Microalgae-Enabled Wastewater Remediation and Nutrient Recovery through Membrane Photobioreactors: Recent Achievements and Future Perspective

Abstract

1. Introduction

2. Wastewater as a Source of Nutrients for Microalgae

3. Microalgae Membrane Photobioreactor

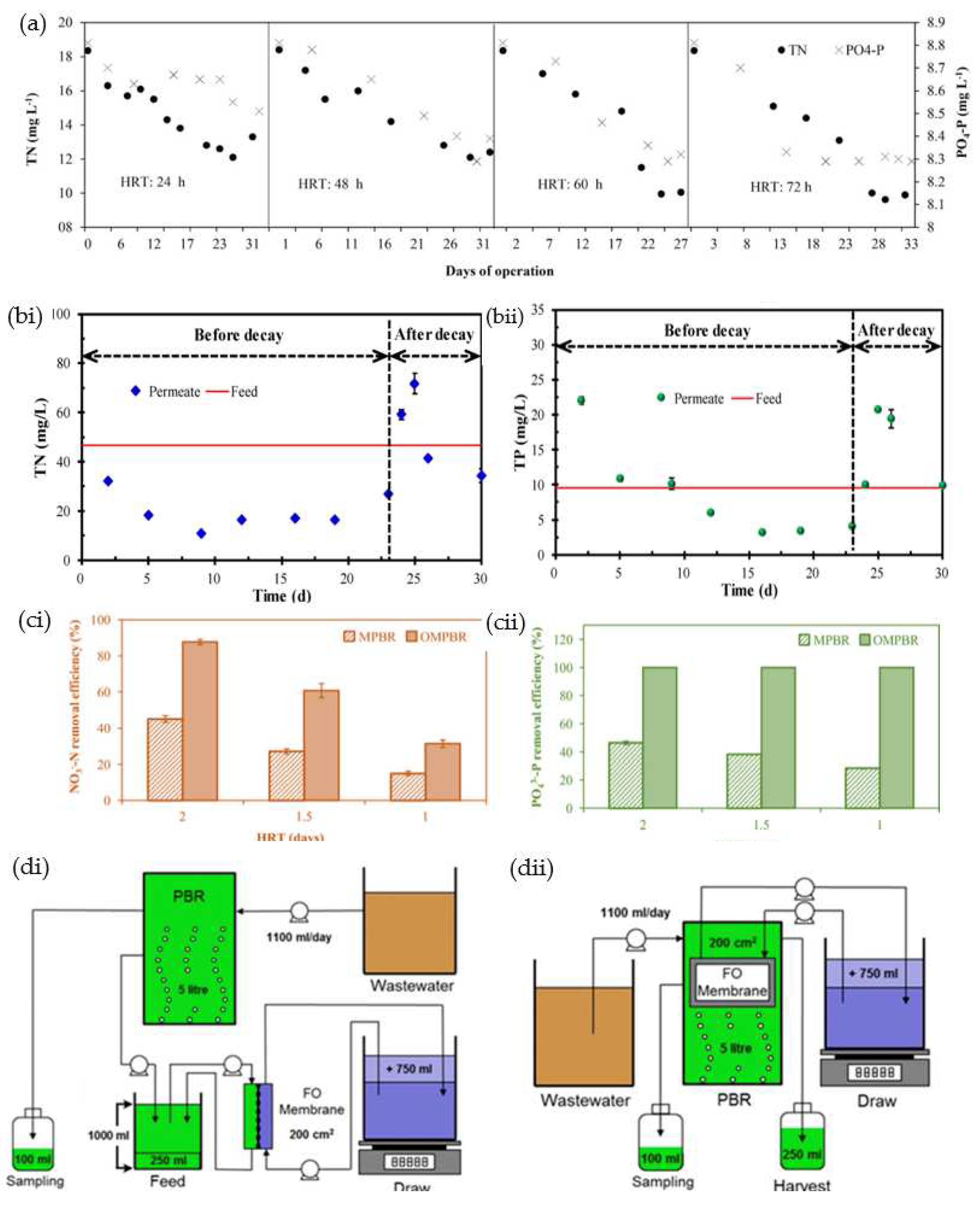

4. Performances of Microalgae-MPBR for Wastewater Treatment and Nutrient Recovery

