A Novel Modeling Optimization Approach for a Seven-Channel Titania Ceramic Membrane in an Oily Wastewater Filtration System Based on Experimentation, Full Factorial Design, and Machine Learning

Abstract

1. Introduction

2. Theory

2.1. Full Factorial Design Methodology

2.2. Multiple Linear Regression Method

- R-squared (the coefficient of determination) is a goodness-of-fit measure for strength linear regression association between the trained model response and experimental data. The closer to one, the better the model is.

- RMSE (Root Mean Square Error) is the root mean of residuals (model error prediction). RMSE depicts the standard deviation of the residuals around the model regression fit. The smaller the value, the better the model is (Equation (10)).

- MSE (Mean Squared Error) is the average squared residuals between the predicted and observed paired response values. MSE is the square of the RMSE. The smaller the MSE, the better the regression model (Equation (11)).

- MAE (Mean absolute error) is an average of the positive residuals between predicted and actual responses. The smaller the MAE, the better the regression model (Equation (12)).

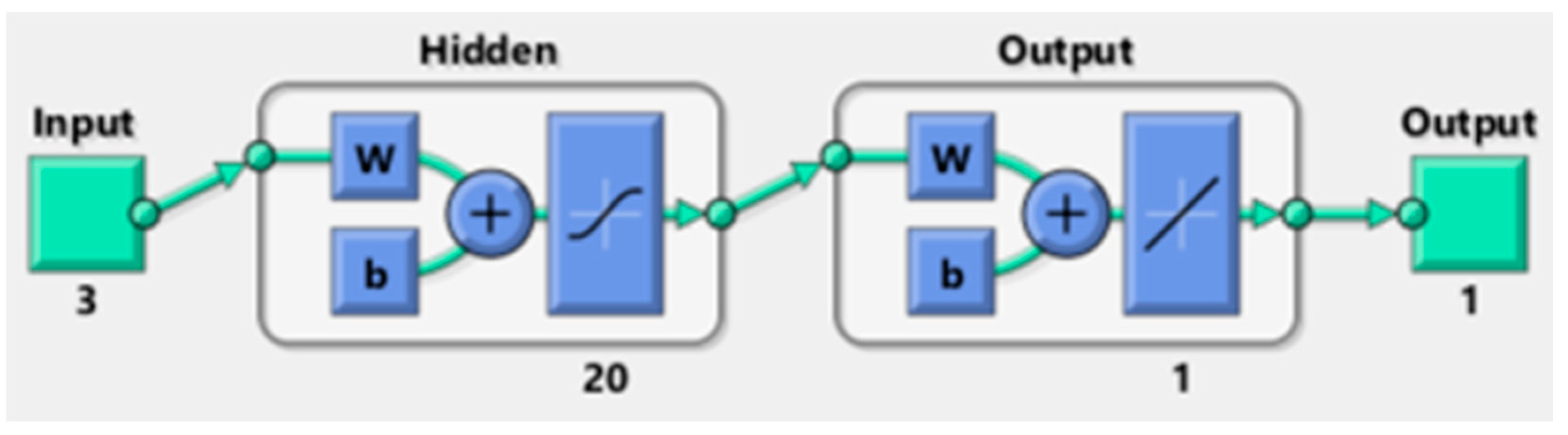

2.3. Artificial Intelligence Method

3. Materials and Methods

3.1. Materials

3.2. Feed Synthesis and Characterization

3.3. Ceramic Membrane Characterization

3.4. Crossflow Filtration System Description

4. Results and Discussion

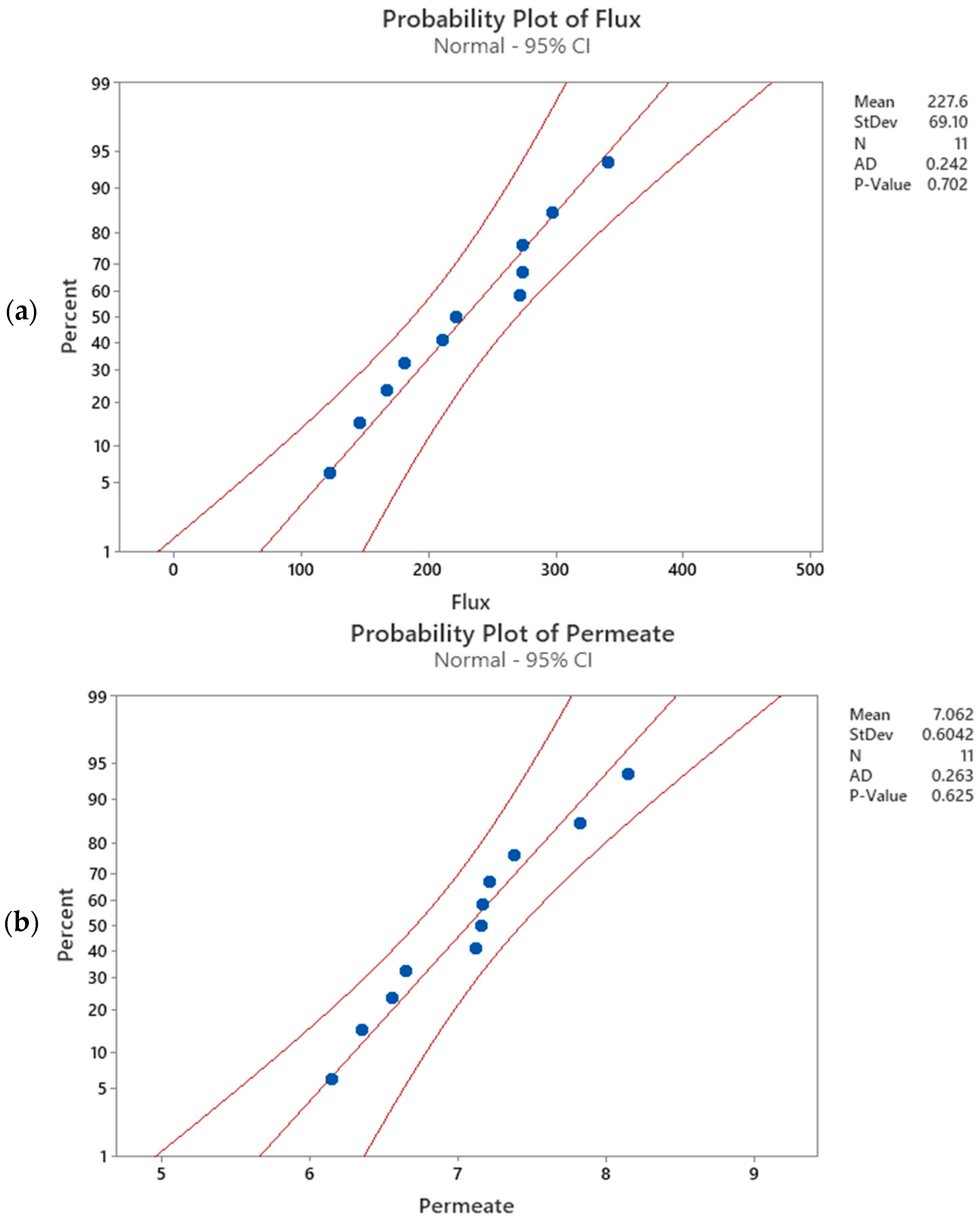

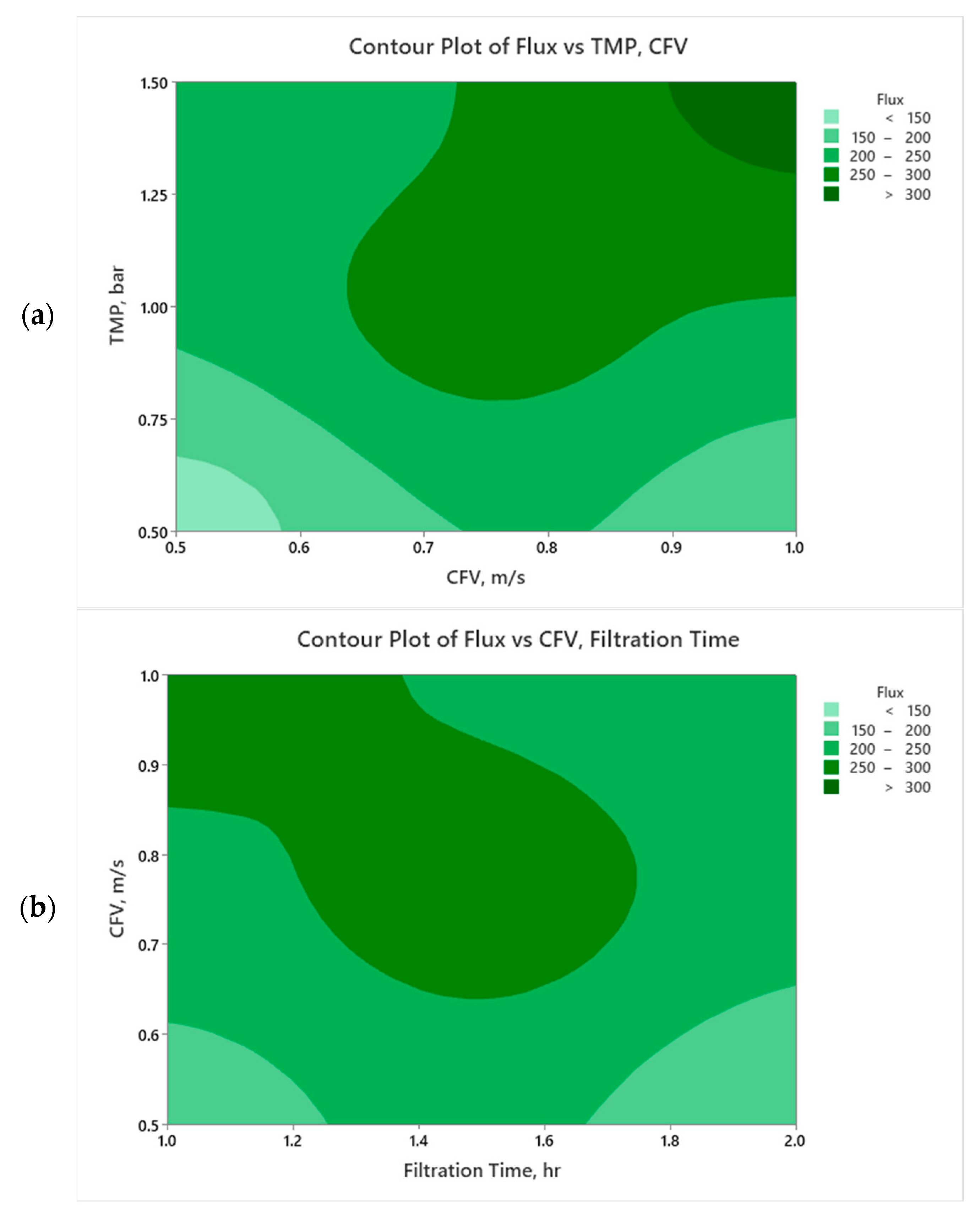

4.1. Full Factorial Design Analysis

4.1.1. Membrane Performance

4.1.2. Statistical Analysis

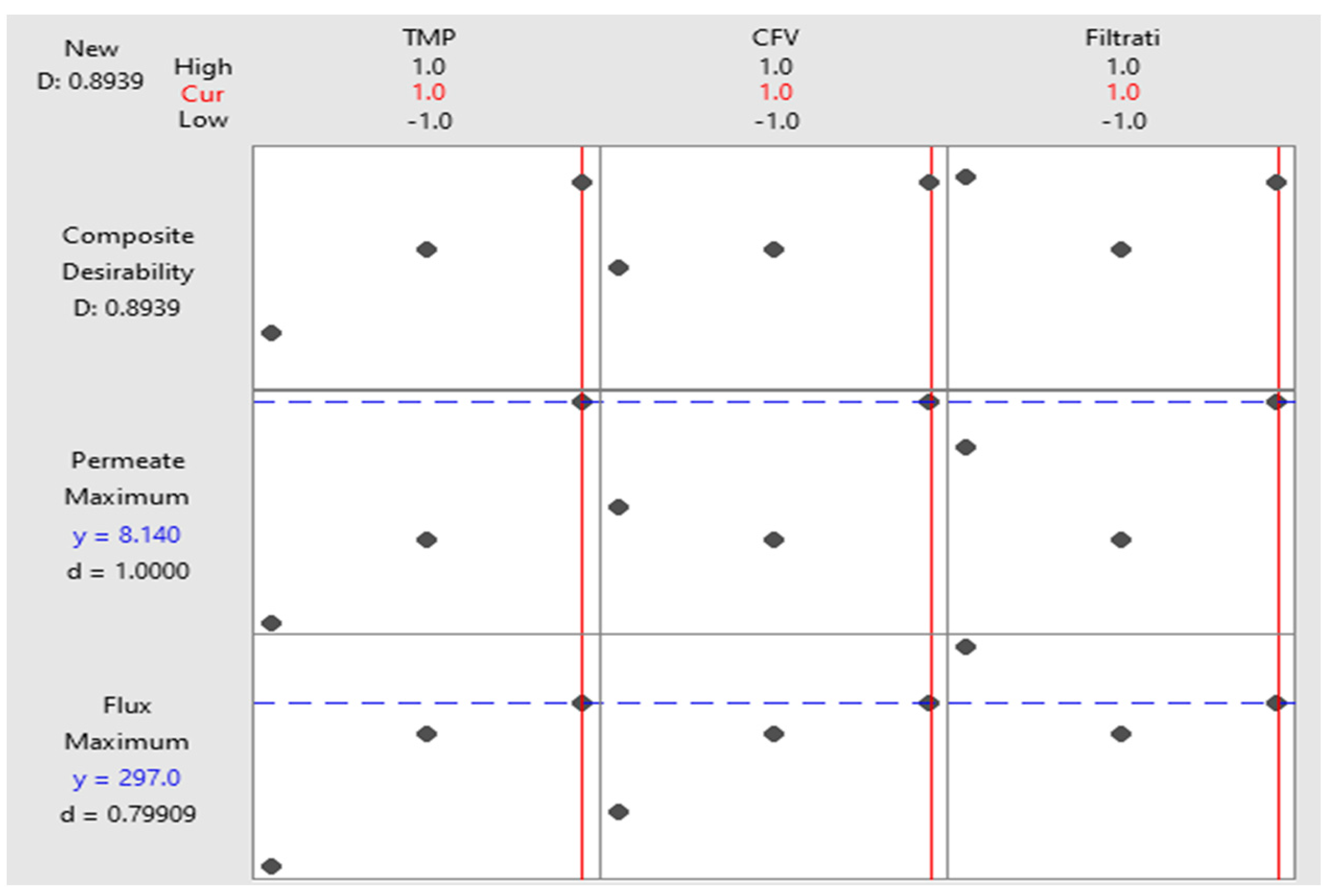

4.1.3. Model Optimization Analysis

4.2. MLR Analysis

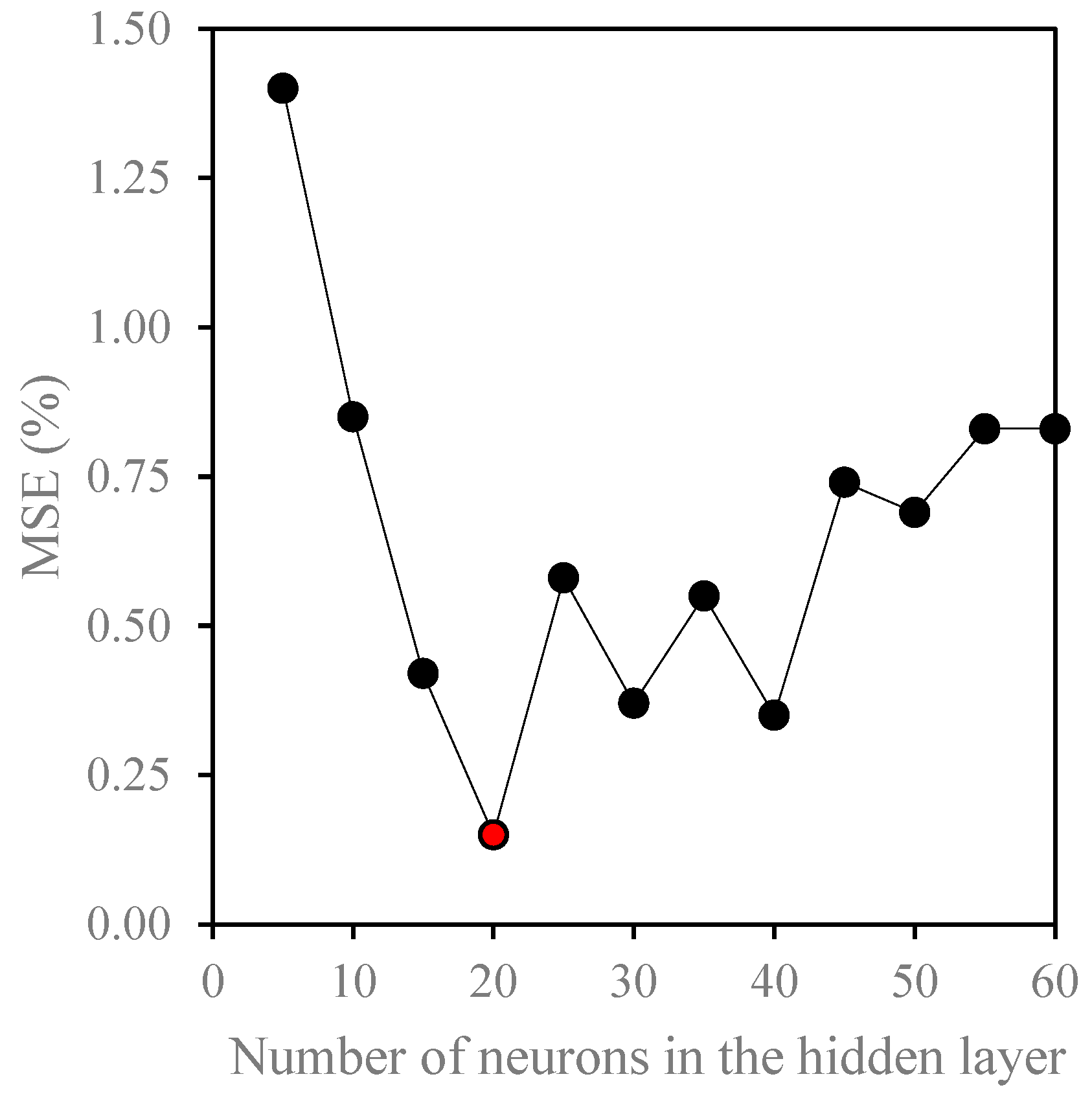

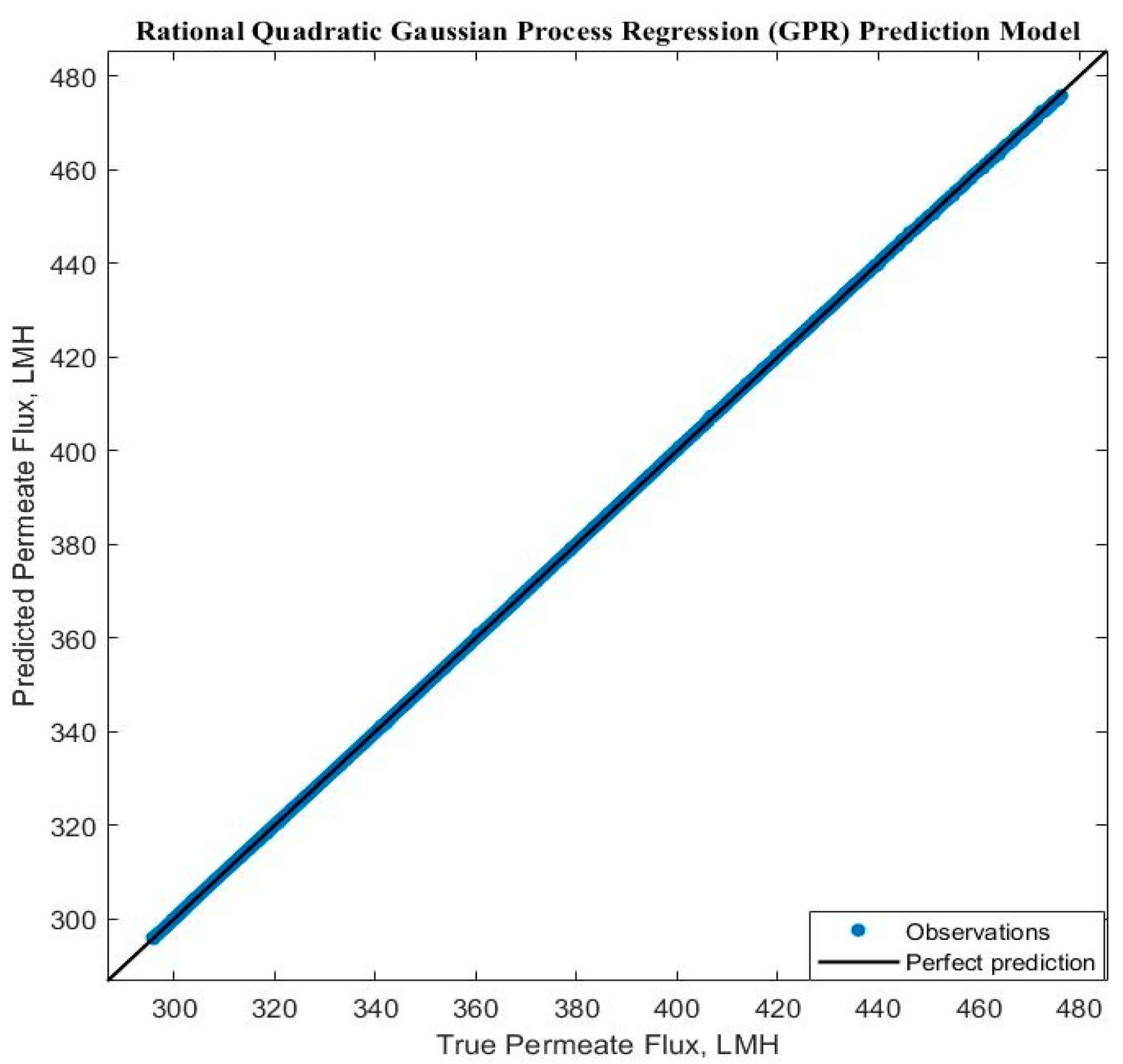

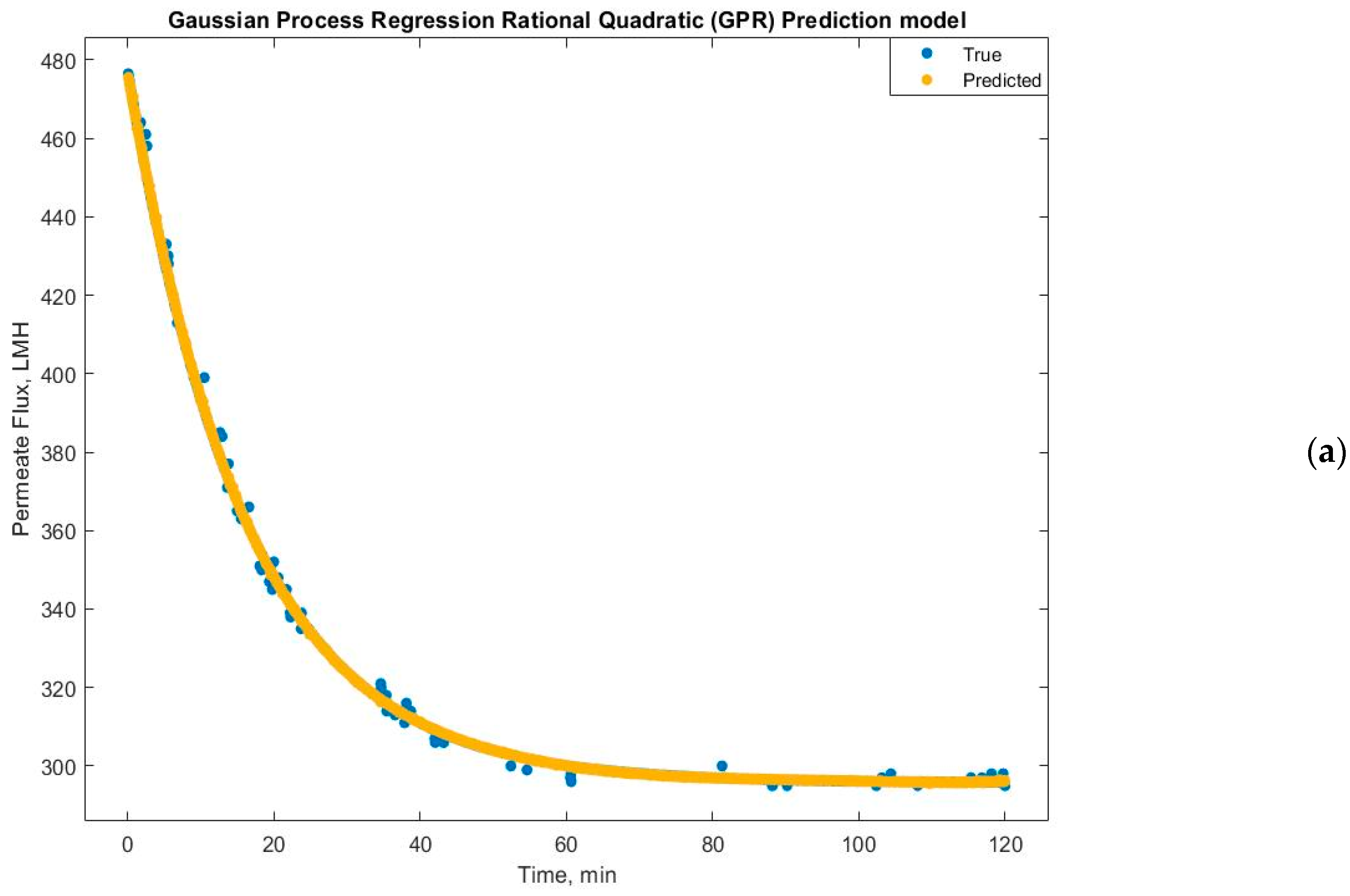

4.3. ANN Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligent |

| ANFIS | Adaptive Neuro-Fuzzy Inference System |

| ANN | Artificial Neural Networks |

| ANN-MPC | ANN Model Predictive Control |

| ANOVA | Analysis of Variance |

| BP | Backpropagation |

| COD | Chemical Oxygen Demand |

| GA | Genetic Algorithm |

