1. Introduction

Forward osmosis (FO) is a membrane separation process in which water molecules migrate from a low-salinity feed solution (FS) to a high-salinity draw solution (DS) across a semi-permeable membrane driven by an osmotic pressure difference. Since FO operates under minimal hydraulic pressure, it enables the energy-efficient concentration of FS or dilution of DS under low-pressure conditions [

1,

2].

In addition to energy efficiency, FO is gaining attention in the field of wastewater treatment and resource recovery due to its potential to concentrate FS and facilitate the selective extraction of valuable solutes. For instance, Mo et al. [

3] demonstrated lithium recovery from spent lithium-ion battery wastewater using FO, while Almoalimi and Liu [

4,

5,

6] reported recovery of phosphorus, calcium, and magnesium from concentrated municipal effluents. Volpin et al. [

7] also proposed an FO-based approach for recovering nitrogen and phosphorus from urine, with several other studies further supporting FO’s potential in nutrient recovery from urine-based wastewater [

8,

9,

10,

11]. Cath et al. (2006) demonstrated the applicability of FO for the low-temperature concentration of heat-sensitive beverages such as fruit juices and coffee extracts [

12]. Holloway et al. [

13] applied FO for the concentration and purification of antibiotics in pharmaceutical processes. Zhao et al. [

14] reported the separation of organic compounds from high-strength industrial wastewater using FO, highlighting its potential for chemical manufacturing and wastewater minimization.

To realize the practical implementation of FO technology, scaling up through the connection of multiple FO modules in a multistage configuration is essential. Although several studies have explored commercially available FO modules, only a limited number of experimental case studies at the module scale have been reported to date. Xu et al. [

15] evaluated the performance of the first commercial FO module by HTI, the Hydrowell module (active membrane area: 0.94 m

2), under varying crossflow rates and draw solution concentrations. Phuntsho et al. [

16] conducted experiments using the 4040MS module (active membrane area: 3.2 m

2) developed by Hydration Technologies, examining the effects of crossflow velocity, pressure, temperature, and different draw solutes. Kim et al. [

17] tested two 8-inch spiral-wound FO modules: the CTA module by HTI (9 m

2) and the thin-film composite module by Toray Industries, Korea (15 m

2), under varying crossflow conditions, solution concentrations, and hydraulic pressures. Kim et al. [

18] further evaluated the performance of a four-stage serial configuration using the TFC 8-inch spiral-wound FO module (active membrane area: 15 m

2) from Toray Chemical Korea. The experiments began with FS and DS flow rates of 5 and 40 L/min, respectively. As the stages progressed, the DS became increasingly diluted and the FS more concentrated, leading to a decrease in osmotic pressure and a corresponding drop in flux from 25 LMH (L/m

2h) to 13.5 LMH.

Ali et al. [

19] developed a forward osmosis system design software based on performance data obtained from the FO8040 module (active membrane area: 15.3 m

2) by Toray Chemical Korea and subsequently applied it to the design of a large-scale 100,000 m

3/day FO system. Field et al. [

20] conducted experiments using the SepraMem 4040 FO spiral element (active membrane area: 1.6 m

2) by HTI (Albany, OR, USA) to evaluate the effects of different spacer types and feedwater sources, including sodium chloride (NaCl) based solutions and NEWater brine. Jeon et al. [

21] investigated the performance of an 8-inch spiral-wound FO module by Toray Chemical Korea to derive characteristic parameters for FO module modeling. Song et al. [

22] performed experiments on a plate-type FO module (active membrane area: 7 m

2) by Porifera, focusing on variations in crossflow velocity and draw solution concentration. Im et al. [

23] evaluated the performance of FO modules for use in a FO-RO hybrid system cost analysis, conducting experiments with both a 4-inch spiral-wound FO module by Toray Chemical Korea (active membrane area: 3.1 m

2) and a plate-type module by Porifera.

In a serially connected FO system, the dilution of the DS and concentration of the FS progressively reduce the osmotic pressure difference, thereby weakening the driving force and diminishing the performance of downstream modules. This phenomenon ultimately limits the overall efficiency of the system. Manufacturers have also recommended maintaining the FS pressure higher than the DS pressure during operation to prevent potential damage to the glue lines of the membrane module, which can occur if excessive pressure is applied to the DS channel [

24]. Furthermore, in spiral-wound FO modules, the DS flow path is structurally more complex than that of the FS, resulting in a greater head loss. As water permeates from the FS to the DS, the flow rate in the DS channel increases toward the downstream end, exacerbating the head loss accumulation [

25]. These hydraulic constraints suggest that the maximum number of modules that can be connected in series may be limited to fewer than four modules.

