Study on Separation of Desulfurization Wastewater in Ship Exhaust Gas Cleaning System with Rotating Dynamic Filtration

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

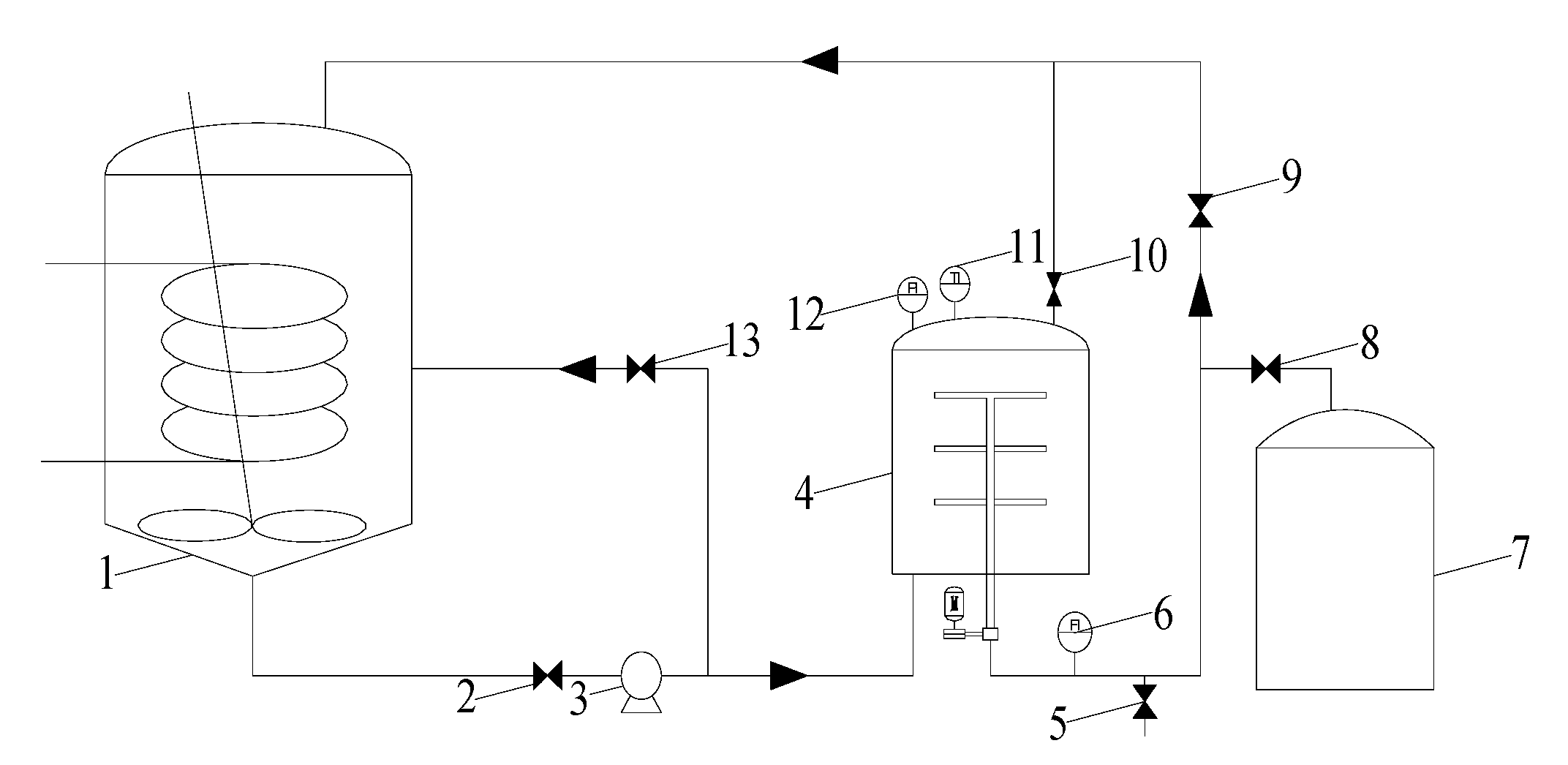

2.2. Experimental Device and Procedure

2.3. Theory and Methods

2.3.1. Determination of the Related Resistance

2.3.2. Determination of Back Pressure and Effective Pressure

2.3.3. Evaluation of the Flow State

2.3.4. Determination of Membrane Surface Shear Force

2.3.5. Determination of Energy Consumption

3. Results and Discussion

3.1. Experimental Study on the Separating Behavior

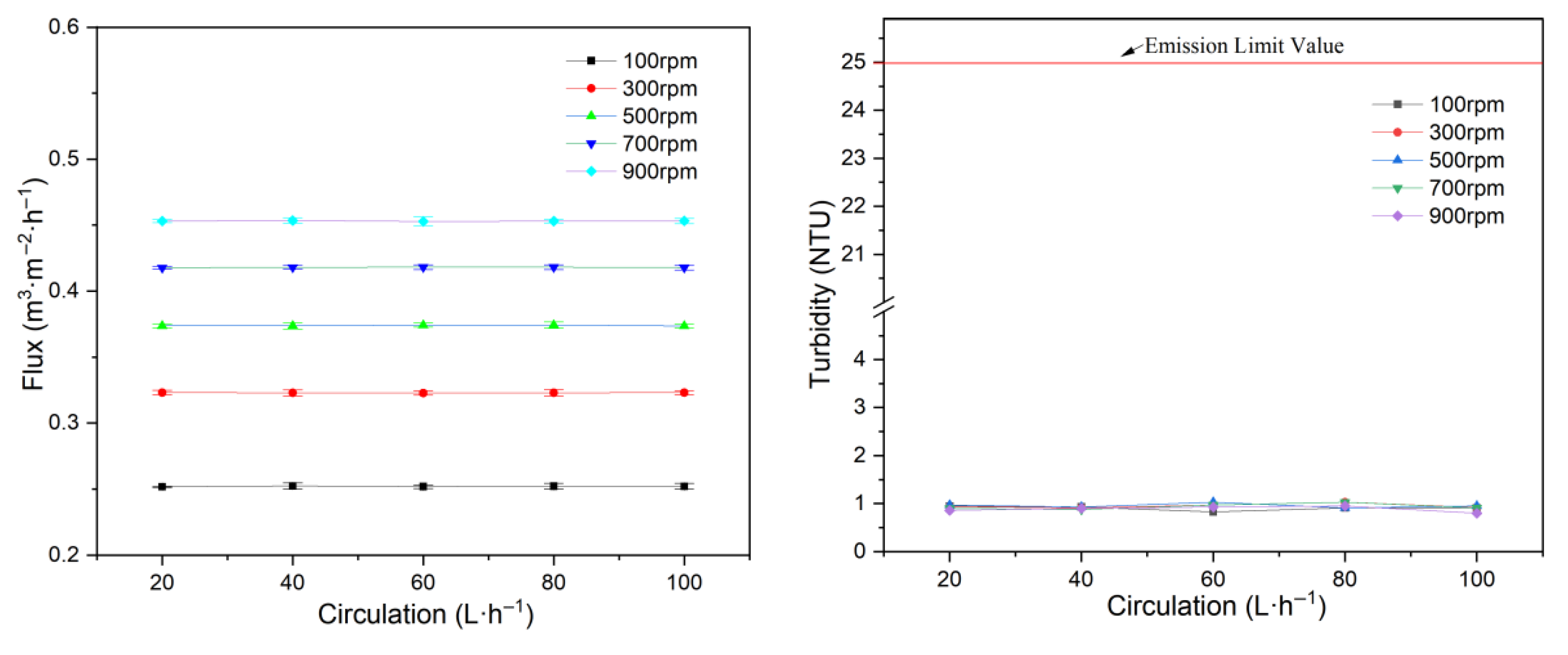

3.1.1. Influence of Feed Circulation

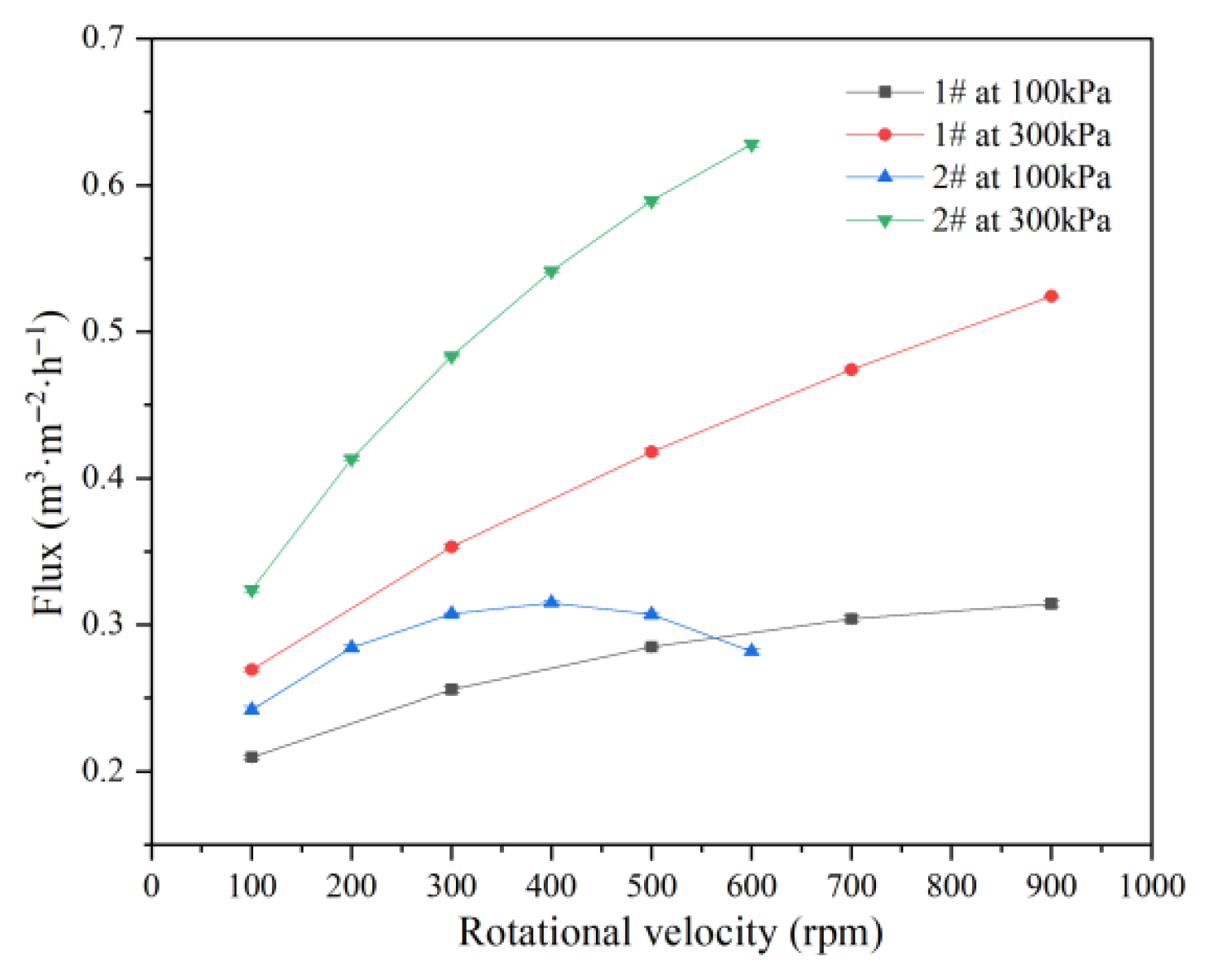

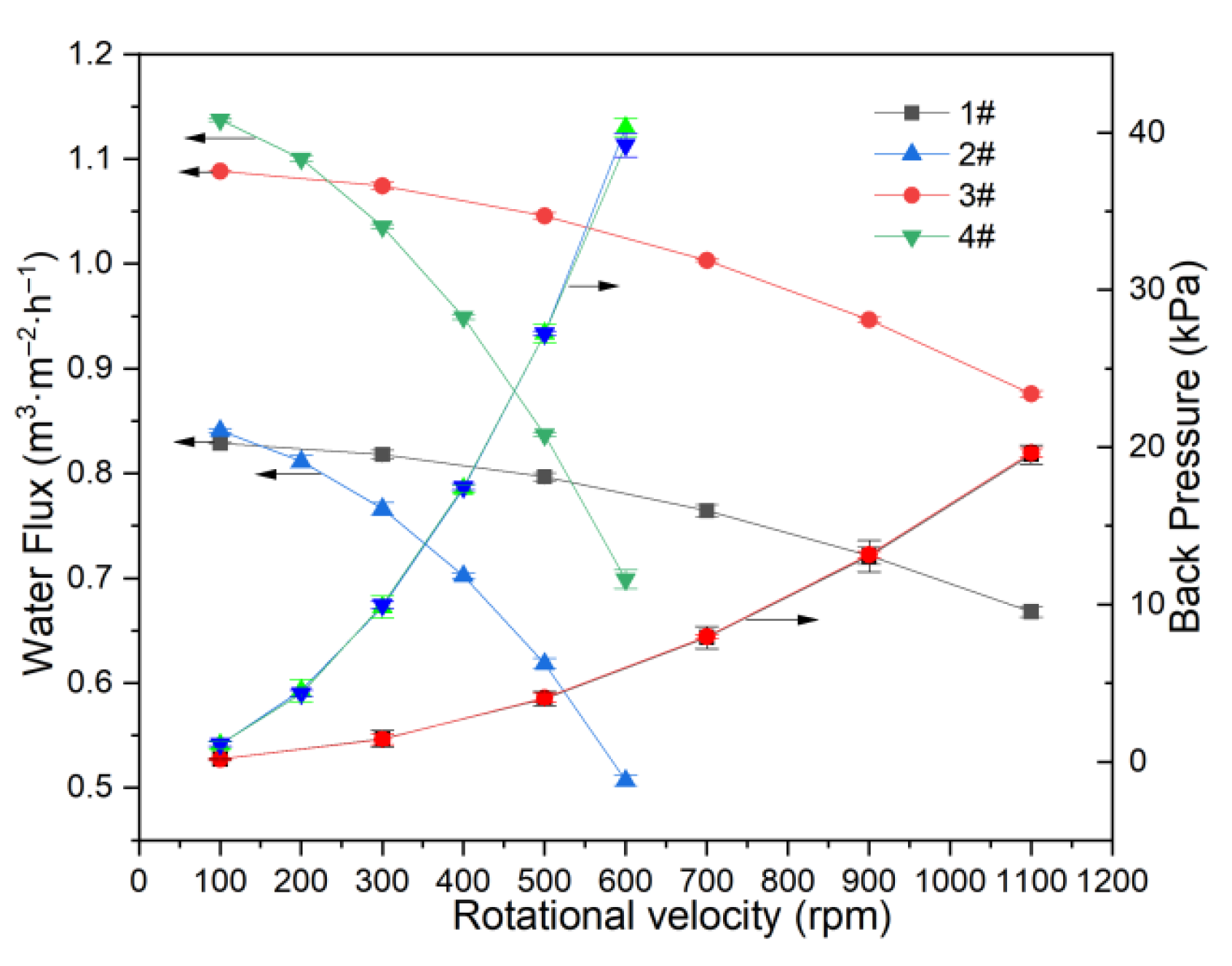

