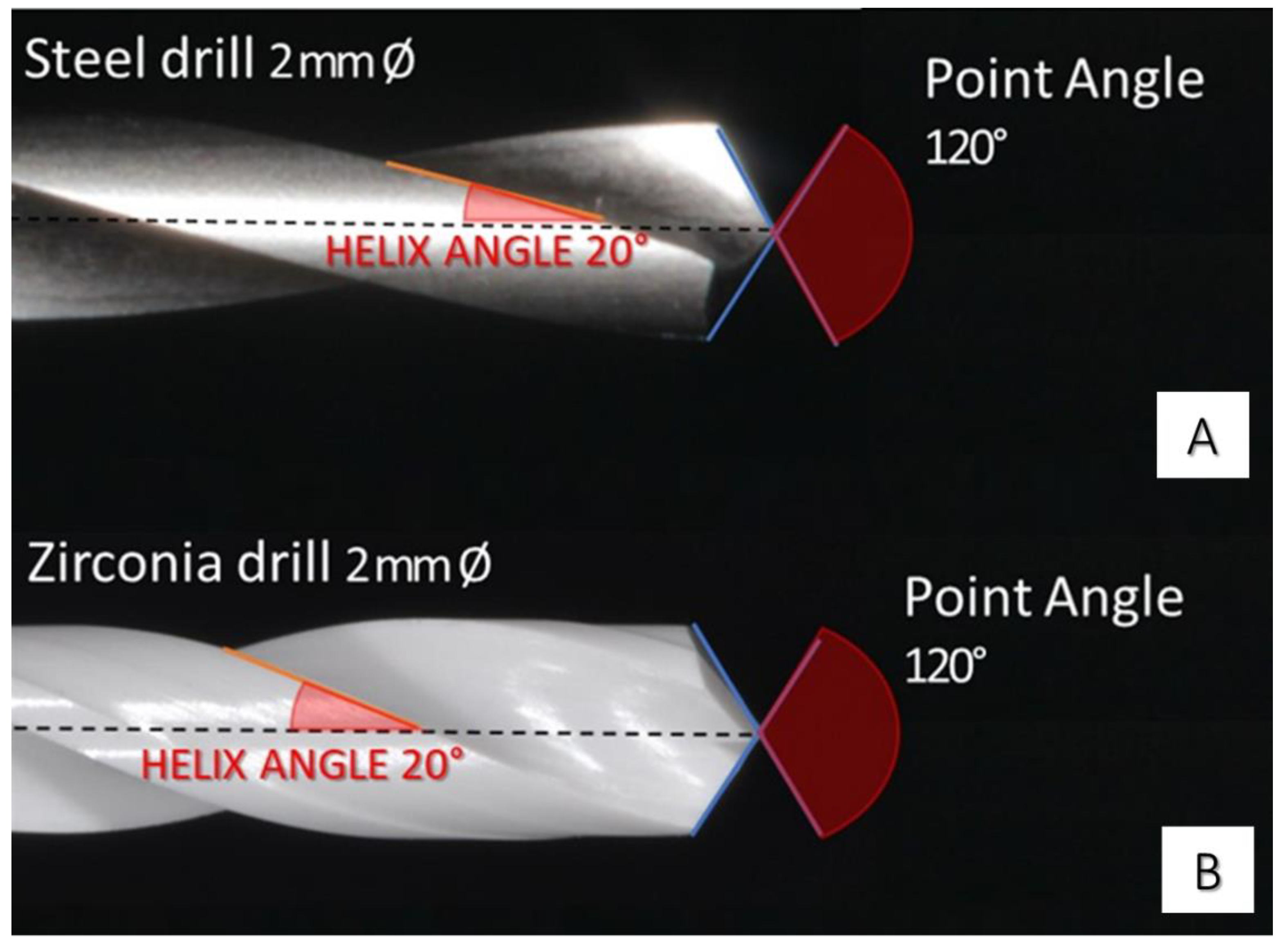

2. Materials and Methods

2.1. Energy-Dispersive X-Ray Spectroscopy (EDX) Analysis

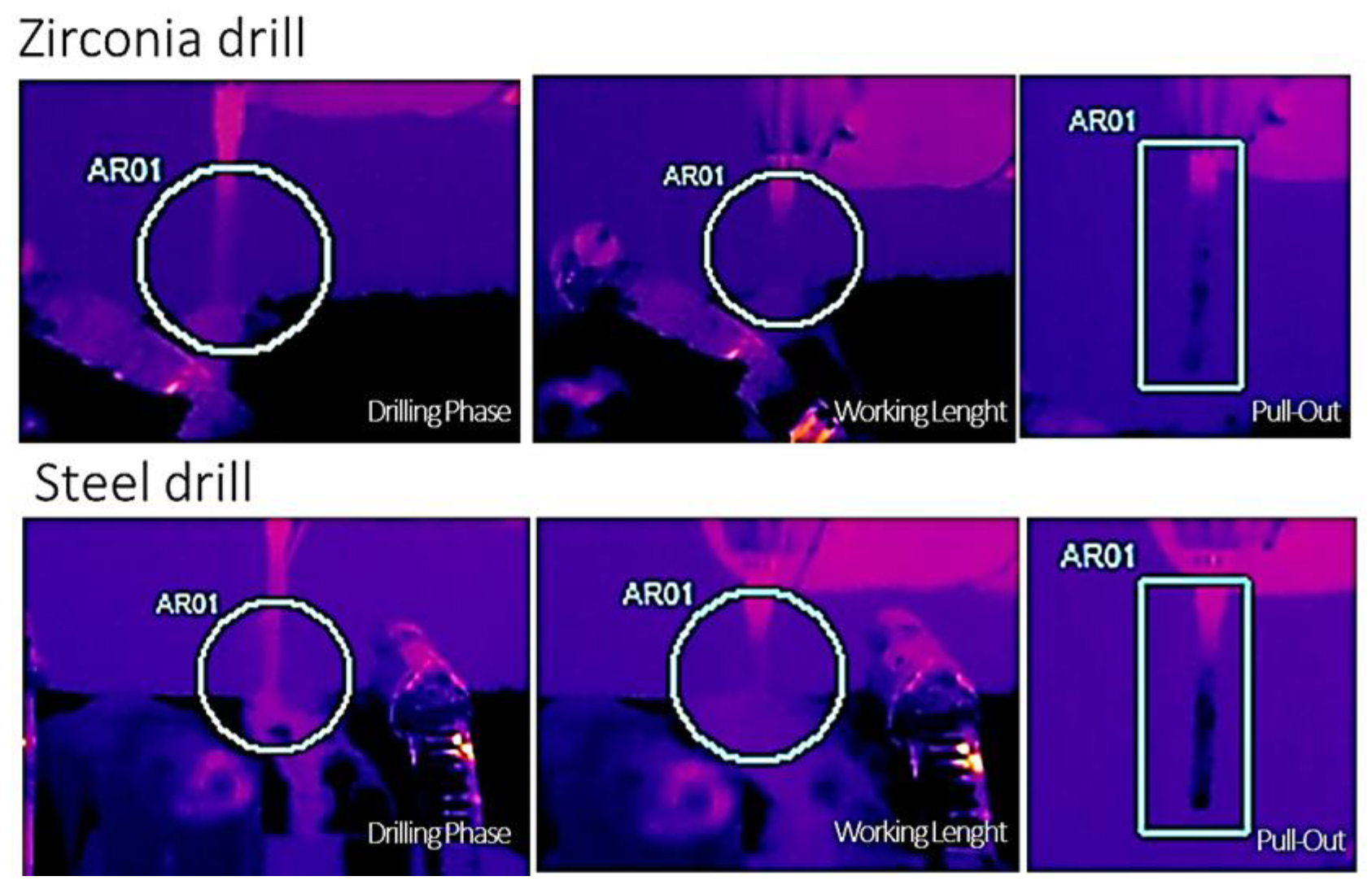

2.2. Infrared Thermography

