Occurrence of Microplastics in Waste Sludge of Wastewater Treatment Plants: Comparison between Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) Technologies

Abstract

:1. Introduction

2. Materials and Methods

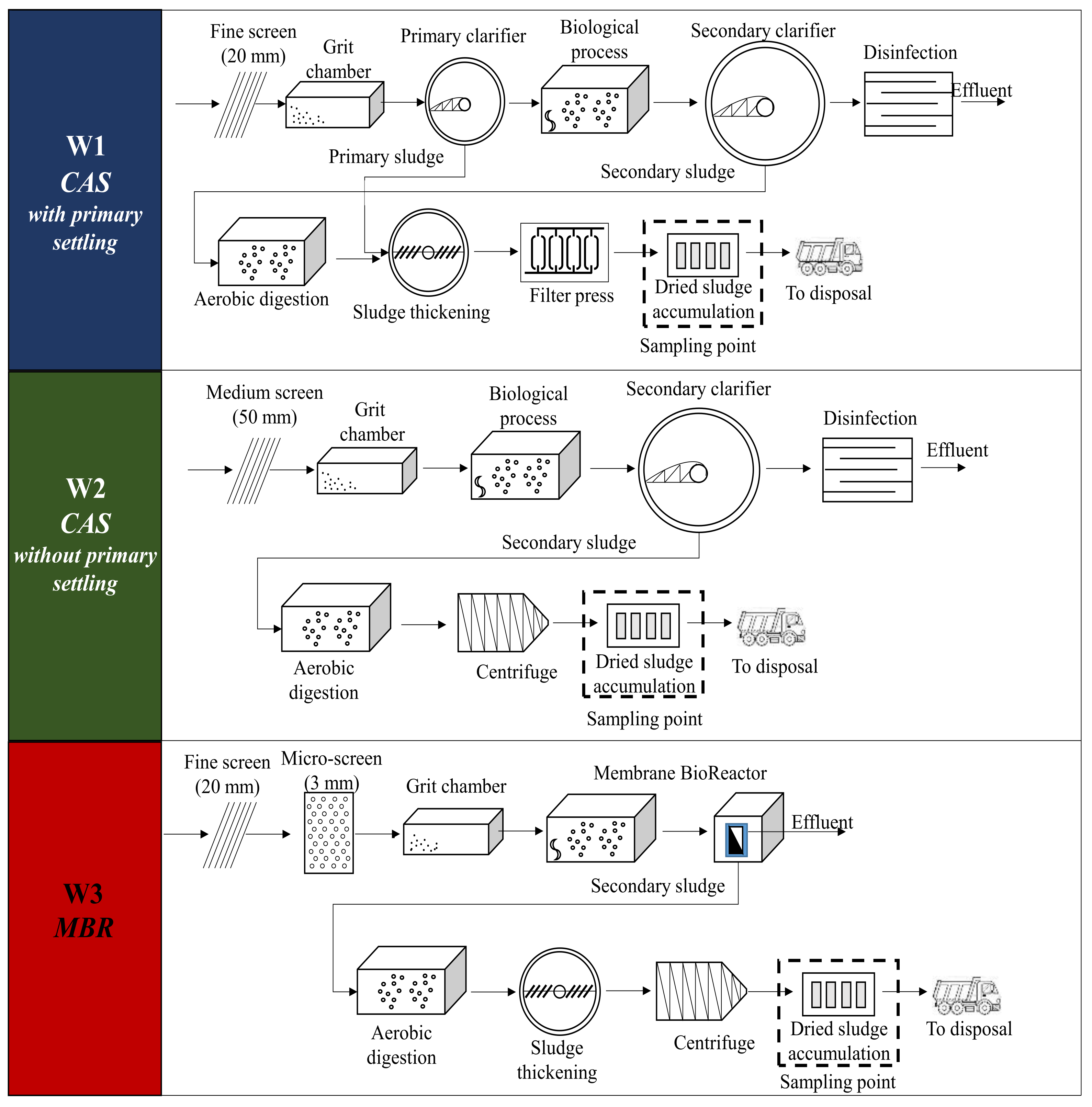

2.1. Description of WWTPs

2.2. Samples Collection

2.3. Samples Treatment

2.4. Examination and Identification of MPs

3. Results and Discussion

3.1. Microplastic Concentration and Distribution

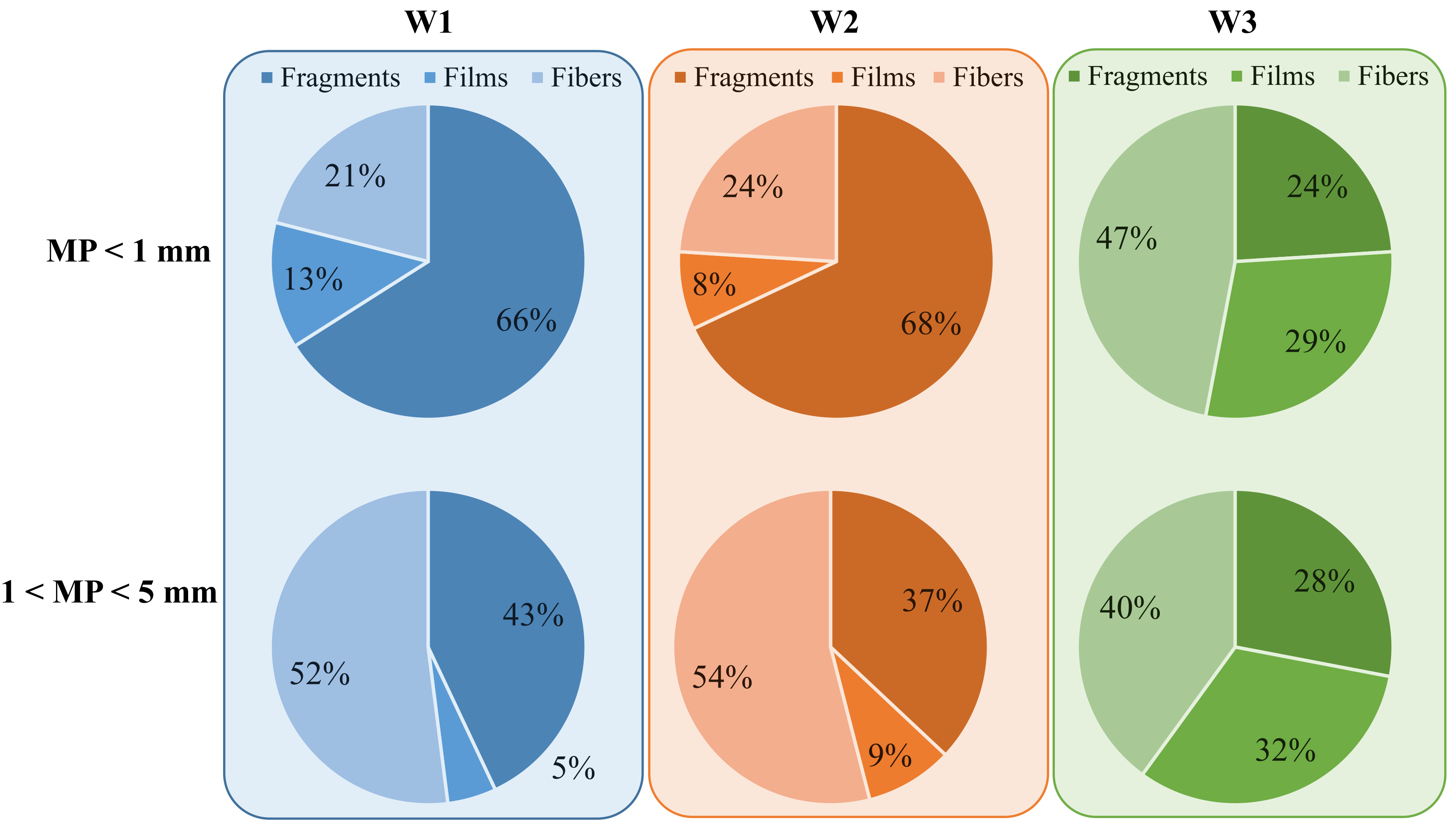

3.2. Morphology of MPs

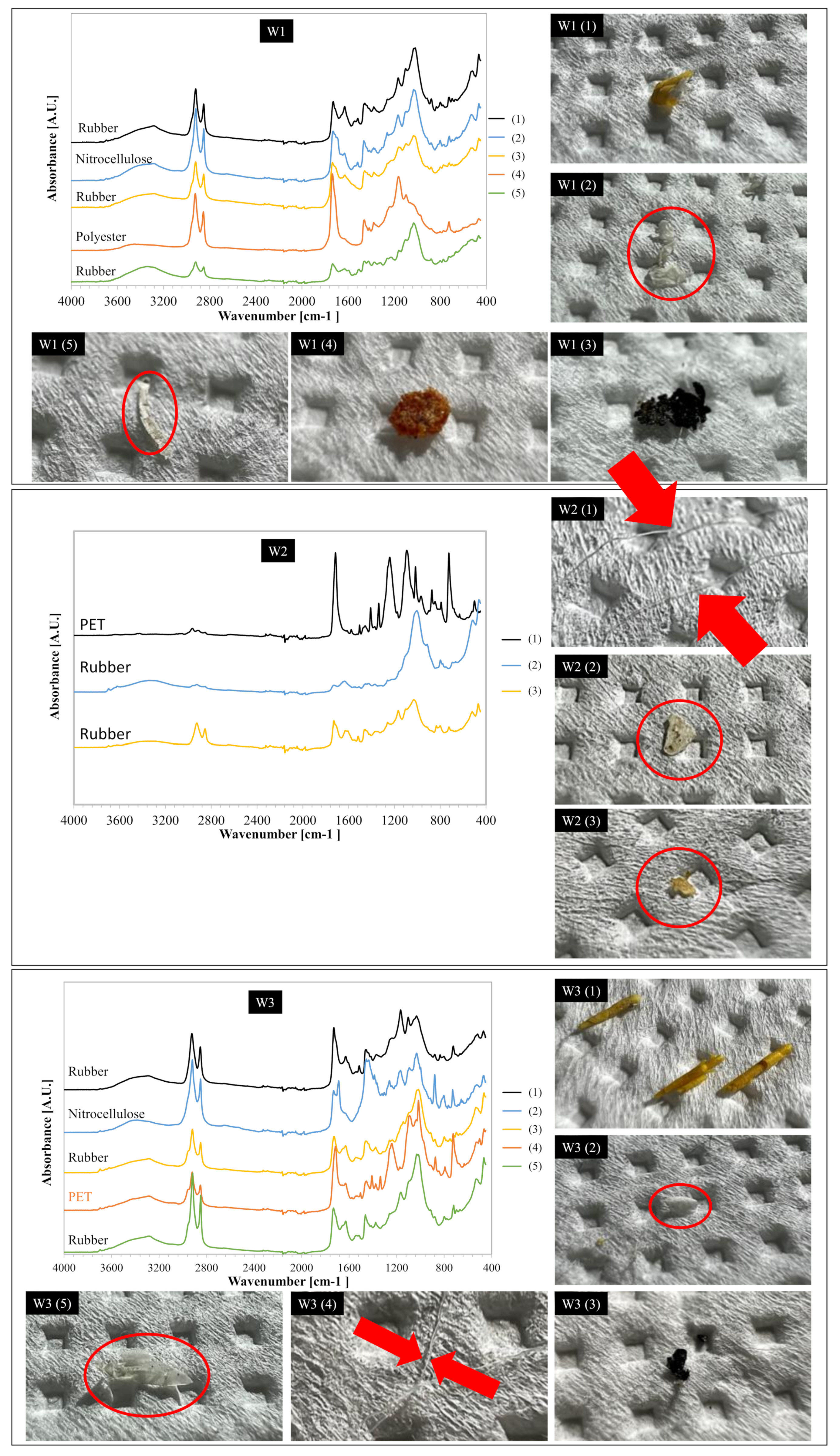

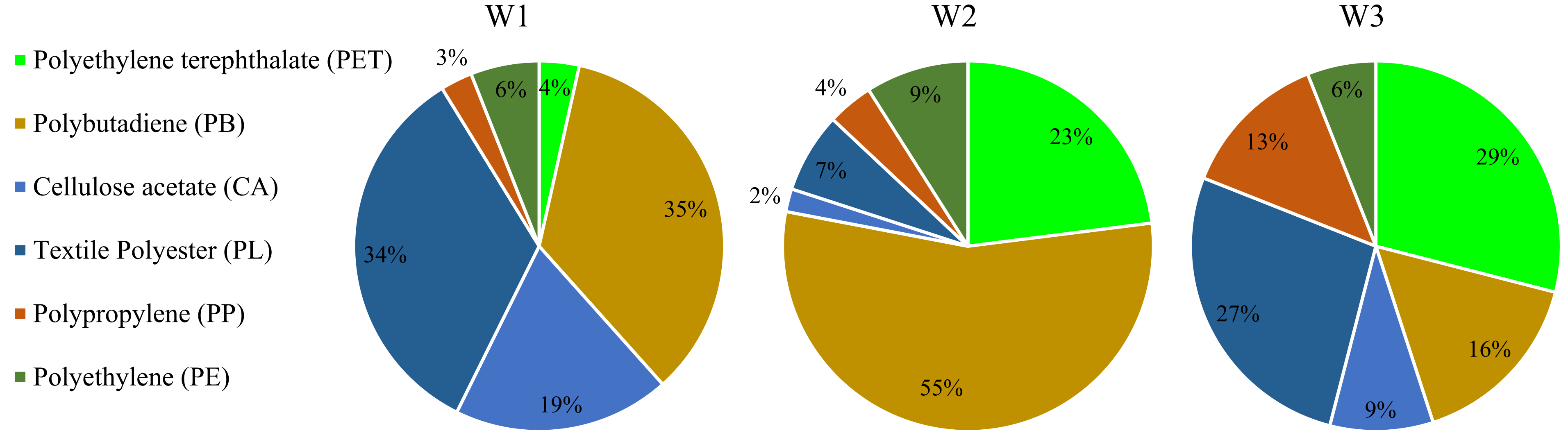