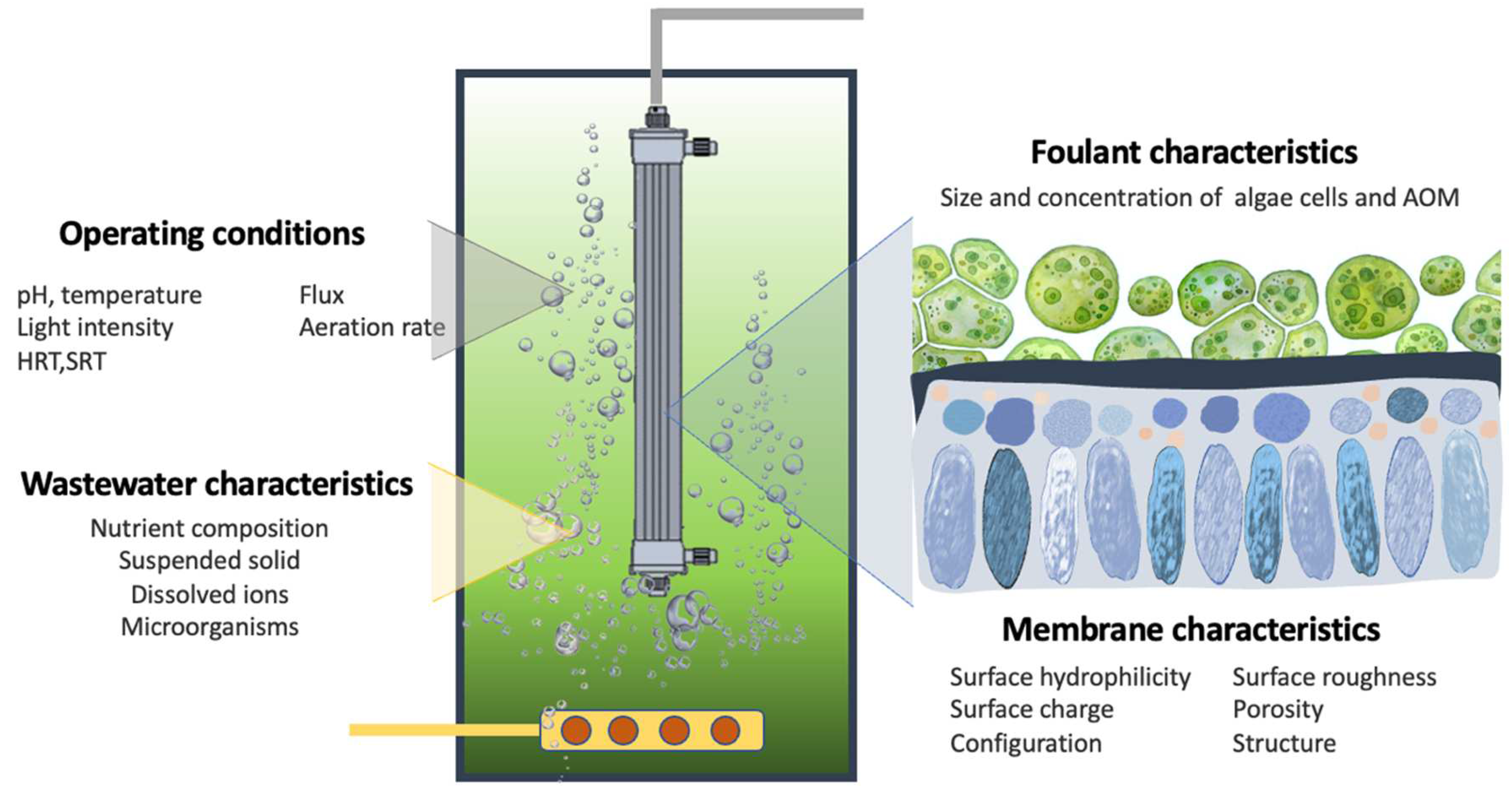

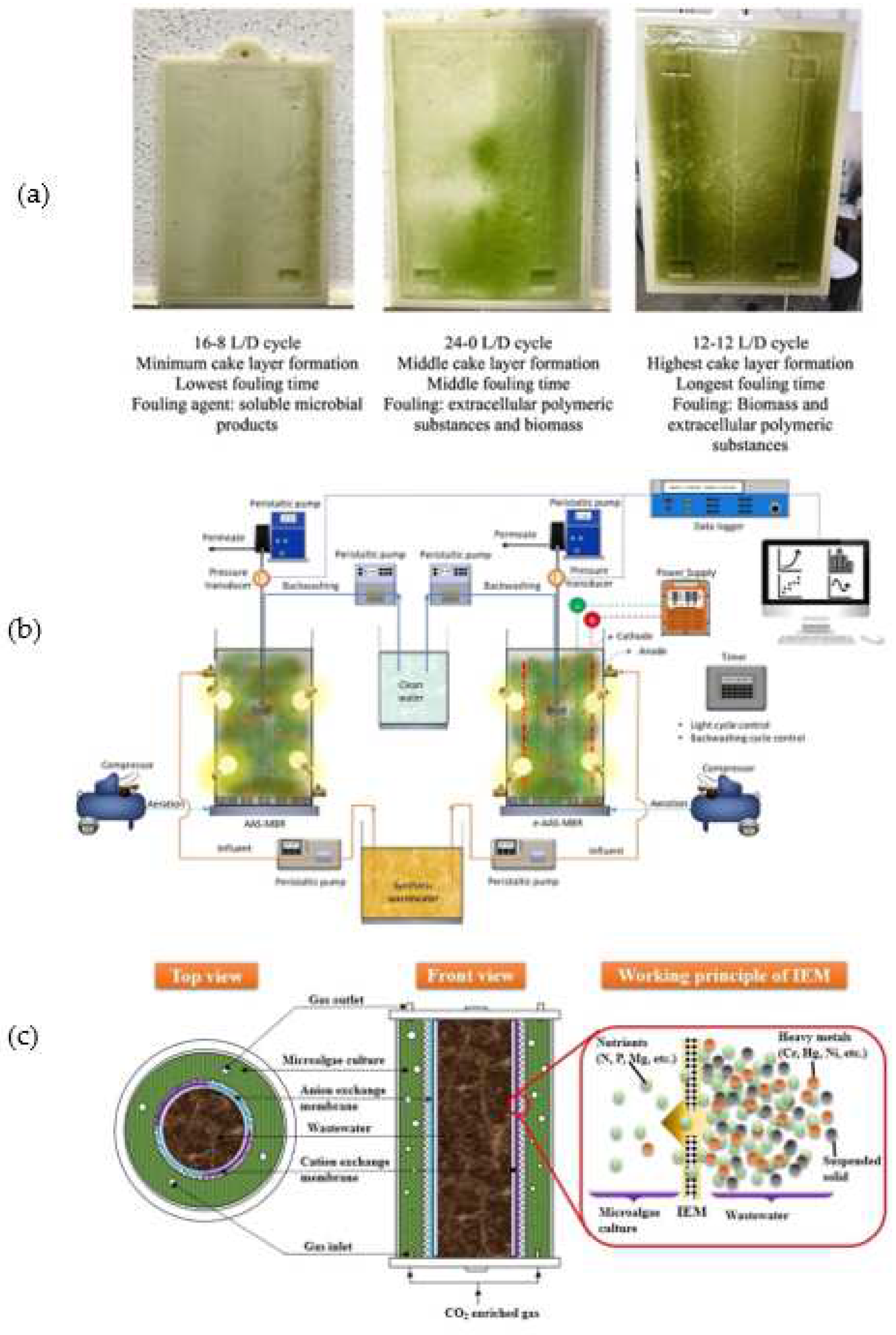

5. Membrane Fouling in Microalgae–Wastewater Medium

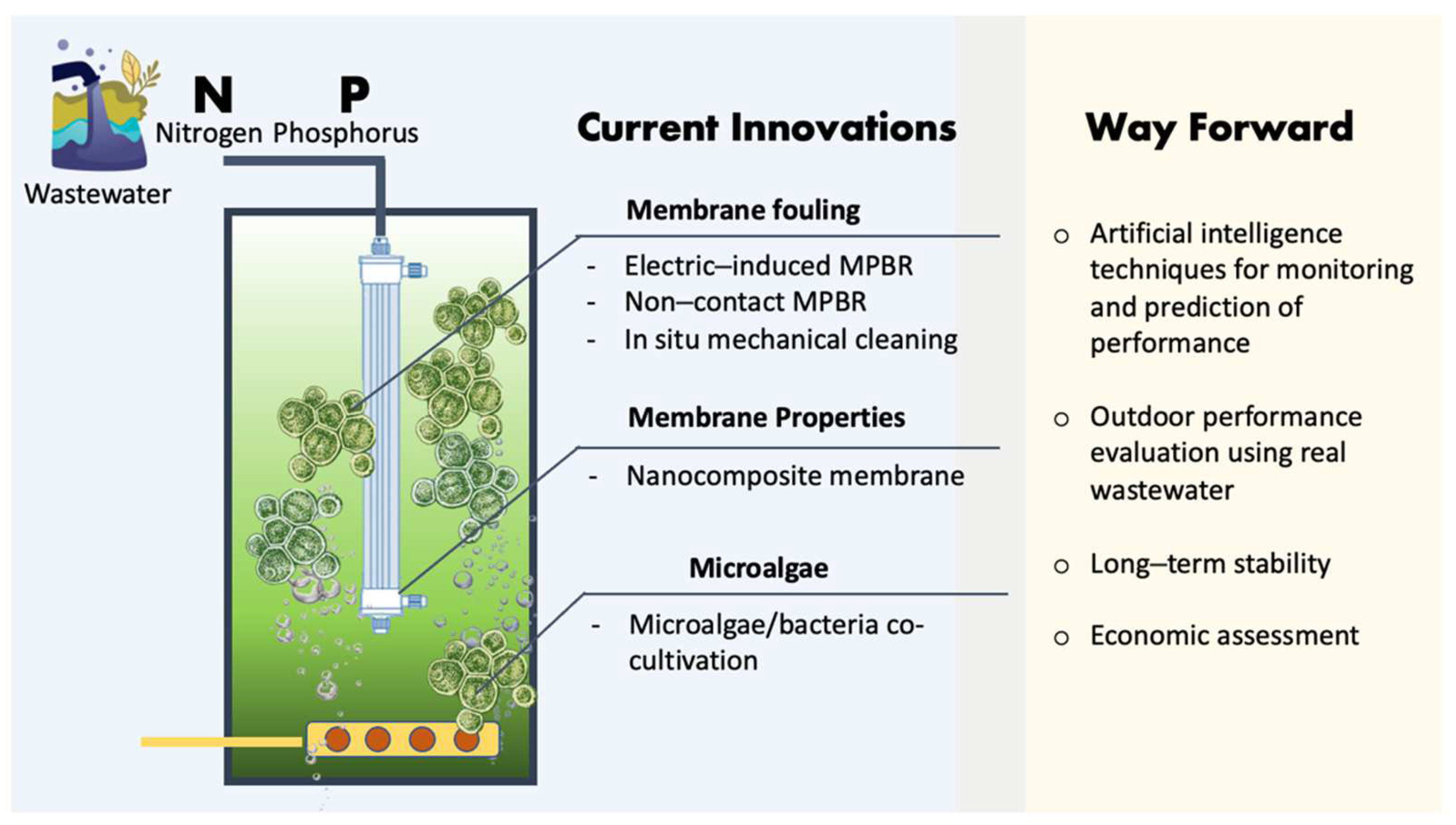

6. Innovations in Membranes and Reactor Design for MPBR

7. Challenges and Future Directions

8. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| AOM | Algal organic matters |

| COD | Chemical oxygen demand |

| EOM | External organic matters |

| EPS | Extracellular polymeric substances |

| FO | Forward osmosis |

| HRT | Hydraulic retention time |

| IOM | Internal organic matters |

| MPBR | Membrane photobioreactor |

| OMBR | Osmotic membrane bioreactor |

| OMPBR | Osmotic membrane photobioreactor |

| PBR | Photobioreactors |

| PVDF | Polyvinylidene fluoride |

| RO | Reverse osmosis |

| Ag/GO | Silver/graphene oxide |

| SRT | Solids retention time |

| TiO2 | Titanium dioxide |

| TMP | Transmembrane pressure |

| TEP | Transparent exopolymer particles |

References

- Boretti, A.; Rosa, L. Reassessing the projections of the World Water Development Report. NPJ Clean Water 2019, 2, 15. [Google Scholar] [CrossRef]