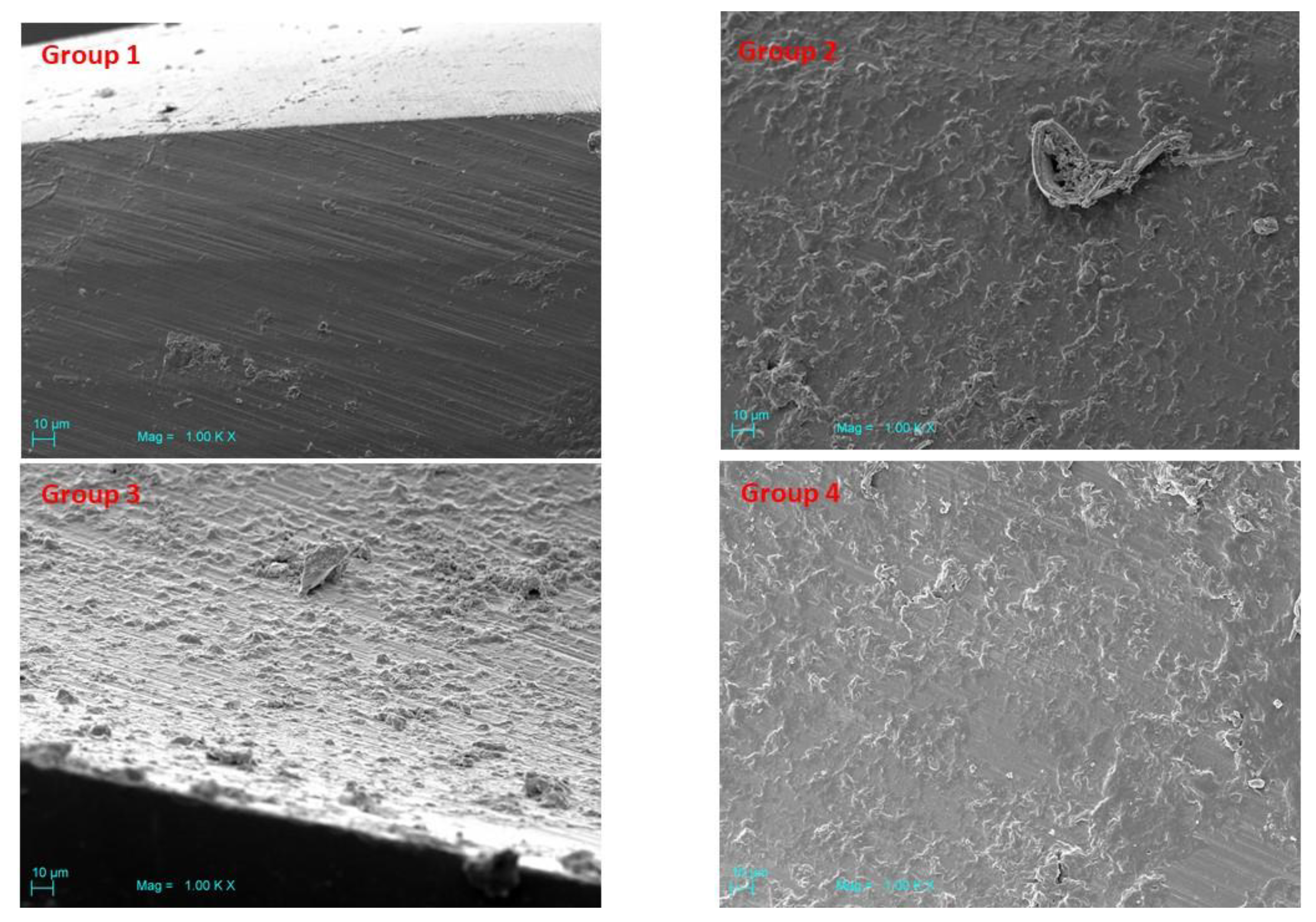

2.3. Scanning Electron Microscopy (SEM)

2.4. Statistical Analysis

3. Results

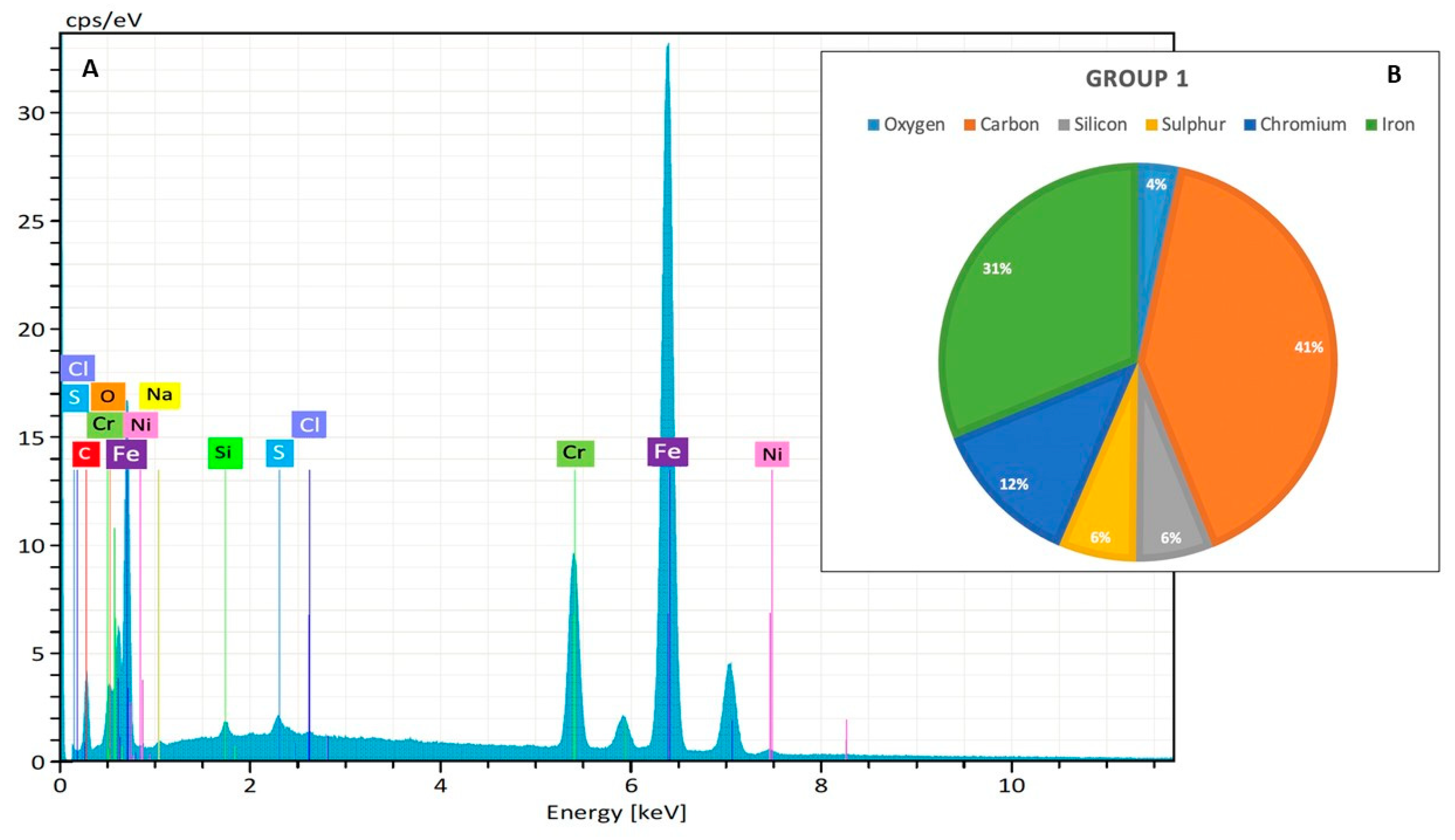

3.1. EDX Analysis

3.1.1. Steel Drill

3.1.2. Zirconia Drill

