Challenges, Opportunities and Future Directions of Membrane Technology for Natural Gas Purification: A Critical Review

Abstract

:1. Introduction

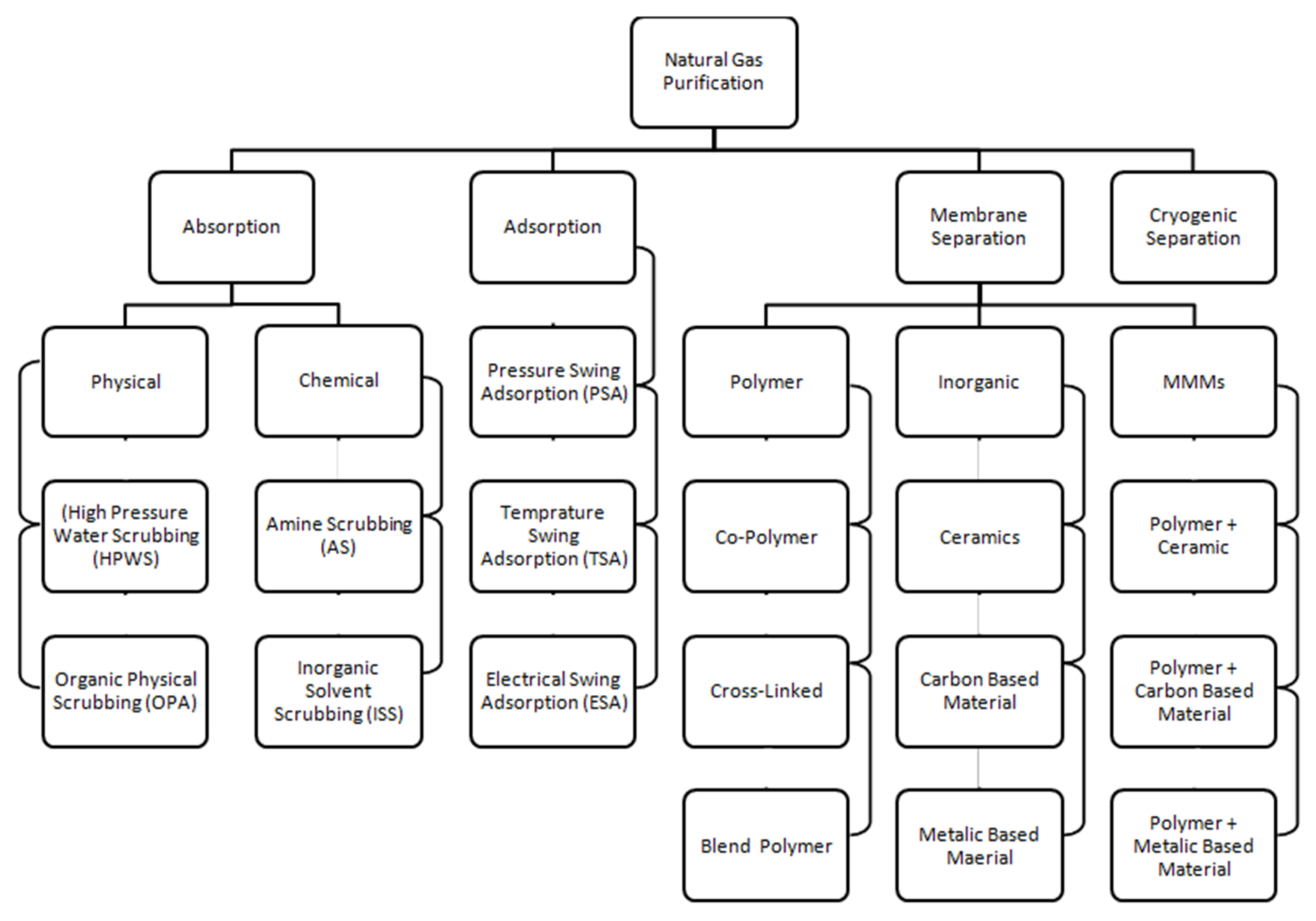

2. General Processes of Gas Purification

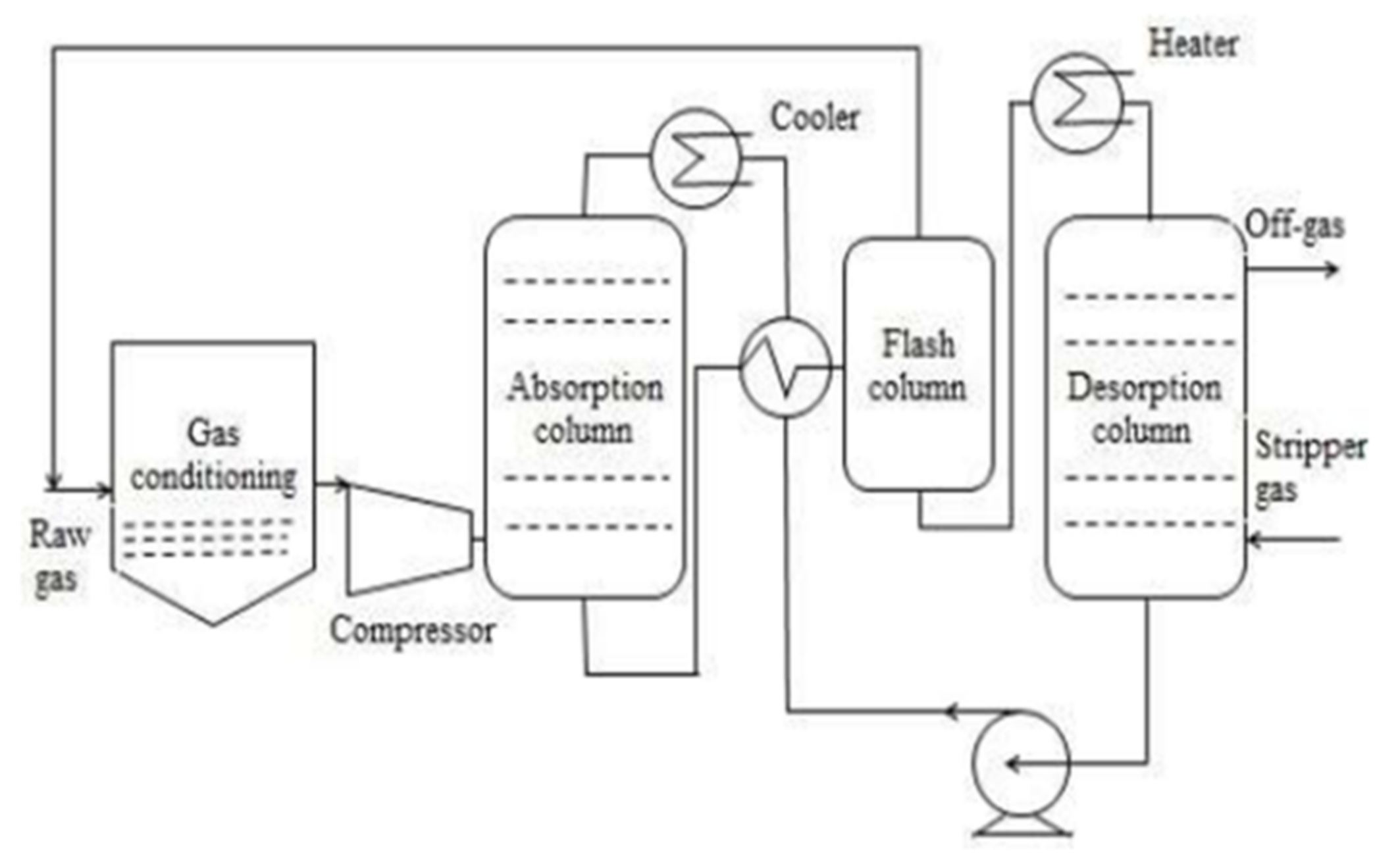

2.1. Absorption

2.1.1. High-Pressure Water Scrubbing

2.1.2. Chemical or Amine Scrubbing Process

2.1.3. Organic Physical Scrubbing (OPS)

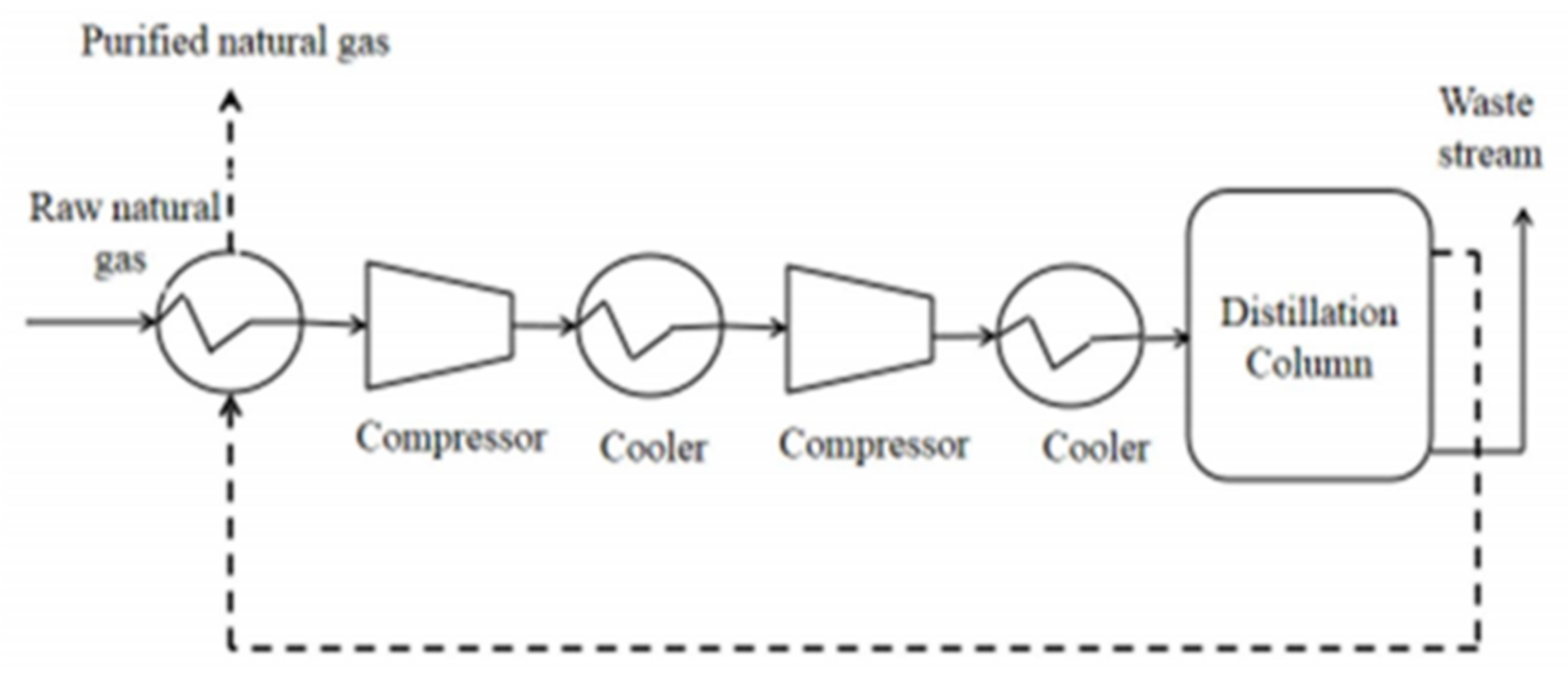

2.2. Cryogenic Separation

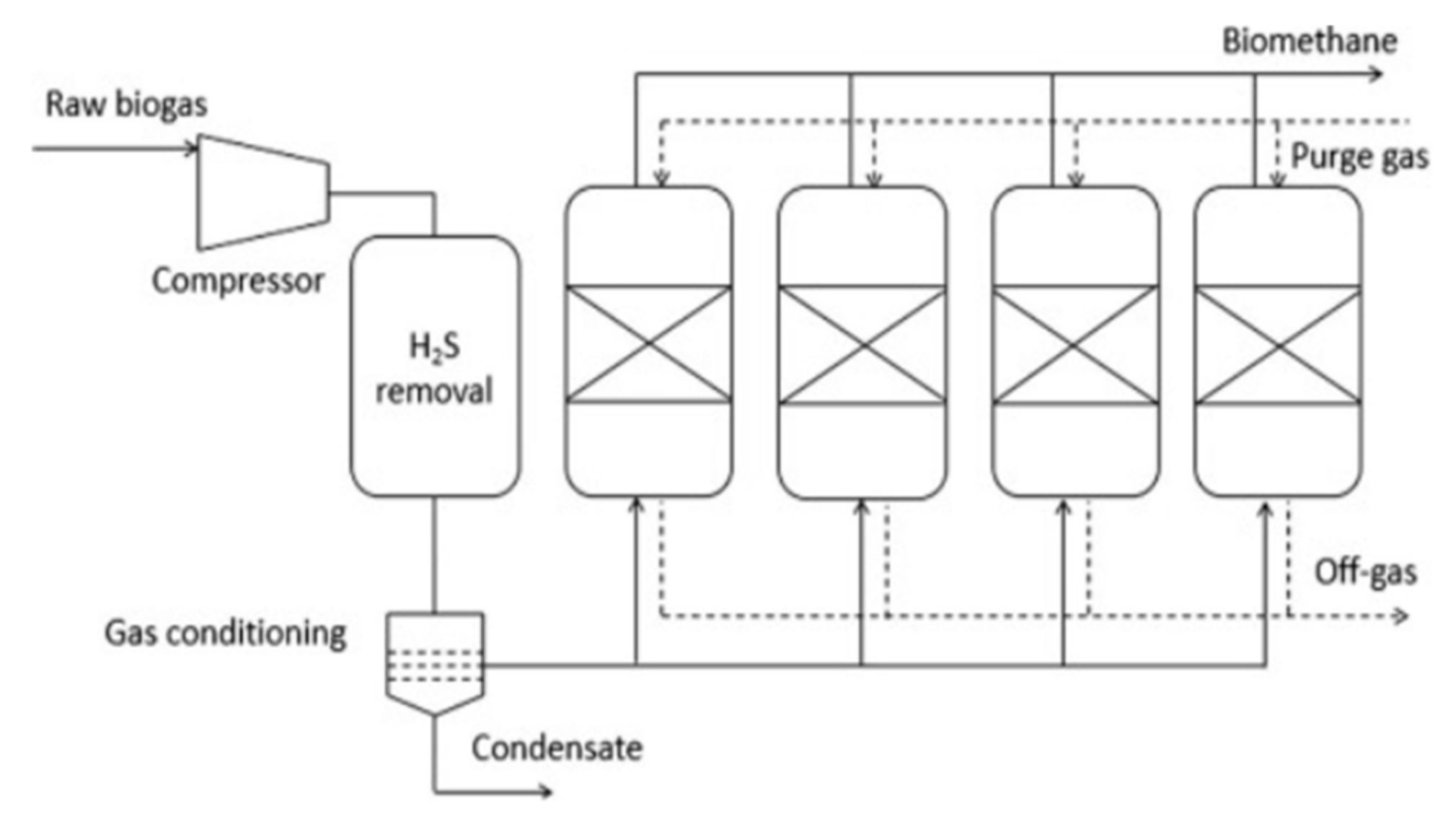

2.3. Pressure Swing Adsorption

2.4. Membrane Separation

3. Membranes for Gas Purification

3.1. Membrane Materials

3.1.1. Polymeric Membranes

3.1.2. Inorganic Membranes

3.2. General Membrane Fabrication Procedures

3.2.1. Phase Inversion Method

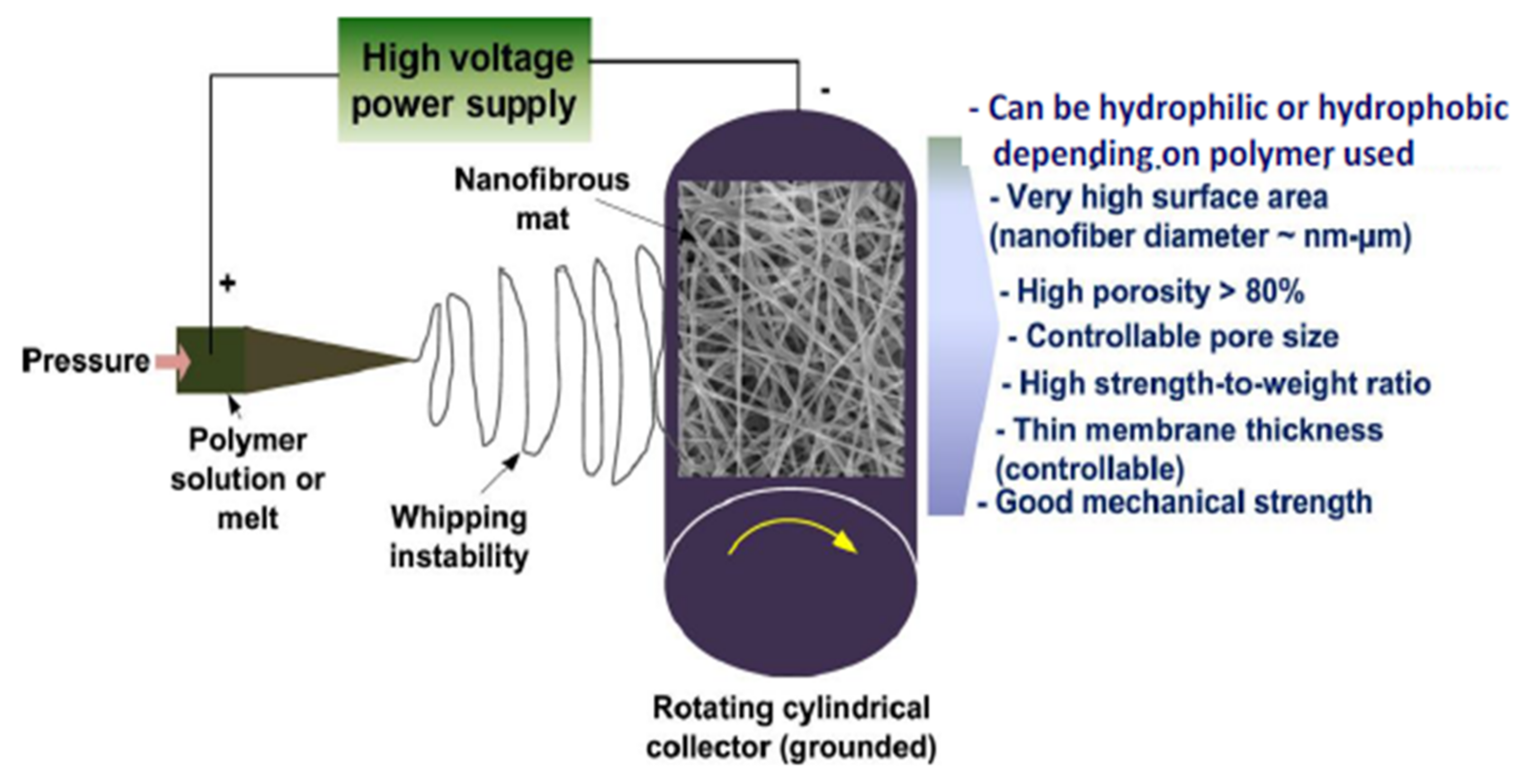

3.2.2. Electrospinning Method

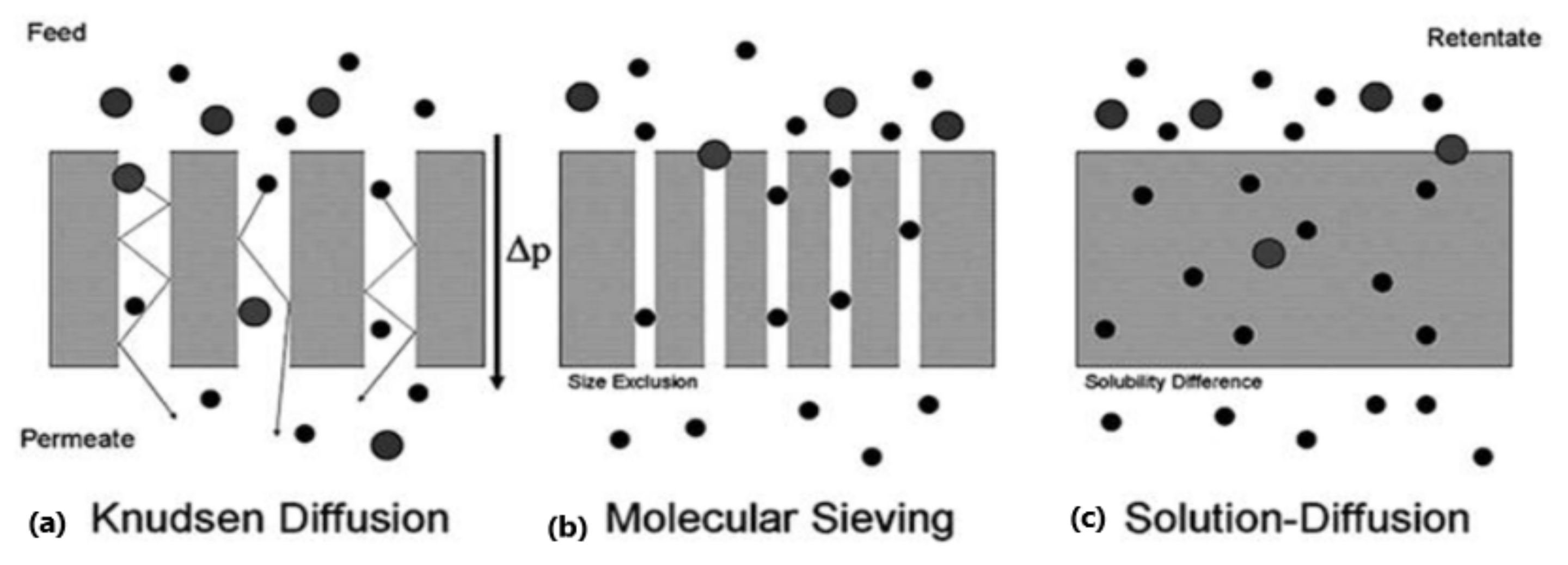

3.3. Main Permeation Mechanism

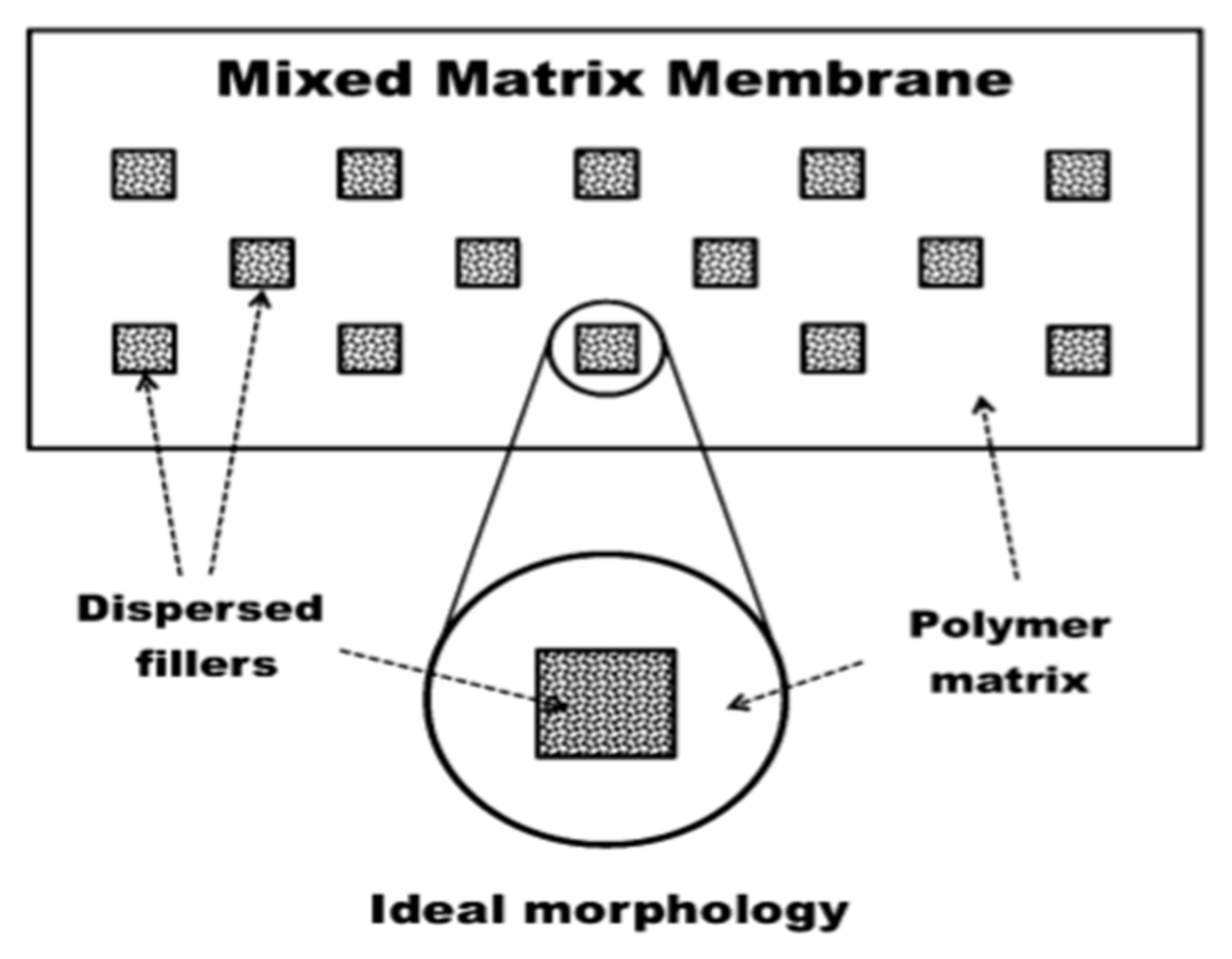

4. Mixed Matrix Membranes

4.1. Incorporation of Different Fillers in Fabrication of MMMs

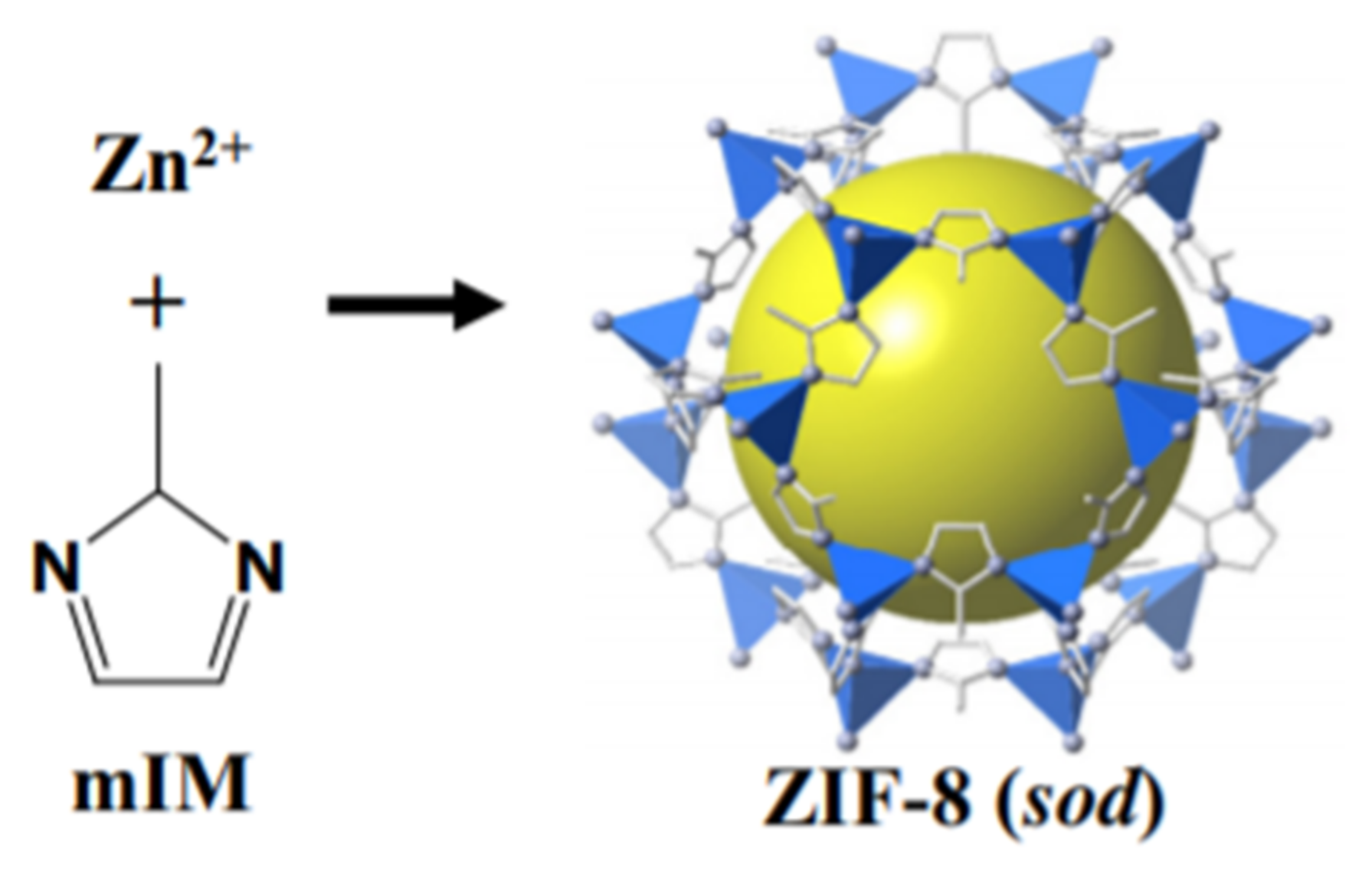

4.1.1. Zeolite Immidazolate Frameworks (ZIFs) as a Promising Filler for MMMs Fabrication

4.1.2. Zeolite Immidazolate Frameworks-8 (ZIF-8)

4.1.3. ZIF-8 Based Filler in Fabrication of Gas Separation MMM

4.2. Separation Performance of Mixed Matrix Membranes

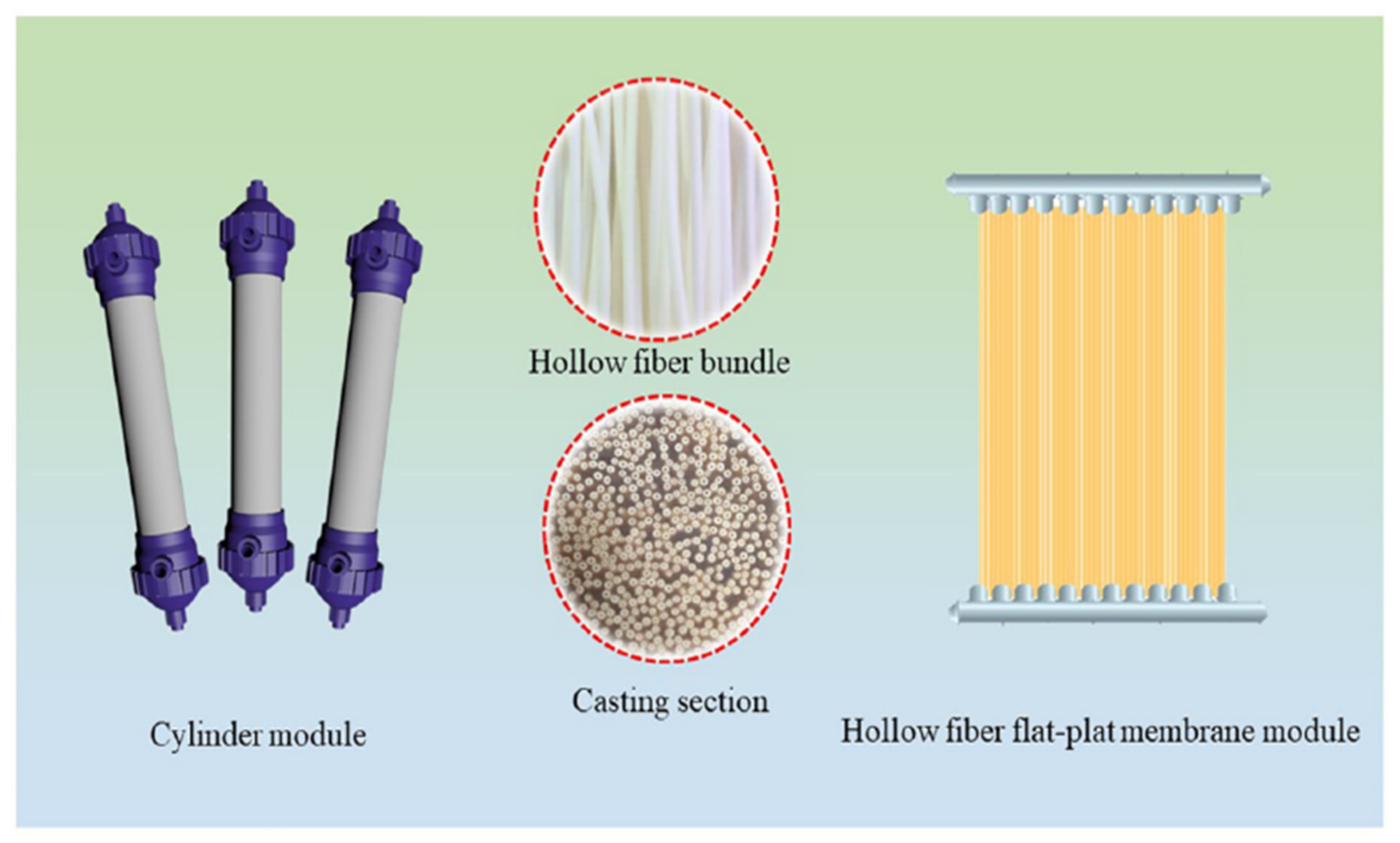

