New Sustainable Multilayered Membranes Based on ZrVTi for Hydrogen Purification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Membrane Preparation

2.2. Characterization

2.3. Life Cycle Assessment

3. Results and Discussion

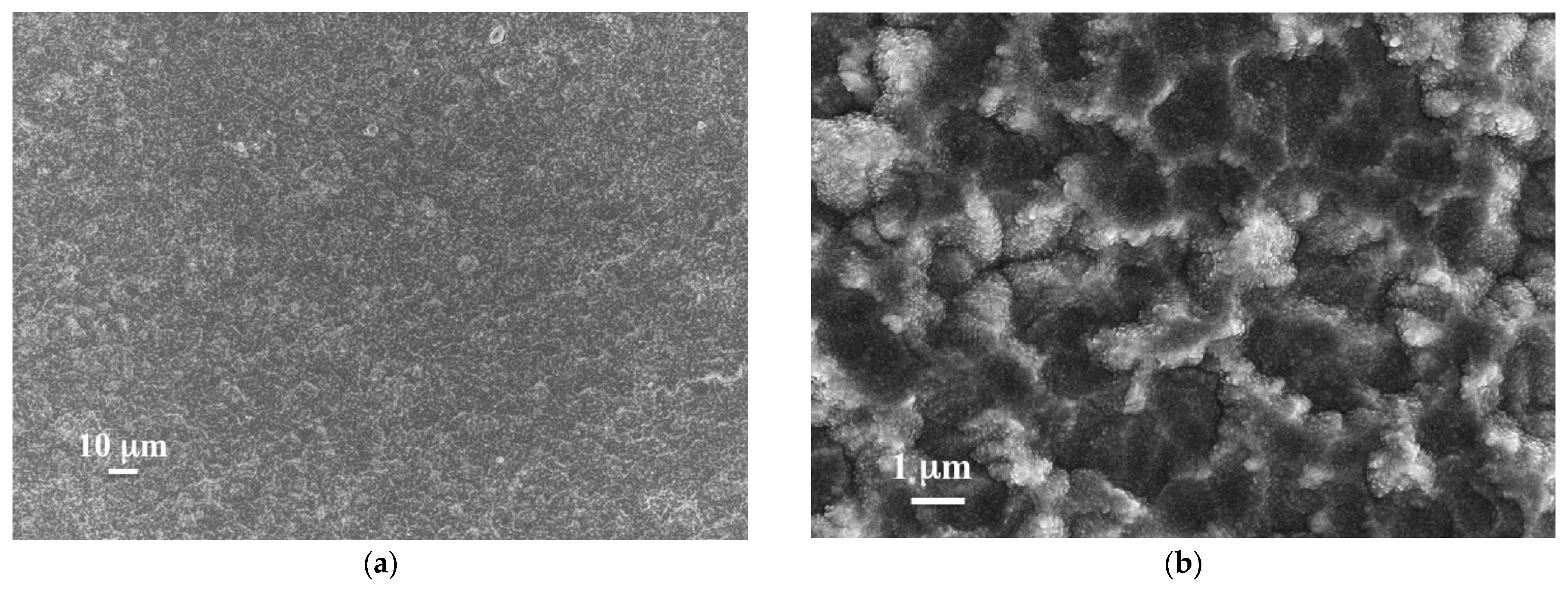

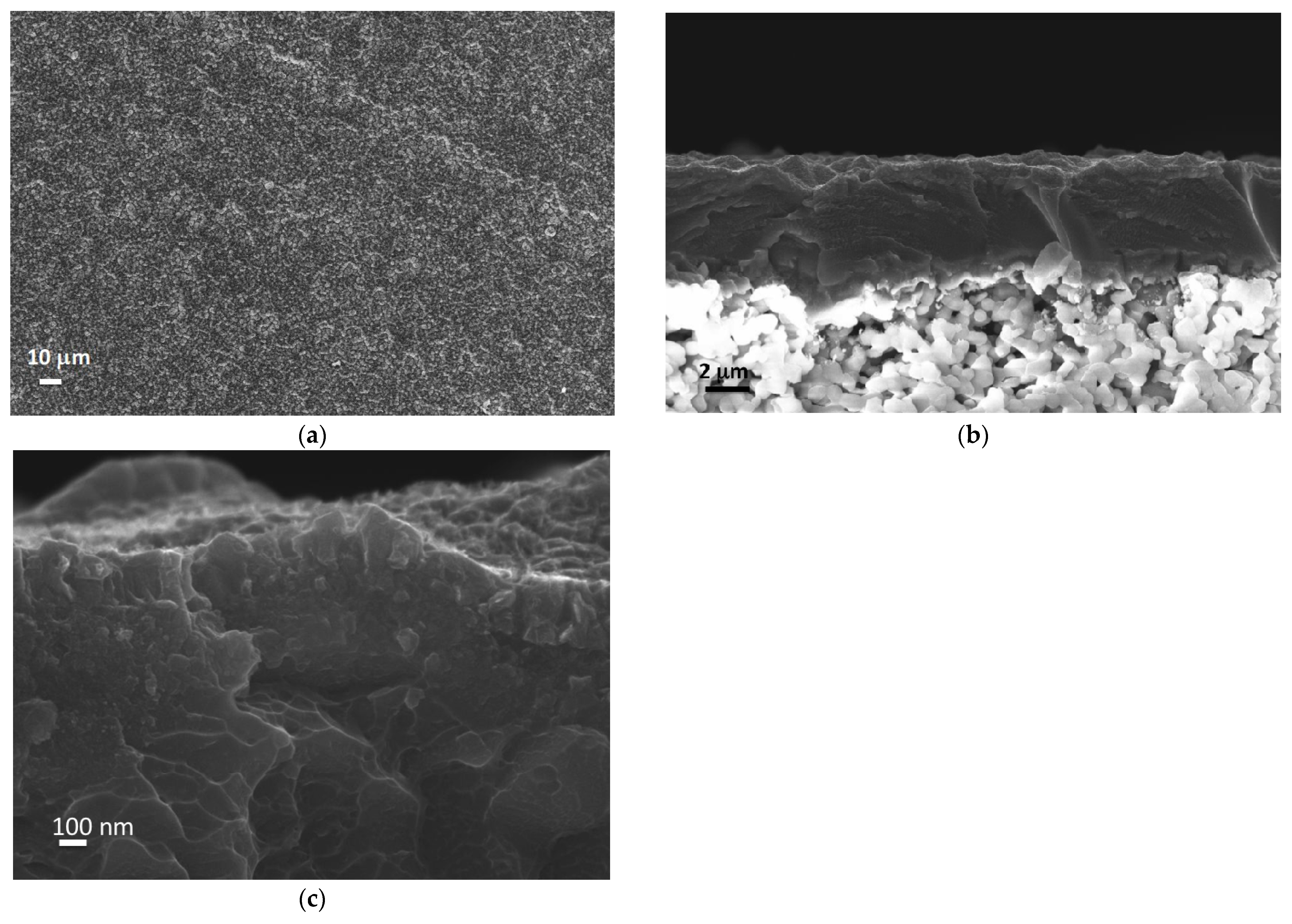

3.1. Membrane Development

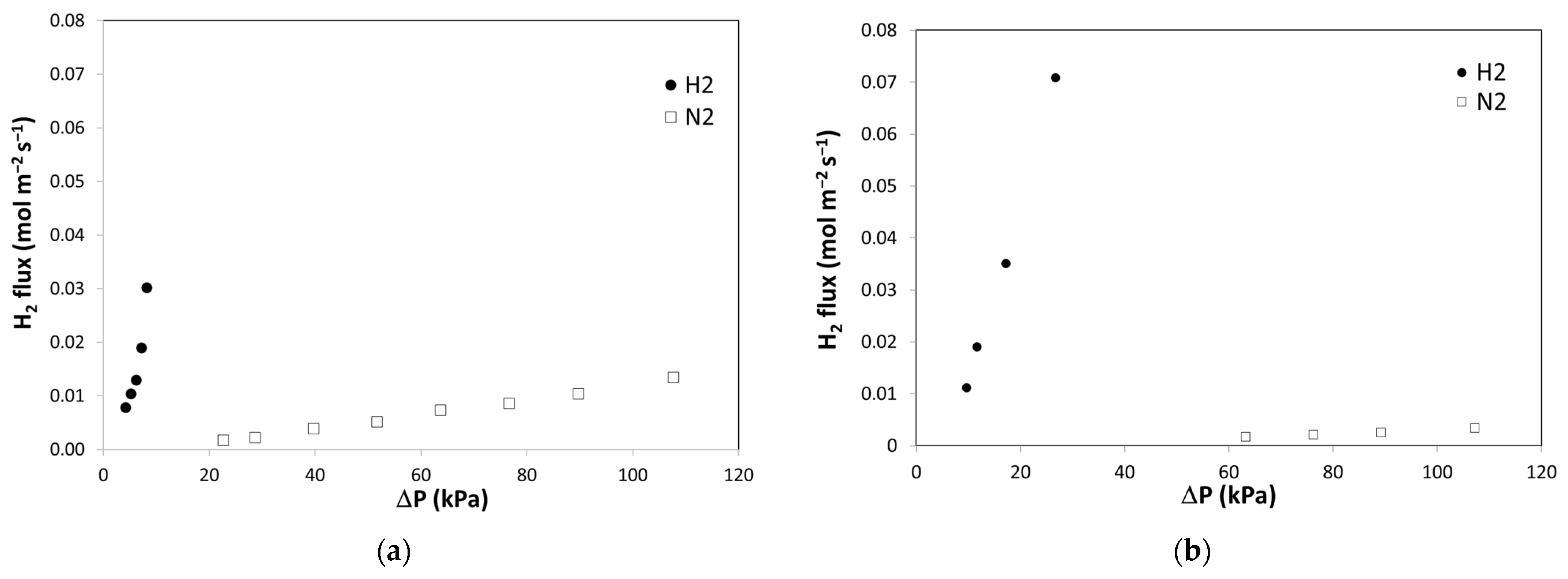