To overcome the limitations associated with conventional serially connected FO systems, this study proposes a novel module configuration strategy termed draw solution split distribution (DSSD). In this configuration, the DS is distributed in parallel to each module while the FS continues to flow in series. By supplying concentrated DS individually to each module, the osmotic driving force can be maintained throughout the system, and the issue of cumulative head loss in the DS channel can be effectively addressed. This study aimed to experimentally and numerically evaluate the performance of the proposed DSSD in terms of energy efficiency and dewatering capability and to compare its performance with both conventional serial FO configurations and reverse osmosis (RO) systems in terms of concentration ratio and energy consumption.

2. Materials and Methods

2.1. Draw Solution Split Distribution

2.1.1. Limitations of Serially Connected Draw Solutions

As illustrated in

Figure 1, in the serial configuration of the FO process, a single DS and FS are passed sequentially through the FO modules. During this process, the DS progressively diluted while the FS became increasingly concentrated. As a result, the osmotic pressure gradient between the DS and FS decreased significantly downstream. In these downstream modules, the reduced driving force leads to a significant decline in water flux, ultimately lowering the overall water recovery and energy efficiency of the system as a whole.

In full-scale FO systems employing spiral-wound modules, the flow characteristics of the FS and DS, as well as the channel geometry, become significantly more complex than those in lab-scale coupon tests. These complexities intensify both internal and external concentration polarization phenomena and introduce design challenges, such as flow maldistribution and dead zone formation. As a result, the water flux is further limited in practical applications.

2.1.2. Concept of Draw Solution Split Arrangement

To address the limitations of the conventional serial configuration, a novel connection strategy, the DSSD, has been proposed. Instead of supplying the entire DS stream sequentially through the FO modules, the DSSD configuration divides the DS flow and delivers it individually to each module. This approach helps maintain a more consistent osmotic pressure gradient across each module, thereby improving the overall system performance.

The DSSD serves not only as a modification of flow routing but also as an effective strategy to address spatial flux imbalances across the system. First, by maintaining a relatively consistent DS concentration at the inlet of each module, the system ensured a more uniform flux and stable performance throughout all modules. Additionally, the dilution rate of the DS can be better controlled, preventing the decline in the osmotic driving force that typically occurs in serial configurations. Consequently, this approach enhances the average water flux and, in the long term, contributes to improved overall water recovery.

Moreover, reducing the flux deviations among the modules enhances operational stability. Sudden drops in flux or pressure imbalances within specific sections can impose mechanical stresses on the system. By adopting the DSSD configuration and supplying the draw solution individually to each module, these risks can be effectively mitigated. This not only improves the treatment performance but also contributes to extending the membrane lifespan and reducing the cleaning frequency.