5. Hollow Fiber Membrane Configuration

6. Potentiality of Braid Support Hollow Fiber Membrane for Use in Gas Separation Applications in Future

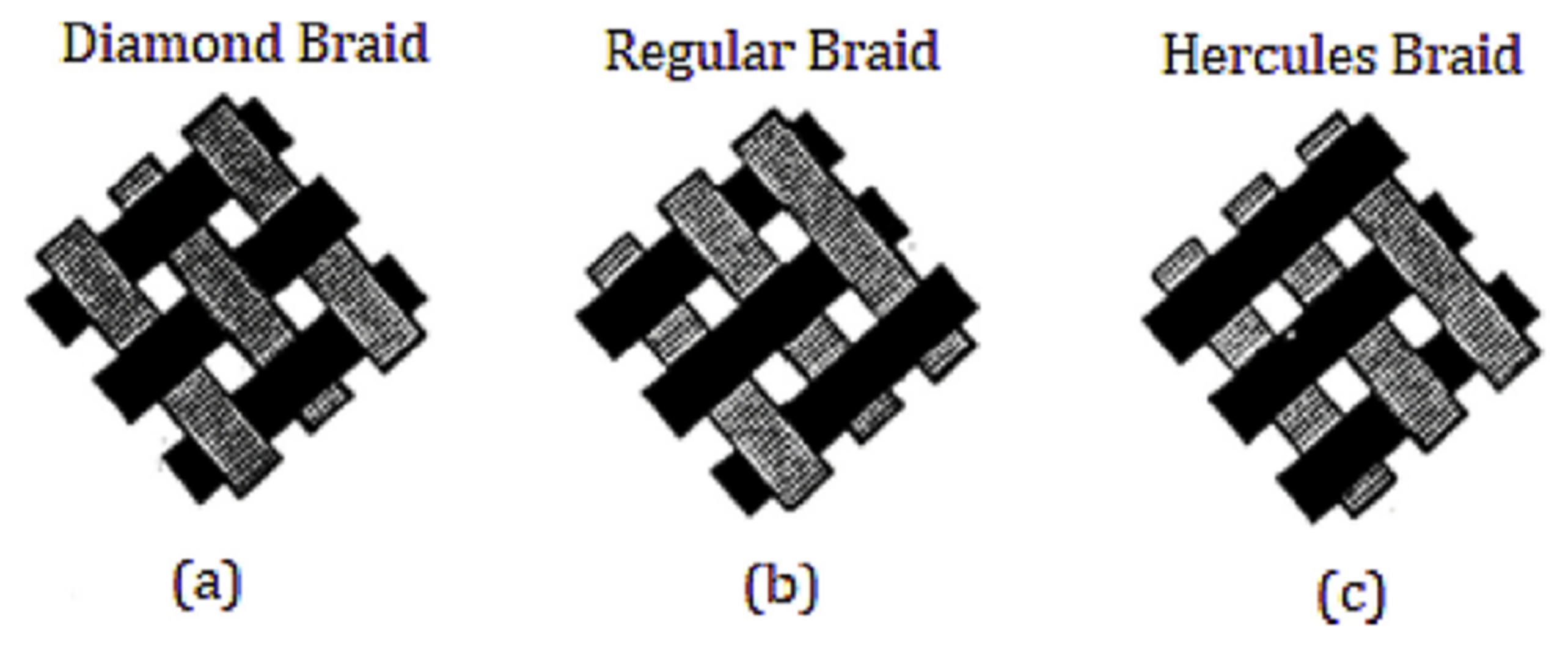

6.1. Fabrication of Braid Reinforced Hollow Fiber Membrane

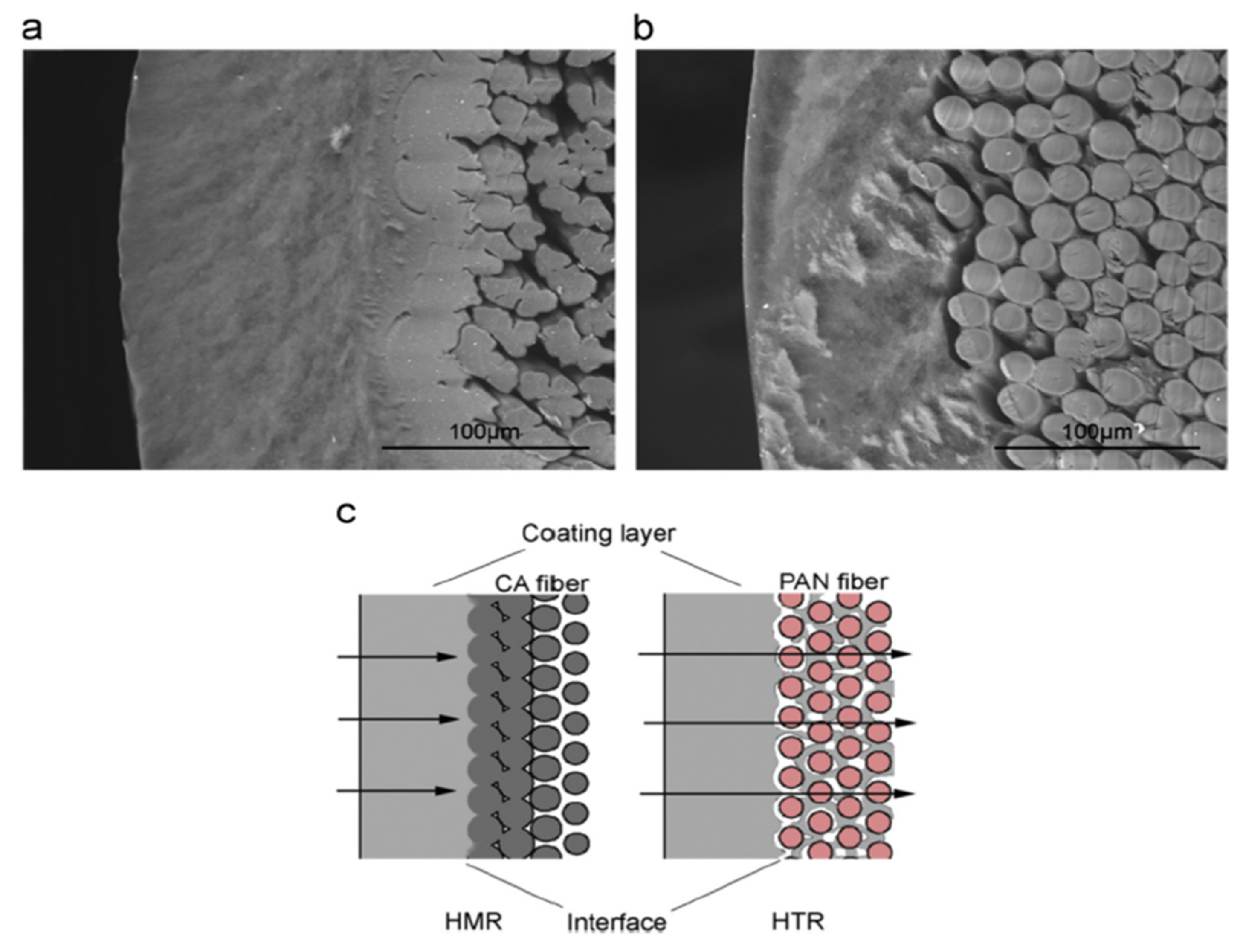

6.2. Effectof Support Layer Composition on BRHF Membrane

6.3. Effect of Polymer on BRHF Membrane

6.4. Influence of Spinneret Design and Spinning Speed on BRHF Membrane

6.5. BRHF Membrane Morphology

7. Future Prospects and Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Glossary

| ABS | Acrylonitrile Butadiene Styren |

| AC | Activated Carbons |

| ALPO | Aluminophosphate |

| AMDEA | Activated Methyl Diethanolamine |

| BET | Brunauer–Emmett–Teller |

| BRHF | Braid Reinforced Hollow Fiber Membranes |

| CA | Cellulose Acetate |

| CMS | Carbon Molecular Sieves |

| CNT | Carbon Nanotubes |

| DEA | Diethanolamine |

| DEF | N,N-Diethylformamide |

| DMAC | Dimethylacetamide |

| DMF | Dimethylformamide |

| FS | Fumed Silica |

| HF | Hollow Fibers |

| HMR | Homogeneous braid-reinforced |

| HTR | Heterogeneous braid-reinforced |

| KOH | Potassium hydroxide |

| LBM | Liquefied Biomethane |

| LNG | Liquefied Natural Gas |

| MBR | Membrane bioreactor |

| MDEA | Methyl Diethanolamine |

| MEA | Monoethanolamine |

| MF | Microfiltration |

| MMM | Mixed Matrix Membranes |

| MOF | Metal Organic Frameworks |

