1. Introduction

Membrane distillation (MD) is a thermally driven process in which only vapor molecules are transported through porous hydrophobic membranes. The liquid feed to be treated by MD must be in direct contact with one side of the membrane, but without wetting the membrane to avoid the entrance inside the dry pores [

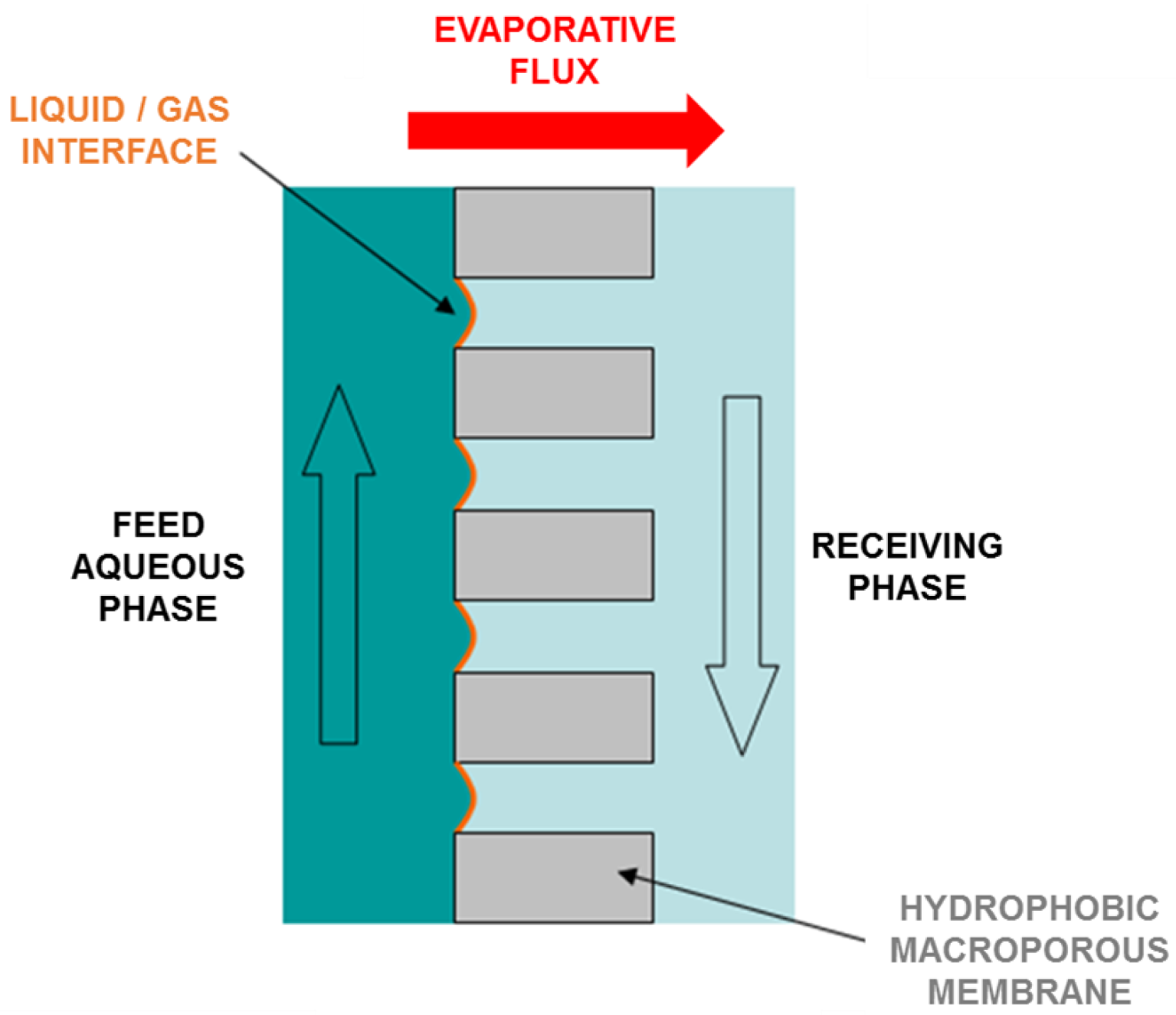

1]. This hydrophobic nature of the membrane prevents the mass transfer in liquid phase and creates a vapor–liquid interface at the pore entrance (

Figure 1). In this interface, the volatile compounds in the liquid feed evaporate and diffuse across the membrane pores. On the opposite side of the membrane, the vapor is condensed or removed, depending of the configuration of the MD system [

2].

The benefits of MD compared to distillation or other separation processes based on membranes must be highlighted [

3]: the complete theoretical rejection of ions, macromolecules, colloids, cells, and other non-volatiles; lower operating temperatures than conventional distillation; lower operating pressures than conventional pressure-driven membrane separation processes; reduced chemical interaction between membrane and process solutions; less demanding membrane mechanical property requirements; and reduced footprint spaces compared to conventional distillation processes.