3.2. Infrared Thermography

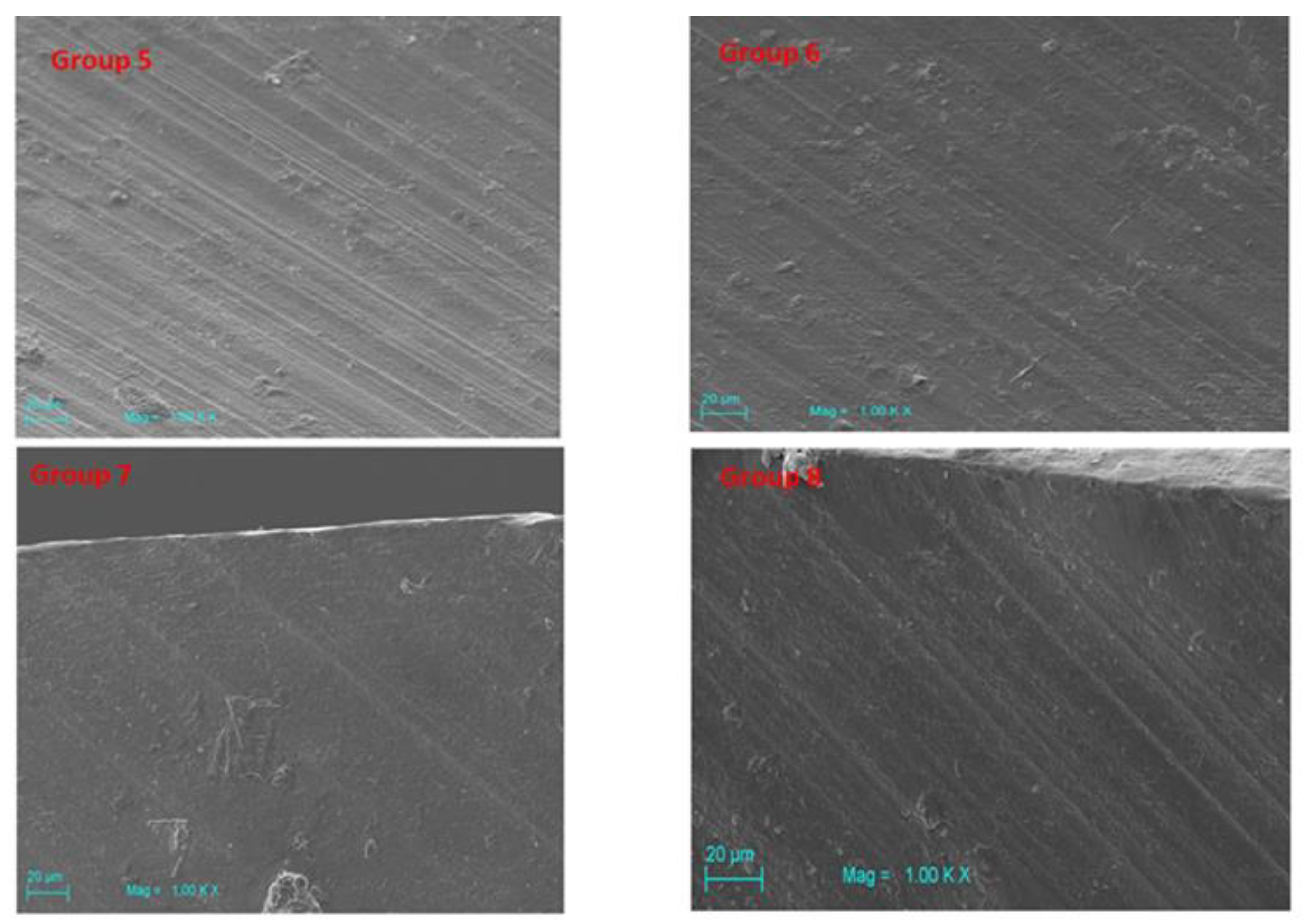

3.3. Scanning Electron Microscopy (SEM)

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Brånemark, P.I.; Hansson, B.O.; Adell, R.; Breine, U.; Lindström, J.; Hallén, O.; Ohman, A. Osseointegrated implants in the treatment of the edentulous jaw. Experience from a 10-year period. Scand. J. Plast. Reconstr. Surg. Suppl. 1977, 16, 1–132. [Google Scholar] [PubMed]