| GRNN | General Regression Neural Network |

| MLR | Multiple Linear Regression |

| MSE | Mean Squared Error |

| RSM | Response Surface Methodology |

| SVM | Support Vector Machine |

| PLSR | Partial least squares regression |

Appendix A

Appendix A.1. Membrane Cleaning in Place Procedure

References

- Echakouri, M.; Salama, A.; Henni, A. Experimental Investigation of the Novel Periodic Feed Pressure Technique in Minimizing Fouling during the Filtration of Oily Water Systems Using Ceramic Membranes. Membranes 2022, 12, 868. [Google Scholar] [CrossRef] [PubMed]

- Zoubeik, M.; Echakouri, M.; Henni, A.; Salama, A. Taguchi Optimization of Operating Conditions of a Microfiltration Alumina Ceramic Membrane and Artificial Neural-Network Modeling. J. Environ. Eng. 2022, 148, 4022001. [Google Scholar] [CrossRef]

- Echakouri, M.; Zoubeik, M.; Salama, A.; Henni, A.; Elgharbi, H. Recent Advances in the Physical Methods to Combat Membrane Fouling: An Emphasis on the Periodic Feed Pressure Technique. In Sustainable Energy-Water-Environment Nexus in Deserts; Springer: Cham, Switzerland, 2022; pp. 197–207. [Google Scholar]

- Echakouri, M.; Henni, A.; Salama, A. High-Frequency Pulsatile Parameterization Study for the Titania Ceramic Membrane Fouling Mitigation in Oily Wastewater Systems Using the Box–Behnken Response Surface Methodology. Membranes 2022, 12, 1198. [Google Scholar] [CrossRef]

- Fonseca Ivo, O.; Imsland, L.S. Framework for produced water discharge management with flow-weighted mean concentration based economic model predictive control. Comput. Chem. Eng. 2022, 157, 107604. [Google Scholar]

- Ezugbe, E.O.; Rathilal, S. Membrane technologies in wastewater treatment: A review. Membranes 2020, 10, 89. [Google Scholar] [CrossRef]

- Suhalim, N.S.; Kasim, N.; Mahmoudi, E.; Shamsudin, I.J.; Mohammad, A.W.; Mohamed Zuki, F.; Jamari, N.L.A. Rejection Mechanism of Ionic Solute Removal by Nanofiltration Membranes: An Overview. Nanomaterials 2022, 12, 437. [Google Scholar] [CrossRef] [PubMed]

- Echakouri, M.; Salama, A.; Henni, A. Experimental and computational fluid dynamics investigation of the deterioration of the rejection capacity of the membranes used in the filtration of oily water systems. ACS EST Water 2021, 1, 728–744. [Google Scholar] [CrossRef]

