Strategic Co-Location in a Hybrid Process Involving Desalination and Pressure Retarded Osmosis (PRO)

Abstract

:1. Introduction

2. Design Considerations

2.1. Plant Capacity and Configurations

2.2. FO/PRO Operating Conditions and Considerations

| Design Conditions | Values | Units | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Coastal Seawater Desalination Plant | ||||||||||

| Feed Flow Rate | 172,800 | m3/day | ||||||||

| Recovery [4] | 50% | – | ||||||||

| Product Flow Rate | 86,400 | m3/day | ||||||||

| Energy for Water Treatment [4,5,6] | 2 | kWh/m3 | ||||||||

| Energy for Pretreatment & Brine Disposal [4,5,6] | 1 | kWh/m3 | ||||||||

| Specific Energy Consumption | 3 | kWh/m3 | ||||||||

| Water Reuse Plant | ||||||||||

| Feed Flow Rate | 345,600 | m3/day | ||||||||

| Recovery [4] | 75% | – | ||||||||

| Product Flow Rate | 259,200 | m3/day | ||||||||

| Energy for Water Treatment [18] | 0.60 | kWh/m3 | ||||||||

| Energy for Pretreatment & Brine Disposal [19] | 0.19 | kWh/m3 | ||||||||

| Specific Energy Consumption | 0.79 | kWh/m3 | ||||||||

| Pressure Retarded Osmosis (PRO) | ||||||||||

| (a) Draw: Seawater; Feed: Water Reuse Brine | ||||||||||

| Flux [21] | 18 | LMH | ||||||||

| Power Density | 5 | W/m2 | ||||||||

| Nominal Membrane Surface Area of 8 Inch Spiral Wound Modules | 18.13 | m2 | ||||||||

| (b) Draw: Seawater Brine; Feed: Concentrated Water Reuse Brine | ||||||||||

| Flux [21] | 15.84 | LMH | ||||||||

| Power Density | 8.8 | W/m2 | ||||||||

| Nominal Membrane Surface Area of 8 Inch Spiral Wound Modules | 18.13 | m2 | ||||||||

| Forward Osmosis (FO) | ||||||||||

| (a) Draw: Seawater; Feed: Water Reuse Brine | ||||||||||

| Flux [21,22,23] | 25 | LMH | ||||||||

| Nominal Membrane Surface Area of 8 Inch Spiral Wound Modules | 18.13 | m2 | ||||||||