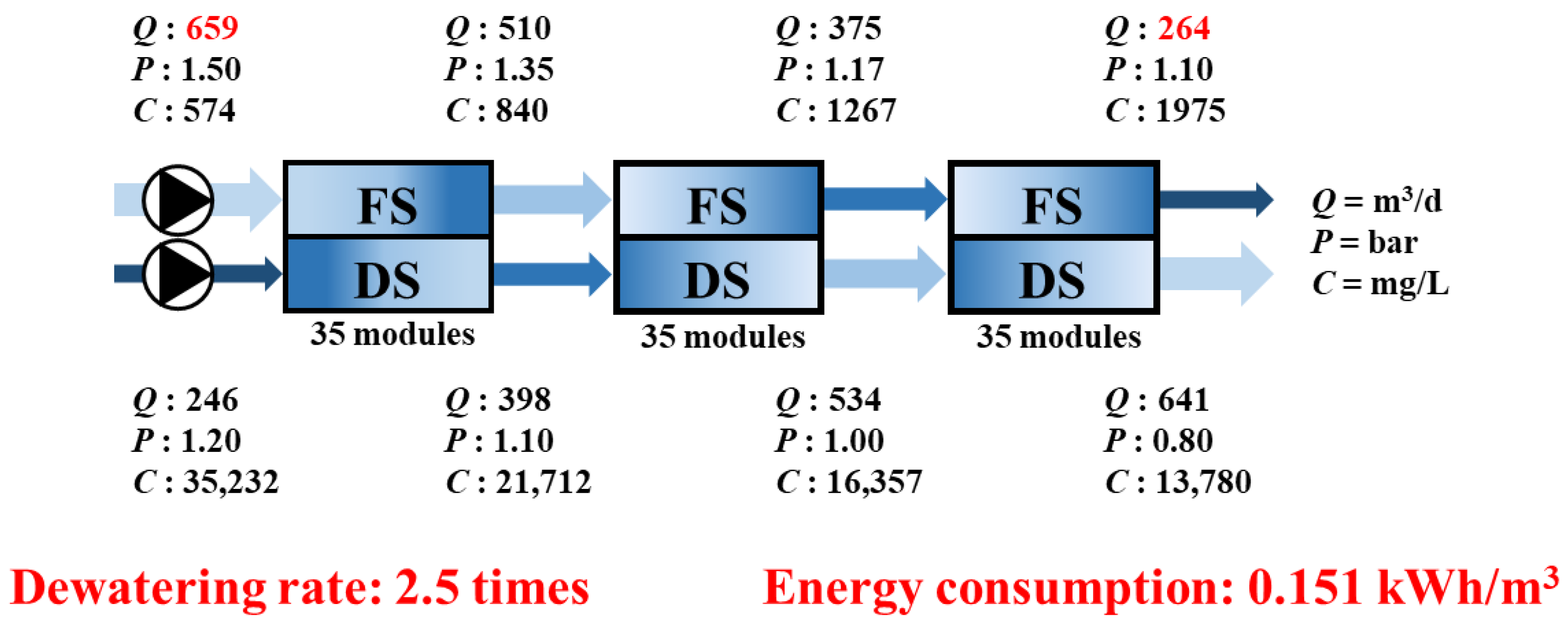

Figure 2 illustrates the concept of the proposed DSSD configuration. The DS was split at three points and fed in parallel to each FO module, with each DS stream collected separately after passing through its respective module. This design allows for the maintenance of a high osmotic driving force by minimizing the DS dilution, thereby sustaining the water flux throughout the system.

In addition, Jeon et al. [

25] reported the phenomenon of flux saturation in spiral-wound FO modules, where the water flux no longer increased beyond a certain point due to the flow complexity within the DS channel. This finding underscores the structural limitations of using a single DS configuration. The DSSD approach mitigates these flow-induced constraints by distributing the DS to each module, thereby enhancing hydrodynamic stability and maintaining a favorable concentration gradient at the membrane surface.

The conventional approach of supplying DS in a single serial flow presents structural limitations, particularly as system performance declines with an increasing number of modules. To overcome this constraint, the DSSD strategy has emerged as a promising alternative, offering both enhanced performance and improved operational flexibility. This study investigates the effectiveness of the DSSD configuration through process design and performance evaluation based on the proposed concept.

2.2. Forward Osmosis Process Design

In this study, an FO module model developed by our research team was utilized [

22]. Due to the structural complexity of spiral-wound FO modules, discrepancies often arise between theoretical predictions and experimental results. To address this issue, a simplified yet reliable performance prediction model was developed for a commercial 8-inch spiral-wound FO module (FO8040, Toray Chemical Korea Inc., Seoul, Republic of Korea).

The initial model was developed as a module-averaged system based on internal concentration polarization (ICP) and external concentration polarizations (ECP), with flow, concentration, and pressure variables simplified into a one-dimensional framework.

In this module-averaged framework, the flow, concentration, and pressure variables were treated as averaged values across the membrane leaf. The effective water flux (

Jw) and reverse salt flux (

Js) were calculated as follows:

where

A and

B are the water and salt permeability coefficients; Δ

πeff is the effective osmotic pressure difference accounting for ICP and ECP; and Δ

P is the transmembrane pressure. The structural parameter

S used in the ICP term was determined using FO coupon tests. ICP resistance was modeled using the following equation:

The mass transfer coefficient

k was estimated using the Sherwood number (

Sh) and diffusion coefficient (

D) correlations for turbulent flow:

where

Re and

Sc are the Reynolds and Schmidt numbers, and

dH is the hydraulic diameter based on the spacer-filled channel geometry.

