Effect of Clamping Compression on the Mechanical Performance of a Carbon Paper Gas Diffusion Layer in Polymer Electrolyte Membrane Fuel Cells

Abstract

:1. Introduction

2. Experimental Details

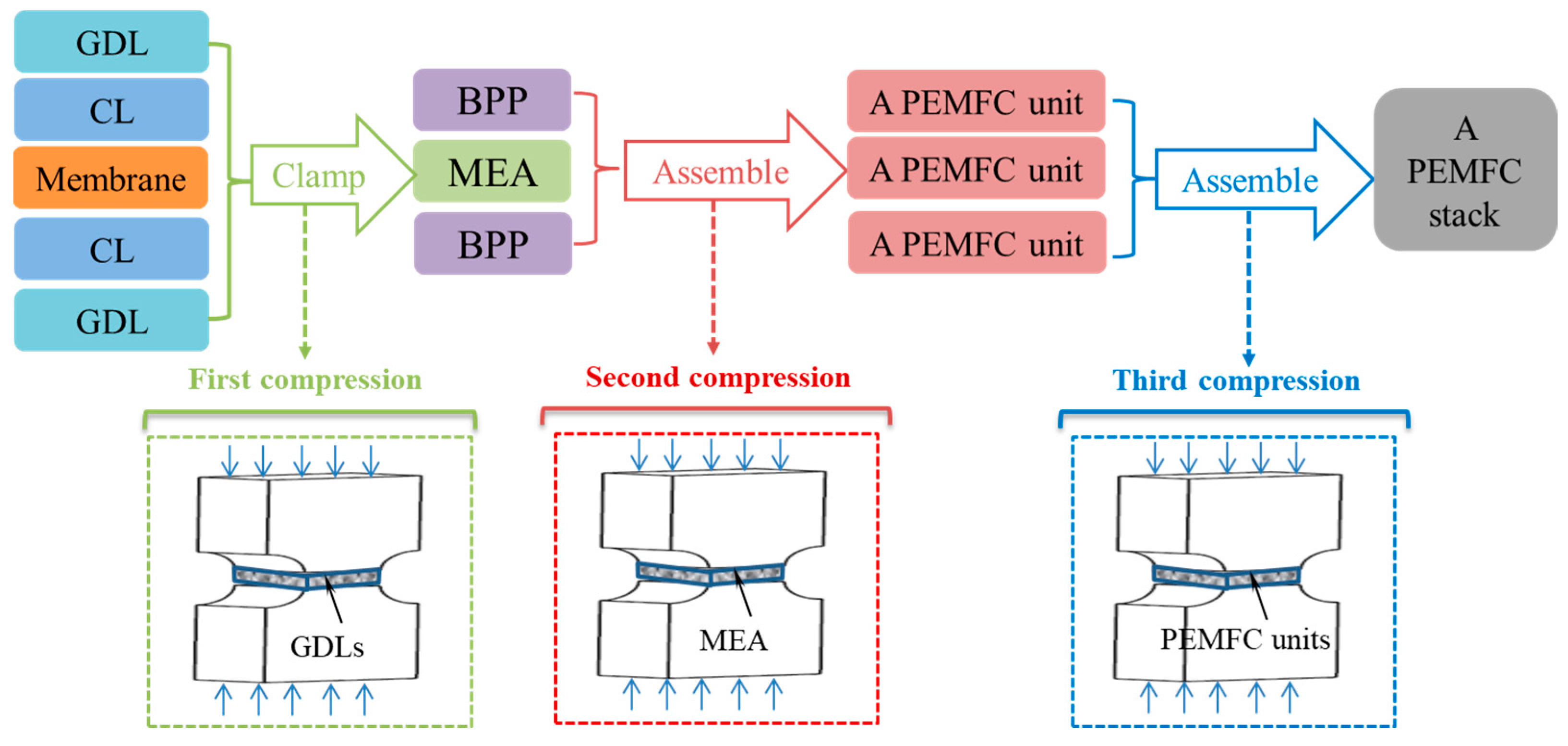

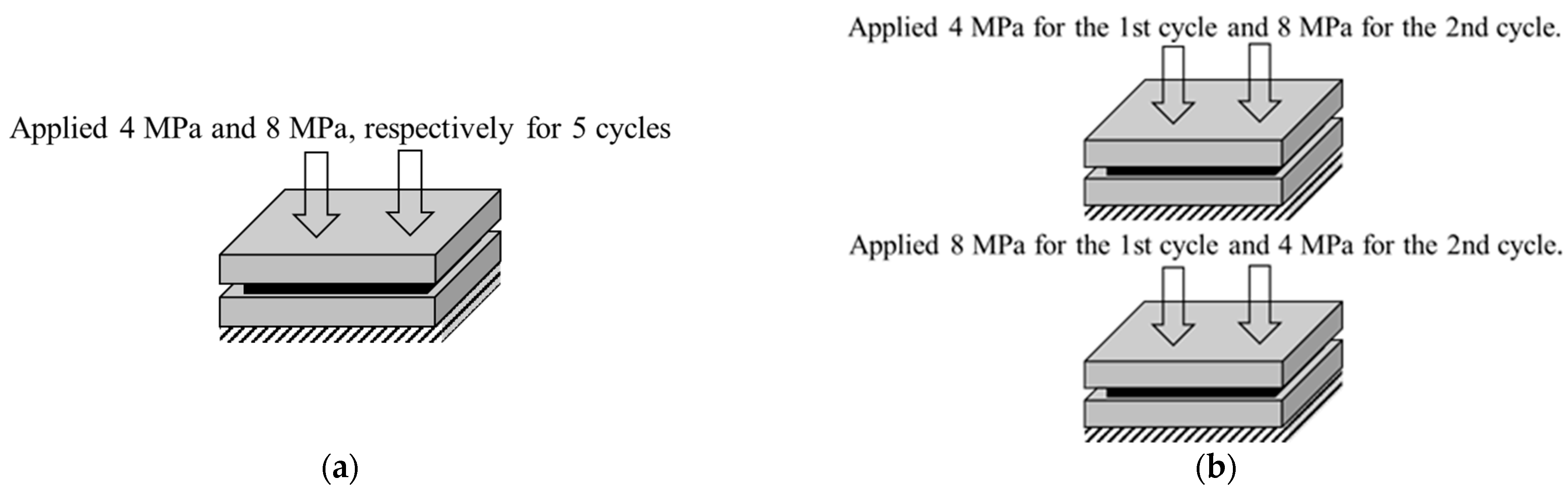

2.1. Clamping Compression Experiments

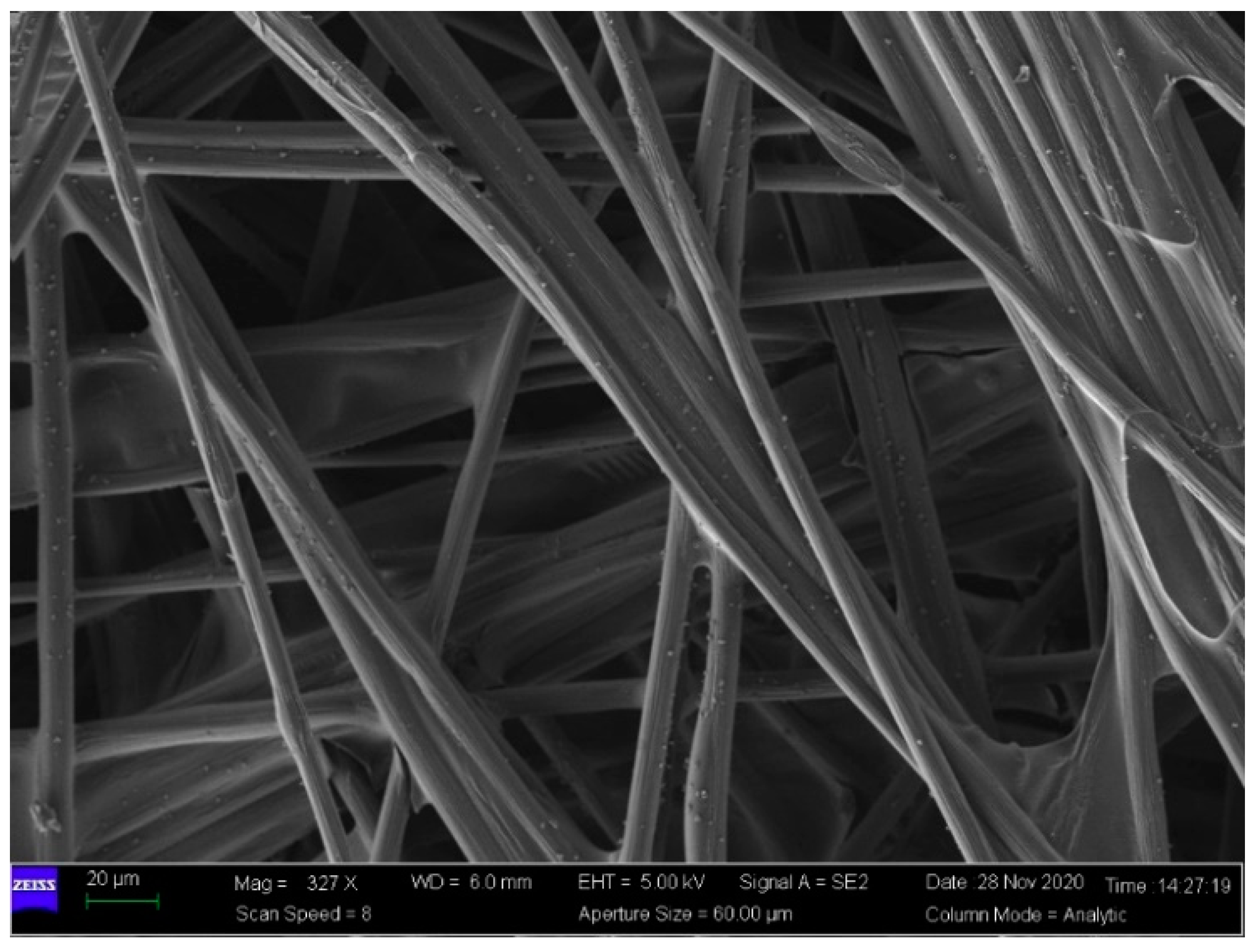

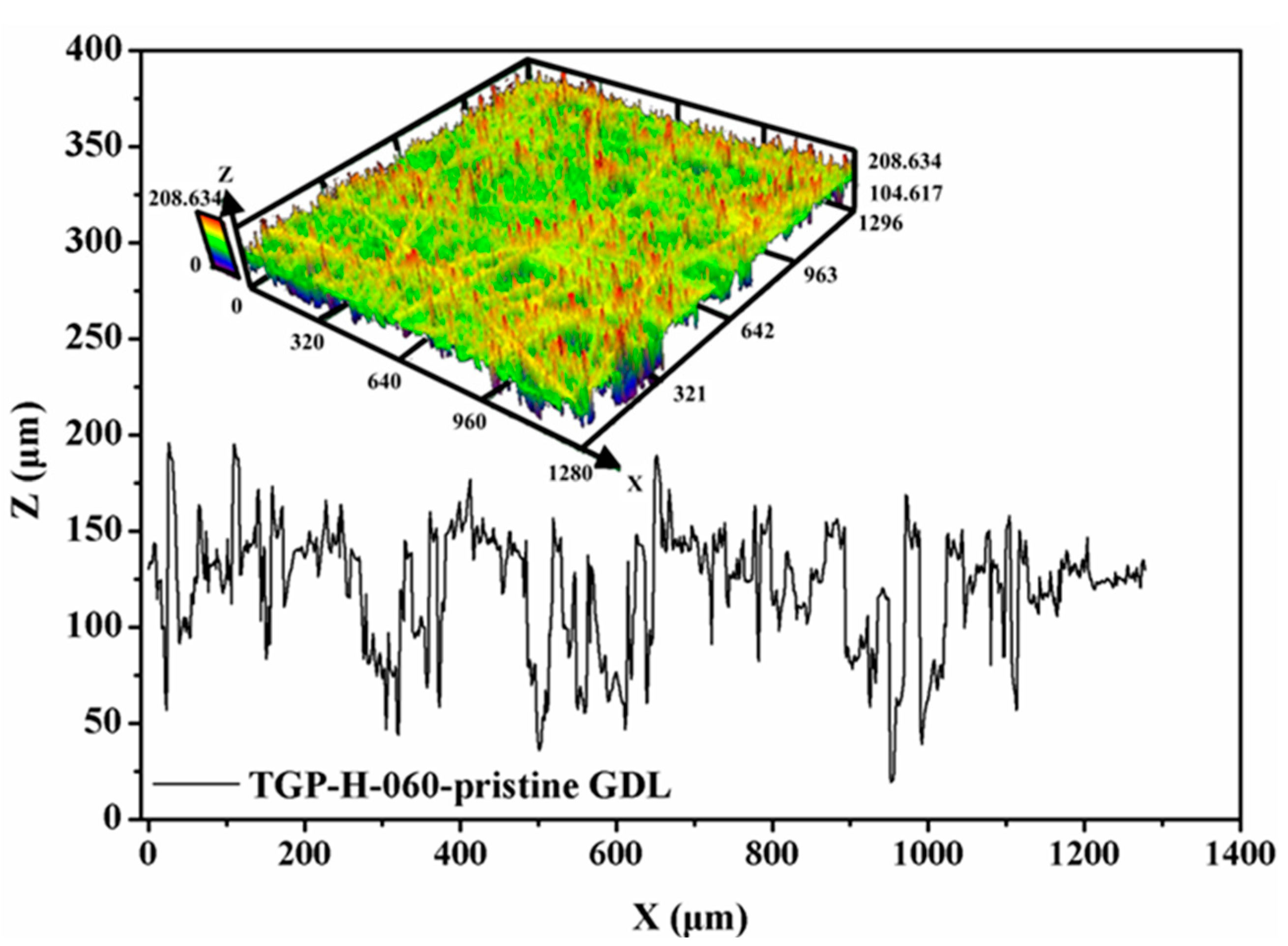

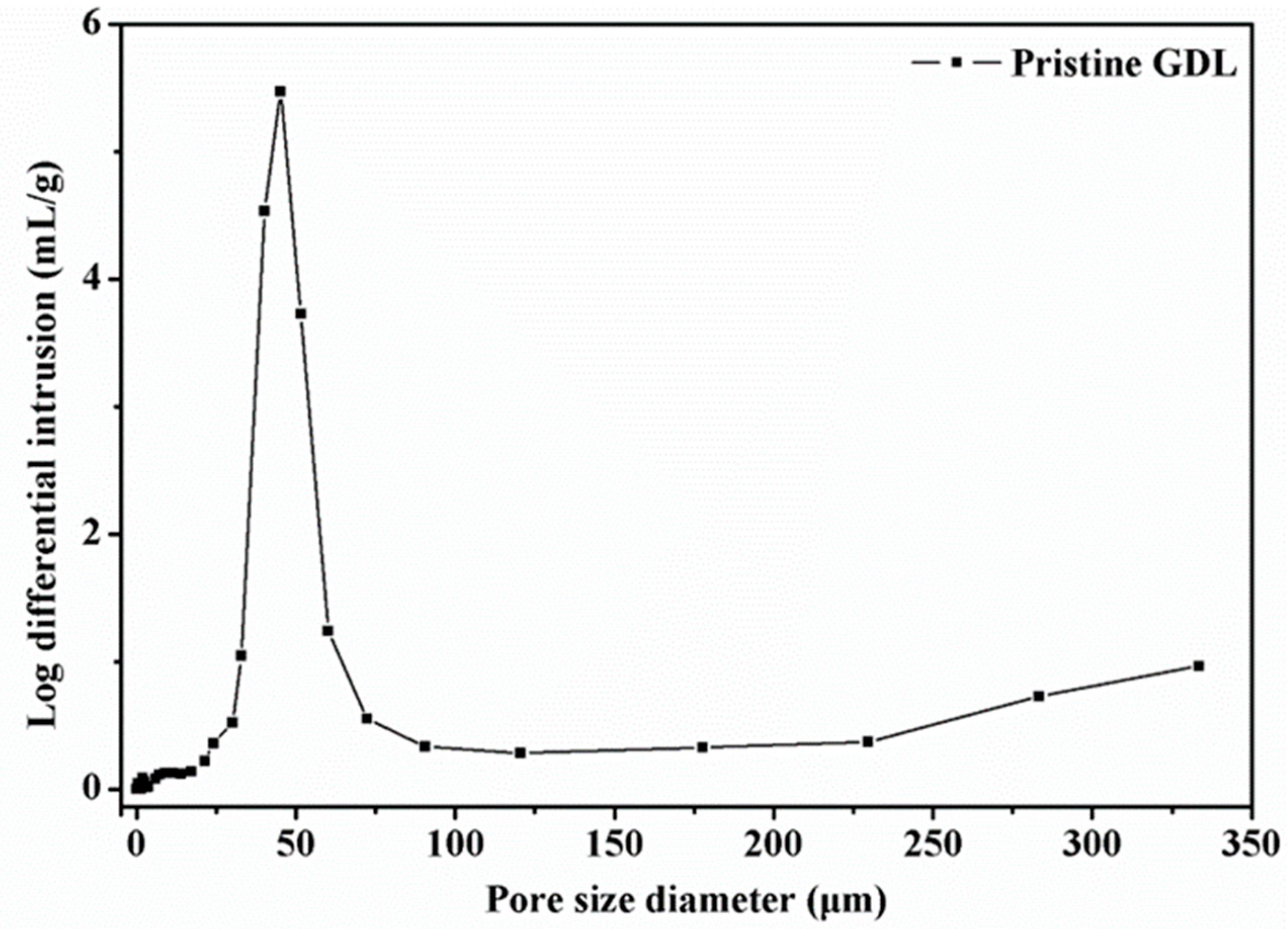

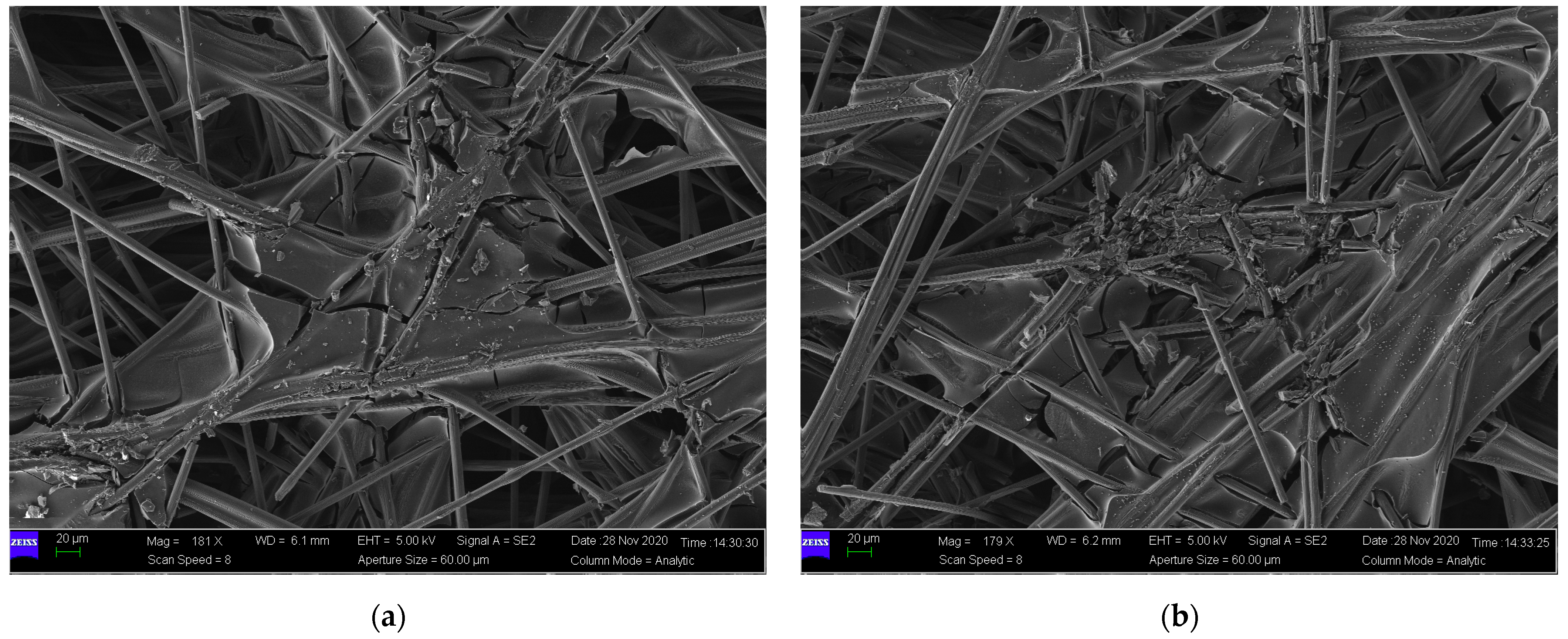

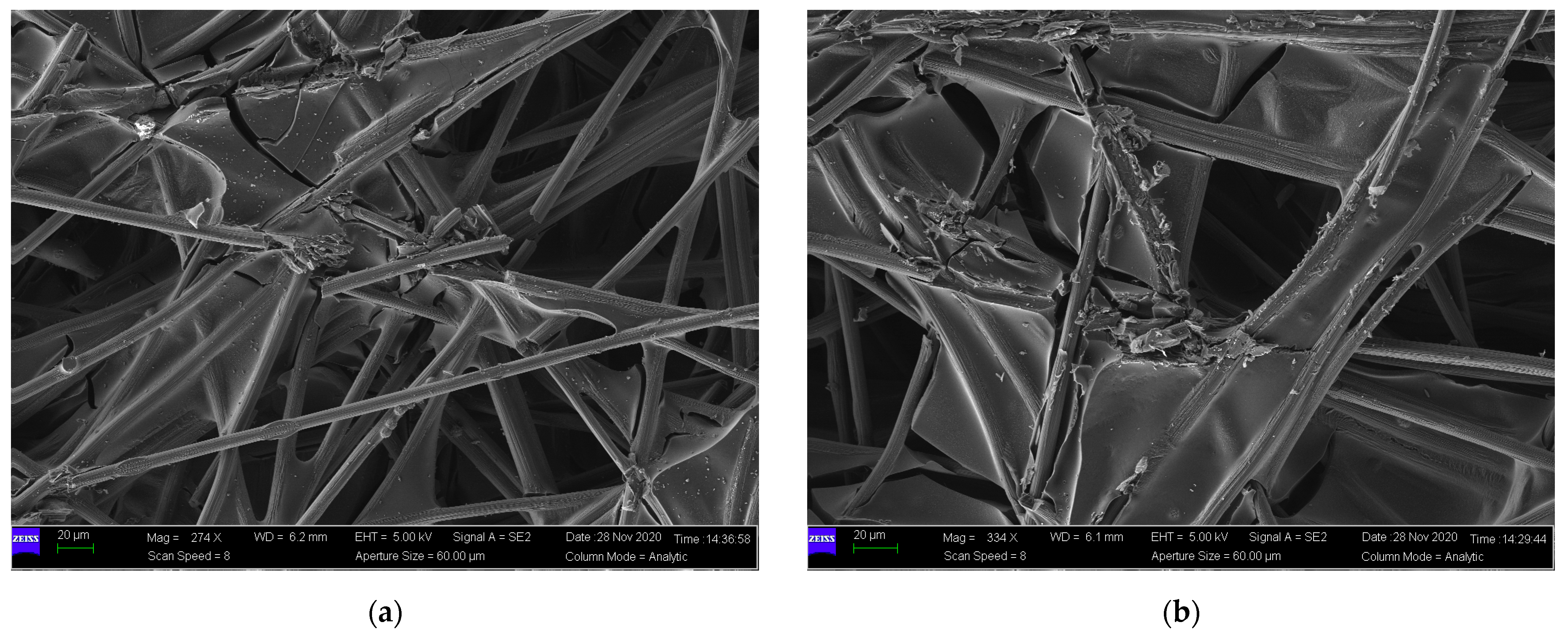

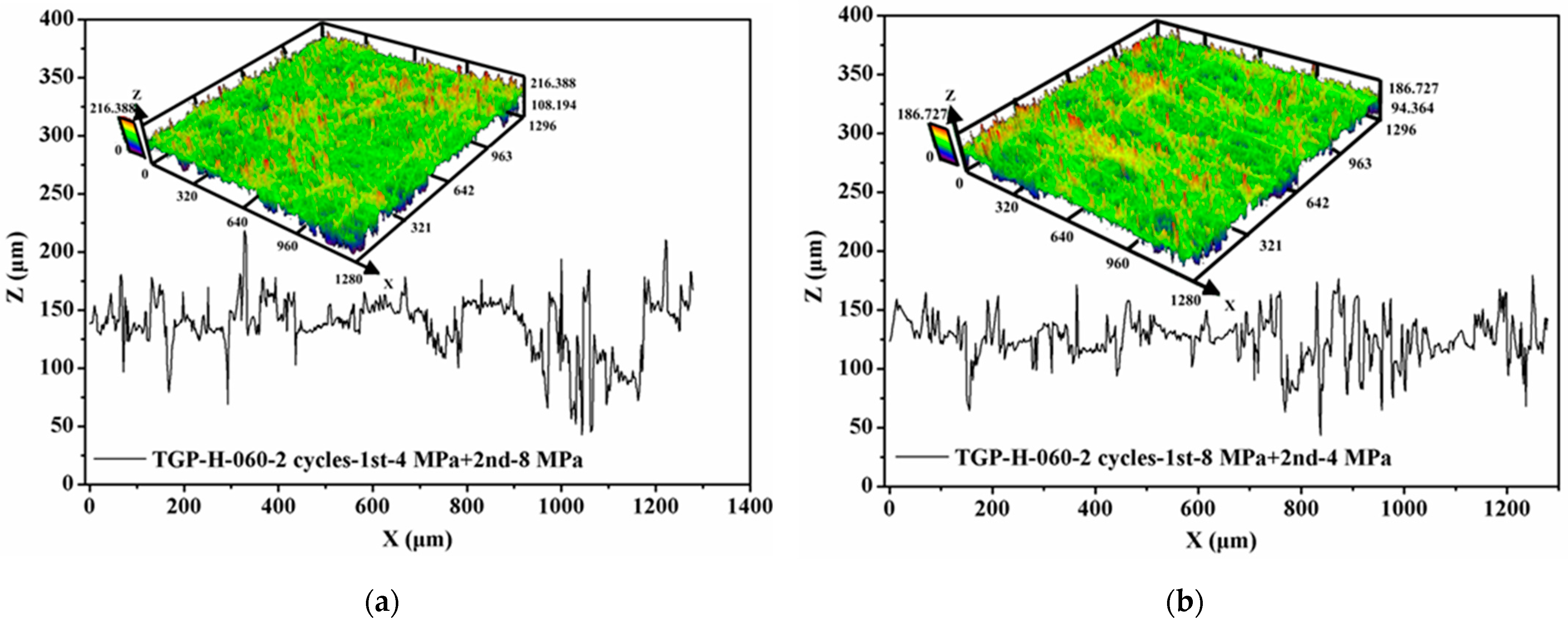

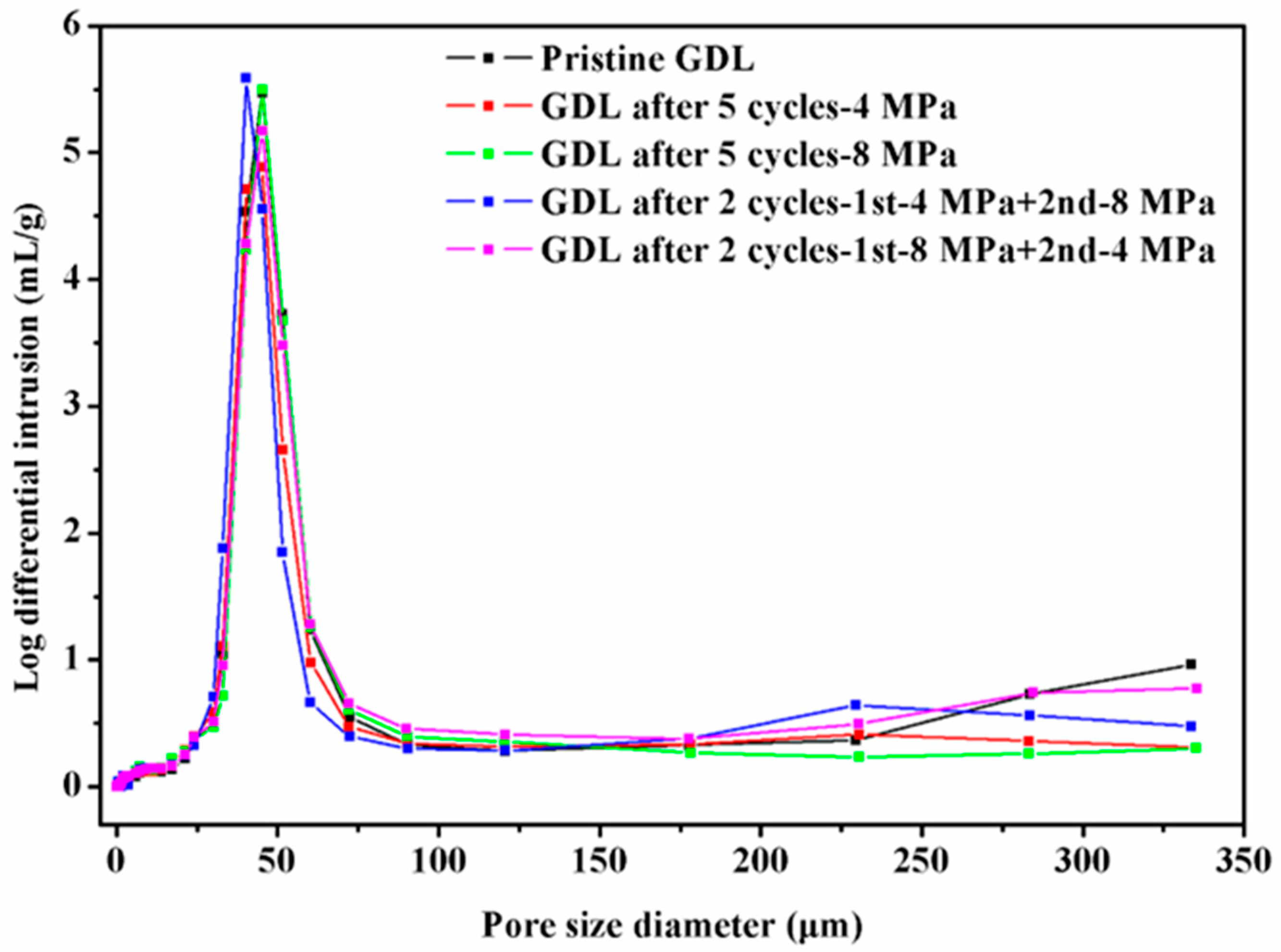

2.2. Structural Characterization of the Carbon Paper GDL

3. Results and Discussion

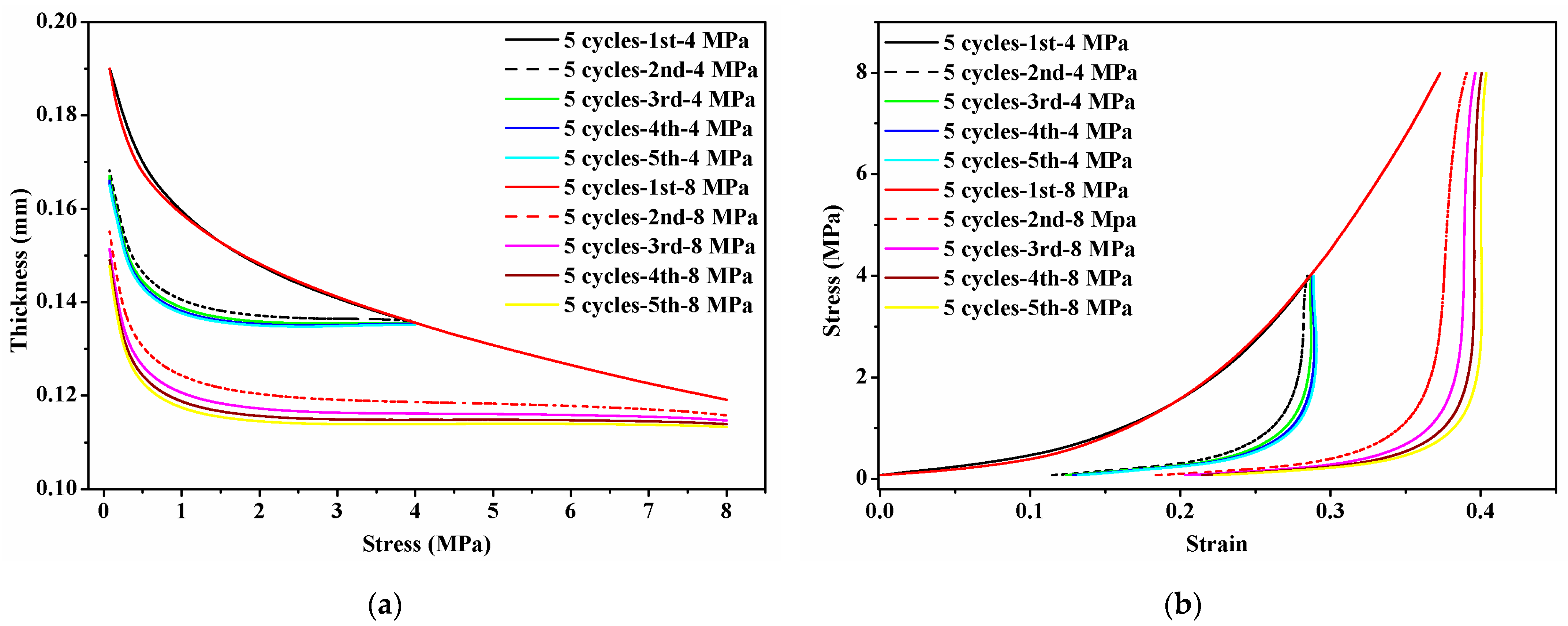

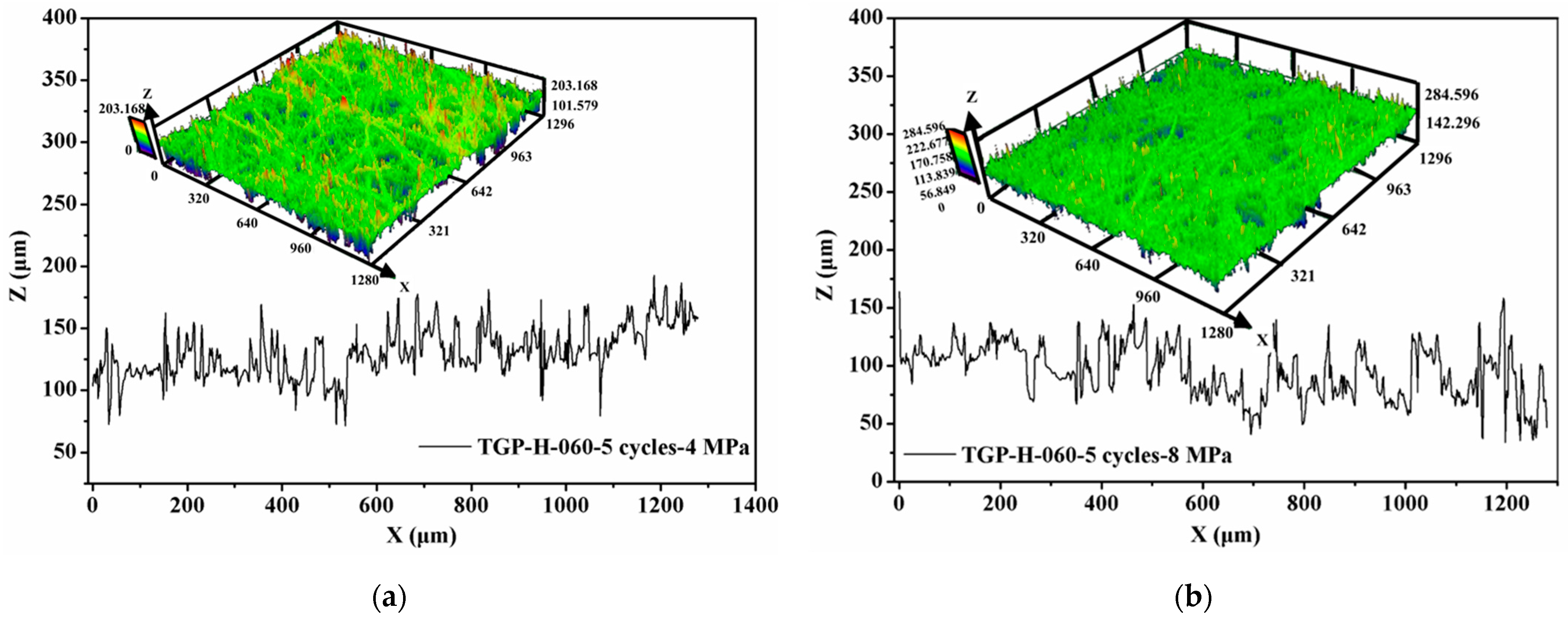

3.1. Mechanical Performance of GDLs under Cyclic Compression with Constant Maximum Clamping Loads