| Energy Recovery Devices (ERDs) [24,25] | ||||||||||

| Isobaric Efficiency | 95% | – | ||||||||

| Non-isobaric Efficiency | 70% | – | ||||||||

2.3. Membrane Fouling and Post Treatment Improvements

2.4. Decision Matrix

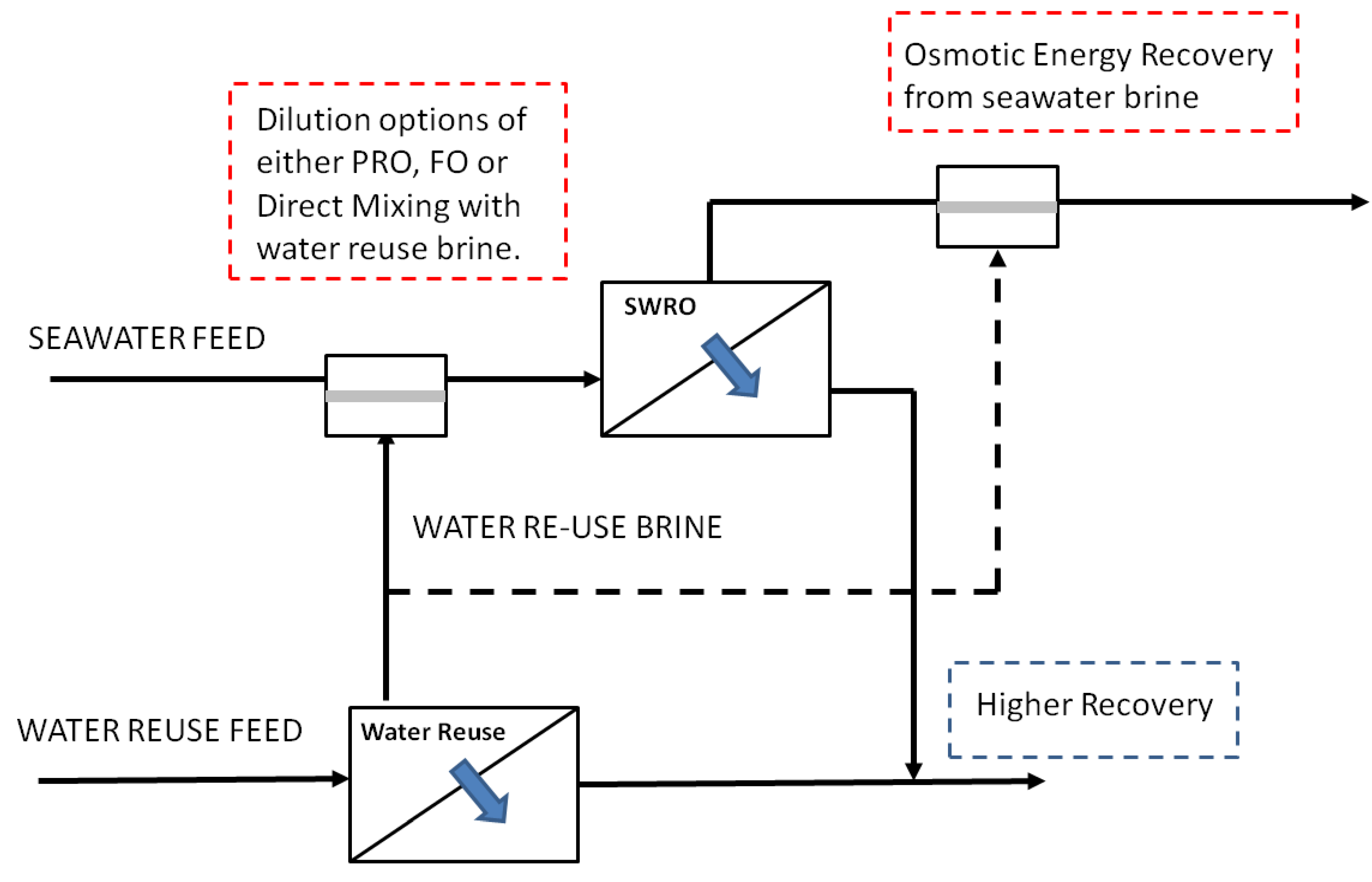

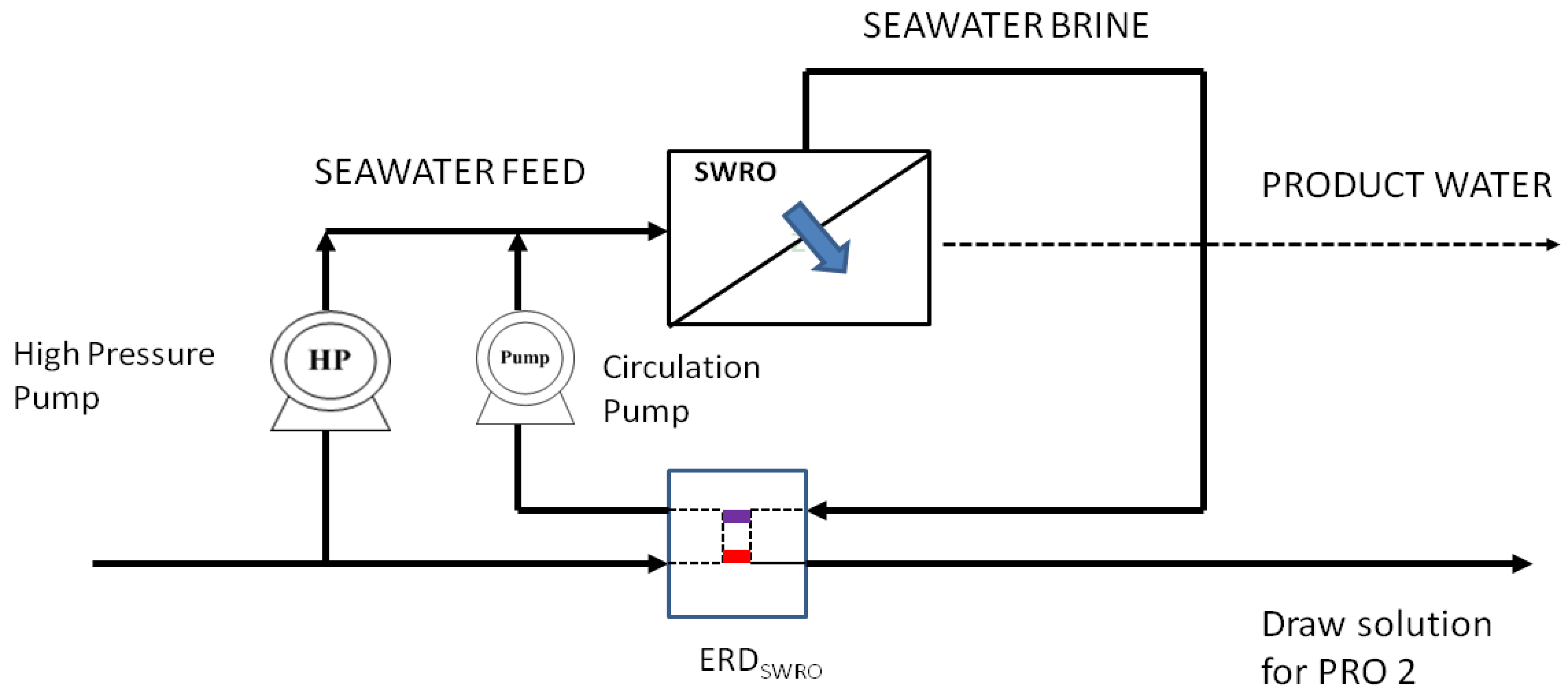

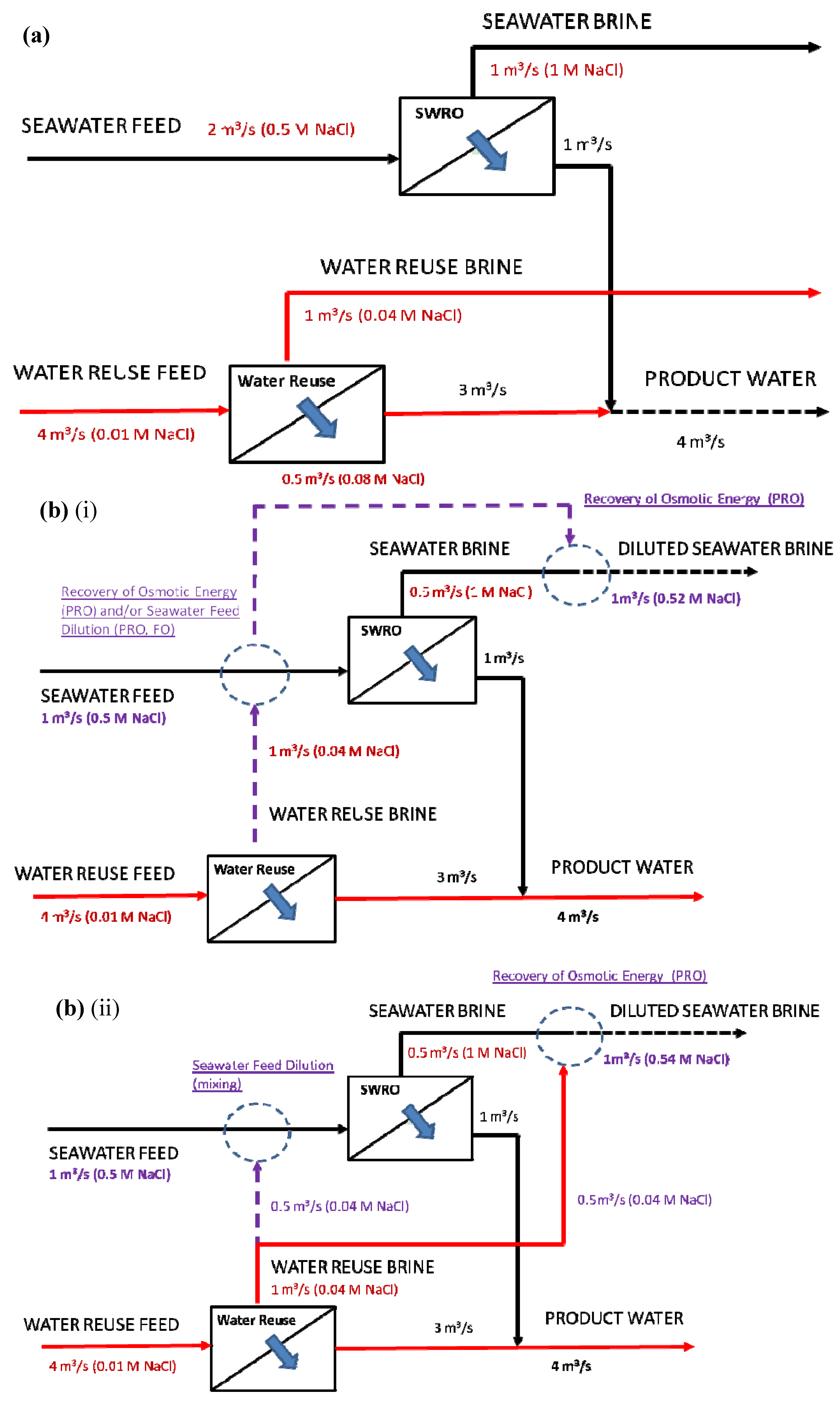