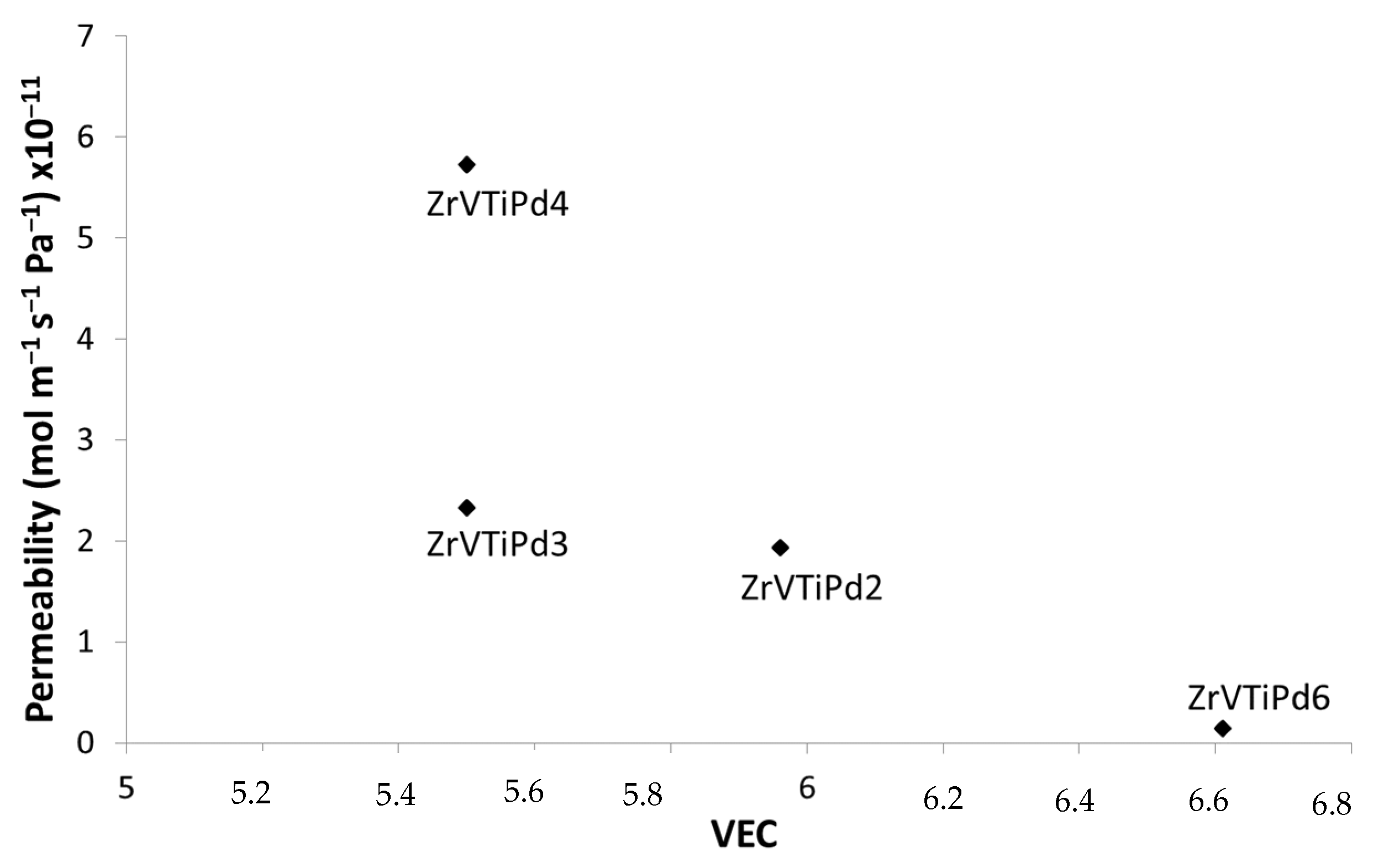

3.2. Functional Characterization

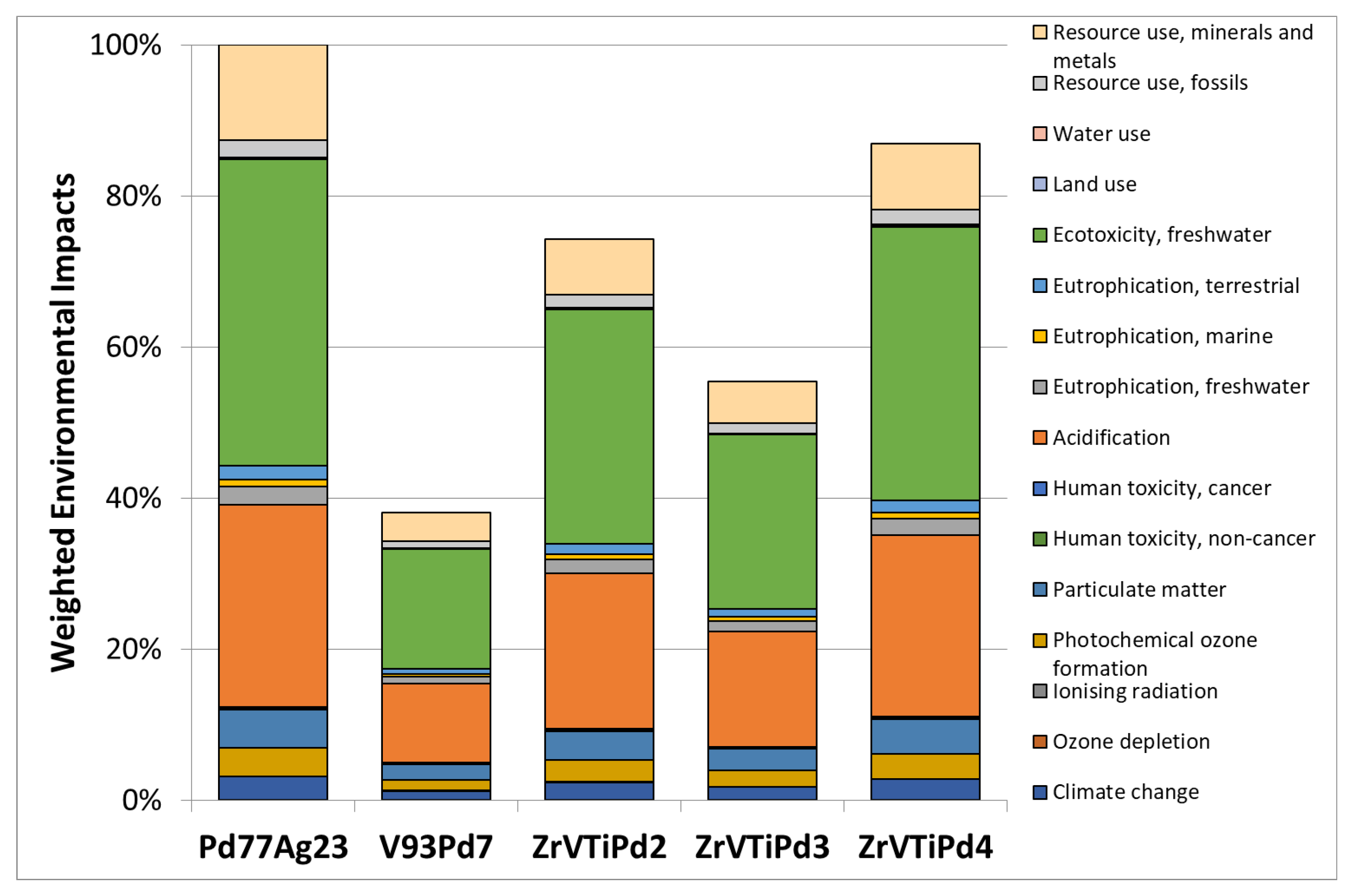

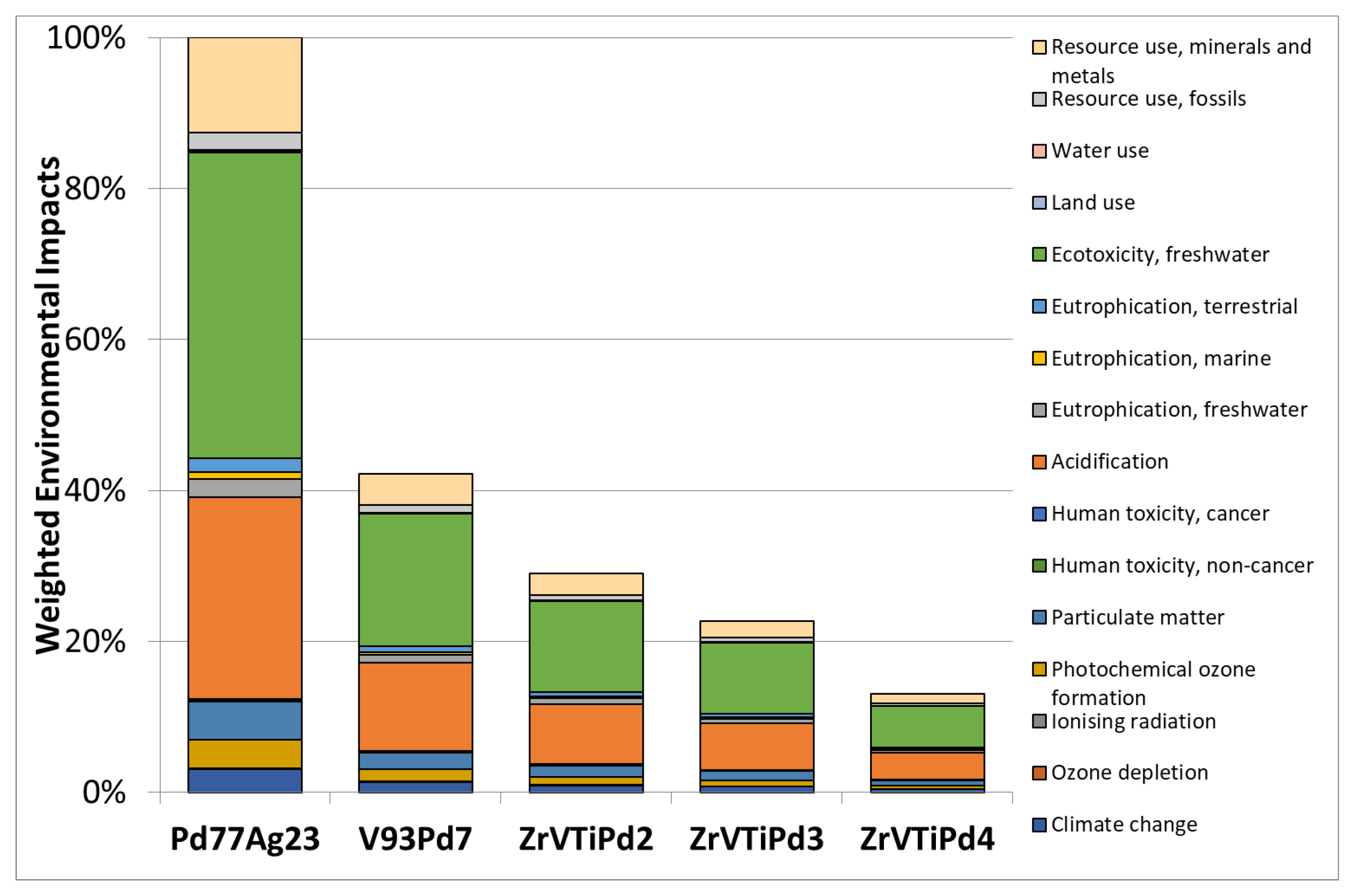

3.3. Comparative Life Cycle Assessment Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- COM/2020/301 Final; A hydrogen strategy for a climate-neutral Europe. European Communication: Brussel, Belgium, 2020.