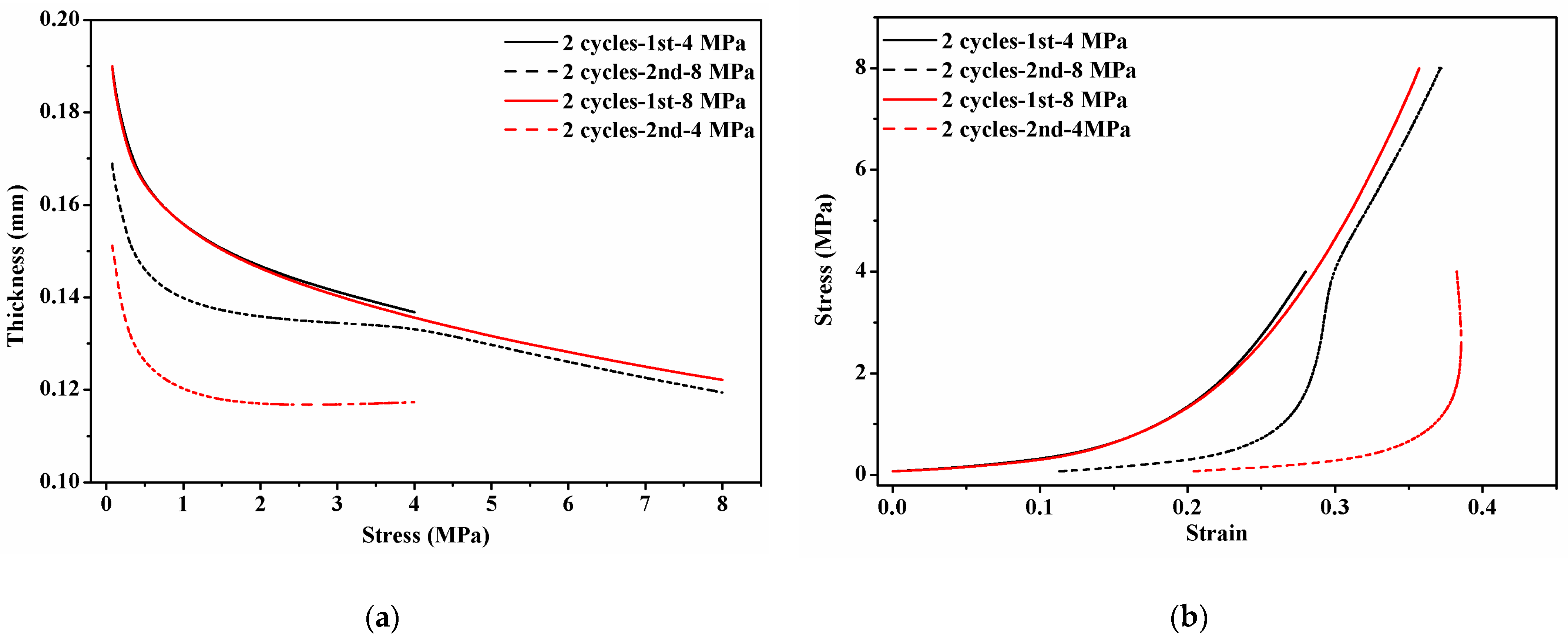

3.2. Mechanical Performance of GDLs under Repetitive Compression with Variable Maximum Clamping Loads

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yuan, X.Z.; Nayoze-Coynel, C.; Shaigan, N.; Fisher, D.; Zhao, N.; Zamel, N.; Gazdzicki, P.; Ulsh, M.; Friedrich, K.A.; Girard, F.; et al. A review of functions, attributes, properties and measurements for the quality control of proton exchange membrane fuel cell components. J. Power Sources 2021, 491, 229540. [Google Scholar] [CrossRef]

- Uzundurukan, A.; Bilgili, M.; Devrim, Y. Examination of compression effects on PEMFC performance by numerical and experimental analyses. Int. J. Hydrog. Energy 2020, 45, 35085–35096. [Google Scholar] [CrossRef]

- Chien, C.H.; Chen, L.C.; Chen, B.S.; Sun, J.H.; Li, S.J.; Che, J.W. Effect of bolts assembly on the deformation and pressure distribution of flow-channel plates in micro-PEMFC. Fuel Cells 2015, 15, 322–326. [Google Scholar] [CrossRef]