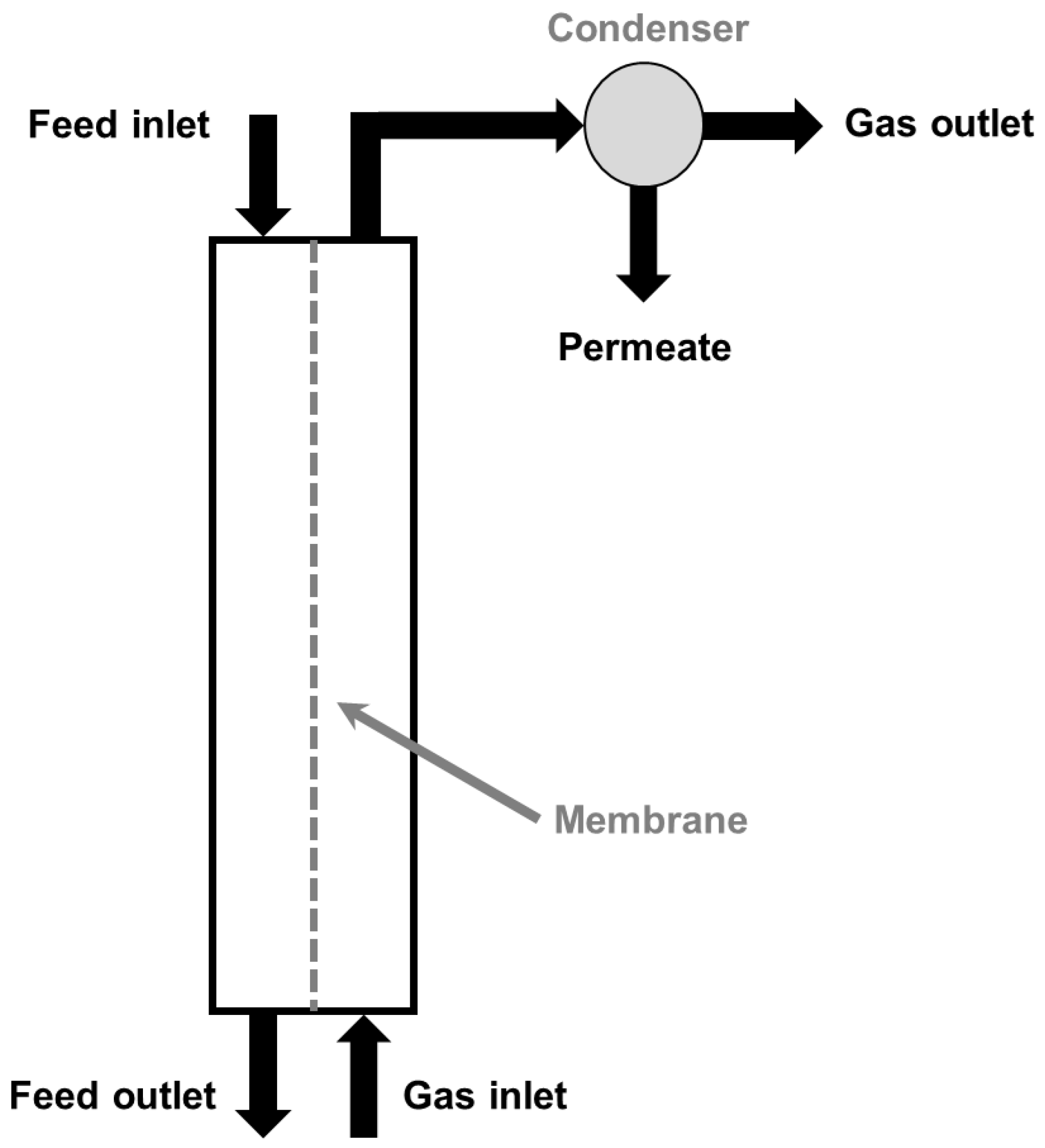

The driving force at the origin of the mass transfer through the membrane is a partial pressure gradient, but this gradient can be induced and maintained by different mechanisms, which define the configuration of the MD system. In the case of sweeping gas membrane distillation (SGMD), a cold inert gas sweeps the permeate side of the membrane and removes the vapor molecules, which condensate outside the membrane module (

Figure 2). SGMD presents some specific advantages when compared to other MD configurations, like relatively low heat loss by conduction through the membrane, low resistance to mass transfer in the gas phase, and a high driving force for transmembrane transport due to the continuous removal of vapor from the permeate side of the membrane [

4].

The membranes are key elements for an effective implementation of SGMD systems. Hydrophobic mesoporous–macroporous membranes (pore diameters between 10 nm and 0.5 μm) made of polymeric materials such as polypropylene, polyethylene, polytetrafluoroethylene or polyvinylidenefluoride are generally selected for this application. As previously commented, the hydrophobic character is crucial to avoid the penetration of the aqueous phase through the membrane’s porosity. This characteristic can be estimated indirectly from the determination of the intrusion pressure. The general influence of other structural characteristics of the membrane on the performance of SGMD processes is shown in

Table 1.

Three important parameters of the membrane have direct influence on the evaporative flux: the thickness of the membrane, the porosity, and the size of the pores. First of all, it is clear that the membrane resistance to mass transfer is proportional to the membrane thickness, so the thicker the membrane, the lower the flux. Moreover, it should be noted that the higher the porosity, the higher the flux. Indeed, a membrane having a high porosity offers a greater exchange surface area to the mass transfer and improved diffusivity [

5]. Similarly, the evaporative flux increases with the pore diameter of the membrane. However, in order to avoid the penetration of liquid into the membrane, the pore diameter should not be too large. An optimum pore diameter value must therefore be determined for each SGMD application for a good compromise between performance and operation.