- Al-Mufachi, N.A.; Rees, N.V.; Steinberger-Wilkens, R. Hydrogen selective membranes: A review of palladium-based dense metal membrane. Renew. Sustain. Energ. Rev. 2015, 47, 540–551. [Google Scholar] [CrossRef]

- Sjardin, M.; Damen, K.J.; Faaij, A.P.C. Techno-economic prospects of small-scale membrane reactors in a future hydrogen-fuelled transportation sector. Energy 2006, 31, 2523–2555. [Google Scholar] [CrossRef] [Green Version]

- Phair, J.W.; Donelson, R. Developments and Design of Novel (Non-Palladium-Based) Metal Membranes for Hydrogen Separation. Ind. Eng. Chem. Res. 2006, 45, 5657–5674. [Google Scholar] [CrossRef]

- Dolan, M.D. Non-Pd bcc alloy membranes for industrial hydrogen separation. J. Membr. Sci. 2010, 362, 12–28. [Google Scholar] [CrossRef]

- Osaki, T.; Zhang, Y.; Komaki, M.; Nishimura, C. Preparation of palladium-coated V and V–15Ni membranes for hydrogen purification by electroless plating technique. Int. J. Hydrogen Energy 2003, 28, 297–302. [Google Scholar] [CrossRef]

- Dolan, M.D.; McLennan, K.G.; Song, G.; Liang, D.; Kellam, M.E. The effect of Ti on hydrogen absorption and diffusivity in V–Ti–Al alloy membranes. J. Membr. Sci. 2013, 446, 405–409. [Google Scholar] [CrossRef]

