Revamping of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment Using Partial Nitritation

Abstract

1. Introduction

2. Materials and Methods

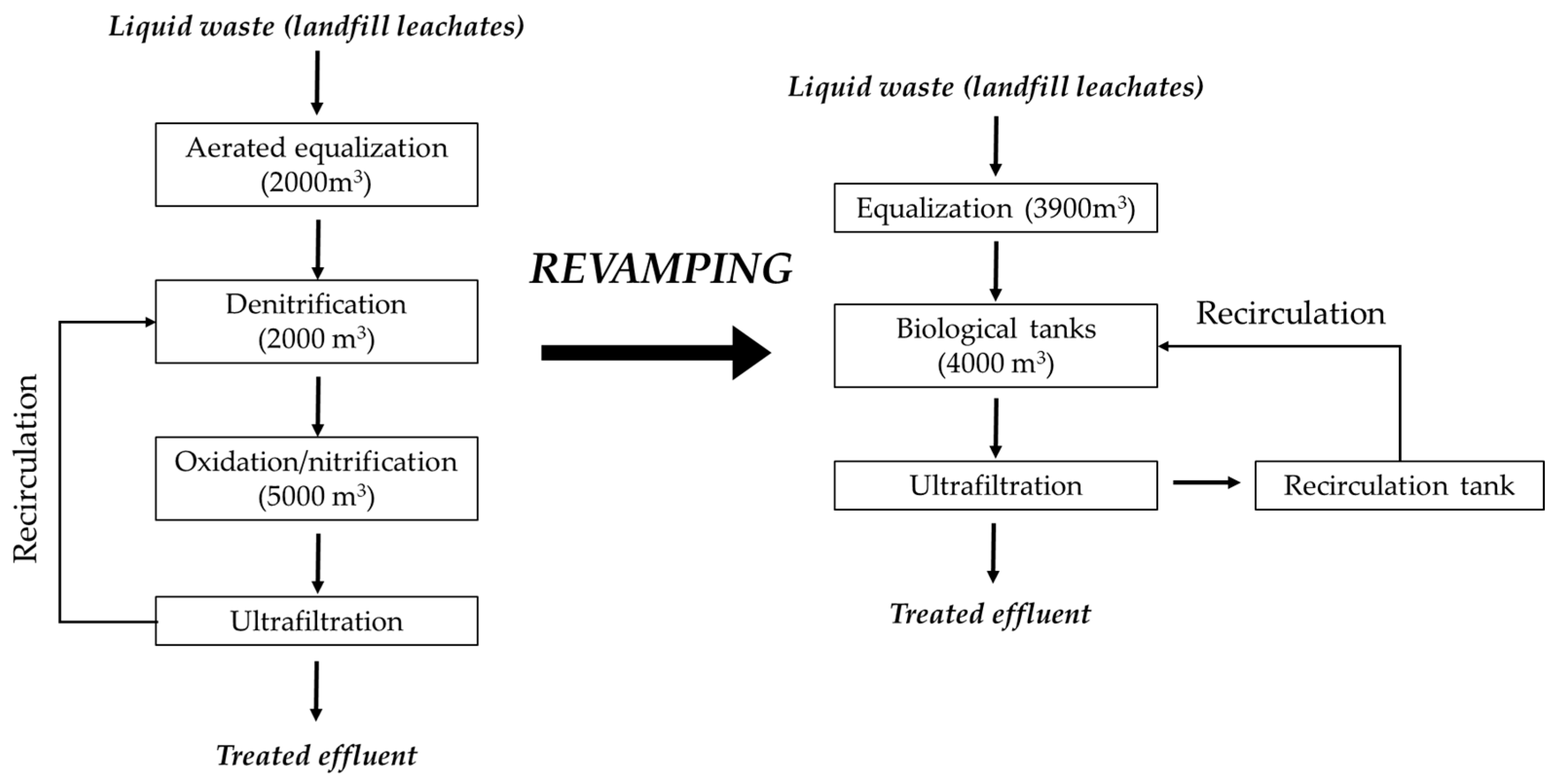