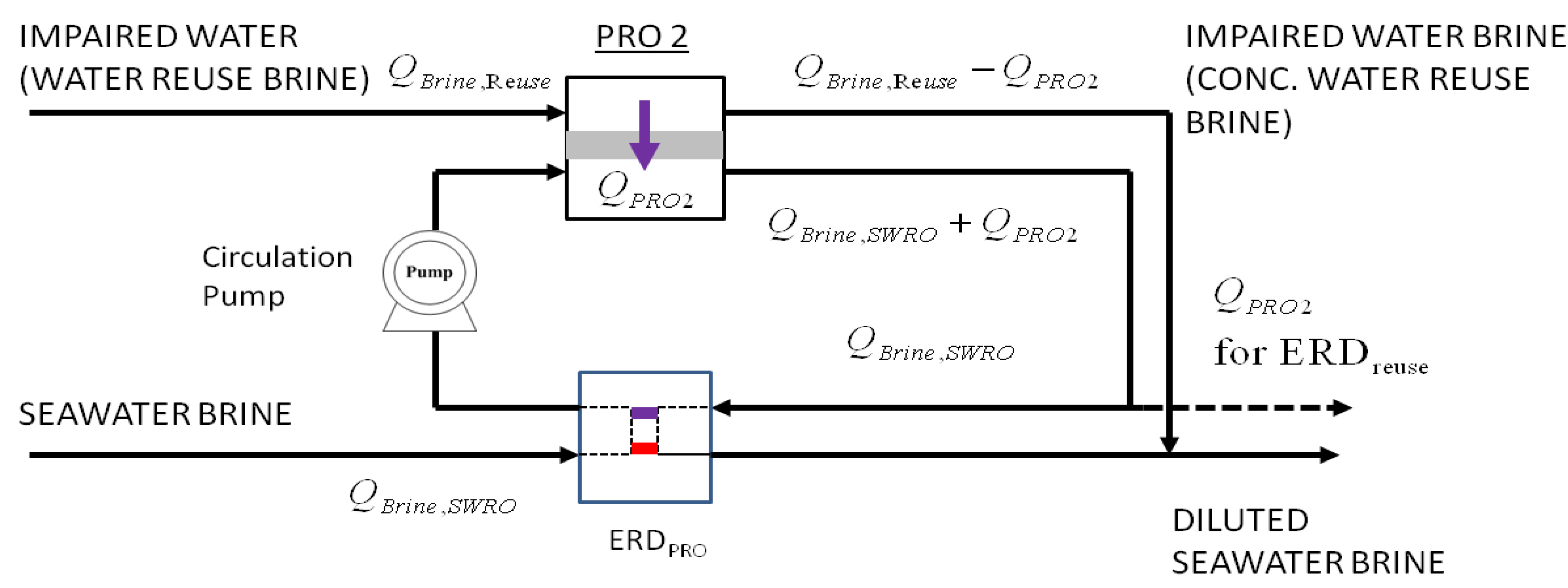

3. Hybrid Process Configurations

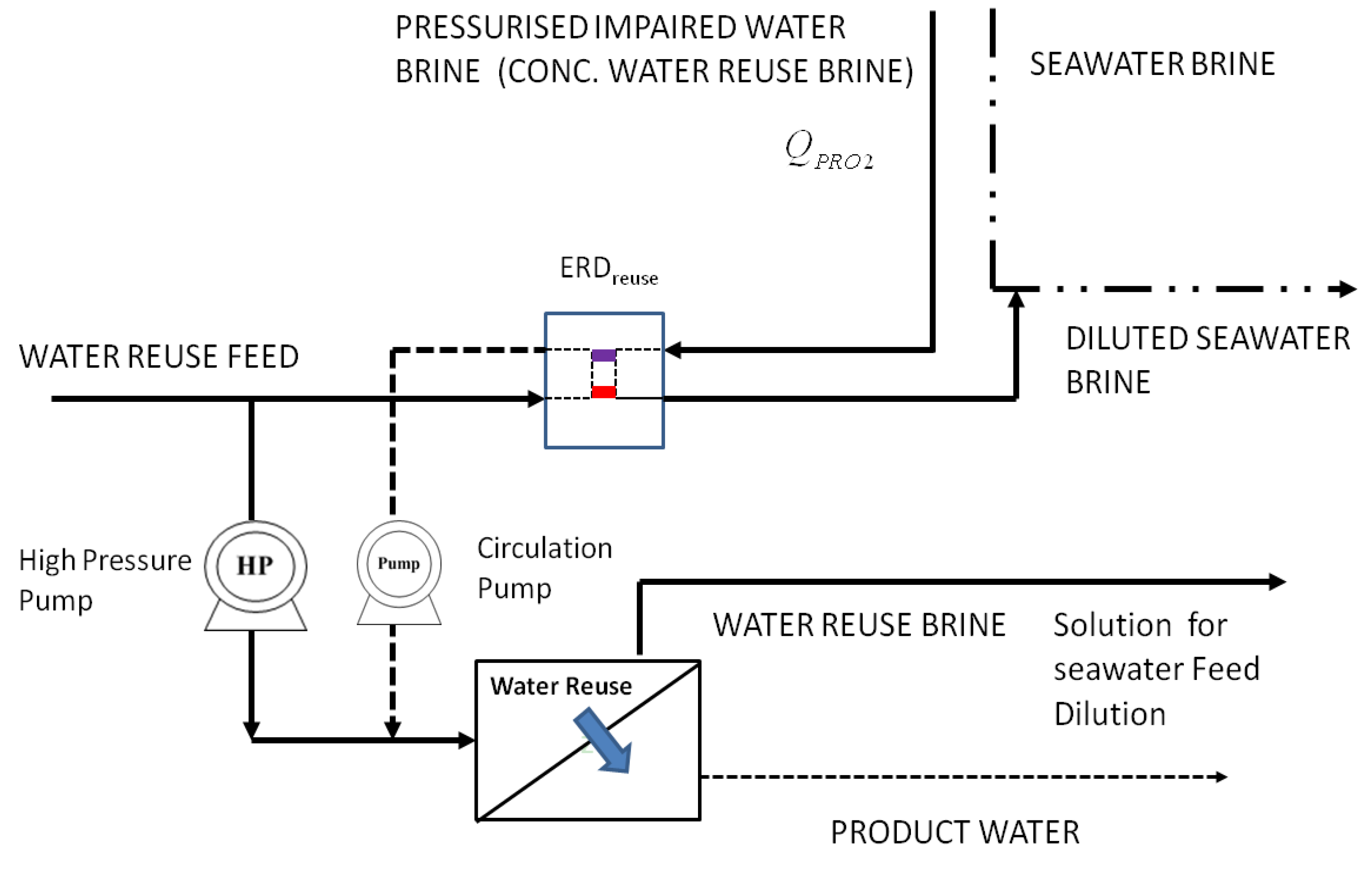

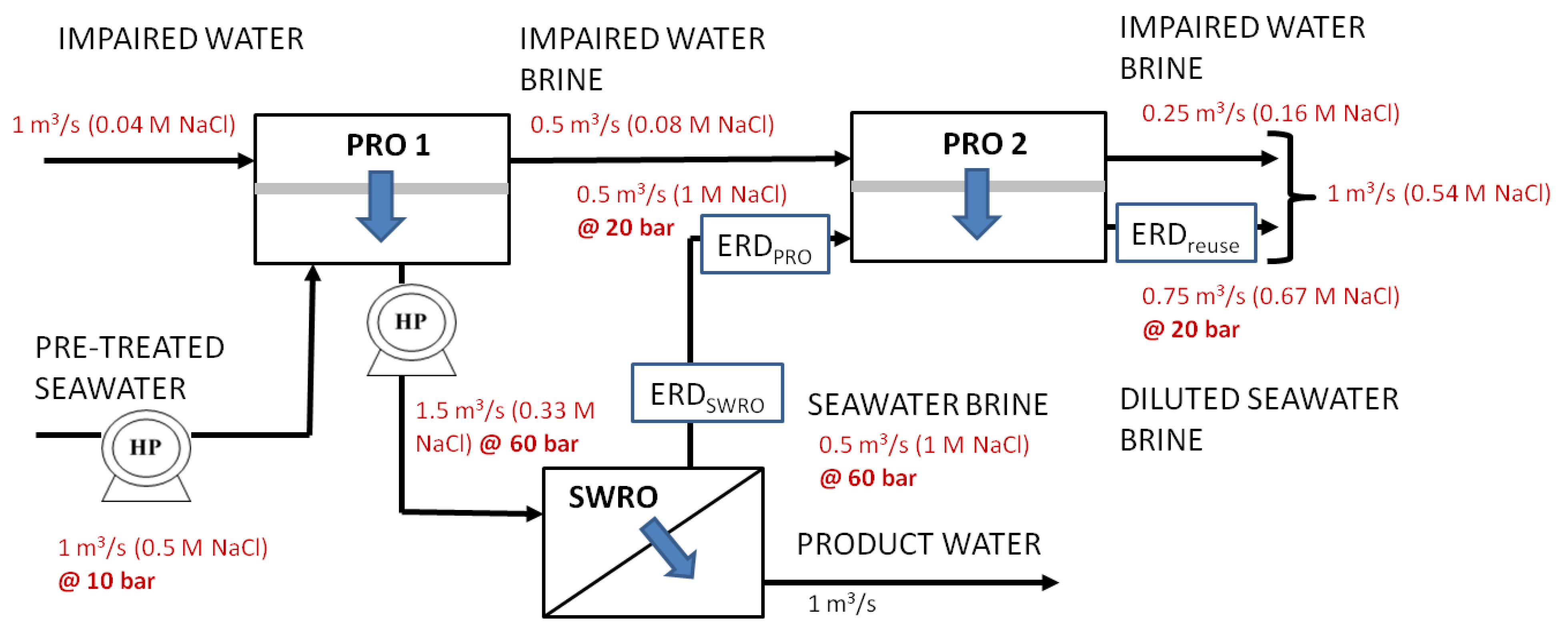

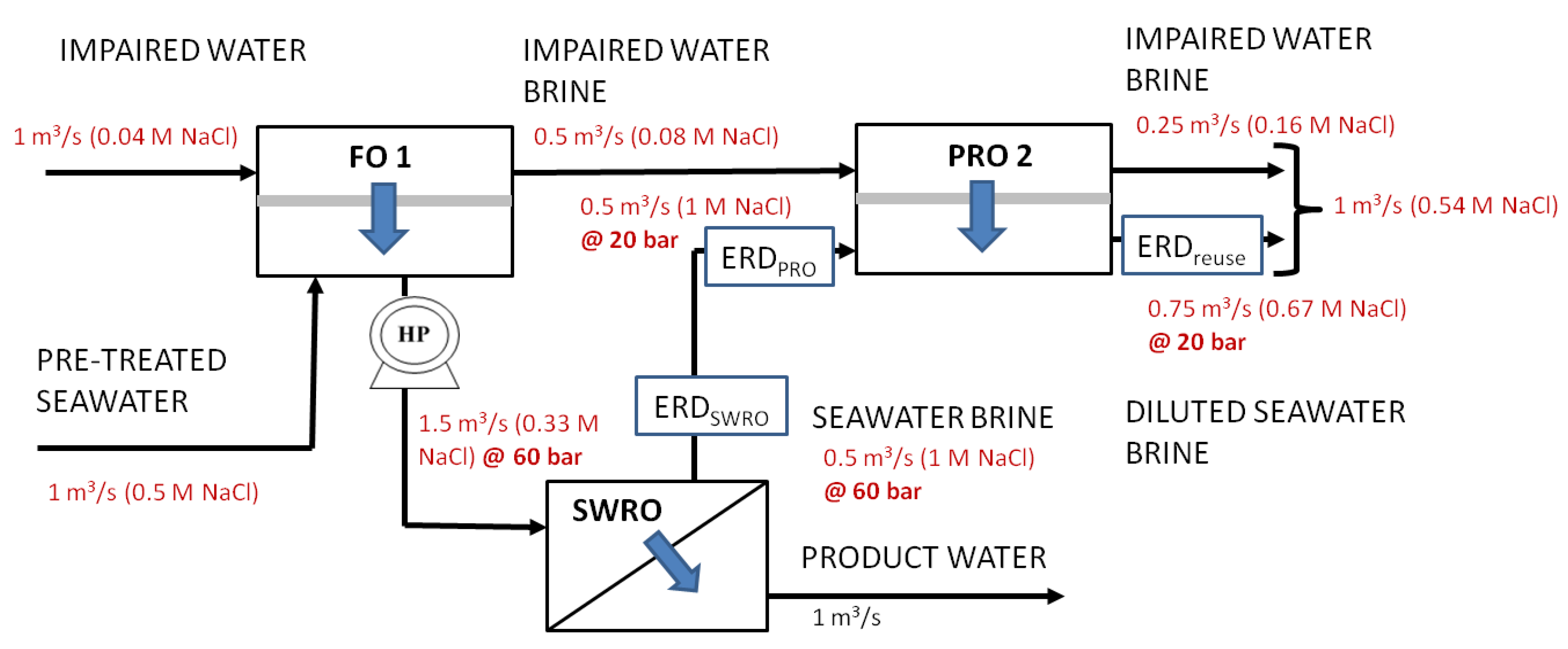

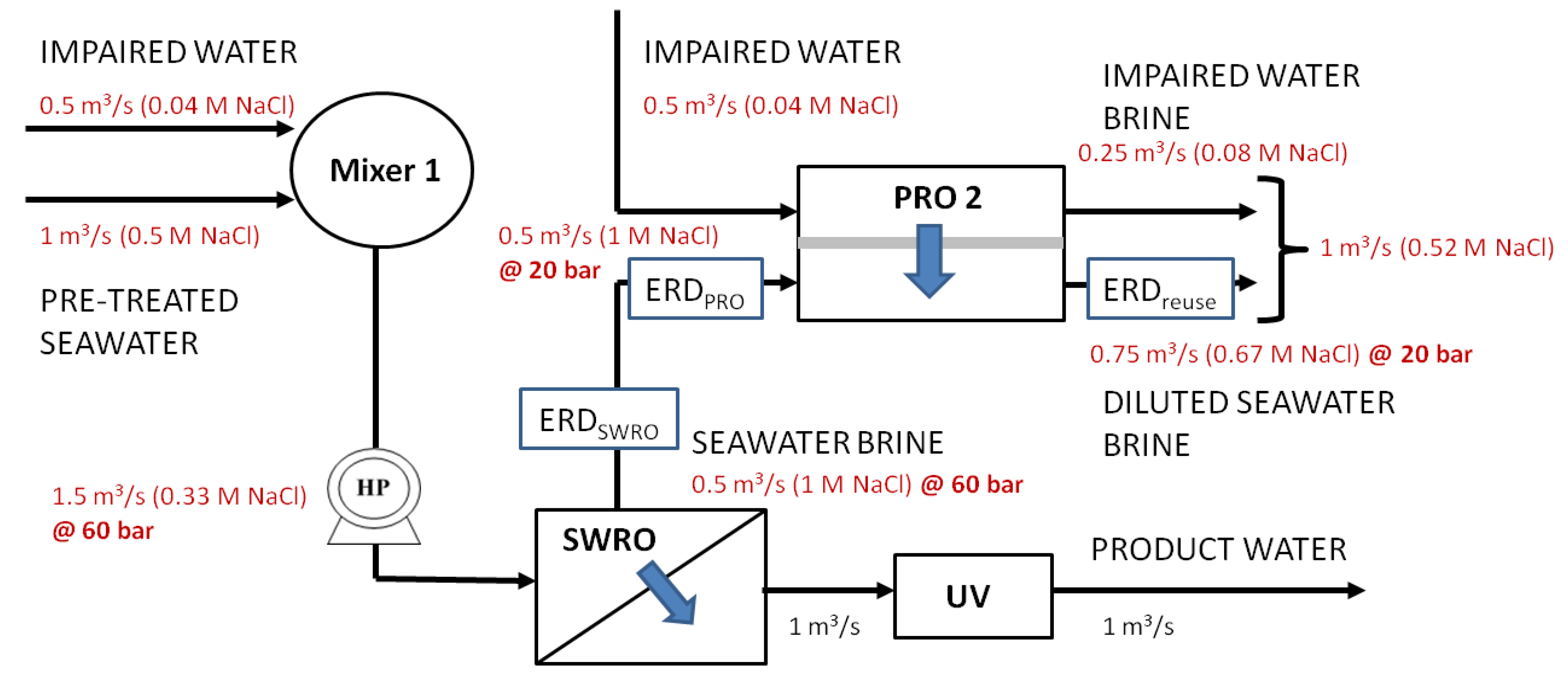

3.1. Various Configurations

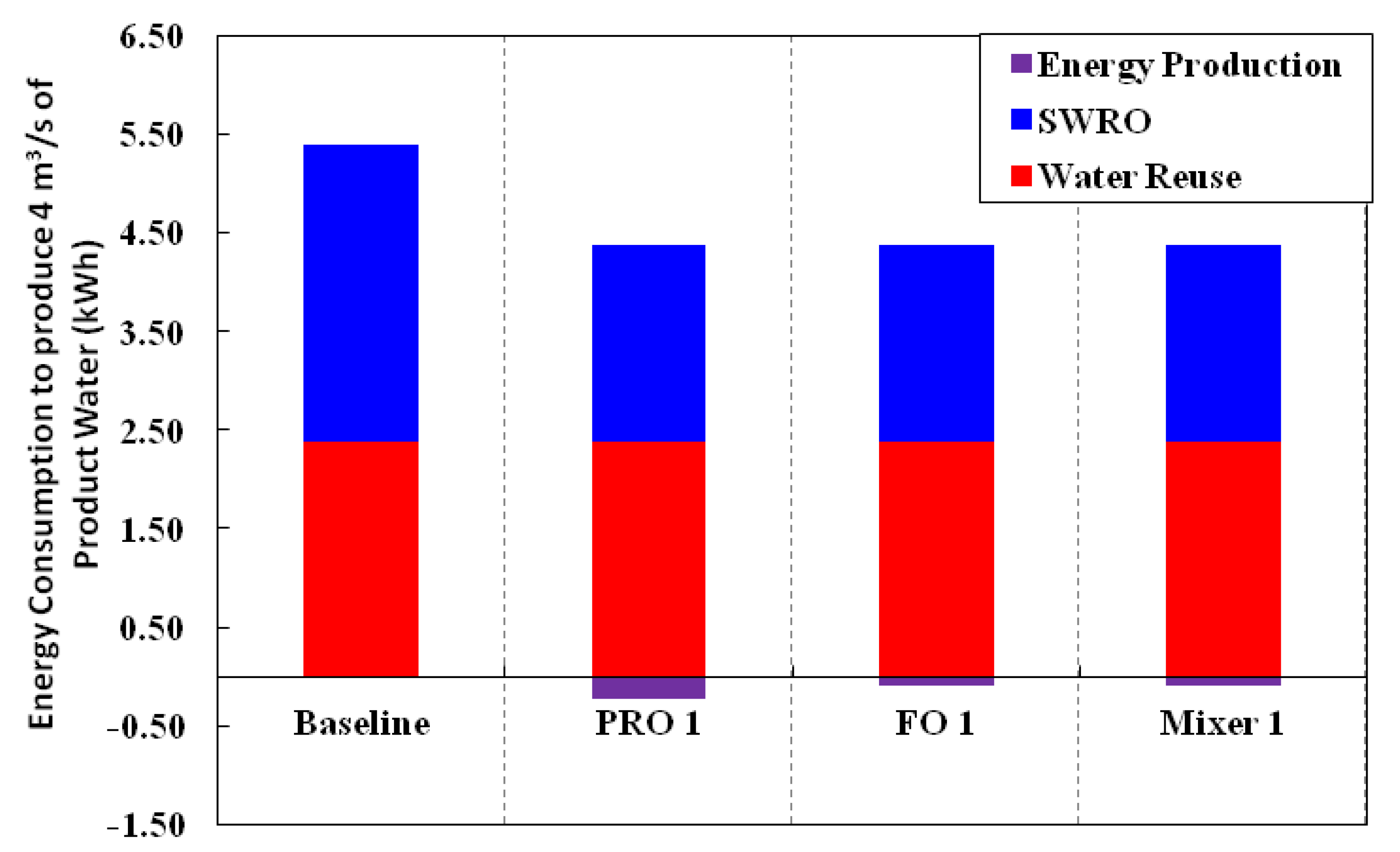

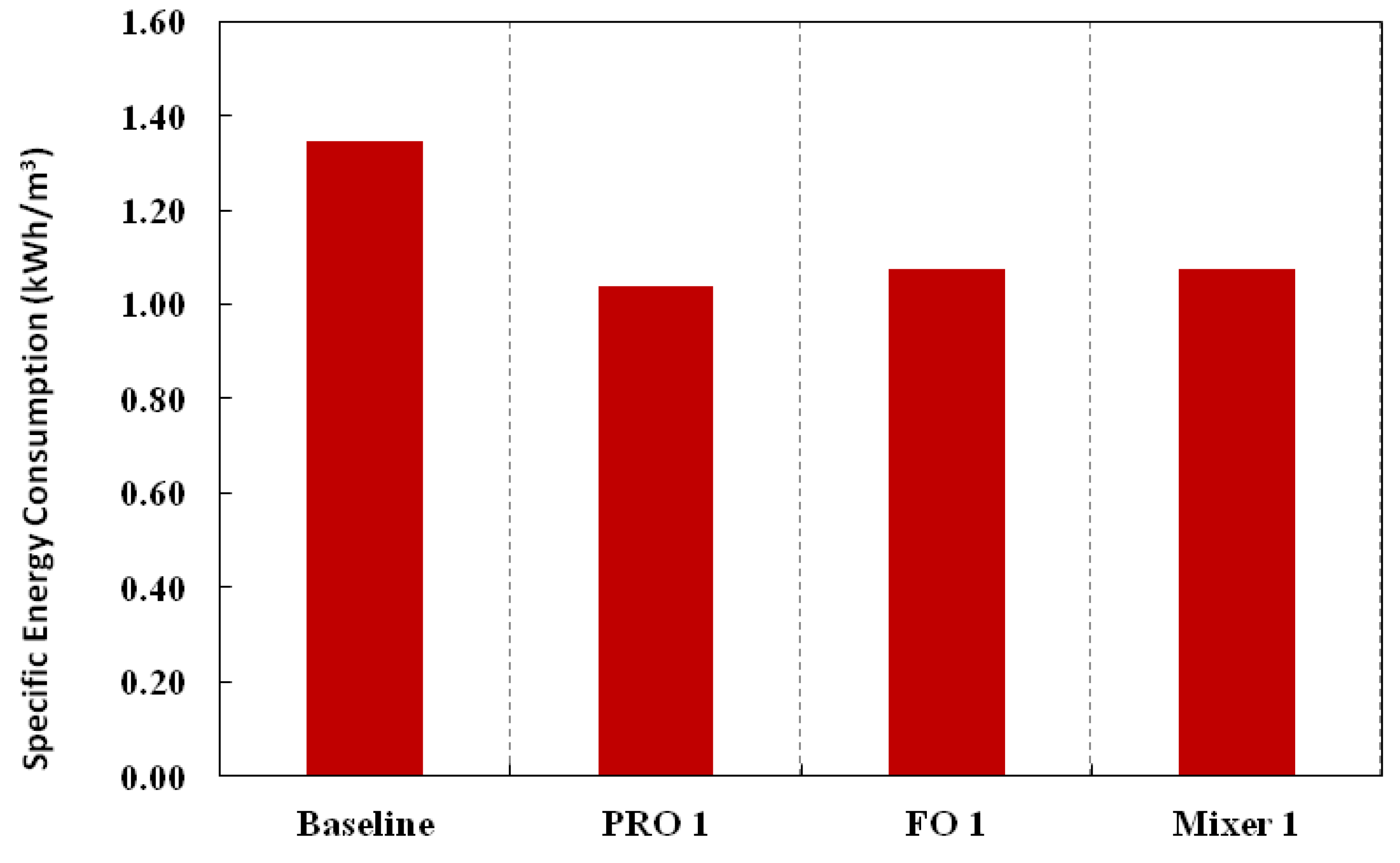