- Dolan, M.D.; Kellam, M.E.; McLennan, K.G.; Liang, D.; Song, G. Hydrogen transport properties of several vanadium-based binary alloys. Int. J. Hydrogen Energy 2013, 38, 9794–9799. [Google Scholar] [CrossRef]

- Kim, K.H.; Park, H.C.; Lee, J.; Cho, E.; Lee, S.M. Vanadium alloy membranes for high hydrogen permeability and suppressed hydrogen embrittlement. Scr. Mater. 2013, 68, 905–908. [Google Scholar] [CrossRef]

- Matsuka, M.; Higashi, M.; Ishihara, T. Hydrogen production from methane using vanadium-based catalytic membrane reactors. Int. J. Hydrogen Energy 2013, 38, 6673–6680. [Google Scholar] [CrossRef]

- Moss, T.S.; Peachey, N.M.; Snow, R.C.; Dye, R.C. Multilayer metal membranes for hydrogen separation. Int. J. Hydrogen Energy 1998, 23, 99–106. [Google Scholar] [CrossRef]

- Buxbaum, R.E.; Subramanian, R.; Park, J.H.; Smith, D.L. Hydrogen transport and embrittlement for palladium coated vanadium—chromium—titanium alloys. J. Nucl. Mater. 1996, 233, 510–512. [Google Scholar] [CrossRef] [Green Version]

- Paglieri, S.N.; Wermer, J.R.; Buxbaum, R.E.; Ciocco, M.V.; Howard, B.H.; Morreale, B.D. Development of membranes for hydrogen separation: Pd coated V–10Pd. Energy Mater. 2008, 3, 169–176. [Google Scholar] [CrossRef]

- Alimov, V.N.; Busnyuk, A.O.; Notkin, M.E.; Peredistov, E.Y.; Livshits, A.I. Substitutional V–Pd alloys for the membranes permeable to hydrogen: Hydrogen solubility at 150–400 °C. Int. J. Hydrogen Energy 2014, 39, 19682–19690. [Google Scholar] [CrossRef]

- Fasolin, S.; Barison, S.; Boldrini, S.; Ferrario, A.; Romano, M.; Montagner, F.; Miorin, E.; Fabrizio, M.; Armelao, L. Hydrogen separation by thin vanadium-based multi-layered membranes. Int. J. Hydrogen Energy 2018, 43, 3235–3243. [Google Scholar] [CrossRef]

- Pickering, L.; Lototskyy, M.V.; Davids, M.W.; Sita, C.; Linkov, V. Induction melted AB(2)-type metal hydrides for hydrogen storage and compression applications. Mater. Today Proc. 2018, 5, 10470–10478. [Google Scholar] [CrossRef]

- Banerjee, S.; Kumar, A.; Ruz, P.; Sengupta, P. Influence of Laves phase on microstructure and hydrogen storage properties of Ti–Cr–V based alloy. Int. J. Hydrogen Energy 2016, 41, 18130–18140. [Google Scholar] [CrossRef]

- Kunce, I.; Polanski, M.; Bystrzycki, J. Structure and hydrogen storage properties of a high entropy ZrTiVCrFeNi alloy synthesized using Laser Engineered Net Shaping (LENS). Int. J. Hydrogen Energy 2013, 38, 12180–12189. [Google Scholar] [CrossRef]

- Sahlberg, M.; Karlsson, D.; Zlotea, C.; Jansson, U. Superior hydrogen storage in high entropy alloys. Sci. Rep. 2016, 6, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Nygård, M.M.; Ek, G.; Karlsson, D.; Sahlberg, M.; Sørby, M.H.; Hauback, B.C. Hydrogen storage in high-entropy alloys with varying degree of local lattice strain. Int. J. Hydrogen Energy 2019, 44, 29140–29149. [Google Scholar] [CrossRef] [Green Version]

- Switendick, A.C. Theoretical Studies of Hydrogen in Metals: Current Status and Further Prospects; Sandia Labs.: Albuquerque, NM, USA, 1978. [Google Scholar] [CrossRef] [Green Version]

- Westlake, D.G. A geometric model for the stoichiometry and interstitial site occupancy in hydrides (deuterides) of LaNi5, LaNi4Al and LaNi4Mn. J. Less-Common Met. 1983, 91, 275–292. [Google Scholar] [CrossRef]

- Young, K.; Nei, J.; Huang, B.; Fetcenko, M.A. Studies of off-stoichiometric AB2 metal hydride alloy: Part 2. Hydrogen storage and electrochemical properties. Int. J. Hydrogen Energy 2011, 36, 11146–11154. [Google Scholar] [CrossRef]

