2.2.1. Solute Concentration

In their original study, G.C. Sarti et al. found a slight inverse relationship between flux and solute concentration. However, in their latest low-energy membrane desalination study, G.C. Sarti et al. identified the significant effects of concentration and flux with respect to temperature. The latter study was conducted using pure water to 0.9 M concentrations, and it was reported that the change in flux was affected by the concentration; as the concentration increased, the flux and rate of change in flux increased, especially for concentrations exceeding 0.5 M [

7,

22].

In their experimental study of the factors that affect the flux of MD on a Durapore 0.45-μm membrane, Scofield et al. stated that flux was affected by the presence of solute [

38]. Moreover, they reported a decrease in the activity coefficient with increasing concentration, by showing that the reduction in flux as the concentration increased from 0 to 0.047 M was less than that as the concentration increased from 0.047 to 0.095 M. However, as the feed temperature increased, the difference between the fluxes at higher and lower concentrations increased. This was demonstrated through experiments that were conducted with salt solutions saturated at the feed temperature, resulting in the formation of a layer of precipitated salt crystals on the membrane surface, which reduced the film heat transfer coefficient considerably and led to a rapid decay in flux. At the end of the experiment, it was possibly to remove the salt scales as sheets.

Through concentration, the relative importance of other factors such as viscosity were determined. Roughly one-third of the flux reduction was reportedly caused by viscosity change. An increase in viscosity was found to apparently affect the Reynolds number and reduce turbulence. The vapor pressure at the membrane wall decreased by 25% with respect to that of pure water. Moreover, the heat transfer coefficient decreased by 30%, reflecting a reduced change in vapor pressure. In relation to solute concentration, the only factor that led to an increase in flux was density. An 18% increase in density led to a 14% increase in the film heat transfer coefficient through the Reynolds number, which, in turn, led to a 4% increase in flux. Solute-related factors such as thermal conductivity and heat capacity had a negligible effect on flux, resulting in only a 5% reduction in the heat transfer coefficient. Different from other membrane processes, concentration polarization, too, had a negligible effect on flux.

F. Lagana et al. reported the strong effect of extremely high feed concentrations on the dimensionless resistance of the MD process, which constitutes temperature polarization and concentration polarization and is defined as the ratio of each polarization and membrane resistance [

18]. Accordingly, as the concentration increased from 400 g/L to 800 g/L, the dimensionless resistance increased exponentially from 0.8 to 2.25. Moreover, among all the resistances, temperature polarization resistance was affected significantly by concentration changes.

The effect of solute concentration was found to vary with the type of solute. For example, the vapor pressure decreased by less than 3% for a 30% sugar solution, but it decreased by 29% for a 30% salt solution. However, for the same concentration, the effect on viscosity is approximately equal, which indicated that the major cause of flux reduction for sugar solutions was viscosity. However, in a study of the transport resistance in DCMD, L. Martinez et al. reported that a decrease in the flux of a sucrose solution was primarily caused by a decrease in the driving force [

13]. Even so, they agreed on the profound effect of viscosity on flux reduction, especially at higher concentrations. A sharp reduction in the feed-side heat transfer coefficient with an increase in sucrose concentration beyond 40 wt% was reported. Accordingly, the predominant flux-controlling resistance was the feed-side film boundary layer resistance. The membranes used in this study were GVHP22 and TF200.

S. Al-Obaidani et al. studied the effect of solution concentration on transmembrane flux for the feed and permeate velocities of 0.39 and 0.28 m/s, respectively. They reported a total flux reduction of up to 50% as the feed concentration increased from 35 to 350 g/L. In addition, thermal efficiency decreased from 58% to 40% [

11].

L. Martinez et al. stated that membrane flux was inversely affected by concentration. They described this effect by using different heat transfer and mass transfer resistances [

13]. Their results indicated that film resistances, mainly the feed-side film resistance, were the most strongly affected by concentration. Generally, this reduction is a consequence of a decrease in the feed water activity as the amount of feed water increases, which is consistent with the point made by Scofield et al. Moreover, they summarized that if the physical properties of the feed, which affects the film transfer coefficients, do not change considerably as the concentration increases, the resistance does not change significantly with the concentration. Furthermore, the reduction in evaporation efficiency was reported as an effect of a reduction in the feed water activity, which is similar to the results of other studies.