| NF | Nanofiltration |

| NMP | N-Methyl-2-Pyrrolidone |

| PAN | Polyacrylonitrile |

| PC | Polycarbonate |

| PDMS | Polydimethylsiloxane |

| PEBAX | Polyether block amide |

| PEG | Polyethylene Glycol |

| PES | Polyethersulfone |

| PET | Polyethylene Terephthalate |

| PI | Polyimide |

| PMIA | Poly(m-phenylene isophthalamide) |

| PMO | Periodic Mesoporous Organosilica |

| PSA | Pressure Swing Adsorption |

| PSF | Polysulfone |

| PTFE | Polytetrafluoroethylene |

| PTMSP | Poly(1-trimethylsilyl-1-propyne) |

| PVC | Polyvinyl Chloride |

| PVDF | Polyvinylidene fluoride |

| PVP | Polyvinylpyrrolidone |

| PZ | Piperazine |

| RO | Reverse Osmosis |

| RTO | Regenerative Thermal Oxidation |

| SAPO | Silico-Alumino-Phosphate |

| TFC | Thin Film Composite |

| TIPS | Thermally Induced Phase Inversion |

| UF | Ultrafiltration |

| ZIFs | Zeolite immidazolate frameworks |

| Q | Dope solution feed rate (ml/min) |

| dope solution density | |

| braid advancing speed | |

| Do | braid outer diameter |

| T | Dope solution thickness |

| A | pre-exponential factor, i.e., weakly dependent upon temperature |

| V* | minimum free volume element size that could accommodate penetrant molecules |

| overlap factor introduced in order to prevent double counting free volume | |

| Vf | average free volume in media that is accessible to transport of penetrants |