3.1.2. Influence of Membrane Element Rotational Velocity

3.1.3. Influence of Membrane Element Size

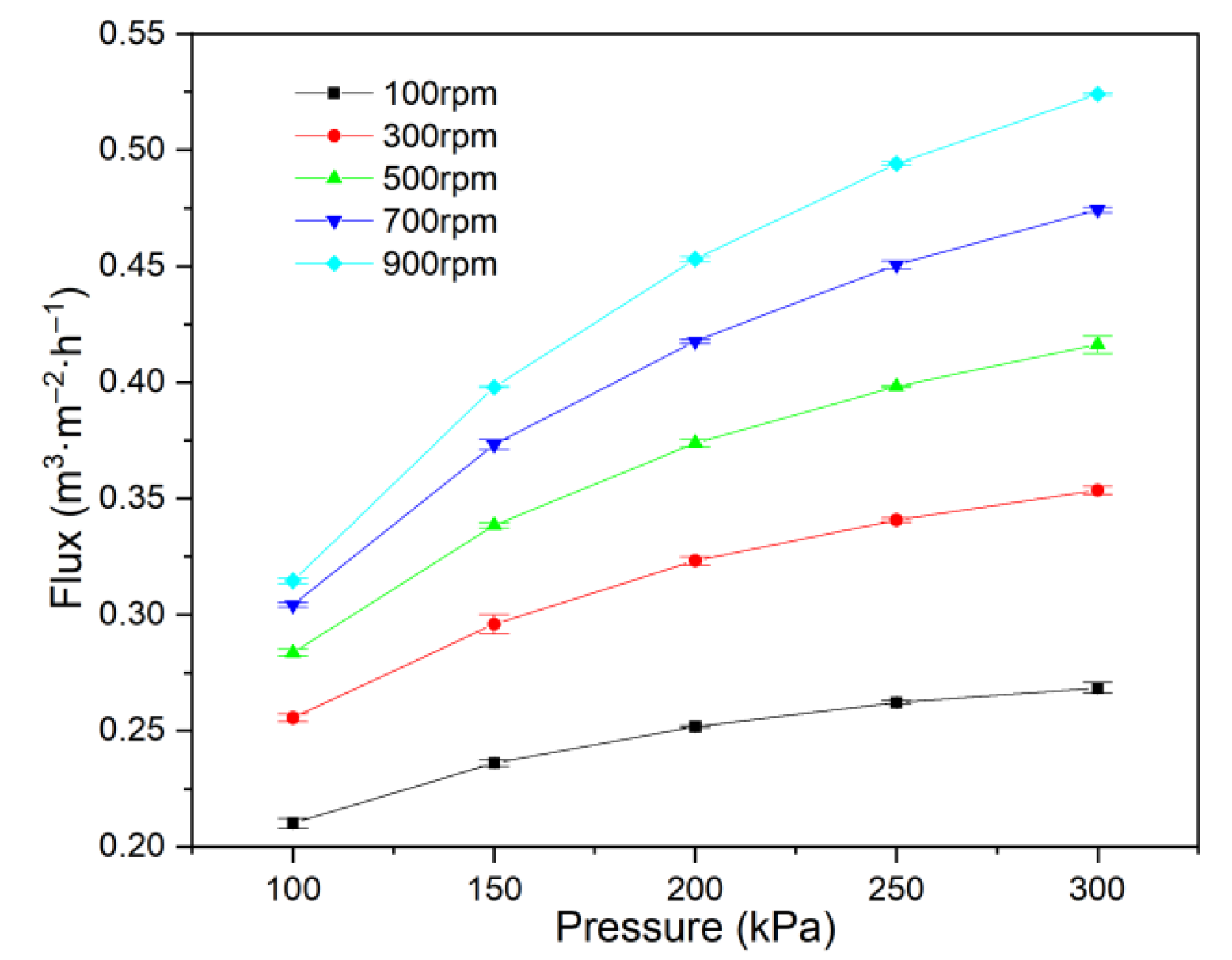

3.1.4. Influence of Operating Pressure

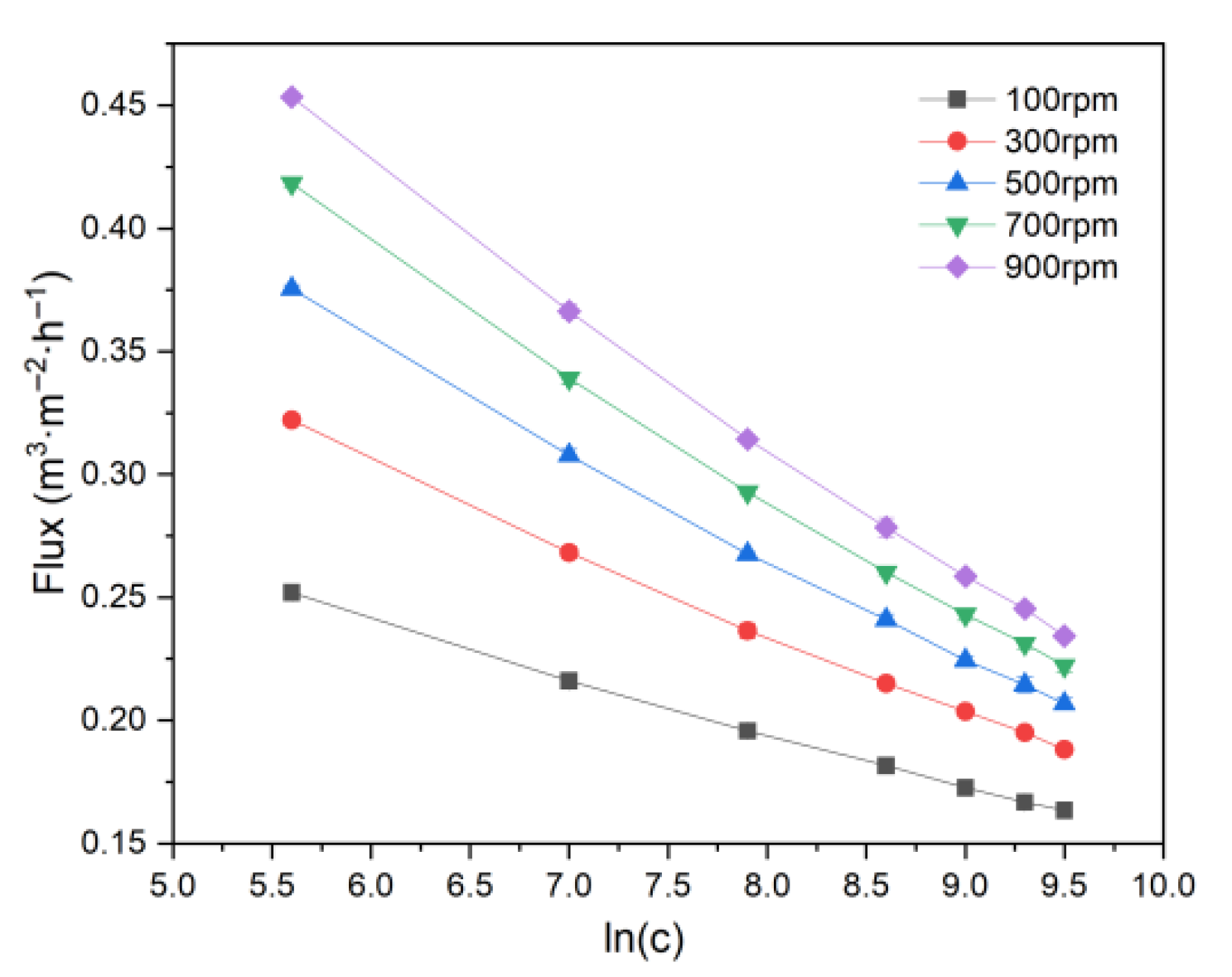

3.1.5. Influence of Feed Concentration

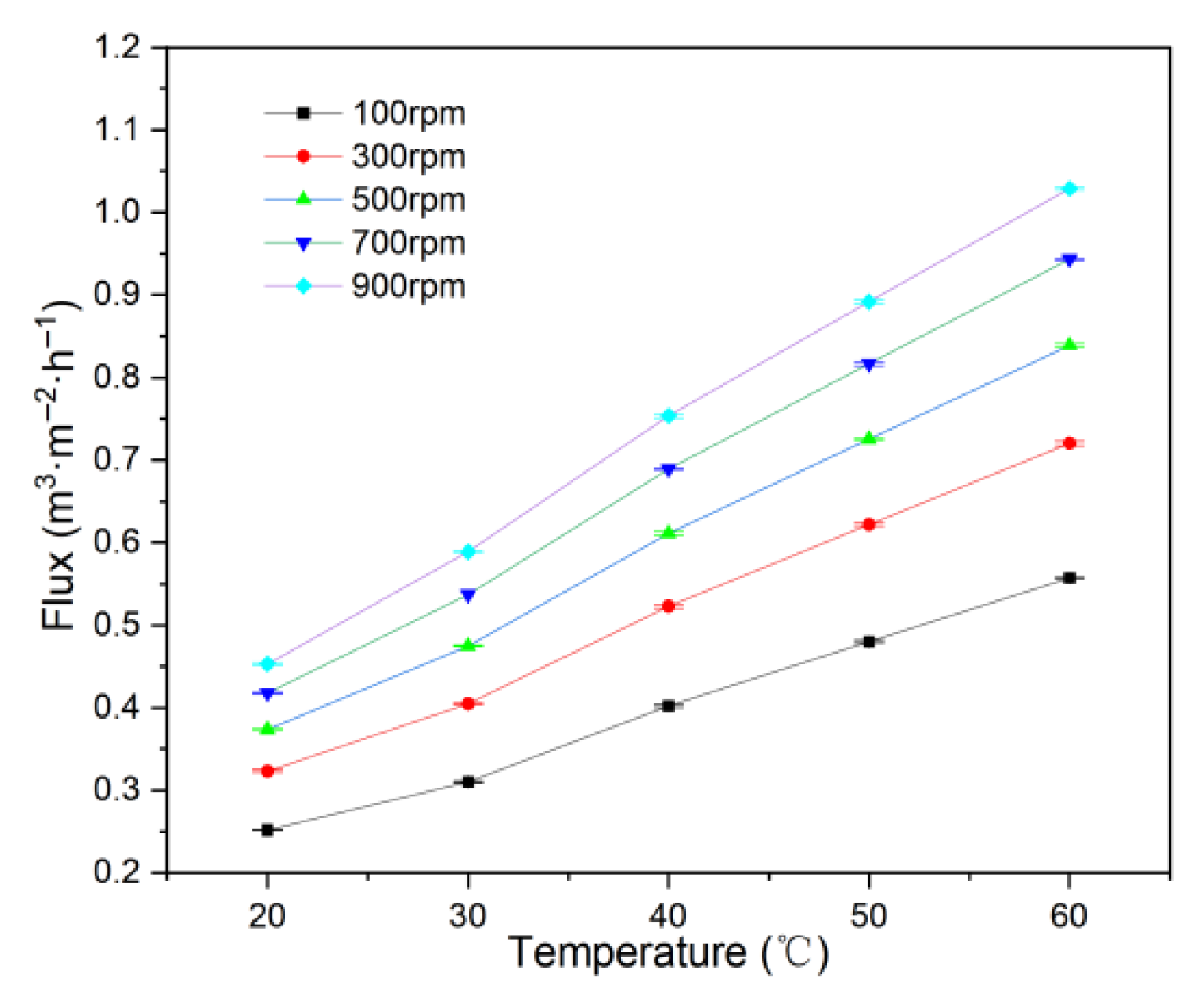

3.1.6. Influence of Operating Temperature

3.2. Theoretical Analysis of the Hydrodynamics in the RDF Process

3.2.1. Determination of Average Back Pressure and Velocity Factor

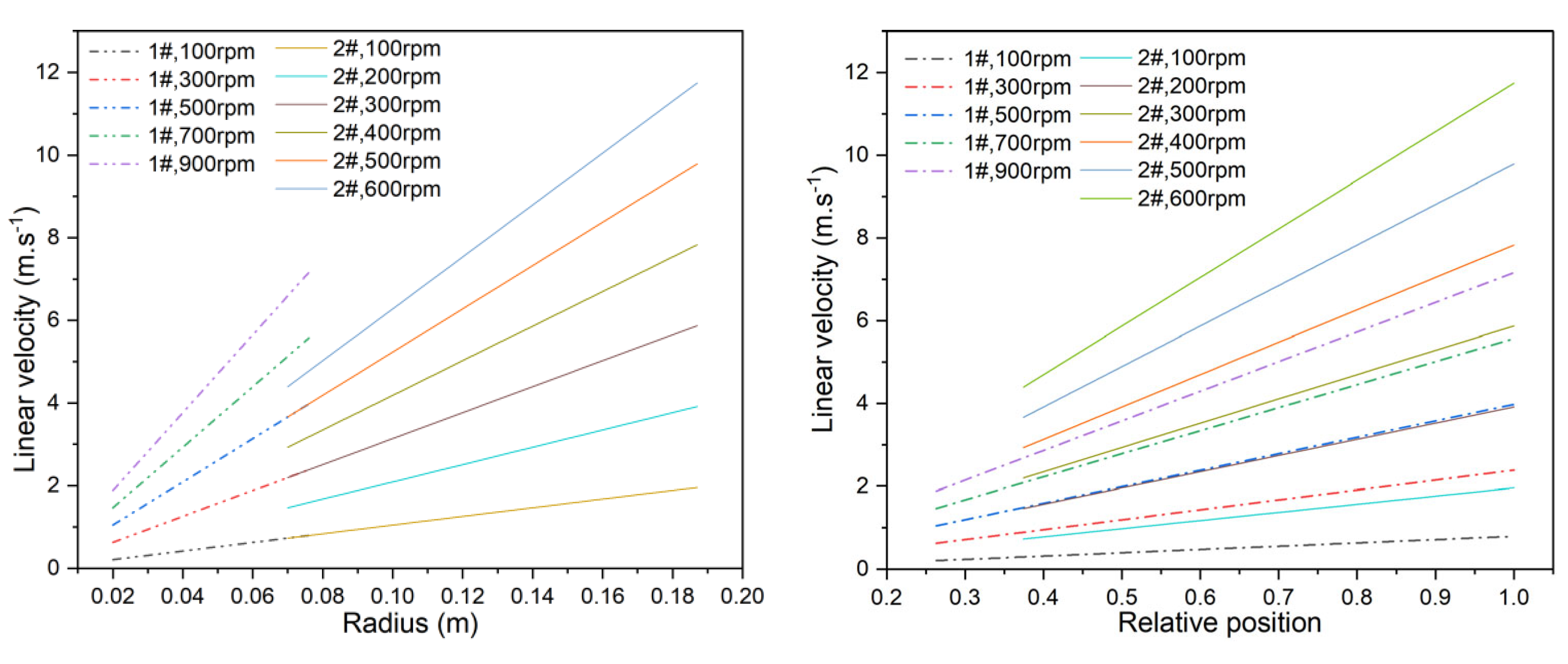

3.2.2. Study on the Velocity of the Membrane and the Flow Status

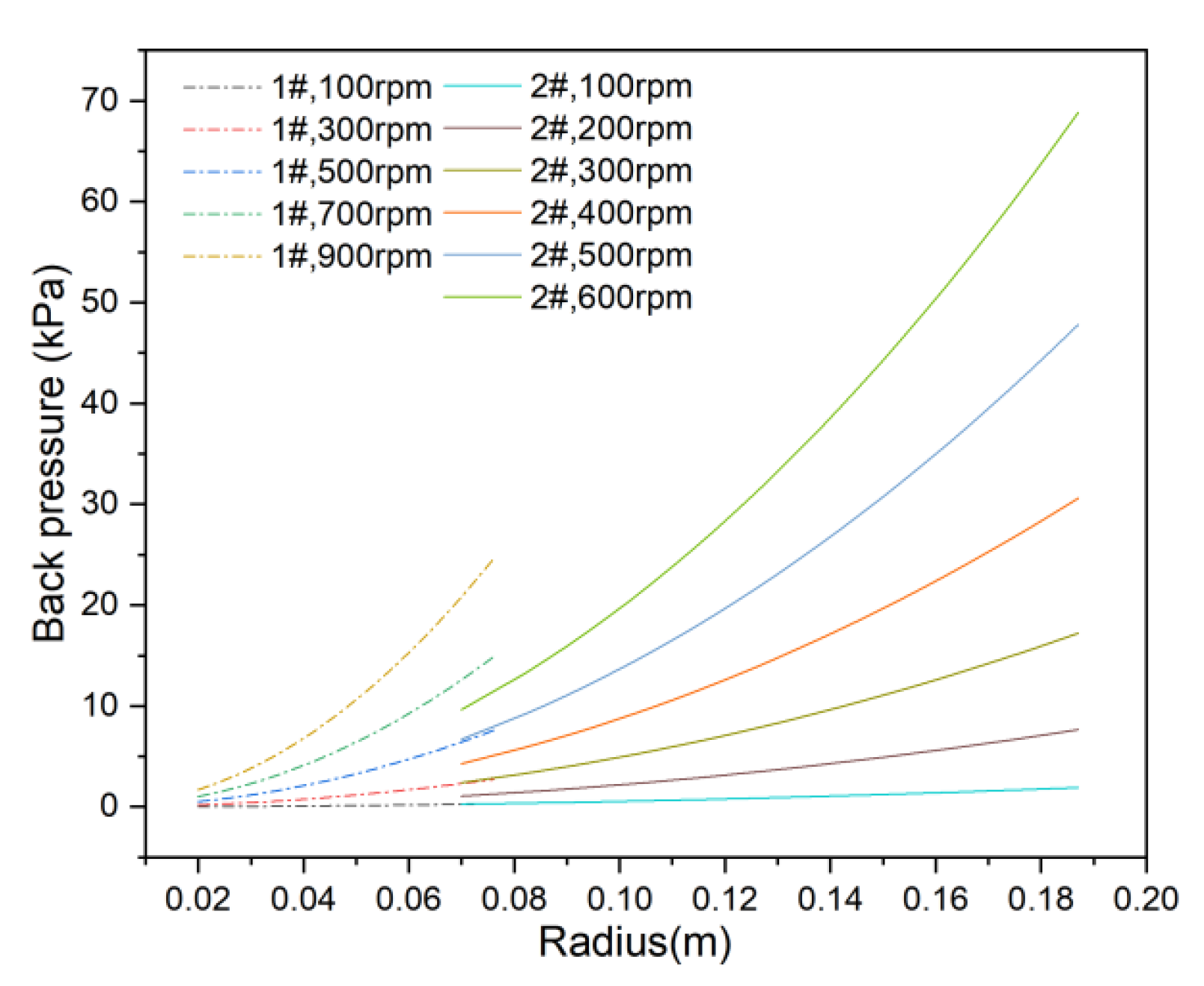

3.2.3. Distribution of Back Pressure and Effective Pressure Difference

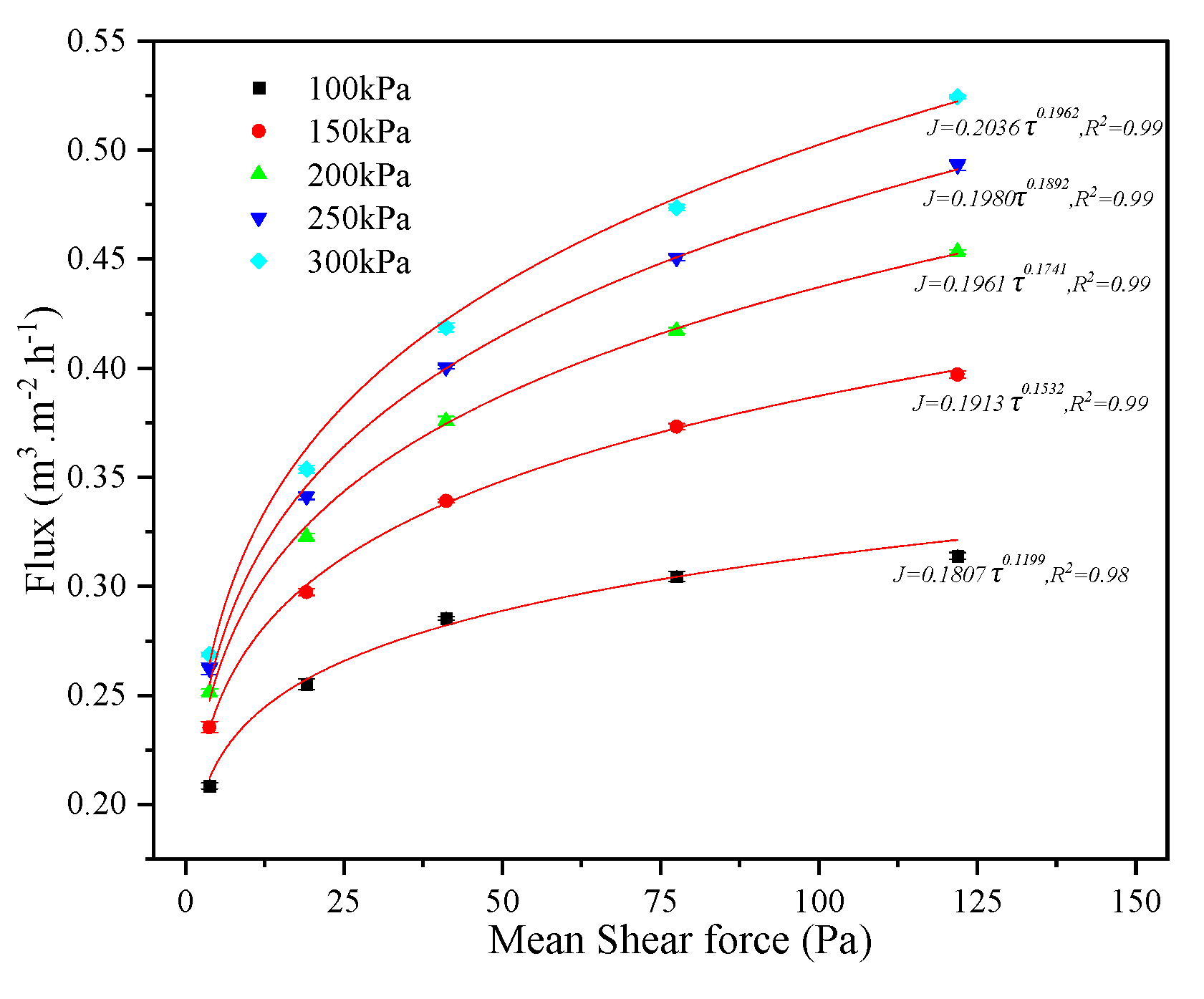