- Ashdot, A.; Kattan, M.; Kitayev, A.; Tal-Gutelmacher, E.; Amel, A.; Page, M. Design strategies for alkaline exchange membrane–electrode assemblies: Optimization for fuel cells and electrolyzers. Membranes 2021, 11, 686. [Google Scholar] [CrossRef]

- Shrivastava, N.K.; Chatterjee, A.; Harris, T.A.L. Effect of cell compression on the performance of a non–hot-pressed MEA for PEMFC. Int. J. Energy Res. 2020, 44, 370–387. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Y.; Han, C.; Zhang, H. Stress response and contact behavior of PEMFC during the assembly and working condition. Int. J. Hydrog. Energy 2021, 46, 30467–30478. [Google Scholar] [CrossRef]

- Tellez-Cruz, M.M.; Escorihuela, J.; Solorza-Feria, O.; Compañ, V. Proton exchange membrane fuel cells (pemfcs): Advances and challenges. Polymers 2021, 13, 3064. [Google Scholar] [CrossRef]

- Branco, C.M.; El-kharouf, A.; Du, S. Materials for Polymer Electrolyte Membrane Fuel Cells (PEMFCs): Eelectrolyte Membrane, Gas Diffusion Layers, and Bipolar Plates; Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–11. [Google Scholar] [CrossRef]

- Irmscher, P.; Qui, D.; Janßen, H.; Lehnert, W.; Stolten, D. Impact of gas diffusion layer mechanics on PEM fuel cell performance. Int. J. Hydrog. Energy 2019, 44, 23406–23415. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Y. Sealing performance and mechanical behavior of PEMFCs sealing system based on thermodynamic coupling. Int. J. Hydrog. Energy 2020, 45, 23480–23489. [Google Scholar] [CrossRef]

- Yoshimune, W.; Kato, S.; Yamaguchi, S.J.I.J.O.H.; Transfer, M. Multi-scale pore morphologies of a compressed gas diffusion layer for polymer electrolyte fuel cells. Int. J. Heat Mass Transf. 2020, 152, 119537. [Google Scholar] [CrossRef]

