Abstract

A comparative study was conducted to investigate membrane fouling control and treatment performance using natural surface water as the feed source. The evaluated processes included: (1) direct filtration–tubular ceramic membrane (DF-TCM, control); (2) coagulation–tubular ceramic membrane (C-TCM); and (3) coagulation–tubular ceramic membrane with concentrate recycling (C-TCM-CR). Experimental results demonstrated that under constant flux operation at 75 L/(m2·h) for 8 h, the C-TCM-CR process reduced the transmembrane pressure (TMP) increase by 83% and 35% compared to DF-TCM and C-TCM, respectively. Floc size distribution analysis and cake layer characterization revealed that the C-TCM-CR process enhanced coagulation efficiency and formed high-porosity cake layers on membrane surfaces, thereby mitigating fouling development. Notably, the coagulation-assisted processes demonstrated improved organic matter removal, with 13%, 10%, and 10% enhancement in CODMn, UV254, and medium molecular weight organics (2000–10,000 Da) removal compared to DF-TCM, along with a moderate enhancement in fluorescent substances removal efficiency. All three processes achieved over 99% turbidity removal efficiency, as the ceramic membranes demonstrate excellent filtration performance.

1. Introduction

Ultrafiltration (UF) is a pressure-driven membrane separation process that has attracted significant attention in the field of drinking water treatment in recent years due to its effective removal of contaminants such as suspended particles, colloids, bacteria (e.g., E. coli and total coliforms), and pathogenic microorganisms (e.g., Giardia and Cryptosporidium). However, its retention efficiency for small viruses (typically <20–30 nm) may be limited due to inherent membrane pore size constraints [1,2]. Currently, polymeric membranes dominate the UF membrane market, benefiting from their early development, mature fabrication processes, and lower production costs [3,4,5]. Compared to polymeric membranes, ceramic membranes (CM) demonstrate notable advantages including a long operational lifespan, high resistance to fouling, stable material properties, chemical corrosion resistance, high mechanical strength, and recyclability [6,7]. However, constrained by their higher costs, current application research on CM technology has primarily focused on industrial wastewater treatment. Its utilization in drinking water treatment remains in its infancy and warrants further exploration [6,8].

Membrane fouling remains a major challenge in CM applications, hindering its development [9,10,11]. Although fouling is inherent to filtration processes, strategies to reduce its impact must be explored to address operational issues. The mitigation of membrane fouling typically involves four principal approaches: pretreatment of feed solutions, membrane cleaning protocols, operational parameter optimization, and membrane fabrication/modification techniques [12]. Among them, pretreatment is an easy-to-use and relatively mature approach for reducing membrane fouling in practical applications [13,14].

Coagulation is a fundamental pretreatment process extensively employed in water purification systems. The primary mechanisms governing this process—including charge neutralization, sweep flocculation, and adsorption—work synergistically to destabilize colloidal particles and promote contaminant aggregation. Through these mechanisms, coagulation effectively removes a wide spectrum of pollutants, ranging from suspended particles and viral pathogens to natural organic matter [15]. By significantly lowering contaminant levels prior to UF treatment, this process mitigates membrane fouling issues [16,17]. The integrated coagulation–ultrafiltration (C-UF) process demonstrates enhanced operational advantages through membrane retention of coagulation-generated flocs: these retained flocs form a loosely structured and porous filter cake layer that adsorbs organic pollutants without substantially compromising membrane flux, thereby reducing irreversible fouling formation. Concurrently, the structural looseness of this layer facilitates efficient detachment during cleaning cycles, leading to significant mitigation of membrane fouling [17,18,19]. Compared to traditional coagulation–sedimentation–ultrafiltration processes, the C-UF process offers distinct advantages, including a smaller footprint, shorter operational procedures, simplified management, and reduced chemical consumption. These features make the C-UF process particularly suitable for small-scale rural water supply applications, where operational efficiency, resource constraints, and ease of maintenance are critical considerations [20]. Wei et al. confirmed stable high-flux operation of both C-UF and UF treating Taihu Lake water, with C-UF significantly lowering transmembrane pressure (TMP). Coagulation pretreatment enhanced UF’s limited dissolved organic removal, particularly for low molecular weight organics [21]. Zhao et al. demonstrated that coagulation with flat-sheet ceramic membranes reduced specific TMP rise and improved organics removal versus direct filtration in Yangtze River water treatment using varied coagulants [22]. By combining contaminant reduction, fouling mitigation, and operational practicality, the C-UF process presents itself as a solution for decentralized water treatment challenges.

One notable research direction in C-UF process development involves either combining this technology with complementary processes like adsorption and advanced oxidation, or designing innovative coagulants/flocculants [12]. A primary objective is to adjust floc properties during coagulation to enable the formation of a permeable cake layer with lower resistance and higher porosity on membrane surfaces [12,23]. Wang et al. demonstrated that in the C-UF process, flocs generated during the coagulation process can be reused as coagulation aids through sludge recirculation to enhance coagulation efficiency [24]. Cross-flow filtration is a common operational mode for separation membranes; the fluid generates sustained high-velocity shear forces along the membrane surface, effectively reducing membrane surface fouling while enabling continuous concentration of the feed solution [11]. Thus, in the C-UF process, cross-flow filtration can be employed to concentrate coagulated water, generating higher-density sludge recirculation that serves as recycled coagulation aids to reinforce coagulation performance.

