Recovery of Model Pharmaceutical Compounds from Water and Organic Solutions with Alginate-Based Composite Membranes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

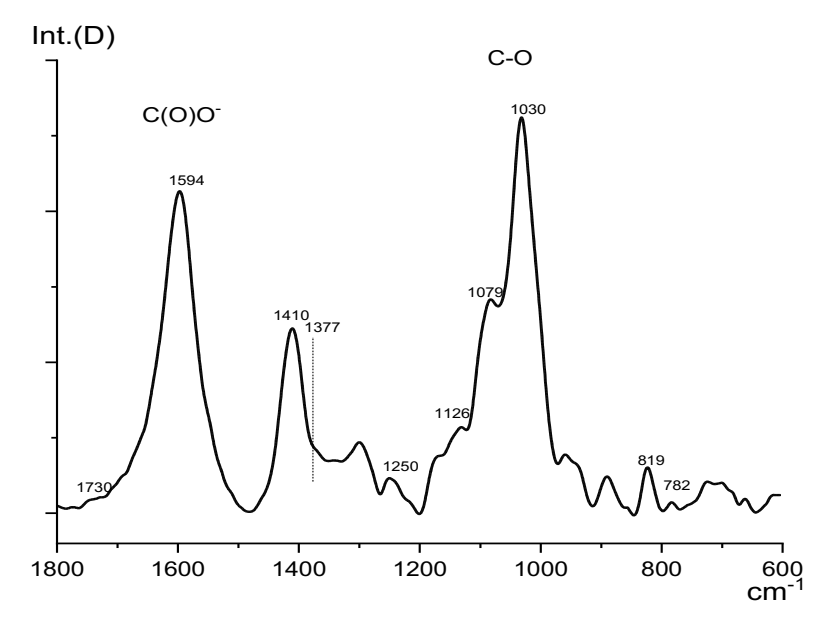

2.2. Characterization of Sodium Alginate

2.3. Preparation of Composite Membranes with Sodium Alginate

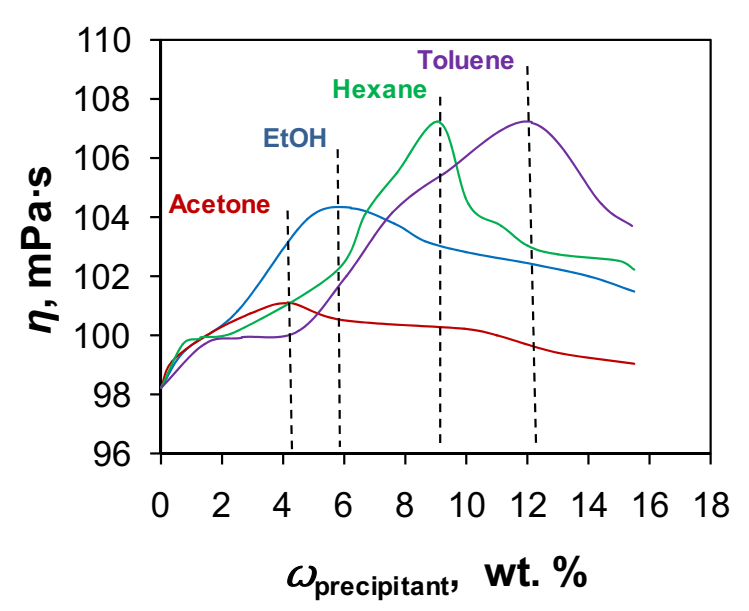

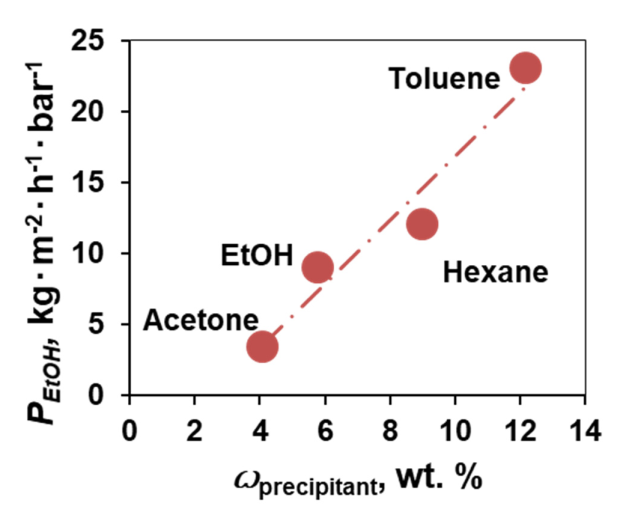

2.4. Study of Precipitation of Sodium Alginate by Organic Solvents

2.5. Filtration Experiments

2.6. Sorption Experiments

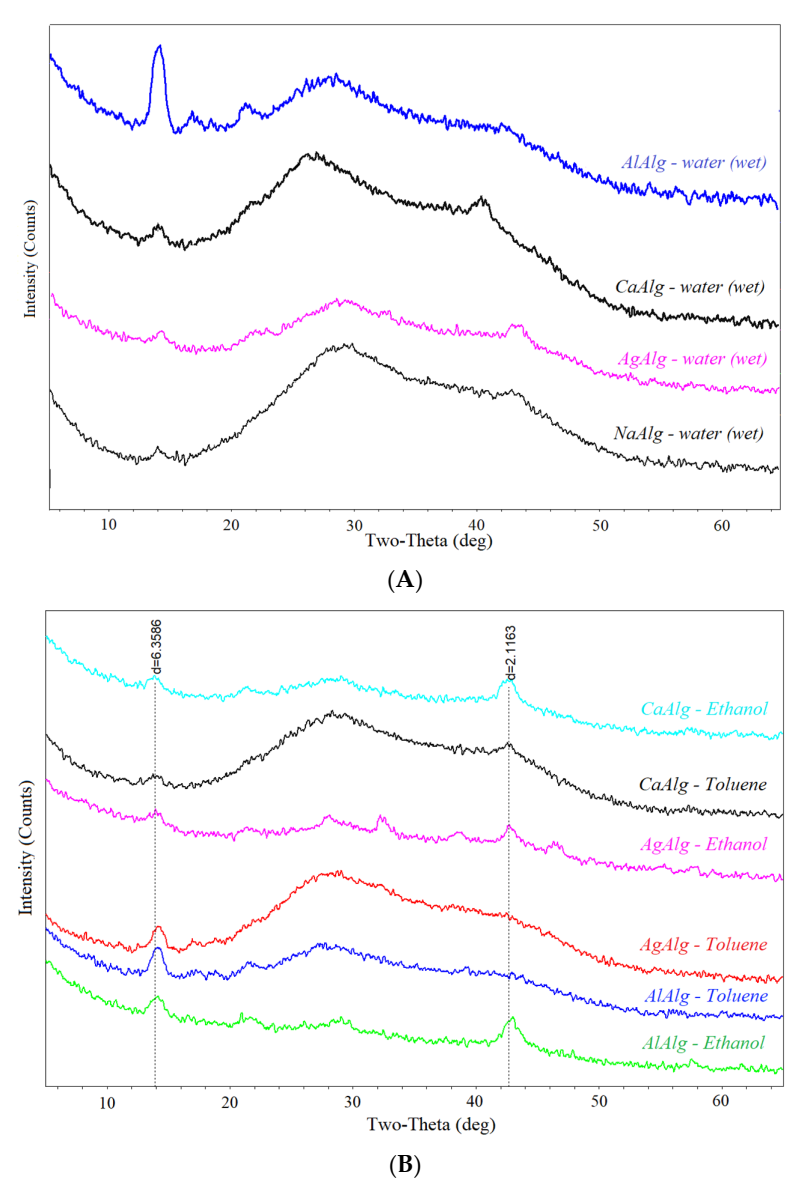

2.7. X-ray Diffraction (XRD)

2.8. Scanning Electron Microscope (SEM)/Energy-Dispersive Elemental Spectroscopy (EDX)

3. Results and Discussion

3.1. Characterization of Sodium Alginate

3.2. Study of Precipitation of Sodium Alginate by Organic Solvents

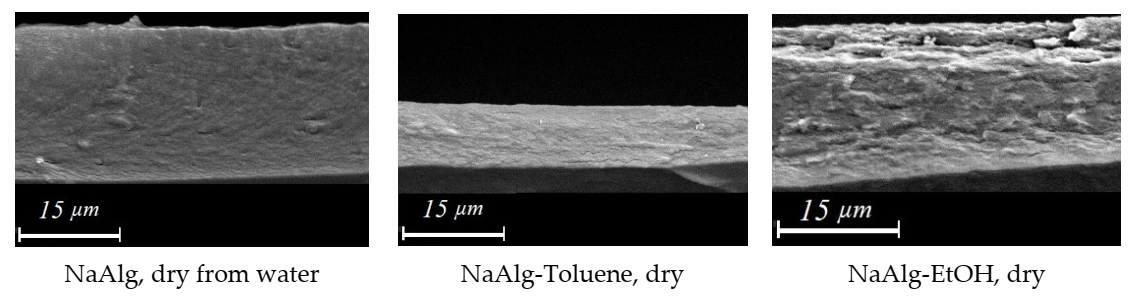

3.3. Effect of Non-Solvent on Precipitation and Properties of Sodium Alginate