- Darowna, D.; Wróbel, R.; Morawski, A.W.; Mozia, S. The influence of feed composition on fouling and stability of a polyethersulfone ultrafiltration membrane in a photocatalytic membrane reactor. Chem. Eng. J. 2017, 310, 360–367. [Google Scholar] [CrossRef]

- Jang, D.; Lee, J.; Jang, A. Impact of pre-coagulation on the ceramic membrane process during oil-water emulsion separation: Fouling behavior and mechanism. Chemosphere 2022, 313, 137596. [Google Scholar] [CrossRef]

- Rey, C.; Hengl, N.; Baup, S.; Karrouch, M.; Dufresne, A.; Djeridi, H.; Dattani, R.; Pignon, F. Velocity, stress and concentration fields revealed by micro-PIV and SAXS within concentration polarization layers during crossflow ultrafiltration of colloidal Laponite clay suspensions. J. Membr. Sci. 2017, 578, 69–84. [Google Scholar] [CrossRef]

- Khan, H.; Khan, S.U.; Hussain, S.; Ullah, A. Modelling of transmembrane pressure using slot/pore blocking model, response surface and artificial intelligence approach. Chemosphere 2022, 290, 133313. [Google Scholar] [CrossRef] [PubMed]

- Zoubeik, M.; Henni, A. Ultrafiltration of oil-in-water emulsion using a 0.04 µm silicon carbide membrane: Taguchi experimental design approach. Desalination Water Treat. 2017, 62, 108–119. [Google Scholar] [CrossRef]

- Zoubeik, M.; Salama, A.; Henni, A. A comprehensive experimental and artificial network investigation of the performance of an ultrafiltration titanium dioxide ceramic membrane: Application in produced water treatment. Water Environ. J. 2019, 33, 459–475. [Google Scholar] [CrossRef]

- Zoubeik, M.; Salama, A.; Henni, A. Table Optimization of Operating Conditions for a Superwetting Ultrafiltration ZrO2 Ceramic Membrane. J. Environ. Eng. 2020, 146, 4020021. [Google Scholar] [CrossRef]

- Aloulou, H.; Attia, A.; Aloulou, W.; Chakraborty, S.; Baklouti, L.; Dammak, L.; Amar, R.B. Statistical Simulation, a Tool for the Process Optimization of Oily Wastewater by Crossflow Ultrafiltration. Membranes 2022, 12, 676. [Google Scholar] [CrossRef]