- Manicone, P.F.; Rossi Iommetti, P.; Raffaelli, L. An overview of zirconia ceramics: Basic properties and clinical applications. J. Dent. 2007, 35, 819–826. [Google Scholar] [CrossRef] [PubMed]

- Scarano, A.; Stoppaccioli, M.; Casolino, T. Zirconia crowns cemented on titanium bars using CAD/CAM: A five-year follow-up prospective clinical study of 9 patients. BMC Oral Health 2019, 19, 286. [Google Scholar] [CrossRef] [PubMed]

- Scarano, A.; Noumbissi, S.; Gupta, S.; Inchingolo, F.; Stilla, P.; Lorusso, F. Scanning Electron Microscopy Analysis and Energy Dispersion X-ray Microanalysis to Evaluate the Effects of Decontamination Chemicals and Heat Sterilization on Implant Surgical Drills: Zirconia vs. Steel. Appl. Sci. 2019, 9, 2837. [Google Scholar] [CrossRef]

- Giro, G.; Tovar, N.; Marin, C.; Bonfante, E.A.; Jimbo, R.; Suzuki, M.; Janal, M.N.; Coelho, P.G. The effect of simplifying dental implant drilling sequence on osseointegration: An experimental study in dogs. Int. J. Biomater. 2013, 2013, 230310. [Google Scholar] [CrossRef]

- Del Giudice, R.; Piattelli, A.; Grande, N.-M.; Cataneo, E.; Crispino, A.; Petrini, M. Implant insertion torque value in immediate loading: A retrospective study. Med. Oral Patol. Oral Cir. Bucal. 2019, 24, e398–e403. [Google Scholar] [CrossRef]

- Eriksson, A.R.; Albrektsson, T. Temperature threshold levels for heat-induced bone tissue injury: A vital-microscopic study in the rabbit. J. Prosthet. Dent. 1983, 50, 101–107. [Google Scholar] [CrossRef]

- D’haese, J.; Ackhurst, J.; Wismeijer, D.; De Bruyn, H.; Tahmaseb, A. Current state of the art of computer-guided implant surgery. Periodontol. 2000 2017, 73, 121–133. [Google Scholar] [CrossRef]

- Möhlhenrich, S.C.; Modabber, A.; Steiner, T.; Mitchell, D.A.; Hölzle, F. Heat generation and drill wear during dental implant site preparation: Systematic review. Br. J. Oral Maxillofac. Surg. 2015, 53, 679–689. [Google Scholar] [CrossRef]

- Allan, W.; Williams, E.D.; Kerawala, C.J. Effects of repeated drill use on temperature of bone during preparation for osteosynthesis self-tapping screws. Br. J. Oral Maxillofac. Surg. 2005, 43, 314–319. [Google Scholar] [CrossRef]

- Kerawala, C.J.; Martin, I.C.; Allan, W.; Williams, E.D. The effects of operator technique and bur design on temperature during osseous preparation for osteosynthesis self-tapping screws. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 1999, 88, 145–150. [Google Scholar] [CrossRef]

- Tehemar, S.H. Factors affecting heat generation during implant site preparation: A review of biologic observations and future considerations. Int. J. Oral Maxillofac. Implant. 1999, 14, 127–136. [Google Scholar]

- Marenzi, G.; Sammartino, J.C.; Quaremba, G.; Graziano, V.; El Hassanin, A.; Qorri, M.E.; Sammartino, G.; Iorio-Siciliano, V. Clinical Influence of Micromorphological Structure of Dental Implant Bone Drills. Biomed. Res. Int. 2018, 2018, 8143962. [Google Scholar] [CrossRef] [PubMed]

- Scarano, A.; Piattelli, A.; Assenza, B.; Carinci, F.; Di Donato, L.; Romani, G.L.; Merla, A. Infrared thermographic evaluation of temperature modifications induced during implant site preparation with cylindrical versus conical drills. Clin. Implant. Dent. Relat. Res. 2011, 13, 319–323. [Google Scholar] [CrossRef]

- Bertollo, N.; Gothelf, T.K.; Walsh, W.R. 3-Fluted orthopaedic drills exhibit superior bending stiffness to their 2-fluted rivals: Clinical implications for targeting ability and the incidence of drill-bit failure. Injury 2008, 39, 734–741. [Google Scholar] [CrossRef]