The influence of several operating variables on the SGMD processes has been previously investigated [

6,

7]. The temperatures of the feed and sweeping phases have been identified as the most relevant process conditions; in particular, the temperature difference between the two phases must be taken into consideration. Indeed, SGMD is a thermal process governed by the gradient of partial pressure induced by the difference of temperature on both sides of the membrane. Therefore, the greater the temperature difference between the two phases, the higher the evaporation flux. In addition, the flow velocities of the phases can have an effect on the performance, but it depends on the specific cases [

5,

8,

9].

Table 2 summarizes the influence of the operation conditions on the evaporative flux in the SGMD processes.

Desalination has been the most investigated application of MD. This hybrid technology can be employed for the removal of salts and other undesired compounds from a saline water solution to produce freshwater, with quality enough for human consumption, agriculture or industrial uses [

10]. Consequently, the development of an improved membrane for this particular application emerges as a very relevant hot topic of research [

11,

12]. Nevertheless, MD has been successfully implemented in other applications. For example, references of the employment of MD for the dehydration of different solutions, such as aloe vera juice [

13], aqueous solutions of glycerol [

14] or diethylene glycol [

15], can be found in the bibliography. More specifically, SGMD has been applied for the recovery of volatile chemicals like aroma compounds, [

16] but examples of its application to the dehydration of glycerol [

17] and triethylene glycol [

18] have been published as well.

Taking into account this available information, the main aim of this work is the analysis of the potential of SGMD for the concentration of aqueous solutions of 1,3-dimethyl-2-imidazolidinone (DMI). This chemical is a dipolar aprotic solvent with characteristics between tetrahydrofuran (THF) and hexamethylphosphoramide (HMPA), suitable for many types of organic reactions (especially organometallic reactions) [

