Performance Comparison of Cross- and Forward-Flow Configurations for Multiple-Effect Vacuum Membrane Distillation

Abstract

:1. Introduction

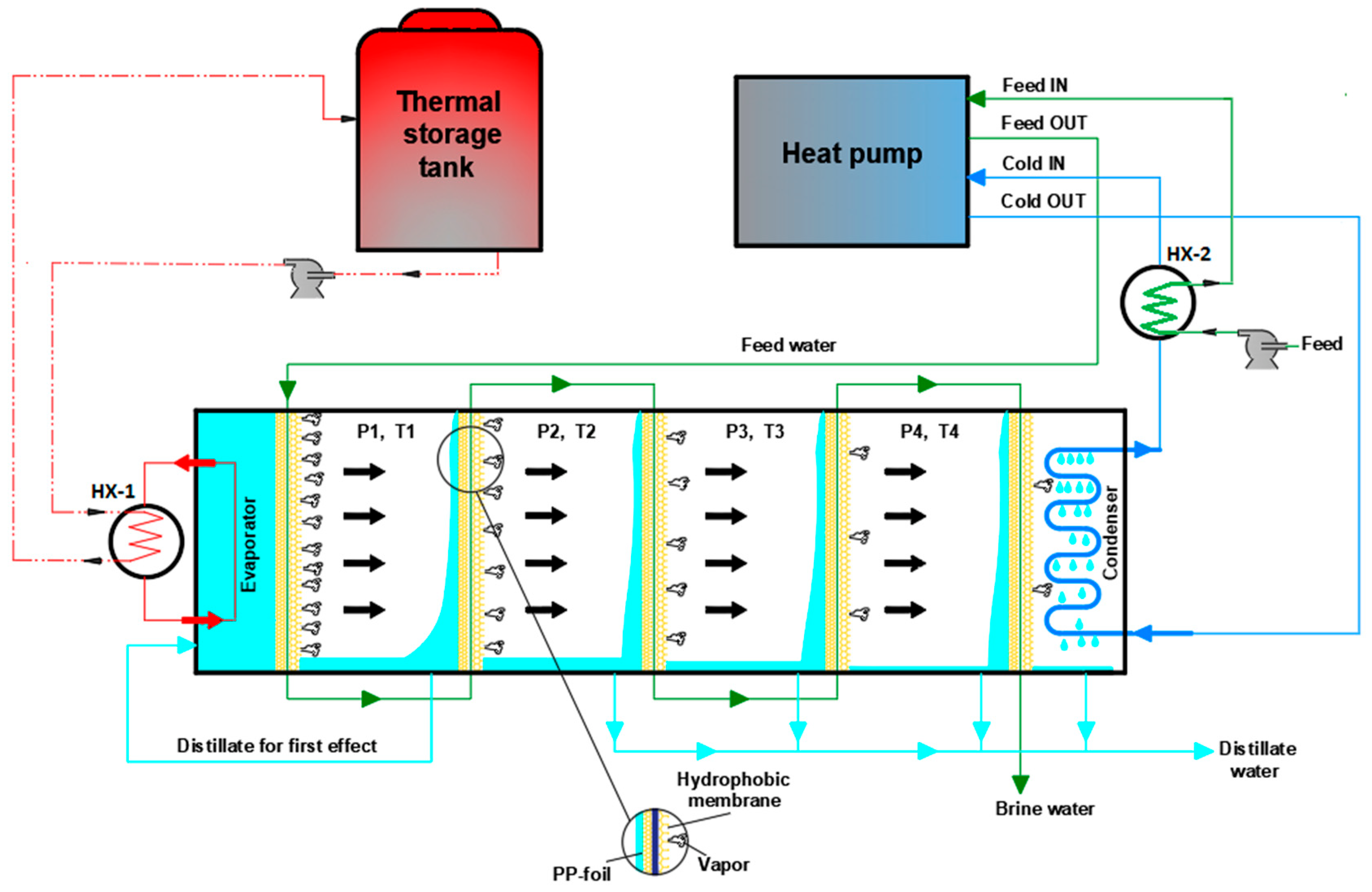

2. Fundamentals of Multiple-Effect Vacuum Membrane Distillation (V-MEMD)

Experimental Device

3. Design Structure and Methodology

4. Mathematical Model

- Flow, heat, and mass transfers are supposed to be one-dimensional and steady-state.