3.3. MPs Composition

3.4. Comparison with Literature Data and General Remarks

| Treatment in Water Line (Biological Phase) | Potential (PE) | Location | MPs (n/kg) * | Reference |

|---|---|---|---|---|

| CAS-based process (no primary settling) | 250 × 103 | China | 44–750 | [8] |

| Primary settling + CAS based process | 0.5–2.5 × 103 | Ireland | 4.19–15.4 × 103 | [40] |

| CAS-based process (no primary settling) | n.a. | The Netherlands | 370–950 | [41] |

| Primary settling + CAS-based process | 12–111 × 103 | China | 1.65–56.3 × 103 | [41] |

| MBR (pilot plant) | n.a. | Finland | 27.3 × 103 | [13] |

| Primary settling + CAS-based process | 10–210 × 103 | Germany | 1.0–24 × 103 | [39] |

| Primary settling + CAS-based process | 20 × 103 | China | 24 × 103 | [21] |

| CAS-based process (no primary settling) | 48 × 103 | Australia | 40 × 103 | [38] |

| Primary settling + CAS-based process | 45 × 103 | Spain | 18.3 × 103 | [42] |

| CAS-based process (no primary settling) | 493 × 103 | Canada | 14.9 × 103 | [37] |

| W1—Primary settling + CAS-based process | 330 × 103 | Italy | 46 × 103 | This study |

| W2—CAS-based process (no primary settling) | 12 × 103 | Italy | 36 × 103 | This study |

| W3—MBR (full-scale plant) | 27 × 103 | Italy | 86 × 103 | This study |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maliwan, T.; Pungrasmi, W.; Lohwacharin, J. Effects of microplastic accumulation on floc characteristics and fouling behavior in a membrane bioreactor. J. Hazard. Mater. 2021, 411, 124991. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.Y.; Li, Y.L.; Liu, Y.Y.; Zhou, Z.; Hu, W.J.; Lin, L.F.; Wu, Z.C. Effects of microplastics accumulation on performance of membrane bioreactor for wastewater treatment. Chemosphere 2022, 287, 131968. [Google Scholar] [CrossRef]