3.4. The Morphology of Selective Layers of Composite Membranes: AgAlg, CaAlg, and AlAlg

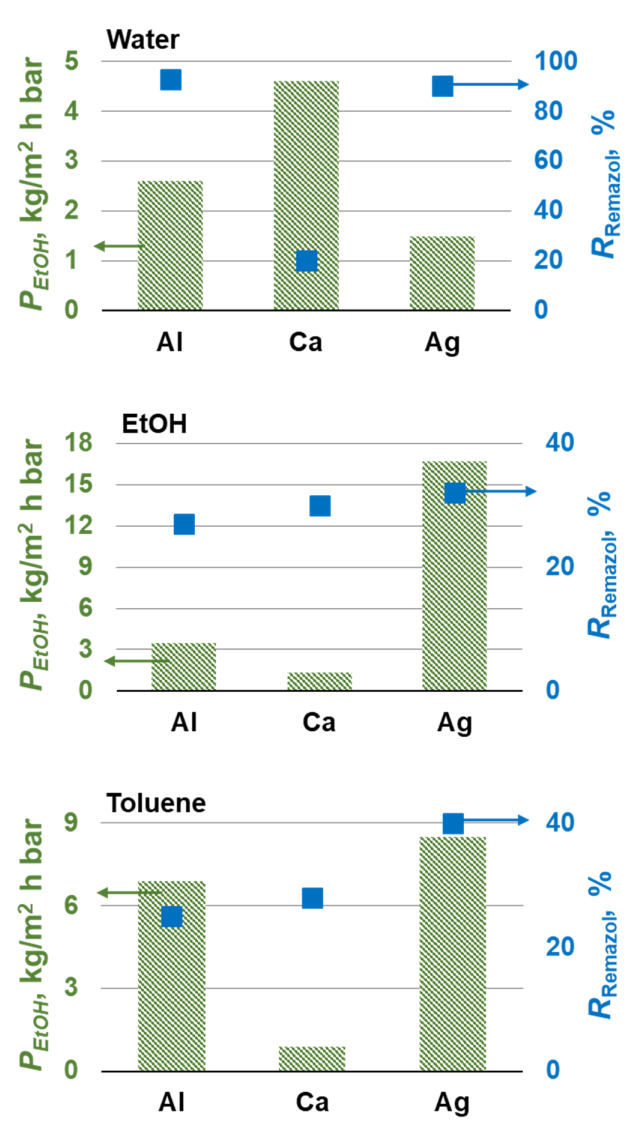

3.5. Nanofiltration Performance of Cross-Linked Membranes

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Symbols and Acronyms

| MW | molecular weight; |

| NaAlg | sodium alginate; |

| OSN | organic solvent nanofiltration; |

| API | active pharmaceutical ingredients; |

| WHO | World Health Organization; |

| CaCl2 | calcium chloride; |

| AlCl3 | aluminum chloride; |

| AgNO3 | silver nitrate; |

| IR | infrared spectroscopy; |

| ATR | attenuated total reflection; |

| MWD | molecular weight distribution; |

| GPC | gel permeation chromatography; |

| NaCl | sodium chloride; |

| NIPS | non–solvent induced phase separation; |

| P | permeance, kg/m2 h bar; |

| m | weight of permeate, kg; |

| S | area of membrane, m2; |

| Δt | filtration time, h; |

| Δp | pressure drop, bar; |

| R | rejection, %; |

| Cp | dye concentrations in the permeate; |

| C0 | dye concentrations in the feed; |

| EDX | dispersive elemental spectroscopy; |

| XRD | X-ray diffraction; |

| Ks | sorption, %; |

| m0 | weight of the dry sample of membrane; |

| m1 | weight of the swollen sample of membrane; |

| SEM | scanning electron microscopy; |

| DMF | dimethylformamide; |

| NMP | N–methyl–2–pyrrolidone; |

| EtOH | ethanol; |

| η | viscosity, mPa∙s; |

| ωprecipitant | concentration of precipitant in alginate solution, %; |

| δt | Hildebrand parameter; |

| δd | dispersion component of Hildebrand parameter; |

| δp | polar component of Hildebrand parameter; |

| δh | hydrogen bond component of Hildebrand parameter; |

| AgAlg | silver alginate; |

| CaAlg | calcium alginate; |

| AlAlg | aluminum alginate. |

References

- Pawar, S.N.; Edgar, K.J. Alginate derivatization: A review of chemistry, properties and applications. Biomaterials 2012, 33, 3279. [Google Scholar] [CrossRef] [PubMed]