3.2. Summary of Energy Consumption

4. Results and Discussion

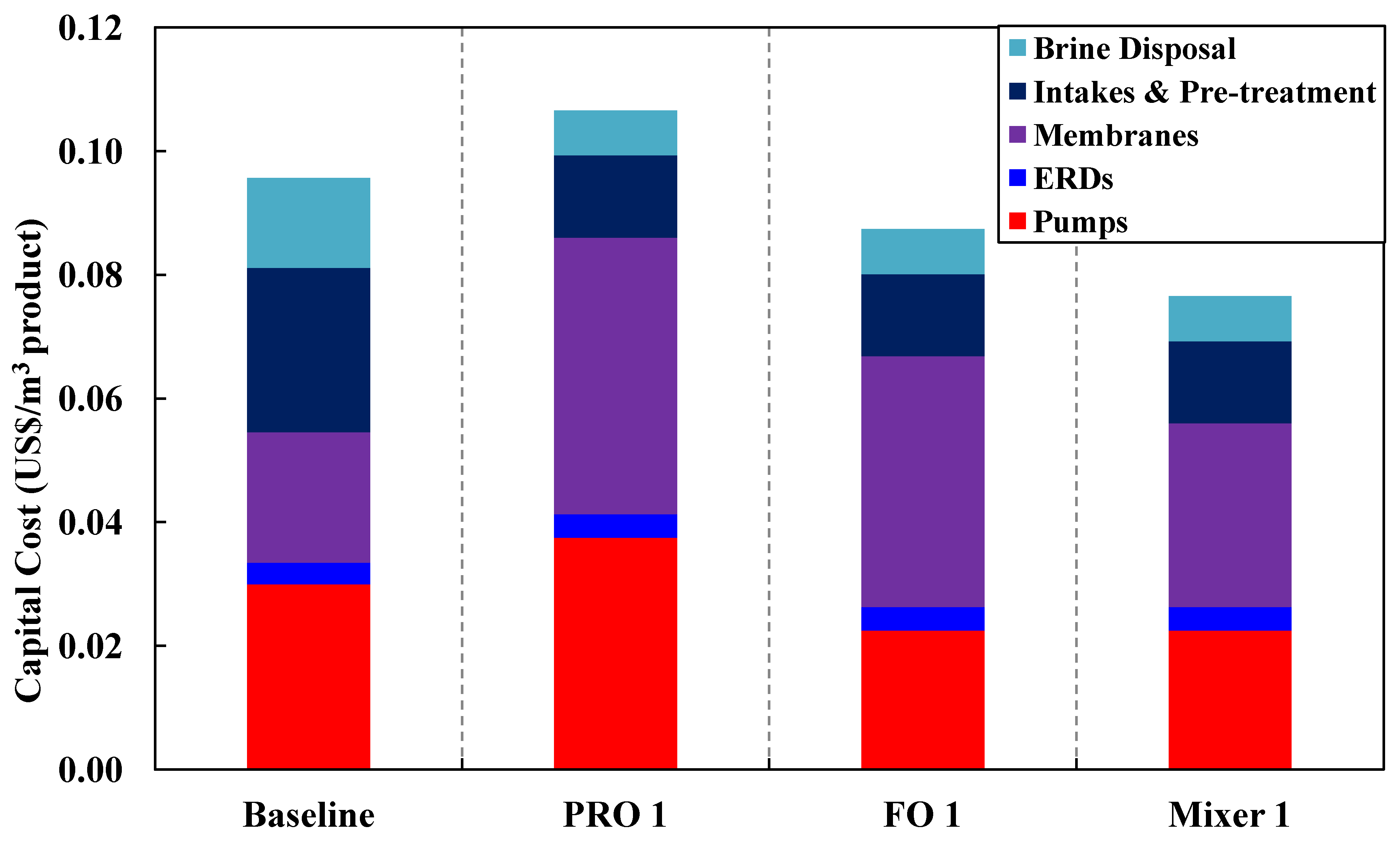

4.1. Summary of Comparison

| Weighing Factors | Baseline | Configurations | ||

|---|---|---|---|---|

| SWRO/Newater | B–PRO 1 | B–FO 1 | B–Mixer 1 | |

| Overall Energy Consumption 3 (kWh/m3) | 4 | 1 | 2 | 2 |

| Membrane Fouling Tendency 1 | 3 | 1 a | 1 a | 4 a |