References

- Rezakazemi, M.; Ebadi Amooghin, A.; Montazer-Rahmati, M.M.; Ismail, A.F.; Matsuura, T. State-of-the-art membrane based CO2 separation using mixed matrix membranes (MMMs): An overview on current status and future directions. Prog. Polym. Sci. 2014, 39, 817–861. [Google Scholar] [CrossRef]

- Kidnay, A.J.; Parrish, W. Fundamentals of Natural Gas Processing; CRC Press: New York, NY, USA, 2006. [Google Scholar]

- Bekkering, J.; Broekhuis, A.A.; van Gemert, W.J.T. Optimisation of a green gas supply chain—A review. Bioresour. Technol. 2010, 101, 450–456. [Google Scholar] [CrossRef]

- Zakria, H.S.; Othman, M.H.D.; Kadir, S.H.S.A.; Kamaludin, R.; Jilani, A.; Omar, M.F.; Bakar, S.A.; Jaafar, J.; Rahman, M.A.; Abdullah, H.; et al. Fabrication of High Performance PVDF Hollow Fiber Membrane Using Less Toxic Solvent at Different Additive Loading and Air Gap. Membranes 2021, 11, 843. [Google Scholar] [CrossRef]

- Samarasinghe, S.A.S.C.; Chuah, C.Y.; Yang, Y.; Bae, T.-H. Tailoring CO2/CH4 separation properties of mixed-matrix membranes via combined use of two- and three-dimensional metal-organic frameworks. J. Membr. Sci. 2018, 557, 30–37. [Google Scholar] [CrossRef]

- Bastani, D.; Esmaeili, N.; Asadollahi, M. Polymeric mixed matrix membranes containing zeolites as a filler for gas separation applications: A review. J. Ind. Eng. Chem. 2013, 19, 375–393. [Google Scholar] [CrossRef]

- Yang, T.; Xiao, Y.; Chung, T.S. Poly-/metal-benzimidazole nano-composite membranes for hydrogen purification. Energy Environ. Sci. 2011, 4, 4171–4180. [Google Scholar] [CrossRef]

- Ge, L.; Zhu, Z.; Li, F.; Liu, S.; Wang, L.; Tang, X.; Rudolph, V. Investigation of Gas Permeability in Carbon Nanotube (CNT)−Polymer Matrix Membranes via Modifying CNTs with Functional Groups/Metals and Controlling Modification Location. J. Phys. Chem. C 2011, 115, 6661–6670. [Google Scholar] [CrossRef]

- Vu, D.Q.; Koros, W.J.; Miller, S.J. Mixed matrix membranes using carbon molecular sieves: I. Preparation and experimental results. J. Membr. Sci. 2003, 211, 311–334. [Google Scholar] [CrossRef]

- Dong, G.; Li, H.; Chen, V. Challenges and opportunities for mixed-matrix membranes for gas separation. J. Mater. Chem. A 2013, 1, 4610–4630. [Google Scholar] [CrossRef]

- Cheng, S.; Wu, Y.; Jin, J.; Liu, J.; Wu, D.; Yang, G.; Wang, Y.-Y. New multifunctional 3D porous metal–organic framework with selective gas adsorption, efficient chemical fixation of CO2 and dye adsorption. Dalton Trans. 2019, 48, 7612–7618. [Google Scholar] [CrossRef]

- Quan, Q.; Xiao, C.; Liu, H.; Zhao, W.; Hu, X.; Huan, G. Preparation and Properties of Two-Dimensional Braid Heterogeneous-Reinforced Polyvinylidene Fluoride Hollow Fiber Membrane. Adv. Mater. Res. 2014, 936, 218–225. [Google Scholar] [CrossRef]

- Li, G.; Kujawski, W.; Válek, R.; Koter, S. A review-The development of hollow fibre membranes for gas separation processes. Int. J. Greenh. Gas Control. 2021, 104, 103195. [Google Scholar] [CrossRef]

- Liu, J.; Kujawski, W.; Válek, R.; Koter, S. Preparation of PET threads reinforced PVDF hollow fiber membrane. Desalination 2009, 249, 453–457. [Google Scholar] [CrossRef]

- Turken, T.; Sengur-Tasdemir, R.; Ates-Genceli, E.; Tarabara, V.V.; Koyuncu, I. Progress on reinforced braided hollow fiber membranes in separation technologies: A review. J. Water Process Eng. 2019, 32, 100938. [Google Scholar] [CrossRef]

- Cooper, W.W.; Shea, E.M. Process for Casting Integrally Supported Tubular Membranes. U.S. Patent 3676193, 11 July 1972. [Google Scholar]

- Hayano, F.; Hashino, Y.; Ichikawa, K. Semipermeable Composite Membranes. U.S. Patent 4061821, 6 December 1977. [Google Scholar]

- Lee, M.; Choi, S.; Shin, Y. Braid-Reinforced Hollow Fiber Membrane. U.S. Patent 7267872, 11 September 2007. [Google Scholar]

- Zakria, H.S.; Othman, M.H.D.; Kamaludin, R.; Jilani, A. Study on the effect of air gap on physico-chemical and performance of PVDF hollow fibre membrane. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1142, 012014. [Google Scholar] [CrossRef]

- Adamu, A.; Abegão, F.R.; Boodhoo, K. Process intensification technologies for CO2 capture and conversion—A review. BMC Chem. Eng. 2020, 2, 2. [Google Scholar] [CrossRef]

- Zhang, Z. Comparisons of various absorbent effects on carbon dioxide capture in membrane gas absorption (MGA) process. J. Nat. Gas Sci. Eng. 2016, 31, 589–595. [Google Scholar] [CrossRef]

- Valappil, R.S.K.; Ghasem, N.; Al-Marzouqi, M. Current and future trends in polymer membrane-based gas separation technology: A comprehensive review. J. Ind. Eng. Chem. 2021, 98, 103–129. [Google Scholar] [CrossRef]

- Khan, I.; Hafiz Dzarfan Othman, M.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-Dasht Arzhandi, M.; Wan Azelee, I. Biogas as a renewable energy fuel—A review of biogas upgrading, utilisation and storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar] [CrossRef]

- Petronela, C.; Ghinea, C.; Mamaliga, I.; Wukovits, W.; Friedl, A.; Gavrilescu, M. Environmental Impact Assessment of High Pressure Water Scrubbing Biogas Upgrading Technology. CLEAN Soil Air Water 2013, 41, 917–927. [Google Scholar]

- Xiao, T.; Wang, P.; Yang, X.; Cai, X.; Lu, J. Fabrication and characterization of novel asymmetric polyvinylidene fluoride (PVDF) membranes by the nonsolvent thermally induced phase separation (NTIPS) method for membrane distillation applications. J. Membr. Sci. 2015, 489, 160–174. [Google Scholar] [CrossRef]

- Wantz, E.; Benizri, D.; Dietrich, N.; Hébrard, G. Rate-based modeling approach for High Pressure Water Scrubbing with unsteady gas flowrate and multicomponent absorption applied to biogas upgrading. Appl. Energy 2022, 312, 118754. [Google Scholar] [CrossRef]

- Petersson, A.; Wellinger, A. Biogas upgrading technologies–developments and innovations. IEA Bioenergy 2009, 20, 1–19. [Google Scholar]

- Abatzoglou, N.; Boivin, S. A review of biogas purification processes. Biofuels Bioprod. Biorefining 2009, 3, 42–71. [Google Scholar] [CrossRef]

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of appropriate biogas upgrading technology—A review of biogas cleaning, upgrading and utilisation. Renew. Sustain. Energy Rev. 2015, 51, 521–532. [Google Scholar] [CrossRef]

- Eze, J.; Agbo, K. Maximizing the potentials of biogas through upgrading. Am. J. Sci. Ind. Res. 2010, 1, 604–609. [Google Scholar] [CrossRef]

- Bauer, F.; Persson, T.; Hulteberg, C.; Tamm, D. Biogas upgrading–technology overview, comparison and perspectives for the future. Biofuels Bioprod. Biorefining 2013, 7, 499–511. [Google Scholar] [CrossRef]

- Kohl, A.L.; Nielsen, R. Gas Purification; Elsevier: Houston, TX, USA, 1997. [Google Scholar]

- Kismurtono, M. Upgrade biogas purification in packed column with chemical absorption of CO2 for energy alternative of small industry (UKM-Tahu). Int. J. Eng. Technol. 2011, 11, 59–62. [Google Scholar]

- Privalova, E.; Rasi, S.; Mäki-Arvela, P.; Eränen, K.; Rintala, J.; Murzin, D.Y.; Mikkola, J.-P. CO2 capture from biogas: Absorbent selection. RSC Adv. 2013, 3, 2979–2994. [Google Scholar] [CrossRef]

- Krich, K.; Augenstein, D.; Batmale, J.; Benemann, J.; Rutledge, B.; Salour, D. Biomethane from dairy waste. A Sourcebook for the Production and Use of Renewable Natural Gas in California; California Institute for Energy and Environment: Berkeley, CA, USA, 2005; pp. 147–162. [Google Scholar]

- Palma, V.; Barba, D.; Ciambelli, P. Biogas purification by selective partial oxidation of H2S on V2O5-CeO2 catalysts. Braz. J. Chem. Eng. 2013, 21, 5–6. [Google Scholar]

- Tock, L.; Gassner, M.; Marechal, F. Thermochemical production of liquid fuels from biomass: Thermo-economic modeling, process design and process integration analysis. Biomass Bioenergy 2010, 34, 1838–1854. [Google Scholar] [CrossRef]

- Tippayawong, N.; Thanompongchart, P. Biogas quality upgrade by simultaneous removal of CO2 and H2S in a packed column reactor. Energy 2010, 35, 4531–4535. [Google Scholar] [CrossRef]

- Andriani, D.; Wresta, A.; Atmaja, T.D.; Saepudin, A. A review on optimization production and upgrading biogas through CO2 removal using various techniques. Appl. Biochem. Biotechnol. 2014, 172, 1909–1928. [Google Scholar] [CrossRef]

- Song, C.; Liu, Q.; Deng, S.; Li, H.; Kitamura, Y. Cryogenic-based CO2 capture technologies: State-of-the-art developments and current challenges. Renew. Sustain. Energy Rev. 2019, 101, 265–278. [Google Scholar] [CrossRef]

- De Hullu, J.J.; Maassen, J.; Van Meel, P.; Shazad, S.; Vaessen, J.; Bini, L.; Reijenga, J. Comparing Different Biogas Upgrading Techniques; Eindhoven University of Technology: Eindhoven, The Netherlands, 2008. [Google Scholar]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for transformation of biogas to biomethane. Biomass- Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- Mondal, M.K.; Balsora, H.K.; Varshney, P. Progress and trends in CO2 capture/separation technologies: A review. Energy 2012, 46, 431–441. [Google Scholar] [CrossRef]

- Zhou, W.H.; Guo, J.P.; Tan, H.Y. Upgrading of methane from biogas by pressure swing adsorption. In Advanced Materials Research; Trans Tech Publications Ltd.: Zurich, Switzerland, 2011. [Google Scholar]

- Grande, C.A. Biogas upgrading by pressure swing adsorption. In Biofuel’s Engineering Process Technology; IntechOpen: London, UK, 2011; pp. 65–84. [Google Scholar]

- Zhang, Y.; Sunarso, J.; Liu, S.; Wang, R. Current status and development of membranes for CO2/CH4 separation: A review. Int. J. Greenh. Gas Control. 2013, 12, 84–107. [Google Scholar] [CrossRef]

- Shindo, R.; Nagai, K. Gas Separation Membranes. In Encyclopedia of Polymeric Nanomaterials; Kobayashi, S., Müllen, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–8. [Google Scholar]

- Veličković, S. Acrylic polymers for denture-base materials. In Advanced Functional Polymers and Composites; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2013; p. 261. [Google Scholar]

- Wisniak, J. Thomas Graham. I. Contributions to thermodynamics, chemistry, and the occlusion of gases. Educ. Quím. 2013, 24, 316–325. [Google Scholar] [CrossRef] [Green Version]

- Loeb, S.; Sourirajan, S. Sea Water Demineralization by Means of an Osmotic Membrane; ACS Publications: Washington, DC, USA, 1962. [Google Scholar]

- Pan, C.Y. Gas separation by permeators with high-flux asymmetric membranes. AIChE J. 1983, 29, 545–552. [Google Scholar] [CrossRef]

- Henis, J.M.; Tripodi, M.K. Composite hollow fiber membranes for gas separation: The resistance model approach. J. Membr. Sci. 1981, 8, 233–246. [Google Scholar] [CrossRef]

- Deng, L.; Hägg, M.-B. Techno-economic evaluation of biogas upgrading process using CO2 facilitated transport membrane. Int. J. Greenh. Gas Control 2010, 4, 638–646. [Google Scholar] [CrossRef]

- Makaruk, A.; Miltner, M.; Harasek, M. Membrane biogas upgrading processes for the production of natural gas substitute. Sep. Purif. Technol. 2010, 74, 83–92. [Google Scholar] [CrossRef]

- Jiang, L.Y.; Chung, T.S.; Kulprathipanja, S. An investigation to revitalize the separation performance of hollow fibers with a thin mixed matrix composite skin for gas separation. J. Membr. Sci. 2006, 276, 113–125. [Google Scholar] [CrossRef]