In contrast to the other solutes studied above, M. Courel et al. conducted a study on calcium chloride and reported an almost three-fold increase in transmembrane flux with increasing solute flux. As the solute concentration increased from 30 to 45 wt.%, the solute flux increased from 4 to 11 kg/m

2/h. There is no explanation as to why the flux increases differently with solute concentration [

30].

In a study of the heat and mass transfer characteristics of a DCMD, P. Termpiyakul et al. briefly discussed the effect of feed concentration on the transmembrane flux and reported that it decreased with an increasing feed concentration because of a reduction in vapor pressure. The flux was found to decrease with time as the feed concentration increased, and this effect was significant at high concentrations. At the feed temperature of 40 °C, as the feed concentration increased from 17,500 ppm to 35,000 ppm, the flux decreased from 8.5 to 6.5 kg/m

2/h [

29].

S. Kimura investigated the effect of concentration on the flux for different types of feeds [

33]. The results indicated that at high concentration ratios, the fluxes were higher in the MD process than in the RO process. In the process of milk concentration, for a 50% increase, the flux decreased by 150%. Apparently, membranes tend to be fouled because of fat adhesion, which reduces the flux considerably. The concentrations of sugar and gelatin were investigated, and the results indicated a relatively non-steep relationship. In the case of sugar, for a 400% increase in concentration, the flux decreased by only 30%.

D. Winter et al. studied the influence of feed concentration on the total product rate with respect to the mass flowrate and found that the total product rate decreased as the salinity of the feed water increased [

16]. The rate of decrease did not differ with the feed flowrate. For example, for the feed flowrate of 200 kg/h, when the feed salinity was increased from 20 to 100 g/kg, the permeate mass rate decreased from 25 to 14 kg/h.

A Boubakri et al. elaborated the inverse relationship between the flux and concentration or ionic strength; as the concentration increased, the dynamic fluid will change as a result of increasing viscosity, and concentration polarization should be added to the temperature polarization, which reduces the imposed DCMD driving force and, consequently, the permeate flux [

36]. According to the experimental results of their study, as the ionic strength increased from 0 to 4.3 M, the flux decreased from 3 to 2.4 L/m

2/h.

H.C. Duong et al. studied the effect of concentration through a different mechanism in the context of recycling brine to achieve high water recoveries [

32]. They found that even if recycling increased water recovery, it deteriorated the system performance. Accordingly, they reported that as the water recovery increased from 60% to 70%, the flux decreased from 8 to 7 L/m

2/h, and there was the risk of scale formation on the membrane surface.

2.2.2. Diffusivity and Mass Transfer Coefficient

In the early 1980s, in studies on thermal membrane processes, mass transport was assumed to be caused by either the Soret effect, according to which flux is induced through thermal diffusion in the bulk liquid phase or through an evaporation-diffusion-condensation process enhanced by capillary forces, or the pervaporation effect, according to which separation is achieved through a partition between a dense membrane and an external vapor phase [

7,

39]. P. Bellucci et al. studied the mass transport in coarsely porous synthetic membranes and confirmed a close relationship between the flux and temperature gradient [

39]. However, according to a thermodialysis study involving PTFE membranes, G.C. Sarti et al. found that the separation in membrane distillation system occurs not because of the Soret effect but rather because of an evaporation-diffusion-condensation process, wherein membrane hydrophobicity plays a crucial role in preventing the liquid phase from entering membrane pores [

7]. In a second study involving a water solution as a feed, the process was first investigated experimentally, and it was concluded that a type of low-temperature distillation, enhanced by capillarity, occurred. It was called capillary distillation because the essential prerequisite of the process was the capillary force that prevented the liquid phase from entering the pores.

Under simplified conditions, a liquid–vapor interface is formed on either side of the liquid, which repulses the membrane: typically, evaporation occurs at the interface on the warmer side, and after mass transport through the vapor phase within the pores, condensation occurs at the interface on the colder side. Accordingly, the mass transfer coefficients were expressed based on the theory that water vapor diffuses from the warm side to the cold side through a substantial film of stagnant air [

22].