- Louhıchı, G.; Bousselmı, L.; Ghrabı, A.; Khounı, I. Process optimization via response surface methodology in the physico-chemical treatment of vegetable oil refinery wastewater. Environ. Sci. Pollut. Res. 2019, 26, 18993–19011. [Google Scholar] [CrossRef]

- Šereš, Z.; Maravić, N.; Takači, A.; Nikolić, I.; Šoronja-Simović, D.; Jokić, A.; Hodur, C. Treatment of vegetable oil refinery wastewater using alumina ceramic membrane: Optimization using response surface methodology. J. Clean. Prod. 2016, 112, 3132–3137. [Google Scholar] [CrossRef]

- Khalifa, O.; Banat, F.; Srinivasakannan, C.; AlMarzooqi, F.; Hasan, S.W. Ozonation-assisted electro-membrane hybrid reactor for oily wastewater treatment: A methodological approach and synergy effects. J. Clean. Prod. 2021, 289, 125764. [Google Scholar] [CrossRef]

- Popović, S.; Karadžić, M.; Cakl, J. Optimization of ultrafiltration of cutting oil wastewater enhanced by application of twisted tapes: Response surface methodology approach. J. Clean. Prod. 2019, 231, 320–330. [Google Scholar] [CrossRef]

- Ruby-Figueroa, R.; Nardi, M.; Sindona, G.; Conidi, C.; Cassano, A. A multivariate statistical analyses of membrane performance in the clarification of citrus press liquor. ChemEngineering 2019, 3, 10. [Google Scholar] [CrossRef]

- Vyas, A.D.; Bennett, R.J.; Marshall, A.D. Influence of operating conditions on membrane fouling in crossflow microfiltration of particulate suspensions. Int. Dairy J. 2000, 10, 477–487. [Google Scholar] [CrossRef]

- De Almeida, M.S.; Martins, R.C.; Quinta-Ferreira, R.M.; Gando-Ferreira, L.M. Optimization of operating conditions for the valorization of olive mill wastewater using membrane processes. Environ. Sci. Pollut. Res. 2018, 25, 21968–21981. [Google Scholar] [CrossRef] [PubMed]

- Haddaji, C.; Ennaciri, K.; Driouich, A.; Digua, K.; Souabi, S. Optimization of the coagulation-flocculation process for vegetable oil refinery wastewater using a full factorial design. Process Saf. Environ. Prot. 2022, 160, 803–816. [Google Scholar] [CrossRef]

- Xu, Q.; Xu, Y.; Li, L.; Fang, K. Uniform experimental design in chemometrics. J. Chemom. 2018, 32, e3020. [Google Scholar] [CrossRef]

