Electro-Conductive Modification of Polyvinylidene Fluoride Membrane for Electrified Wastewater Treatment: Optimization and Antifouling Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

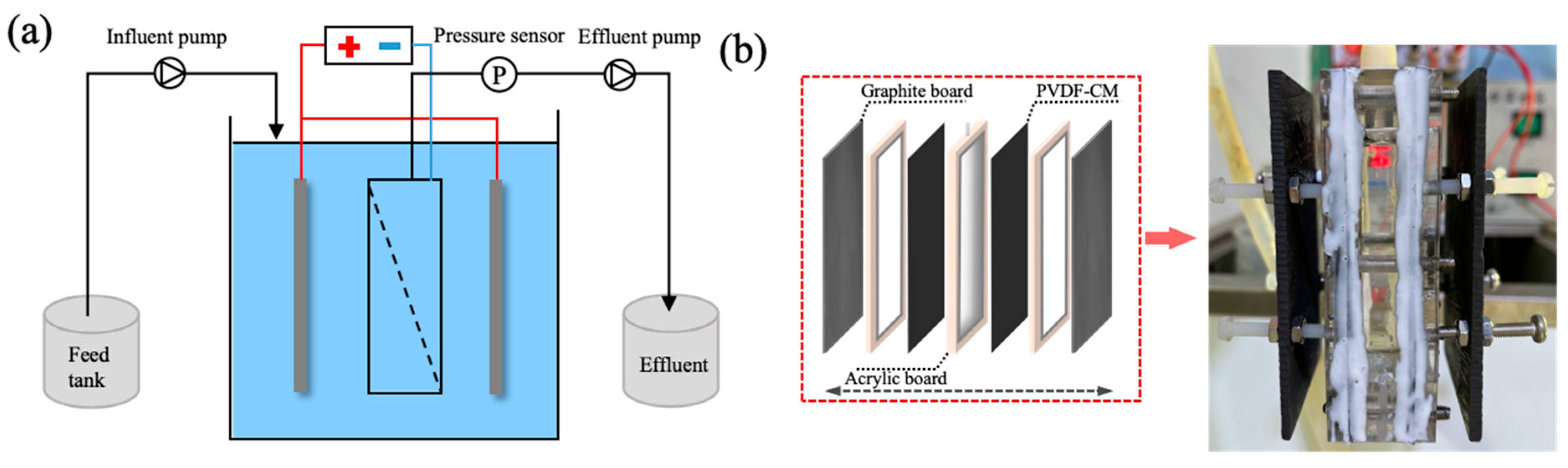

2.2. Preparation and Characterization of Conductive Membrane

2.2.1. Modification of the Conductive Membrane

2.2.2. Characterization of the Conductive Membrane

2.3. Anti-Fouling Performance of Conductive Membranes

3. Results and Discussion

3.1. Optimization of Conductive Membrane Preparation Methods

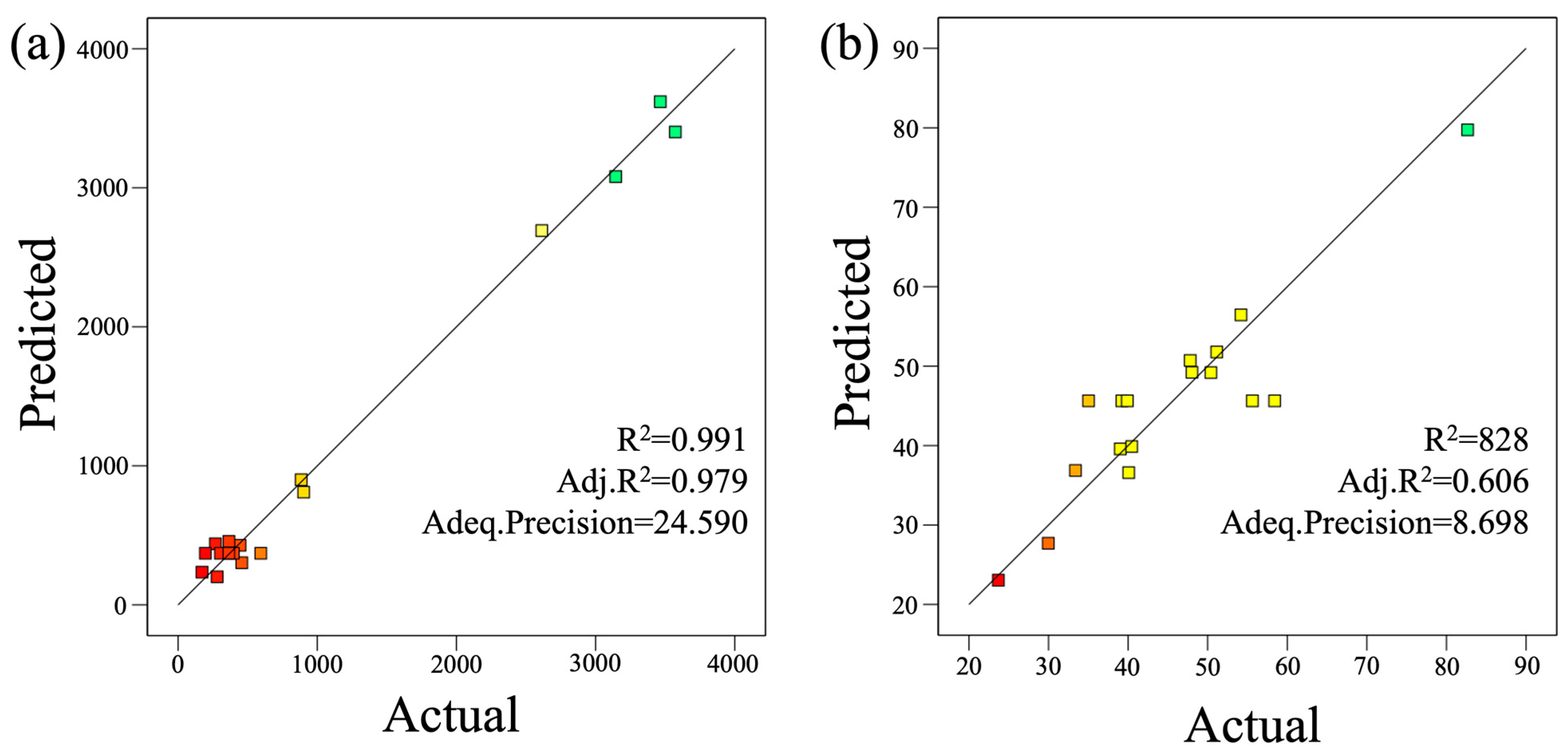

3.1.1. Regression Model and Variance Analysis

+ 263.56B − 1517.53C − 19.19AB + 257.07AC − 163.88BC + 96.40A2 + 283.71B2 + 1236.42C2

(R12 = 0.9907)

(R22 = 0.8276)