19,

20,

21,

22,

23,

24,

25,

26,

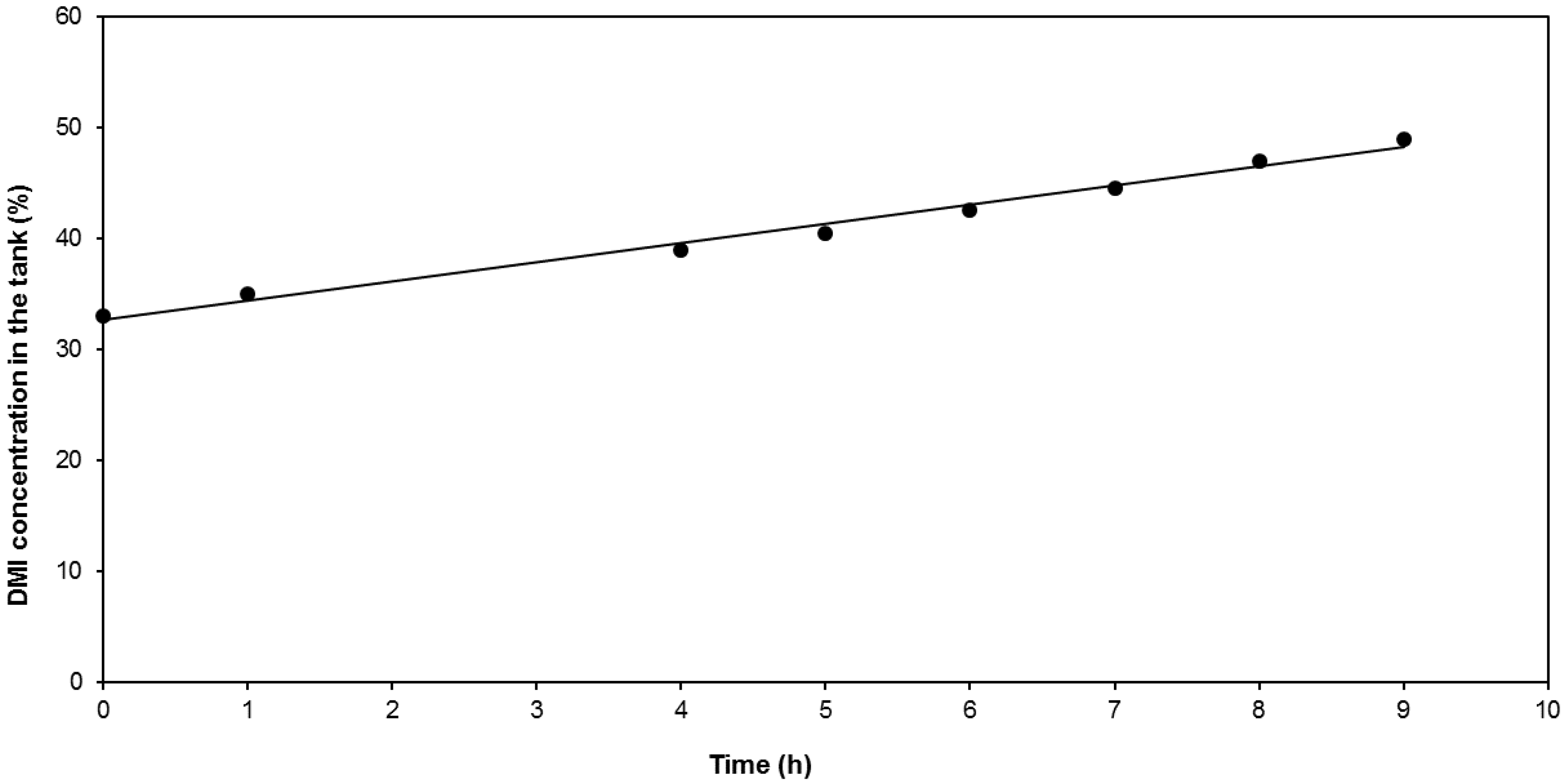

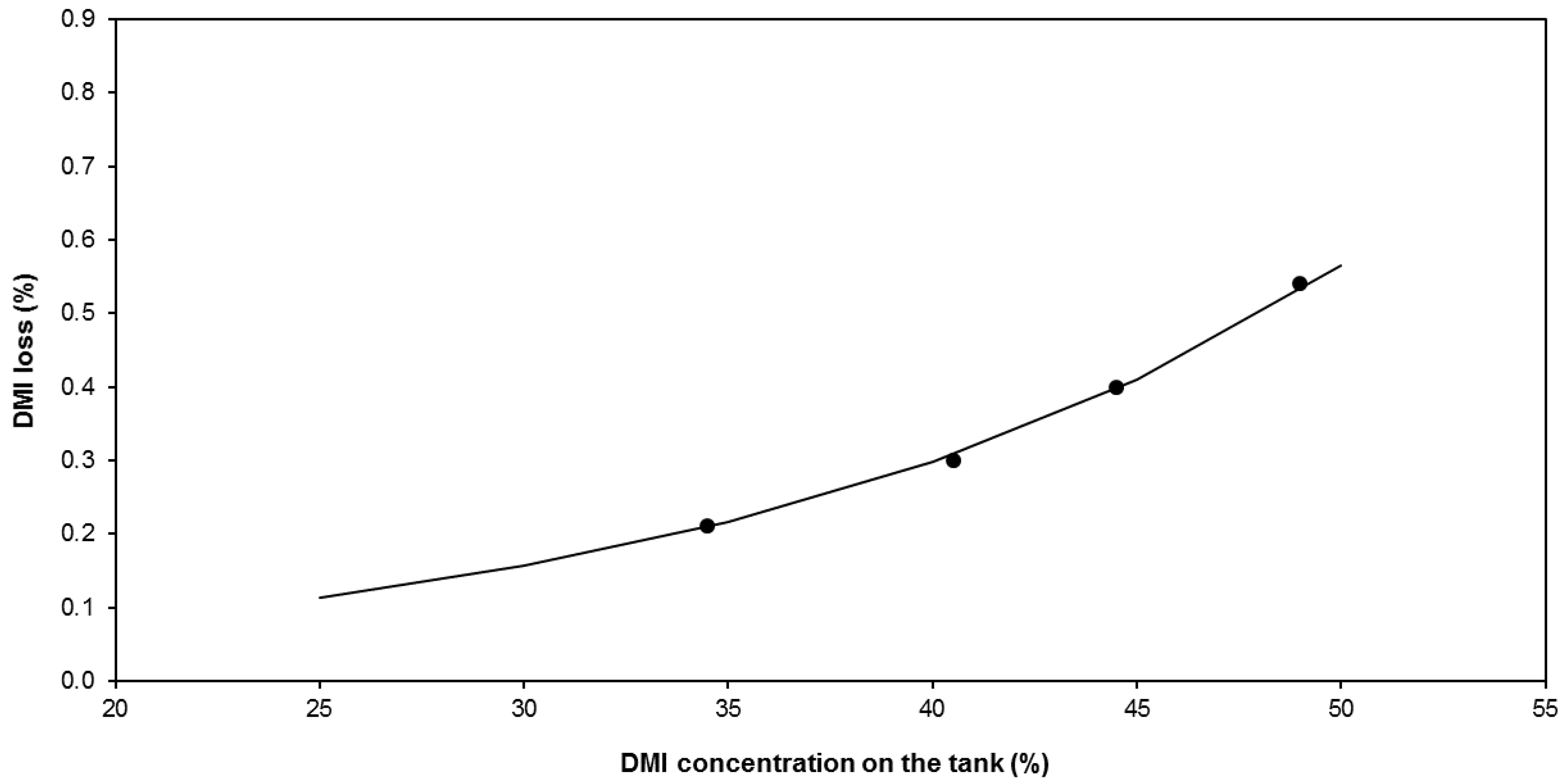

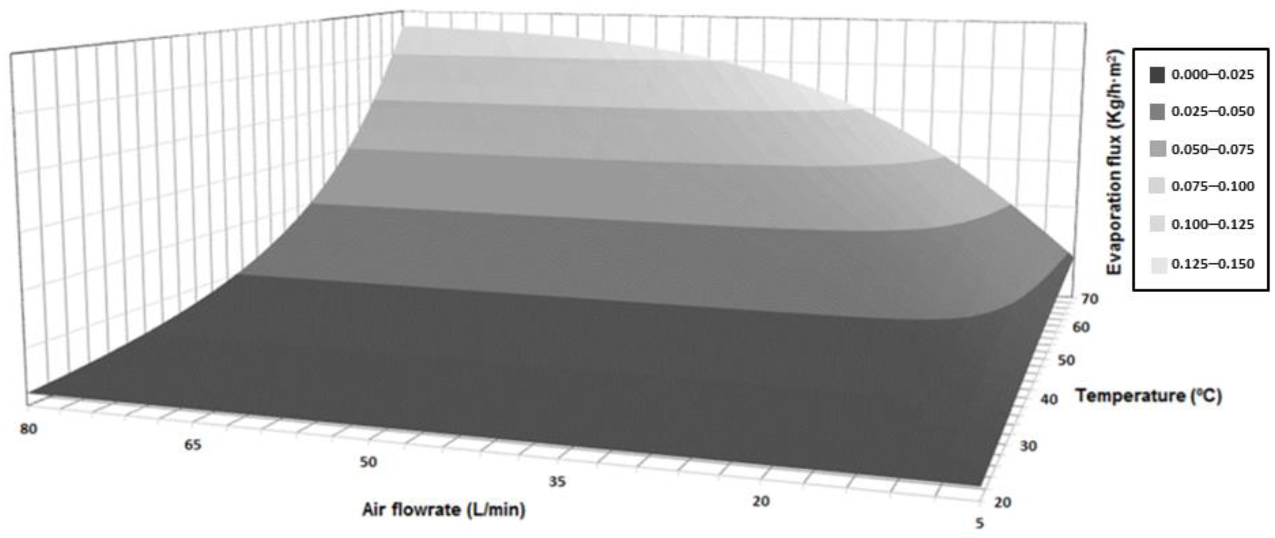

27]. Moreover, DMI is used in the manufacture of polymers, as well as in the industry of detergents, dyestuffs, and electronic materials. The recycling of this solvent from aqueous solutions without significant losses is very important for the sustainability of industrial processes. In this work, the concentration from 30% to 50% of aqueous DMI solutions was investigated, paying attention to the main variables of the process: temperatures and flowrates of the feed and sweep gas streams. From these experimental data, simple empirical models were developed to simulate the performance of the installation and calculate the vapor permeation and the DMI losses through the membranes. These empirical models can imply relevant simplification when compared with more complex models developed to represent the performance of SGMD. Finally, the preliminary scaling-up of the process was covered under different multi-objective optimization frameworks.

2. Experimental

2.1. Chemicals

DMI (99.9% of purity) was supplied by Kermel. Ultrapure water (>18.0 MΩ·cm resistivity) was obtained by a Milli-Q Element (Merck KGaA, Darmstadt, Germany).