- Bertollo, N.; Milne, H.R.M.; Ellis, L.P.; Stephens, P.C.; Gillies, R.M.; Walsh, W.R. A comparison of the thermal properties of 2- and 3-fluted drills and the effects on bone cell viability and screw pull-out strength in an ovine model. Clin. Biomech. 2010, 25, 613–617. [Google Scholar] [CrossRef]

- Queiroz, T.P.; Souza, F.A.; Okamoto, R.; Margonar, R.; Pereira-Filho, V.A.; Garcia Júnior, I.R.; Vieira, E.H. Evaluation of immediate bone-cell viability and of drill wear after implant osteotomies: Immunohistochemistry and scanning electron microscopy analysis. J. Oral Maxillofac. Surg. 2008, 66, 1233–1240. [Google Scholar] [CrossRef]

- Delgado-Ruiz, R.; Romanos, G. Potential Causes of Titanium Particle and Ion Release in Implant Dentistry: A Systematic Review. Int. J. Mol. Sci. 2018, 19, 3585. [Google Scholar] [CrossRef]

- Scarano, A.; Lorusso, F.; Noumbissi, S. Infrared Thermographic Evaluation of Temperature Modifications Induced during Implant Site Preparation with Steel vs. Zirconia Implant Drill. J. Clin. Med. 2020, 9, 148. [Google Scholar] [CrossRef]

- Whitworth, C.L.; Martin, M.V.; Gallagher, M.; Worthington, H.V. A comparison of decontamination methods used for dental burs. Br. Dent. J. 2004, 197, 635–640. [Google Scholar] [CrossRef][Green Version]

- Bapna, M.S.; Mueller, H.J. Corrosion of dental burs in sterilizing and disinfecting solutions. J. Prosthet. Dent. 1988, 59, 503–511. [Google Scholar] [CrossRef]

- Veitz-Keenan, A.; Ferraiolo, D.M.; Keenan, J.R. Impact of asepsis technique on implant success. A review. Eur. J. Oral Implantol. 2018, 11 (Suppl. 1), S113–S121. [Google Scholar]

- Augustin, G.; Zigman, T.; Davila, S.; Udilljak, T.; Staroveski, T.; Brezak, D.; Babic, S. Cortical bone drilling and thermal osteonecrosis. Clin. Biomech. 2012, 27, 313–325. [Google Scholar] [CrossRef] [PubMed]

- Porto, A.N.; Borges, Á.H.; Semenoff-Segundo, A.; Raslan, S.A.; Pedro, F.L.M.; Jorge, A.O.C.; Bandeca, M.C. Effect of repeated sterilization cycles on the physical properties of scaling instruments: A scanning electron microscopy study. J. Int. Oral Health 2015, 7, 1–4. [Google Scholar] [PubMed]

- Sansone, V.; Pagani, D.; Melato, M. The effects on bone cells of metal ions released from orthopaedic implants. A review. Clin. Cases Miner. Bone Metab. 2013, 10, 34–40. [Google Scholar] [CrossRef] [PubMed]

- Favero, V.; Sakuma, S.; Apaza Alccayhuaman, K.A.; Benedetto, G.A.; Bengazi, F.; Botticelli, D. Healing at sites prepared using different drilling protocols. An experimental study in the tibiae of sheep. PLoS ONE 2018, 13, e0202957. [Google Scholar] [CrossRef]

- Matthews, L.S.; Hirsch, C. Temperatures measured in human cortical bone when drilling. J. Bone Jt. Surg. Am. 1972, 54, 297–308. [Google Scholar] [CrossRef]

- Jacobs, C.H.; Pope, M.H.; Berry, J.T.; Hoaglund, F. A study of the bone machining process-orthogonal cutting. J. Biomech. 1974, 7, 131–136. [Google Scholar] [CrossRef]

- Chacon, G.E.; Bower, D.L.; Larsen, P.E.; McGlumphy, E.A.; Beck, F.M. Heat production by 3 implant drill systems after repeated drilling and sterilization. J. Oral Maxillofac. Surg. 2006, 64, 265–269. [Google Scholar] [CrossRef]

- Scarano, A.; Carinci, F.; Quaranta, A.; Di Iorio, D.; Assenza, B.; Piattelli, A. Effects of bur wear during implant site preparation: An in vitro study. Int. J. Immunopathol. Pharmacol. 2007, 20, 23–26. [Google Scholar] [CrossRef]

- Di Fiore, A.; Sivolella, S.; Stocco, E.; Favero, V.; Stellini, E. Experimental Analysis of Temperature Differences during Implant Site Preparation: Continuous Drilling Technique Versus Intermittent Drilling Technique. J. Oral Implantol. 2018, 44, 46–50. [Google Scholar] [CrossRef] [PubMed]

- Lucchiari, N.; Frigo, A.C.; Stellini, E.; Coppe, M.; Berengo, M.; Bacci, C. In Vitro Assessment with the Infrared Thermometer of Temperature Differences Generated During Implant Site Preparation: The Traditional Technique Versus the Single-Drill Technique. Clin. Implant. Dent. Relat. Res. 2016, 18, 182–191. [Google Scholar] [CrossRef] [PubMed]