This study proposes a comprehensive “coagulation-tubular ceramic membrane filtration” process incorporating concentrated water recirculation, capitalizing on the exceptional engineering merits of tubular ceramic membranes (TCM). By recycling residual flocs from concentrated water back to the flocculation tank, the process optimizes coagulation conditions and improves the pore structure of the filter cake layer on the TCM surface, thereby effectively delaying membrane fouling progression. Combining the concentrated water recycling mechanism of cross-flow filtration, the investigation explores the enhanced effects of residual flocs in concentrated water on coagulation processes and their regulatory mechanisms on the pore structure of membrane surface filter cake layers. This reveals the operational mechanisms underlying membrane fouling mitigation in this process, providing empirical support for CM fouling control and water purification efficiency enhancement.

2. Materials and Methods

2.1. Tubular Ceramic Membrane

TCM performance characteristics are presented in Table 1.

Table 1.

TCM performance characteristics.

2.2. Experimental Setups

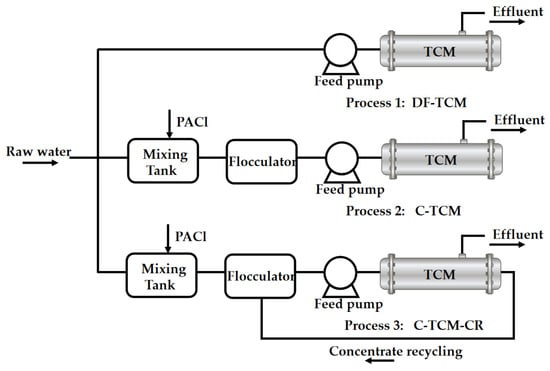

This study systematically evaluated three treatment processes (see Figure 1 for the Experimental process):

Figure 1.

Experimental process.

The experimental steps of this study are as follows:

- Process 1: Direct filtration–tubular ceramic membrane (DF-TCM).

- Raw water was directly subjected to constant-flux dead-end filtration through TCM without pretreatment.

- Process 2: Coagulation–tubular ceramic membrane (C-TCM).

- The raw water was first mixed with polyaluminum chloride (PACl) at a dose of 1.5 mg-Al/L in a rapid mixing tank (200 rpm, 1 min), followed by flocculation in a flocculator (80 rpm, 10 min), and finally treated by constant-flux dead-end membrane filtration.

- Process 3: Coagulation–tubular ceramic membrane with concentrate recycling (C-TCM-CR).

- Based on Process 2, this modified process implemented cross-flow filtration for the TCM, operating with the cross-flow stream equivalent to 3% of the total influent flow, while ensuring complete recycling of all generated concentrate back to the flocculator.

- All three treatment processes employed identical TCM operating parameters, maintaining a constant flux of 75 L/(m2·h) during the 1 h filtration cycles. Each cycle concluded with an automated hydraulic backwash at 120 L/(m2·h) for 1 min duration to ensure optimal membrane performance.

- After every 8 filtration cycles, comprehensive chemical cleaning was conducted: Alkaline cleaning: 1000 mg/L NaClO + 1000 mg/L NaOH, injected for 1 min, circulated for 2 h; acid cleaning: 2% citric acid, injected for 1 min, circulated for 2 h.

2.3. Raw Water

The raw water used in this study was sourced from a municipal water treatment plant located in Zhejiang Province, China. The overall chemical characteristics of the raw water are presented in Table 2.

Table 2.

Chemical component of the raw water in this study.

2.4. Analytical Methods

Water quality parameters, including turbidity, permanganate index (CODMn), and UV254 absorbance, were measured according to standard methods [25,26,27,28]. Fluorescent compounds were analyzed using a fluorescence spectrophotometer (Model F-97, Shanghai Lengguang, Shanghai, China) [7,29]. Organic matter molecular weight distribution was determined by gel permeation chromatography (GPC, PL-GPC 220, Agilent Technologies, Santa Clara, CA, USA) [30]. Floc size generated during coagulation was characterized with a laser particle size analyzer (Mastersizer 3000, Malvern Panalytical, Malvern, UK) [31]. Membrane surface morphology was examined via scanning electron microscopy (SEM, Sigma 360, Carl Zeiss, Oberkochen, Germany). Total fouling (TF) of TCM was categorized into reversible fouling (RF) and irreversible fouling (IF) based on TMP variations before and after backwashing [29], calculated as:

where TMP0 is the instantaneous TMP difference measured during the initial stable operation of the TCM, (kPa); TMPn and TMPn+1 are the instantaneous TMP difference recorded under stable operating conditions immediately after the n-th and (n + 1)-th backwashing cycle, (kPa).