A total of 12 module-scale experiments (116 data points) using deionized water as the FS and NaCl as the DS were used to validate the model. Initial simulations showed a normalized root mean square error (NRMSE) of ~35%, which was primarily attributed to non-ideal phenomena, such as DS channel compression under elevated Δ

P. As demonstrated by Jeon et al. [

21], increased transmembrane pressure reduces the DS channel height, thus lowering the ECP and increasing the flux. Incorporating this effect into the model via a pressure-corrected fitting term significantly improved the prediction accuracy, reducing the NRMSE to ~10%.

The final model incorporated ΔP and Cd⋅ΔP as the empirical correction terms. This model was validated to be accurate and applicable for full-scale process design with relatively low experimental data requirements (~30 points).

2.3. Forward Osmosis Module Experiment

In this study, the operational performance of a spiral-wound FO module was experimentally evaluated, and the results were compared with the predictions of a developed numerical model. To facilitate this, an experimental system capable of analyzing water flux and reverse salt flux was constructed using a full-scale FO module.

The experimental setup consisted of two circulation loops for the FS and DS, each connected to a 400 L storage tank, centrifugal pump, flowmeter, pressure gauge, and temperature control unit. The FO module (FO8040, Toray Chemical Korea Inc., Republic of Korea, 15.3 m

2 membrane area) was installed in a standard 8-inch pressure vessel. In this study,

A,

B, and

S of FO8040 were 1.59 × 10

−11 m/sPa, 3.87 × 10

−7 m/s, and 280 μm, respectively, at 18 °C [

22].

The flow rates and pressures were continuously monitored, and data were recorded at fixed intervals. The hydraulic layout is illustrated in

Figure 3a, and the physical setup is shown in

Figure 3b. The FS and DS were supplied via separate circuits, enabling individual control of the flow and operating conditions across the membrane.

The experiments were conducted using a module-scale FO test unit equipped with an 8-inch spiral-wound module.

Figure 3a illustrates the flow configuration of the system. In the diagram,

Q,

C, and

P represent the flow rate, concentration, and pressure, respectively, while the subscripts

f,

c,

d, and

dd indicate the FS, concentrated FS, DS, and diluted DS, respectively.

During the operation, the FS and DS were supplied from and recirculated to separate 400 L water tanks. As the process proceeded, the FS gradually became concentrated while the DS was progressively diluted. The flow rates (

Qf,

Qc, and

Qd), concentrations (

Cf,

Cc,

and Cd), and pressures were continuously monitored using sensors integrated into the system. In contrast, the flow rate (

Qdd) and concentration (

Cdd) of the diluted draw solution were not measured directly but calculated using material balance equations (Equations (6) and (7)) based on the internal module flow dynamics.

The feed water used in the experiments was produced by treating tap water with a 4-inch RO membrane (RE4040-SHN, Toray Chemical Korea Inc., Seoul, Republic of Korea). To remove residual chlorine from the tap water, sodium bisulfite (NaHSO4) was added as a pretreatment step. For DS preparation, industrial-grade purified sodium chloride (NaCl) supplied by OCI Co., Ltd. (Shanghai, China) was used to adjust the concentration. All experiments were conducted at a controlled temperature of 18 °C. To prevent cross-contamination between tests and maintain membrane performance, each experimental set was followed by a cleaning procedure using purified water prior to the next run.

To evaluate the hydraulic head loss associated with the flow characteristics of the FS and DS within the membrane module, the pressures at the inlets and outlets of both streams,

Pf,

Pc,

Pd, and

Pdd, were measured using pressure sensors. The water flux (

Jw) and reverse salt flux (

Js) were calculated using Equations (8) and (9). To investigate the module performance under various operating conditions, flow rates and pressures were adjusted by adjusting the valves installed at the module inlet and outlet.

Among them, Qf and Cf represent flow rate and salt concentration of the FS, respectively, while Qc and Cc correspond to those of the concentrated feed stream. Am refers to the active membrane area used in the experiments.

2.4. Calculation Method for Energy Consumption

In this study, the energy consumption of both FO and RO processes was quantitatively evaluated by applying energy calculation equations that incorporate flow rate, pressure, and pump efficiency for each process. The energy consumption was determined using Equation (5), where all variables were evaluated using a combination of simulation data from the design program and experimentally measured values.