- Augustin, G.; Davila, S.; Udiljak, T.; Vedrina, D.S.; Bagatin, D. Determination of spatial distribution of increase in bone temperature during drilling by infrared thermography: Preliminary report. Arch. Orthop. Trauma Surg. 2009, 129, 703–709. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.; Niu, B.; Yi, J.; Deng, Z.; Song, J.; Chen, Q. Toxicity and Metal Corrosion of Glutaraldehyde-Didecyldimethylammonium Bromide as a Disinfectant Agent. Biomed. Res. Int. 2018, 2018, 9814209. [Google Scholar] [CrossRef]

- Laopaiboon, L.; Phukoetphim, N.; Laopaiboon, P. Effect of glutaraldehyde biocide on laboratory-scale rotating biological contactors and biocide efficacy. Electron. J. Biotechnol. 2006, 9, 358–369. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, V. Behavior of steels against corrosion in peroxide solutions. J. Mater. Environ. Sci. 2012, 3, 76–84. [Google Scholar]

- ASTM. G48-11 Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless; ASTM Internaltional: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Pourbaix, M. Atlas of Electrochemical Equilibria in Aqueous Solutions; Version 2; National Association of Corrosion: Houston, TX, USA, 2016; ISBN 0915567989. [Google Scholar]

- Singh, A.K.; Chaudhary, V.; Sharma, A. Electrochemical Studies of Stainless Steel Corrosion in Peroxide Solutions. Port. Electrochim. Acta 2012, 30, 99–109. [Google Scholar] [CrossRef]

- Tian, Q.; Wu, S.; Dai, Z.; Yang, J.; Zheng, J.; Zheng, Q.; Liu, Y. Iron overload induced death of osteoblasts In Vitro: Involvement of the mitochondrial apoptotic pathway. PeerJ 2016, 4, e2611. [Google Scholar] [CrossRef]

- Lane, B.; Whitenton, E.; Madhavan, V.; Donmez, A. Uncertainty of temperature measurements by infrared thermography for metal cutting applications. Metrologia 2013, 50, 637. [Google Scholar] [CrossRef]

- Grinzato, E.; Ludwig, N.; Cadelano, G.; Bertucci, M.; Gargano, M.; Bison, P. Infrared thermography for moisture detection: A laboratory study and in-situ test. Mater. Eval. 2011, 69, 97–104. [Google Scholar]

- Scarano, A.; Carinci, F.; Lorusso, F.; Festa, F.; Bevilacqua, L.; Santos de Oliveira, P.; Maglione, M. Ultrasonic vs Drill Implant Site Preparation: Post-Operative Pain Measurement Through VAS, Swelling and Crestal Bone Remodeling: A Randomized Clinical Study. Materials 2018, 11, 2516. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.J.; Lee, M.H.; Lee, D.Y.; Han, J.S. Mechanical properties, phase stability, and biocompatibility of (Y, Nb)-TZP/Al(2)O(3) composite abutments for dental implant. J. Biomed. Mater. Res. 2000, 53, 438–443. [Google Scholar] [CrossRef]