TF = RF + IF

RF = (TMPn − TMPn+1)/TMP0

IF = (TMPn+1 − TMP0)/TMP0

3. Results

3.1. Primary Characteristics of TCM Fouling

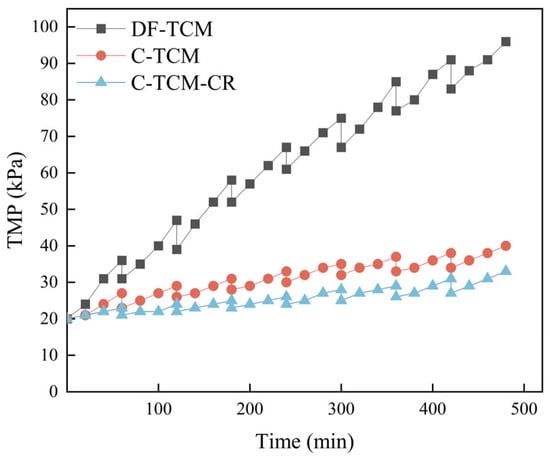

3.1.1. Evolution of TMP in TCM

TMP serves as a vital parameter reflecting membrane fouling severity, directly correlating with hydraulic resistance during filtration [32]. Figure 2 illustrates the TMP variations across the three processes. The C-TCM-CR process demonstrated superior performance, with TMP increasing merely to 33 kPa after eight filtration cycles, representing 83% and 35% reductions in TMP elevation compared to DF-TCM and C-TCM processes, respectively. Specifically, the standalone C-TCM process reached a terminal TMP of 40 kPa, while DF-TCM exhibited the most severe fouling with a final TMP of 96 kPa. These findings conclusively indicate that: coagulation significantly alleviates membrane fouling relative to DF-TCM, and the integrated C-TCM-CR approach achieves optimal fouling mitigation through synergistic effects of enhanced coagulation and hydrodynamic control.

Figure 2.

TMP variations across the three processes.

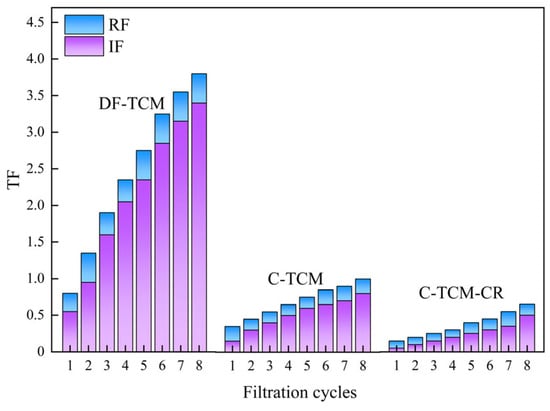

Figure 3 delineates the fouling characteristics of three operational processes across successive filtration cycles. The C-TCM-CR process demonstrated the most effective fouling control, with TF ultimately reaching 0.65 and an average RF of 0.13, which accounted for the highest proportion of TF, highlighting its superior hydraulic backwashing efficiency. This enhanced performance stemmed from synergistic mechanisms: the loose cake layer generated by coagulation mitigated fouling, cross-flow shear stress reduced cake layer adsorption load, and concentrate recirculation further optimized coagulation and floc structure. In comparison, the C-TCM process exhibited a higher TF of 1.0 at the filtration endpoint, though still significantly lower than direct filtration, with an average RF of 0.17 attributed to improved backwashing efficiency from its porous cake layer. In contrast, the DF-TCM process showed severe contamination (TF 3.8 after eight cycles) and poor reversibility, as hydraulic backwashing removed only 0.36 RF on average, reflecting limited mitigation capacity.

Figure 3.

Membrane fouling characteristics variations across the three processes.

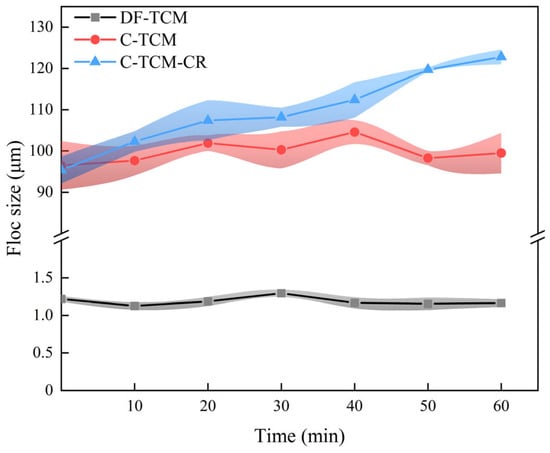

3.1.2. Floc Size Distribution Characteristics

The flocs generated during the coagulation pretreatment phase directly influence the extent of TCM fouling [12,20]. Figure 4 illustrates the variations in floc size during the flocculation stage. Experimental results revealed that the contaminant particle size in the raw water was predominantly concentrated around 0.987 μm, with a significant presence of fine particles and colloidal substances. The DF-TCM process led to the formation of dense and compact cake layers on the membrane surface, resulting in severe fouling. Coagulation facilitated the aggregation of suspended particles, colloids, and macromolecular organics into flocs with an average floc size of 99.8 μm. These flocs formed a porous cake layer on the membrane surface, effectively alleviating fouling. The C-TCM-CR process further optimized floc structure and enhanced coagulation performance. During the initial filtration phase, the average floc size was 95.4 μm. As filtration and concentrate recirculation progressed, the floc size gradually increased, reaching 122.8 μm after 1 h. In contrast, the floc size remained relatively stable in the standalone coagulation process, while direct filtration resulted in smaller particle sizes that aggravated membrane fouling. Previous studies have demonstrated that the floc size and fractal dimension in coagulation significantly influence cake layer formation. Larger flocs facilitate the development of a functional porous cake layer, which effectively intercepts smaller contaminants and mitigates membrane fouling [31,33].