- Hecht, H.; Srebnik, S. Structural characterization of sodium alginate and calcium alginate. Biomacromolecules 2016, 17, 2160. [Google Scholar] [CrossRef] [PubMed]

- Skriptsova, A.; Khomenko, V.; Isakov, V. Seasonal changes in growth rate, morphology and alginate content in Undariapinnatifida at the northern limit in the Sea of Japan (Russia). J. Appl. Phycol. 2004, 16, 17. [Google Scholar] [CrossRef]

- Gaggero, G.; Delucchi, M.; Allegretta, G.; Vicini, S.; Botter, R. Interaction of sodium alginate thickener with components of architectural water-based coatings. Prog. Org. Coat. 2021, 151, 106016. [Google Scholar] [CrossRef]

- Jaramillo, M.C.; Pimiento, Q.C.; Hoyos, G.C.; Gallego, Z.R.; Cordoba, L.A. Alginate-Edible Coatings for Application on Wild Andean Blueberries (Vacciniummeridionale Swartz): Effect of the Addition of Nanofibrils Isolated from Cocoa By-Products. Polymers 2020, 12, 824. [Google Scholar] [CrossRef]

- Chaturvedi, K.; Ganguly, K.; More, U.A.; Reddy, K.R.; Dugge, T.; Naik, B. Chapter 3—Sodium alginate in drug delivery and biomedical areas. Applications 2019, 59–100. [Google Scholar] [CrossRef]

- Tonnesen, H.H.; Karlsen, J. Alginate in drug delivery systems. Drug Dev. Ind. Pharm. 2002, 28, 621. [Google Scholar] [CrossRef]

- Sachan, N.K.; Pushkar, S.; Jha, A.; Bhattcharya, A. Sodium alginate: The wonder polymer for controlled drug delivery. J. Pharm. Res. 2009, 2, 1191, ISSN: 0974-6943. [Google Scholar]

- Bi, Y.G.; Lin, Z.T.; Deng, S.T. Fabrication and characterization of hydroxyapatite/sodium alginate/chitosan composite microspheres for drug delivery and bone tissue engineering. Mater. Sci. Eng. 2019, 100, 576. [Google Scholar] [CrossRef]

- Aburabie, J.H.; Puspasari, T.; Peinemann, K.V. Alginate-based membranes: Paving the way for green organic solvent nanofiltration. J. Membr. Sci. 2020, 596, 117615. [Google Scholar] [CrossRef]

- Huang, R.Y.M.; Pal, R.; Moon, G.Y. Characteristics of sodium alginate membranes for the pervaporation dehydration of ethanol–water and isopropanol–water mixtures. J. Membr. Sci. 1999, 160, 101. [Google Scholar] [CrossRef]

- KogaI, A.Y.; Felix, J.C.; Silvestre, R.G.M.; Lipinski, L.C.; Carletto, B.; Kawahara, F.A.; Pereira, A.V. Evaluation of wound healing effect of alginate film containing Aloe vera gel and cross-linked with zinc chloride. Acta Cir. Bras. 2020, 35, 202000507. [Google Scholar] [CrossRef]

- Aneem, T.H.; Wong, S.Y.; Afrin, H.; Nurunnabi, M.; Li, X.; Arafat, M.T. Investigation of coagulation process of wet-spun sodium alginate polymannuronate fibers with varied functionality using organic coagulants and cross-linkers. Mater. Today Chem. 2021, 22, 100580. [Google Scholar] [CrossRef]

- Khattak, A.Z.; Ross, R.; Ngo, T.; Shoemaker, C.T. A randomized controlled evaluation of absorption of silver with the use of silver alginate (Algidex) patches in very low birth weight (VLBW) infants with central lines. J. Perinatol. 2010, 30, 337. [Google Scholar] [CrossRef][Green Version]