2.2. Membrane Selection

The selection of a membrane for concentration by SGMD is strictly related to the intended application, as it depends on the nature of the solution to be concentrated. Among the SGMD membranes available on the market, the Liqui-Cel SuperPhobic

® membrane (provided by Alting, Hoerdt, France) appears to be the most suitable, since it is made of polypropylene, an inert polymer stable in contact with DMI. The membrane is hydrophobic and intended for applications with solutions characterized by surface tension values between 20 dyne/cm and 40 dyne/cm (in the case of DMI, its value is 40 dyne/cm). The membrane is commercially available as tubular modules of hollow fibers, in several different geometries. The module Liqui-Cel SuperPhobic

® X50 was selected and the characteristics of its fibers can be found in

Table 3. The total membrane area of the module was 1.2 m

2.

2.3. Experimental Installation

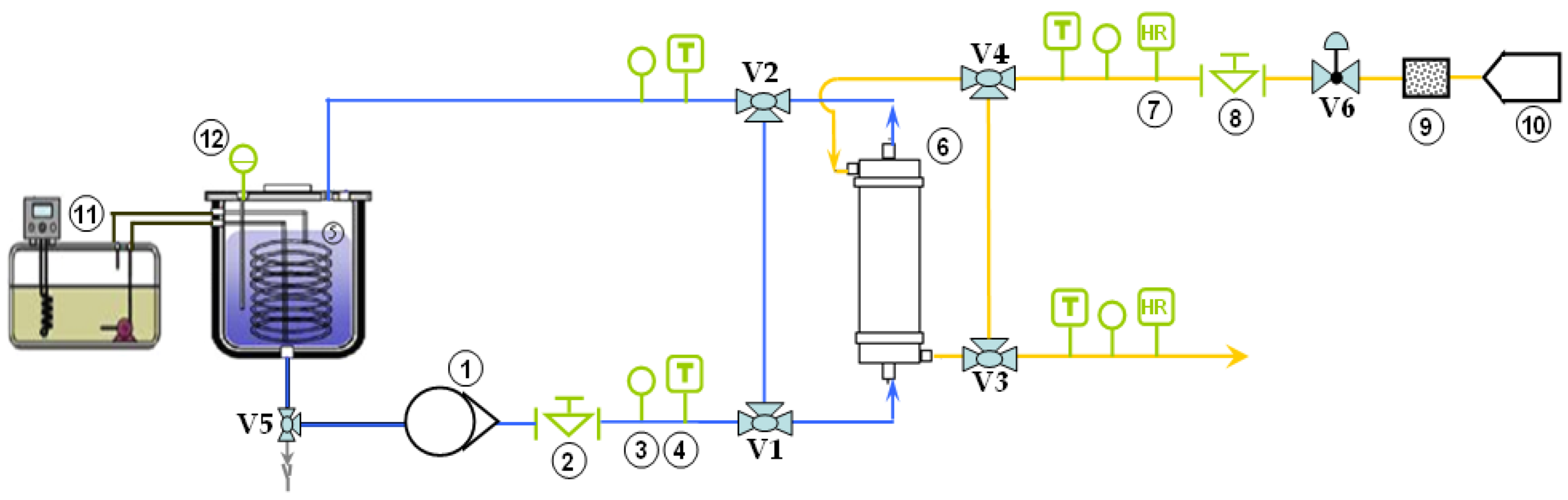

On the basis of the characteristics of the module described in the previous section, a SGMD bench installation was designed (

Figure 3). Due to the nature of the solution to be concentrated, all of the equipment employed in the bench installation was made of stainless steel in order to be compatible with DMI.