3.2.4. Shear Force on Membrane Surface and Its Effect on Filtration Process

3.2.5. Comparison of Energy Consumption Between RDF and CFF

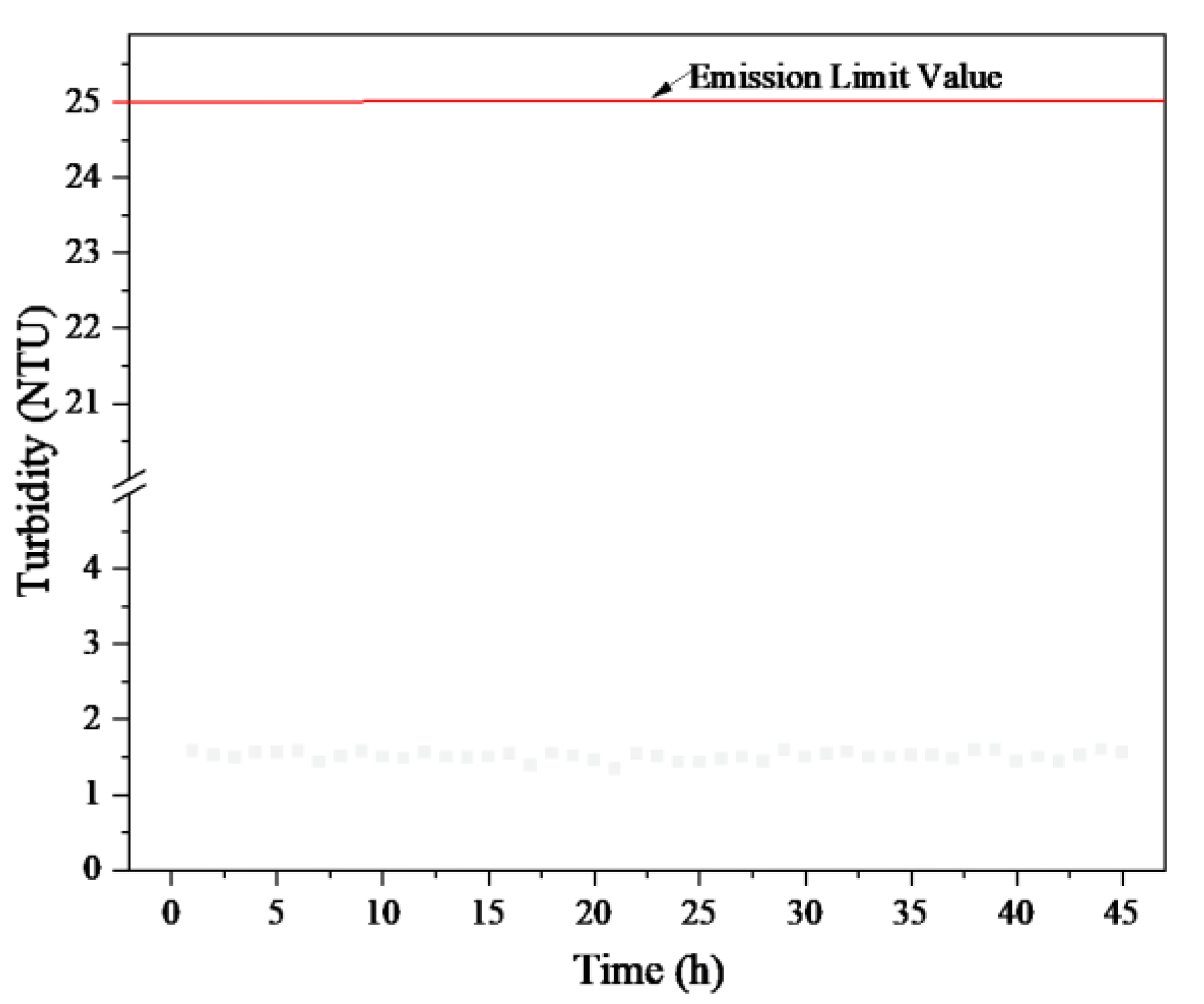

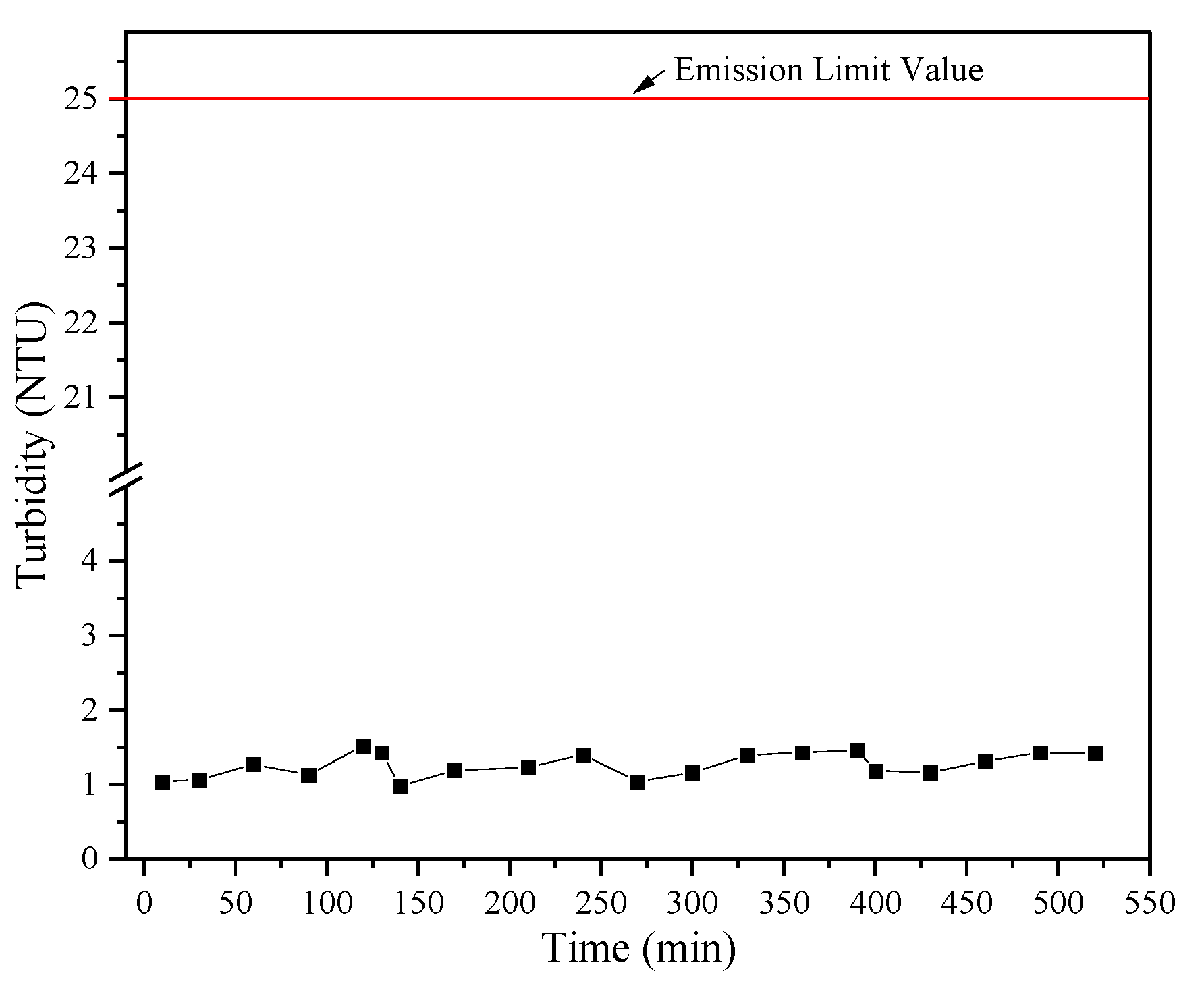

3.3. Pilot Validation Study for EGC Desulfurization Wastewater

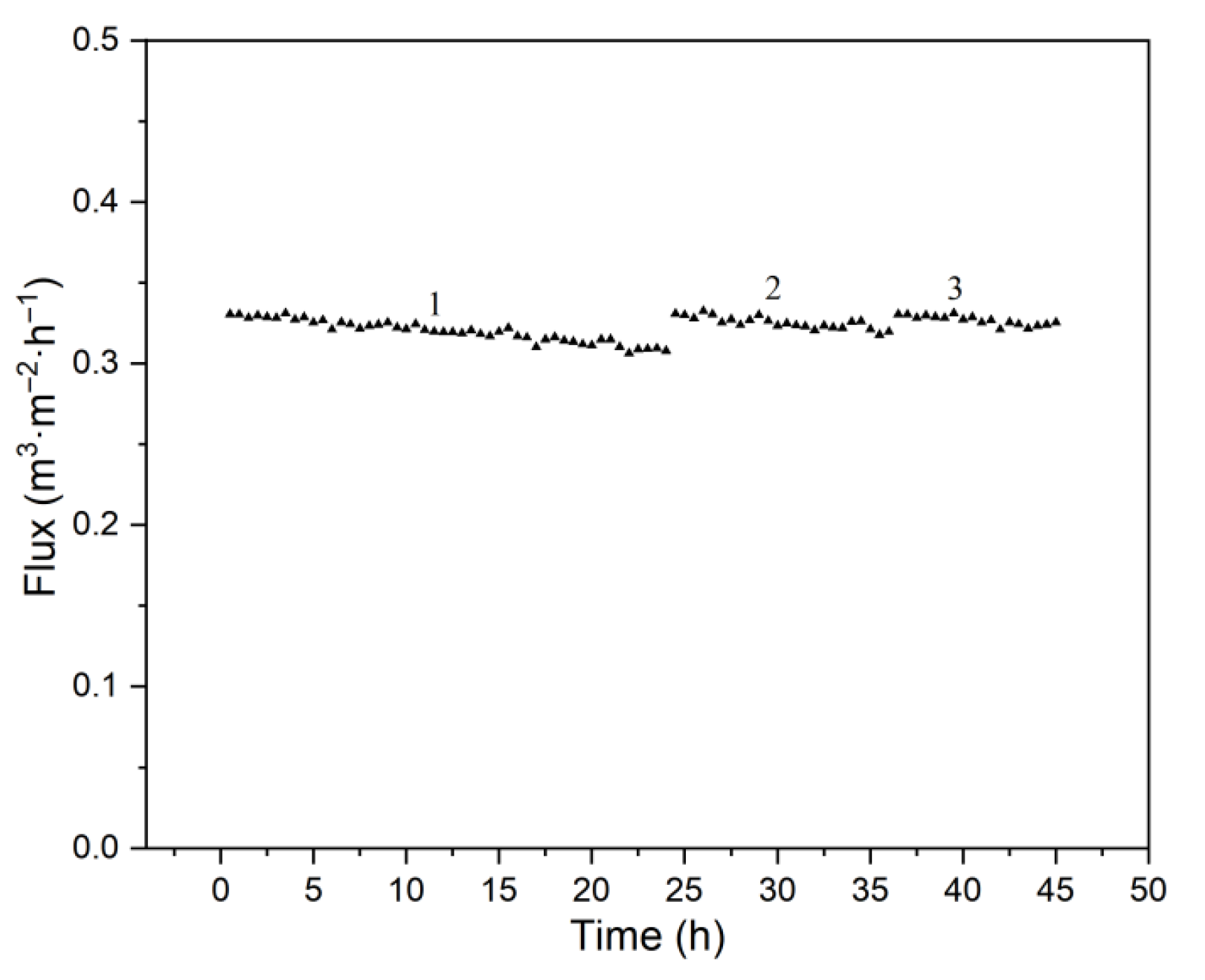

3.3.1. Intermittent Operation Mode

3.3.2. Continuous Operation Mode

3.3.3. Comparison of Continuous and Intermittent Modes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Poulsen, R.T.; Johnson, H. The logic of business vs. the logic of energy management practice: Understanding the choices and effects of energy consumption monitoring systems in shipping companies. J. Clean. Prod. 2016, 112, 3785–3797. [Google Scholar] [CrossRef]