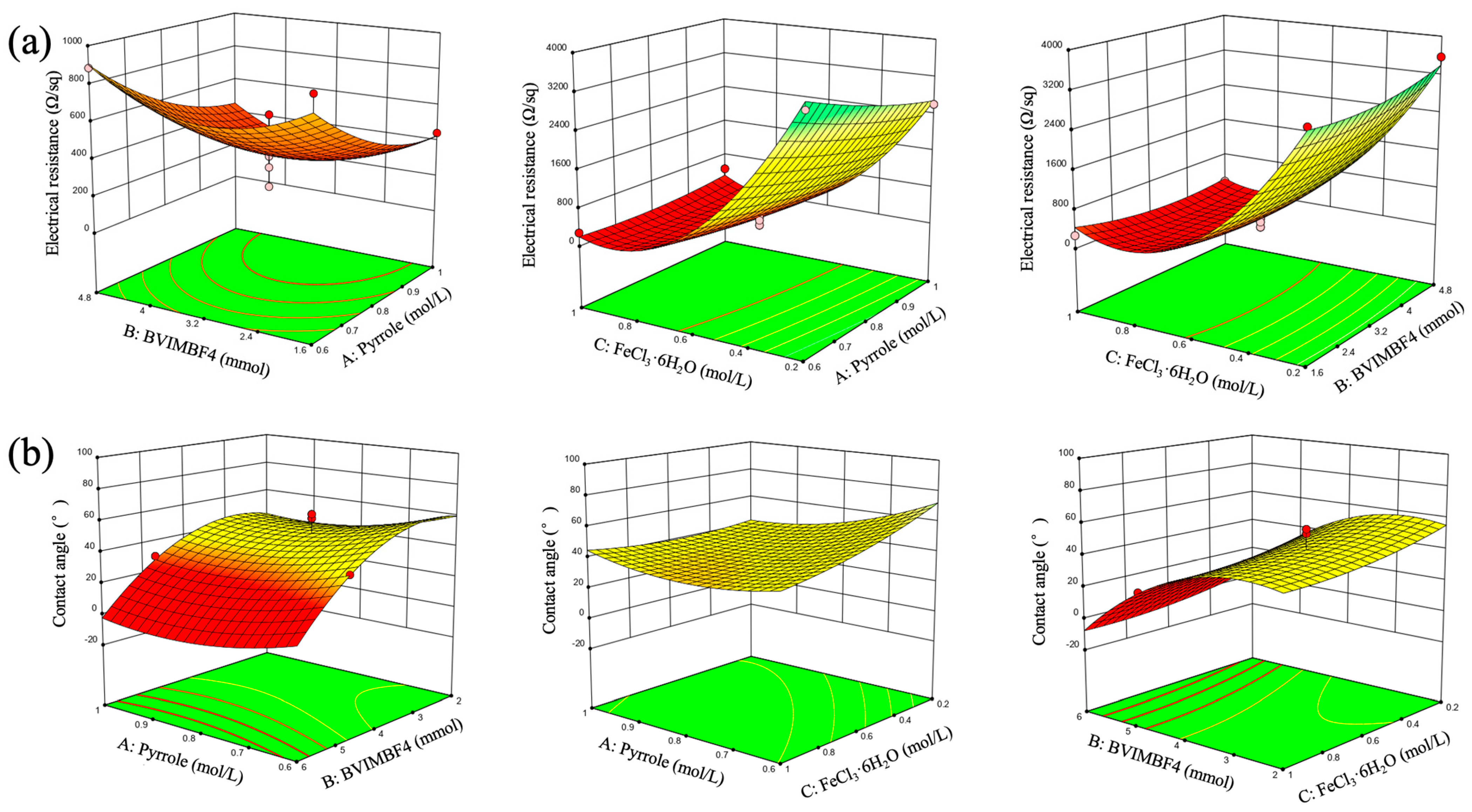

3.1.2. Data Analysis and Optimization

3.2. Performance of the Conductive Membranes

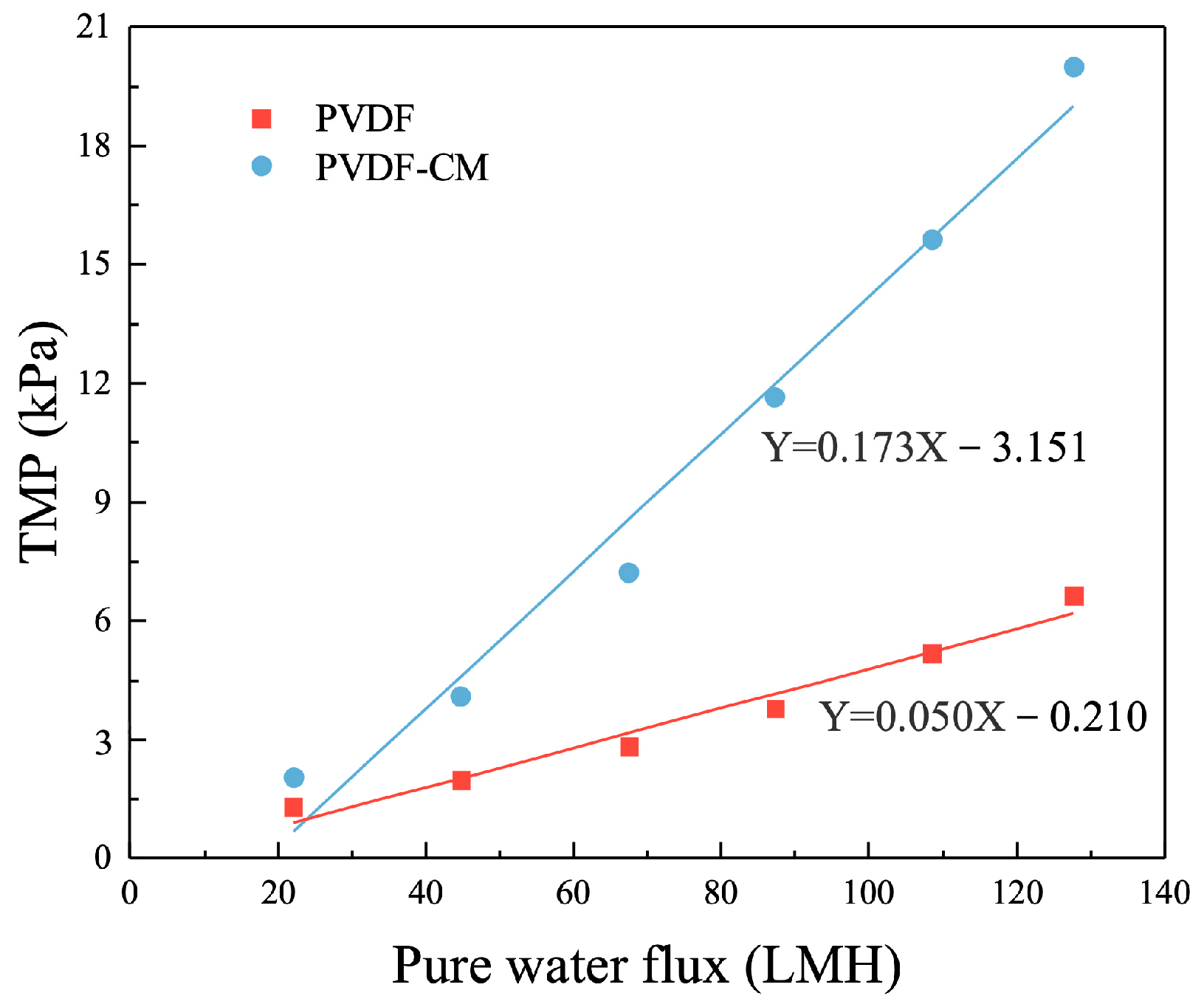

3.2.1. Permeability and Physicochemical Properties

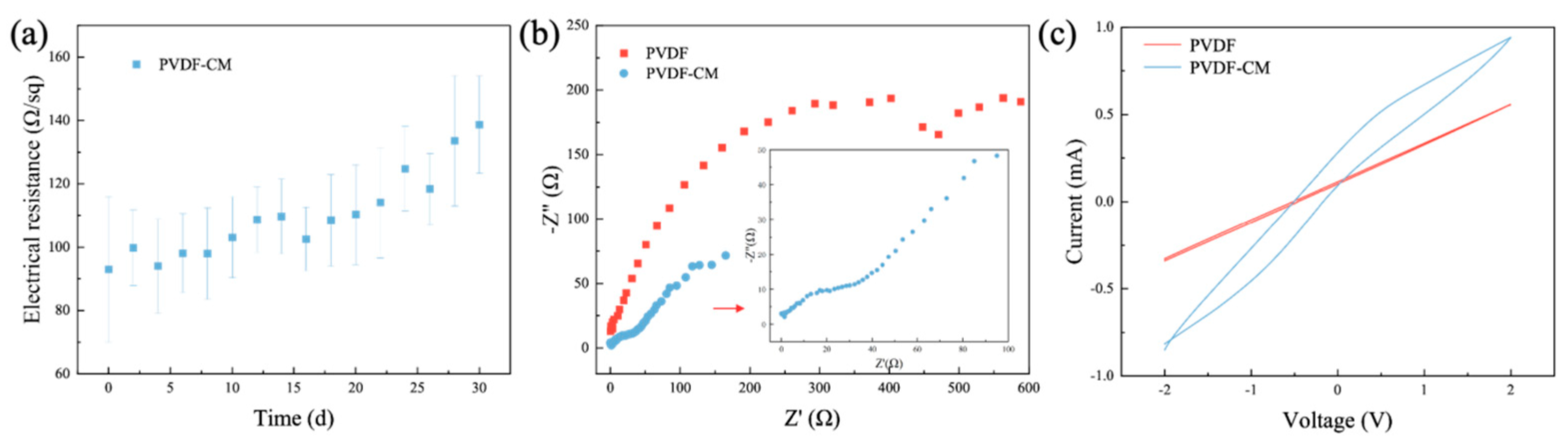

3.2.2. Electrochemical Performance of Conductive Membranes

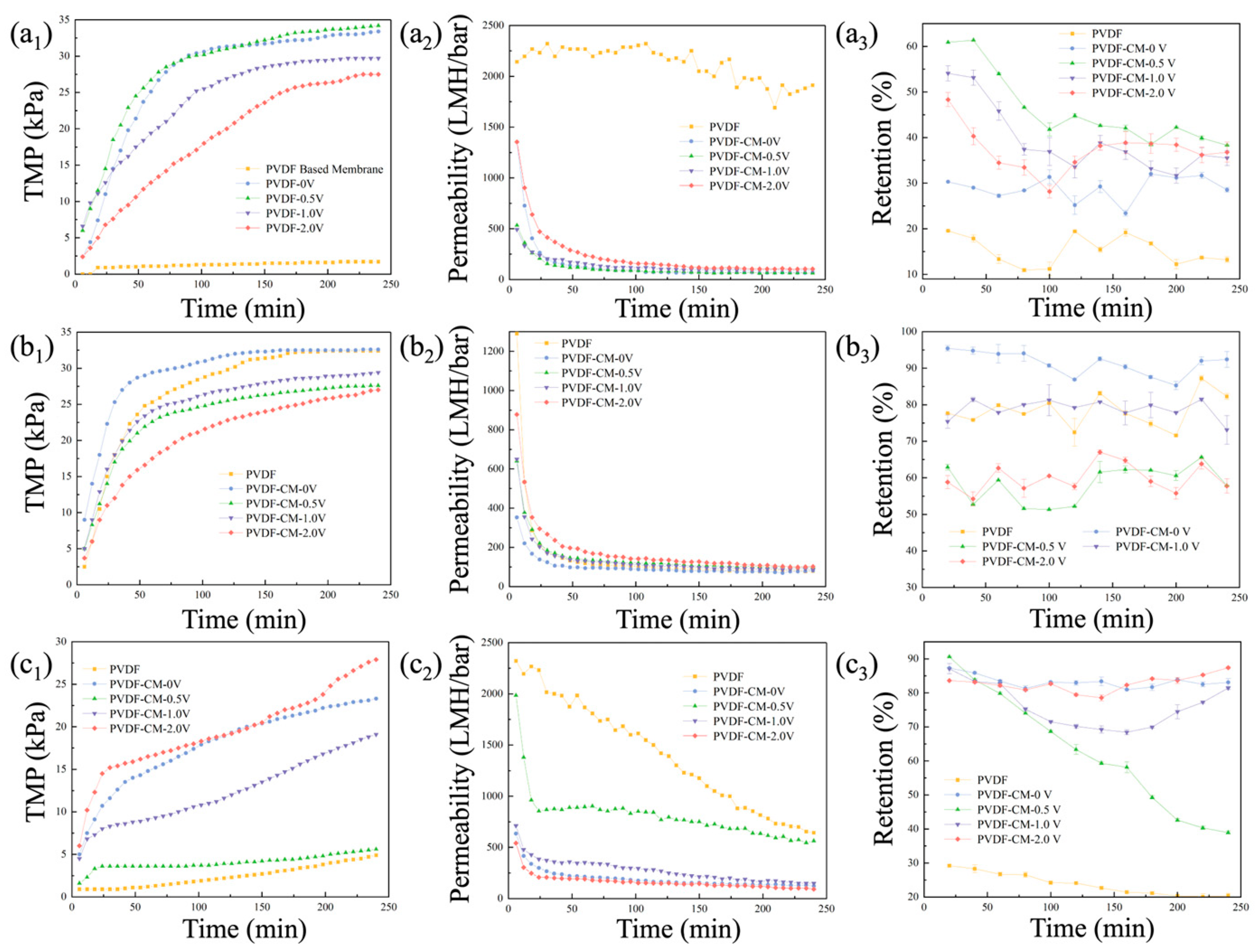

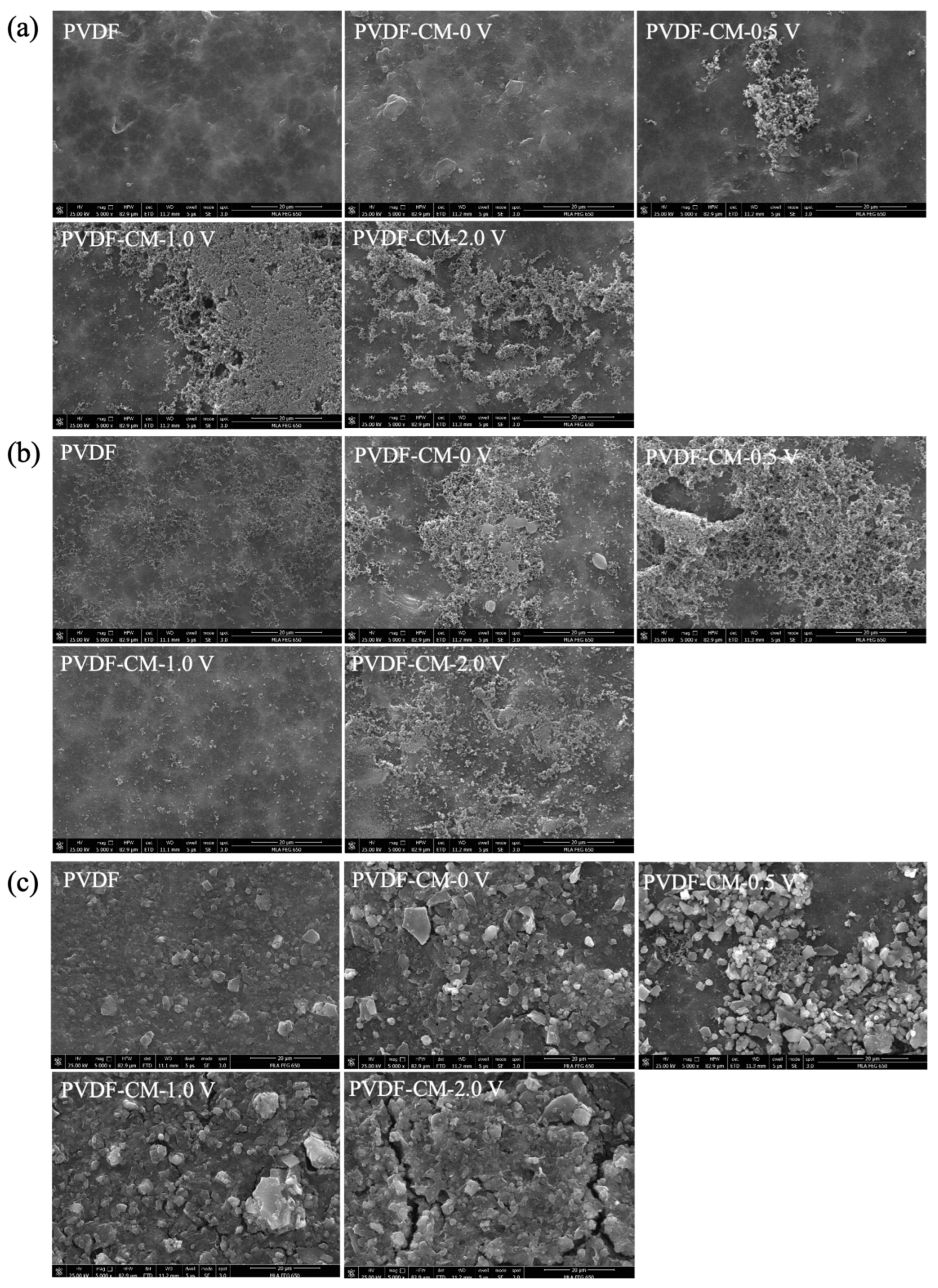

3.3. Anti-Fouling Performance of Conductive Membranes

3.4. Implication of This Study

4. Conclusions

- (1)

- After optimization, the best conditions for preparing PVDF-CM were pyrrole concentration of 0.9 mol/L, BVIMBF4 concentration of 4.80 mmol, and FeCl3·6H2O concentration of 0.80 mol/L. The optimized PVDF-CM exhibited an electrical resistance of 93 Ω/sq and a water contact angle of 31°.

- (2)

- The permeability of the control PVDF membrane was 2118.13 LMH/bar, while the permeability of PVDF-CM decreased to 832.29 LMH/bar, indicating a substantial reduction in permeability after modification.

- (3)