As shown in

Figure 3, the counter current configuration was selected. The DMI solution was stored in a 6 L stainless steel tank (5). During the operation, the volume inside the tank was controlled by a level sensor (12) (Immersion Piezo-Resistive Pressure, Keller 46X). The temperature of the solution was self-regulated by a heat exchanger consisting of a dipping coil (stainless steel), connected to a circulating cryo-thermostat (11). The solution circulation to the module was provided by a gear pump (1) (Micropump M520513), equipped with a speed controller (20–600 L/h). The flow rate was measured by a flow meter (2) with a micro-oval counter (Oval LSN45 LO). The solution passed through the module (6) outside the fibers and was recirculated back to the feed tank after leaving the module. The temperature and pressure were measured at the inlet and outlet of the module by a piezo-resistive pressure transmitter (0–5 bar) and a thermocouple (4), respectively. These same sensors were also installed at the inlet and outlet of the dry air compartment to measure the flow of air circulated in countercurrent inside the fibers. The relative humidity of the air (% RH) was measured at the inlet and outlet of the module by a humidity transmitter (7) (Delta Ohm HD2007) equipped with a remote sensor. Before entering the module, the air from the compressor (10) (7% RH) passed through a desiccant cartridge (9). The airflow was measured by a rotameter (8), in the range of 4–80 L/min (Brooks GT-1000). The airflow was regulated by means of the V6 control valve.

Depending on the position of the valves V1 to V4, the flows of the solution and the air can be done either in closed loop (without passing through the module) or in open loop (passing through the module). This makes it possible to stabilize the operating parameters (temperature, pressure, RH) before starting the concentration step. The V5 valve allows the tank to be drained. Each sensor was connected to a digital display to view the value in real time. The displays were assembled in a box that also provides power to the entire system.

2.4. Experimental Procedures

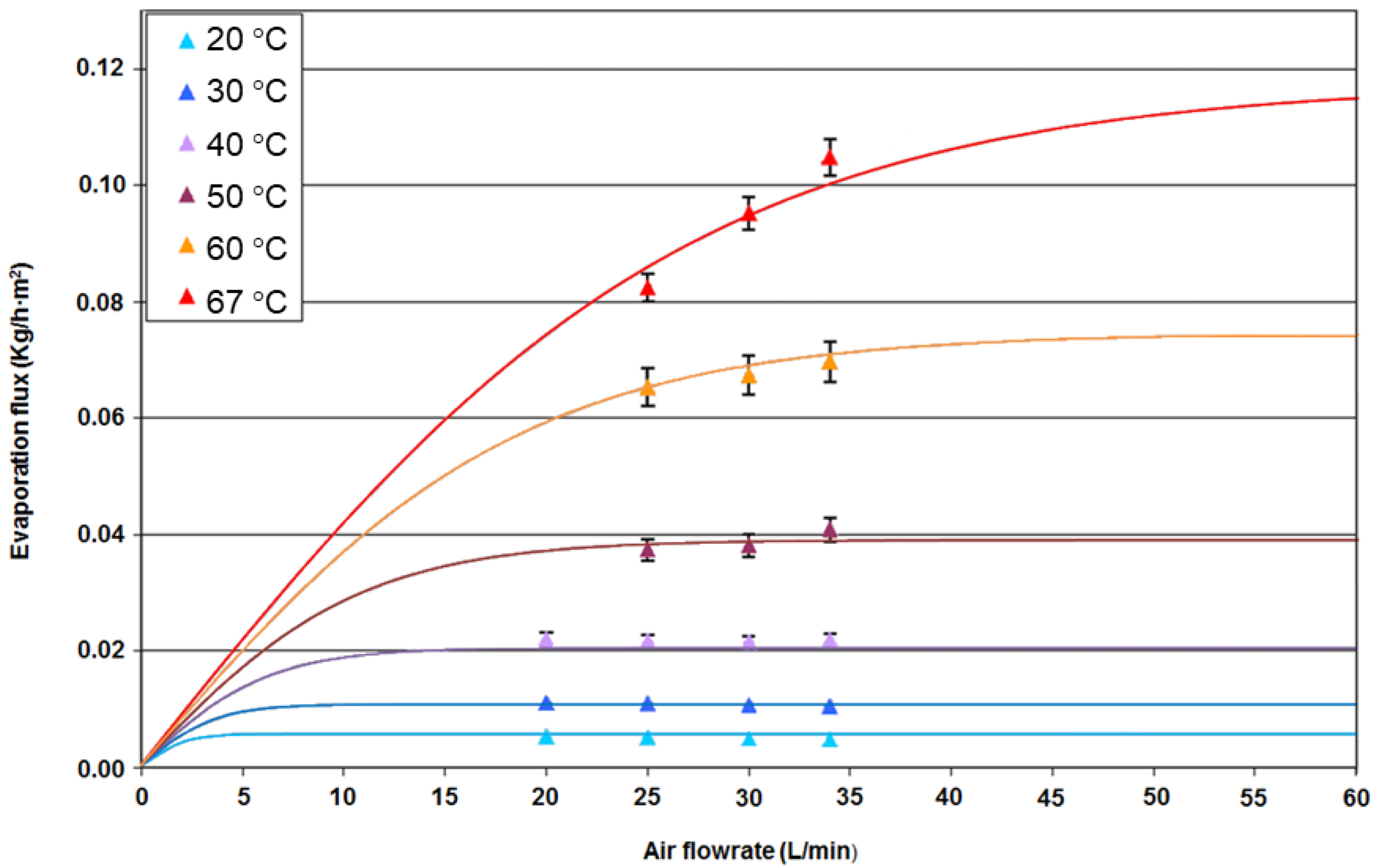

After the installation and testing of all the capabilities of the bench installation, the characterization of the system performance was carried out by determining its productivity in terms of evaporative flow through the membrane. These initial experiments were carried out by circulating ultrapure water in countercurrent with dry air (1.7% < RH < 5.0%). The resulting productivity was determined under different conditions by varying several parameters (water stream temperature and flowrate, air stream temperature and flowrate), to characterize the most relevant operation conditions. Each time a parameter was varied, the rest of the parameters were kept constant to analyze the influence of each variable individually. The evaporative flow was calculated from the difference in the measured relative humidity in the air stream before and after its pass through the module.