Water flux is expressed under the condition that water vapor diffuses though a substantial film of stagnant air. The diffusion coefficient accounts for both the ordinary and Knudsen transport models [

24,

40].

where,

is porosity,

is tortuosity,

is membrane thickness,

and

are warm and cold side pressures,

is the partial pressure of air and

is the partial pressure of the vapor,

is the arithmetic mean temperature between the warm side and cold side and

is molecular weight. In the above-referenced studies, even though the diffusion coefficients account for both ordinary and Knudsen transports, it was assumed that the contribution of ordinary diffusion dominated the transport process. The coefficients were primarily estimated based on the gas-phase diffusion coefficients derived from the Stefan–Maxwell hard sphere model and the principle of additive volumes, which was first employed to estimate diffusion coefficients [

41]. Then, at low-to-moderate temperature and pressure, they were predicted using the corresponding-states methods. According to Bird et al., in these methods, for binary gas mixtures at low pressures, the diffusion coefficient is inversely proportional to pressure, increases with increasing temperature, and is almost independent of the composition of the given gas pair [

24].

which leads to

where,

is binary diffusivity,

is the total pressure, T is the system temperature,

and

,

are critical pressures and temperature of components, respectively,

and

are molecular weights of the components, and

and

are dimensionless constants. The above relationship helps correlate the average values of pressure, temperature, and diffusion coefficient with that at any point.

M.E. Findley et al. are among the early researchers in the United States (1969) to study the mass and heat transfer relationships of porous membranes. Their experimental results indicated that the major factor influencing the rates of transfer was diffusion through a stagnant gas in the membrane pores [

23]. G.C. Sarti et al. described the mechanism of mass transfer for multicomponent fluids in MD [

7,

22]. A porous partition in contact with two liquid phases that are stalled at the pore entrances by capillary forces was considered. In this study, the pressure on either liquid was smaller than the capillary pressure of the membrane, that is, the liquid phases were kept out of the pores by the capillary forces. Thus, a gaseous phase was immobilized within the membrane pores, where because of a difference in vapor pressure at the opposite membrane surfaces, evaporation at one end and condensation at the opposite capillary end occurred.

However, M.E. Findley et al. illustrated that the above equation was oversimplified and should be corrected for heat transfer effects. In addition to diffusion, factors such as heat transfer coefficients, membrane thermal conductivity, and temperature difference should be considered when determining the mass transfer coefficient in MD. Accordingly, the following mass transfer coefficient formula was derived:

In general, the mass flux across an MD membrane can be expressed as follows:

where,

where

,

, and

are the membrane mass transfer coefficient, the average temperature on the solution side and condensate side, total pressure minus average of solution side and condensate side vapor pressures, boiling point elevation of solution, and thickness of membrane expressed as weight per area, respectively. The above coefficient was computed by conducting three groups of experiments for determining the effect of vapor pressure difference on evaporation rates, the effect of membrane thickness on mass transfer, and the effect of temperature on air gas partial pressure. The first experiment and determination of mass transfer coefficient ended up short of missing the heat transfer effects on the coefficient, and therefore, it was corrected in the second experiment. Even so, to establish the independent effect of temperature stemming from an external heat source, the third experiment was set up to correlate the equations based on a diffusive mass transfer mechanism though stagnant air.

2.2.3. Mass Transfer Coefficient Models

In recent studies, the mass transfer in MD has been described using the dusty-gas model (DGM), which is the most general model for a flux through a porous medium, where the medium is dust particles. This model was first described by Maxwell for dilute gases. Even though it was derived for isothermal fluxes, it has been successfully applied to non-isothermal systems through the inclusion of thermal diffusion and thermal transpiration terms, which are negligible in the MD operating regime [

42]. This model represents a more theoretically sound approach to address diffusion through a porous medium. In its most general form, the DGM applicable to MD (neglecting surface tension) can be expressed as follows:

where

is the diffusive flux,

is the viscous flux,

is the total pressure,

is the partial pressure of component i, and

is the fluid viscosity; the effective ordinary and Knudsen diffusivities are defined as

and

, respectively.

The constants, which were estimated from the membrane pore radius r, tortuosity , and porosity (assuming the membrane consisted of uniform cylindrical pores), , , and were found to depend on membrane geometry and membrane–molecule interactions. These constants are best determined experimentally because the complex geometries of most membranes make it impossible to perform direct calculations.