- During batch filtration experiments, the application of an electric field at 2 V significantly reduced membrane fouling rates for BSA and SA, with a reduction of 17.72% and 17.18%, respectively. For HA, the membrane fouling rate decreased by 72.6% at 0.5 V.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bai, L.M.; Wu, H.Y.; Ding, J.W.; Ding, A.; Zhang, X.Y.; Ren, N.Q.; Li, G.B.; Liang, H. Cellulose nanocrystal-blended polyethersulfone membranes for enhanced removal of natural organic matter and alleviation of membrane fouling. Chem. Eng. J. 2020, 382, 11. [Google Scholar] [CrossRef]

- Pan, Z.L.; Song, C.W.; Li, L.; Wang, H.; Pan, Y.Q.; Wan, C.L.; Li, J.X.; Wang, T.H.; Feng, X.S. Membrane technology coupled with electrochemical advanced oxidation processes for organic wastewater treatment: Recent advances and future prospects. Chem. Eng. J. 2019, 376, 19. [Google Scholar] [CrossRef]

- Efligenir, A.; Déon, S.; Fievet, P.; Druart, C.; Morin-Crini, N.; Crini, G. Decontamination of polluted discharge waters from surface treatment industries by pressure-driven membranes: Removal performances and environmental impact. Chem. Eng. J. 2014, 258, 309–319. [Google Scholar] [CrossRef]

