Polymer of Intrinsic Microporosity (PIM-1) Membranes Treated with Supercritical CO2

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. CO2 Sorption Isotherm of PIM-1

3.2. Gas Permeability in Original PIM-1 Membrane

3.3. Supercritical CO2 Treatment

3.3.1. Density

3.3.2. Gas Permeability

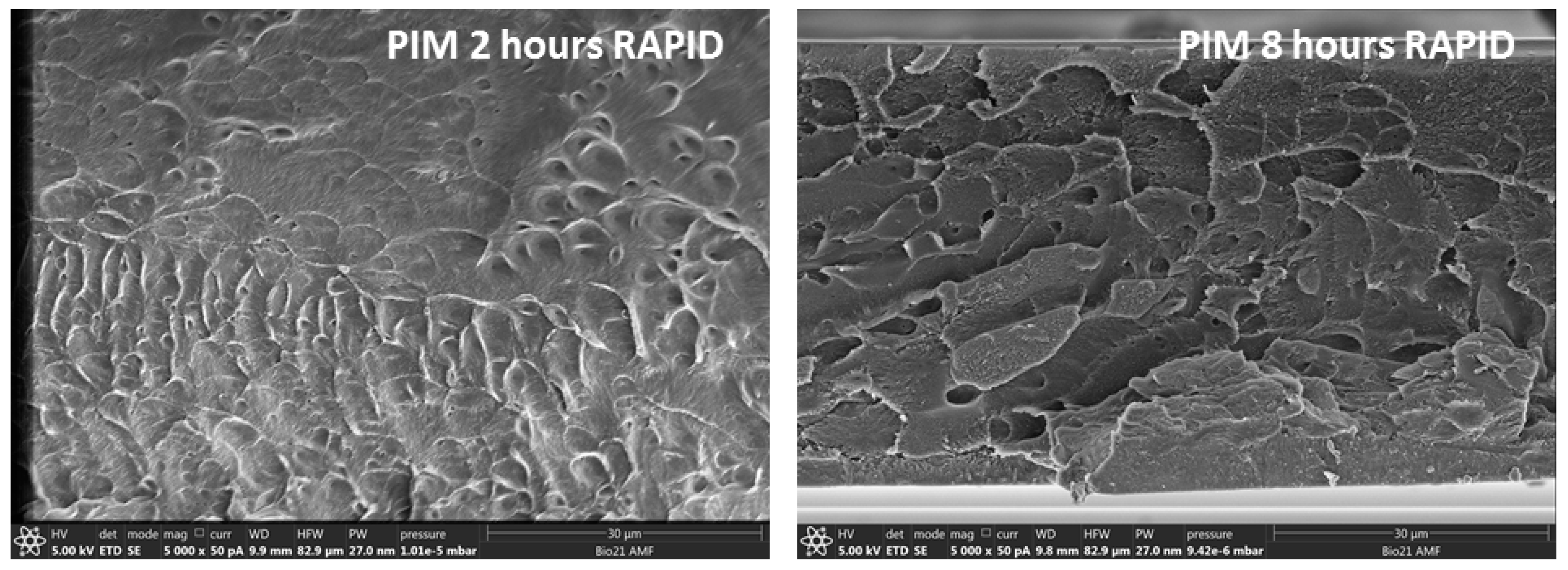

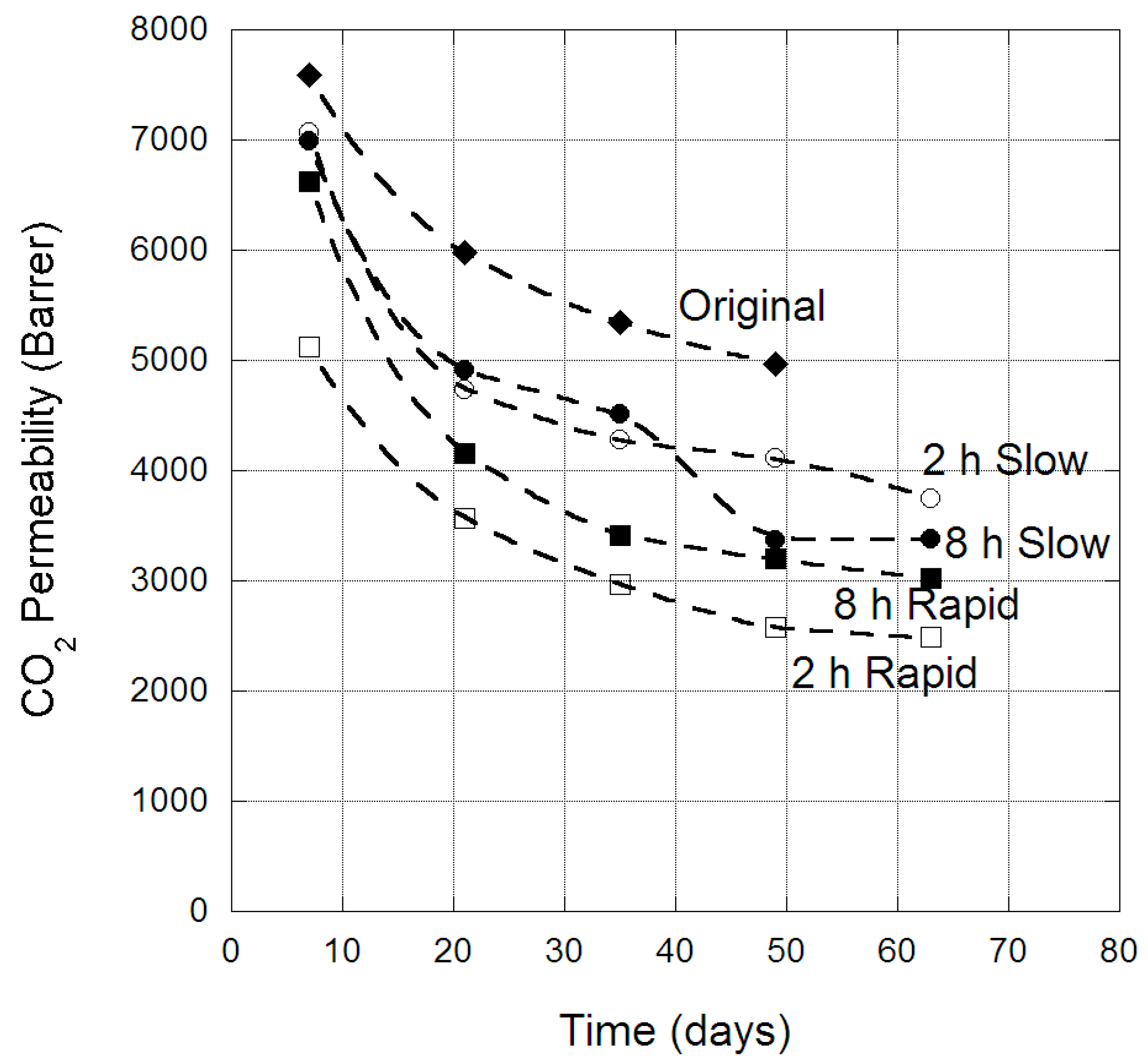

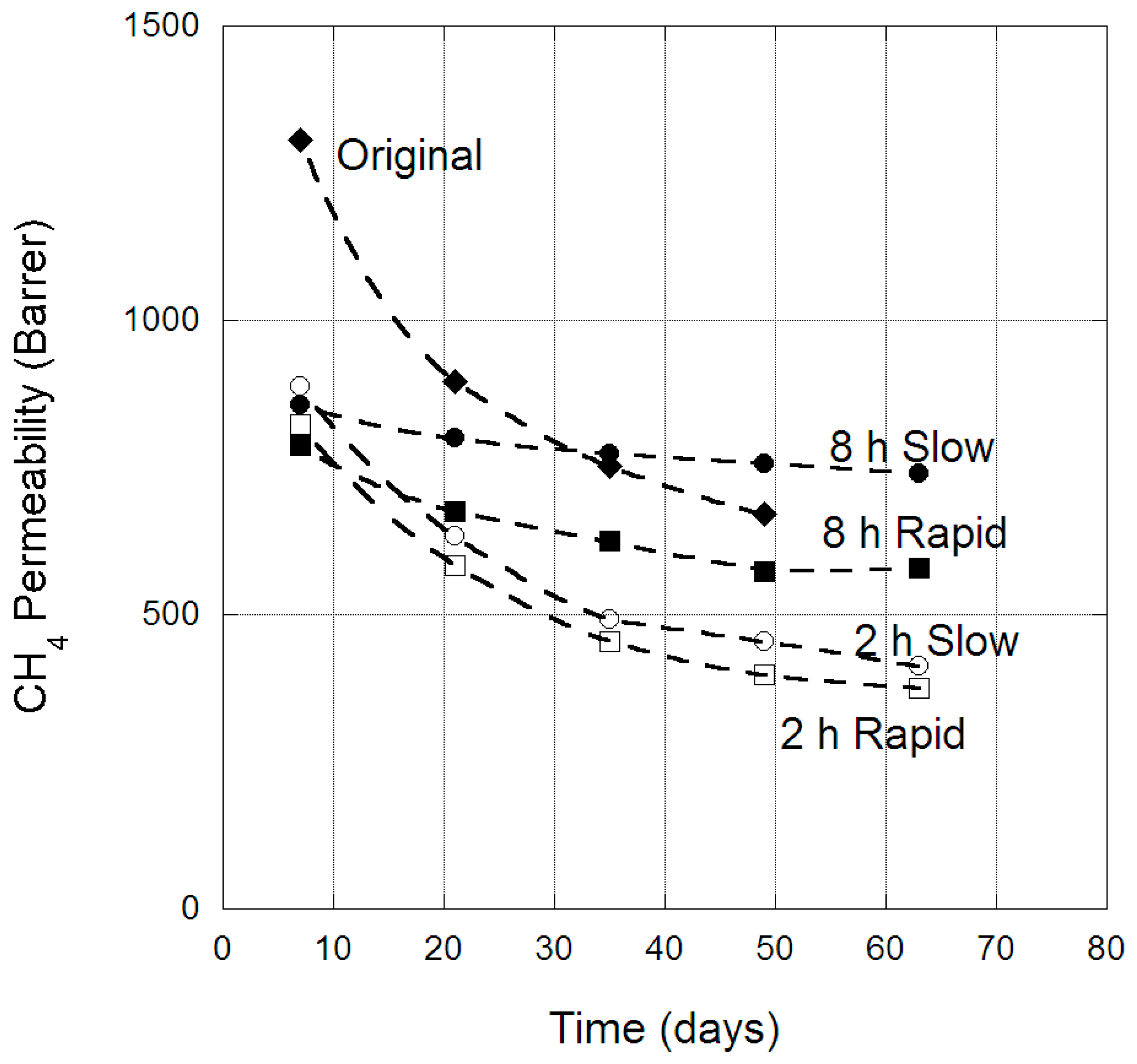

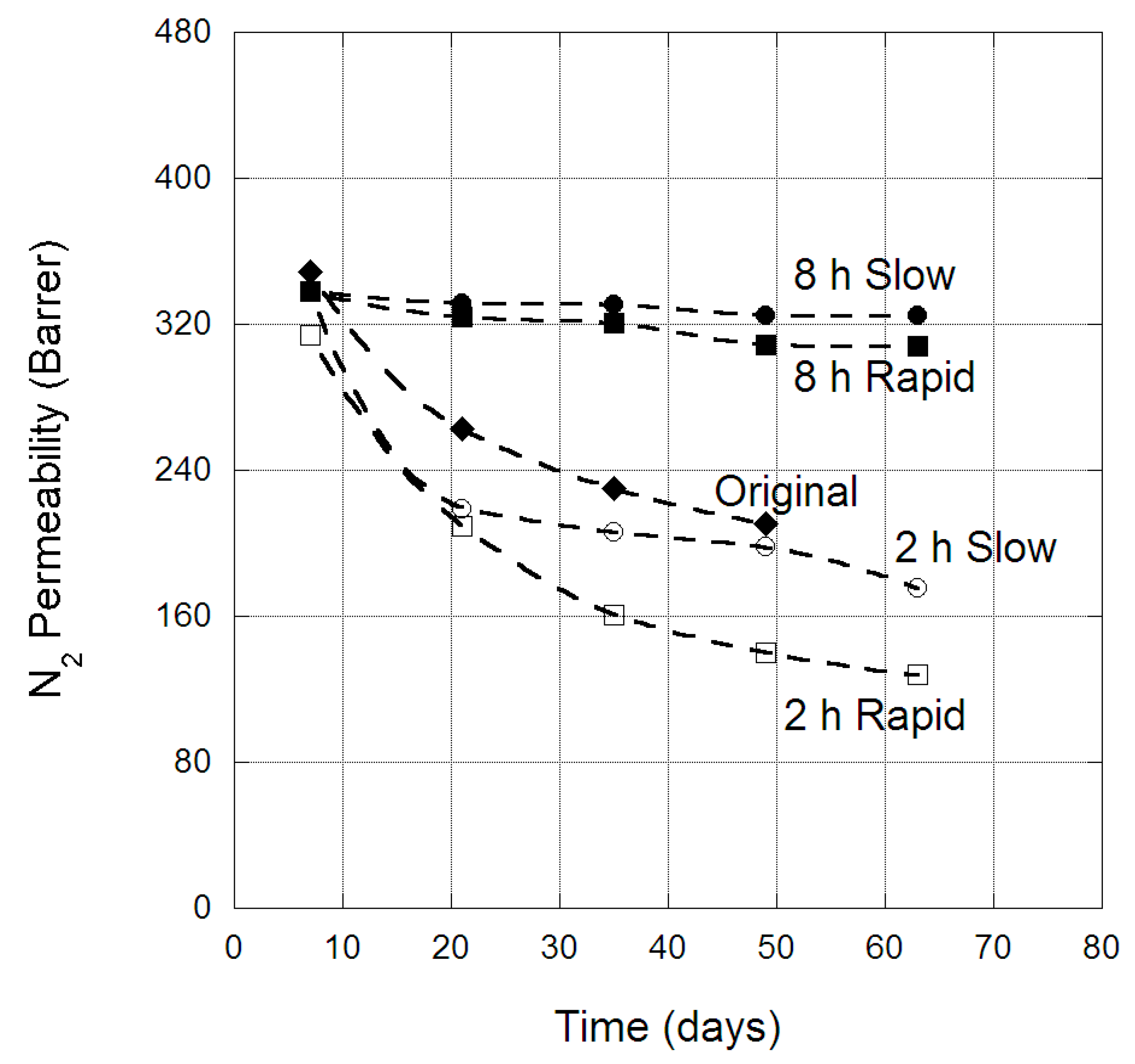

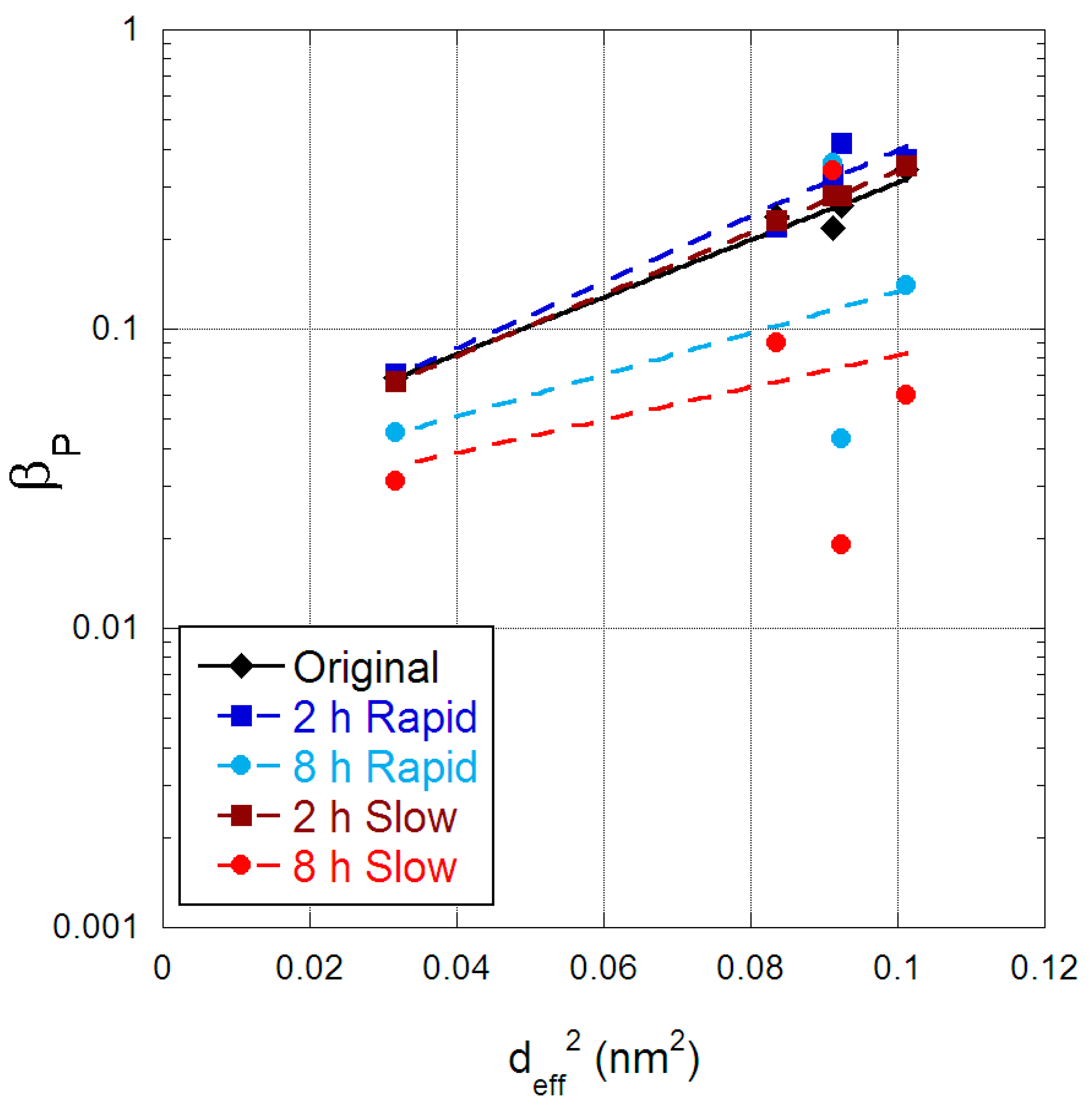

3.3.3. Aging Study

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McKeown, N.B.; Budd, P.M. Polymers of intrinsic microporosity (PIMs): Organic materials for membrane separation, hetergeneous catalysis and hydrogen storage. Chem. Soc. Rev. 2006, 35, 675–683. [Google Scholar] [CrossRef]

- Li, P.; Chung, T.S.; Paul, D.R. Gas sorption and permeation in PIM-1. J. Membr. Sci. 2013, 432, 50–57. [Google Scholar] [CrossRef]

- Robeson, L.M. The upper bound revisited. J. Membr. Sci. 2008, 320, 390–400. [Google Scholar] [CrossRef]

- Pilnacek, K.; Vopicka, O.; Lanc, M.; Dendisova, M.; Zgazar, M.; Budd, P.M.; Carta, M.; Malpass-Evans, R.; McKeown, N.B.; Friess, K. Aging of polymers of intrinsic microporosity tracked by methanol vapour permeation. J. Membr. Sci. 2016, 520, 895–906. [Google Scholar] [CrossRef]