- Lengert, E.; Yashchenok, A.M.; Atkin, V.; Lapanje, A.; Gorin, D.A.; Sukhorukov, G.B.; Parakhonskiy, B.V. Hollow silver alginate microspheres for drug delivery and surface enhanced Raman scattering detection. RSC Adv. 2016, 6, 20447. [Google Scholar] [CrossRef]

- Lengert, E.; Saveleva, M.; Abalymov, A.; Atkin, V.; Wuytens, P.C.; Kamyshinsky, R.; Vasiliev, A.L.; Gorin, D.A.; Sukhorukov, G.B.; Skirtach, A.G.; et al. Silver alginate hydrogel micro-and nanocontainers for theranostics: Synthesis, encapsulation, remote release, and detection. ACS Appl. Mater. Interfaces 2017, 9, 21949. [Google Scholar] [CrossRef]

- Zhang, W.; Yong, P.C.; Ge, Q.; Zhang, L.; Wang, X.P. Fabrication and Characterization of Chitosan/Alginate Multilayer Composite Membrane Supported by a Porous Poly (Acrylonitrile) Substrate for Pervaporation Dehydration of Alcohol. J. Membr. Sci. Res. 2017, 3, 272. [Google Scholar] [CrossRef]

- Kalyani, S.; Smitha, B.; Sridhar, S.; Krishnaiah, A. Separation of ethanol−water mixtures by pervaporation using sodium alginate/poly (vinyl pyrrolidone) blend membrane crosslinked with phosphoric acid. Ind. Eng. Chem. Res. 2006, 45, 9088. [Google Scholar] [CrossRef]

- Hajiali, H.; Heredia-Guerrero, J.A.; Liakos, I.; Athanassiou, A.; Mele, E. Alginate nanofibrous mats with adjustable degradation rate for regenerative medicine. Biomacromolecules 2015, 16, 936. [Google Scholar] [CrossRef]

- Santhosh, C.; Velmurugan, V.; Jacob, G.; Jeong, S.K.; Grace, A.N.; Bhatnagar, A. Role of nanomaterials in water treatment applications: A review. Chem. Eng. J. 2016, 306, 1116. [Google Scholar] [CrossRef]

- Kanti, P.A.; Srigowri, K.; Madhuri, J.; Smitha, B.; Sridhar, S. Dehydration of ethanol through blend membranes of chitosan and sodium alginate by pervaporation. Sep. Purif. Technol. 2004, 40, 259. [Google Scholar] [CrossRef]

- Dmitrenko, M.; Liamin, V.; Kuzminova, A.; Lahderanta, E.; Solovyev, N.; Penkova, A. Modification Approaches to Enhance Dehydration Properties of Sodium Alginate-Based Pervaporation Membranes. Membranes 2021, 11, 255. [Google Scholar] [CrossRef] [PubMed]

- Dmitrenko, M.; Zolotarev, A.; Liamin, V.; Kuzminova, A.; Mazur, A.; Semenov, K.; Ermakov, S.; Penkova, A. Novel Membranes Based on Hydroxyethyl Cellulose/Sodium Alginate for Pervaporation Dehydration of Isopropanol. Polymers 2021, 13, 674. [Google Scholar] [CrossRef] [PubMed]

- Kuzminova, A.I.; Dmitrenko, M.E.; Poloneeva, D.Y.; Selyutina, A.A.; Mazur, A.S.; Emeline, A.V.; Mikhailovskii, V.Y.; Solovyev, N.D.; Ermakov, S.S.; Penkova, A.V. Sustainable composite pervaporation membranes based on sodium alginate modified by metal organic frameworks for dehydration of isopropanol. J. Membr. Sci. 2021, 626, 119194. [Google Scholar] [CrossRef]

- Mohanapriya, S.; Bhat, S.D.; Sahu, A.K.; Manokaran, A.; Vijayakumar, R.; Pitchumani, S.; Shukla, A.K. Sodium-alginate-based proton-exchange membranes as electrolytes for DMFCs. Energy Environ. Sci. 2010, 3, 1746. [Google Scholar] [CrossRef]

- Shaari, N.; Kamarudin, S.K. Characterization studies of sodium alginate/sulfonated graphene oxide based polymer electrolyte membrane for direct methanol fuel cell. Malays. J. Anal. Sci. 2017, 21, 113. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhao, X.; Manthiram, A. Sulfonated poly (ether ether ketone) membranes with sulfonated graphene oxide fillers for direct methanol fuel cells. Int. J. Hydrog. Energy 2013, 38, 5875. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, B.; Zhao, K.; Wei, J.; Guo, J.; Cui, W.; Li, J. A free-standing calcium alginate/polyacrylamide hydrogel nanofiltration membrane with high anti-fouling performance: Preparation and characterization. Desalination 2015, 365, 234. [Google Scholar] [CrossRef]