- Young, K.; Ouchi, T.; Yang, J.; Fetcenko, M.A. Studies of off-stoichiometric AB2 metal hydride alloy: Part 1. Structural characteristics. Int. J. Hydrogen Energy 2011, 36, 11137–11145. [Google Scholar] [CrossRef]

- Yun, S.; Oyama, S.T. Correlations in palladium membranes for hydrogen separation: A review. J. Membr. Sci. 2011, 375, 28–45. [Google Scholar] [CrossRef]

- Yukawa, H.; Nambu, T.; Matsumoto, Y. V–W alloy membranes for hydrogen purification, J. Alloys Compd. 2011, 509, S881–S884. [Google Scholar] [CrossRef]

- Peters, T.A.; Stange, M.; Bredesen, R. Palladium Membrane Technology for Hydrogen Production, Carbon Capture and Other Applications; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Barison, S.; Fasolin, S.; Boldrini, S.; Ferrario, A.; Romano, M.; Montagner, F.; Deambrosis, S.M.; Fabrizio, M.; Armelao, L. PdAg/alumina membranes prepared by high power impulse magnetron sputtering for hydrogen separation. Int. J. Hydrogen Energy 2018, 43, 7982–7989. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Lundin, D.; Sarakinos, K.J. An introduction to thin film processing using high-power impulse magnetron sputtering. Mater. Res. 2012, 27, 780–792. [Google Scholar] [CrossRef] [Green Version]

- Lutterotti, L.; Mattheis, S.; Wenk, H.R. MAUD (Materials Analysis Using Diffraction): A user friendly Java program for Ritveld Texture Analysis and more. In Proceedings of the Twelfth International Conference on Textures of Materials (ICOTOM-12), Montreal, QC, Canada, 9–13 August 1999; p. 1599. [Google Scholar]

- Kroll, W. The Production of Ductile Titanium. Trans. Electrochem. Soc. 1940, 78, 35. [Google Scholar] [CrossRef]

- Nuss, P.; Eckelman, M.J. Life cycle assessment of metals: A scientific synthesis. PLoS ONE 2014, 9, e101298. [Google Scholar] [CrossRef]

- da Silva Lima, L.; Quartier, M.; Buchmayr, A.; Sanjuan-Delmás, D.; Laget, H.; Corbisier, D.; Mertens, J.; Dewulf, J. Life cycle assessment of lithium-ion batteries and vanadium redox flow batteries-based renewable energy storage systems. Sustain. Energy Technol. Assess. 2021, 46, 101286. [Google Scholar] [CrossRef]

- 2013/179/EU; Recommendation of 9 April 2013 on the use of common methods to measure and communicate the life cycle environmental performance of products and organisations. European Commission: Brussel, Belgium, 2013.

- Thornton, J.A. High Rate Thick Film Growth. An. Rev. Mat. Sci. 1977, 7, 239. [Google Scholar] [CrossRef]

- Xing, Q.; Zhang, Y. Amorphous phase formation rules in high-entropy alloys. Chin. Phys. B 2017, 26, 018104. [Google Scholar] [CrossRef]

- Guazzone, F. Engineering of Substrate Surface for the synthesis of Ultra-Thin Composite Pd and Pd-Cu Membranes for H2 Separation. Ph.D. Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2005. [Google Scholar]

- Maneerung, T.; Hidajat, K.; Kawi, S. Ultra-thin (<1 µm) internally-coated Pd–Ag alloy hollow fiber membrane with superior thermal stability and durability for high temperature H2 separation. J. Membr. Sci. 2014, 452, 127–142. [Google Scholar]

- Morreale, B.D.; Ciocco, M.V.; Enick, R.M.; Morsi, B.I.; Howard, B.H.; Cugini, A.V.; Rothenberger, K.S. The permeability of hydrogen in bulk palladium at elevated temperatures and pressures. J. Membr. Sci. 2003, 212, 87–97. [Google Scholar] [CrossRef]

- Guazzone, F.; Ma, Y.H. Leak growth mechanism in composite Pd membranes prepared by the electroless deposition method. AiCHE J. 2008, 54, 487–492. [Google Scholar] [CrossRef]

- Ward, T.L.; Dao, T. Model of hydrogen permeation behavior in palladium membranes. J. Membr. Sci. 1999, 153, 211–231. [Google Scholar] [CrossRef]