Figure 4.

Floc size variations across the three processes.

3.1.3. Microstructural Characterization of Cake Layers

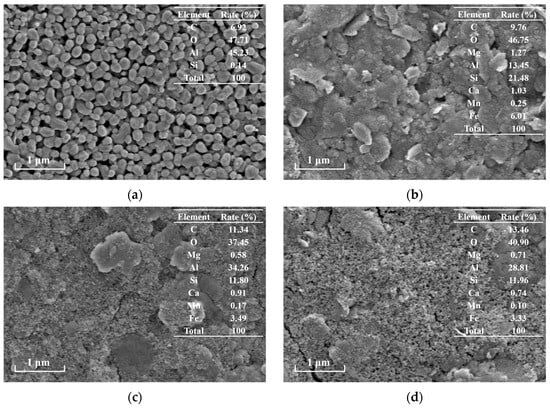

SEM analysis was performed to investigate the microstructural characteristics of TCM under different operational conditions, as shown in Figure 5. The virgin membrane (Figure 5a) exhibited uniformly distributed pores with well-defined morphology, and energy-dispersive X-ray spectroscopy (EDS) confirmed its primary composition of Al, O, and trace C. For operational processes, the C-TCM-CR process (Figure 5b) formed a porous cake layer with high structural integrity, whereas the standalone C-TCM (Figure 5c) showed moderately compacted deposits. In stark contrast, DF-TCM (Figure 5d) resulted in dense fouling layers completely occluding membrane pores. Elemental mapping revealed significantly elevated Al content in coagulation-assisted processes compared to DF-TCM, directly attributable to PACl residuals rather than membrane constituents. This porous architecture in C-TCM-CR was governed by hydrodynamic shear forces induced by cross-flow filtration, which dynamically maintained cake layer permeability through two synergistic mechanisms: selective removal of loosely bound foulants and continuous recirculation of concentrated particles to enhance flocs growth in the flocculator.

Figure 5.

Microstructural characterization of TCM surface: (a) virgin membrane; (b) DF-TCM; (c) C-TCM; and (d) C-TCM-CR.

The combined evidence of TMP dynamics (Figure 2), floc size evolution (Figure 4), and cake layer ultrastructure (Figure 5) conclusively demonstrates that the C-TCM-CR hybrid process achieves superior fouling mitigation via three interlinked pathways: (1) optimized flocs formation enabling preliminary contaminant interception; (2) functional cake layers acting as dynamic secondary filtration barriers; and (3) enhanced hydraulic reversibility through shear-enhanced backwash efficiency. These multiscale interactions between hydrodynamic conditions, floc morphology, and membrane interface properties establish a sustainable operational paradigm for TCM applications in decentralized water treatment systems.

3.2. Contaminant-Specific Removal Performance

3.2.1. CODMn

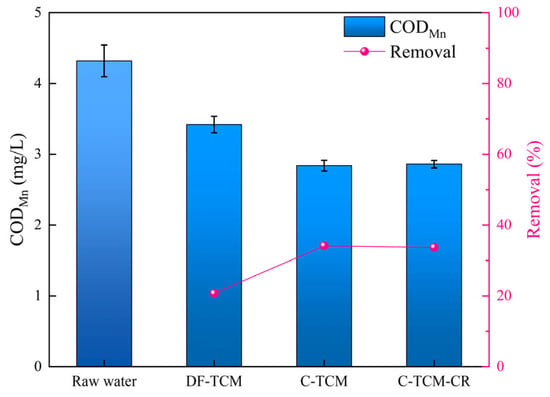

The permanganate index (CODMn), serving as a comprehensive indicator of oxidizable organic matter through potassium permanganate titration, revealed critical differences in dissolved organic matter removal across the evaluated processes. As depicted in Figure 6, the raw water exhibited an average CODMn of 4.32 mg/L. Coagulation-integrated processes demonstrated superior performance, with C-TCM and C-TCM-CR achieving 34% removal efficiency, significantly outperforming DF-TCM’s 21% reduction, which is consistent with previous studies [34,35]. This disparity stems from distinct removal mechanisms: DF-TCM primarily relies on size-exclusion (30 nm pores), exhibiting limited efficacy for sub-nanometer organics, whereas coagulation facilitates molecular aggregation of low molecular weight compounds into filterable flocs while forming porous cake layers that provide secondary adsorption sites [31,36,37].

Figure 6.

CODMn removal efficiency across the three processes.