- Corbatón-Báguena, M.J.; Vincent-Vela, M.C.; Gozálvez-Zafrilla, J.M.; Álvarez-Blanco, S.; Lora-García, J.; Catalán-Martínez, D. Comparison between artificial neural networks and Hermia’s models to assess ultrafiltration performance. Sep. Purif. Technol. 2016, 170, 434–444. [Google Scholar] [CrossRef]

- Merma, A.G.; Santos, B.F.; Rego, A.S.; Hacha, R.R.; Torem, M.L. Treatment of oily wastewater from mining industry using electrocoagulation: Fundamentals and process optimization. J. Mater. Res. Technol. 2020, 9, 15164–15176. [Google Scholar] [CrossRef]

- Chen, Y.; Shen, L.; Li, R.; Xu, X.; Hong, H.; Lin, H.; Chen, J. Quantification of interfacial energies associated with membrane fouling in a membrane bioreactor by using BP and GRNN artificial neural networks. J. Colloid Interface Sci. 2020, 565, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Yu, G.; Long, Y.; Teng, J.; You, X.; Liao, B.-Q.; Lin, H. Application of radial basis function artificial neural network to quantify interfacial energies related to membrane fouling in a membrane bioreactor. Bioresour. Technol. 2019, 293, 122103. [Google Scholar] [CrossRef]

- Waqas, S.; Harun, N.Y.; Sambudi, N.S.; Arshad, U.; Nordin, N.A.H.M.; Bilad, M.R.; Saeed, A.A.H.; Malik, A.A. SVM and ANN Modelling Approach for the Optimization of Membrane Permeability of a Membrane Rotating Biological Contactor for Wastewater Treatment. Membranes 2022, 12, 821. [Google Scholar] [CrossRef]

- Yogarathinam, L.T.; Velswamy, K.; Gangasalam, A.; Ismail, A.F.; Goh, P.S.; Subramaniam, M.N.; Satya Narayana, M.; Yaacob, N.; Abdullah, M.S. Parametric analysis of lignocellulosic ultrafiltration in lab scale crossflow module using pore blocking and artificial neural network model. Chemosphere 2022, 286, 131822. [Google Scholar] [CrossRef]

- Irfan, M.; Waqas, S.; Arshad, U.; Khan, J.A.; Legutko, S.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Rahman, S.; Skrzypczak, A. Response Surface Methodology and Artificial Neural Network Modelling of Membrane Rotating Biological Contactors for Wastewater Treatment. Materials 2022, 15, 1932. [Google Scholar] [CrossRef] [PubMed]

- Schmitt, F.; Banu, R.; Yeom, I.-T.; Do, K.-U. Development of artificial neural networks to predict membrane fouling in an anoxic-aerobic membrane bioreactor treating domestic wastewater. Biochem. Eng. J. 2018, 133, 47–58. [Google Scholar] [CrossRef]

- Jawad, J.; Hawari, A.H.; Zaidi, S.J. Modeling and sensitivity analysis of the forward osmosis process to predict membrane flux using a novel combination of neural network and response surface methodology techniques. Membranes 2021, 11, 70. [Google Scholar] [CrossRef]

- Ghaedi, A.M.; Ghaedi, M.; Pouranfard, A.R.; Ansari, A.; Avazzadeh, Z.; Vafaei, A.; Tyagi, I.; Agarwal, S.; Gupta, V.K. Adsorption of Triamterene on multi-walled and single-walled carbon nanotubes: Artificial neural network modeling and genetic algorithm optimization. J. Mol. Liq. 2016, 216, 654–665. [Google Scholar] [CrossRef]

- Ibrahim, S.; Wahab, N.A.; Ismail, F.S.; Sam, Y.M. Optimization of artificial neural network topology for membrane bioreactor filtration using response surface methodology. IAES Int. J. Artif. Intell. 2020, 9, 117. [Google Scholar] [CrossRef]

- Pendashteh, A.R.; Fakhru’l-Razi, A.; Chaibakhsh, N.; Abdullah, L.C.; Madaeni, S.S.; Abidin, Z.Z. Modeling of membrane bioreactor treating hypersaline oily wastewater by artificial neural network. J. Hazard. Mater. 2011, 192, 568–575. [Google Scholar] [CrossRef]

- Xu, H.; Xiao, K.; Yu, J.; Huang, B.; Wang, X.; Liang, S.; Wei, C.; Wen, X.; Huang, X. A simple method to identify the dominant fouling mechanisms during membrane filtration based on piecewise multiple linear regression. Membranes 2020, 10, 171. [Google Scholar] [CrossRef]

- Öztürk, O.B.; Başar, E. Multiple linear regression analysis and artificial neural networks based decision support system for energy efficiency in shipping. Ocean Eng. 2022, 243, 110209. [Google Scholar] [CrossRef]

- Al Aani, S.; Bonny, T.; Hasan, S.W.; Hilal, N. Can machine language and artificial intelligence revolutionize process automation for water treatment and desalination? Desalination 2019, 458, 84–96. [Google Scholar] [CrossRef]

- Ullah, H.; Khan, I.; AlSalman, H.; Islam, S.; Raja, M.A.Z.; Shoaib, M.; Gumaei, A.; Fiza, M.; Ullah, K.; Mizanur Rahman, S.M.; et al. Levenberg–Marquardt backpropagation for numerical treatment of micropolar flow in a porous channel with mass injection. Complexity 2021, 2021, 5337589. [Google Scholar] [CrossRef]

- Tang, S.Z.; Li, M.J.; Wang, F.L.; He, Y.L.; Tao, W.Q. Fouling potential prediction and multi-objective optimization of a flue gas heat exchanger using neural networks and genetic algorithms. Int. J. Heat Mass Transf. 2020, 152, 119488. [Google Scholar] [CrossRef]

- Monfared, M.A.; Kasiri, N.; Mohammadi, T. A CFD model for prediction of critical electric potential preventing membrane fouling in oily wastewater treatment. J. Membr. Sci. 2017, 539, 320–328. [Google Scholar] [CrossRef]

- Jang, H.; Park, S.-J.; Kim, J. Response surface methodology to investigate the effects of operational parameters on membrane fouling and organic matter rejection in hard-shell encased hollow-fiber membrane. Chemosphere 2022, 287, 132132. [Google Scholar] [CrossRef] [PubMed]

- Hakim, M.L.; Nugroho, B.; Suastika, I.K.; Utama, I.K.A.P. Alternative Empirical Formula for Predicting the Frictional Drag Penalty due to Fouling on the Ship Hull using the Design of Experiments (DOE) Method. Int. J. Technol. 2021, 12, 829–842. [Google Scholar] [CrossRef]

- Li, L.; Rong, S.; Wang, R.; Yu, S. Recent advances in artificial intelligence and machine learning for nonlinear relationship analysis and process control in drinking water treatment: A review. Chem. Eng. J. 2021, 405, 126673. [Google Scholar] [CrossRef]

- Viet, N.D.; Jang, D.; Yoon, Y.; Jang, A. Enhancement of membrane system performance using artificial intelligence technologies for sustainable water and wastewater treatment: A critical review. Crit. Rev. Environ. Sci. Technol. 2022, 52, 3689–3719. [Google Scholar] [CrossRef]

- Jawad, J.; Hawari, A.H.; Zaidi, S.J. Artificial neural network modeling of wastewater treatment and desalination using membrane processes: A review. Chem. Eng. J. 2021, 419, 129540. [Google Scholar] [CrossRef]

- Naghibi, S.A.; Salehi, E.; Khajavian, M.; Vatanpour, V.; Sillanpää, M. Multivariate data-based optimization of membrane adsorption process for wastewater treatment: Multilayer perceptron adaptive neural network versus adaptive neural fuzzy inference system. Chemosphere 2021, 267, 129268. [Google Scholar] [CrossRef]

- Belfort, G. Membrane filtration with liquids: A global approach with prior successes, new developments and unresolved challenges. Angew. Chem. 2019, 131, 1908–1918. [Google Scholar] [CrossRef]

- Kamali, M.; Appels, L.; Yu, X.; Aminabhavi, T.M.; Dewil, R. Artificial intelligence as a sustainable tool in wastewater treatment using membrane bioreactors. Chem. Eng. J. 2021, 417, 128070. [Google Scholar] [CrossRef]

- Park, S.; Baek, S.S.; Pyo, J.; Pachepsky, Y.; Park, J.; Cho, K.H. Deep neural networks for modeling fouling growth and flux decline during NF/RO membrane filtration. J. Membr. Sci. 2019, 587, 117164. [Google Scholar] [CrossRef]