- Nygård, M.M.; Ek, G.; Karlsson, D.; Sørby, M.H.; Sahlberg, M.; Hauback, B.C. Counting electrons – a new approach to tailor the hydrogen sorption properties of high-entropy alloys. Acta Mater. 2019, 175, 121–129. [Google Scholar] [CrossRef]

| Sample Name | VTi Target Power (W) | Zr Target Power (W) | Pd Target Power (W) | Multilayer Thickness (µm) | Composition (at%) |

|---|---|---|---|---|---|

| ZrVTi1 | 400 | 100 | -- | 5.4 | Zr 35 |

| V 34 | |||||

| Ti 31 | |||||

| ZrVTi2 | 400 | 35 | -- | 5.3 | Zr 21 |

| V 42 | |||||

| Ti 37 | |||||

| ZrVTiPd1 | 400 | 100 | 15 | 7.4 | Zr 19 |

| V 36 | |||||

| Ti 26 | |||||

| Pd 19 | |||||

| ZrVTiPd2 | 400 | 35 | 15 | 5.3 | Zr 9 |

| V 34 | |||||

| Ti 30 | |||||

| Pd 27 | |||||

| ZrVTiPd3 | 130 | 260 | 15 | 6.7 | Zr 52 |

| V 12 | |||||

| Ti 13 | |||||

| Pd 23 | |||||

| ZrVTiPd4 | 250 | 130 | 15 | 7.1 | Zr 39 |

| V 20 | |||||

| Ti 19 | |||||

| Pd 22 | |||||

| ZrVTiPd5 | 100 | 300 | 15 | 7.8 | Zr 61 |

| V 9 | |||||

| Ti 9 | |||||

| Pd 21 | |||||

| ZrVTiPd6 | 400 | 35 | 20 | 5.2 | Zr 11 |

| V 27 | |||||

| Ti 23 | |||||

| Pd 39 |

| Sample | Composition (at%) | Permeance (mol m−2 s−1 Pa−1) | Hydrogen Embrittlement | Selectivity (Permeance H2/Permeance N2) |

|---|---|---|---|---|

| ZrVTi1 | Zr 35 V 34 Ti 31 | ∆P~0 kPa | ||

| ZrVTi2 | Zr 21 V 42 Ti 37 | ∆P~0 kPa | ||

| ZrVTiPd1 | Zr 19 V 36 Ti 26 Pd 19 | ∆P~0 kPa | ||

| ZrVTiPd2 | Zr 9 V 34 Ti 30 Pd 27 | 3.49 × 10−6 at 350 °C | ∆P > 10 kPa | 50 |

| ZrVTiPd3 | Zr 52 V 12 Ti 13 Pd 23 | 3.48 × 10−6 at 350 °C | ∆P > 30 kPa | 100 |

| ZrVTiPd4 | Zr 39 V 20 Ti 19 Pd 22 | 8.07 × 10−6 at 300 °C | ∆P > 5 kPa ∆P~0 kPa for T > 300 °C | 75 |

| ZrVTiPd5 | Zr 61 V 9 Ti 9 Pd 21 | ∆P~0 kPa | ||

| ZrVTiPd6 | Zr 11 | 2.67 × 10−7 at 350 °C | ∆P > 300 kPa | 5 |

| V 27 | ||||

| Ti 23 | ||||

| Pd 39 |

| Sample | Permeance (mol m−2 s−1 Pa−1) | Quantity (kg) |

|---|---|---|

| Pd77Ag23 | 1.8 × 10−6 | 1 |

| V93Pd7 | 9.0 × 10−7 | 1.11 a |

| ZrVTiPd2 (Zr9V34Ti30Pd27) | 3.5 × 10−6 | 0.39 a |

| ZrVTiPd3 (Zr52V12Ti13Pd23) | 3.5 × 10−6 | 0.41 a |

| ZrVTiPd4 (Zr39V20Ti19Pd22) | 8.1 × 10−6 b | 0.15 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fasolin, S.; Barison, S.; Agresti, F.; Battiston, S.; Fiameni, S.; Isopi, J.; Armelao, L. New Sustainable Multilayered Membranes Based on ZrVTi for Hydrogen Purification. Membranes 2022, 12, 722. https://doi.org/10.3390/membranes12070722

Fasolin S, Barison S, Agresti F, Battiston S, Fiameni S, Isopi J, Armelao L. New Sustainable Multilayered Membranes Based on ZrVTi for Hydrogen Purification. Membranes. 2022; 12(7):722. https://doi.org/10.3390/membranes12070722

Chicago/Turabian StyleFasolin, Stefano, Simona Barison, Filippo Agresti, Simone Battiston, Stefania Fiameni, Jacopo Isopi, and Lidia Armelao. 2022. "New Sustainable Multilayered Membranes Based on ZrVTi for Hydrogen Purification" Membranes 12, no. 7: 722. https://doi.org/10.3390/membranes12070722

APA StyleFasolin, S., Barison, S., Agresti, F., Battiston, S., Fiameni, S., Isopi, J., & Armelao, L. (2022). New Sustainable Multilayered Membranes Based on ZrVTi for Hydrogen Purification. Membranes, 12(7), 722. https://doi.org/10.3390/membranes12070722