- Shi, Q.; Feng, C.; Ming, P.; Tang, F.; Zhang, C. Compressive stress and its impact on the gas diffusion layer: A review. Int. J. Hydrog. Energy 2022, 47, 3994–4009. [Google Scholar] [CrossRef]

- Aldakheel, F.; Ismail, M.; Hughes, K.; Ingham, D.; Ma, L.; Pourkashanian, M. Effects of compression on mechanical integrity, gas permeability and thermal stability of gas diffusion layers with/without sealing gaskets. Int. J. Hydrog. Energy 2021, 46, 22907–22919. [Google Scholar] [CrossRef]

- Xia, L.; Ni, M.; He, Q.; Xu, Q.; Cheng, C. Optimization of gas diffusion layer in high temperature PEMFC with the focuses on thickness and porosity. Appl. Energy 2021, 300, 117357. [Google Scholar] [CrossRef]

- Kim, G.H.; Kim, D.; Kim, J.; Kim, H.; Park, T. Impact of cracked gas diffusion layer on performance of polymer electrolyte membrane fuel cells. J. Ind. Eng. Chem. 2020, 91, 311–316. [Google Scholar] [CrossRef]

- Zhang, Z.; He, P.; Dai, Y.J.; Jin, P.H.; Tao, W.Q. Study of the mechanical behavior of paper-type GDL in PEMFC based on microstructure morphology. Int. J. Hydrog. Energy 2020, 45, 29379–29394. [Google Scholar] [CrossRef]

- Zhiani, M.; Kamali, S.; Majidi, S. In-plane gas permeability and thought-plane resistivity of the gas diffusion layer influenced by homogenization technique and its effect on the proton exchange membrane fuel cell cathode performance. Int. J. Hydrog. Energy 2016, 41, 1112–1119. [Google Scholar] [CrossRef]

- Toghyani, S.; Nafchi, F.M.; Afshari, E.; Hasanpour, K.; Baniasadi, E.; Atyabi, S. Thermal and electrochemical performance analysis of a proton exchange membrane fuel cell under assembly pressure on gas diffusion layer. Int. J. Hydrog. Energy 2018, 43, 4534–4545. [Google Scholar] [CrossRef]