2.1. Plant Description

2.2. Biological Compartment

2.3. Ultrafiltration

3. Results

3.1. Characteristics of the Influent Mixture

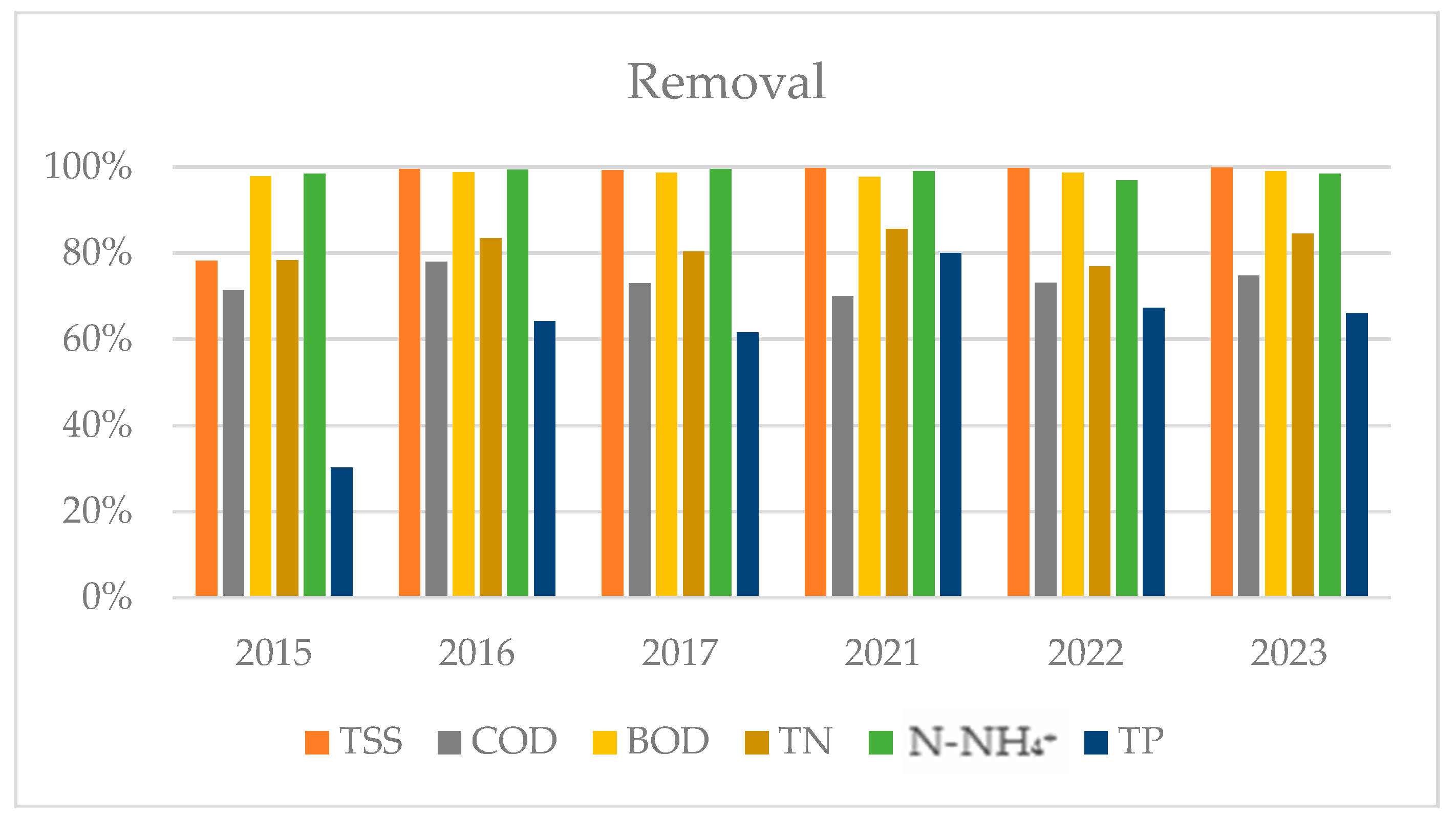

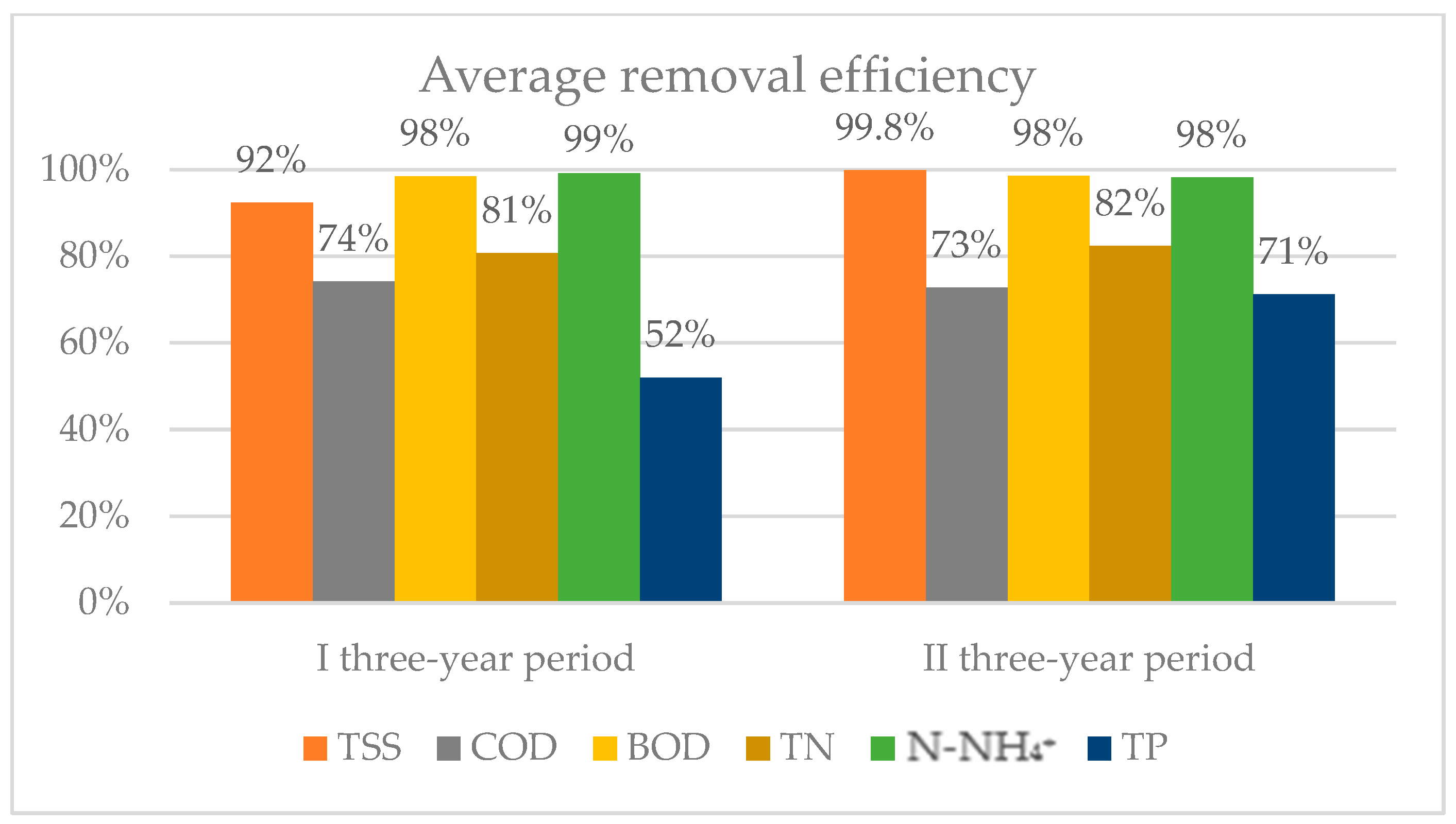