- Johnson, H.; Johanson, M.; Andersson, K. Barriers to improving energy efficiency in short sea shipping: An action research case study. J. Clean. Prod. 2014, 66, 317–327. [Google Scholar] [CrossRef]

- Picone, M.; Russo, M.; Distefano, G.G.; Baccichet, M.; Marchetto, D.; Volpi Ghirardini, A.; Hermansson, A.L.; Petrovic, M.; Gros, M.; Garcia, E.; et al. Impacts of exhaust gas cleaning systems (EGCS) discharge waters on planktonic biological indicators. Mar. Pollut. Bull. 2023, 190, 114846. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.L. Application analysis of exhaust emission control technology for the diesel engine of Wärtsilä marine low speed. Shanghai Shipbuild. 2010, 4, 46. [Google Scholar]

- Pana, P.; Sun, Y.; Yuan, C.; Yan, X.; Tang, X. Research progress on ship power systems integrated with new energy sources: A review. Renew. Sustain. Energy Rev. 2021, 144, 111048. [Google Scholar] [CrossRef]

- Yi, P.; Li, T.; Wei, Y.J.; Zhou, X.Y. Experimental and numerical investigation of low sulfur heavy fuel oil spray characteristics under high temperature and pressure conditions. Fuel 2021, 286, 119327. [Google Scholar] [CrossRef]

- Thalis, P.V.; Kevin, C. The desulfurization of shipping: Past, present and the future under a global cap. Transp. Res. Part D 2020, 82, 102316. [Google Scholar]

- Yue, H. The background and countermeasures of shipping sulfur limit regulation. Ship Goods Mark. 2017, 4, 46–49. [Google Scholar]

- Li, J.W.; Zhang, X.H.; Zhang, X.M. Study on the ships emission and control of air pollutants in China. Resour. Sav. Environ. Prot. 2020, 10, 94–97. [Google Scholar]

- Wang, J.Q. Application of desulphurization tower in ship engineering. Ship Goods Mark. 2020, 12, 45–46. [Google Scholar]

- Wang, N.; Shen, H.T. Marine engine exhaust gas desulfurization technology and economic analysis. J. Ningbo Univ. 2021, 34, 117–120. [Google Scholar]

- Li, X.; Chen, L.; Osaka, Y.; He, Z.H.; Deng, L.S.; Huang, H.Y. Preparation and desulfurization performance of various MnOx materials for ship exhaust emissions control. Sep. Purif. Technol. 2020, 253, 117182. [Google Scholar] [CrossRef]

- MEPC 259(68); Guidelines for Exhaust Gas Cleaning Systems. IMO: London, UK, 2015.