- Vuori, L.; Ollikainen, M. How to remove microplastics in wastewater? A cost-effectiveness analysis. Ecol. Econ. 2022, 192, 107246. [Google Scholar] [CrossRef]

- Yuan, F.; Zhao, H.; Sun, H.; Sun, Y.; Zhao, J.; Xia, T. Investigation of microplastics in sludge from five wastewater treatment plants in Nanjing, China. J. Environ. Manag. 2022, 301, 113793. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, J.; Liu, H.; Guo, X.; Zhang, X.; Yao, X.; Cao, Z.; Zhang, T. A review of the removal of microplastics in global wastewater treatment plants: Characteristics and mechanisms. Environ. Int. 2021, 146, 106277. [Google Scholar] [CrossRef]

- Magni, S.; Binelli, A.; Pittura, L.; Avio, C.G.; Della Torre, C.; Parenti, C.C.; Gorbi, S.; Regoli, F. The fate of microplastics in an Italian Wastewater Treatment Plant. Sci. Total Environ. 2019, 652, 602–610. [Google Scholar] [CrossRef]

- Tang, K.H.D.; Hadibarata, T. Microplastics removal through water treatment plants: Its feasibility, efficiency, future prospects and enhancement by proper waste management. Environ. Chall. 2021, 5, 100264. [Google Scholar] [CrossRef]

- Wei, F.; Xu, C.; Chen, C.; Wang, Y.; Lan, Y.; Long, L.; Xu, M.; Wu, J.; Shen, F.; Zhang, Y.; et al. Distribution of microplastics in the sludge of wastewater treatment plants in chengdu, China. Chemosphere 2022, 287, 132357. [Google Scholar] [CrossRef]

- Jiang, F.; Wang, M.; Ding, J.; Cao, W.; Sun, C. Occurrence and Seasonal Variation of Microplastics in the Effluent from Wastewater Treatment Plants in Qingdao, China. J. Mar. Sci. Eng. 2022, 10, 58. [Google Scholar] [CrossRef]

- Okoffo, E.D.; Tscharke, B.J.; O’Brien, J.W.; O’Brien, S.; Ribeiro, F.; Burrows, S.D.; Choi, P.M.; Wang, X.; Mueller, J.F.; Thomas, K.V. Release of Plastics to Australian Land from Biosolids End-Use. Environ. Sci. Technol. 2020, 54, 15132–15141. [Google Scholar] [CrossRef]

- Akkoyunlu, B.; Daly, S.; Casey, E. Membrane bioreactors for the production of value-added products: Recent developments, challenges and perspectives. Bioresour. Technol. 2021, 341, 125793. [Google Scholar] [CrossRef] [PubMed]

- Poerio, T.; Piacentini, E.; Mazzei, R. Membrane processes for microplastic removal. Molecules 2019, 24, 4148. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lares, M.; Ncibi, M.C.; Sillanpää, M.; Sillanpää, M. Occurrence, identification and removal of microplastic particles and fibers in conventional activated sludge process and advanced MBR technology. Water Res. 2018, 133, 236–246. [Google Scholar] [CrossRef]

- Talvitie, J.; Mikola, A.; Koistinen, A.; Setälä, O. Solutions to microplastic pollution—Removal of microplastics from wastewater effluent with advanced wastewater treatment technologies. Water Res. 2017, 123, 401–407. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ngo, P.L.; Pramanik, B.K.; Shah, K.; Roychand, R. Pathway, classification and removal efficiency of microplastics in wastewater treatment plants. Environ. Pollut. 2019, 255, 113326. [Google Scholar] [CrossRef]

- Alavian Petroody, S.S.; Hashemi, S.H.; van Gestel, C.A.M. Transport and accumulation of microplastics through wastewater treatment sludge processes. Chemosphere 2021, 278, 130471. [Google Scholar] [CrossRef]

- Li, Q.; Wu, J.; Zhao, X.; Gu, X.; Ji, R. Separation and identification of microplastics from soil and sewage sludge. Environ. Pollut. 2019, 254, 113076. [Google Scholar] [CrossRef]