3.2.2. UV254

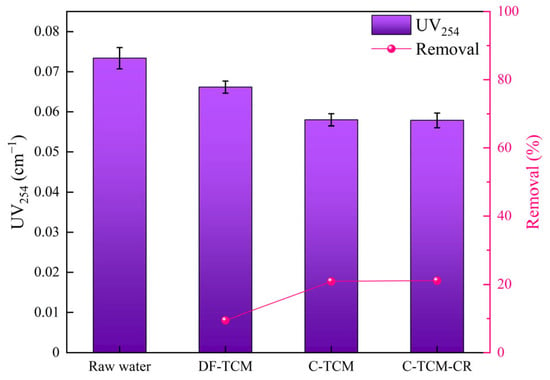

UV254 is determined by measuring the ultraviolet light absorption of water samples at 254 nm, which reflects the concentration of aromatic compounds with conjugated double bonds and humic macromolecular organic matter [38]. Figure 7 demonstrates the UV254 removal efficiencies of the three processes. The raw water exhibited stable UV254 values ranging from 0.071 to 0.076 cm−1, with an average of 0.073 cm−1. The C-TCM and C-TCM-CR demonstrated moderate UV254 removal efficiency, producing an average effluent UV254 of 0.058 cm−1 and achieving a removal rate of approximately 20%. In contrast, direct filtration showed inferior performance, with an average effluent UV254 of 0.066 cm−1 and a removal rate of approximately 10%. This discrepancy is primarily attributed to the coagulation process, which promotes the aggregation of hydrophobic aromatic compounds into flocs that are more effectively retained by the ceramic membrane, thereby reducing UV254 [38,39].

Figure 7.

UV254 removal efficiency across the three processes.

3.2.3. Turbidity

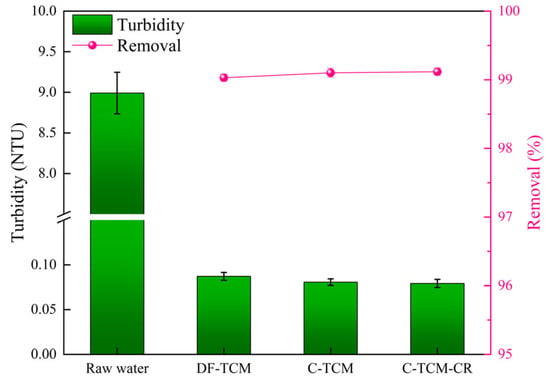

The raw water exhibited an average turbidity of 8.99 NTU. As illustrated in Figure 8, all three processes achieved comparable and stable turbidity removal efficiencies without statistically significant differences. Specifically, the C-TCM-CR process produced marginally lower effluent turbidity (0.079 NTU) compared to the C-TCM (0.080 NTU) and DF-TCM (0.087 NTU) processes. All three processes achieved over 99% turbidity removal efficiency, as the TCM demonstrates excellent filtration performance.

Figure 8.

Turbidity removal efficiency across the three processes.

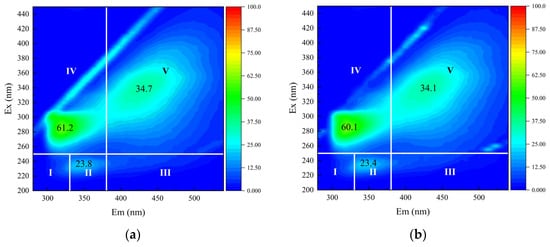

3.2.4. Fluorescent Compounds

The fluorescence properties of humic acids, protein-like substances, and other fluorescent compounds in water were analyzed using three-dimensional excitation-emission matrix fluorescence spectroscopy, with distinct characteristic peaks corresponding to functional groups in specific fluorophores [29,40]. Figure 9 illustrates the removal efficiencies of fluorescent substances by the three treatment processes. The raw water displayed fluorescence response regions in regions II, IV, and V, attributed to aromatic proteins, soluble microbial products, and humic acids, respectively. Experimental results indicated that both C-TCM and C-TCM-CR process marginally improved the removal efficiencies of these fluorescent contaminants, achieving approximate removal rates of 5% for aromatic proteins, 9% for soluble microbial products, and 15% for humic acids. In contrast, direct filtration exhibited negligible removal efficiency. Humic acid-like pollutants were identified as a major contributor to irreversible ceramic membrane fouling. Compared to direct filtration, coagulation moderately enhanced humic acid removal, thereby alleviating membrane fouling due to their hydrophilic nature [21,31,41].

Figure 9.

Fluorescent compounds removal efficiency across the three processes: (a) Raw water; (b) DF-TCM; (c) C-TCM; and (d) C-TCM-CR.