- Xu, R.; Qin, W.; Zhang, B.; Wang, X.M.; Li, T.Y.; Zhang, Y.; Wen, X.H. Nanofiltration in pilot scale for wastewater reclamation: Long-term performance and membrane biofouling characteristics. Chem. Eng. J. 2020, 395, 9. [Google Scholar] [CrossRef]

- Shahid, M.K.; Kashif, A.; Rout, P.R.; Aslam, M.; Fuwad, A.; Choi, Y.; Banu, R.; Park, J.H.; Kumar, G. A brief review of anaerobic membrane bioreactors emphasizing recent advancements, fouling issues and future perspectives. J. Environ. Manag. 2020, 270, 12. [Google Scholar] [CrossRef]

- Krzeminski, P.; Leverette, L.; Malamis, S.; Katsou, E. Membrane bioreactors—A review on recent developments in energy reduction, fouling control, novel configurations, LCA and market prospects. J. Membr. Sci. 2016, 527, 207–227. [Google Scholar] [CrossRef]

- Arvind, K.C.A.; Barbara, B.; Schneider, E.S.; Tomi, M.; Mathias, E.; Volkan, F.; Sarah, G. Modification of Polyacrylonitrile Ultrafiltration Membranes to Enhance the Adsorption of Cations and Anions. Membranes 2022, 12, 580. [Google Scholar] [CrossRef] [PubMed]

- Liao, X.J.; Lim, Y.J.; Khayet, M.; Liao, Y.; Yao, L.; Zhao, Y.L.; Razaqpur, A.G. Applications of electrically conductive membranes in water treatment via membrane distillation: Joule heating, membrane fouling/scaling/wetting mitigation and monitoring. Water Res. 2023, 244, 22. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.X.; Huang, G.H.; Li, Y.P.; Chen, X.J.; Yao, Y.; Ren, S.J.; Li, M.N.; Wu, Y.W.; An, C.J. Electrically conductive inorganic membranes: A review on principles, characteristics and applications. Chem. Eng. J. 2022, 427, 19. [Google Scholar] [CrossRef]

- Ying, X.B.; Huang, J.J.; Shen, D.S.; Feng, H.J.; Jia, Y.F.; Guo, Q.Q. Fouling behaviors are different at various negative potentials in electrochemical anaerobic membrane bioreactors with conductive ceramic membranes. Sci. Total Environ. 2021, 761, 10. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.F.; Zhao, F.; Liu, J.D.; Yang, F.L. Preparation of highly conductive cathodic membrane with graphene (oxide)/PPy and the membrane antifouling property in filtrating yeast suspensions in EMBR. J. Membr. Sci. 2013, 437, 99–107. [Google Scholar] [CrossRef]

- Fan, X.F.; Zhao, H.M.; Quan, X.; Liu, Y.M.; Chen, S. Nanocarbon-based membrane filtration integrated with electric field driving for effective membrane fouling mitigation. Water Res. 2016, 88, 285–292. [Google Scholar] [CrossRef] [PubMed]