| Total Capital Cost ** (US$/m3) | 3 | 4 | 2 | 1 |

| Space Footprint 2 | 1 | 4 | 3 | 2 |

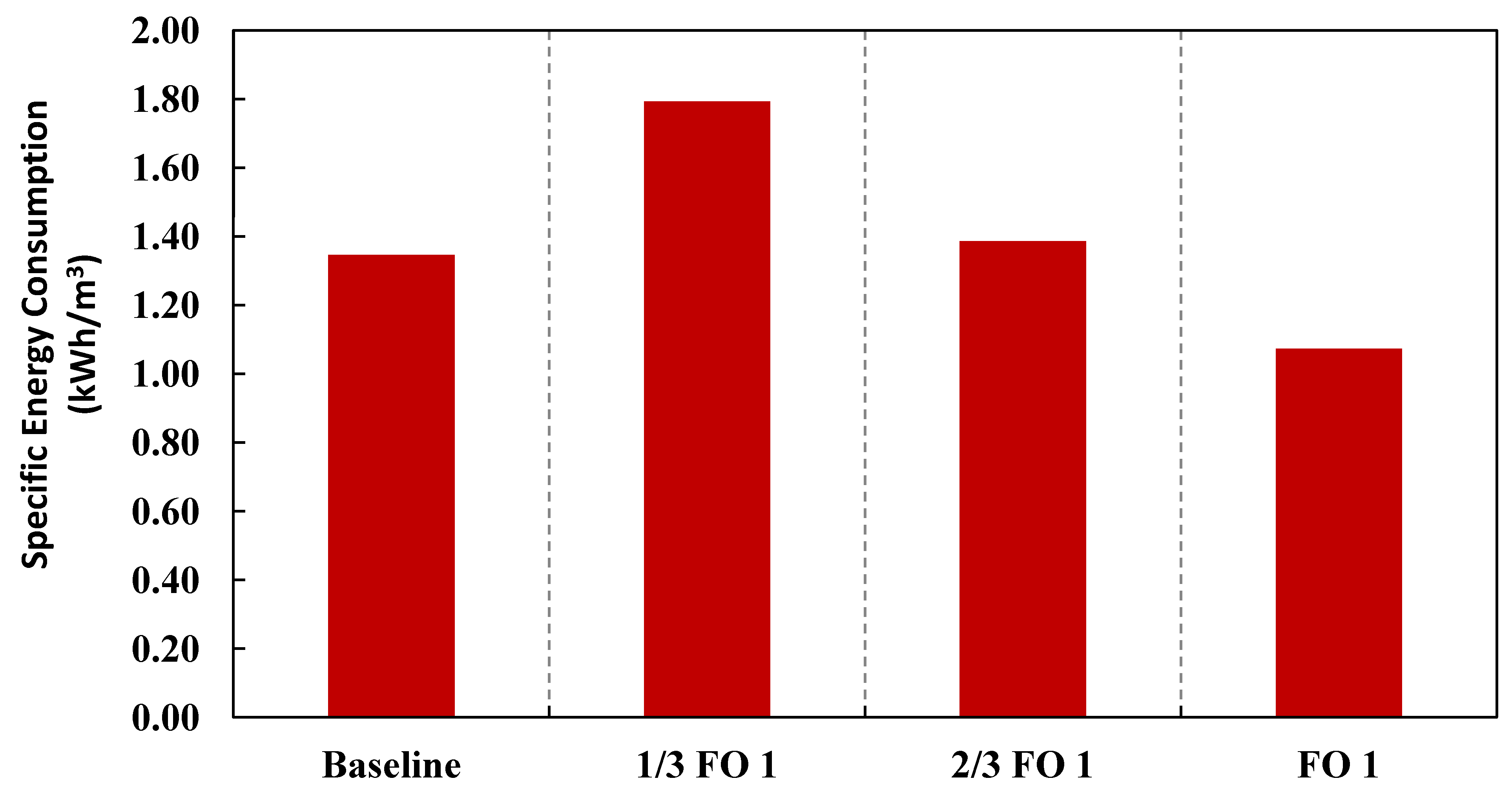

4.2. Sensitivity Analysis of Hybrid Process

4.3. Further Improvements

5. Conclusions

Appendix A (Glossary of Terms)

- Water reuse plants: Water reclamation plants utilizing brackish water reverse osmosis membranes.