- Kinetic and potential energies of fluids are neglected.

- Viscous diffusion throughout the membrane is negligible.

- Each component of the system is rigid and with no fluid leakage.

- No chemical reactions are involved.

- Homogeneity and thermal equilibrium of fluids are assumed in both effects and channels.

- Complete condensation is assumed in each effect.

4.1. Mass and Energy Balances

4.2. Performance Indicators

4.2.1. Productivity Indicators

4.2.2. Energy Indicators

4.2.3. Exergy Indicators

5. Results and Discussion

5.1. Model Validation

5.2. Estimating the Thermodynamic Properties

5.3. Performance Evaluation

5.3.1. Internal Performance Evaluation

5.3.2. Global Performance Evaluation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Membrane area: m2 |

| C | Salinity, ppm |

| CFC | Cross-flow configuration |

| Cf | Concentration factor |

| COP | Coefficient of performance |

| FFC | Forward-flow configuration |

| GOR | Gain output ratio |

| h | Enthalpy, kJ/kg |

| hfg | Vaporization enthalpy, kJ/kg |

| Hr | Heat recovery factor |

| J | Permeate flux, kg/m2·h |

| m° | Mass flow rate, kg/s |

| P | Pressure, kPa |

| Cold-side absolute pressure, kPa | |

| Recovery ratio, % | |

| s | Entropy, kJ/kg·k |

| SEEC | Specific electrical energy consumption, kWh/m3 |

| STEC | Specific thermal energy consumption, kWh/m3 |

| STXC | Specific thermal exergy consumption, kWh/m3 |

| T | Temperature, °C |

| Total work consumed by the V-MEMD unit’s pumps, W | |

| Work supplied on the heat pump, W | |

| Minimum work, W | |

| Volume flow rate, L/h | |

| Greek | |

| ρ | Density, kg/m3 |

| ηex | Exergetic efficiency, % |

| Effectiveness of the heat pump system | |

| ε | Porosity, % |

| Heat supplied on the first heat exchanger, W | |

| Heat supplied on the evaporator compartment, W | |

| Heat rejected from the heat pump, W | |

| Cooling heat, W | |

| Heat loss, W | |

| Latent heat, W | |

| Exergy flow, kJ/kg | |

| Exergy destruction, W | |

| Subscript | |

| F | Feed water |

| H | Hot water |

| C | Cold water |

| D | Distillate water |

| B | Brine stream |

| hp | Heat pump |

| E | Evaporator |

| i | ith effects |

References

- Qtaishat, M.R.; Banat, F. Desalination by solar powered membrane distillation systems. Desalination 2013, 308, 186–197. [Google Scholar] [CrossRef]

- Najib, A.; Orfi, J.; Ali, E.; Ajbar, A.; Boumaaza, M.; Alhumaizi, K. Performance analysis of cascaded membrane distillation arrangements for desalination of brackish water. Desalin. Water Treat. 2017, 76, 19–29. [Google Scholar] [CrossRef]

- Emad, A.; Jamel, O.; Abdullah, N.; Jehad, S. Comparison of energy-efficient configurations of direct-contact membrane distillation for brackish water desalination. Desalin. Water Treat. 2019, 142, 24–36. [Google Scholar]

- Khayet, M.; Matsuura, T. Membrane Distillation, Principles and Applications; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Huang, C.-Y.; Ko, C.-C.; Chen, L.-H.; Huang, C.-T.; Tung, K.-L.; Liao, Y.-C. A simple coating method to prepare superhydrophobic layers on ceramic alumina for vacuum membrane distillation. Sep. Purif. Technol. 2018, 198, 79–86. [Google Scholar] [CrossRef]