- Sun, J.; Dai, X.; Wang, Q.; van Loosdrecht, M.C.M.; Ni, B.J. Microplastics in wastewater treatment plants: Detection, occurrence and removal. Water Res. 2019, 152, 21–37. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Carnevale Miino, M.; Caccamo, F.M.; Milanese, C. Microplastics in sewage sludge: A known but underrated pathway in wastewater treatment plants. Sustainability 2021, 13, 2591. [Google Scholar] [CrossRef]

- Van Do, M.; Le, T.X.T.; Vu, N.D.; Dang, T.T. Distribution and occurrence of microplastics in wastewater treatment plants. Environ. Technol. Innov. 2022, 26, 102286. [Google Scholar] [CrossRef]

- Liu, X.; Yuan, W.; Di, M.; Li, Z.; Wang, J. Transfer and fate of microplastics during the conventional activated sludge process in one wastewater treatment plant of China. Chem. Eng. J. 2019, 362, 176–182. [Google Scholar] [CrossRef]

- Carr, S.A.; Liu, J.; Tesoro, A.G. Transport and fate of microplastic particles in wastewater treatment plants. Water Res. 2016, 91, 174–182. [Google Scholar] [CrossRef] [PubMed]

- Iyare, P.U.; Ouki, S.K.; Bond, T. Microplastics removal in wastewater treatment plants: A critical review. Environ. Sci. Water Res. Technol. 2020, 6, 2664–2675. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, J.; Xie, Y.; Zhong, S.; Gao, P. Occurrence and removal of microplastics from wastewater treatment plants in a typical tourist city in China. J. Clean. Prod. 2021, 291, 125968. [Google Scholar] [CrossRef]

- Talvitie, J.; Mikola, A.; Setälä, O.; Heinonen, M.; Koistinen, A. How well is microlitter purified from wastewater?—A detailed study on the stepwise removal of microlitter in a tertiary level wastewater treatment plant. Water Res. 2017, 109, 164–172. [Google Scholar] [CrossRef] [Green Version]

- Judd, S.; Judd, C. The MBR Book; Elsevier: Amsterdam, The Netherlands, 2006; ISBN 9781856174817. [Google Scholar]

- Cai, Y.; Wu, J.; Lu, J.; Wang, J.; Zhang, C. Fate of microplastics in a coastal wastewater treatment plant: Microfibers could partially break through the integrated membrane system. Front. Environ. Sci. Eng. 2022, 16, 48. [Google Scholar] [CrossRef]

- Di Bella, G.; Di Trapani, D.; Judd, S. Fouling mechanism elucidation in membrane bioreactors by bespoke physical cleaning. Sep. Purif. Technol. 2018, 199, 124–133. [Google Scholar] [CrossRef] [Green Version]

- Gkotsis, P.K.; Banti, D.C.; Peleka, E.N.; Zouboulis, A.I.; Samaras, P.E. Fouling issues in Membrane Bioreactors (MBRs) for wastewater treatment: Major mechanisms, prevention and control strategies. Processes 2014, 2, 795–866. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, X.C.; Yu, Z.Z.; Ngo, H.H.; Sun, Q.; Zhang, Q. New insight into fouling behavior and foulants accumulation property of cake sludge in a full-scale membrane bioreactor. J. Membr. Sci. 2016, 510, 10–17. [Google Scholar] [CrossRef]

- Mohammed Khalaf, E. Improvement of Chemical and Thermal Properties of Polyethylene Terephthalate (PET) by Using Multi-walled Carbon Nanotubes (MWCNTs). Int. J. Mater. Sci. Appl. 2016, 5, 297. [Google Scholar] [CrossRef]

- Rouhani, S.T.; Fashandi, H. Breathable dual-layer textile composed of cellulose dense membrane and plasma-treated fabric with enhanced comfort. Cellulose 2018, 25, 5427–5442. [Google Scholar] [CrossRef]

- Vane, L.; Namboodiri, V.; Lin, G.; Abar, M.; Alvarez, F. Preparation of water-selective polybutadiene membranes and their use in drying alcohols by pervaporation and vapor permeation technologies. ACS Sustain. Chem. Eng. 2016, 4, 4442–4450. [Google Scholar] [CrossRef]

- Parvinzadeh, M.; Ebrahimi, I. Influence of atmospheric-air plasma on the coating of a nonionic lubricating agent on polyester fiber. Radiat. Eff. Defects Solids 2011, 166, 408–416. [Google Scholar] [CrossRef]