- Rongwong, W.; Boributh, S.; Assabumrungrat, S.; Laosiripojana, N.; Jiraratananon, R. Simultaneous absorption of CO2 and H2S from biogas by capillary membrane contactor. J. Membr. Sci. 2012, 392, 38–47. [Google Scholar] [CrossRef]

- Kentish, S.E.; Scholes, C.A.; Stevens, G.W. Carbon dioxide separation through polymeric membrane systems for flue gas applications. Recent Pat. Chem. Eng. 2008, 1, 52–66. [Google Scholar] [CrossRef]

- Akhmetshina, A.I.; Yanbikov, N.R.; Atlaskin, A.A.; Trubyanov, M.M.; Mechergui, A.; Otvagina, K.V.; Razov, E.N.; Mochalova, A.E.; Vorotyntsev, I.V. Acidic gases separation from gas mixtures on the supported ionic liquid membranes providing the facilitated and solution-diffusion transport mechanisms. Membranes 2019, 9, 9. [Google Scholar] [CrossRef] [Green Version]

- Park, H.B.; Kamcev, J.; Robeson, L.M.; Elimelech, M.; Freeman, B.D. Maximizing the right stuff: The trade-off between membrane permeability and selectivity. Science 2017, 356, eaab0530. [Google Scholar] [CrossRef] [Green Version]

- Shekhawat, D.; Luebke, D.R.; Pennline, H.W. A Review of Carbon Dioxide Selective Membranes: A Topical Report; National Energy Technology Laboratory (NETL): Pittsburgh, PA, USA, 2003. [Google Scholar]

- Song, C.; Luebke, D.R.; Pennline, H.W. Natural gas purification by heat pump assisted MEA absorption process. Appl. Energy 2017, 204, 353–361. [Google Scholar] [CrossRef]

- Knuutila, H.K.; Rennemo, R.; Ciftja, A.F. New solvent blends for post-combustion CO2 capture. Green Energy Environ. 2019, 4, 439–452. [Google Scholar] [CrossRef]

- Chen, X.; Liu, G.; Jin, W. Natural gas purification by asymmetric membranes: An overview. Green Energy Environ. 2020, 6, 176–192. [Google Scholar] [CrossRef]

- Koros, W.J.; Mahajan, R. Pushing the limits on possibilities for large scale gas separation: Which strategies? J. Membr. Sci. 2000, 175, 181–196. [Google Scholar] [CrossRef]

- Carreon, M.; Dahe, G.; Feng, J.; Venna, S.R. Mixed matrix membranes for gas separation applications. In Membranes for Gas Separations; World Scientific: Singapore, 2018; pp. 1–57. [Google Scholar]

- Harasimowicz, M.; Orluk, P.; Zakrzewska-Trznadel, G.; Chmielewski, A. Application of polyimide membranes for biogas purification and enrichment. J. Hazard. Mater. 2007, 144, 698–702. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Vaidya, M.M.; Duval, S.A.; Hamad, F. Polymer-Based Membranes for C3+ Hydrocarbon Removal from Natural Gas; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Scholz, M.; Melin, T.; Wessling, M. Transforming biogas into biomethane using membrane technology. Renew. Sustain. Energy Rev. 2013, 17, 199–212. [Google Scholar] [CrossRef]

- Koros, W.; Fleming, G. Membrane-based gas separation. J. Membr. Sci. 1993, 83, 1–80. [Google Scholar] [CrossRef]

- Bos, A.; Pünt, I.; Wessling, M.; Strathmann, H. CO2-induced plasticization phenomena in glassy polymers. J. Membr. Sci. 1999, 155, 67–78. [Google Scholar] [CrossRef]

- Frisch, H.L.; Stern, S.A. Diffusion of small molecules in polymers. Crit. Rev. Solid State Mater. Sci. 1983, 11, 123–187. [Google Scholar] [CrossRef]

- Sridhar, S.; Smitha, B.; Aminabhavi, T.M. Separation of carbon dioxide from natural gas mixtures through polymeric membranes—A review. Sep. Purif. Rev. 2007, 36, 113–174. [Google Scholar] [CrossRef]

- Robeson, L.M. The upper bound revisited. J. Membr. Sci. 2008, 320, 390–400. [Google Scholar] [CrossRef]

- Merkel, T.C.; Lin, H.; Wei, X.; Baker, R. Power plant post-combustion carbon dioxide capture: An opportunity for membranes. J. Membr. Sci. 2010, 359, 126–139. [Google Scholar] [CrossRef]

- Budd, P.M.; Ghanem, B.S.; Makhseed, S.; McKeown, N.B.; Msayib, K.J.; Tattershall, C.E. Polymers of intrinsic microporosity (PIMs): Robust, solution-processable, organic nanoporous materials. Chem. Commun. 2003, 230–231. [Google Scholar] [CrossRef]

- Park, H.B.; Jung, C.H.; Lee, Y.M.; Hill, A.J.; Pas, S.J.; Mudie, S.T.; Van Wagner, E.; Freeman, B.D.; Cookson, D.J. Polymers with cavities tuned for fast selective transport of small molecules and ions. Science 2007, 318, 254–258. [Google Scholar] [CrossRef]

- Dechnik, J.; Gascon, J.; Doonan, C.J.; Janiak, C.; Sumby, C.J. Mixed-Matrix Membranes. Angewandte Chemie International Edition 2017, 56, 9292–9310. [Google Scholar] [CrossRef]

- Baker, R.W.; Lokhandwala, K. Natural gas processing with membranes: An overview. Ind. Eng. Chem. Res. 2008, 47, 2109–2121. [Google Scholar] [CrossRef]

- Rahman, W.A.W.A.; Aizan, W.; Ismail, A.F. Formation and Characterization of Mixed Matrix Composite Materials for Efficient Energy Gas Separation; Universiti Teknologi Malaysia: Johor Bahru, Malaysia, 2006. [Google Scholar]

- Wind, J.D.; Sirard, S.M.; Paul, D.R.; Green, P.F.; Johnston, K.P.; Koros, W.J. Relaxation dynamics of CO2 diffusion, sorption, and polymer swelling for plasticized polyimide membranes. Macromolecules 2003, 36, 6442–6448. [Google Scholar] [CrossRef]

- De Meis, D.; Richetta, M.; Serra, E. Microporous inorganic membranes for gas separation and purification. Interceram Int. Ceram. Rev. 2018, 67, 16–21. [Google Scholar] [CrossRef]

- Koresh, J.E.; Soffer, A. Mechanism of permeation through molecular-sieve carbon membrane. Part 1.—The effect of adsorption and the dependence on pressure. J. Chem. Soc. Faraday Trans. 1 Phys. Chem. Condens. Phases 1986, 82, 2057–2063. [Google Scholar] [CrossRef]

- Cardoso, S.P.; Azenha, I.S.; Lin, Z.; Portugal, I.; Rodrigues, A.E.; Silva, C.M. Inorganic membranes for hydrogen separation. Separ. Purific. Rev. 2018, 47, 229–266. [Google Scholar] [CrossRef]

- Chung, T.-S.; Jiang, L.Y.; Li, Y.; Kulprathipanja, S. Mixed matrix membranes (MMMs) comprising organic polymers with dispersed inorganic fillers for gas separation. Prog. Polym. Sci. 2007, 32, 483–507. [Google Scholar] [CrossRef]

- Rezaei, M.; Ismail, A.; Hashemifard, S.; Bakeri, G.; Matsuura, T. Experimental study on the performance and long-term stability of PVDF/montmorillonite hollow fiber mixed matrix membranes for CO2 separation process. Int. J. Greenh. Gas Control 2014, 26, 147–157. [Google Scholar] [CrossRef]

- Kim, J.F.; Kim, J.H.; Lee, Y.M.; Drioli, E. Thermally induced phase separation and electrospinning methods for emerging membrane applications: A review. AIChE J. 2016, 62, 461–490. [Google Scholar] [CrossRef]

- Tang, Y.; Lin, Y.; Ford, D.M.; Qian, X.; Cervellere, M.R.; Millett, P.C.; Wang, X. A review on models and simulations of membrane formation via phase inversion processes. J. Membr. Sci. 2021, 640, 119810. [Google Scholar] [CrossRef]

- Megelski, S.; Stephens, J.S.; Chase, D.B.; Rabolt, J.F. Micro-and nanostructured surface morphology on electrospun polymer fibers. Macromolecules 2002, 35, 8456–8466. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Lalia, B.S.; Hashaikeh, R. A review on electrospinning for membrane fabrication: Challenges and applications. Desalination 2015, 356, 15–30. [Google Scholar] [CrossRef]

- Liu, R.; Qiao, X.; Chung, T.-S. The development of high performance P84 co-polyimide hollow fibers for pervaporation dehydration of isopropanol. Chem. Eng. Sci. 2005, 60, 6674–6686. [Google Scholar] [CrossRef]

- Asad, A.; Sameoto, D.; Sadrzadeh, M. Overview of membrane technology. In Nanocomposite Membranes for Water and Gas Separation; Elsevier: Amsterdam, The Nethgerlands, 2020; pp. 1–28. [Google Scholar]

- Tijing, L.D.; Choi, J.-S.; Lee, S.; Kim, S.-H.; Shon, H.K. Recent progress of membrane distillation using electrospun nanofibrous membrane. J. Membr. Sci. 2014, 453, 435–462. [Google Scholar] [CrossRef]

- Zito, P.F.; Caravella, A.; Brunetti, A.; Drioli, E.; Barbieri, G. Discrimination among gas translation, surface and Knudsen diffusion in permeation through zeolite membranes. J. Membrane Sci. 2018, 564, 166–173. [Google Scholar] [CrossRef]

- Ding, L.; Wei, Y.; Li, L.; Zhang, T.; Wang, H.; Xue, J.; Ding, L.-X.; Wang, S.; Caro, J.; Gogotsi, Y. MXene molecular sieving membranes for highly efficient gas separation. Nat. Commun. 2018, 9, 155. [Google Scholar] [CrossRef] [PubMed]

- Razzaz, Z. Continuous Production of Porous Hollow Fiber Mixed Matrix Membranes for Gas Separation. Ph.D. Thesis, Université Laval, Quebec, QC, Canada, 2019. [Google Scholar]

- Sridhar, S.; Bee, S.; Bhargava, S. Membrane-based gas separationrinciple, applications and future potential. Chem. Eng. Dig. 2014, 1, 1–25. [Google Scholar]

- Gür, T.M. Permselectivity of zeolite filled polysulfone gas separation membranes. J. Membr. Sci. 1994, 93, 283–289. [Google Scholar] [CrossRef]

- Casado-Coterillo, C. Mixed Matrix Membranes; Multidisciplinary Digital Publishing Institute: Basel, Switzerland, 2019; p. 149. [Google Scholar]

- Yi, L. Development of Mixed Matrix Membranes for Gas Separation Application; National University of Singapore: Singapore, 2006. [Google Scholar]

- Aroon, M.; Ismail, A.; Matsuura, T.; Montazer-Rahmati, M. Performance studies of mixed matrix membranes for gas separation: A review. Sep. Purif. Technol. 2010, 75, 229–242. [Google Scholar] [CrossRef]

- Okumus, E.; Gurkan, T.; Yilmaz, L. Development of a mixed-matrix membrane for pervaporation. Sep. Sci. Technol. 1994, 29, 2451–2473. [Google Scholar] [CrossRef]

- Azizi, N.; Mohammadi, T.; Behbahani, R.M. Synthesis of a PEBAX-1074/ZnO nanocomposite membrane with improved CO2 separation performance. J. Energy Chem. 2017, 26, 454–465. [Google Scholar] [CrossRef] [Green Version]

- Cong, H.; Radosz, M.; Towler, B.F.; Shen, Y. Polymer–inorganic nanocomposite membranes for gas separation. Sep. Purif. Technol. 2007, 55, 281–291. [Google Scholar] [CrossRef]

- Thür, R.; Van Velthoven, N.; Slootmaekers, S.; Didden, J.; Verbeke, R.; Smolders, S.; Dickmann, M.; Egger, W.; De Vos, D.; Vankelecom, I.F. Bipyridine-based UiO-67 as novel filler in mixed-matrix membranes for CO2-selective gas separation. J. Membr. Sci. 2019, 576, 78–87. [Google Scholar] [CrossRef]

- Vinoba, M.; Bhagiyalakshmi, M.; Alqaheem, Y.; Alomair, A.A.; Pérez, A.; Rana, M.S. Recent progress of fillers in mixed matrix membranes for CO2 separation: A review. Sep. Purif. Technol. 2017, 188, 431–450. [Google Scholar] [CrossRef]

- Şen, D.; Kalıpçılar, H.; Yilmaz, L. Development of polycarbonate based zeolite 4A filled mixed matrix gas separation membranes. J. Membr. Sci. 2007, 303, 194–203. [Google Scholar] [CrossRef]

- Moore, T.T.; Koros, W.J. Non-ideal effects in organic–inorganic materials for gas separation membranes. J. Mol. Struct. 2005, 739, 87–98. [Google Scholar] [CrossRef]

- Duval, J.M.; Kemperman, A.; Folkers, B.; Mulder, M. Preparation of zeolite filled glassy polymer membranes. J. Appl. Polym. Sci. 1994, 54, 409–418. [Google Scholar] [CrossRef] [Green Version]

- Husain, S.; Koros, W.J. Mixed matrix hollow fiber membranes made with modified HSSZ-13 zeolite in polyetherimide polymer matrix for gas separation. J. Membr. Sci. 2007, 288, 195–207. [Google Scholar] [CrossRef]

- Hamid, M.R.A.; Jeong, H.-K. Recent advances on mixed-matrix membranes for gas separation: Opportunities and engineering challenges. Korean J. Chem. Eng. 2018, 35, 1577–1600. [Google Scholar] [CrossRef]

- Zhang, M.; Deng, L.; Xiang, D.; Cao, B.; Hosseini, S.S.; Li, P. Approaches to suppress CO2-induced plasticization of polyimide membranes in gas separation applications. Processes 2019, 7, 51. [Google Scholar] [CrossRef] [Green Version]

- Scholes, C.A.; Chen, G.Q.; Stevens, G.W.; Kentish, S.E. Plasticization of ultra-thin polysulfone membranes by carbon dioxide. J. Membr. Sci. 2010, 346, 208–214. [Google Scholar] [CrossRef]