3.2. Removal Efficiency

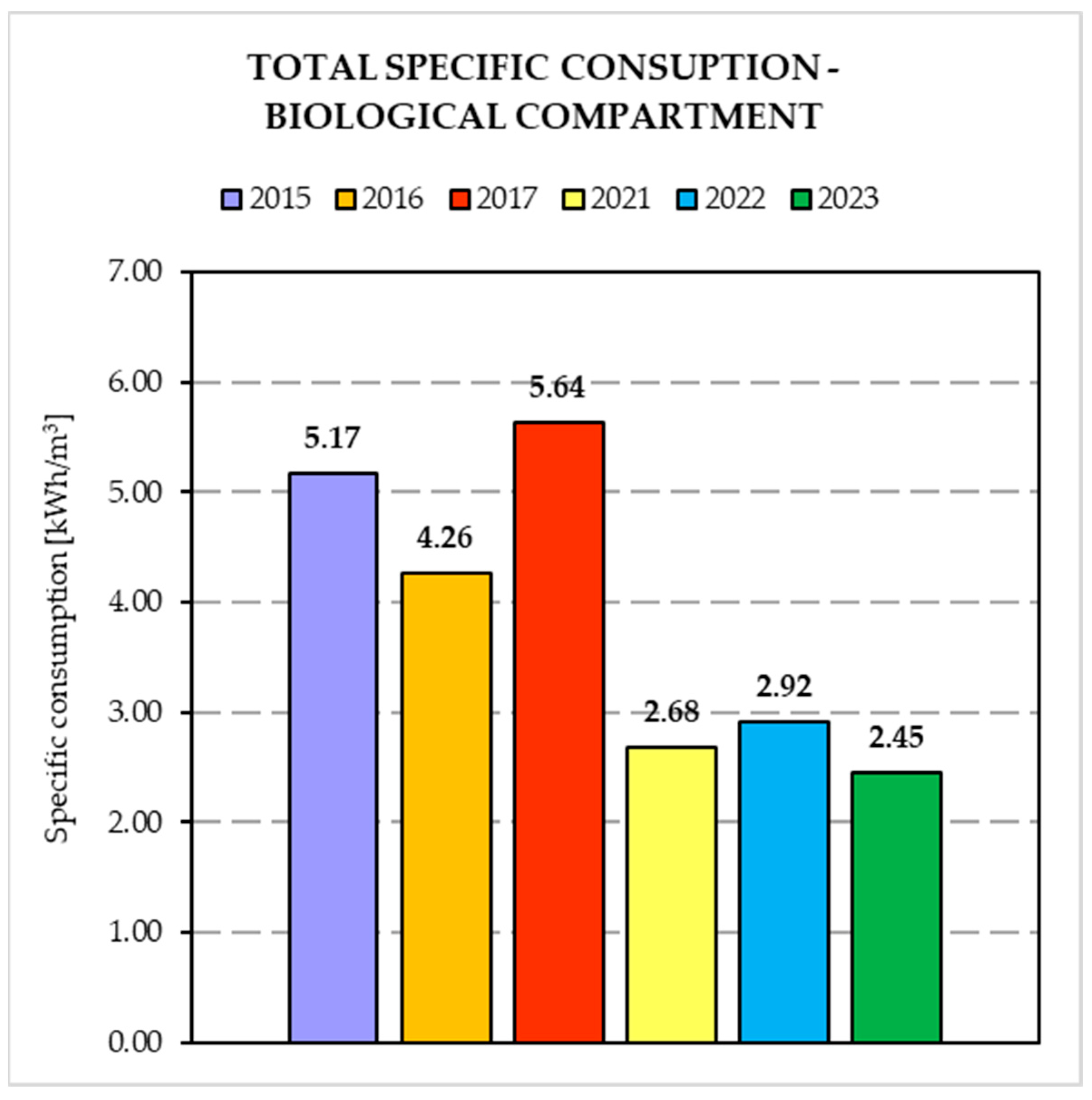

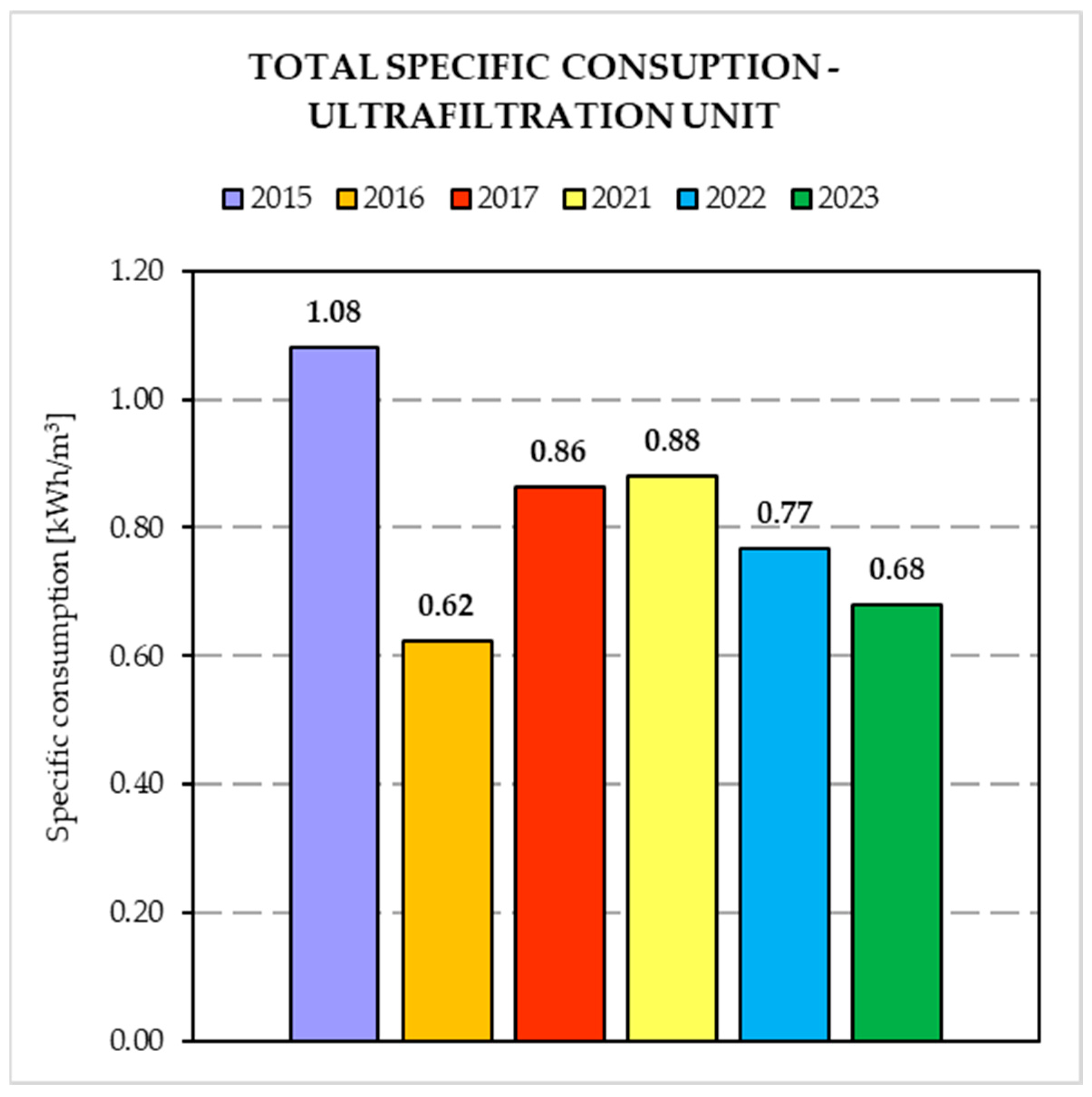

3.3. Energy Consumptions

3.4. Membrane Treatment

4. Discussion

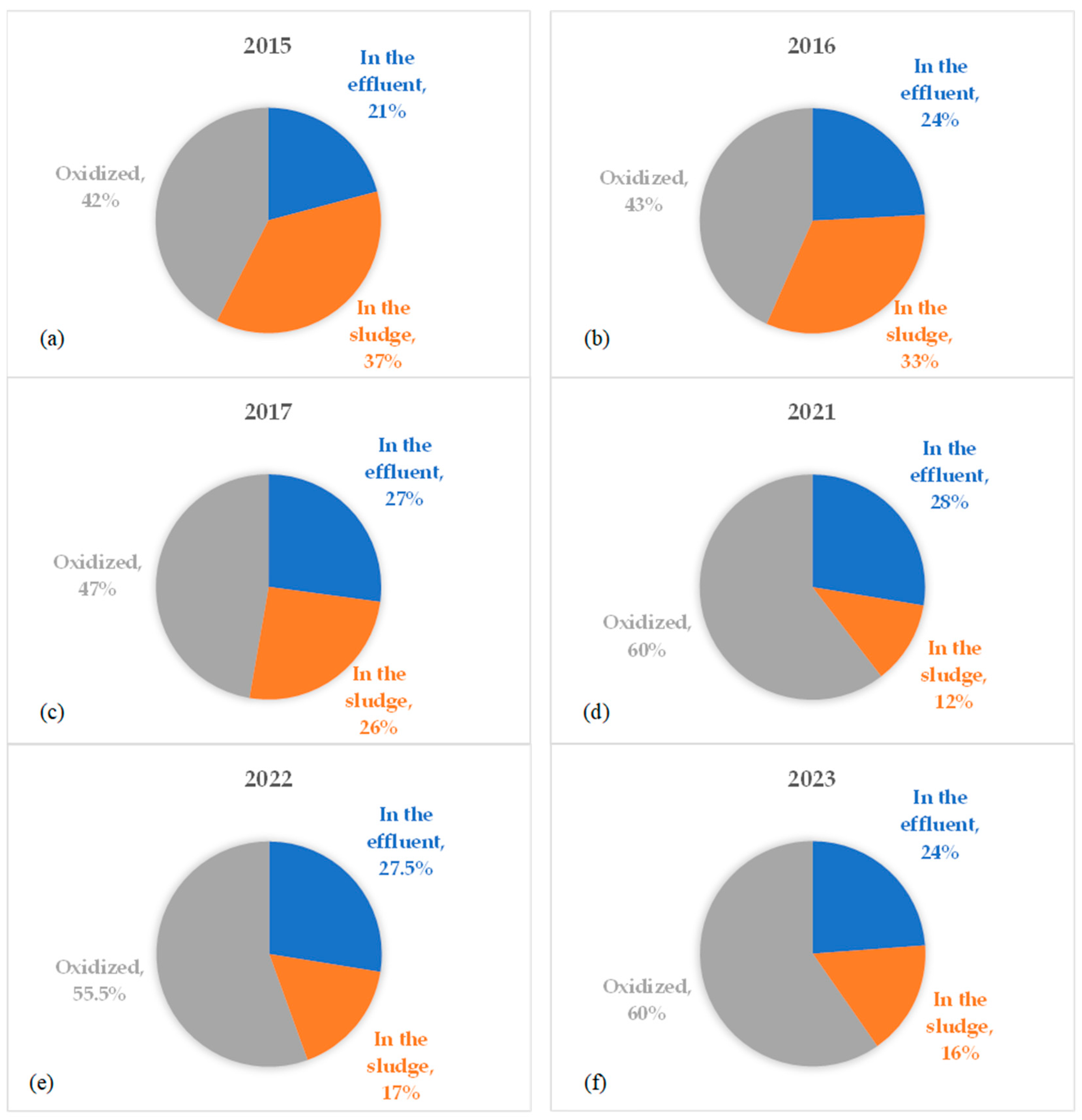

4.1. Biological Section

4.2. Membrane Separation

4.3. Energy Consumption

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Keyikoglu, R.; Karatas, O.; Rezania, H.; Kobya, M.; Vatanpour, V.; Khataee, A. A Review on Treatment of Membrane Concentrates Generated from Landfill Leachate Treatment Processes. Sep. Purif. Technol. 2021, 259, 118182. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Chen, Y. Recent Advances in Partial Denitrification in Biological Nitrogen Removal: From Enrichment to Application. Bioresour. Technol. 2020, 298, 122444. [Google Scholar] [CrossRef] [PubMed]