- Chen, Y.-R.; Chen, L.-H.; Chen, C.-H.; Ko, C.-C.; Huang, A.; Li, C.-L.; Chuang, C.-J.; Tung, K.-L. Hydrophobic alumina hollow fiber membranes for sucrose concentration by vacuum membrane distillation. J. Membr. Sci. 2018, 555, 250–257. [Google Scholar] [CrossRef]

- Ko, C.-C.; Ali, A.; Drioli, E.; Tung, K.-L.; Chen, C.-H.; Chen, Y.-R.; Macedonio, F. Performance of ceramic membrane in vacuum membrane distillation and in vacuum membrane crystallization. Desalination 2018, 440, 48–58. [Google Scholar] [CrossRef]

- Winter, D. Membrane Distillation: A Thermodynamic, Technological and Economic Analysis; Shaker Verlag: Herzogenrath, Germany, 2015. [Google Scholar]

- Mohamed, E.S.; Boutikos, P.; Mathioulakis, E.; Belessiotis, V. Experimental evaluation of the performance and energy efficiency of a Vacuum Multi-Effect Membrane Distillation system. Desalination 2017, 408, 70–80. [Google Scholar] [CrossRef]

- Najib, A.; Orfi, J.; Alansary, H.; Ali, E.; Abdulwahed, Z.; Alzahrani, S.; Chafidz, A. An experimental investigation of a solar-driven desalination system based on multi-effect membrane distillation. Desalin. Water Treat. 2020, 198, 1–18. [Google Scholar] [CrossRef]

- Ong, C.L.; Escher, W.; Paredes, S.; Khalil, A.; Michel, B. A novel concept of energy reuse from high concentration photovoltaic thermal (HCPVT) system for desalination. Desalination 2012, 295, 70–81. [Google Scholar] [CrossRef]

- Andrés-Mañas, J.; Roca, L.; Ruiz-Aguirre, A.; Acién, F.; Gil, J.; Zaragoza, G. Application of solar energy to seawater desalination in a pilot system based on vacuum multi-effect membrane distillation. Appl. Energy 2020, 258, 114068. [Google Scholar] [CrossRef] [Green Version]

- Andrés-Mañas, J.A.; Ruiz-Aguirre, A.; Acién, F.G.; Zaragoza, G. Assessment of a pilot system for seawater desalination based on vacuum multi-effect membrane distillation with enhanced heat recovery. Desalination 2018, 443, 110–121. [Google Scholar] [CrossRef]

- Zaragoza, G.; Ruiz-Aguirre, A.; Guillen-Burrieza, E. Efficiency in the use of solar thermal energy of small membrane desalination systems for decentralized water production. Appl. Energy 2014, 130, 491–499. [Google Scholar] [CrossRef]

- Zhao, K.; Heinzl, W.; Wenzel, M.; Büttner, S.; Bollen, F.; Lange, G.; Heinzl, S.; Sarda, N. Experimental study of the memsys vacuum-multi-effect-membrane-distillation (V-MEMD) module. Desalination 2013, 323, 150–160. [Google Scholar] [CrossRef]

- Bouguecha, S.T.; Aly, S.E.; Al-Beirutty, M.H.; Hamdi, M.M.; Boubakri, A. Solar driven DCMD: Performance evaluation and thermal energy efficiency. Chem. Eng. Res. Des. 2015, 100, 331–340. [Google Scholar] [CrossRef]

- Khayet, M. Solar desalination by membrane distillation: Dispersion in energy consumption analysis and water production costs (a review). Desalination 2013, 308, 89–101. [Google Scholar] [CrossRef]

- Boutikos, P.; Mohamed, E.; Mathioulakis, E.; Belessiotis, V. A theoretical approach of a vacuum multi-effect membrane distillation system. Desalination 2017, 422, 25–41. [Google Scholar] [CrossRef]

- Chafidz, A.; Al-Zahrani, S.; Al-Otaibi, M.N.; Hoong, C.F.; Lai, T.F.; Prabu, M. Portable and integrated solar-driven desalination system using membrane distillation for arid remote areas in Saudi Arabia. Desalination 2014, 345, 36–49. [Google Scholar] [CrossRef]