- Yu, Q.L.; Zhang, Y.B. Fouling-resistant biofilter of an anaerobic electrochemical membrane reactor. Nat. Commun. 2019, 10, 10. [Google Scholar] [CrossRef]

- Hu, Y.S.; Wang, J.S.; Shi, J.Z.; Yang, Y.; Ji, J.Y.; Chen, R. A review of electro-conductive membrane enabled electrochemical anaerobic membrane bioreactor process for low-carbon wastewater treatment. J. Environ. Chem. Eng. 2024, 12, 14. [Google Scholar] [CrossRef]

- Roy, D.; Drogui, P.; Rahni, M.; Lemay, J.F.; Tyagi, R.D. Effect of cathode material and charge loading on the nitrification performance and bacterial community in leachate treating Electro-MBRs. Water Res. 2020, 182, 115990. [Google Scholar] [CrossRef] [PubMed]

- Shakeri, A.; Salehi, H.; Rastgar, M. Antifouling electrically conductive membrane for forward osmosis prepared by polyaniline/graphene nanocomposite. J. Water Process Eng. 2019, 32, 100932. [Google Scholar] [CrossRef]

- Xing, C.Y.; Zhao, M.M.; Zhao, L.P.; You, J.C.; Cao, X.J.; Li, Y.J. Ionic liquid modified poly(vinylidene fluoride): Crystalline structures, miscibility, and physical properties. Polym. Chem. 2013, 4, 5726–5734. [Google Scholar] [CrossRef]

- Song, H.C.; Shao, J.H.; He, Y.L.; Liu, B.; Zhong, X.Q. Natural organic matter removal and flux decline with PEG-TiO2-doped PVDF membranes by integration of ultrafiltration with photocatalysis. J. Membr. Sci. 2012, 405, 48–56. [Google Scholar] [CrossRef]

- Radjenovic, J.; Sedlak, D.L. Challenges and Opportunities for Electrochemical Processes as Next-Generation Technologies for the Treatment of Contaminated Water. Environ. Sci. Technol. 2015, 49, 11292–11302. [Google Scholar] [CrossRef]

- Zhao, K.; Su, F.; Gu, K.H.; Qi, J.; Liu, R.P.; Hu, C.Z. Antifouling potential and microbial characterization of an electrochemical anaerobic membrane bioreactor utilizing membrane cathode and iron anode. Bioresour. Technol. 2021, 334, 8. [Google Scholar] [CrossRef]

- Jia, T.Z.; Feng, R.; Cui, C.; Chen, Q.; Cseri, L.; Zhou, R.F.; Szekely, G.; Cao, X.L.; Sun, S.P. Conductive nanofiltration membranes via in situ PEDOT-polymerization for electro-assisted membrane fouling mitigation. Water Res. 2024, 252, 10. [Google Scholar] [CrossRef]

- Sui, J.; Travas-Sejdic, J.; Chu, S.Y.; Li, K.C.; Kilmartin, P.A. The actuation behavior and stability of p-toluene sulfonate doped polypyrrole films formed at different deposition current densities. J. Appli. Polym. Sci. 2009, 111, 876–882. [Google Scholar] [CrossRef]

- Arroyo, J.; Akieh-Pirkanniemi, M.; Lisak, G.; Latonen, R.M.; Bobacka, J. Electrochemically controlled transport of anions across polypyrrole-based membranes. J. Membr. Sci. 2019, 581, 50–57. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, Y.W.; Li, Y.Y.; Liu, J.P. Construction of High-Capacitance 3D CoO@Polypyrrole Nanowire Array Electrode for Aqueous Asymmetric Supercapacitor. Nano Lett. 2013, 13, 2078–2085. [Google Scholar] [CrossRef]

- Chen, J.S.; Liu, J.F.; Thundat, T.; Zeng, H.B. Polypyrrole-Doped Conductive Supramolecular Elastomer with Stretchability, Rapid Self-Healing, and Adhesive Property for Flexible Electronic Sensors. ACS Appl. Mater. Interfaces 2019, 11, 18720–18729. [Google Scholar] [CrossRef] [PubMed]

- Park, S.J.; Cho, M.S.; Nam, J.D.; Kim, I.H.; Choi, H.R.; Koo, J.C.; Lee, Y. The linear stretching actuation behavior of polypyrrole nanorod in AAO template. Sens. Actuat. B-Chem. 2009, 135, 592–596. [Google Scholar] [CrossRef]

- Long, Y.Z.; Li, M.M.; Gu, C.Z.; Wan, M.X.; Duvail, J.L.; Liu, Z.W.; Fan, Z.Y. Recent advances in synthesis, physical properties and applications of conducting polymer nanotubes and nanofibers. Prog. Polym. Sci. 2011, 36, 1415–1442. [Google Scholar] [CrossRef]

- Wang, L.X.; Li, X.G.; Yang, Y.L. Preparation, properties and applications of polypyrroles. React. Funct. Poly. 2001, 47, 125–139. [Google Scholar] [CrossRef]

- Benson, J.; Kovalenko, I.; Boukhalfa, S.; Lashmore, D.; Sanghadasa, M.; Yushin, G. Multifunctional CNT-Polymer Composites for Ultra-Tough Structural Supercapacitors and Desalination Devices. Adv. Mater. 2013, 25, 6625–6632. [Google Scholar] [CrossRef] [PubMed]

- Dudchenko, A.V.; Rolf, J.; Russell, K.; Duan, W.Y.; Jassby, D. Organic fouling inhibition on electrically conducting carbon nanotube-polyvinyl alcohol composite ultrafiltration membranes. J. Membr. Sci. 2014, 468, 1–10. [Google Scholar] [CrossRef]

- Ahmed, F.; Lalia, B.S.; Kochkodan, V.; Hilal, N.; Hashaikeh, R. Electrically conductive polymeric membranes for fouling prevention and detection: A review. Desalination 2016, 391, 1–15. [Google Scholar] [CrossRef]