- Werbowski, L.M.; Gilbreath, A.N.; Munno, K.; Zhu, X.; Grbic, J.; Wu, T.; Sutton, R.; Sedlak, M.D.; Deshpande, A.D.; Rochman, C.M. Urban Stormwater Runoff: A Major Pathway for Anthropogenic Particles, Black Rubbery Fragments, and Other Types of Microplastics to Urban Receiving Waters. ACS ES&T Water 2021, 1, 1420–1428. [Google Scholar] [CrossRef]

- Harley-Nyang, D.; Memon, F.A.; Jones, N.; Galloway, T. Investigation and analysis of microplastics in sewage sludge and biosolids: A case study from one wastewater treatment works in the UK. Sci. Total Environ. 2022, 823, 153735. [Google Scholar] [CrossRef]

- Gies, E.A.; LeNoble, J.L.; Noël, M.; Etemadifar, A.; Bishay, F.; Hall, E.R.; Ross, P.S. Retention of microplastics in a major secondary wastewater treatment plant in Vancouver, Canada. Mar. Pollut. Bull. 2018, 133, 553–561. [Google Scholar] [CrossRef]

- Ziajahromi, S.; Neale, P.A.; Telles Silveira, I.; Chua, A.; Leusch, F.D.L. An audit of microplastic abundance throughout three Australian wastewater treatment plants. Chemosphere 2021, 263, 128294. [Google Scholar] [CrossRef]

- Mintenig, S.M.; Int-Veen, I.; Löder, M.G.J.; Primpke, S.; Gerdts, G. Identification of microplastic in effluents of waste water treatment plants using focal plane array-based micro-Fourier-transform infrared imaging. Water Res. 2017, 108, 365–372. [Google Scholar] [CrossRef]

- Mahon, A.M.; O’Connell, B.; Healy, M.G.; O’Connor, I.; Officer, R.; Nash, R.; Morrison, L. Microplastics in sewage sludge: Effects of treatment. Environ. Sci. Technol. 2017, 51, 810–818. [Google Scholar] [CrossRef]

- Li, X.; Chen, L.; Mei, Q.; Dong, B.; Dai, X.; Ding, G.; Zeng, E.Y. Microplastics in sewage sludge from the wastewater treatment plants in China. Water Res. 2018, 142, 75–85. [Google Scholar] [CrossRef]

- Edo, C.; González-Pleiter, M.; Leganés, F.; Fernández-Piñas, F.; Rosal, R. Fate of microplastics in wastewater treatment plants and their environmental dispersion with effluent and sludge. Environ. Pollut. 2020, 259, 113837. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Bella, G.; Corsino, S.F.; De Marines, F.; Lopresti, F.; La Carrubba, V.; Torregrossa, M.; Viviani, G. Occurrence of Microplastics in Waste Sludge of Wastewater Treatment Plants: Comparison between Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) Technologies. Membranes 2022, 12, 371. https://doi.org/10.3390/membranes12040371

Di Bella G, Corsino SF, De Marines F, Lopresti F, La Carrubba V, Torregrossa M, Viviani G. Occurrence of Microplastics in Waste Sludge of Wastewater Treatment Plants: Comparison between Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) Technologies. Membranes. 2022; 12(4):371. https://doi.org/10.3390/membranes12040371

Chicago/Turabian StyleDi Bella, Gaetano, Santo Fabio Corsino, Federica De Marines, Francesco Lopresti, Vincenzo La Carrubba, Michele Torregrossa, and Gaspare Viviani. 2022. "Occurrence of Microplastics in Waste Sludge of Wastewater Treatment Plants: Comparison between Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) Technologies" Membranes 12, no. 4: 371. https://doi.org/10.3390/membranes12040371

APA StyleDi Bella, G., Corsino, S. F., De Marines, F., Lopresti, F., La Carrubba, V., Torregrossa, M., & Viviani, G. (2022). Occurrence of Microplastics in Waste Sludge of Wastewater Treatment Plants: Comparison between Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) Technologies. Membranes, 12(4), 371. https://doi.org/10.3390/membranes12040371