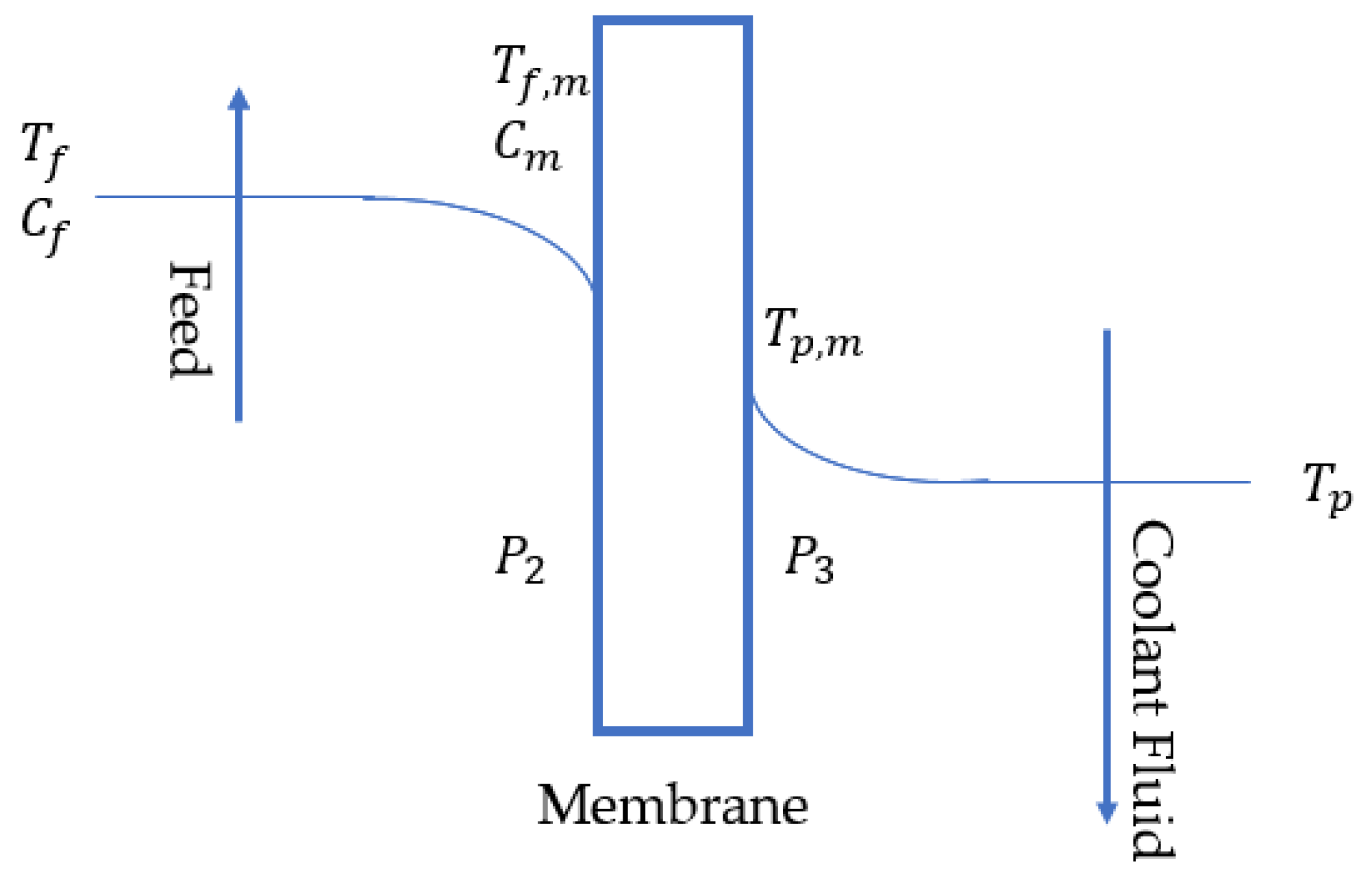

However, when the more general DGM is broken down, the mass transfer resistance across an MD membrane in a typical MD process can be conveniently described in terms of the serial electrical resistances upon the transfer between the bulks of two phases in contact with the membrane, as illustrated in

Figure 1. The mass transfer boundary layers adjoining the membrane generally make negligible contributions to the overall mass transfer resistance. The mass transfer through the membrane can be divided into three models based on collisions between molecules, and/or molecules within the membrane. Molecular diffusion across the polymeric membrane often represents the controlling step. Resistance to mass transfer on the distillate side is omitted whenever MD is operated with pure water as the condensing fluid in direct contact with the membrane, or when the configuration used to establish the required driving force is based on a vacuum [

10,

30,

42].