- Mittal, S.; Gupta, A.; Srivastava, S.; Jain, M. Artificial Neural Network based modeling of the vacuum membrane distillation process: Effects of operating parameters on membrane fouling. Chem. Eng. Process.-Process Intensif. 2021, 164, 108403. [Google Scholar] [CrossRef]

- Bagheri, M.; Akbari, A.; Mirbagheri, S.A. Advanced control of membrane fouling in filtration systems using artificial intelligence and machine learning techniques: A critical review. Process Saf. Environ. Prot. 2019, 123, 229–252. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, Z.; Jaffrin, M.Y.; Ding, L. Effects of hydraulic conditions on effluent quality, flux behavior, and energy consumption in a shear-enhanced membrane filtration using box-behnken response surface methodology. Ind. Eng. Chem. Res. 2014, 53, 7176–7185. [Google Scholar] [CrossRef]

- Myers, R.H.; Montgomery, D.C.; Vining, G.G.; Robinson, T.J. Generalized Linear Models: With Applications in Engineering and the Sciences; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Fan, M.; Hu, J.; Cao, R.; Ruan, W.; Wei, X. A review on experimental design for pollutants removal in water treatment with the aid of artificial intelligence. Chemosphere 2018, 200, 330–343. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.; Ahmad, I.; Ahsan, M.; Kano, M.; Caliskan, H. Prediction of optimum operating conditions of a furnace under uncertainty: An integrated framework of artificial neural network and genetic algorithm. Fuel 2022, 330, 125563. [Google Scholar] [CrossRef]

- Jawad, J.; Hawari, A.H.; Zaidi, S. Modeling of forward osmosis process using artificial neural networks (ANN) to predict the permeate flux. Desalination 2020, 484, 114427. [Google Scholar] [CrossRef]

- Gaudio, M.T.; Coppola, G.; Zangari, L.; Curcio, S.; Greco, S.; Chakraborty, S. Artificial intelligence-based optimization of industrial membrane processes. Earth Syst. Environ. 2021, 5, 385–398. [Google Scholar] [CrossRef]

- Phil, K. Matlab Deep Learning with Machine Learning, Neural Networks, and Artificial Intelligence; Apress: New York, NY, USA, 2017. [Google Scholar]

- Paluszek, M.; Thomas, S. Practical Matlab Deep Learning. In A Project-Based Approach, Michael Paluszek and Stephanie Thomas; Apress: New York, NY, USA, 2020. [Google Scholar]

- Viet, N.D.; Jang, A. Development of artificial intelligence-based models for the prediction of filtration performance and membrane fouling in an osmotic membrane bioreactor. J. Environ. Chem. Eng. 2021, 9, 105337. [Google Scholar] [CrossRef]

- Esfe, M.H.; Toghraie, D.; Amoozadkhalili, F. Optimization and design of ANN with Levenberg-Marquardt algorithm to increase the accuracy in predicting the viscosity of SAE40 oil-based hybrid nano-lubricant. Powder Technol. 2023, 415, 118097. [Google Scholar] [CrossRef]

- Giwa, A.; Daer, S.; Ahmed, I.; Marpu, P.R.; Hasan, S.W. Experimental investigation and artificial neural networks ANNs modeling of electrically-enhanced membrane bioreactor for wastewater treatment. J. Water Process Eng. 2016, 11, 88–97. [Google Scholar] [CrossRef]

- Paluszek, M.; Thomas, S. MATLAB Machine Learning Recipes: A Problem-Solution Approach; Apress: New York, NY, USA, 2019. [Google Scholar]

- El Batouti, M.; Alharby, N.F.; Elewa, M.M. Review of New Approaches for Fouling Mitigation in Membrane Separation Processes in Water Treatment Applications. Separations 2021, 9, 1. [Google Scholar] [CrossRef]

- Zsirai, T.; Qiblawey, H.; Buzatu, P.; Al-Marri, M.; Judd, S.J. Cleaning of ceramic membranes for produced water filtration. J. Pet. Sci. Eng. 2018, 166, 283–289. [Google Scholar] [CrossRef]

- Weschenfelder, S.E.; Fonseca, M.J.C.; Costa, B.R.S.; Borges, C.P. Influence of the use of surfactants in the treatment of produced water by ceramic membranes. J. Water Process Eng. 2019, 32, 100955. [Google Scholar] [CrossRef]

- Kordkandi, S.A.; Forouzesh, M. Application of full factorial design for methylene blue dye removal using heat-activated persulfate oxidation. J. Taiwan Inst. Chem. Eng. 2014, 45, 2597–2604. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Hejase, C.A.; Tarabara, V.V. Nanofiltration of saline oil-water emulsions: Combined and individual effects of salt concentration polarization and fouling by oil. J. Membr. Sci. 2021, 617, 118607. [Google Scholar] [CrossRef]

- Salama, A.; Zoubeik, M.; Henni, A. A multicontinuum approach for the problem of filtration of oily water systems across thin flat membranes: I. The framework. AIChE J. 2017, 63, 4604–4615. [Google Scholar] [CrossRef]

- Salama, A.; Zoubeik, M.; Henni, A. A multicontinuum approach for the problem of filtration of oily-water systems across thin flat membranes: II. Validation and examples. AIChE J. 2018, 64, 1095–1105. [Google Scholar] [CrossRef]

- Echakouri, M.; Salama, A.; Henni, A. A comparative study between three of the physical antifouling techniques for oily wastewater filtration using ceramic membranes: Namely; the novel periodic transmembrane pressure technique, pulsatile flow, and backflushing. J. Water Process Eng. 2023, 54, 103921. [Google Scholar] [CrossRef]

| Process | Feed | Operating Conditions | Response | Optimization Methodology | Performance | Refs. |

|---|---|---|---|---|---|---|

| Crossflow filtration unit (LiqTech) | Produced water | TMP, CFV, Temp, and pH | Permeate flux | Taguchi, ANOVA, and ANN | Oil rejection = 98.25% | [2] |

| Crossflow filtration unit (LiqTech) | Produced water | TMP, CFV, and pulsatile cycle | Permeate flux and Permeate volume | Box–Behnken and ANOVA | 99% oil rejection, R2 = 99% | [4] |

| Crossflow filtration unit (LiqTech) | Produced water | TMP, CFV, Temp, and pH | Permeate flux fouling resistance | Taguchi, ANOVA, and ANN | 96% oil rejection | [13] |

| Crossflow filtration unit (LiqTech) | Produced water | TMP, CFV, Temp, and pH | Permeate flux | Taguchi, ANOVA, and ANN | 98.93% oil rejection 99% organic carbon removal (TOC) 99.82% turbidity removal | [14] |

| Crossflow filtration unit (LiqTech) | Produced water | TMP, CFV, Temp, and pH | Permeate flux | Taguchi, ANOVA, and ANN | Oil rejection = 98% Toral organic carbon = 99% Turbidity rejection = 99% | [15] |

| Crossflow filtration unit | Industrial wastewater | Oil concentration, TMP, and Temp | COD Permeate flux | Box–Behnken and ANOVA | COD removal, R = 0.985 Permeate flux, R = 0.901 | [16] |

| Conventional jar-test apparatus | Vegetable oil refinery | Coagulant concentration, flocculent dosage, and Initial pH | COD removal Residual turbidity | Box–Behnken and ANOVA | COD removal, R2 = 92.9% Turbidity removal, R2 = 83.6% | [17] |

| Crossflow filtration unit | Vegetable oil seed wastewater | TMP, CFV, and Temp | Permeate flux Chemical oxygen demand reduction (%) | RSM | COD removal enhanced from 40% to 75%. | [18] |

| Ozonation-assisted hybrid reactor | Oil and gas oily wastewater | Hydraulic residence time, Aeration, Current density, Intermittent power, and initial pH | COD rejection | One-factor-at-a-time experimentation and RSM | Efficiency was considerably improved, attaining 53.1% COD removal. | [19] |

| Ultrafiltration crossflow filtration unit | Cutting oil wastewater | Oil content, CFV, TMP, aspect ratio, and (AR) of twisted tape | Permeate flux Energy consumption | Central composite face-centred design | Maximal Steady flux = 201 LMH Minimal specific energy consumption = 1.34 kWh/m3 | [20] |

| Laboratory bench plant | Orange press liquor | Contact angle, membrane thickness, pore size distribution, TMP, temperature, and process time | Permeate flux, hesperidin, glucose, fructose, and sucrose rejection | Partial least squares regression (PLSR) | Permeate flux, R2 = 96.2% Hesperidin rejection, R2 = 95.8% Glucose rejection, R2 = 91.7% Fructose rejection, R2 = 97.5% Sucrose rejection, R2 = 94.3% | [21] |