- Staiger, C.L.; Pas, S.J.; Hill, A.J.; Cornelius, C.J. Gas separation, free volume distribution, and physical aging of a highly microporous spirobisindane polymer. Chem. Mater. 2008, 20, 2606–2608. [Google Scholar] [CrossRef]

- Baschetti, M.G.; Ghisellini, M.; Quinzi, M.; Doghieri, F.; Stagnaro, P.; Costa, G.; Sarti, G.C. Effects on sorption and diffusion in PTMSP and TMSP/TMSE copolymers of free volume changes due to polymer aging. J. Mol. Struct. 2005, 739, 75–86. [Google Scholar] [CrossRef]

- Masuda, T.; Isobe, E.; Higashimura, T.; Takada, K. Poly[1-(trimethylsilyl)-1-propyne]: A new high polymer synthesized with transition-metal catalysts and characterized by extremely high gas permeability. J. Am. Chem. Soc. 1983, 105, 7473–7474. [Google Scholar] [CrossRef]

- Swaidan, R.; Ghanem, B.; Litwiller, E.; Pinnau, I. Physical aging, plasticization and their effects on gas permeation in “rigid” polymers of intrinsic microporosity. Macromolecules 2015, 48, 6553–6561. [Google Scholar] [CrossRef]

- Budd, P.M.; McKeown, N.B.; Ghanem, B.S.; Msayib, K.J.; Fritsch, D.; Starannikova, L.; Belov, N.; Sanfirova, O.; Yampolskii, Y.; Shantarovich, V. Gas permeation parameters and other physicochemical properties of a polymer of intrinsic microporosity: Polybenzodioxane PIM-1. J. Membr. Sci. 2008, 325, 851–860. [Google Scholar] [CrossRef]

- Mason, C.R.; Maynard-Atem, L.; Heard, K.W.J.; Satilmis, B.; Budd, P.M.; Friess, K.; Lanc, M.; Bernardo, P.; Clarizia, G.; Jansen, J.C. Enhancement of CO2 affinity in a polymer of intrinsic microporosity by amine modification. Macromolecules 2014, 47, 1021–1029. [Google Scholar] [CrossRef]

- Li, F.Y.; Chung, T.S. Physical aging, high temperature and water vapor permeation studies of UV-rearranged PIM-1 membranes for advanced hydrogen purification and production. Int. J. Hydrog. Energy 2013, 38, 9786–9793. [Google Scholar] [CrossRef]

- Du, N.; Cin, M.M.D.; Pinnau, I.; Nicalek, A.; Robertson, G.P.; Guiver, M.D. Azide-based cross-linking of polymers of intrinsic microporosity (PIMs) for condensable gas seapration. Macromol. Rapid Commun. 2011, 32, 631–636. [Google Scholar] [CrossRef]

- Bushell, A.F.; Attfield, M.P.; Mason, C.R.; Budd, P.M.; Yampolskii, Y.; Starannikova, L.; Robrov, A.; Bazzarelli, F.; Bernardo, P.; Jansen, J.C.; et al. Gas permeation parameters of mixed matrix membranes based on the polymer of intrinsic microporosity PIM-1 and the zeolitic imidazolate framework ZIF-8. J. Membr. Sci. 2013, 427, 48–62. [Google Scholar] [CrossRef]

- Du, N.; Park, H.B.; Robertson, G.P.; Dal-Cin, M.M.; Visser, T.; Scoles, L.; Guiver, M.D. Polymer nanosieve membranes for CO2-capture application. Nat. Mater. 2011, 10, 372–375. [Google Scholar] [CrossRef] [PubMed]

- Scholes, C.A.; Kanehashi, S. Polymeric membrane gas separation performance improvements thorugh supercritical CO2 treatment. J. Membr. Sci. 2018, 566, 239–248. [Google Scholar] [CrossRef]