- Jie, G.; Zhao, K.; Zhang, X.; Cai, Z.; Min, C.; Tian, C.; Wei, J. Preparation and characterization of carboxyl multi-walled carbon nanotubes/calcium alginate composite hydrogel nano-filtration membrane. Mater. Lett. 2015, 157, 112. [Google Scholar] [CrossRef]

- Wang, X.L.; Qin, W.; Wang, L.X.; Zhao, K.Y.; Wang, H.C.; Liu, H.Y.; Wei, J.F. Desalination of dye utilizing carboxylated TiO2/calcium alginate hydrogel nanofiltration membrane with high salt permeation. Sep. Purif. Technol. 2020, 253, 117475. [Google Scholar] [CrossRef]

- Dmitrieva, E.S.; Pankratova, E.E.; Anokhina, T.S.; Vinokurov, V.A.; Volkov, A.V. Crosslinked Sodium Alginate as a Material for Nanolfiltration Protonic and Aprotonic Solvents. Key Eng. Mater. 2021, 899, 745. [Google Scholar] [CrossRef]

- Anokhina, T.; Borisov, I.; Yushkin, A.; Vaganov, G.; Didenko, A.; Volkov, A. Phase Separation within a Thin Layer of Polymer Solution as Prompt Technique to Predict Membrane Morphology and Transport Properties. Polymers 2020, 12, 2785. [Google Scholar] [CrossRef]

- Peeva, L.; Burgal, J.S.; Valtcheva, I.; Livingston, A.G. Continuous purification of active pharmaceutical ingredients using multistage organic solvent nanofiltration membrane cascade. Chem. Eng. Sci. 2014, 116, 183–194. [Google Scholar] [CrossRef]

- Ferreira, F.; Resina, L.; Esteves, T.; Ferreira, F.C. Comparison and Combination of Organic Solvent Nanofiltration and Adsorption Processes: A Mathematical Approach for Mitigation of Active Pharmaceutical Ingredient Losses during Genotoxin Removal. Membranes 2020, 10, 73. [Google Scholar] [CrossRef]

- Slater, C.S.; Savelski, M.G.; Moroz, T.M.; Raymond, M.G. Pervaporation as a green drying process for tetrahydrofuran recovery in pharmaceutical synthesis. Green Chem. Lett. Rev. 2012, 5, 5564. [Google Scholar] [CrossRef]

- Székely, G.; Bandarra, J.; Heggie, W.; Sellergren, B.; Ferreira, F.C. Organic solvent nanofiltration: A platform for removal of genotoxins from active pharmaceutical ingredients. J. Membr. Sci. 2011, 381, 21. [Google Scholar] [CrossRef]

- Laxminarayan, R.; Boeckel, T.V.; Frost, I.; Kariuki, S.; Khan, E.A.; Limmathurotsakul, D.; Larsson, D.G.J.; Levy-Hara, G.; Mendelson, M.; Outterson, K.; et al. The Lancet Infectious Diseases Commission on antimicrobial resistance: 6 years later. Lancet Infect. Dis. 2020, 20, e51–e60. [Google Scholar] [CrossRef]

- Cars, O.; Chandy, S.J.; Mpundu, M.; Peralta, A.O.; Zorzet, A.; So, A.D. Resetting the agenda for antibiotic resistance through a health systems perspective. Lancet Glob. Health 2021, 9, e1022–e1027. [Google Scholar] [CrossRef]

- Van Boeckel, T.; Brower, C.; Gilbert, M.; Grenfell, T.B.; Levin, S.A.; Robinsoni, P.T.; Teillant, A.; Laxminarayan, R. Global trends in antimicrobial use in food animals. Proc. Natl. Acad. Sci. USA 2015, 112, 5649–5654. [Google Scholar] [CrossRef]

- Martínez, J.L. Antibiotics and Antibiotic Resistance Genes in Natural Environments. Science 2008, 321, 365. [Google Scholar] [CrossRef]

- Norman, H.; Johannes, A.; Christian, H.; Arne, W.; Thomas, S. Dissemination prevention of antibiotic resistant and facultative pathogenic bacteria by ultrafiltration and ozone treatment at an urban wastewater treatment plant. Sci. Rep. 2019, 9, 12843. [Google Scholar] [CrossRef]