When the pore size is too small, such that the collision between the molecules and the inside walls of the membrane suitably express the mass transport, that is,

(Knudsen region), the molecular collisions can be ignored, and the resistance can be expressed as follows:

When the molecules travel corresponding to each other under the influence of a concentration gradient, that is,

(continuum region), the mass transfer resistance can be expressed as follows:

Among the specific models, K. W. Lawson et al. and other reviewers of the process suggested that for de-aerated DCMD, the reduced Knudsen–molecular diffusion transition form of the DGM should be applied to describe the vapor flux of pure water across a membrane [

10,

11,

42]. It is expressed as follows for

(transition region):

where

;

is the partial pressure of the air in the pores,

is the total pressure inside the pore,

is the mean molecular free path,

is the Knudsen number. The above equations can be derived from the equation of the DGM model.

2.2.4. Experimental Values of Mass Transfer Coefficients

P. Termpiyakul et al. experimentally verified the mass transfer coefficient from a flux versus vapor pressure difference graph and computed the mass transfer coefficient, which was found to be dependent on membrane characteristics and vapor properties, such as porosity and tortuosity; the computed value was 0.0024 kg/m

2/h/Pa. In a study of heat and mass transfer in MD, R.W. Schofield computed the mass transfer coefficient as 0.00306 kg/m

2/h/Pa or 8.5 × 10

−7 kg/m

2/s/Pa on the basis of Hanbury and Hodgkiess analysis [

40,

43]. It was determined from the slope of a plot of temperature over flux vs. change in pressure over change in temperature.

In a study investigating the effect of the MD mass transfer coefficient C on the performance enhancement of non-baffled and baffled modules, H. Yu et al. found that the TPC decreased significantly with an increasing C value, regardless of the existence of baffles, signifying a loss of the overall driving force [

44]. However, a higher C value compensated for this loss, and the mass flux showed an increasing trend. A membrane with a lower C value was found to be less vulnerable to the TP effect. In this case, the introduction of turbulence aids such, as baffles did not have a substantial effect in terms of improving the system performance. By contrast, the introduction of baffles into the module greatly enhanced the mass flux and TPC for a membrane with a high C value, where the main heat transfer resistance was determined by the fluid-side boundary layers. In this study, the mass transfer coefficient values ranged from 2.0 × 10

−7 to 1.0 × 10

−6 kg/m

2/s/Pa.

H.J. Hwang et al. investigated the effect of velocity on the mass transfer coefficient under different temperature conditions and reported an increase in the mass transfer coefficient with velocity, because of a decrease in temperature polarization owing to increases in the flow rate and Reynolds number, and a decrease in the boundary layer thickness. This influence was significant as the feed temperature increased. The experimental results indicated that at the feed temperature of 60 °C, as the velocity increased from 0.15 to 0.55 m/s, the mass transfer coefficient increased from 0.003 to 0.0042 L/m2/h/Pa. By contrast, at the feed temperature of 40 °C, it only increased from 0.0028 to 0.003 L/m2/h/Pa. In this study, the effect of velocity on flux was studied independently; it was found that likewise, the flux improved as the velocity increased, especially at higher feed temperatures. At low feed temperatures, the effect of velocity on mass transfer was less significant than that on the overall flux. Another important consideration in this study was the effect of velocity on the flux with respect to flow arrangements, such that for a 0.15 m × 0.4 m module, the flow was arranged along both the width and length. As a result, the flow along the width, that is 0.15 m, had a higher permeate flux under the same velocity conditions because the length or water path was shorter and, therefore, there was a lower temperature drop along the membrane in this configuration. Moreover, velocity was found to have an indirect effect on pressure and must not exceed the tested membrane LEP value to prevent permeation of the salt solution.

2.2.7. Heat Transfer Coefficient

The main concern of early MD developers was whether the system is economically competitive, followed by its technical feasibility. Therefore, the first step was to measure the heat transfer coefficients, where most of the values were obtained from laboratory experiments, and energy, membrane, and plant volume cost were interrelated. In those studies, heat transfer coefficients were expressed based on the feed temperature, rather than the velocity or channel geometry.

In 1985, an MD assessment was conducted by W.T. Hanbury et al. at a constant permeate temperature by increasing the feed temperature. The following empirical relationship between the heat transfer coefficient and the average temperature between the feed and permeate was formulated from the experimental results [

43]:

According to the aforementioned study, the heat transfer coefficient in MD was substantially lower than the equivalent values normally achieved in distillation plants, which indicated that the surface requirements for the process were likely substantial.