| Double crossflow filtration unit (SEPA CF II-GE Osmonics) | Olive mill wastewater | TMP, Temp, and pH | COD removal Total phenolic removal | Full factorial design | COD removal, R2 = 83.3% Total phenolic removal, R2 = 93.1% | [23] |

| Refining operating unit | Vegetable oil refineries wastewater | pH, coagulant dose, flocculant dose, and pollutant load | Turbidity COD removal | Full factorial design and ANOVA analysis | Turbidity, R = 0.96 COD removal, R = 0.9 | [24] |

| Conventional crossflow pilot plant | Polyethylene glycol (PEG) | TMP, CFV, and time | Permeate flux | Hermia model and ANN | Permeability, R² = 0.99 | [26] |

| Flocculation and electrocoagulation laboratory unit | Mining oily wastewater | pH, current density, electrolyte concentration, oil concentration, and Electrode gap | COD removal | ANN and Polynomial GA | Polynomial GA, R2 = 0.89 ANN, R2 = 0.99 | [27] |

| Membrane rotating biological contactor | Synthetic wastewater | Disk Rotational Speed, hydraulic-retention time, and sludge-retention time | Permeability | SVM and ANN | R2 = 99% | [30] |

| Crossflow module (Rayflow 100 Plate and Frame Mode) | Agricultural palm oily wastewater | TMP, pH, and feed oil content | Lignocellulosic permeate flux | ANN and blocking laws | Water recovery = 82% Rejection = 98% | [31] |

| Rotating biological contactors | Food leftovers wastewater | Disk rotational speed, membrane-to-disk gap, and organic loading rate | Permeability | RSM and ANN | ANN, R2 = 0.9982 RSM, R2 = 0.9762 | [32] |

| Anoxic–aerobic membrane bioreactor | Domestic wastewater | COD, MLSS, MLVSS, pH, DO, Alkalinity, TN, TP, NO3-N, and NH4-N | Transmembrane pressure | ANN | R2 = 0.850 | [33] |

| SEPA CF forward osmosis cell (Sterlitec) | Distilled water or 0.086 M NaCl solution | The osmotic pressure difference, feed solution (FS) velocity, draw solution (DS) velocity, FS temperature, and DS temperature | Permeate flux | RSM and ANN | ANN, R2 = 0.98036 RSM, R2 = 0.9408 | [34] |

| Batch experiment apparatus | Drug solution | pH, contact time, temperature adsorbent dosage, and initial triamterene concentration | Naphthalene removal efficiency | ANN-GA and MLR | MSE = 0.0005 R = 0.9856 | [35] |

| Membrane bioreactor (MBR) filtration | Palm oil mill wastewater | Airflow rate, transmembrane pressure, permeate pump, and aeration pump | Permeate flux | RSM and ANN | MSE = 0.00220 R = 0.9906 | [36] |

| Membrane sequencing batch reactor | Produced water | Time, organic loading rate, reaction time, and TDS | COD, TOC, MLSS, Oil in sludge | ANN-MPC | COD removal = 98%. R2 = 0.9822 | [37] |

| Membrane bioreactor | Sludge foulants | Morphology, contact angle, surface tension, zeta potential, and separation distance | Interfacial energy | BP ANN and GRNN | Interfacial energy model prediction, R = 100% | [28] |

| Membrane bioreactor | Water and wastewater | Mixed liquor suspended solid (MLSS), dissolved oxygen (DO), electrical conductivity (EC), and time | Water flux | ANN and ANFIS | ANN, R2 = 0.9822 ANFIS, R2 = 0.9822 | [29] |

| Factors | Coded Symbol | Values of Coded Levels | ||

|---|---|---|---|---|

| Low (−1) | Middle (0) | High (+1) | ||

| TMP (bar) | A | 0.5 | 1 | 1.5 |

| CFV (m/s) | B | 0.5 | 0.75 | 1 |

| FT (h) | C | 1 | 1.5 | 2 |

| Uncoded Factors | Code Factors | Responses | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Std Run | Run Test Order | TMP | CFV | FT | A: TMP | B: CFV | C: FT | Permeate Flux (Jni) | Permeate Volume (Ynf) | ||

| Experimental | Predicted | Experimental | Predicted | ||||||||

| (bar) | (m/s) | (h) | (LMH) | (LMH) | (L) | (L) | |||||

| 11 | 1 | 1 | 0.75 | 1.5 | 0 | 0 | 0 | 271 | 273 | 7.15 | 7.14 |

| 1 | 2 | 0.5 | 0.5 | 1 | −1 | −1 | −1 | 146 | 146 | 6.15 | 6.15 |

| 2 | 3 | 1.5 | 0.5 | 1 | 1 | −1 | −1 | 221 | 221 | 7.21 | 7.22 |

| 10 | 4 | 1 | 0.75 | 1.5 | 0 | 0 | 0 | 274 | 273 | 7.16 | 7.14 |

| 8 | 5 | 1.5 | 1 | 2 | 1 | 1 | 1 | 297 | 297 | 8.14 | 8.14 |

| 4 | 6 | 1.5 | 1 | 1 | 1 | 1 | −1 | 341 | 341 | 7.82 | 7.82 |

| 6 | 7 | 1.5 | 0.5 | 2 | 1 | −1 | 1 | 211 | 211 | 7.38 | 7.39 |

| 9 | 8 | 1 | 0.75 | 1.5 | 0 | 0 | 0 | 273 | 273 | 7.12 | 7.14 |

| 3 | 9 | 0.5 | 1 | 1 | −1 | 1 | −1 | 181 | 181 | 6.35 | 6.35 |

| 7 | 10 | 0.5 | 1 | 2 | −1 | 1 | 1 | 167 | 167 | 6.55 | 6.55 |

| 5 | 11 | 0.5 | 0.5 | 2 | −1 | −1 | 1 | 122 | 122 | 6.65 | 6.65 |

| Optimized design | 1.5 | 1 | 2 | 1 | 1 | 1 | 297 | 297 | 8.14 | 8.14 | |

| Synthetic Feed | Permeate | Turbidity | |||||

|---|---|---|---|---|---|---|---|

| Std Run | Run Test Order | Mean Oil Droplet Size | Oil Content | Oil Content | Rejection | Feed | Permeate |

| (μm) | (ppm) | (ppm) | (%) | (NTU) | (NTU) | ||

| 11 | 1 | 6.5 | 200 | 9 | 96 | 578 | 3.64 |

| 1 | 2 | 5.4 | 194 | 15 | 92 | 596 | 5.16 |

| 2 | 3 | 5.3 | 199 | 11 | 94 | 583 | 4.89 |

| 10 | 4 | 5.9 | 196 | 11 | 94 | 576 | 4.73 |

| 8 | 5 | 6.4 | 199 | 5 | 97 | 559 | 2.47 |

| 4 | 6 | 6.3 | 196 | 4 | 98 | 568 | 0.83 |

| 6 | 7 | 6.9 | 197 | 12 | 94 | 579 | 4.62 |

| 9 | 8 | 5.1 | 198 | 10 | 95 | 586 | 4.15 |

| 3 | 9 | 6.8 | 197 | 13 | 93 | 566 | 5.09 |

| 7 | 10 | 5.5 | 200 | 14 | 93 | 574 | 5.13 |

| 5 | 11 | 5.4 | 197 | 18 | 91 | 592 | 5.62 |

| Optimized design | 6.4 | 199 | 5 | 97 | 559 | 2.47 | |

| Chemicals | Usage | Suppliers |

|---|---|---|

| Sodium dodecyl sulfate (SDS, 99 wt%) | Feed synthesis | Sigma-Aldrich (St. Louis, MO, USA) |

| Hydrochloric acid (HCl, SA431-500, 2N) | Oil/solvent extraction | Fisher Chemicals (Waltham, MA, USA) |

| Horiba S-316 #100690 | Oil/solvent extraction solvent | Horiba (Kyoto, Janpan) |

| Phosphoric acid (H₃PO₄, 85 wt%) | Ceramic cleaning | BDH Chemicals (London, UK) |

| Sodium hydroxide (NaOH, 95 wt %) | Ceramic cleaning | EMD chemicals (Burlington, MA, USA) |

| Oil Parameters | Feed |

|---|---|

| Oil Content, ppm | 197 ± 2 |

| Chemical Oxygen Demand (COD), mg/L | 1352 ± 25 |

| Turbidity, NTU | 578 ± 11 |

| pH | 6.225 ± 0.001 |

| Zeta potential, mV | −32 ± 4.0 |

| Mean droplet size, μm | 6.4 ± 0.1 |

| Density, g/cc | 0.87844 ± 5 × 10−5 |

| Viscosity, cP | 5.23 ± 0.01 |

| Equipment | Measured Parameter/Function | Supplier Area |

|---|---|---|

| Horiba Oil Content Analyzer (OCMA-350) | Oil content, ppm | Burlington, ON, Canada |