- Da, J.; Cai, J.; Wang, W. Ship domestic wastewater pollution and treatment methods. Sci. Technol. Inf. 2007, 18, 137–138. [Google Scholar]

- Chen, C.D. Research on the ship domestic wastewater system. Ship Goods Mark. 2022, 30, 7–9. [Google Scholar]

- Lin, W. Discharge and treatment measures of ship domestic wastewater. Ship Goods Mark. 2022, 30, 74–76. [Google Scholar]

- Ding, L.; Tang, J.C.; Ying, Y.Y. Treatment of Marine oily wastewater by combined process of coagulation. China Water Wastewater 2010, 26, 116–119. [Google Scholar]

- Ban, F.Y.; Li, Y.F.; Cheng, L.; Pen, X. Design example of treating oily wastewater from marine ships. Environ. Eng. 2009, 27, 20–22. [Google Scholar]

- Luo, Y.Y. Study on the treatment of ship oily wastewater by hydrolysis acidification-biological contact oxidation-ozone catalytic oxidation. Technol. Innov. Appl. 2016, 11, 15–16. [Google Scholar]

- Chen, A.L. Ship ballast water treatment method. Journal of Qingdao Ocean Shipping Mariners College 2003, 24, 70–74. [Google Scholar]

- Lin, F.C. Design of ship ballast water treatment system. Tech. Mark. 2017, 24, 94–95. [Google Scholar]

- Wang, W.C.; Gong, F.; Zheng, Y.; Yuan, W.Q. A Review of Ship Ballast Water Treatment. J. Shanghai Inst. Shipp. Transp. Sci. 2013, 36, 11–14. [Google Scholar]

- Wu, X.M. Analysis and Treatment of Wastewater from Ship Magnesium Seawater Flue Gas Desulfurization. Master’s Thesis, Dalian Maritime University, Liaoning, China, 2012. [Google Scholar]

- Chen, C. Experiments on Removal Oily Pollutants of Waste Liquid from Magnesium Flue Gas Desulfurization. Master’s Thesis, Dalian Maritime University, Liaoning, China, 2015. [Google Scholar]

- Rosa, D.; Cifaldi, D.; Palma, L.D. Boron removal from wastewater via coordinative adsorption assisted by Fenton-Induced Oxoprecipitation/Flocculation. Chem. Eng. J. 2024, 498, 155572. [Google Scholar] [CrossRef]

- Sun, K.Q. Design and Study of Ship Engine Exhaust Gas Desulfurization System Based on Sodium Alkali Seawater. Master’s Thesis, Dalian Maritime University, Liaoning, China, 2016. [Google Scholar]

- Shen, T.; Huang, H.; Zhang, X.Z.; Li, X.B.; Feng, J.Y.; Zhao, S.Y. Study on the purification performance of ultrafiltration for ship exhaust desulfurization wastewater. J. Green Sci. Technol. 2021, 23, 80ߝ83, 87. [Google Scholar]

- Zhang, B.L. Experimental Research on Wastewater Treatment of Marine Exhaust Scrubbing Desulfurization. Master’s Thesis, Harbin Engineering University, Heilongjiang, China, 2014. [Google Scholar]

- Ding, L.H.; Jaffrin, M.Y. Benefits of High Shear Rate Dynamic Nanofiltration and Reverse Osmosis: A Review. Sep. Sci. Technol. 2014, 49, 1953–1967. [Google Scholar] [CrossRef]

- Jaffrin, M.Y. Hydrodynamic Techniques to Enhance Membrane Filtration. Annu. Rev. Fluid Mech. 2012, 44, 77–96. [Google Scholar] [CrossRef]

- Jaffrin, M.Y. Dynamic shear-enhanced membrane filtration: A review of rotating disks, rotating membranes and vibrating systems. J. Membr. Sci. 2008, 324, 7–25. [Google Scholar] [CrossRef]

- Liebermann, F. Dynamic cross flow filtration with Novoflow’s single shaft disk filters. Desalination 2010, 250, 1087–1090. [Google Scholar] [CrossRef]

- Serra, C.A.; Wiesner, M.R.; Laine, J.M. Rotating membrane disk filters: Design evaluation using computational fluid dynamics. Chem. Eng. J. 1999, 72, 1–17. [Google Scholar] [CrossRef]

- Chai, M.; Ye, Y.; Chen, V. Application of rotating vibration in a submerged hollow fiber membrane system for bioseparation of high concentration yeast suspensions. J. Membr. Sci. 2019, 573, 145–156. [Google Scholar] [CrossRef]

- Dahiya, D.; Pugazhenthi, G.; Kumar, M.; Vasanth, D. Separation of bacteria Kocuria rhizophila BR-1 from its broth during synthesis of gold nanoparticles using ceramic membrane by shear-enhanced filtration process. Chemosphere 2021, 281, 130761. [Google Scholar] [CrossRef]

- Hwang, K.J.; Lin, S.J. Filtration flux-shear stress-cake mass relationships in microalgae rotating-disk dynamic microfiltration. Chem. Eng. J. 2014, 244, 429–437. [Google Scholar] [CrossRef]

- Hwang, K.J.; Wu, S.E. Disk structure on the performance of a rotating-disk dynamic filter: A case study on microalgae microfiltration. Chem. Eng. Res. Des. 2015, 94, 44–51. [Google Scholar] [CrossRef]

- Kim, K.; Jung, J.Y.; Kwon, J.H.; Yang, J.W. Dynamic microfiltration with a perforated disk for effective harvesting of microalgae. J. Membr. Sci. 2015, 475, 252–258. [Google Scholar] [CrossRef]

- Villafaña-López, L.; Rivera, E.C.; Liu, S.L.; Couallier, E.; Frappart, M. Shear-enhanced membrane filtration of model and real microalgae extracts for lipids recovery in biorefinery context. Bioresour. Technol. 2019, 288, 121539. [Google Scholar] [CrossRef]

- Zhu, Z.Z.; Luo, J.; Ding, L.Q.; Bals, O.; Jaffrin, M.Y.; Vorobiev, E. Chicory juice clarification by membrane filtration using rotating disk module. J. Food Eng. 2013, 115, 264–271. [Google Scholar] [CrossRef]

- Zhu, Z.Z.; Ladeg, S.; Ding, L.H.; Bals, O.; Moulai-Mostefa, N.; Jaffrin, M.Y.; Vorobiev, E. Study of rotating disk assisted dead-end filtration of chicory juice and its performance optimization. Ind. Crops Prod. 2014, 53, 154–162. [Google Scholar] [CrossRef]

- Zhu, Z.Z.; Mhemdi, H.; Zhang, W.X.; Ding, L.H.; Bals, O.; Jaffrin, M.Y.; Grimi, N.; Vorobiev, E. Rotating Disk-Assisted Cross-Flow Ultrafiltration of Sugugar Beet Juice. Food Bioprocess Technol. 2016, 9, 493–500. [Google Scholar] [CrossRef]

- Fillaudeau, L.; Boissier, B.; Moreau, A.; Blanpain-avet, P.; Ermolaev, S.; Jitariouk, N.; Gourdon, A. Investigation of rotating and vibrating filtration for clarification of rough beer. J. Food Eng. 2007, 80, 206–217. [Google Scholar] [CrossRef]

- Schafer, J.; Bast, R.; Atamer, Z.; Nobel, S.; Kohlus, R.; Hinrichs, J. Concentration of skim milk by means of dynamic filtration using overlapping rotating ceramic membrane disks. Int. Dairy J. 2018, 78, 11–19. [Google Scholar] [CrossRef]