- Aldakheel, F.; Ismail, M.; Hughes, K.; Ingham, D.; Ma, L.; Pourkashanian, M.; Cumming, D.; Smith, R. Gas permeability, wettability and morphology of gas diffusion layers before and after performing a realistic ex-situ compression test. Renew. Energy 2020, 151, 1082–1091. [Google Scholar] [CrossRef]

- Faydi, Y.; Lachat, R.; Meyer, Y. Thermomechanical characterisation of commercial gas diffusion layers of a proton exchange membrane fuel cell for high compressive pre-loads under dynamic excitation. Fuel 2016, 182, 124–130. [Google Scholar] [CrossRef]

- Meng, L.; Zhou, P.; Yan, Y.; Guo, D. Compression properties of gas diffusion layers and its constitutive model under cyclic loading. Int. J. Hydrog. Energy 2021, 46, 15965–15975. [Google Scholar] [CrossRef]

- Yan, X.; Lin, C.; Zheng, Z.; Chen, J.; Wei, G.; Zhang, J. Effect of clamping pressure on liquid-cooled PEMFC stack performance considering inhomogeneous gas diffusion layer compression. Appl. Energy 2020, 258, 114073. [Google Scholar] [CrossRef]

- Koorata, P.K.; Bhat, S.D. Compressive cyclic response of PEM fuel cell gas diffusion media. Int. J. Hydrog. Energy 2021, 46, 5570–5579. [Google Scholar] [CrossRef]

- Radhakrishnan, V.; Haridoss, P. Effect of cyclic compression on structure and properties of a gas diffusion layer used in PEM fuel cells. Int. J. Hydrog. Energy 2010, 35, 11107–11118. [Google Scholar] [CrossRef]

- Bouziane, K.; Lachat, R.; Zamel, N.; Meyer, Y.; Candusso, D. Impact of cyclic mechanical compression on the electrical contact resistance between the gas diffusion layer and the bipolar plate of a polymer electrolyte membrane fuel cell. Renew. Energy 2020, 153, 349–361. [Google Scholar] [CrossRef]

- Carral, C.; Melé, P. A constitutive law to predict the compression of gas diffusion layers. Int. J. Hydrog. Energy 2018, 43, 19721–19729. [Google Scholar] [CrossRef]

- Qiu, D.; Janßen, H.; Peng, L.; Irmscher, P.; Lai, X.; Lehnert, W. Electrical resistance and microstructure of typical gas diffusion layers for proton exchange membrane fuel cell under compression. Appl. Energy 2018, 231, 127–137. [Google Scholar] [CrossRef]

- Bao, Z.; Li, Y.; Zhou, X.; Gao, F.; Du, Q.; Jiao, K. Transport properties of gas diffusion layer of proton exchange membrane fuel cells: Effects of compression. Int. J. Heat Mass Transf. 2021, 178, 121608. [Google Scholar] [CrossRef]

- Holzer, L.; Pecho, O.; Schumacher, J.; Marmet, P.; Stenzel, O.; Büchi, F.; Lamibrac, A.; Münch, B. Microstructure-property relationships in a gas diffusion layer (GDL) for polymer electrolyte fuel cells, part I: Effect of compression and anisotropy of dry GDL. Electrochim. Acta 2017, 227, 419–434. [Google Scholar] [CrossRef]

- Wang, H.; Yang, G.; Li, S.; Shen, Q.; Liao, J.; Jiang, Z.; Zhang, G.; Zhang, H.; Su, F. Effect of binder and compression on the transport parameters of a multilayer gas diffusion layer. Energy Fuels 2021, 35, 15058–15073. [Google Scholar] [CrossRef]

- Beaumont, P.W.R.; Soutis, C.; Hodzic, A. The Structural Integrity of Carbon Fiber Composites: Fifty Years of Progress and Achievement of the Science, Development, and Applications; Springer: Cham, Switzerland, 2017; p. 385. [Google Scholar] [CrossRef]

- Zhang, Z.; Klein, P.; Friedrich, K. Dynamic mechanical properties of PTFE based short carbon fibre reinforced composites: Experiment and artificial neural network prediction. Compos. Sci. Technol. 2002, 62, 1001–1009. [Google Scholar] [CrossRef]

- Ramani, D.; Khattra, N.; Singh, Y.; Mohseni-Javid, A.; Orfino, F.; Dutta, M.; Kjeang, E. Mitigation of mechanical membrane degradation in fuel cells–part 1: Gas diffusion layers with low surface roughness. J. Power Sources 2021, 512, 230446. [Google Scholar] [CrossRef]

- Pan, Y.; Wang, H.; Brandon, N.P. Gas diffusion layer degradation in proton exchange membrane fuel cells: Mechanisms, characterization techniques and modelling approaches. J. Power Sources 2021, 513, 230560. [Google Scholar] [CrossRef]

- Mason, T.J.; Millichamp, J.; Neville, T.P.; Shearing, P.R.; Simons, S.; Brett, D.J. A study of the effect of water management and electrode flooding on the dimensional change of polymer electrolyte fuel cells. J. Power Sources 2013, 242, 70–77. [Google Scholar] [CrossRef] [Green Version]

- Therdthianwong, A.; Manomayidthikarn, P.; Therdthianwong, S. Investigation of membrane electrode assembly (MEA) hot-pressing parameters for proton exchange membrane fuel cell. Energy 2007, 32, 2401–2411. [Google Scholar] [CrossRef]

- Elias, Q.K. Principles of High Performance Membrane Electrode Assembly Fabrication. Bachelor’s Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 27 April 2007. [Google Scholar]

- Hack, J.; Heenan, T.; Iacoviello, F.; Mansor, N.; Meyer, Q.; Shearing, P.; Brandon, N.; Brett, D. A structure and durability comparison of membrane electrode assembly fabrication methods: Self-assembled versus hot-pressed. J. Electrochem. Soc. 2018, 165, F3045. [Google Scholar] [CrossRef]

- Sassin, M.B.; Garsany, Y.; Gould, B.D.; Swider-Lyons, K.E. Fabrication method for laboratory-scale high-performance membrane electrode assemblies for fuel cells. Anal. Chem. 2017, 89, 511–518. [Google Scholar] [CrossRef]

- Alizadeh, E.; Ghadimi, M.; Barzegari, M.; Momenifar, M.; Saadat, S. Development of contact pressure distribution of PEM fuel cell’s MEA using novel clamping mechanism. Energy 2017, 131, 92–97. [Google Scholar] [CrossRef]

- Atyabi, S.A.; Afshari, E.; Wongwises, S.; Yan, W.-M.; Hadjadj, A.; Shadloo, M.S. Effects of assembly pressure on PEM fuel cell performance by taking into accounts electrical and thermal contact resistances. Energy 2019, 179, 490–501. [Google Scholar] [CrossRef]

- Montanini, R.; Squadrito, G.; Giacoppo, G. Experimental evaluation of the clamping pressure distribution in a PEM fuel cell using matrix-based piezoresistive thin-film sensors. In Proceedings of the XIX IMEKO World Congress Fundamental and Applied Metrology, Lisbon, Portugal, 6–11 September 2009. [Google Scholar]

- Chung, T.T.; Lin, C.T.; Shiu, H.R. Mechanical design and analysis of a proton exchange membrane fuel cell stack. J. Chin. Inst. Eng. 2016, 39, 353–362. [Google Scholar] [CrossRef]

- Weng, L.F.; Jhuang, J.W.; Bhavanari, M.; Lee, K.R.; Lai, Y.H.; Tseng, C.J. Effects of assembling method and force on the performance of proton-exchange membrane fuel cells with metal foam flow field. Int. J. Energy Res. 2020, 44, 9707–9713. [Google Scholar] [CrossRef]