- Budd, P.M.; Ghanem, B.S.; Makhseed, S.; McKeown, N.B.; Msayib, K.J.; Tattershall, C.E. Polymers of intrinsic microporosity (PIMs): Robust, solution-processable, organic nanoporous materials. Chem. Commun. 2004, 10, 230–231. [Google Scholar] [CrossRef]

- Hill, A.J.; Pas, S.J.; Bastow, T.J.; Burgar, M.I.; Nagai, K.; Toy, L.G.; Freeman, B.D. Influence of methanol conditioning and physical aging on carbon spin-lattice relaxation times of poly(1-trimethylsilyl-1-propyne). J. Membr. Sci. 2004, 243, 37–44. [Google Scholar] [CrossRef]

- ASTM. Standard Test Methods for Density and Specific Gravity (Relative Density) of Plasticis by Displacement; ASTM International: West Conshohocken, PA, USA, 1993. [Google Scholar]

- Scholes, C.A.; Tao, W.X.; Stevens, G.W.; Kentish, S.E. Sorption of methane, nitrogen, carbon dioxide, and water in Matrimid 5218. Appl. Polym. Sci. 2010, 117, 2284–2289. [Google Scholar] [CrossRef]

- Duthie, X.; Kentish, S.E.; Powell, C.; Nagai, K.; Qiao, G.; Stevens, G.W. Operating temperature effects on the plasticization of polyimide gas separation membranes. J. Membr. Sci. 2007, 294, 40–49. [Google Scholar] [CrossRef]

- Poling, B.E.; Prausnitz, J.M.; O’Connell, J.P. The Properties of Gaes and Liquids; McGraw Hill: New York, NY, USA, 2001. [Google Scholar]

- Petropoulos, J.H. Mechanisms and theories for sorption and diffusion of gases in polymers. In Polymeric Gas Separation; Paul, D.R., Yampolskii, Y., Eds.; CRC Press: Boca Raton, FL, USA, 1994; pp. 17–81. [Google Scholar]

- Scholes, C.A.; Jin, J.; Stevens, G.W.; Kentish, S.E. Competitive permeation of gas and water vapour in high free volume polymeric membranes. J. Polym. Sci. B Polym. Phys. 2015, 53, 719–728. [Google Scholar] [CrossRef]

- Budd, P.M.; Msayib, K.J.; Tattershall, C.E.; Ghanem, B.S.; Reynolds, K.J.; McKeown, N.B.; Fritsch, D. Gas separation membranes from polymers of intrinsic microporosity. J. Membr. Sci. 2005, 251, 263–269. [Google Scholar] [CrossRef]

- Thomas, S.; Pinnau, I.; Du, N.; Guiver, M.D. Pure- and mixed-gas permeation properties of a microporous spirobisindane-based ladder polymer (PIM-1). J. Membr. Sci. 2009, 333, 125–131. [Google Scholar] [CrossRef]

- Starannikova, L.; Belov, N.; Shantarovich, V.; Zhang, J.; Jin, J.; Yampolskii, Y. Effective increase in permeability and free volume of PIM copolymers containing ethanoanthracene unit and comparison between the alternating and random copolymers. J. Membr. Sci. 2018, 548, 593–597. [Google Scholar] [CrossRef]

- Bernardo, P.; Bazzarelli, F.; Tasselli, F.; Clarizia, G.; Mason, C.R.; Maynard-Atem, L.; Budd, P.M.; Lanc, M.; Pilnacek, K.; Vopicka, O.; et al. Effect of physical aging on the gas transport and sorption in PIM-1 membranes. Polymer 2017, 113, 283–294. [Google Scholar] [CrossRef]

| Parameter | This Work | Mason et al. [10] |

|---|---|---|

| kD (cm3/cm3 atm) | 1.3 ± 0.1 | 3.86 |

| C’H (cm3/cm3) | 56 ± 2 | 52.8 |

| b (atm−1) | 0.52 ± 0.03 | 0.706 |

| This Work | Budd et al. [24] | Staiger et al. [5] | Thomas et al. [25] | Starannikova et al. [26] | |