- Dong, K.; Feng, X.; Wang, W.; Chen, Y.; Hu, W.; Li, H.; Wang, D. Simultaneous Partial Nitrification and Denitrification Maintained in Membrane Bioreactor for Nitrogen Removal and Hydrogen Autotrophic Denitrification for Further Treatment. Membranes 2021, 11, 911. [Google Scholar] [CrossRef] [PubMed]

- Ge, S.; Wang, S.; Yang, X.; Qiu, S.; Li, B.; Peng, Y. Detection of Nitrifiers and Evaluation of Partial Nitrification for Wastewater Treatment: A Review. Chemosphere 2015, 140, 85–98. [Google Scholar] [CrossRef] [PubMed]

- Du, R.; Peng, Y.; Ji, J.; Shi, L.; Gao, R.; Li, X. Partial Denitrification Providing Nitrite: Opportunities of Extending Application for Anammox. Environ. Int. 2019, 131, 105001. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wang, X.; Yang, Y.Y.; Mirino, M.W.; Yuan, Y. Partial Nitrification and Denitrification of Mature Landfill Leachate Using a Pilot-Scale Continuous Activated Sludge Process at Low Dissolved Oxygen. Bioresour. Technol. 2016, 218, 580–588. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Kim, M.; Nakhla, G.; Andalib, M.; Fang, Y. Partial Nitrification-Reactor Configurations, and Operational Conditions: Performance Analysis. J. Environ. Chem. Eng. 2020, 8, 103984. [Google Scholar] [CrossRef]

- Guisasola, A.; Jubany, I.; Baeza, J.A.; Carrera, J.; Lafuente, J. Respirometric Estimation of the Oxygen Affinity Constants for Biological Ammonium and Nitrite Oxidation. J. Chem. Technol. Biotechnol. 2005, 80, 388–396. [Google Scholar] [CrossRef]

- Coppini, E.; Palli, L.; Fibbi, D.; Gori, R. Long-Term Performance of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment: A Case Study. Membranes 2018, 8, 52. [Google Scholar] [CrossRef] [PubMed]

- Battistoni, P.; Chemitec. Metodo e Dispositivo di Controllo un Processo di Trattamento Biologico, a Cicli Alternati, di Acque. Italian Patent No. ITRN990018, 2 December 2000. [Google Scholar]

- Metcalf & Eddy; Abu-Orf, M.; Bowden, G.; Burton, F.L.; Pfrang, W.; Stensel, H.D.; Tchobanoglous, G.; Tsuchihashi, R.; AECOM (Firm). Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; Metcalf & Eddy: Wakefield, MA, USA, 2013. [Google Scholar]

- Melidis, P. Landfill Leachate Nutrient Removal Using Intermittent Aeration. Environ. Process. 2014, 1, 221–230. [Google Scholar] [CrossRef]

- Shi, C.; Yan, B.; Zuo, X.; Wang, C.; Li, Z.; Zhu, L. The Effect of Aeration Mode on the Operational Effectiveness and Membrane Bioreactors for Greywater Treatment and Membrane Fouling. Environ. Eng. Res. 2023, 28, 210637. [Google Scholar] [CrossRef]

- Kornboonraksa, T.; Lee, S.H. Factors Affecting the Performance of Membrane Bioreactor for Piggery Wastewater Treatment. Bioresour. Technol. 2009, 100, 2926–2932. [Google Scholar] [CrossRef] [PubMed]

- El-Fadel, M.; Sleem, F.; Hashisho, J.; Saikaly, P.E.; Alameddine, I.; Ghanimeh, S. Impact of SRT on the Performance of MBRs for the Treatment of High Strength Landfill Leachate. Waste Manag. 2018, 73, 165–180. [Google Scholar] [CrossRef] [PubMed]

- Campo, R.; Capodici, M.; Di Bella, G.; Torregrossa, M. The Role of EPS in the Foaming and Fouling for a MBR Operated in Intermittent Aeration Conditions. Biochem. Eng. J. 2017, 118, 41–52. [Google Scholar] [CrossRef]