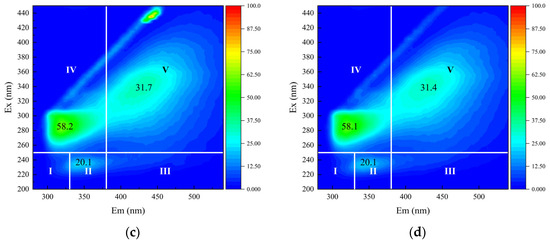

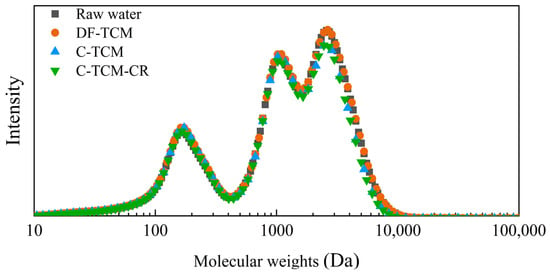

3.2.5. Organic Compounds with Different Molecular Weights

GPC was employed to analyze organic matter molecular weight distribution by correlating retention times with a calibration curve established using standard molecular weight markers. The organic content was quantified based on UV absorbance at 254 nm. As shown in Figure 10, raw water primarily contained organics in the 100–10,000 Da range. TCM processes with coagulation exhibited limited removal (average 10%) of medium molecular weight organics (2000–10,000 Da), predominantly humic-like substances, consistent with findings from three-dimensional fluorescence analysis. In contrast, DF-TCM showed negligible removal of these sub-30 nm pore-sized organics. This enhanced removal in coagulation-assisted processes likely stems from porous cake layer adsorption, which prevents direct contact between low molecular weight organics (<2000 Da) and membrane surfaces, thereby reducing their permeation [42,43]. The nominal 30 nm membrane pore size corresponds to a theoretical 100,000 Da molecular weight cut-off, though this relationship is influenced by molecular shape, polarity, and other physicochemical interactions, yet actual retention efficiency for smaller organics relies heavily on synergistic cake layer filtration mechanisms rather than pure size exclusion [12,40].

Figure 10.

Organic compounds with different molecular weight removal efficiencies across the three processes.

4. Conclusions

The C-TCM-CR process achieved 83% and 35% reductions in TMP escalation, compared to DF-TCM and C-TCM during 8 h operation, respectively. This significant enhancement originated from two synergistic hydrodynamic mechanisms: (1) Cross-flow shear forces continuously disrupt foulant accumulation at the membrane surface, preferentially removing weakly adhered foulants before they undergo irreversible adhesion. This action effectively prevents progressive compaction of the cake layer while maintaining membrane permeability; (2) Simultaneously, the recycled concentrate promoted dynamic particle-fluid interactions that optimized floc architecture through enhanced collision efficiency, strengthening structural integrity. Together, these complementary mechanisms promote the formation of a highly porous cake layer with preserved flow channels, thereby substantially reducing overall hydraulic resistance. Microstructural analysis confirmed C-TCM-CR generated high-porosity cake layers with interconnected pore networks, significantly outperforming C-TCM and DF-TCM in fouling mitigation.

Coagulation pretreatment improved organic removal efficiency relative to DF-TCM, with 13%, 10%, and 10% enhancements for CODMn, UV254, and medium molecular weight organics (2000–10,000 Da), respectively, along with a moderate increase in fluorescent substances removal. These gains stemmed from dual mechanisms: aluminum-based flocs entrapment of low molecular weight organics and limited adsorption by porous cake layers. All processes maintained >99% turbidity removal.

Author Contributions

Y.X.: investigation and writing—original draft. Y.F.: investigation and data curation. D.C.: formal analysis and data curation. J.W.: data curation. C.F.: formal analysis and data curation. X.Z.: conceptualization and writing—review and editing. H.L.: resources, supervision, writing—review and editing, funding acquisition, and project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Science and Technology Major Project of China—Water Pollution Control and Treatment (2017ZX07201004). This work was also supported by Water Engineering and Emergency Technology Research and Development Center, Zhejiang University of Technology, and Engineering Research Center of Ministry of Education for Renewable Energy Infrastructure Construction Technology.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Malkoske, T.A.; Bérubé, P.R.; Andrews, R.C. Coagulation/flocculation prior to low pressure membranes in drinking water treatment: A review. Environ. Sci. Water Res. Technol. 2020, 6, 2993–3023. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, B.; Ulbricht, M.; Dong, Y.; Zhao, X. Progress in alumina ceramic membranes for water purification: Status and prospects. Water Res. 2022, 226, 119173. [Google Scholar] [CrossRef]

- Kurth, C.J.; Wise, B.L.; Smith, S. Design considerations for implementing ceramics in new and existing polymeric UF systems. Water Pract. Technol. 2018, 13, 725–737. [Google Scholar] [CrossRef]

- Jarvis, P.; Carra, I.; Jafari, M.; Judd, S. Ceramic vs. polymeric membrane implementation for potable water treatment. Water Res. 2022, 215, 118269. [Google Scholar] [CrossRef]

- Sánchez-Arévalo, C.M.; Vincent-Vela, M.C.; Luján-Facundo, M.J.; Alvarez-Blanco, S. Ultrafiltration with organic solvents: A review on achieved results, membrane materials and challenges to face. Process Saf. Environ. Prot. 2023, 177, 118–137. [Google Scholar] [CrossRef]

- Asif, M.B.; Zhang, Z. Ceramic membrane technology for water and wastewater treatment: A critical review of performance, full-scale applications, membrane fouling and prospects. Chem. Eng. J. 2021, 418, 129481. [Google Scholar] [CrossRef]

- Xie, Y.; Fan, C.; Fang, Y.; Zhu, X.; Yan, J.; Liu, H.; Liu, H. Ceramic ultrafiltration membrane as pretreatment for drinking water nanofiltration treatment: Performance, cleaning, and costs based on an engineering case. J. Clean. Prod. 2025, 506, 145527. [Google Scholar] [CrossRef]

- Dong, Y.; Wu, H.; Yang, F.; Gray, S. Cost and efficiency perspectives of ceramic membranes for water treatment. Water Res. 2022, 220, 118629. [Google Scholar] [CrossRef]