- SWRO plants: Seawater desalination plants utilizing seawater reverse osmosis membranes.

- Product water: Water that permeates in either a SWRO plant or a water reuse plant.

- Water reuse feed: the feed source used for a water reuse plant.

- Water reuse brine: the retentate for a water reuse plant.

- Seawater feed: the feed source used for a SWRO plant.

- Seawater brine: the retentate for a water reuse plant.

- Specific Energy Consumption: Amount of energy required to produce unit volume of product water.

- Impaired water: Water reuse brine when used in the Hybrid Process configuration to dilute the feed source of SWRO plants or seawater feed.

- Impaired water brine: The retentate from the hybrid process involving Forward Osmosis (FO) and Pressure Retarded Osmosis (PRO) utilizing impaired water.

- Industrial water: non-potable water used for industrial purposes.

- Outfall: a pipeline or tunnel that discharges seawater or water reuse brine to the sea.

- Outfall height: the height a brine plume must reach to ensure proper dispersal of brine.

Appendix B (PRO State-of-the-Art)

Appendix C (Capital Cost Simulation)

C.1. Capital Cost Calculations

C.2. RO Data Calculations

| Membrane Element | SWC4+ |

|---|---|

| Membrane Active Area | 400 ft2 (37.1 m2) |

| Membrane Polymer | Composite Polyamide |

| Configuration | 8–inch Spiral Wound |

| Permeate Flow | 6500 gpd (24.6 m3/day) |

| Salt Rejection | 99.8% |

| Max. Applied Pressure | 1200 psig (8.27 MPa) |

| Max. Feed Flow | 75 GPM (17.0 m3/h) |

| Minimum Concentrate/Permeate Flow | 5:1 |

| Max. Pressure Drop per Element | 10 psi |

| Maximum Feed Water SDI (15 mins) | 5.0 |

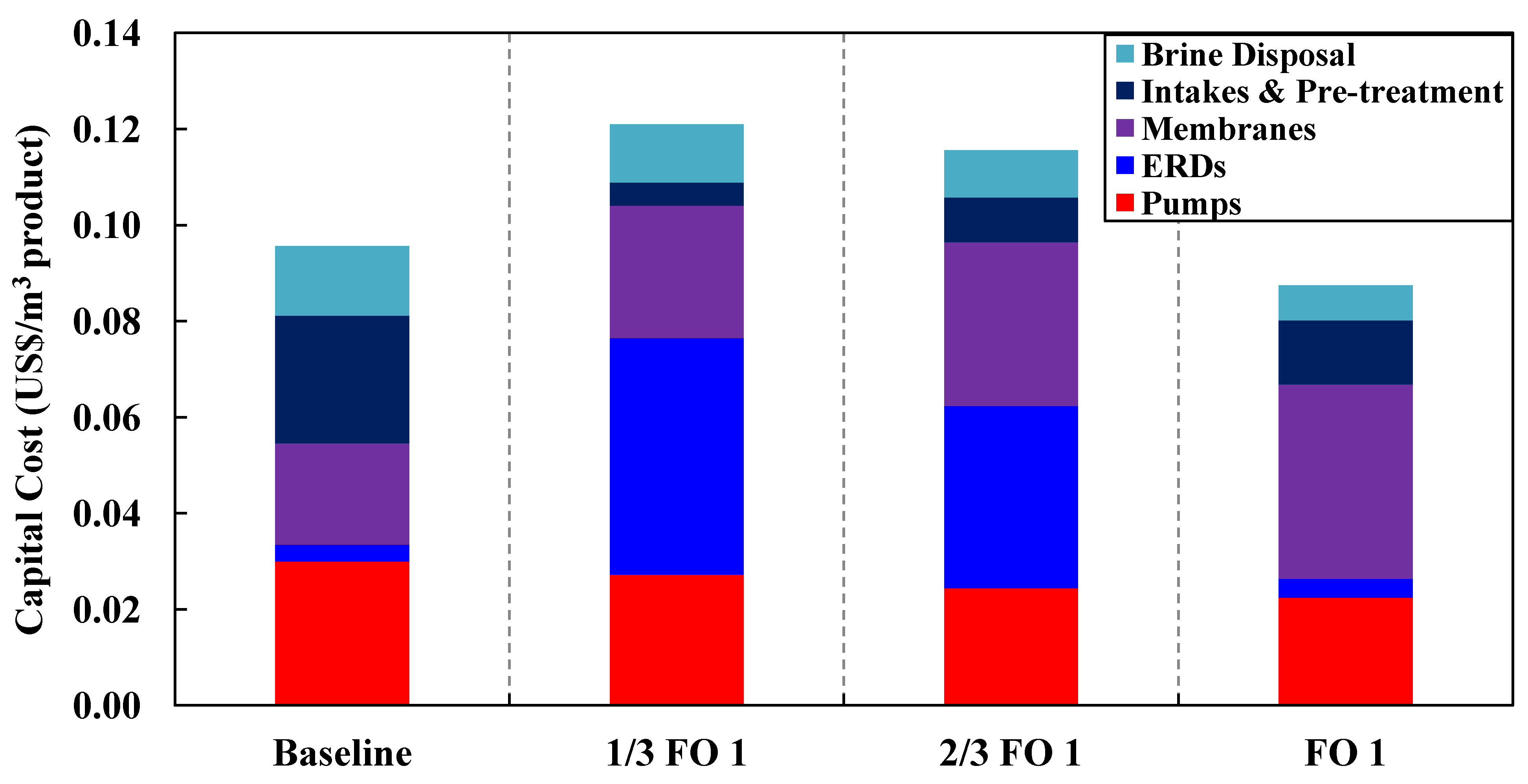

C.3. Breakdown of Capital Cost Calculations

| Capital Cost and Space Footprint | Baseline | Configurations | |||||

| SWRO | PRO 1 3 | (% change) | FO 1 4 | (% change) | Mixer 1 5 | (% change) | |

| Capital Cost of Pumps (US$/m3) | |||||||

| High Pressure Pumps | 0.030 | 0.037 | (25%) | 0.022 | (−25%) | 0.022 | (−25%) |

| Capital Cost of ERDs 6 (US$/m3) | |||||||

| Isobaric | 0.0035 | 0.0035 | 0.0035 | 0.0035 | |||

| Non-isobaric (Water Reuse ERD only for PRO 2) | – | 0.0003 | 0.0003 | 0.0003 | |||

| 0.0035 | 0.0038 | (8.6%) | 0.0038 | (8.6%) | 0.0038 | (8.6%) | |

| Capital Cost of Membranes 7 (US$/m3) | |||||||

| 0.021 | 0.045 | (112%) | 0.041 | (92%) | 0.030 | (41%) | |

| Capital Cost of Intakes and Pre-treatment (US$/m3) | |||||||

| 0.027 | 0.013 | (−50%) | 0.013 | (−50%) | 0.013 | (−50%) | |

| Capital Cost of Brine Disposal (US$/m3) | |||||||

| 0.015 | 0.0073 | (−50%) | 0.0073 | (−50%) | 0.0073 | (−50%) | |

| Total Capital Cost ** (US$/m3) | |||||||

| 0.096 | 0.1066 | (11%) | 0.0874 | (−8.7%) | 0.0765 | (−20%) | |

| Space Footprint | |||||||

| 8′′ spiral wound elements 1 | 5,405 | 11,460 | (112%) | 10,380 | (92%) | 7,600 | (41%) |

| SWRO intake/outfall and Water Reuse Outfall 2 | 4 m3/s | 2 m3/s | (−50%) | 2 m3/s | (−50%) | 2 m3/s | (−50%) |

Appendix D (Energy Consumption)

| Breakdown of Specific Energy Consumption | Baseline | Configuration-PRO 1 | Configuration-FO 1 | Configuration-Mixer 1 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Water Re-use | SWRO | Water Re-use | SWRO | Water Re-use | SWRO | Water Re-use | SWRO | |||

| Volume of Product Water (m3/s) | 3 | 1 | 3 | 1.0 | 3 | 1.0 | 3 | 1.0 | ||

| Volume of Total Feed Water 1 (m3/s) | 4 | 2 | 4 | 1.0 | 4 | 1.0 | 4 | 1.0 | ||

| Pressurized Feed Water (m3/s) | 4 | 2 | 4 | 1.5 | 4 | 1.5 | 4 | 1.5 | ||

| Volume of Brine (m3/s) | 1 | 1 | 1 | 1 | 1 | |||||

| Concentration of Brine (M NaCl) | 0.04 | 1 | 0.54 | 0.54 | 0.52 | |||||

| Energy Consumption (kWh/m3) | ||||||||||

| Entire system for water recovery | 0.60 | 2 | 0.60 | 1.50 | 0.60 | 1.50 | 0.60 | 1.50 | ||

| Pre-treatment/Brine Disposal | 0.19 | 1 | 0.19 | 0.50 a | 0.19 | 0.50 a | 0.194 | 0.50 a | ||

| Energy Recovery from PRO 2 (kWh/m3) | N.A. | 0.23 | 0.09 | 0.09 | ||||||

| Specific Energy Consumption (kWh/m3) | ||||||||||

| In terms of Product Water | 1.35 | 1.04 | 1.07 | 1.07 | ||||||

Conflict of Interest

Acknowledgements

References

- Kraas, F. Megacities and global change: Key priorities. Geogr. J. 2007, 173, 79–82. [Google Scholar] [CrossRef]

- Pearce, G.K. UF/MF pre-treatment to RO in seawater and wastewater reuse applications: A comparison of energy costs. Desalination 2008, 222, 66–73. [Google Scholar] [CrossRef]

- Global Water Intelligence–GWI, New Revenue Stream Springs Up: Water Reuse Market set for Explosive Growth. In Municipal Water Reuse Markets 2010; Media Analytics Ltd.: Oxford, UK, 2009.