- Mahesh, C.; Ramavatar, M.; Kamalesh, P.; Siddhanta, A.K. Microwave assisted rapid method for hydrolysis of sodium alginate for M/G ratio determination. Carbohydr. Polym. 2009, 76, 650. [Google Scholar] [CrossRef]

- Hansen, C.M. Hansen Solubility Parameters: A User′s Handbook/C/M/Hansen; CRC Press: Boca Raton, FL, USA, 2007; p. 544. [Google Scholar]

- Subrahmanyam, R.; Gurikov, P.; Dieringer, P.; Sun, M.; Smirnova, I. On the Road to Biopolymer Aerogels—Dealing with the Solvent. Gels 2015, 1, 291. [Google Scholar] [CrossRef] [PubMed]

- Ugraskan, V.; Isik, B.; Yazici, O.; Cakar, F. Thermodynamic Characterization of Sodium Alginate by Inverse Gas Chromatography. J. Chem. Eng. Data 2020, 65, 1795. [Google Scholar] [CrossRef]

- Richardson, J.C.; Dettmar, P.W.; Hampson, F.C.; Melia, C.D. Oesophageal bioadhesion of sodium alginate suspensions: Particle swelling and mucosal retention. Eur. J. Pharm. Sci. 2004, 23, 49. [Google Scholar] [CrossRef]

- Huq, T.; Salmieri, S.; Khan, A.; Khan, R.A.; LeTien, C.; Riedl, B. Lacroix, M. Nanocrystalline cellulose (NCC) reinforced alginate based biodegradable nanocomposite film. Carbohydr. Polym. 2012, 90, 1757. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Zhang, L.; Peng, T.; Zhong, W. Effects of Ca2+ bridge cross-linking on structure and pervaporation of cellulose/alginate blend membranes. J. Membr. Sci. 2020, 175, 53. [Google Scholar] [CrossRef]

- Li, L.; Fang, Y.; Vreeker, R.; Appelqvist, I.; Mendes, E. Reexamining the Egg-Box Model in Calcium−Alginate Gels with X-ray Diffraction. Biomacromolecules 2007, 8, 464. [Google Scholar] [CrossRef] [PubMed]

- Chaobo, X.; Hongjuan, L.; Yongshang, L.; Lina, Z. Blend films from sodium alginate and gelatin solutions. J. Macromol. Sci. 2001, 38, 317. [Google Scholar] [CrossRef]

- Sikorski, P.; Mo, F.; Skjåk-Bræk, G.; Bjørn, T.S. Evidence for Egg-Box-Compatible Interactions in Calcium−Alginate Gels from Fiber X-ray Diffraction. Biomacromolecules 2007, 8, 2098. [Google Scholar] [CrossRef]

- Perepechkin, L.P. Methods for obtaining polymeric membranes. Russ. Chem. Rev. 1988, 57, 539. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, M.; Luo, B.; Li, J.; Yuan, Q.; Yang, X.J. The performance of integrally skinned polyetherimide asymmetric nanofiltration membranes with organic solvents. J. Membr. Sci. 2017, 544, 119. [Google Scholar] [CrossRef]

- Jegal, J.; Lee, K.H. Nanofiltration membranes based on poly (vinyl alcohol) and ionic polymers. J. Appl. Polym. Sci. 1999, 72, 1755. [Google Scholar] [CrossRef]

- Artuğ, G.; Roosmasari, I.; Richau, K.; Hapke, J. A comprehensive characterization of commercial nanofiltration membranes. Sep. Sci. Technol. 2007, 42, 2947. [Google Scholar] [CrossRef]

- Yushkin, A.A.; Anokhina, T.S.; Volkov, A.V. Application of cellophane films as nanofiltration membranes. Pet. Chem. 2015, 55, 746–752. [Google Scholar] [CrossRef]

| Compound | δt, MPa1/2 | δd, MPa1/2 | δp, MPa1/2 | δh, MPa1/2 | Ref. |

|---|---|---|---|---|---|

| NaAlg | 37 | - | - | - | [23,44,45] |

| Water | 47.8 | 15.5 | 16.0 | 42.3 | [43] |

| Ethanol | 26.5 | 15.8 | 8.8 | 19.4 | |

| Acetone | 19.9 | 15.5 | 10.4 | 7.0 | |

| Hexane | 14.9 | 14.9 | 0.0 | 0.0 | |

| Toluene | 18.2 | 18.0 | 1.4 | 2.0 |

| Precipitant | Ks (precipitant), g/g | Thinkeness of Swollen NaAlg Layer, µm | NaAlg Layer Appearance | Photo Precipitation NaAlg | P, kg∙m−2·h−1·bar−1 | |||