- Lin, P.; Zhou, P.; Wu, C.W. A high efficient assembly technique for large PEMFC stacks: Part I. theory. J. Power Sources 2009, 194, 381–390. [Google Scholar] [CrossRef]

- Liu, B.; Wei, M.Y.; Zhang, W.; Wu, C.W. Effect of impact acceleration on clamping force design of fuel cell stack. J. Power Sources 2016, 303, 118–125. [Google Scholar] [CrossRef]

- Wu, C.W.; Liu, B.; Wei, M.Y.; Zhang, W. Mechanical response of a large fuel cell stack to impact: A numerical analysis. Fuel Cells 2015, 15, 344–351. [Google Scholar] [CrossRef]

- Bhosale, A.C.; Rengaswamy, R. Interfacial contact resistance in polymer electrolyte membrane fuel cells: Recent developments and challenges. Renew. Sust. Energy Rev. 2019, 115, 109351. [Google Scholar] [CrossRef]

- Gigos, P.; Faydi, Y.; Meyer, Y. Mechanical characterization and analytical modeling of gas diffusion layers under cyclic compression. Int. J. Hydrog. Energy 2015, 40, 5958–5965. [Google Scholar] [CrossRef]

- Xiao, Y.; Gao, Z.; Gao, F.; Zhang, T.; Zhang, W.; Li, Z.; Ma, X.; Qi, J. Improved analytical modeling and mechanical characterization of gas diffusion layers under compression load. Energy Sci. Eng. 2020, 8, 2799–2807. [Google Scholar] [CrossRef] [Green Version]

| Type of GDLs | Compression Conditions | Key Findings | Sources |

|---|---|---|---|

| GDM (BC-39) | Three cyclic compression was applied with the maximum load of 1 MPa. | An accurate compressible GDM model is proposed to capture the experimental cyclic response. | [23] |

| Freudenberg H24CX483 | Two cyclic compression: one with the stress of 3 MPa and the other with three levels of stress (1 MPa, 2 MPa, 3 MPa). | A new nonlinear constitutive model considering historical maximum stress and a prediction method for cyclic compression properties of GDL are developed. | [21] |

| TGP-H-120 | Cyclic compression was set up to 1.7 MPa and 3.4 MPa for 5 cycles. | Static cyclic compression causes structural and property changes of GDL. | [24] |

| Toray GDLs | Cyclic compression was between 0 and 8 MPa according to the transmission line method. | The smallest contact resistance. | [25] |

| SGL GDLs | The highest contact resistance. | ||

| Felt GDLs | The smallest difference rates between the cycles of compression. | ||

| SGL 24AA, 24BA, and 24 BC | High compressive loads were under dynamic excitation and over a large temperature range. | The dynamic compression modulus increases linearly with temperature until 280 °C then it decreases linearly. | [20] |

| Carbon paper GDL-A and GDL-B | Apply different levels of mechanical stress on two regions. | Stress-relative density curves were built to predict experimental compressive behavior of GDLs. | [26] |

| Uncoated GDLs(Toray-H-090) | An initial assembling compression was with 0–1 MPa, followed by 10 cycles of loading and unloading between 1 and 3 MPa. | Uncoated GDLs show the least reduction in thickness and gas permeability after compression. | [19] |

| Coated GDLs(SGL 24BA, 10BA, 34BC, 35BC | SGL 35BC shows substantially much higher reduction in thickness and gas permeability compared to SGL 34BC. | ||

| SGL 29BC | Compression ratio was set with different levels (0, 8.6, 23.6, and 38.6% of the initial thickness). | The average pore diameter of the fibrous substrate reduces with the compression pressure, whereas that of the microporous layer remained unchanged even at high compression (38.6%). | [11] |

| Carbon paper GDL | Steady load in the constant conditions (2 MPa, 4 MPa, and 6 MPa) and cyclic load up to 6 MPa for 6 cycles. | The electrical resistance decreases as the load cycles increases. | [27] |

| Woven carbon cloth | More uniform decline of the resistance is caused by the increasing fiber cracks. | ||

| Felt GDL | Tortuous and thick fibers lead to higher stability in electric resistance. | ||

| Reconstructed GDL | Finite element volume method was used to simulate GDL compression with the ratio 0–30%. | Compression reduces the oxygen diffusivity and intrinsic permeability. | [28] |

| SGL 25BA | Compression ratio ranges from 0 to 49%. | Compression is mainly related to changes in porosity and geodesic tortuosity. | [29] |

| Simulated multilayered GDLs | Compression ratio ranges from 0 to 30%. | The pore size distribution, permeability, tortuosity, and electric conductivity are influenced with compression. | [30] |

| Properties | Value |

|---|---|

| Thickness | 190 μm |

| Density | 0.44 g/cm3 |

| Porosity | 78% |

| PTFE treated | No |

| MPL | No |

| Components | Applied Load Conditions | Maximum Load | Sources |

|---|---|---|---|

| MEA | Hot-press with 450 psi at 170 °C for 4 min | 450 psi | [35] |

| Hot-press with 500 and 1500 psi, at 100 and 160 °C for 2 and 5 min, respectively | 1500 psi | [36] | |

| Hot-press with 5000–15,000 KPa at 160–270 °C for 1–5 min | 15 MPa | [37] | |

| Hot-press with 400 psi at 130 °C for 3 min | 400 psi | [38] | |

| Without hot-press under a torque of2 Nm | 2 Nm | ||

| A PEMFC unit | Hot-press with stress varying from 0.068 to 13.8 MPa, at 135 °C for 2 min | 13.8 MPa | [39] |

| 13 Nm per bolt, together with pneumatically pressurized pocket end plate pressure up to 7 bars | 13 Nm per bolt and 7 bars | [40] | |

| Assembly pressure from 1.5 MPa to 5.5 MPa | 5.5 MPa | [41] | |

| Bolt torque from 2 to 11 Nm | 11 Nm per bolt | [42] | |

| Plate pressure up to 6 MPa | 6 MPa | [43] | |

| Clamping force from 0 to 400 kgf | 400 kgf | [44] | |

| PEMFC stack | 1865 N per bolt, 6 cells and 8 bolts for the stack | 1865 N per bolt | [45] |

| Clamping pressure from 1.5 MPa to 3.5 MPa | 3.5 MPa | [22] | |

| Clamping force per belt from 5 to 7 KN | 7 KN per bolt | [46] | |

| Clamping force per clamping belt from 10 to 35 KN | 35 KN per bolt | [47] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zhao, J.; Jin, C.; Ke, Y.; Li, D.; Wang, Z. Effect of Clamping Compression on the Mechanical Performance of a Carbon Paper Gas Diffusion Layer in Polymer Electrolyte Membrane Fuel Cells. Membranes 2022, 12, 645. https://doi.org/10.3390/membranes12070645

Chen Y, Zhao J, Jin C, Ke Y, Li D, Wang Z. Effect of Clamping Compression on the Mechanical Performance of a Carbon Paper Gas Diffusion Layer in Polymer Electrolyte Membrane Fuel Cells. Membranes. 2022; 12(7):645. https://doi.org/10.3390/membranes12070645

Chicago/Turabian StyleChen, Yanqin, Jinghui Zhao, Cuihong Jin, Yuchao Ke, Decai Li, and Zixi Wang. 2022. "Effect of Clamping Compression on the Mechanical Performance of a Carbon Paper Gas Diffusion Layer in Polymer Electrolyte Membrane Fuel Cells" Membranes 12, no. 7: 645. https://doi.org/10.3390/membranes12070645

APA StyleChen, Y., Zhao, J., Jin, C., Ke, Y., Li, D., & Wang, Z. (2022). Effect of Clamping Compression on the Mechanical Performance of a Carbon Paper Gas Diffusion Layer in Polymer Electrolyte Membrane Fuel Cells. Membranes, 12(7), 645. https://doi.org/10.3390/membranes12070645