- Shen, Q.; Xing, D.Y.; Sun, F.Y.; Dong, W.Y.; Shang, W.T.; Zhao, L.Y.; Dong, Z.J. Facile pyrrole oxidative polymerization with ionic liquid to modify ceramic membrane for sustainable fouling control. J. Environ. Chem. Eng. 2021, 9, 9. [Google Scholar] [CrossRef]

- Choi, J.; Cho, H.; Choi, Y.; Lee, S. Combination of computational fluid dynamics and design of experiments to optimize modules for direct contact membrane distillation. Desalination 2022, 524, 15. [Google Scholar] [CrossRef]

- Liu HLChiou, Y.R. Optimal decolorization efficiency of Reactive Red 239 by UV/ZnO photocatalytic process. J. Chin. Inst. Chem. Eng. 2006, 37, 289–298. [Google Scholar] [CrossRef]

- Gaudy, A.F. Colorimetric Determination of Protein and Carbohydrate. Ind. Water Wastes 1962, 7, 17–22. [Google Scholar]

- The State Environmental Protection Administration the Water and Wastewater Monitoring Analysis Method Editorial Board. Water and Wastewater Monitoring Analysis Method, 4th ed.; China Environmental Science Press: Beijing, China, 2002. [Google Scholar]

- Jankovic, A.; Chaudhary, G.; Goia, F. Designing the design of experiments (DOE)-An investigation on the influence of different factorial designs on the characterization of complex systems. Energy Build. 2021, 250, 17. [Google Scholar] [CrossRef]

- Jang, H.; Park, S.J.; Kim, J. Response surface methodology to investigate the effects of operational parameters on membrane fouling and organic matter rejection in hard-shell encased hollow-fiber membrane. Chemosphere 2022, 287, 9. [Google Scholar] [CrossRef]

- Tibi, F.; Park, S.J.; Kim, J. Improvement of Membrane Distillation Using PVDF Membrane Incorporated with TiO2 Modified by Silane and Optimization of Fabricating Conditions. Membranes 2021, 11, 18. [Google Scholar] [CrossRef]

- Milano, J.; Ong, H.C.; Masjuki, H.H.; Silitonga, A.S.; Chen, W.H.; Kusumo, F.; Dharma, S.; Sebayang, A.H. Optimization of biodiesel production by microwave irradiation-assisted transesterification for waste cooking oil-Calophyllum inophyllum oil via response surface methodology. Energy Conv. Manag. 2018, 158, 400–415. [Google Scholar] [CrossRef]

- Noshadi, I.; Amin, N.A.S.; Parnas, R.S. Continuous production of biodiesel from waste cooking oil in a reactive distillation column catalyzed by solid heteropolyacid: Optimization using response surface methodology (RSM). Fuel 2012, 94, 156–164. [Google Scholar] [CrossRef]

- Ni, C.J.; Zheng, X.; Zhang, Y.; Zhang, X.W.; Li, Y.J. Multifunctional porous materials with simultaneous high water flux, antifouling and antibacterial performances from ionic liquid grafted polyethersulfone. Polymer 2021, 212, 10. [Google Scholar] [CrossRef]

- Meng, F.; Chae, S.-R.; Drews, A.; Kraume, M.; Shin, H.-S.; Yang, F. Recent advances in membrane bioreactors (MBRs): Membrane fouling and membrane material. Water Res. 2009, 43, 1489–1512. [Google Scholar] [CrossRef]

- Salehi, E.; Madaeni, S. Influence of conductive surface on adsorption behavior of ultrafiltration membrane. Appl. Surf. Sci. 2010, 256, 3010–3017. [Google Scholar] [CrossRef]

- Sun, J.Q.; Wang, G.G.; Zhang, H.; Zhang, B.; Hu, C.Z. Facile fabrication of a conductive polypyrrole membrane for anti-fouling enhancement by electrical repulsion and in situ oxidation. Chemosphere 2021, 270, 9. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Huang, Q.L.; Wang, Y.F.; Xiao, C.F. PTFE conductive membrane for EVMD process and the application of electro-catalysis. Sep. Purif. Technol. 2017, 187, 327–333. [Google Scholar] [CrossRef]

- Huang, J.; He, Y.R.; Shen, Z.H. Joule heating membrane distillation enhancement with multi-level thermal concentration and heat recovery. Energy Conv. Manag. 2021, 238, 11. [Google Scholar] [CrossRef]

- Meng, Y.T.; Zhang, L.X.; Xing, R.R.; Huang, H.; Qu, Y.; Jiao, T.F.; Zhou, J.X.; Peng, Q.M. Facile preparation and electrochemical characterization of self-assembled core-shell diamond-polypyrrole nanocomposites. Colloid Surf. A-Physicochem. Eng. Asp. 2018, 555, 787–794. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Wang, T.; Meng, J.J.; Lei, J.; Zheng, X.; Wang, Y.F.; Zhang, J.; Cao, X.; Li, X.L.; Qiu, X.P.; et al. A novel conductive composite membrane with polypyrrole (PPy) and stainless-steel mesh: Fabrication, performance, and anti-fouling mechanism. J. Membr. Sci. 2021, 621, 10. [Google Scholar] [CrossRef]

- Akamatsu, K.; Yoshida, Y.; Suzaki, T.; Sakai, Y.; Nagamoto, H.; Nakao, S. Development of a membrane-carbon cloth assembly for submerged membrane bioreactors to apply an intermittent electric field for fouling suppression. Sep. Purif. Technol. 2012, 88, 202–207. [Google Scholar] [CrossRef]

- Liu, J.D.; Liu, L.F.; Gao, B.; Yang, F.L. Integration of bio-electrochemical cell in membrane bioreactor for membrane cathode fouling reduction through electricity generation. J. Membr. Sci. 2013, 430, 196–202. [Google Scholar] [CrossRef]