In the case of the concentration of DMI solutions, the experimental procedure was similar to that described for the tests with ultrapure water, with enough stabilization time to attain steady-state conditions. Based on the results of the analysis of the system with water, the operation conditions were chosen to obtain a high yield in terms of evaporative flow and, consequently, a high concentration rate of the DMI solution. The implementation of a valid method for the determination of the DMI concentration was essential for monitoring the performance of the concentration process of the aqueous solution. Moreover, any loss of DMI across the membrane during the concentration process must be identified and quantified. The concentration of DMI solutions was measured by refractometry (the evolution of the refractometer signal as a function of the DMI concentration for a range of 40–3000 ppm was lineal). Therefore, the proposed assay method was validated with a detection limit of 40 ppm.

4. Conclusions

This work investigated the applicability of sweeping gas membrane distillation (SGMD) to concentrate by dehydration aqueous solutions of 1,3-dimethyl-2-imidazolidinone (DMI). An experimental bench installation equipped with Liqui-Cel SuperPhobic® membranes was employed to analyze the influence of the main operation variables on the process performance. This way, the temperature of the feed stream and the air flowrate were identified as the most relevant variables.

The installation was successfully employed to achieve a concentration of DMI solutions from 30% to 50% under batch conditions. The selected membranes were responsible for the low vapor flux observed but were also effective for the minimization of DMI losses through the membrane since these losses were maintained below 1% of the evaporated water flux. This fact implied that more than 99.2% of the DMI fed to the system was recovered in the produced concentrated solution.