- Desalination Committee, Seawater Desalination Power Consumption, White Paper; WaterReuse Association: Alexandra, VA, USA, 2011; p. 11.

- Shaffer, D.L.; Yip, N.Y.; Gilron, J.; Elimelech, M. Seawater desalination for agriculture by integrated forward and reverse osmosis: Improved product water quality for potentially less energy. J. Membr. Sci. 2012, 415–416, 1–8. [Google Scholar] [CrossRef]

- Elimelech, M.; Phillip, W.A. The future of seawater desalination: Energy, technology and the environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef]

- Shannon, M.A.; Bohn, P.W.; Elimelech, M.; Georgiadis, J.G.; Mariñas, B.J.; Mayes, A.M. Science and technology for water purification in the coming decades. Nature 2008, 452, 301–310. [Google Scholar] [CrossRef]

- Sim, S.T.V.; Tang, C.-Y.; Krantz, W.B.; Fane, A.G. Pressure Retarded Osmosis for Marina Barrage and Sustainable Brine Disposal. In Singapore-Netherlands Water Challenge 2011/2012, Singapore, 19 April 2012.

- Feinberg, B.; Ramon, G.; Hoek, E.M.V. A thermodynamic analysis of osmotic energy recovery at a reverse osmosis desalination plant. Environ. Sci. Technol. 2013, 47, 2982–2989. [Google Scholar]

- Cath, T.Y. Osmotically and thermally driven membrane processes for enhancement of water recovery in desalination process. Desalin. Water Treat. 2010, 15, 279–286. [Google Scholar] [CrossRef]

- Bamaga, O.A.; Yokochi, A.; Zabara, B.; Babaqi, A.S. Hybrid FO/RO desalination system: Preliminary assessment of osmotic energy recovery and designs of new FO membrane module configurations. Desalination 2011, 258, 153–159. [Google Scholar]

- Sharqawy, M.H.; Zubair, S.M.; Lienhard, V.J.H. Second law analysis of reverse osmosis desalination plants: An alternative design using pressure retarded osmosis. Energy 2011, 36, 6617–6626. [Google Scholar] [CrossRef]

- Knutson, C. Discussion of “Second law analysis of reverse osmosis desalination plants: An alternative design using pressure retarded osmosis [Energy (2011) 36: 6617–6626]”. Energy 2012, 46, 688–690. [Google Scholar] [CrossRef]

- Sharqawy, M.H.; Zubair, S.M.; Lienhard, V.J.H. Rebuttal to “Discussion of ‘Second law analysis of reverse osmosis desalination plants: An alternative design using pressure retarded osmosis’ [Energy (2011) 36: 6617–6626]”. Energy 2012, 46, 691–693. [Google Scholar] [CrossRef]

- Li, W.; Krantz, W.B.; Cornelissen, E.R.; Post, J.W.; Verliefde, A.R.D.; Tang, C.-Y. A novel hybrid process of reverse electrodialysis and reverse osmosis for low energy seawater desalination and brine management. Appl. Energ. 2013, 104, 592–602. [Google Scholar] [CrossRef]

- Côté, P.; Masini, M.; Mourato, D. Comparison of membrane options for water reuse and reclamation. Desalination 2004, 167, 1–11. [Google Scholar] [CrossRef]

- Qin, J.-J.; Oo, M.H.; Wai, M.N.; Lee, H.; Hong, S.P.; Kim, J.E.; Xing, Y.; Zhang, M. Pilot study for reclamation of secondary treated sewage effluent. Desalination 2004, 171, 299–305. [Google Scholar]

- National Research Foundation. Factsheet on EWI’s Challenge Request-for-Proposal on Achieving ≥93% Water Recovery from Membrane Bioreactor Filtrate, Research, Innovation and Technology Administration (RITA) System. 2012. Available online: https://rita.nrf.gov.sg/ewi/ChallengeRFP1201/default.aspx (accessed on 7 February 2013).

- Qin, J.-J.; Oo, M.H.; Lee, H.; Kolkman, R. Dead-end filtration for pretreatment of RO in reclamation of municipal wastewater effluent. J. Membr. Sci. 2004, 243, 107–113. [Google Scholar] [CrossRef]

- Saito, K.; Irie, M.; Zaitsu, S.; Sakai, H.; Hayashi, H.; Tanioka, A. Power generation with salinity gradient by pressure retarded osmosis using concentrated brine from SWRO system and treated sewage as pure water. Desalin. Water Treat. 2012, 4, 114–121. [Google Scholar]

- Chou, S.; Wang, R.; Shi, L.; She, Q.; Tang, C.-Y.; Fane, A.G. Thin-film composite hollow fibre membranes for pressure retarded osmosis (PRO) process with high power density. J. Membr. Sci. 2012, 389, 25–33. [Google Scholar] [CrossRef]

- Qi, S.; Qiu, C.Q.; Zhao, Y.; Tang, C.-Y. Double-skinned forward osmosis membranes based on layer-by-layer assembly–FO performance and fouling behaviour. J. Membr. Sci. 2012, 405–406, 20–29. [Google Scholar] [CrossRef]

- Ma, N.; Wei, J.; Liao, R.; Tang, C.-Y. Zeolite-polyamide thin film composite membranes: Towards enhanced performance for forward osmosis. J. Membr. Sci. 2012, 405–406, 149–157. [Google Scholar] [CrossRef]

- Farooque, A.M.; Jamaluddin, A.T.M.; Al-Reweli, A.R.; Jalaluddin, P.A.M.; Al-Mobeyed, S.M.; Qasim, A.H. Parametric analyses of energy consumption and losses in SWCC SWRO plants utilizing energy recovery devices. Desalination 2008, 219, 137–159. [Google Scholar] [CrossRef]

- Stover, R.L. Seawater reverse osmosis with isobaric energy recovery devices. Desalination 2007, 203, 168–175. [Google Scholar] [CrossRef]

- Stover, R.L.; Martin, J. Reverse osmosis and osmotic power generation with isobaric energy recovery. Desalin. Water Treat. 2010, 15, 267–270. [Google Scholar] [CrossRef]

- Arkhangelsky, E.; Wicaksana, F.; Chou, S.; Al-Rabiah, A.A.; Al-Zahrani, S.M.; Wang, R. Effects of scaling and cleaning on the performance of forward osmosis hollow fiber membranes. J. Membr. Sci. 2012, 415–416, 101–108. [Google Scholar] [CrossRef]

- Tang, C.-Y.; She, Q.; Ma, N.; Wei, J.; Sim, S.T.V.; Fane, A.G. Reinforced Membranes for Producing Osmotic Power in Pressure Retarded Osmosis. U.S. Provisional Patent 61/683,475, 15 August 2012. [Google Scholar]

- Kurihara, M.; Hanakawa, M. Mega-ton Water System: Japanese national research and development project on seawater desalination and wastewater reclamation. Desalination 2013, 308, 131–137. [Google Scholar] [CrossRef]

- Saliby, I.E.; Okour, Y.; Shon, H.K.; Kandasamy, J.; Kim, I.S. Desalination plants in Australia, review and facts. Desalination 2009, 247, 1–14. [Google Scholar] [CrossRef]

- Department of Climate Change and Energy Efficiency, Australian Government. Clean energy legislation: the way ahead. 2012. Available online: http://www.climatechange.gov.au/en/government/Carbon%20Pricing%20Policy/legislation.aspx (accessed on 7 February 2013).