- Yang, Y.; Qiao, S.; Jin, R.F.; Zhou, J.T.; Quan, X. Novel Anaerobic Electrochemical Membrane Bioreactor with a CNTs Hollow Fiber Membrane Cathode to Mitigate Membrane Fouling and Enhance Energy Recovery. Environ. Sci. Technol. 2019, 53, 1014–1021. [Google Scholar] [CrossRef] [PubMed]

- Salvestrini, S.; Fenti, A.; Chianese, S.; Iovino, P.; Musmarra, D. Electro-Oxidation of Humic Acids Using Platinum Electrodes: An Experimental Approach and Kinetic Modelling. Water 2020, 12, 2250. [Google Scholar] [CrossRef]

- Hu, C.; Li, M.; Sun, J.; Liu, R.; Liu, H.; Qu, J. NOM fouling resistance in response to electric field during electro-ultrafiltration: Significance of molecular polarity and weight. J. Colloid Interf. Sci. 2019, 539, 11–18. [Google Scholar] [CrossRef] [PubMed]

- Aryanti, N.; Nafiunisa, A.; Adina, A.R.; Kusworo, T.D. Synthesis, characterization and anti-fouling properties of poly[vinylidene fluoride]-incorporated SiO2, TiO2, ZrO2 nanoparticle-LiCl pore former ultrafiltration membranes. Case Stud. Chem. Environ. Eng. 2024, 9, 100664. [Google Scholar] [CrossRef]

- Ho, C.-C.; Su, J.F. Boosting permeation and separation characteristics of polyethersulfone ultrafiltration membranes by structure modification via dual-PVP pore formers. Polymer 2022, 241, 124560. [Google Scholar] [CrossRef]

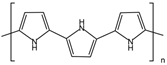

| Name | Molecular Formula | Structural Formula |

|---|---|---|

| Pyrrole | C4H5N |  |

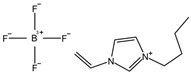

| 1-vinyl-3-butylimidazolium tetrafluoroborate | C9H5BF4N2 |  |

| Polypyrrole | (C4H5N)n |  |

| Factors | Parameters | Units | Code | ||

|---|---|---|---|---|---|

| −1 | 0 | 1 | |||

| A | Pyrrole | mol/L | 0.6 | 0.8 | 1.0 |

| B | BVIMBF4 | mmol | 1.6 | 3.2 | 4.8 |

| C | FeCl3·6H2O | mol/L | 0.2 | 0.6 | 1.0 |

| Operating Factors | Results | ||||

|---|---|---|---|---|---|

| Run | A: Pyrrole (mol/L) | B: BVIMBF4 (mmol/L) | C: FeCl3·6H2O (mol/L) | Electrical Resistance (Ω/sq) | Water Contact Angle (°) |

| 1 | 0.8 | 3.2 | 0.6 | 594.07 | 55.61 |

| 2 | 0.8 | 3.2 | 0.6 | 397.60 | 58.42 |

| 3 | 0.6 | 3.2 | 0.2 | 3464.67 | 82.66 |

| 4 | 1 | 4.8 | 0.6 | 365.40 | 29.97 |

| 5 | 0.8 | 3.2 | 0.6 | 304.00 | 35.03 |

| 6 | 1 | 3.2 | 1 | 458.00 | 47.80 |

| 7 | 0.6 | 4.8 | 0.6 | 884.73 | 40.45 |

| 8 | 0.8 | 3.2 | 0.6 | 196.40 | 39.22 |

| 9 | 0.6 | 3.2 | 1 | 281.07 | 48.00 |

| 10 | 1 | 3.2 | 0.2 | 2613.33 | 50.40 |

| 11 | 0.6 | 1.6 | 0.6 | 902.73 | 54.18 |

| 12 | 1 | 1.6 | 0.6 | 444.80 | 39.02 |

| 13 | 0.8 | 3.2 | 0.6 | 365.13 | 39.90 |

| 14 | 0.8 | 4.8 | 1 | 172.00 | 23.70 |

| 15 | 0.8 | 1.6 | 0.2 | 3144.67 | 51.14 |

| 16 | 0.8 | 4.8 | 0.2 | 3572.67 | 33.39 |

| 17 | 0.8 | 1.6 | 1 | 268.40 | 40.48 |

| Parameter | Predicted Optimum Value | Experimental Optimum Value |

|---|---|---|

| Electrical resistance (Ω/sq) | 73.17 | 93 |

| Water contact angle (°) | 23.08 | 31 |

| Pyrrole (mol/L) | 0.87 | 0.9 |

| BVIMBF4 (mmol) | 4.84 | 4.8 |

| FeCl3·6H2O (mol/L) | 0.84 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Hu, Y.; Li, S.; Xiao, W.; Yang, Y.; Ji, J. Electro-Conductive Modification of Polyvinylidene Fluoride Membrane for Electrified Wastewater Treatment: Optimization and Antifouling Performance. Membranes 2025, 15, 1. https://doi.org/10.3390/membranes15010001

Shi J, Hu Y, Li S, Xiao W, Yang Y, Ji J. Electro-Conductive Modification of Polyvinylidene Fluoride Membrane for Electrified Wastewater Treatment: Optimization and Antifouling Performance. Membranes. 2025; 15(1):1. https://doi.org/10.3390/membranes15010001

Chicago/Turabian StyleShi, Jinzhuo, Yisong Hu, Songhua Li, Wenqian Xiao, Yuan Yang, and Jiayuan Ji. 2025. "Electro-Conductive Modification of Polyvinylidene Fluoride Membrane for Electrified Wastewater Treatment: Optimization and Antifouling Performance" Membranes 15, no. 1: 1. https://doi.org/10.3390/membranes15010001

APA StyleShi, J., Hu, Y., Li, S., Xiao, W., Yang, Y., & Ji, J. (2025). Electro-Conductive Modification of Polyvinylidene Fluoride Membrane for Electrified Wastewater Treatment: Optimization and Antifouling Performance. Membranes, 15(1), 1. https://doi.org/10.3390/membranes15010001