A schematic diagram of the RO process is shown in

Figure 4, and the specific energy consumption per cubic meter of treated water was calculated using Equation (10) [

26].

In Equation (5),

E represents the specific energy consumption (kWh/m

3),

Q is the flow rate (m

3/d),

P indicates the pressure (bar), and η refers to the efficiency (%) of the pumps and energy recovery devices.

HP,

LP, and

BP indicate the high-pressure, low-pressure, and booster pumps, respectively. The LP is responsible for delivering water to the energy recovery device (ERD), while the BP increases the pressure of the stream pressurized by the ERD to match that of the HP. The efficiency of the ERD was assumed to be 90%, and the efficiencies of the pumps and motors were obtained using the Power Model Pro software developed by Energy Recovery, Inc., San Leandro, CA, USA. [

27]. The flow rate, pressure, and other parameters required for calculating the energy consumption of the RO process were obtained from the simulation results using the WAVE software developed by DuPont (Wilmington, DE, USA). Similar to the RO process, the energy consumption of the FO process was calculated based on the product of the flow rate and pressure across the feed solution pump and draw solution pump, taking into account the respective efficiencies of each pump. In this study, Equation (10) was adopted to calculate the specific energy consumption based on a simplified system-level approach and validated through DuPont WAVE simulations and experimental measurements. Although this formulation is widely used for comparative system analysis, it inherently assumes simplified hydrodynamics.

4. Discussion

In this study, a DSSD was proposed and validated through experiments and simulations to overcome the inherent limitations of the conventional FO process. These limitations include the reduction in the osmotic driving force caused by DS dilution and FS concentration. The DSSD achieved a concentration factor of 12.5, which was more than 2.5 times higher than that of the conventional serial configuration under identical membrane area and operating conditions. Furthermore, the specific energy consumption was as low as 0.137 kWh/m3, demonstrating superior energy efficiency compared to conventional membrane separation processes.

Additionally, a simulation of the RO process under the same feed conditions showed an energy consumption of 0.58 kWh/m3, which was approximately 76.4% higher than that of the FO process. This highlights the superior energy efficiency of the FO process, particularly in concentration-focused applications.

In particular, FO processes can operate under low-pressure conditions and are less susceptible to membrane fouling. However, one of the main challenges that remain is the regeneration or post-treatment of the DS. Therefore, future studies should address the treatment strategies and economic feasibility of DS treatment. For example, if seawater is used as the DS, the diluted DS can be treated using a subsequent RO process, enabling low-energy seawater desalination. Nevertheless, this approach requires the FO facility to be located near coastal areas, which may pose geographical constraints for widespread implementation.

To achieve sustainable desalination, it is important to establish target values for specific energy consumption that reflect both technical feasibility and long-term environmental sustainability. Conventional seawater reverse osmosis processes typically consume between 3 and 4 kWh/m

3, with advanced configurations incorporating energy recovery devices that reduce this value to approximately 2.9 kWh/m

3 [

29]. In contrast, solar-powered FO systems, particularly when integrated with hybrid technologies such as FO–MD (membrane distillation) or FO–MED (multi-effect distillation), have demonstrated significantly lower specific energy consumption values, ranging from 1.1 to 3.57 kWh/m

3 depending on the configuration and draw solute regeneration methods applied [

30]. However, certain approaches, such as thermal regeneration using solar ponds, still require a much higher energy input (e.g., up to 107 kWh/m

3), underscoring the importance of careful selection of draw solutes and optimization of thermal energy storage systems [

30]. Similarly, multistage solar–thermal desalination processes benefit from latent heat recovery and achieve enhanced thermal efficiency but require optimization of capital cost and heat recovery strategies to ensure scalability [

31]. Based on current evidence, an attainable specific energy consumption target of below 2 kWh/m

3 appears to be a realistic benchmark for small-to medium-scale sustainable desalination systems that leverage solar integration and hybrid processing [

30,

31].

In summary, this study demonstrated the effectiveness of the DSSD as a novel design strategy for simultaneously enhancing the concentration performance and energy efficiency of the FO process. The results also highlight the potential applicability of this high-efficiency dewatering and resource recovery approach in a wide range of industrial sectors.