|---|---|---|---|---|---|

| He | 2055 ± 90 | 660 | 1061 | 1500 | 1740 |

| N2 | 349 ± 8 | 92 | 238 | 340 | 830 |

| O2 | 1865 ± 75 | 370 | 786 | 1300 | 2390 |

| CH4 | 1307 ± 26 | 125 | 360 | 430 | 1440 |

| CO2 | 7595 ± 84 | 2300 | 3496 | 6500 | 15,300 |

| This Work | Budd et al. [24] | Staiger et al. [5] | Thomas et al. [25] | Starannikova et al. [26] | |

|---|---|---|---|---|---|

| CO2/CH4 | 5.8 ± 0.2 | 18.4 | 9.7 | 15.1 | 10.6 |

| CO2/N2 | 21.8 ± 0.7 | 25.0 | 14.7 | 19.1 | 18.4 |

| O2/N2 | 5.3 ± 0.3 | 4.0 | 3.3 | 3.8 | 2.9 |

| He/N2 | 5.9 ± 0.4 | 7.2 | 4.5 | 4.4 | 2.1 |

| He/CH4 | 1.6 ± 0.1 | 5.3 | 2.9 | 3.5 | 1.2 |

| Exposure Time | 2 h | 8 h | ||

|---|---|---|---|---|

| Depressurization | Rapid | Slow | Rapid | Slow |

| Density (g/cm3) | 1.142 | 1.215 | 1.184 | 1.306 |

| Permeability (barrer) | ||||

| He | 1421 ± 88 | 1768 ± 92 | 1744 ± 68 | 1966 ± 72 |

| N2 | 314 ± 19 | 338 ± 12 | 338 ± 14 | 338 ± 16 |

| O2 | 1245 ± 64 | 1577 ± 69 | 1444 ± 63 | 1513 ± 72 |

| CH4 | 823 ± 21 | 887 ± 24 | 788 ± 16 | 857 ± 22 |

| CO2 | 5118 ± 157 | 7068 ± 83 | 6621 ± 164 | 6989 ± 96 |

| Exposure Time | 2 h | 8 h | ||

|---|---|---|---|---|

| Depressurization | Rapid | Slow | Rapid | Slow |

| CO2/CH4 | 6.2 ± 0.3 | 8.0 ± 0.3 | 8.4 ± 0.4 | 8.2 ± 0.3 |

| CO2/N2 | 16.3 ± 1.5 | 20.9 ± 1.0 | 19.6 ± 1.3 | 20.7 ± 1.3 |

| O2/N2 | 4.0 ± 0.4 | 4.7 ± 0.4 | 4.3 ± 0.4 | 4.5 ± 0.4 |

| He/N2 | 4.5 ± 0.6 | 5.2 ± 0.5 | 5.2 ± 0.4 | 5.8 ± 0.5 |

| He/CH4 | 1.7 ± 0.1 | 2.0 ± 0.2 | 2.2 ± 0.1 | 2.3 ± 0.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scholes, C.A.; Kanehashi, S. Polymer of Intrinsic Microporosity (PIM-1) Membranes Treated with Supercritical CO2. Membranes 2019, 9, 41. https://doi.org/10.3390/membranes9030041

Scholes CA, Kanehashi S. Polymer of Intrinsic Microporosity (PIM-1) Membranes Treated with Supercritical CO2. Membranes. 2019; 9(3):41. https://doi.org/10.3390/membranes9030041

Chicago/Turabian StyleScholes, Colin A., and Shinji Kanehashi. 2019. "Polymer of Intrinsic Microporosity (PIM-1) Membranes Treated with Supercritical CO2" Membranes 9, no. 3: 41. https://doi.org/10.3390/membranes9030041

APA StyleScholes, C. A., & Kanehashi, S. (2019). Polymer of Intrinsic Microporosity (PIM-1) Membranes Treated with Supercritical CO2. Membranes, 9(3), 41. https://doi.org/10.3390/membranes9030041