| Bone Temperature (°C) | ||||

|---|---|---|---|---|

| Stainless Steel Drill | Group 1 | Group 2 | Group 3 | Group 4 |

| 38.92 ± 1.13 | 41.47 ± 1.06 | 41.51 ± 1.22 | 41.38 ± 1.15 | |

| Zirconia Drill | Group 5 | Group 6 | Group 7 | Group 8 |

| 38.21 ± 1.01 | 38.9 ± 1.36 | 39.55 ± 1.79 | 39.43 ±0.98 | |

| p value | p = 0.925 | p = 0.041 (*) | p = 0.029 (*) | p = 0.037 (*) |

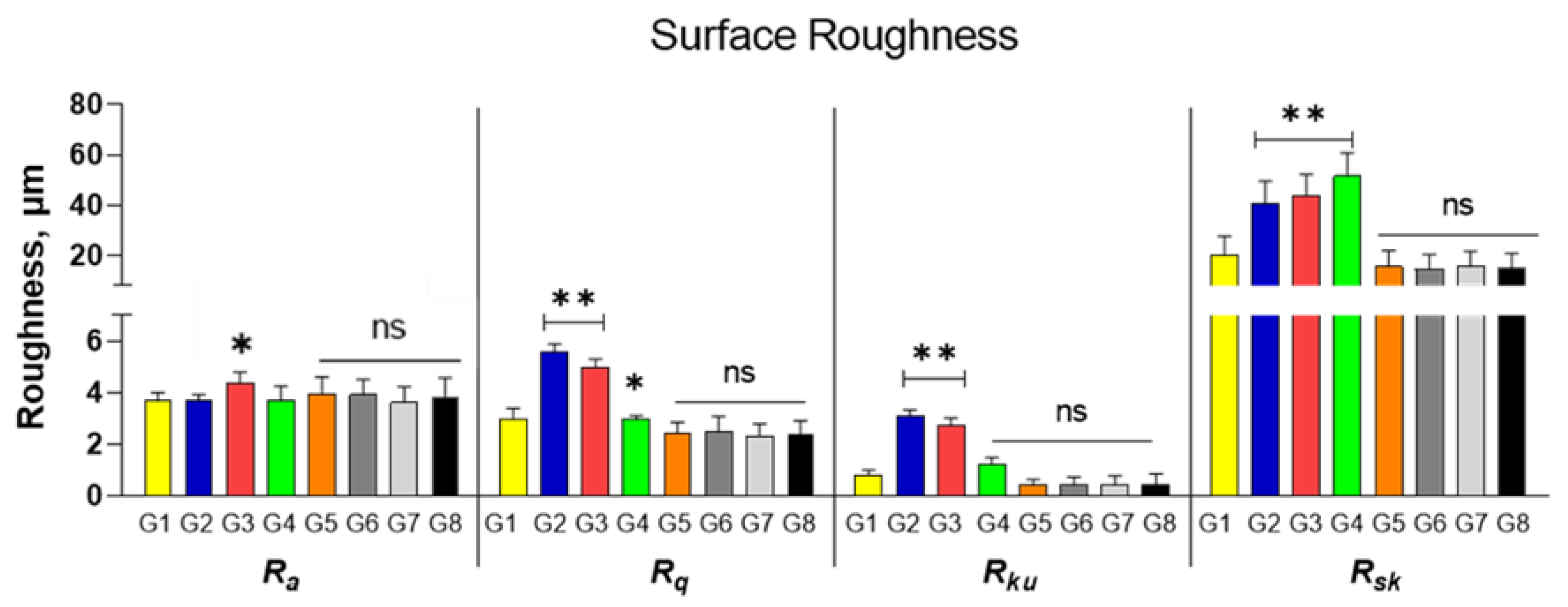

| Surface Roughness [μm] | Ra | Rq | Rku | Rsk |

|---|---|---|---|---|

| Group 1 | 3.671 ± 0.317 | 2.992 ± 0.391 | 0.832 ± 0.173 | 20.324 ± 7.413 |

| Group 2 | 3.683 ± 0.236 | 5.592 ± 0.297 | 3.120 ± 0.214 | 40.683 ± 8.835 |

| Group 3 | 4.341 ± 0.461 | 4.992 ± 0.313 | 2.720 ± 0.292 | 43.683 ± 8.591 |

| Group 4 | 3.721 ± 0.532 | 3.001 ± 0.112 | 1.220 ± 0.261 | 51.683 ± 9.142 |

| Group 5 | 3.945 ± 0.651 | 2.412 ± 0.437 | 0.4623 ± 0.169 | 15.648 ± 6.392 |

| Group 6 | 3.912 ± 0.591 | 2.512 ± 0.554 | 0.4627 ± 0.271 | 14.623 ± 5.902 |

| Group 7 | 3.622 ± 0.613 | 2.313 ± 0.471 | 0.4645 ± 0.308 | 15.661 ± 6.102 |

| Group 8 | 3.845 ± 0.733 | 2.411 ± 0.494 | 0.4522 ± 0.405 | 15.111 ± 5.925 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scarano, A.; Petrini, M.; Mastrangelo, F.; Noumbissi, S.; Lorusso, F. The Effects of Liquid Disinfection and Heat Sterilization Processes on Implant Drill Roughness: Energy Dispersion X-ray Microanalysis and Infrared Thermography. J. Clin. Med. 2020, 9, 1019. https://doi.org/10.3390/jcm9041019

Scarano A, Petrini M, Mastrangelo F, Noumbissi S, Lorusso F. The Effects of Liquid Disinfection and Heat Sterilization Processes on Implant Drill Roughness: Energy Dispersion X-ray Microanalysis and Infrared Thermography. Journal of Clinical Medicine. 2020; 9(4):1019. https://doi.org/10.3390/jcm9041019

Chicago/Turabian StyleScarano, Antonio, Morena Petrini, Filiberto Mastrangelo, Sammy Noumbissi, and Felice Lorusso. 2020. "The Effects of Liquid Disinfection and Heat Sterilization Processes on Implant Drill Roughness: Energy Dispersion X-ray Microanalysis and Infrared Thermography" Journal of Clinical Medicine 9, no. 4: 1019. https://doi.org/10.3390/jcm9041019

APA StyleScarano, A., Petrini, M., Mastrangelo, F., Noumbissi, S., & Lorusso, F. (2020). The Effects of Liquid Disinfection and Heat Sterilization Processes on Implant Drill Roughness: Energy Dispersion X-ray Microanalysis and Infrared Thermography. Journal of Clinical Medicine, 9(4), 1019. https://doi.org/10.3390/jcm9041019