- Adewole, J.; Ahmad, A.; Ismail, S.; Leo, C. Current challenges in membrane separation of CO2 from natural gas: A review. Int. J. Greenh. Gas Control 2013, 17, 46–65. [Google Scholar] [CrossRef]

- Zarshenas, K.; Raisi, A.; Aroujalian, A. Mixed matrix membrane of nano-zeolite NaX/poly (ether-block-amide) for gas separation applications. J. Membr. Sci. 2016, 510, 270–283. [Google Scholar] [CrossRef]

- Tantekin-Ersolmaz, Ş.B.; Atalay-Oral, Ç.; Tatlıer, M.; Erdem-Şenatalar, A.; Schoeman, B.; Sterte, J. Effect of zeolite particle size on the performance of polymer–zeolite mixed matrix membranes. J. Membr. Sci. 2000, 175, 285–288. [Google Scholar] [CrossRef]

- Liu, G.; Labreche, Y.; Chernikova, V.; Shekhah, O.; Zhang, C.; Belmabkhout, Y.; Eddaoudi, M.; Koros, W.J. Zeolite-like MOF nanocrystals incorporated 6FDA-polyimide mixed-matrix membranes for CO2/CH4 separation. J. Membr. Sci. 2018, 565, 186–193. [Google Scholar] [CrossRef]

- Shishatskiy, S.; Pauls, J.R.; Nunes, S.P.; Peinemann, K.-V. Quaternary ammonium membrane materials for CO2 separation. J. Membr. Sci. 2010, 359, 44–53. [Google Scholar] [CrossRef] [Green Version]

- Isanejad, M.; Mohammadi, T. Effect of amine modification on morphology and performance of poly (ether-block-amide)/fumed silica nanocomposite membranes for CO2/CH4 separation. Mater. Chem. Phys. 2018, 205, 303–314. [Google Scholar] [CrossRef]

- Bertelle, S.S.; Gupta, T.; Roizard, D.; Vallières, C.; Favre, E. Study of polymer-carbon mixed matrix membranes for CO2 separation from flue gas. Desalination 2006, 199, 401–402. [Google Scholar] [CrossRef]

- Rafizah, W.; Ismail, A. Effect of carbon molecular sieve sizing with poly (vinyl pyrrolidone) K-15 on carbon molecular sieve–polysulfone mixed matrix membrane. J. Membr. Sci. 2008, 307, 53–61. [Google Scholar] [CrossRef]

- Ahn, J.; Chung, W.-J.; Pinnau, I.; Song, J.; Du, N.; Robertson, G.P.; Guiver, M.D. Gas transport behavior of mixed-matrix membranes composed of silica nanoparticles in a polymer of intrinsic microporosity (PIM-1). J. Membr. Sci. 2010, 346, 280–287. [Google Scholar] [CrossRef] [Green Version]

- Goh, P.; Ismail, A.; Sanip, S.; Ng, B.; Aziz, M. Recent advances of inorganic fillers in mixed matrix membrane for gas separation. Sep. Purif. Technol. 2011, 81, 243–264. [Google Scholar] [CrossRef]

- Ladhe, A.; Frailie, P.; Hua, D.; Darsillo, M.; Bhattacharyya, D. Thiol-functionalized silica–mixed matrix membranes for silver capture from aqueous solutions: Experimental results and modeling. J. Membr. Sci. 2009, 326, 460–471. [Google Scholar] [CrossRef] [Green Version]

- Zornoza, B.; Téllez, C.; Coronas, J. Mixed matrix membranes comprising glassy polymers and dispersed mesoporous silica spheres for gas separation. J. Membr. Sci. 2011, 368, 100–109. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Pinnavaia, T.J. Steam-stable aluminosilicate mesostructures assembled from zeolite type Y seeds. J. Am. Chem. Soc. 2000, 122, 8791–8792. [Google Scholar] [CrossRef]

- Vinh-Thang, H.; Huang, Q.; Eić, M.; Trong-On, D.; Kaliaguine, S. Adsorption of C7 hydrocarbons on biporous SBA-15 mesoporous silica. Langmuir 2005, 21, 5094–5101. [Google Scholar] [CrossRef]

- Hamoudi, S.; Royer, S.; Kaliaguine, S. Propyl-and arene-sulfonic acid functionalized periodic mesoporous organosilicas. Microporous Mesoporous Mater. 2004, 71, 17–25. [Google Scholar] [CrossRef]

- Cong, H.; Zhang, J.; Radosz, M.; Shen, Y. Carbon nanotube composite membranes of brominated poly (2, 6-diphenyl-1, 4-phenylene oxide) for gas separation. J. Membr. Sci. 2007, 294, 178–185. [Google Scholar] [CrossRef]

- Xie, X.-L.; Mai, Y.-W.; Zhou, X.-P. Dispersion and alignment of carbon nanotubes in polymer matrix: A review. Mater. Sci. Eng. R Rep. 2005, 49, 89–112. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Kim, J.S.; Yun, J.H.; Kim, I.; Shim, S.E. Electrical properties of graphene/SBR nanocomposite prepared by latex heterocoagulation process at room temperature. J. Ind. Eng. Chem. 2011, 17, 325–330. [Google Scholar] [CrossRef]

- Jilani, A.; Othman, M.H.D.; Ansari, M.O.; Hussain, S.Z.; Ismail, A.F.; Khan, I.U. Graphene and its derivatives: Synthesis, modifications, and applications in wastewater treatment. Environ. Chem. Lett. 2018, 16, 1301–1323. [Google Scholar] [CrossRef]

- Jilani, A.; Othman, M.H.D.; Ansari, M.O.; Oves, M.; Hussain, S.Z.; Khan, I.U.; Abdel-wahab, M.S. Structural and optical characteristics, and bacterial decolonization studies on non-reactive RF sputtered Cu–ZnO@ graphene based nanoparticles thin films. J. Mater. Sci. 2019, 54, 6515–6529. [Google Scholar] [CrossRef]

- Ortiz, O.L.; Ramírez, L.D. Coordination Polymers and Metal Organic Frameworksroperties, Types and Applications; Nova Science Publishers: Hauppauge, NY, USA, 2012. [Google Scholar]

- Basu, S.; Odena, A.; Vankelecom, I.F. Asymmetric Matrimid®/[Cu3(BTC)2] mixed-matrix membranes for gas separations. J. Membr. Sci. 2010, 362, 478–487. [Google Scholar] [CrossRef]

- Ma, S.; Sun, D.; Simmons, J.M.; Collier, C.D.; Yuan, D.; Zhou, H.-C. Metal-organic framework from an anthracene derivative containing nanoscopic cages exhibiting high methane uptake. J. Am. Chem. Soc. 2008, 130, 1012–1016. [Google Scholar] [CrossRef]

- Schlichte, K.; Kratzke, T.; Kaskel, S. Improved synthesis, thermal stability and catalytic properties of the metal-organic framework compound Cu3 (BTC) 2. Microporous Mesoporous Mater. 2004, 73, 81–88. [Google Scholar] [CrossRef]

- Perez, E.V.; Balkus Jr, K.J.; Ferraris, J.P.; Musselman, I.H. Mixed-matrix membranes containing MOF-5 for gas separations. J. Membr. Sci. 2009, 328, 165–173. [Google Scholar] [CrossRef]

- Burmann, P.; Zornoza, B.; Téllez, C.; Coronas, J. Mixed matrix membranes comprising MOFs and porous silicate fillers prepared via spin coating for gas separation. Chem. Eng. Sci. 2014, 107, 66–75. [Google Scholar] [CrossRef]

- Caro, J. Are MOF membranes better in gas separation than those made of zeolites? Curr. Opin. Chem. Eng. 2011, 1, 77–83. [Google Scholar] [CrossRef]

- Semino, R.; Ramsahye, N.A.; Ghoufi, A.; Maurin, G. Role of MOF surface defects on the microscopic structure of MOF/polymer interfaces: A computational study of the ZIF-8/PIMs systems. Microporous Mesoporous Mater. 2017, 254, 184–191. [Google Scholar] [CrossRef]

- Rowe, B.W.; Robeson, L.M.; Freeman, B.D.; Paul, D.R. Influence of temperature on the upper bound: Theoretical considerations and comparison with experimental results. J. Membr. Sci. 2010, 360, 58–69. [Google Scholar] [CrossRef]

- Yang, T.; Shi, G.M.; Chung, T.S. Symmetric and asymmetric zeolitic imidazolate frameworks (ZIFs)/polybenzimidazole (PBI) nanocomposite membranes for hydrogen purification at high temperatures. Adv. Energy Mater. 2012, 2, 1358–1367. [Google Scholar] [CrossRef]

- Ordonez, M.J.C.; Balkus Jr, K.J.; Ferraris, J.P.; Musselman, I.H. Molecular sieving realized with ZIF-8/Matrimid® mixed-matrix membranes. J. Membr. Sci. 2010, 361, 28–37. [Google Scholar] [CrossRef]

- Zhang, Y.; Musselman, I.H.; Ferraris, J.P.; Balkus, K.J., Jr. Gas permeability properties of Matrimid® membranes containing the metal-organic framework Cu–BPY–HFS. J. Membr. Sci. 2008, 313, 170–181. [Google Scholar] [CrossRef]

- Nafisi, V.; Hägg, M.-B. Gas separation properties of ZIF-8/6FDA-durene diamine mixed matrix membrane. Sep. Purif. Technol. 2014, 128, 31–38. [Google Scholar] [CrossRef]

- Ishaq, S.; Tamime, R.; Bilad, M.R.; Khan, A.L. Mixed matrix membranes comprising of polysulfone and microporous Bio-MOF-1reparation and gas separation properties. Sep. Purif. Technol. 2019, 210, 442–451. [Google Scholar] [CrossRef]

- Chang, Y.-W.; Chang, B.K. Influence of casting solvents on sedimentation and performance in metal–organic framework mixed-matrix membranes. J. Taiwan Inst. Chem. Eng. 2018, 89, 224–233. [Google Scholar] [CrossRef]

- Jeazet, H.B.; Koschine, T.; Staudt, C.; Raetzke, K.; Janiak, C. Correlation of gas permeability in a metal-organic framework MIL-101 (Cr)–polysulfone mixed-matrix membrane with free volume measurements by positron annihilation lifetime spectroscopy (PALS). Membranes 2013, 3, 331–353. [Google Scholar] [CrossRef]

- Car, A.; Stropnik, C.; Peinemann, K.-V. Hybrid membrane materials with different metal–organic frameworks (MOFs) for gas separation. Desalination 2006, 200, 424–426. [Google Scholar] [CrossRef]

- Park, K.S.; Ni, Z.; Côté, A.P.; Choi, J.Y.; Huang, R.; Uribe-Romo, F.J.; Chae, H.K.; O’Keeffe, M.; Yaghi, O.M. Exceptional chemical and thermal stability of zeolitic imidazolate frameworks. Proc. Natl. Acad. Sci. USA 2006, 103, 10186–10191. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bao, Z.; Yu, L.; Ren, Q.; Lu, X.; Deng, S. Adsorption of CO2 and CH4 on a magnesium-based metal organic framework. J. Colloid Interface Sci. 2010, 353, 549–556. [Google Scholar] [CrossRef] [PubMed]

- Li, J.-R.; Sculley, J.; Zhou, H.-C. Metal–organic frameworks for separations. Chem. Rev. 2012, 112, 869–932. [Google Scholar] [CrossRef] [PubMed]

- Li, J.-R.; Ma, Y.; McCarthy, M.C.; Sculley, J.; Yu, J.; Jeong, H.-K.; Balbuena, P.B.; Zhou, H.-C. Carbon dioxide capture-related gas adsorption and separation in metal-organic frameworks. Coord. Chem. Rev. 2011, 255, 1791–1823. [Google Scholar] [CrossRef]

- Banerjee, R.; Phan, A.; Wang, B.; Knobler, C.; Furukawa, H.; O’Keeffe, M.; Yaghi, O.M. High-throughput synthesis of zeolitic imidazolate frameworks and application to CO2 capture. Science 2008, 319, 939–943. [Google Scholar] [CrossRef]

- Zhang, C.; Lively, R.P.; Zhang, K.; Johnson, J.R.; Karvan, O.; Koros, W.J. Unexpected molecular sieving properties of zeolitic imidazolate framework-8. J. Phys. Chem. Lett. 2012, 3, 2130–2134. [Google Scholar] [CrossRef]

- Tagliabue, M.; Farrusseng, D.; Valencia, S.; Aguado, S.; Ravon, U.; Rizzo, C.; Corma, A.; Mirodatos, C. Natural gas treating by selective adsorption: Material science and chemical engineering interplay. Chem. Eng. J. 2009, 155, 553–566. [Google Scholar] [CrossRef]

- Rahmani, M.; Kazemi, A.; Talebnia, F. Matrimid mixed matrix membranes for enhanced CO2/CH4 separation. J. Polym. Eng. 2016, 36, 499–511. [Google Scholar] [CrossRef]

- Jeong, H.-K.; Krych, W.; Ramanan, H.; Nair, S.; Marand, E.; Tsapatsis, M. Fabrication of polymer/selective-flake nanocomposite membranes and their use in gas separation. Chem. Mater. 2004, 16, 3838–3845. [Google Scholar] [CrossRef]

- Khan, I.U.; Othman, M.H.D.; Jilani, A.; Ismail, A.; Hashim, H.; Jaafar, J.; Zulhairun, A.; Rahman, M.A.; Rehman, G.U. ZIF-8 based polysulfone hollow fiber membranes for natural gas purification. Polym. Test. 2020, 84, 106415. [Google Scholar] [CrossRef]

- Chakrabarty, T.; Giri, A.K.; Sarkar, S. Mixed-matrix gas separation membranes for sustainable future: A mini review. Polym. Adv. Technol. 2022, 33, 1747–1761. [Google Scholar] [CrossRef]

- Anson, M.; Marchese, J.; Garis, E.; Ochoa, N.; Pagliero, C. ABS copolymer-activated carbon mixed matrix membranes for CO2/CH4 separation. J. Membr. Sci. 2004, 243, 19–28. [Google Scholar] [CrossRef]

- Nordin, N.A.H.M.; Ismail, A.F.; Mustafa, A.; Murali, R.S.; Matsuura, T. Utilizing low ZIF-8 loading for an asymmetric PSf/ZIF-8 mixed matrix membrane for CO2/CH4 separation. RSC Adv. 2015, 5, 30206–30215. [Google Scholar] [CrossRef]