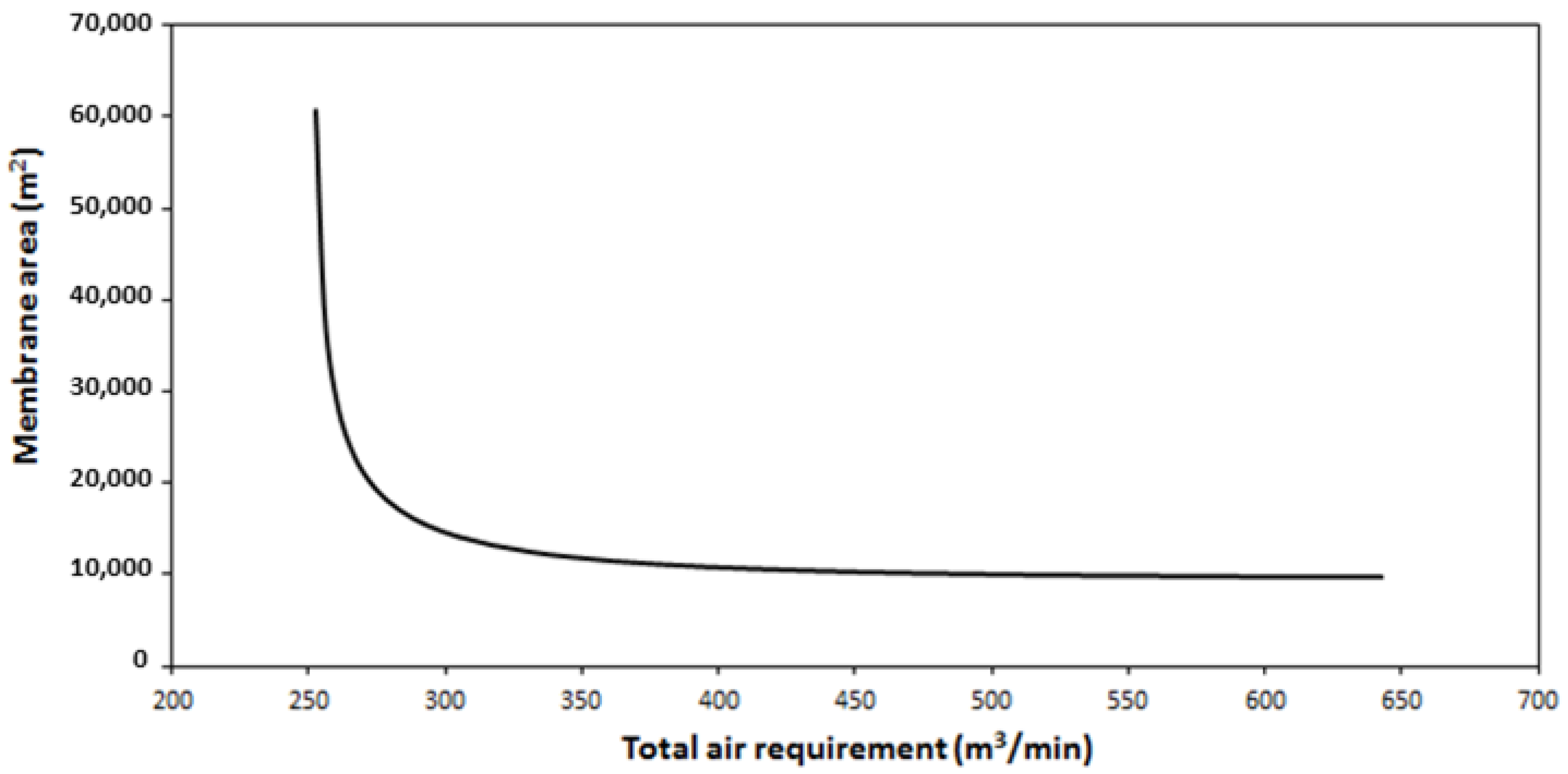

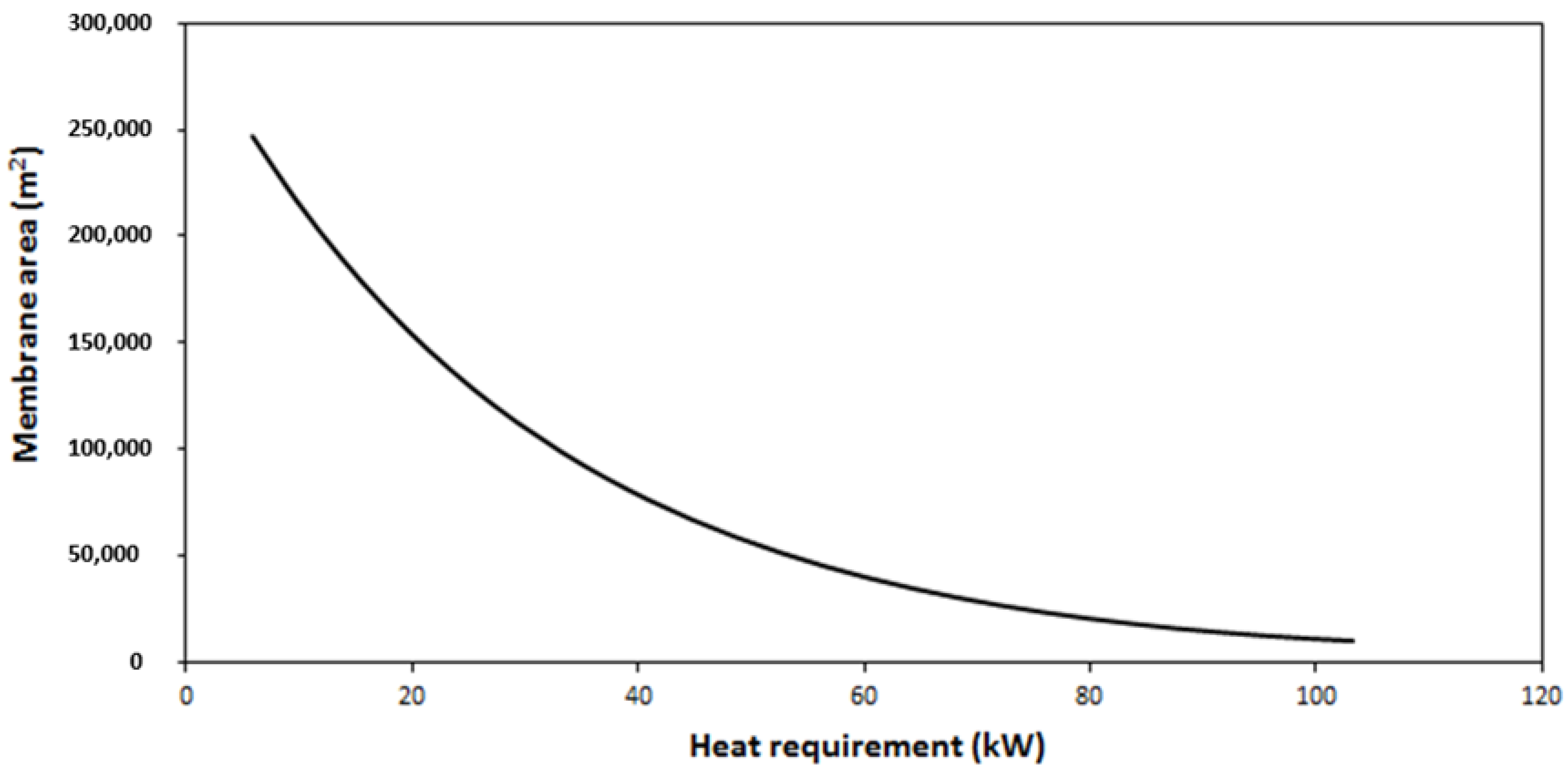

Once the technical viability of the process was confirmed, simple empirical models were developed to simulate the performance of the SGMD process for DMI concentration. These models were applied to the design of a scaled-up installation able to concentrate 3400 kg/h of a 30% DMI solution under continuous operation. The analysis of the influence of the main operation variables was taken into consideration to have a preliminary multi-objective optimization of the system by simultaneous minimization of the total membrane area, the heat requirement and the air consumption. The simulation results show that maximal feed temperature and air flowrate (and the corresponding high operation costs), as well as very high membrane area (9635 m2) were necessary to reach the contradictory objectives of the process. Under these conditions, the process was deemed to not be competitive for an industrial application and it should be improved before a definitive cost analysis that could be very carefully compared with classical distillation processes.