Moreover, it was suggested from the outset that for the MD process to become competitive for seawater desalination, one or both of the following conditions must be fulfilled:

In the initial membrane distillation studies, the heat transfer coefficients and Nusselt number were expressed based on the Raleigh number

, which is a product of the Grashof and Prandtl numbers, as follows:

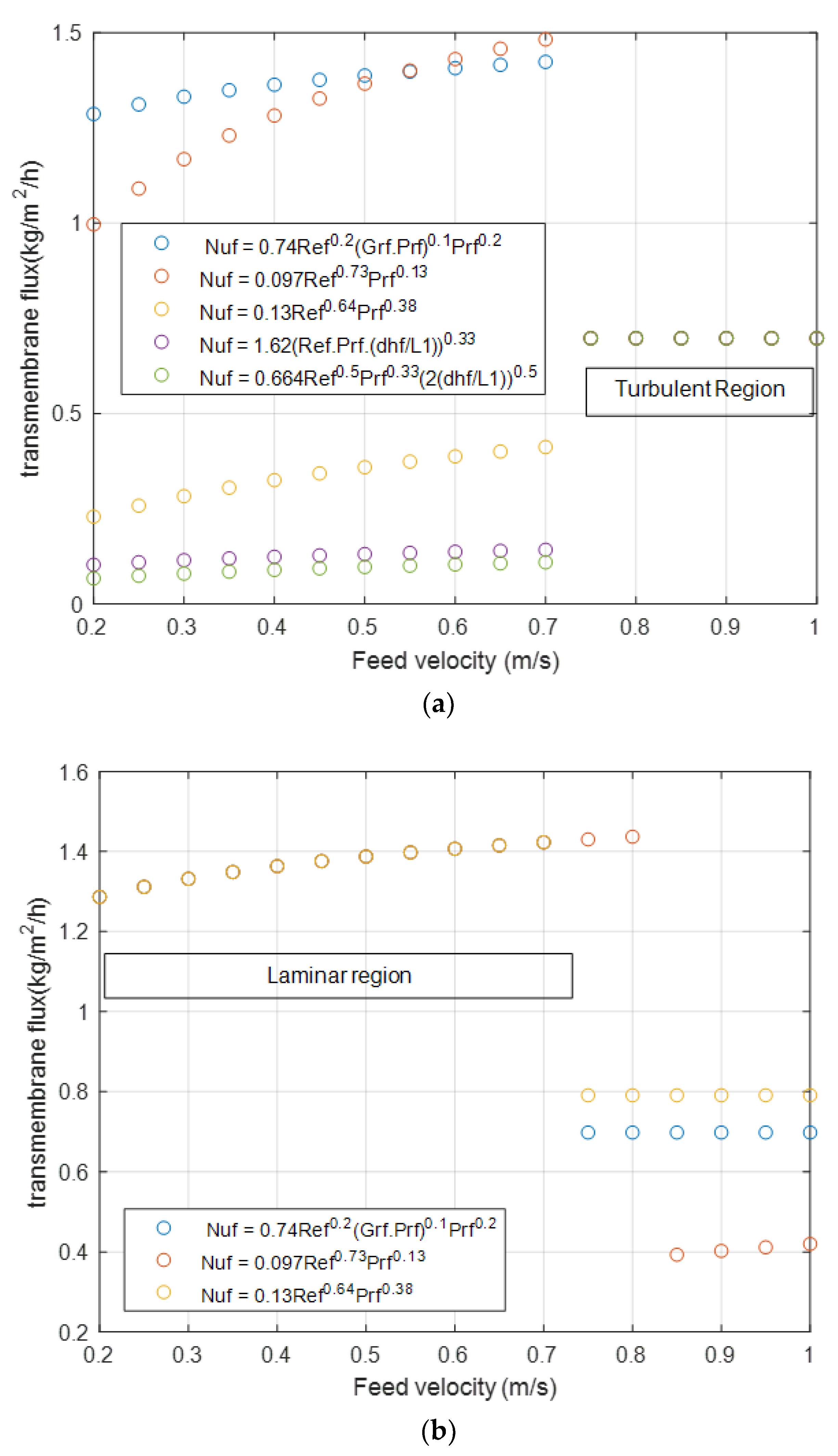

A variety of empirical correlations have been derived from the literature to evaluate the boundary layer heat transfer coefficient. The following correlations were selected from the proposed ones, as suggested in previous studies [

10,

12,

28,

29]:

For turbulent flows:

where

,

,

,

are the Reynolds number, Prandtl number, hydraulic diameter, and module length, respectively.