- Niu, C.; Li, X.; Dai, R.; Wang, Z. Artificial intelligence-incorporated membrane fouling prediction for membrane-based processes in the past 20 years: A critical review. Water Res. 2022, 216, 118299. [Google Scholar] [CrossRef]

- Luo, H.; Wang, Z. A new ultrasonic cleaning model for predicting the flux recovery of the UF membrane fouled with humic acid. J. Environ. Chem. Eng. 2022, 10, 107156. [Google Scholar] [CrossRef]

- Xiao, T.; Zhu, Z.; Li, L.; Shi, J.; Li, Z.; Zuo, X. Membrane fouling and cleaning strategies in microfiltration/ultrafiltration and dynamic membrane. Sep. Purif. Technol. 2023, 318, 123977. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Yang, H. A review on mitigation of pressure-driven membrane fouling by coagulation/flocculation as a pretreatment in membrane separation processes. Sep. Purif. Technol. 2025, 36, 132370. [Google Scholar] [CrossRef]

- Huang, H.; Schwab, K.; Jacangelo, J.G. Pretreatment for low pressure membranes in water treatment: A review. Environ. Sci. Technol. 2009, 43, 3011–3019. [Google Scholar] [CrossRef]

- Gao, W.; Liang, H.; Ma, J.; Han, M.; Chen, Z.; Han, Z.; Li, G. Membrane fouling control in ultrafiltration technology for drinking water production: A review. Desalination 2011, 272, 1–8. [Google Scholar] [CrossRef]

- Wei, H.; Gao, B.; Ren, J.; Li, A.; Yang, H. Coagulation/flocculation in dewatering of sludge: A review. Water Res. 2018, 143, 608–631. [Google Scholar] [CrossRef]

- Xu, M.; Wang, X.; Zhou, B.; Zhou, L. Pre-coagulation with cationic flocculant-composited titanium xerogel coagulant for alleviating subsequent ultrafiltration membrane fouling by algae-related pollutants. J. Hazard. Mater. 2021, 407, 124838. [Google Scholar] [CrossRef]

- Li, L.; Chen, X.; Shao, S.; Zhang, X.; Zhang, H. Study on the mechanism of hydrodynamic manipulation of floc structure to achieve high-flux of coagulation macro-filtration for the rapid removal of Aphanizomenon flos-aquae. J. Clean. Prod. 2024, 434, 140397. [Google Scholar] [CrossRef]

- He, H.; Liu, Y.; Wang, L.; Qiu, W.; Li, D.; Liu, Z.; Ma, J. Improvements of ferrate (VI) pretreatment on membrane flux and membrane rejection using cheap NaClO reagent. Water Res. 2023, 229, 119520. [Google Scholar] [CrossRef]

- Dotto, J.; Fagundes-Klen, M.R.; Veit, M.T.; Palacio, S.; Bergamasco, R. Performance of different coagulants in the coagulation/flocculation process of textile wastewater. J. Clean. Prod. 2019, 208, 656–665. [Google Scholar] [CrossRef]

- Srivastava, S.; Das, C. Advanced hybridization of coagulation–ultrafiltration systems: A critical techno-economic review of integration strategies. J. Water Process Eng. 2024, 68, 106297. [Google Scholar] [CrossRef]

- Wei, Y.; Yao, W.; Gui, B.; Dong, B. Treatment of Taihu Lake Water by On-line Coagulation/Ultrafiltration. China Water Wastewater 2019, 35, 54–58. [Google Scholar] [CrossRef]

- Zhao, Y.; Liang, X.; Huang, Y.; Xia, S. Study on treatment of Yangtze River raw water using online coagulation-plate ceramic membrane filtration process. Ind. Water Wastewater 2020, 51, 11–16. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Xu, M.; Qi, F.; Li, C.; Sun, D.; Nan, J.; Li, W.; Guan, X.; Ikhlaq, A. Unveiling the role of cake layer in coagulation-ultrafiltration on membrane fouling and emerging application as dynamic membrane before ultrafiltration. Sep. Purif. Technol. 2024, 350, 127932. [Google Scholar] [CrossRef]

- Wang, W.; Yue, Q.; Guo, K.; Bu, F.; Shen, X.; Gao, B. Application of Al species in coagulation/ultrafiltration process: Influence of cake layer on membrane fouling. J. Membr. Sci. 2019, 572, 161–170. [Google Scholar] [CrossRef]

- Kitchener, B.G.B.; Wainwright, J.; Parsons, A.J. A review of the principles of turbidity measurement. Prog. Phys. Geogr. 2017, 41, 620–642. [Google Scholar] [CrossRef]

- Laszakovits, J.R.; Somogyi, A.; MacKay, A.A. Chemical alterations of dissolved organic matter by permanganate oxidation. Environ. Sci. Technol. 2020, 54, 3256–3266. [Google Scholar] [CrossRef]

- Pang, Z.; Cai, Y.; Xiong, W.; Xiao, J.; Zou, j. A spectrophotometric method for measuring permanganate index (CODMn) by N, N-diethyl-p-phenylenediamine (DPD). Chemosphere 2021, 266, 128936. [Google Scholar] [CrossRef]