- Lin, Y.-T.; Wey, M.-Y.; Tseng, H.-H. Highly Permeable Mixed Matrix Hollow Fiber Membrane as a Latent Route for Hydrogen Purification from Hydrocarbons/Carbon Dioxide. Membranes 2021, 11, 865. [Google Scholar] [CrossRef]

- Li, J.-Y.; Wang, D.K.; Lin, Y.-T.; Wey, M.-Y.; Tseng, H.-H. Homogeneous sub-nanophase network tailoring of dual organosilica membrane for enhancing CO2 gas separation. J. Membr. Sci. 2021, 644, 120170. [Google Scholar] [CrossRef]

- El-Dessouky, H.T.; Ettouney, H.M. Fundamentals of Salt Water Desalination; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Bin Amer, A.O. Development and optimization of ME-TVC desalination system. Desalination 2009, 249, 1315–1331. [Google Scholar] [CrossRef]

- Najib, A.; Orfi, J.; Alansary, H.; Ali, E. Assessing the Impact of Operating Conditions on the Energy and Exergy Efficiency for Multi-Effect Vacuum Membrane Distillation Systems. Water 2021, 13, 1500. [Google Scholar] [CrossRef]

- Swaminathan, J.; Nayar, K.G.; Lienhard V, J.H. Mechanical vapor compression—Membrane distillation hybrids for reduced specific energy consumption. Desalin. Water Treat. 2016, 57, 26507–26517. [Google Scholar] [CrossRef]

- Andersson, S.-I.; Kjellander, N.; Rodesjö, B. Design and field tests of a new membrane distillation desalination process. Desalination 1985, 56, 345–354. [Google Scholar] [CrossRef]

- Burhan, M.; Shahzad, M.W.; Ybyraiymkul, D.; Oh, S.J.; Ghaffour, N.; Ng, K.C. Performance investigation of MEMSYS vacuum membrane distillation system in single effect and multi-effect mode. Sustain. Energy Technol. Assess. 2019, 34, 9–15. [Google Scholar] [CrossRef]

- Sharqawy, M.H.; Lienhard, J.H.; Zubair, S.M. Thermophysical properties of seawater: A review of existing correlations and data. Desalin. Water Treat. 2010, 16, 354–380. [Google Scholar] [CrossRef]

- Najib, A.; Orfi, J.; Alansary, H.; Ali, E. Application of the Buckingham Π Theorem to Model the Multiple Effect Vacuum Membrane Distillation. J. Therm. Sci. Eng. Appl. 2022, 14, 031003. [Google Scholar] [CrossRef]

- Chen, Q.; Ja, M.K.; Li, Y.; Chua, K. Thermodynamic optimization of a vacuum multi-effect membrane distillation system for liquid desiccant regeneration. Appl. Energy 2018, 230, 960–973. [Google Scholar] [CrossRef]