|---|---|---|---|---|---|---|---|---|

| Toluene | Hexane | Ethanol | Acetone | |||||

| Toluene | 0.24 | 110 | gel |  | 415 | 123 | 23 | 28 |

| Hexane | 0.11 | 80 | gel |  | 41 | 23 | 12 | 9 |

| Ethanol | <0.05 | 55 | precipitated polymer |  | 3 | 4 | 9 | 7 |

| Acetone | <0.05 | 40 | precipitated polymer |  | 0.1 | 0.4 | 3.4 | 3.7 |

| Water | EtOH | Toluene | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Na+ | Al3+ | Ca2+ | Ag+ | Na+ | Al3+ | Ca2+ | Ag+ | Na+ | Al3+ | Ca2+ | Ag+ | |

| Na, % | 10.4 ± 2.3 | 0 | 0.4± 0.1 | 0 | 11.2 ± 2.3 | 0 | 0.3± 0.1 | 0 | 10.9 ± 2.3 | 0 | 0.5± 0.1 | 0 |

| Al, % | 0 | 6.4 ± 2.2 | 0 | 0 | 0 | 7.7 ± 2.2 | 0 | 0 | 0 | 7.1± 2.2 | 0 | 0 |

| Ca, % | 0 | 0 | 6.2 ± 1.3 | 0 | 0 | 0 | 7.5 ± 1.3 | 0 | 0 | 0 | 5.9 ± 1.3 | 0 |

| Ag, % | 0 | 0 | 0 | 7.7 ± 0.2 | 0 | 0 | 0 | 7.9 ± 0.2 | 0 | 0 | 0 | 8.2 ± 0.2 |

| Membrane Type | Filtered Media | P, kg·m−2·h−1·bar−1 | Selectable Component | MW, g/mol | R, % | Ref. |

|---|---|---|---|---|---|---|

| CaAlg | MeOH | 1.3–1.6 | Vitamin B12 | 1355 | 90–98 | [10] |

| MPF-44 | EtOH + Methylene Blue | 0.1 | Methylene Blue | 374 | 95 | [53] |

| MPF-34 | 0.1 | 94 | ||||

| M4 | 0.5 | 97 | ||||

| Starmem | 4.3 | 43 | ||||

| Solsep | 7.1 | 70 | ||||

| Cellophane | EtOH | 0.05 | Remazol Brilliant Blue R | 626 | 79 | [56] |

| Orange II | 350 | 55 | ||||

| AlAlg | EtOH | 2.6 | Remazol Brilliant Blue R | 626 | 93 | This work |

| AgAlg | 1.5 | 90 | ||||

| alginate crosslinked + PVA | water + PEG600 | 4 | PEG600 | 600 | 80 | [54] |

| AlAlg | water | 7.8 | Remazol Brilliant Blue R | 626 | 99 | This work |

| Orange II | 350 | |||||

| AgAlg | 6.8 | Remazol Brilliant Blue R | 626 | 99 | ||

| Orange II | 350 | 95 | ||||

| Cellophane | water | 0.11 | Remazol Brilliant Blue R | 626 | 100 | [56] |

| Orange II | 350 | 97 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anokhina, T.; Dmitrieva, E.; Volkov, A. Recovery of Model Pharmaceutical Compounds from Water and Organic Solutions with Alginate-Based Composite Membranes. Membranes 2022, 12, 235. https://doi.org/10.3390/membranes12020235

Anokhina T, Dmitrieva E, Volkov A. Recovery of Model Pharmaceutical Compounds from Water and Organic Solutions with Alginate-Based Composite Membranes. Membranes. 2022; 12(2):235. https://doi.org/10.3390/membranes12020235

Chicago/Turabian StyleAnokhina, Tatyana, Evgenia Dmitrieva, and Alexey Volkov. 2022. "Recovery of Model Pharmaceutical Compounds from Water and Organic Solutions with Alginate-Based Composite Membranes" Membranes 12, no. 2: 235. https://doi.org/10.3390/membranes12020235

APA StyleAnokhina, T., Dmitrieva, E., & Volkov, A. (2022). Recovery of Model Pharmaceutical Compounds from Water and Organic Solutions with Alginate-Based Composite Membranes. Membranes, 12(2), 235. https://doi.org/10.3390/membranes12020235