- Guo, X.; Huang, H.; Ban, Y.; Yang, Q.; Xiao, Y.; Li, Y.; Yang, W.; Zhong, C. Mixed matrix membranes incorporated with amine-functionalized titanium-based metal-organic framework for CO2/CH4 separation. J. Membr. Sci. 2015, 478, 130–139. [Google Scholar] [CrossRef]

- Peydayesh, M.; Asarehpour, S.; Mohammadi, T.; Bakhtiari, O. Preparation and characterization of SAPO-34–Matrimid® 5218 mixed matrix membranes for CO2/CH4 separation. Chem. Eng. Res. Des. 2013, 91, 1335–1342. [Google Scholar] [CrossRef]

- Ahmad, M.Z.; Navarro, M.; Lhotka, M.; Zornoza, B.; Téllez, C.; Fila, V.; Coronas, J. Enhancement of CO2/CH4 separation performances of 6FDA-based co-polyimides mixed matrix membranes embedded with UiO-66 nanoparticles. Sep. Purif. Technol. 2018, 192, 465–474. [Google Scholar] [CrossRef] [Green Version]

- Rezakazemi, M.; Shahidi, K.; Mohammadi, T. Hydrogen separation and purification using crosslinkable PDMS/zeolite A nanoparticles mixed matrix membranes. Int. J. Hydrogen Energy 2012, 37, 14576–14589. [Google Scholar] [CrossRef]

- Jomekian, A.; Behbahani, R.M.; Mohammadi, T.; Kargari, A. CO2/CH4 separation by high performance co-casted ZIF-8/Pebax 1657/PES mixed matrix membrane. J. Nat. Gas Sci. Eng. 2016, 31, 562–574. [Google Scholar] [CrossRef]

- Cakal, U.; Yilmaz, L.; Kalipcilar, H. Effect of feed gas composition on the separation of CO2/CH4 mixtures by PES-SAPO 34-HMA mixed matrix membranes. J. Membr. Sci. 2012, 417, 45–51. [Google Scholar] [CrossRef]

- Diestel, L.; Wang, N.; Schwiedland, B.; Steinbach, F.; Giese, U.; Caro, J. MOF based MMMs with enhanced selectivity due to hindered linker distortion. J. Membr. Sci. 2015, 492, 181–186. [Google Scholar] [CrossRef]

- Askari, M.; Chung, T.-S. Natural gas purification and olefin/paraffin separation using thermal cross-linkable co-polyimide/ZIF-8 mixed matrix membranes. J. Membr. Sci. 2013, 444, 173–183. [Google Scholar] [CrossRef]

- Rabiee, H.; Alsadat, S.M.; Soltanieh, M.; Mousavi, S.A.; Ghadimi, A. Gas permeation and sorption properties of poly (amide-12-b-ethyleneoxide)(Pebax1074)/SAPO-34 mixed matrix membrane for CO2/CH4 and CO2/N2 separation. J. Ind. Eng. Chem. 2015, 27, 223–239. [Google Scholar] [CrossRef]

- Yaghi, O.M. Metal-Organic and Zeolite Imidazolate Frameworks (MOFs and ZIFs) for Highly Selective Separations; University of California—Los Angeles: Los Angeles, CA, USA, 2012. [Google Scholar]

- Shah, M.; McCarthy, M.C.; Sachdeva, S.; Lee, A.K.; Jeong, H.-K. Current status of metal–organic framework membranes for gas separationsromises and challenges. Ind. Eng. Chem. Res. 2012, 51, 2179–2199. [Google Scholar] [CrossRef]

- Kitagawa, S.; Noro, S.-I.; Nakamura, T. Pore surface engineering of microporous coordination polymers. Chem. Commun. 2006, 701–707. [Google Scholar] [CrossRef]

- Khan, I.U.; Othman, M.H.D.; Jilani, A.; Ismail, A.F.; Hashim, H.; Jaafar, J.; Rahman, M.A.; Rehman, G.U. Economical, environmental friendly synthesis, characterization for the production of zeolitic imidazolate framework-8 (ZIF-8) nanoparticles with enhanced CO2 adsorption. Arab. J. Chem. 2018, 11, 1072–1083. [Google Scholar] [CrossRef]

- Kasik, A.; Dong, X.; Lin, Y. Synthesis and stability of zeolitic imidazolate framework-68 membranes. Microporous Mesoporous Mater. 2015, 204, 99–105. [Google Scholar] [CrossRef]

- Lotfi, R.; Saboohi, Y. Effect of metal doping, boron substitution and functional groups on hydrogen adsorption of MOF-5: A DFT-D study. Comput. Theor. Chem. 2014, 1044, 36–43. [Google Scholar] [CrossRef]

- Bux, H.; Liang, F.; Li, Y.; Cravillon, J.; Wiebcke, M.; Caro, J.r. Zeolitic imidazolate framework membrane with molecular sieving properties by microwave-assisted solvothermal synthesis. J. Am. Chem. Soc. 2009, 131, 16000–16001. [Google Scholar] [CrossRef]

- Cliffe, M.J.; Mottillo, C.; Stein, R.S.; Bučar, D.-K.; Friščić, T. Accelerated aging: A low energy, solvent-free alternative to solvothermal and mechanochemical synthesis of metal–organic materials. Chem. Sci. 2012, 3, 2495–2500. [Google Scholar] [CrossRef]

- Lin, J.-B.; Lin, R.-B.; Cheng, X.-N.; Zhang, J.-P.; Chen, X.-M. Solvent/additive-free synthesis of porous/zeolitic metal azolate frameworks from metal oxide/hydroxide. Chem. Commun. 2011, 47, 9185–9187. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, S.; Kida, K.; Okita, M.; Ito, Y.; Miyake, Y. Size-controlled synthesis of zeolitic imidazolate framework-8 (ZIF-8) crystals in an aqueous system at room temperature. Chem. Lett. 2012, 41, 1337–1339. [Google Scholar] [CrossRef]

- Sumida, K.; Rogow, D.L.; Mason, J.A.; McDonald, T.M.; Bloch, E.D.; Herm, Z.R.; Bae, T.-H.; Long, J.R. Carbon dioxide capture in metal–organic frameworks. Chem. Rev. 2012, 112, 724–781. [Google Scholar] [CrossRef] [PubMed]

- Tan, J.C.; Bennett, T.D.; Cheetham, A.K. Chemical structure, network topology, and porosity effects on the mechanical properties of Zeolitic Imidazolate Frameworks. Proc. Natl. Acad. Sci. USA 2010, 107, 9938–9943. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moggach, S.A.; Bennett, T.D.; Cheetham, A.K. The Effect of Pressure on ZIF-8: Increasing Pore Size with Pressure and the Formation of a High-Pressure Phase at 1.47 GPa. Angew. Chem. Int. Ed. 2009, 48, 7087–7089. [Google Scholar] [CrossRef] [Green Version]

- Zhao, P.; Bennett, T.D.; Casati, N.P.; Lampronti, G.I.; Moggach, S.A.; Redfern, S.A. Pressure-induced oversaturation and phase transition in zeolitic imidazolate frameworks with remarkable mechanical stability. Dalton Trans. 2015, 44, 4498–4503. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.-R.; Jang, M.-S.; Cho, H.-Y.; Kwon, H.-J.; Kim, S.; Ahn, W.-S. ZIF-8: A comparison of synthesis methods. Chem. Eng. J. 2015, 271, 276–280. [Google Scholar] [CrossRef]

- Cravillon, J.; Münzer, S.; Lohmeier, S.-J.; Feldhoff, A.; Huber, K.; Wiebcke, M. Rapid room-temperature synthesis and characterization of nanocrystals of a prototypical zeolitic imidazolate framework. Chem. Materials 2009, 21, 1410–1412. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, Y.; Zeng, G.; Zhao, L.; Lai, Z. Rapid synthesis of zeolitic imidazolate framework-8 (ZIF-8) nanocrystals in an aqueous system. Chem. Commun. 2011, 47, 2071–2073. [Google Scholar] [CrossRef]

- Banerjee, R.; Furukawa, H.; Britt, D.; Knobler, C.; O’Keeffe, M.; Yaghi, O.M. Control of pore size and functionality in isoreticular zeolitic imidazolate frameworks and their carbon dioxide selective capture properties. J. Am. Chem. Soc. 2009, 131, 3875–3877. [Google Scholar] [CrossRef]

- Li, K.; Olson, D.H.; Seidel, J.; Emge, T.J.; Gong, H.; Zeng, H.; Li, J. Zeolitic imidazolate frameworks for kinetic separation of propane and propene. J. Am. Chem. Soc. 2009, 131, 10368–10369. [Google Scholar] [CrossRef]

- Li, Y.S.; Liang, F.Y.; Bux, H.; Feldhoff, A.; Yang, W.S.; Caro, J. Inside cover: Molecular sieve membrane: Supported metal–organic framework with high hydrogen selectivity (Angew. Chem. Int. Ed. 3/2010). Angew. Chem. Int. Ed. 2010, 49, 464. [Google Scholar] [CrossRef]

- Qiu, S.; Zhu, G. Molecular engineering for synthesizing novel structures of metal–organic frameworks with multifunctional properties. Coord. Chem. Rev. 2009, 253, 2891–2911. [Google Scholar] [CrossRef]

- Chizallet, C.; Lazare, S.; Bazer-Bachi, D.; Bonnier, F.; Lecocq, V.; Soyer, E.; Quoineaud, A.-A.; Bats, N. Catalysis of transesterification by a nonfunctionalized metal− organic framework: Acido-basicity at the external surface of ZIF-8 probed by FTIR and ab initio calculations. J. Am. Chem. Soc. 2010, 132, 12365–12377. [Google Scholar] [CrossRef]

- Ullah Khan, I.; Othman, M.H.D.; Ismail, A.F.; Matsuura, T.; Hashim, H.; Nordin, N.A.H.M.; Rahman, M.A.; Jaafar, J.; Jilani, A. Status and improvement of dual-layer hollow fiber membranes via co-extrusion process for gas separation: A review. J. Nat. Gas Sci. Eng. 2018, 52, 215–234. [Google Scholar] [CrossRef]

- Khan, I.U.; Othman, M.H.D.; Ismail, A.F.; Ismail, N.; Jaafar, J.; Hashim, H.; Rahman, M.A.; Jilani, A. Structural transition from two-dimensional ZIF-L to three-dimensional ZIF-8 nanoparticles in aqueous room temperature synthesis with improved CO2 adsorption. Mater. Charact. 2018, 136, 407–416. [Google Scholar] [CrossRef]

- Lin, R.; Hernandez, B.V.; Ge, L.; Zhu, Z. Metal organic framework based mixed matrix membranes: An overview on filler/polymer interfaces. J. Mater. Chem. A 2018, 6, 293–312. [Google Scholar] [CrossRef]

- Hashemifard, S.; Ismail, A.F.; Matsuura, T. Effects of montmorillonite nano-clay fillers on PEI mixed matrix membrane for CO2 removal. Chem. Eng. J. 2011, 170, 316–325. [Google Scholar] [CrossRef]

- Zhang, Z.; Xian, S.; Xi, H.; Wang, H.; Li, Z. Improvement of CO2 adsorption on ZIF-8 crystals modified by enhancing basicity of surface. Chem. Eng. Sci. 2011, 66, 4878–4888. [Google Scholar] [CrossRef]

- Cheng, Y.; Ying, Y.; Japip, S.; Jiang, S.D.; Chung, T.S.; Zhang, S.; Zhao, D. Advanced porous materials in mixed matrix membranes. Adv. Mater. 2018, 30, 1802401. [Google Scholar] [CrossRef]

- Dai, Z.; Løining, V.; Deng, J.; Ansaloni, L.; Deng, L. Poly (1-trimethylsilyl-1-propyne)-based hybrid membranes: Effects of various nanofillers and feed gas humidity on CO2 permeation. Membranes 2018, 8, 76. [Google Scholar] [CrossRef] [Green Version]

- Clarizia, G.; Bernardo, P. A Review of the Recent Progress in the Development of Nanocomposites Based on Poly(ether-block-amide) Copolymers as Membranes for CO(2) Separation. Polymers 2021, 14, 10. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, Y.M. Gas permeation properties of poly (amide-6-b-ethylene oxide)–silica hybrid membranes. J. Membr. Sci. 2001, 193, 209–225. [Google Scholar] [CrossRef]

- Markova, S.Y.; Dukhov, A.V.; Pelzer, M.; Shalygin, M.G.; Vad, T.; Gries, T.; Teplyakov, V.V. Designing 3D Membrane Modules for Gas Separation Based on Hollow Fibers from Poly (4-methyl-1-pentene). Membranes 2021, 12, 36. [Google Scholar] [CrossRef]

- Mahon, H.I. Permeability Separatory Apparatus and Process Utilizing Hollow Fibers. U.S. Patent 3228876, 11 January 1966. [Google Scholar]

- Wan, C.F.; Yang, T.; Lipscomb, G.G.; Stookey, D.J.; Chung, T.-S. Design and fabrication of hollow fiber membrane modules. J. Membr. Sci. 2017, 538, 96–107. [Google Scholar] [CrossRef]

- Goh, K.; Setiawan, L.; Wei, L.; Si, R.; Fane, A.G.; Wang, R.; Chen, Y. Graphene oxide as effective selective barriers on a hollow fiber membrane for water treatment process. J. Membr. Sci. 2015, 474, 244–253. [Google Scholar] [CrossRef]

- Sharpe, I.D.; Ismail, A.F.; Shilton, S.J. A study of extrusion shear and forced convection residence time in the spinning of polysulfone hollow fiber membranes for gas separation. Sep. Purif. Technol. 1999, 17, 101–109. [Google Scholar] [CrossRef]

- Ekiner, O.; Vassilatos, G. Polyaramide hollow fibers for H2/CH4 separation: II. Spinning and properties. J. Membr. Sci. 2001, 186, 71–84. [Google Scholar] [CrossRef]

- Huang, Y.; Xiao, C.; Huang, Q.; Liu, H.; Zhao, J. Progress on polymeric hollow fiber membrane preparation technique from the perspective of green and sustainable development. Chem. Eng. J. 2021, 403, 126295. [Google Scholar] [CrossRef]

- Chung, T.S.; Kafchinski, E.R. The effects of spinning conditions on asymmetric 6FDA/6FDAM polyimide hollow fibers for air separation. J. Appl. Polym. Sci. 1997, 65, 1555–1569. [Google Scholar] [CrossRef]

- Chung, T.S.; Hu, X. Effect of air-gap distance on the morphology and thermal properties of polyethersulfone hollow fibers. J. Appl. Polym. Sci. 1997, 66, 1067–1077. [Google Scholar] [CrossRef]