- Shi, Z.; Chow, C.W.K.; Fabris, R.; Zheng, T.; Liu, J.; Jin, B. Evaluation of the impact of suspended particles on the UV absorbance at 254 nm (UV 254) measurements using a submersible UV-Vis spectrophotometer. Environ. Sci. Pollut. Res. 2021, 28, 12576–12586. [Google Scholar] [CrossRef]

- Fan, C.; Yan, J.; Liu, H.; Xie, Y.; Liu, H. Performance and membrane fouling characteristics of a drinking water multistage NF system based on membrane autopsy from a full-scale system. J. Water Process Eng. 2024, 58, 104909. [Google Scholar] [CrossRef]

- Tang, X.; Guo, T.; Chang, H.; Yue, X.; Wang, J.; Yu, H.; Xie, B.; Zhu, X.; Li, G.; Liang, H. Membrane fouling alleviation by chemically enhanced backwashing in treating algae-containing surface water: From bench-scale to full-scale application. Engineering 2022, 19, 40–49. [Google Scholar] [CrossRef]

- Xu, M.; Ju, W.; Wang, Z.; Nan, J.; Qi, F.; Li, C.; Liu, Y.; Li, W.; Sun, D. New insights into membrane fouling in coagulation-ultrafiltration by cake characteristics analysis: A case study with PACl-Al13 and PACl. J. Environ. Sci. 2024, 146, 217–225. [Google Scholar] [CrossRef]

- Shi, J.; Wang, J.; Yang, S.; Li, S.; Liu, j. Membrane fouling and influencing factors of a submerged commercial ceramic flat membrane bioreactor in treatment of coal chemical wastewater. J. Environ. Chem. Eng. 2023, 11, 111510. [Google Scholar] [CrossRef]

- Feng, L.; Zhao, S.; Sun, S.; Wang, W.; Gao, B.; Yue, Q. Effect of pH with different purified aluminum species on coagulation performance and membrane fouling in coagulation/ultrafiltration process. J. Hazard. Mater. 2015, 300, 67–74. [Google Scholar] [CrossRef]

- Ma, C.; Zhang, Z.; Xu, L.; Rashid, S.; Li, G.; Graham, N.; Yu, W. Overlooked Influence of Phosphate on the Performance of a Dual Membrane Process with Coagulation Pretreatment. Water Res. 2025, 285, 124082. [Google Scholar] [CrossRef]

- Yan, M.; Shen, X.; Gao, B.; Guo, K.; Yue, Q. Coagulation-ultrafiltration integrated process for membrane fouling control: Influence of Al species and SUVA values of water. Sci. Total Environ. 2021, 793, 148517. [Google Scholar] [CrossRef]

- Wu, S.; Ma, B.; Hu, C.; Hua, X.; Fan, H.; Ulbricht, M.; Qu, J. Cake layer 3D structure regulation to optimize water channels during Al-based coagulation-ultrafiltration process. Water Res. 2023, 236, 119941. [Google Scholar] [CrossRef]

- Wang, W.; Yang, M.; Ma, H.; Liu, Z.; Gai, L.; Zheng, Z.; Ma, H. Removal behaviors and mechanism of polystyrene microplastics by coagulation/ultrafiltration process: Co-effects of humic acid. Sci. Total Environ. 2023, 881, 163408. [Google Scholar] [CrossRef]

- Altmann, J.; Massa, L.; Sperlich, A.; Gnirss, R.; Jekel, M. UV254 absorbance as real-time monitoring and control parameter for micropollutant removal in advanced wastewater treatment with powdered activated carbon. Water Res. 2016, 94, 240–245. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Xiong, X.; Wang, Q.; Yan, Y.; Tu, J.; Cui, Y.; Li, X.; Wen, G.; Wu, X. Potential of the integration of coagulation and ozonation as a pretreatment of reverse osmosis concentrate from coal gasification wastewater reclamation. Chemosphere 2019, 222, 696–704. [Google Scholar] [CrossRef]

- Wang, H.; Ding, A.; Gan, Z.; Qu, F.; Cheng, X.; Bai, L.; Guo, S.; Li, G.; Liang, H. Fluorescent natural organic matter responsible for ultrafiltration membrane fouling: Fate, contributions and fouling mechanisms. Chemosphere 2017, 182, 183–193. [Google Scholar] [CrossRef]

- Zhang, R.; Fan, Z.; Han, Z.; Yan, H.; Song, j.; Tian, J. Combined Process of Micro-flocculation + Hollow Flat-sheet Ceramic Membrane for Treatment of Micro-polluted Surface Water. China Water Wastewater 2023, 39, 23–29. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, C.; Tian, L.; Wang, H.; Yang, Y.; Wang, X.; Cheng, X. Moderate pre-photocatalysis-enhanced coagulation alleviates ultrafiltration membrane fouling of algae-laden water. J. Water Process Eng. 2023, 56, 104406. [Google Scholar] [CrossRef]

- Zhang, Y.; Teng, J.; Zou, H.; Zhang, W.; Cheng, S.; Zhang, M.; Lin, H. The molecular weight-fouling matrix: A novel dissection of polysaccharide interactions in ultrafiltration processes. Sep. Purif. Technol. 2024, 345, 127340. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).