- Jin, X.; Jawor, A.; Kim, S.; Hoek, E.M.V. Effects of feed water temperature on separation performance and organic fouling of brackish water RO membranes. Desalination 2009, 239, 346–359. [Google Scholar] [CrossRef]

- Thorsen, T.; Holt, T. The potential for power production from salinity gradients by pressure retarded osmosis. J. Membr. Sci. 2009, 335, 103–110. [Google Scholar] [CrossRef]

- Loeb, S. Production of energy from concentrated brines by pressure retarded osmosis. I. Preliminary technical and economic correlations. J. Membr. Sci. 1976, 1, 49–63. [Google Scholar] [CrossRef]

- Loeb, S.; Hessen, F.V.; Shahaf, D. Production of energy from concentrated brines by pressure retarded osmosis. II. Experimental results and projected energy costs. J. Membr. Sci. 1976, 1, 249–269. [Google Scholar] [CrossRef]

- Loeb, S. Energy production at the Dead Sea by pressure-retarded osmosis: Challenge or chimera? Desalination 1998, 120, 247–262. [Google Scholar] [CrossRef]

- Loeb, S. One hundred and thirty benign and renewable megawatts from Great Salt Lake? The possibilities of hydroelectric power by pressure-retarded osmosis. Desalination 2001, 141, 85–91. [Google Scholar]

- Ramon, G.Z.; Feinberg, B.J.; Hoek, E.M.V. Membrane-based production of salinity gradient power. Energy Environ. Sci. 2011, 4, 4423–4434. [Google Scholar] [CrossRef]

- Lee, K.L.; Baker, R.W.; Lonsdale, H.K. Membranes for power generation by pressure-retarded osmosis. J. Membr. Sci. 1981, 8, 141–171. [Google Scholar] [CrossRef]

- Tiraferri, A.; Yip, N.Y.; Phillip, W.A.; Schiffman, J.D.; Elimelech, M. Relating performance of thin-film composite forward osmosis membranes to support layer formation and structure. J. Membr. Sci. 2011, 367, 340–352. [Google Scholar] [CrossRef]

- Wei, J.; Qiu, C.; Tang, C.-Y.; Wang, R.; Fane, A.G. Synthesis and characterization of flat-sheet thin film composite forward osmosis membranes. J. Membr. Sci. 2011, 372, 292–302. [Google Scholar] [CrossRef]

- McGinnis, R.L.; McCutcheon, J.R.; Elimelech, M. A novel ammonia–carbon dioxide osmotic heat engine for power generation. J. Membr. Sci. 2007, 305, 13–19. [Google Scholar] [CrossRef]

- Achilli, A.; Cath, T.Y.; Childress, A.E. Power generation with pressure retarded osmosis: An experimental and theoretical investigation. J. Membr. Sci. 2009, 343, 42–52. [Google Scholar] [CrossRef]

- Xu, Y.; Peng, X.; Tang, C.-Y.; Fu, Q.S.; Nie, S. Effect of draw solution concentration and operating conditions on forward osmosis and pressure retarded osmosis performance in a spiral wound module. J. Membr. Sci. 2010, 348, 298–309. [Google Scholar] [CrossRef]

- Yip, N.Y.; Tiraferri, A.; Phillip, W.A.; Schiffman, J.D.; Hoover, L.A.; Kim, Y.C.; Elimelech, M. Thin-film composite pressure retarded osmosis membranes for sustainable power generation from salinity gradients. Environ. Sci. Technol. 2011, 45, 4360–4369. [Google Scholar]

- She, Q.; Jin, X.; Tang, C.-Y. Osmotic power production from salinity gradient resource by pressure retarded osmosis: Effects of operating conditions and reverse solute flux diffusion. J. Membr. Sci. 2012, 401–402, 262–273. [Google Scholar] [CrossRef]

- Chou, S.; Shi, L.; Wang, R.; Tang, C.-Y.; Qiu, C.; Fane, A.G. Characteristics and potential applications of a novel forward osmosis hollow fiber membrane. Desalination 2010, 261, 365–372. [Google Scholar]

- Wang, R.; Shi, L.; Tang, C.-Y.; Chou, S.; Qiu, C.; Fane, A.G. Characterization of novel forward osmosis hollow fiber membranes. J. Membr. Sci. 2010, 355, 158–167. [Google Scholar]

- Yip, N.Y.; Tiraferri, A.; Phillip, W.A.; Schiffman, J.D.; Elimelech, M. High performance thin-film composite forward osmosis membrane. Environ. Sci. Technol. 2010, 44, 3812–3818. [Google Scholar] [CrossRef]

- Nijmeijer, K.; Metz, S. Salinity Gradient Energy. In Sustainable Water for the Future: Water Recycling versus Desalination; Escobar, I.C., Schäfer, A.I., Eds.; Elsevier: Amsterdam, the Netherlands and Oxford, UK, 2010; pp. 95–140. [Google Scholar]

- Song, X.; Liu, Z.; Sun, D.D. Energy recovery from concentrated seawater brine by thin-film nanofiber composite pressure retarded osmosis membranes with high power density. Energy Environ. Sci. 2013, 6, 1199–1210. [Google Scholar] [CrossRef]

- Malek, A.; Hawlader, M.N.A.; Ho, J.C. Design and economics of RO seawater desalination. Desalination 1996, 105, 245–261. [Google Scholar] [CrossRef]

- Park, C.; Park, P.-K.; Mane, P.P.; Hyung, H.; Gandhi, V.; Kim, S.-H.; Kim, J.-H. Stochastic cost estimatation approach for full-scale reverse osmosis desalination plants. J. Membr. Sci. 2010, 364, 52–64. [Google Scholar] [CrossRef]

- Kim, Y.M.; Kim, S.J.; Kim, Y.S.; Lee, S.; Kim, I.S.; Kim, J.H. Overview of systems engineering approaches for a large-scale seawater desalination plant with a reverse osmosis network. Desalination 2009, 238, 312–332. [Google Scholar] [CrossRef]

- Gille, D. Seawater intakes for desalination plants. Desalination 2003, 156, 249–256. [Google Scholar] [CrossRef]

- Wade, N.M. RO design optimization. Desalination 1987, 64, 3–16. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Hu, Y.D.; Xu, D.M.; Wu, L.Y. Optimum design of reverse osmosis seawater desalination system considering membrane cleaning and replacing. J. Membr. Sci. 2006, 282, 7–13. [Google Scholar] [CrossRef]

- Watson, I.C.; Morin, O.J.J.; Henthorne, L. Desalting Handbook for Planners; United States Department of Interior, Bureau of Reclamation: Denver, CO, USA, 2003. [Google Scholar]

- Moch, I.J.; Querns, W.R.; Steward, D. WT Cost II–Modeling the Capital and Operating Costs of Thermal Desalination Processes Utilizing a Recently Developed Computer Program that Evaluates Membrane Desalting, Electrodialysis, and Ion Exchange Plants; United States Department of Interior, Bureau of Reclamation: Denver, CO, USA, 2008. [Google Scholar]

- Ahmed, M.; Shayya, W.; Hoey, D. Use of evaporation ponds for brine disposal in desalination plants. Desalination 2000, 130, 155–168. [Google Scholar] [CrossRef]

- Stover, R.L. Energy Recovery Devices in Desalination Applications. In Proceedings of the International Water Association (IWA) North American Membrane Research Conference, Amherst, MA, USA, 10–13 August 2008.

Nomenclature

| CCT | Total capital cost ($) |

| CCSI | Capital cost of seawater intake ($) |

| CCPre | Capital cost of pre-treatment ($) |

| CCRO | Capital cost of RO system ($) |

| CCPost | Capital cost of post-treatment ($) |

| CCBD | Capital cost of brine disposal ($) |

| CCOC | Capital cost of others including construction and engineering ($) |

| CCHPP | Capital cost of high pressure pump ($) |

| CCERD | Capital cost of energy recovery device ($) |

| CCE | Capital cost of RO element ($) |

| CCPV | Capital cost of pressure vessel ($) |

| QP | Plant capacity (m3/h) |

| QFeed | Total feed flow rate (m3/h) |

| QProduct | Total product water flow rate (m3/h) |

| QBrine | Total flow rate of brine (m3/h) |

| ETotal,Osmotic | Total energy consumption (kWh) |

| ESpec | Specific energy consumption (kWh/m3) |

| EPRO2 | Energy required to run the second PRO process (kWh) |

| EReuse | Energy recovered from the second PRO process for the water reuse process (kWh) |

| PFeed | Feed pressure (bar) |

| PBrine | Brine pressure (bar) |

| NHPP,A | Number of high pressure pumps in category A (dimensionless) |

| NHPP,B | Number of high pressure pumps in category B (dimensionless) |

| NHPP,C | Number of high pressure pumps in category C (dimensionless) |

| NE | Total number of RO elements (dimensionless) |

| NPV | Total number of pressure vessels into each of which seven membrane elements can be fitted (dimensionless) |

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Sim, V.S.T.; She, Q.; Chong, T.H.; Tang, C.Y.; Fane, A.G.; Krantz, W.B. Strategic Co-Location in a Hybrid Process Involving Desalination and Pressure Retarded Osmosis (PRO). Membranes 2013, 3, 98-125. https://doi.org/10.3390/membranes3030098

Sim VST, She Q, Chong TH, Tang CY, Fane AG, Krantz WB. Strategic Co-Location in a Hybrid Process Involving Desalination and Pressure Retarded Osmosis (PRO). Membranes. 2013; 3(3):98-125. https://doi.org/10.3390/membranes3030098

Chicago/Turabian StyleSim, Victor S.T., Qianhong She, Tzyy Haur Chong, Chuyang Y. Tang, Anthony G. Fane, and William B. Krantz. 2013. "Strategic Co-Location in a Hybrid Process Involving Desalination and Pressure Retarded Osmosis (PRO)" Membranes 3, no. 3: 98-125. https://doi.org/10.3390/membranes3030098

APA StyleSim, V. S. T., She, Q., Chong, T. H., Tang, C. Y., Fane, A. G., & Krantz, W. B. (2013). Strategic Co-Location in a Hybrid Process Involving Desalination and Pressure Retarded Osmosis (PRO). Membranes, 3(3), 98-125. https://doi.org/10.3390/membranes3030098