| Horiba F-55 benchtop meter (Horiba 2003) | pH | Irvine, CA, USA |

| Hanna turbidity meter (HI 83414, Hanna 2007) | Turbidity, NTU | Leighton Buzzard, UK |

| Hach DR5000 UV-Vis spectrophotometer | Chemical Oxygen Demand (COD), mg/L | London, ON, Canada |

| Zetasizer Nano ZS (ZEN3600, Malvern 2009) | Zeta potential, mV | Great Malvern, UK |

| Zetasizer Nano ZS (ZEN3600, Malvern 2009) | Droplet size, μm | Great Malvern, UK |

| Brookfield viscometer DV-II +Pro | Viscosity, cP | Middleborough, MA, USA |

| Anton Paar 5000 DSA 5000 digital | Density, g/cc | Montreal, QC, Canada |

| RX-5000 refractometer (ATAGO) | Refractive index (RI.) | Toronto, ON, Canada |

| Waring Commercial MX1000 Series | Blender | Stamford, CT, USA |

| Membrane | Characteristics | |

|---|---|---|

| Dimensions, mm | 25 ± 1 × 305 ± 1 | |

| Number of channels | 7 | |

| Dimensions | Filtration area, m2 | 0.04186 ± 0.006 |

| Cross-sectional area, m2 | 0.001172 ± 0.006 | |

| Channel diameter, mm | 6.0 ± 0.1 | |

| Parameters | Porosity of support | ~38% |

| Pore size/MWCO | 150 kDa | |

| Maximum working pressure | 10 bar | |

| Best operating pressure | 3 bar | |

| Applied pH scale | 0–14 | |

| Max operating temperature | <250 °C | |

| Thermal shock resistance | ΔT instantaneous < 60 °C (Temperature difference between feed and membrane) | |

| Materials | Active layer: Titania Support layer: Zirconia |

| Source | DF | Sum of Square | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8 | 47,742 | 5968 | 2557.6 | 0.000 |

| Linear | 3 | 37,047 | 12,349 | 5292.4 | 0.000 |

| TMP | 1 | 25,764 | 25,764 | 11,042 | 0.000 |

| CFV | 1 | 10,224 | 10,224 | 4381.93 | 0.001 |

| FT | 1 | 1058 | 1058 | 453.43 | 0.002 |

| 2-Way Interactions | 3 | 2088.5 | 696.2 | 298.36 | 0.003 |

| TMP × CFV | 1 | 1984.5 | 1984.5 | 850.50 | 0.001 |

| TMP × FT | 1 | 32.0 | 32.0 | 13.71 | 0.066 * |

| CFV × FT | 1 | 72.0 | 72.0 | 30.86 | 0.031 |

| 3-Way Interactions | 1 | 242.0 | 242.0 | 103.71 | 0.010 |

| TMP × CFV × FT | 1 | 242.0 | 242.0 | 103.71 | 0.010 |

| Curvature | 1 | 8364 | 8364 | 3584 | 0.001 |

| Error | 2 | 4.7 | 2.3 | ||

| Total | 10 | 47,746 |

| Source | DF | Sum of Square | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8 | 3.65010 | 0.45626 | 1052.91 | 0.001 |

| Linear | 3 | 3.38744 | 1.12915 | 2605.72 | 0.000 |

| TMP | 1 | 2.94031 | 2.94031 | 6785.34 | 0.001 |

| CFV | 1 | 0.27011 | 0.27011 | 623.34 | 0.002 |

| FT | 1 | 0.17701 | 0.17701 | 408.49 | 0.002 |

| 2-Way Interactions | 3 | 0.20994 | 0.06998 | 161.49 | 0.006 |

| TMP × CFV | 1 | 0.20161 | 0.20161 | 465.26 | 0.002 |

| TMP × FT | 1 | 0.00551 | 0.00551 | 12.72 | 0.070 * |

| CFV × FT | 1 | 0.00281 | 0.00281 | 6.49 | 0.126 * |

| 3-Way Interactions | 1 | 0.02531 | 0.02531 | 58.41 | 0.017 |

| TMP × CFV × FT | 1 | 0.02531 | 0.02531 | 58.41 | 0.017 |

| Curvature | 1 | 0.02741 | 0.02741 | 63.25 | 0.015 |

| Error | 2 | 0.00087 | 0.00043 | ||

| Total | 10 | 3.651 |

| Response | Goal | Lower | Target | Upper | Weight | Importance |

|---|---|---|---|---|---|---|

| Permeate (L) | Maximum | 6.15 | 8.14 | 8.14 | 1 | 3 |

| Flux (LMH) | Maximum | 122.00 | 341.00 | 341.00 | 1 | 3 |

| Solution | TMP | CFV | FT | Permeate Fit (L) | Flux Fit (LMH) | Composite Desirability |

|---|---|---|---|---|---|---|

| 1 | +1 | +1 | −1 | 7.82 | 341 | 0.916 |

| 2 | +1 | +1 | +1 | 8.14 | 297 | 0.894 |

| Run 1 | Run 2 | Run 3 | Run 4 | Run 5 | Run 6 | Run 7 | Run 8 | Run 9 | Run 10 | Run 11 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RMSE | 0.111581 | 0.20797 | 0.14351 | 0.11066 | 0.062188 | 0.10318 | 0.14963 | 0.10843 | 0.14578 | 0.16317 | 0.23217 |

| R2 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 |

| MSE | 0.013412 | 0.043251 | 0.020595 | 0.12246 | 0.0038674 | 0.010647 | 0.02239 | 0.011757 | 0.021251 | 0.063572 | 0.31526 |

| MAE | 0.076448 | 0.14847 | 0.097105 | 0.075797 | 0.044647 | 0.070112 | 0.10718 | 0.074881 | 0.099163 | 0.27709 | 1.15277 |

| Runs | Runs Coded Levels | SAMPLES SIZE | MSE | R |

|---|---|---|---|---|

| 1 | (0, 0, 0) | 1800 | 7.68518 × 10−2 | 9.99984 × 10−1 |

| 2 | (−1, −1, −1) | 1200 | 8.291179 × 10−2 | 9.99993 × 10−1 |

| 3 | (+1, −1, −1) | 1200 | 8.10541 × 10−2 | 9.99990 × 10−1 |

| 4 | (0, 0, 0) | 1800 | 8.80532 × 10−2 | 9.99981 × 10−1 |

| 5 | (+1, +1, +1) | 2400 | 5.57747 × 10−2 | 9.99979 × 10−1 |

| 6 | (+1, +1, −1) | 1200 | 8.20400 × 10−2 | 9.99966 × 10−1 |

| 7 | (+1, −1, 1) | 2400 | 6.52329 × 10−2 | 9.99989 × 10−1 |

| 8 | (0, 0, 0) | 1800 | 7.74612 × 10−2 | 9.99983 × 10−1 |

| 9 | (−1, +1, −1) | 1200 | 8.30276 × 10−2 | 9.99992 × 10−1 |

| 10 | (−1, +1, +1) | 2400 | 6.17985 × 10−2 | 9.99992 × 10−1 |

| 11 | (−1, −1, +1) | 2400 | 6.67827 × 10−2 | 9.99994 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Echakouri, M.; Henni, A.; Salama, A. A Novel Modeling Optimization Approach for a Seven-Channel Titania Ceramic Membrane in an Oily Wastewater Filtration System Based on Experimentation, Full Factorial Design, and Machine Learning. Membranes 2024, 14, 199. https://doi.org/10.3390/membranes14090199

Echakouri M, Henni A, Salama A. A Novel Modeling Optimization Approach for a Seven-Channel Titania Ceramic Membrane in an Oily Wastewater Filtration System Based on Experimentation, Full Factorial Design, and Machine Learning. Membranes. 2024; 14(9):199. https://doi.org/10.3390/membranes14090199

Chicago/Turabian StyleEchakouri, Mohamed, Amr Henni, and Amgad Salama. 2024. "A Novel Modeling Optimization Approach for a Seven-Channel Titania Ceramic Membrane in an Oily Wastewater Filtration System Based on Experimentation, Full Factorial Design, and Machine Learning" Membranes 14, no. 9: 199. https://doi.org/10.3390/membranes14090199

APA StyleEchakouri, M., Henni, A., & Salama, A. (2024). A Novel Modeling Optimization Approach for a Seven-Channel Titania Ceramic Membrane in an Oily Wastewater Filtration System Based on Experimentation, Full Factorial Design, and Machine Learning. Membranes, 14(9), 199. https://doi.org/10.3390/membranes14090199