| Character of Layer | Specification |

|---|---|

| Hydrophobic membrane material | Polytetrafluoroethylene (PTFE) |

| Foil material | Polypropylene (PP) |

| Dimension | 335 mm × 475 mm |

| Effective area of one effect | 0.64 m2 |

| Membrane thickness | ~0.2 mm |

| Porosity (ε) | 75% |

| Tortuosity (1/ε) | ~1.33 |

| Mean pore size | ~0.2 µm |

| Device | Symbol | Description |

|---|---|---|

| Pumps | P-1 | Hot water pump |

| P-2 | Feed water pump | |

| P-3 | Cold water pump | |

| P-4 | Vacuum pump | |

| P-5 | Heated water pump | |

| Heat exchangers | HX-1 | First heat exchanger |

| HX-2 | Second heat exchanger |

| Operating Condition | Range | Max. Relative Uncertainty (%) |

|---|---|---|

| Hot water flow, (L/h) | 574.8–902.4 | ±2.74 |

| Hot water temperature, (°C) | 54.5–75.03 | ±1.27 |

| Feed water flow, (L/h) | 59.4–154.2 | ±3.05 |

| Feed water temperature, (°C) | 24–59.4 | ±2.12 |

| Cold water flow, (L/h) | 249.6–863.4 | ±2.99 |

| Cold water temperature, (°C) | 17.7–41 | ±3.69 |

| Feed salinity, (ppm) | 1260 | ±2.00 |

| Cold-side absolute pressue, (kPa) | 9.8–20 | ±1.27 |

| State | FFC | CFC | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) | P (kPa) | m (kg/s) | C (ppm) | h (kJ/kg) | s (kJ/kg·k) | (kJ/kg) | T (°C) | P (kPa) | m (kg/s) | C (ppm) | h (kJ/kg) | s (kJ/kg·k) | (kJ/kg) | |

| S1 | 95 | 101.3 | 0.1417 | 0 | 398.0 | 1.25 | 29.9 | 95 | 101.3 | 0.1417 | 0 | 398.0 | 1.25 | 29.9 |

| S2 | 95.3 | 217.2 | 0.1417 | 0 | 399.3 | 1.26 | 30.2 | 95.3 | 217.2 | 0.1417 | 0 | 399.3 | 1.26 | 30.2 |

| S3 | 76.8 | 205.1 | 0.1417 | 0 | 321.5 | 1.03 | 17.1 | 77.9 | 205.1 | 0.1417 | 0 | 326.2 | 1.05 | 17.7 |

| H1 | 75 | 46.1 | 0.2437 | 0 | 313.9 | 1.02 | 15.9 | 75 | 46.1 | 0.2437 | 0 | 313.9 | 1.02 | 15.9 |

| H2 | 64.5 | 31.8 | 0.2409 | 0 | 269.8 | 0.89 | 10.2 | 66.2 | 32.4 | 0.2403 | 0 | 276.9 | 0.91 | 10.9 |

| H3 | 64.5 | 31.8 | 0.2437 | 0 | 269.8 | 0.89 | 10.2 | 66.2 | 32.4 | 0.2403 | 0 | 276.9 | 0.91 | 10.9 |

| F0 | 25 | 101.3 | 0.0438 | 1260 | 104.6 | 0.37 | 0 | 25 | 101.3 | 0.0438 | 1260 | 104.6 | 0.37 | 0 |

| F1 | 25 | 155.1 | 0.0438 | 1260 | 104.6 | 0.37 | 0.05 | 25 | 155.1 | 0.0438 | 1260 | 104.6 | 0.37 | 0.05 |

| F2 | 25 | 143.1 | 0.0438 | 1260 | 104.4 | 0.37 | 0.04 | 31 | 148.1 | 0.0438 | 1260 | 129.7 | 0.45 | 0.29 |

| F3 | 41.9 | 131.1 | 0.0438 | 1260 | 175.4 | 0.6 | 1.9 | 60 | 131.1 | 0.0438 | 1260 | 250.7 | 0.83 | 8.0 |

| F4 | 64.4 | 124.3 | 0.0438 | 1260 | 268.9 | 0.89 | 9.9 | 66.1 | 125.1 | 0.0438 | 1260 | 276.1 | 0.90 | 10.8 |

| D1 | 64.4 | 24.5 | 0.0028 | 0 | 269.8 | 0.89 | 10.1 | 66.2 | 26.3 | 0.0034 | 0 | 276.9 | 0.91 | 10.6 |

| D2 | 62.6 | 22.5 | 0.0023 | 0 | 262.1 | 0.86 | 9.2 | 63.9 | 23.8 | 0.0032 | 0 | 267.0 | 0.88 | 9.6 |

| D3 | 59.7 | 19.7 | 0.0016 | 0 | 249.9 | 0.83 | 7.9 | 60 | 20.0 | 0.0029 | 0 | 250.7 | 0.83 | 7.8 |

| D4 | 57.9 | 18.2 | 0.0012 | 0 | 242.7 | 0.81 | 7.1 | 56.4 | 16.8 | 0.0026 | 0 | 235.9 | 0.79 | 6.3 |

| D5 | 56.6 | 17.1 | 0.001 | 0 | 237 | 0.79 | 6.6 | 53.2 | 14.5 | 0.0024 | 0 | 222.5 | 0.74 | 5.1 |

| B1 | 56.6 | 101.3 | 0.0377 | 1464 | 236.5 | 0.79 | 6.4 | 58.3a | 101.3 | 0.0327 | 1695.2 a | 243.6 a | 0.81 a | 7.2 a |