- Clausi, D.T.; Koros, W.J. Formation of defect-free polyimide hollow fiber membranes for gas separations. J. Membr. Sci. 2000, 167, 79–89. [Google Scholar] [CrossRef]

- Qin, J.-J.; Chung, T.-S. Effects of orientation relaxation and bore fluid chemistry on morphology and performance of polyethersulfone hollow fibers for gas separation. J. Membr. Sci. 2004, 229, 1–9. [Google Scholar] [CrossRef]

- Widjojo, N.; Chung, T.-S. The Thickness and Air Gap Dependence of Macrovoid Evolution in Phase-inversion Asymmetric Hollow Fiber Membranes. In Hollow Fiber Membranes; Elsevier: Amsterdam, The Netherlands, 2021; pp. 123–140. [Google Scholar]

- Kesting, R.; Fritzsche, A.; Murphy, M.; Cruse, C.; Handermann, A.; Malon, R.; Moore, M. The second-generation polysulfone gas-separation membrane. I. The use of lewis acid: Base complexes as transient templates to increase free volume. J. Appl. Polym. Sci. 1990, 40, 1557–1574. [Google Scholar] [CrossRef]

- Baker, R.W. Future directions of membrane gas separation technology. Ind. Eng. Chem. Res. 2002, 41, 1393–1411. [Google Scholar] [CrossRef]

- Feng, C.; Khulbe, K.; Matsuura, T.; Ismail, A. Recent progresses in polymeric hollow fiber membrane preparation, characterization and applications. Sep. Purif. Technol. 2013, 111, 43–71. [Google Scholar] [CrossRef]

- Wei, X.; Kong, X.; Wang, S.; Xiang, H.; Wang, J.; Chen, J. Removal of heavy metals from electroplating wastewater by thin-film composite nanofiltration hollow-fiber membranes. Ind. Eng. Chem. Res. 2013, 52, 17583–17590. [Google Scholar] [CrossRef]

- Ashrafizadeh, S.; Khorasani, Z. Ammonia removal from aqueous solutions using hollow-fiber membrane contactors. Chem. Eng. J. 2010, 162, 242–249. [Google Scholar] [CrossRef]

- Sengur-Tasdemir, R.; Sayinli, B.; Urper, G.M.; Tutuncu, H.E.; Gul-Karaguler, N.; Ates-Genceli, E.; Tarabara, V.V.; Koyuncu, I. Hollow fiber nanofiltration membranes with integrated aquaporin Z. New J. Chem. 2018, 42, 17769–17778. [Google Scholar] [CrossRef]

- Ji, J. Method for Producing Defect Free Composite Membranes. U.S. Patent 0289350, 25 July 2006. [Google Scholar]

- Hu, X.Y.; Liang, H.; Xiao, C. Preparation of polyurethane/poly (vinylidene fluoride) blend hollow fibre membrane using melt spinning and stretching. Mater. Sci. Technol. 2011, 27, 661–665. [Google Scholar] [CrossRef]

- Lee, M.-S.; Choi, S.-H.; Shin, Y.-C. Braid-Reinforced Hollow Fiber Membrane. U.S. Patent 7267872, 19 August 2008. [Google Scholar]

- Mailvaganam, M.; Fabbricino, L.; Rodrigues, C.F.; Donnelly, A.R. Hollow Fiber Semipermeable Membrane of Tubular Braid. U.S. Patent 5472607, 5 December 1995. [Google Scholar]

- Van der Meer, W.; Van Dijk, J. Theoretical optimization of spiral-wound and capillary nanofiltration modules. Desalination 1997, 113, 129–146. [Google Scholar] [CrossRef]

- Fan, Z.; Xiao, C.; Liu, H.; Huang, Q. Preparation and performance of homogeneous braid reinforced cellulose acetate hollow fiber membranes. Cellulose 2015, 22, 695–707. [Google Scholar] [CrossRef]

- Chen, M.; Xiao, C.; Wang, C.; Liu, H. Study on the structural design and performance of novel braid-reinforced and thermostable poly (m-phenylene isophthalamide) hollow fiber membranes. RSC Adv. 2017, 7, 20327–20335. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Xiao, C.; Hu, X.; Jin, X.; Bai, Q. Study on the interfacial bonding state and fouling phenomena of polyvinylidene fluoride matrix-reinforced hollow fiber membranes during microfiltration. Desalination 2013, 330, 49–60. [Google Scholar] [CrossRef]

- Fan, Z.; Xiao, C.; Liu, H.; Huang, Q.; Zhao, J. Structure design and performance study on braid-reinforced cellulose acetate hollow fiber membranes. J. Membr. Sci. 2015, 486, 248–256. [Google Scholar] [CrossRef]

- Quan, Q.; Xiao, C.; Liu, H.; Huang, Q.; Zhao, W.; Hu, X.; Huan, G. Preparation and characterization of braided tube reinforced polyacrylonitrile hollow fiber membranes. J. Appl. Polym. Sci. 2015, 132, 41795. [Google Scholar] [CrossRef]

- Zhou, Z.; Fang, L.F.; Wang, S.Y.; Matsuyama, H. Improving bonding strength between a hydrophilic coating layer and poly (ethylene terephthalate) braid for preparing mechanically stable braid-reinforced hollow fiber membranes. J. Appl. Polym. Sci. 2018, 135, 46104. [Google Scholar] [CrossRef]

- Liu, H.; Wang, S.; Mao, J.; Xiao, C.; Huang, Q. Preparation and performance of braid-reinforced poly (vinyl chloride) hollow fiber membranes. J. Appl. Polym. Sci. 2017, 134, 45068. [Google Scholar] [CrossRef]

- Mahendran, M.; Goodboy, K.P.; Fabbricino, L. Hollow Fiber Membrane and Braided Tubular Support Therefor. U.S. Patent 6354444, 12 March 2002. [Google Scholar]

- Qin, J.-J.; Gu, J.; Chung, T.-S. Effect of wet and dry-jet wet spinning on the shear-induced orientation during the formation of ultrafiltration hollow fiber membranes. J. Membr. Sci. 2001, 182, 57–75. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, C.; Huang, Q.; Hu, X. Structure design and performance study on homogeneous-reinforced polyvinyl chloride hollow fiber membranes. Desalination 2013, 331, 35–45. [Google Scholar] [CrossRef]

- Zhang, Y.; Du, Q.; Wu, Y.; Wang, P.; Wu, J. Fabrication of polysulfone asymmetric hollow-fiber membranes by coextrusion through a triple-orifice spinneret. J. Appl. Polym. Sci. 2004, 94, 259–266. [Google Scholar] [CrossRef]

- Deshmukh, S.; Li, K. Effect of ethanol composition in water coagulation bath on morphology of PVDF hollow fibre membranes. J. Membr. Sci. 1998, 150, 75–85. [Google Scholar] [CrossRef]

- Saljoughi, E.; Amirilargani, M.; Mohammadi, T. Effect of PEG additive and coagulation bath temperature on the morphology, permeability and thermal/chemical stability of asymmetric CA membranes. Desalination 2010, 262, 72–78. [Google Scholar] [CrossRef]

- Hao, J.; Xiao, C.; Zhang, T.; Zhao, J.; Fan, Z.; Chen, L. Preparation and performance of PET-braid-reinforced poly (vinylidene fluoride)/graphene hollow-fiber membranes. Ind. Eng. Chem. Res. 2016, 55, 2174–2182. [Google Scholar] [CrossRef]

- Beckers, H.; Doyen, W.; Dotremont, C. Reinforced Capillary Membranes and Process for Manufacturing Thereof. U.S. Patent 3615024, 4 January 2011. [Google Scholar]

- García-Payo, M.d.C.; Essalhi, M.; Khayet, M. Effects of PVDF-HFP concentration on membrane distillation performance and structural morphology of hollow fiber membranes. J. Membr. Sci. 2010, 347, 209–219. [Google Scholar] [CrossRef]

| Component | Formula | Composition (mol%) | Maximum Pipeline Specification | Composition |

|---|---|---|---|---|

| Methane | CH4 | 70–90 | Methane | 75-none mol% |

| Ethane | C2H6 | 0–20 | Ethane | 10 mol% |

| Propane | C3 H8 | 0–20 | Propane | 5 mol% |

| N-Butane | C4 H10 | 2.54 | N-Butane | 2 mol% |

| Carbon dioxide | CO2 | 0.1–5 | Carbon dioxide | 2–3 mol% |

| Nitrogen | N2 | 0–5 | Nitrogen | 3 mol% |

| oxygen | O2 | 0–0.2 | Oxygen | 0.01 mol% |

| Hydrogen sulphide | H2S | 0–5 | Hydrogen sulphide | 0.25–0.3 g/100 scg |

| Rare gases | Ar, He, Xe, Ne | trace | Water vapor | 4.0–7.0 lb/MM scf |

| Components Likely to Be Permeated | Preferential Polymeric Material Category | Polymers Utilized | Selectivities over Methane |

|---|---|---|---|

| H2S | Rubbery | ether-amide block co-polymer | 20–30 (%) a |

| CO2 | Glassy | Polyimide, CA, perfluoropolymer | 10–20 (%) a |

| N2 | Rubbery | Silicon rubber | 0–3(%) a |

| Glassy | perfluoropolymer | 2–3 (%) a | |

| C3+hydrocarbons | Rubbery | Silicon rubber | 5–20(%) a |

| Characteristics |

|

| Disadvantages |

|

| Examples | Cellulose acetate, polysulfones, polydimethylsiloxane, polyethersulfone, polyethylene, polyimide, polyether, polypyrrolonesetc |

| Advantages | Disadvantages |

|---|---|

| Stability in high-pressure applications | Brittleness |

| Resistance towards high-pressure drop | High operational costs |

| Easy catalytic activation | Problems in attaining high selectivity in micro porous large-scale membranes. |

| Resistance towards harsh environmental effects | At high-temperature conditions membrane-to-module sealing becomes difficult. |

| Easy cleaning | At medium temperature, permeability of highly selective dense membranes is low |

| Material | PCH4 | PCO2 | αCO2/CH4 | References |

|---|---|---|---|---|

| Pure Matrimid | 0.21 | 7.29 | 34.71 | [9,158] |

| Matrimid + MOF-5 | 0.45 | 20.20 | 44.89 | [9,138] |

| Matrimid + CMS | 0.24 | 12.60 | 52.5 | [9] |

| Pure PSf | 0.22 | 6.30 | 28.64 | [159,160] |

| PSf + AlPO | 1.30 | 51.00 | 39.3 | [160,161] |

| Pure ABS | 0.12 | 2.87 | 24.10 | [162] |

| ABS + AC-2 | 0.41 | 20.50 | 50.10 | [163] |

| Polymer | Filler Used | Filler Loading (wt%) | Gaseous Pair | Pure Polymeric Membrane | Matrix Membranes | References | ||

|---|---|---|---|---|---|---|---|---|

| Permeability (GPU) | Selectivity | Permeability (GPU) | Selectivity | |||||

| Polysulfone | ZIF-8 | 1 | CO2/CH4 | 21.4 | 19.5 | 31.3 | 13.5 | [163] |

| Polysulfone | MIL-125(Ti) | 20 | CO2/CH4 | 9.3 | 22 | 29.1 | 29.5 | [164] |

| Matrimid® | SAPO-34 | 20 | CO2/CH4 | 4.3 | 34 | 6.8 | 67 | [165] |

| 6FDA-ODA | UiO-66 | 7 | CO2/CH4 | 25.8 | 20.2 | 43.3 | 56.9 | [166] |

| PDMS | 4A | 50 | H2/CH4 | 1200 | 0.8 | 13,700 | 14.7 | [167] |

| Pebax 1657 | ZIF-8 | 8 | CO2/CH4 | 130 | 9 | 450 | 15 | [168] |

| Polyethersulfone | SAPO-34 | 20 | CO2/CH4 | 0.9 | 32.2 | 2.1 | 40.5 | [169] |

| Matrimid® | ZIF-8 | 10 | H2/CH4 | 34 | 32 | 25 | 50 | [170] |

| 6FDA-durene | ZIF-8 | 42 | CO2/CH4 | 256 | 19.4 | 779 | 20.8 | [171] |

| Pebax 1657 | SAPO-34 | 50 | CO2/CH4 | 110 | 18 | 320 | 18 | [172] |

| Parameters | Examples | Effect |

|---|---|---|

| Polymer type | PS, PVDF, CA, PES, PAN, PAI, PMIA, PI, PSF, PVC | On interfacial bonding between polymer and braid |

| Support layer | Heterogeneous, Homogeneous and hybrid braid types | On interfacial bonding between polymer and braid |

| Spinneret design | Diameter of nozzle for coating layer | On membrane morphology and performance, also determines the thickness of coating layer on braid support |

| Speed of spinning | Fabrication speed | On thickness of coating layer, pore size distribution |

| Coagulation bath | Temperature | Pore size distribution, morphology and performance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imtiaz, A.; Othman, M.H.D.; Jilani, A.; Khan, I.U.; Kamaludin, R.; Iqbal, J.; Al-Sehemi, A.G. Challenges, Opportunities and Future Directions of Membrane Technology for Natural Gas Purification: A Critical Review. Membranes 2022, 12, 646. https://doi.org/10.3390/membranes12070646

Imtiaz A, Othman MHD, Jilani A, Khan IU, Kamaludin R, Iqbal J, Al-Sehemi AG. Challenges, Opportunities and Future Directions of Membrane Technology for Natural Gas Purification: A Critical Review. Membranes. 2022; 12(7):646. https://doi.org/10.3390/membranes12070646

Chicago/Turabian StyleImtiaz, Aniqa, Mohd Hafiz Dzarfan Othman, Asim Jilani, Imran Ullah Khan, Roziana Kamaludin, Javed Iqbal, and Abdullah G. Al-Sehemi. 2022. "Challenges, Opportunities and Future Directions of Membrane Technology for Natural Gas Purification: A Critical Review" Membranes 12, no. 7: 646. https://doi.org/10.3390/membranes12070646

APA StyleImtiaz, A., Othman, M. H. D., Jilani, A., Khan, I. U., Kamaludin, R., Iqbal, J., & Al-Sehemi, A. G. (2022). Challenges, Opportunities and Future Directions of Membrane Technology for Natural Gas Purification: A Critical Review. Membranes, 12(7), 646. https://doi.org/10.3390/membranes12070646