- Ding, L.H.; Akoum, O.; Abraham, A.; Jaffrin, M.Y. High Shear Skim Milk Ultrafiltration Using Rotating Disk Filtration Systems. Am. Inst. Chem. Eng. J. 2003, 49, 2433–2441. [Google Scholar] [CrossRef]

- Espina, V.S.; Jaffrin, M.Y.; Frappart, M.; Ding, L.H. Separation of casein micelles from whey proteins by high shear microfiltration of skim milk using rotating ceramic membranes and organic membranes in a rotating disk module. J. Membr. Sci. 2008, 325, 872–879. [Google Scholar] [CrossRef]

- Espina, V.; Jaffrin, M.Y.; Frappart, M.; Ding, L.H. Separation of casein from whey proteins by dynamic filtration. Desalination 2010, 250, 1109–1112. [Google Scholar] [CrossRef]

- Ding, L.H.; Al-Akoum, O.; Abraham, A.; Jaffrin, M.Y. Milk protein concentration by ultrafiltration with rotating disk modules. Desalination 2002, 144, 307–311. [Google Scholar] [CrossRef]

- Zhang, W.X.; Ding, L.H.; Grimi, N.; Jaffrin, M.Y.; Tang, B. Application of UF-RDM (Ultrafiltration Rotating Disk Membrane) module for separation and concentration of leaf protein from alfalfa juice: Optimization of operation conditions. Sep. Purif. Technol. 2017, 75, 365–375. [Google Scholar] [CrossRef]

- Dal-Cin, M.M.; Lick, C.N.; Kumar, A.; Lealess, S. Dispersed phase back transport during ultrafiltration of cutting oil emulsions with a spinning membrane disc geometry. J. Membr. Sci. 1998, 141, 165–181. [Google Scholar] [CrossRef]

- Yang, Y.L.; Liu, G.H.; Liu, H.; Wang, Q.K.; Wang, Y.Q.; Zhou, J.; Chang, Q.B. Separation of oil-water emulsion by disc ceramic membrane under dynamic membrane filtration mode. Sep. Purif. Technol. 2022, 300, 121862. [Google Scholar] [CrossRef]

- Moulai-Mostefa, N.; Akoum, O.; Nedjihoui, M.; Ding, L.; Jaffrin, M.Y. Comparison between rotating disk and vibratory membranes in the ultrafiltration of oil-in-water emulsions. Desalination 2007, 206, 494–498. [Google Scholar] [CrossRef]

- Hwang, K.J.; Wang, S.Y.; Iritani, E.; Katagiri, N. Fine particle removal from seawater by using cross-flow and rotating-disk dynamic filtration. J. Taiwan Inst. Chem. Eng. 2016, 62, 45–53. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, X.M.; Zhang, W.J.; Fu, G.H.; Guo, Z.X. The effect of operating conditions on membrane resistance. Chem. Eng. 2005, 4, 60–62. [Google Scholar]

- Li, G.S.; Wu, Z.P.; Xu, F. Analysis and experimental study on dynamic filtration resistance of inorganic membrane. J. Tianjin Univ. Sci. Technol. 2006, 4, 86–88. [Google Scholar]

- Marke, H.S.; Breil, M.P.; Hansen, E.B.; Pinelo, M.; Kruhne, U. Cake resistance in rotating dynamic filtration: Determination and modeling. Sep. Purif. Technol. 2020, 250, 117100. [Google Scholar] [CrossRef]

- Bouzerar, R.; Jaffrin, M.Y.; Ding, L.H.; Paullier, P. Influence of geometry and angular velocity on performance of a rotating disk filter. Am. Inst. Chem. Eng. J. 2000, 46, 257–265. [Google Scholar] [CrossRef]

- Bouzerar, R.; Ding, L.H.; Jaffrin, M.Y. Local permeate-flux-shear-pressure relationships in a rotating disk microfiltration module: Implications for global performance. J. Membr. Sci. 2000, 170, 127–141. [Google Scholar] [CrossRef]

- Cheng, M.; Xie, X.M.; Schmitz, P.; Fillaudeau, L. Extensive review about industrial and laboratory dynamic filtration modules: Scientific production, configurations and performances. Sep. Purif. Technol. 2021, 265, 118293. [Google Scholar] [CrossRef]

- John, B.; Brian, R.; Patrick, M.; Tracy, C. Using a high shear rotary membrane system to treat shipboard wastewaters: Experimental disc diameter, rotation and flux relationships. J. Membr. Sci. 2014, 462, 178–184. [Google Scholar] [CrossRef]

- Luo, J.; Ding, L.; Wan, Y.; Paullier, P.; Jaffrin, M.Y. Application of NF-RDM (nanofiltration rotating disk membrane) module under extreme hydraulic conditions for the treatment of dairy wastewater. Chem. Eng. J. 2010, 163, 307–316. [Google Scholar] [CrossRef]

- Akoum, O.; Richfield, D.; Jaffrin, M.Y.; Ding, L.H.; Swart, P. Recovery of trypsin inhibitor by soy milk ultrafiltration using a rotating disk system. Desalination 2006, 191, 438–445. [Google Scholar] [CrossRef]

- Zhang, W.; Huang, G.; Wei, J.; Yan, D. Gemini micellar enhanced ultrfilltration (GMEUF) process for the treatment of phenol wastewater. Desalination 2013, 311, 31–36. [Google Scholar] [CrossRef]

- Taamneh, Y.; Rippergeret, S. Performance of Single and Double Shaft Disk Separators. Phys. Sep. Sci. Eng. 2008, 5, 508617. [Google Scholar] [CrossRef]

- Marke, H.S.; Breil, M.P.; Hansen, E.B.; Pinelo, M.; Krühne, U. Investigation of the velocity factor in a rotating dynamic microfiltration system. Sep. Purif. Technol. 2019, 220, 69–77. [Google Scholar] [CrossRef]

- Pinilla, A.; Berrio, J.C.; Guerrero, E.; Valdés, J.P.; Becerra, D.; Pico, P.; Vargas, L.; Madsen, S.; Bentzen, T.R.; Ratkovich, N. CFD modelling of the hydrodynamics in a filtration unit with rotating Membranes. J. Water Process Eng. 2020, 36, 101368. [Google Scholar] [CrossRef]

- Tu, Z.H.; Ding, L.H. Microfiltration of mineral suspensions using a MSD module with rotating ceramic and polymeric membranes. Sep. Purif. Technol. 2010, 73, 363–370. [Google Scholar] [CrossRef]

| Type | Diameter (mm) | Area (m2) | Pore Size (μm) | Resistance (1010 m−1) | Material |

|---|---|---|---|---|---|

| 1# | 152 | 0.035 | 0.2 | 42.94 | Al2O3 |

| 2# | 374 | 0.20 | 0.2 | 41.93 | Al2O3 |

| 3# | 152 | 0.035 | 0.5 | 32.70 | Al2O3 |

| 4# | 374 | 0.20 | 0.5 | 30.99 | Al2O3 |

| No. | Rotational Velocity (rpm) | Equivalent Velocity (m·s−1) | Specific Energy Consumption (100 kPa) | |

|---|---|---|---|---|

| CFF(Wh·m−3) | RDF(Wh·m−3) | |||

| 1 | 300 | 1.74 | 3153.12 | 316.80 |

| 2 | 500 | 2.91 | 4733.50 | 588.00 |

| 3 | 700 | 4.07 | 6204.14 | 1270.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wu, J.; Wu, Y.; Dong, W. Study on Separation of Desulfurization Wastewater in Ship Exhaust Gas Cleaning System with Rotating Dynamic Filtration. Membranes 2025, 15, 214. https://doi.org/10.3390/membranes15070214

Wang S, Wu J, Wu Y, Dong W. Study on Separation of Desulfurization Wastewater in Ship Exhaust Gas Cleaning System with Rotating Dynamic Filtration. Membranes. 2025; 15(7):214. https://doi.org/10.3390/membranes15070214

Chicago/Turabian StyleWang, Shiyong, Juan Wu, Yanlin Wu, and Wenbo Dong. 2025. "Study on Separation of Desulfurization Wastewater in Ship Exhaust Gas Cleaning System with Rotating Dynamic Filtration" Membranes 15, no. 7: 214. https://doi.org/10.3390/membranes15070214

APA StyleWang, S., Wu, J., Wu, Y., & Dong, W. (2025). Study on Separation of Desulfurization Wastewater in Ship Exhaust Gas Cleaning System with Rotating Dynamic Filtration. Membranes, 15(7), 214. https://doi.org/10.3390/membranes15070214