| C1 | 20 | 23.6 | 0.1123 | 0 | 83.9 | 0.30 | 0.19 | 20 | 23.6 | 0.1123 | 0 | 83.9 | 0.30 | 0.19 |

| C2 | 25 | 17.0 | 0.1123 | 0 | 104.5 | 0.37 | 0.005 | 32.1 | 17.0 | 0.1123 | 0 | 134.3 | 0.47 | 0.35 |

| C3 | 25 | 12.6 | 0.1123 | 0 | 104.5 | 0.37 | 0 | 29.7 | 12.6 | 0.1123 | 0 | 124.6 | 0.43 | 0.15 |

| Reference Number | Q. Chen et al. [30] | Najib et al. [10] | The Present Work | |

|---|---|---|---|---|

| Feed-flow configuration | Forward | Forward | Forward | Cross |

| Membrane area, A (m2) | 3.84 | 5.12 | 5.12 | 5.12 |

| Feed water type | Liquid desiccant (LiCl) | Brackish water | Brackish water | Brackish water |

| Hot water temperature, (°C) | 50–70 | 55–75 | 75 | 75 |

| Hot-flow rate, (L/h) | N/A | 840 | 900 | 900 |

| Cold-side absolute pressue, (kPa) | 3.17–15.76 | 7.54–30.11 | 11.5 | 11.5 |

| Cold water temperature, (°C) | 20–30 | 25–30 | 20 | 20 |

| Feed-flow rate, (L/h) | 10–50 | 87–139 | 87–231 | 87–231 |

| Water output, (L/h) | 0–25 | 0–31.8 | 20.2–22.4 | 35–40 |

| Permeate mass flux, (kg/m2·h) | 0–13.1 b | 0–12.3 | 7.9–8.7 | 13.7–15.3 |

| Recovery ratio, (%) | 0–60 b | 0–36.8 | 8.8–25.7 | 15.3–46 |

| Gain output ratio, (-) | N/A | 0–4.24 | 1.5–2.5 | 2.8–3.9 |

| Specific thermal energy consumption, STEC (kWh/m3) | 208–3334 b | 151–675 | 410–606 | 219–302 |

| Specific electrical energy consumption, SEEC (kWh/m3) | N/A | 61–399 | 39–48 | 41–45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Najib, A.; Al-Ansary, H.; Orfi, J.; Ali, E.; Almehmadi, F.A. Performance Comparison of Cross- and Forward-Flow Configurations for Multiple-Effect Vacuum Membrane Distillation. Membranes 2022, 12, 495. https://doi.org/10.3390/membranes12050495

Najib A, Al-Ansary H, Orfi J, Ali E, Almehmadi FA. Performance Comparison of Cross- and Forward-Flow Configurations for Multiple-Effect Vacuum Membrane Distillation. Membranes. 2022; 12(5):495. https://doi.org/10.3390/membranes12050495

Chicago/Turabian StyleNajib, Abdullah, Hany Al-Ansary, Jamel Orfi, Emad Ali, and Fahad Awjah Almehmadi. 2022. "Performance Comparison of Cross- and Forward-Flow Configurations for Multiple-Effect Vacuum Membrane Distillation" Membranes 12, no. 5: 495. https://doi.org/10.3390/membranes12050495

APA StyleNajib, A., Al-Ansary, H., Orfi, J., Ali, E., & Almehmadi, F. A. (2022). Performance Comparison of Cross- and Forward-Flow Configurations for Multiple-Effect Vacuum Membrane Distillation. Membranes, 12(5), 495. https://doi.org/10.3390/membranes12050495