- Singh, N.K.; Pandey, S.; Singh, R.P.; Dahiya, S.; Gautam, S.; Kazmi, A.A. Effect of Intermittent Aeration Cycles on EPS Production and Sludge Characteristics in a Field Scale IFAS Reactor. J. Water Process Eng. 2018, 23, 230–238. [Google Scholar] [CrossRef]

- Santinelli, M.; Eusebi, A.L.; Cola, E.; Battistoni, P. A Hybrid DenitrificationÀAlternate Cycles Reactor To Enhance the Nitrogen Biological Removal in a Real Wastewater Treatment Plant. Ind. Eng. Chem. Res. 2011, 50, 13947–13953. [Google Scholar] [CrossRef]

- Siegrist, H.; Brunner, I.; Koch, G.; Phan, L.C.; Van Le, C. Reduction of Biomass Decay Rate under Anoxic and Anaerobic Conditions. Water Sci. Technol. 1999, 39, 129–137. [Google Scholar] [CrossRef]

| Before Revamping | After Revamping | |||||

|---|---|---|---|---|---|---|

| Parameter | Mean Value ± SD | Minimum | Maximum | Mean Value ± SD | Minimum | Maximum |

| pH | 8.1 ± 0.3 | 7.02 | 8.76 | 8.2 ± 0.21 | 7.45 | 8.87 |

| TSSs (mg·L−1) | 421 ± 808 | 55 | 7592 | 657 ± 629 | 142 | 6561 |

| COD (mg·L−1) | 9676 ± 4544 | 1649 | 34,767 | 6350 ± 2184 | 2676 | 27,233 |

| BOD5 (mg·L−1) | 3160 ± 1353 | 698 | 6333 | 2212 ± 1090 | 725 | 5920 |

| TN (mg·L−1) | 1826 ± 437 | 621 | 3205 | 1510 ± 463 | 656 | 5693 |

| N-NH4+ (mg·L−1) | 1404 ± 385 | 206 | 2593 | 1197 ± 373 | 186 | 4412 |

| N-NO3− (mg·L−1) | 13.5 ± 12.7 | 0.05 | 95 | 20 ± 20 | 0.05 | 233 |

| N-NO2− (mg·L−1) | 1.7 ± 2.3 | 0.05 | 25 | 0.17 ± 1.75 | 0.05 | 29.7 |

| TP (mg·L−1) | 47.1 ± 28.6 | 12 | 193 | 42 ± 26 | 7.68 | 195 |

| Before Revamping | After Revamping | |||||

|---|---|---|---|---|---|---|

| Parameter | Mean Value | Minimum | Maximum | Mean Value | Minimum | Maximum |

| MLSSs (g·L−1) | 23.8 | 16.6 | 30.5 | 24.0 | 18.3 | 31.2 |

| Waste flow rate (TSSs/year) | 415 | 250 | 528 | 188 | 126 | 240 |

| SRT (d) | 311 | 57 | 1583 | 254 | 142 | 548 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palli, L.; Tuci, F.; Franca, L.M.L.; Fibbi, D.; Gori, R. Revamping of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment Using Partial Nitritation. Membranes 2024, 14, 115. https://doi.org/10.3390/membranes14050115

Palli L, Tuci F, Franca LML, Fibbi D, Gori R. Revamping of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment Using Partial Nitritation. Membranes. 2024; 14(5):115. https://doi.org/10.3390/membranes14050115

Chicago/Turabian StylePalli, Laura, Francesca Tuci, Letizia Macellaro La Franca, Donatella Fibbi, and Riccardo Gori. 2024. "Revamping of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment Using Partial Nitritation" Membranes 14, no. 5: 115. https://doi.org/10.3390/membranes14050115

APA StylePalli, L., Tuci, F., Franca, L. M. L., Fibbi, D., & Gori, R. (2024). Revamping of a Full-Scale Membrane Plant for Landfill Leachate Pretreatment Using Partial Nitritation. Membranes, 14(5), 115. https://doi.org/10.3390/membranes14050115