- Poustie, A.; Yang, Y.; Verburg, P.; Pagilla, K.; Hanigan, D. Reclaimed wastewater as a viable water source for agricultural irrigation: A review of food crop growth inhibition and promotion in the context of environmental change. Sci. Total Environ. 2020, 739, 139756. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, Y. Reverse osmosis concentrate: An essential link for closing loop of municipal wastewater reclamation towards urban sustainability. Chem. Eng. J. 2021, 421. [Google Scholar] [CrossRef]

- Wu, H.; Vaneeckhaute, C. Nutrient recovery from wastewater: A review on the integrated Physicochemical technologies of ammonia stripping, adsorption and struvite precipitation. Chem. Eng. J. 2021, 433, 133664. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y. Resource recovery from municipal wastewater: A critical paradigm shift in the post era of activated sludge. Bioresour. Technol. 2022, 363, 932. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, Y. Circular economy-driven ammonium recovery from municipal wastewater: State of the art, challenges and solutions forward. Bioresour. Technol. 2021, 334, 125231. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.; Mavukkandy, M.O.; Giwa, A.; Elektorowicz, M.; Katsou, E.; Khelifi, O.; Naddeo, V.; Hasan, S.W. Recent developments in hazardous pollutants removal from wastewater and water reuse within a circular economy. NPJ Clean Water 2022, 5, 12. [Google Scholar] [CrossRef]

- Imwene, K.O.; Ngumba, E.; Kairigo, P.K. Emerging technologies for enhanced removal of residual antibiotics from source-separated urine and wastewaters: A review. J. Environ. Manag. 2022, 322, 65. [Google Scholar] [CrossRef]

- Grandclément, C.; Seyssiecq, I.; Piram, A.; Wong-Wah-Chung, P.; Vanot, G.; Tiliacos, N.; Roche, N.; Doumenq, P. From the conventional biological wastewater treatment to hybrid processes, the evaluation of organic micropollutant removal: A review. Water Res. 2017, 111, 297–317. [Google Scholar] [CrossRef]

- Dhangar, K.; Kumar, M. Tricks and tracks in removal of emerging contaminants from the wastewater through hybrid treatment systems: A review. Sci. Total Environ. 2020, 738, 140320. [Google Scholar] [CrossRef]

- Khan, N.A.; Khan, A.H.; Tiwari, P.; Zubair, M.; Naushad, M. New insights into the integrated application of Fenton-based oxidation processes for the treatment of pharmaceutical wastewater. J. Water Process Eng. 2021, 44, 102440. [Google Scholar] [CrossRef]

- Patnaik, R.; Mallick, N. Microalgal Biodiesel Production: Realizing the Sustainability Index. Front. Bioeng. Biotechnol. 2021, 9, 777. [Google Scholar] [CrossRef] [PubMed]

- Mathimani, T.; Baldinelli, A.; Rajendran, K.; Prabakar, D.; Matheswaran, M.; van Leeuwen, R.P.; Pugazhendhi, A. Review on cultivation and thermochemical conversion of microalgae to fuels and chemicals: Process evaluation and knowledge gaps. J. Clean Prod. 2018, 208, 1053–1064. [Google Scholar] [CrossRef]

- Díaz, V.; Leyva-Díaz, J.C.; Almécija, M.C.; Poyatos, J.M.; Muñío, M.D.M.; Martín-Pascual, J. Microalgae bioreactor for nutrient removal and resource recovery from wastewater in the paradigm of circular economy. Bioresour. Technol. 2022, 363, 127968. [Google Scholar] [CrossRef] [PubMed]

- Bhatt, P.; Bhandari, G.; Bhatt, K.; Simsek, H. Microalgae-based removal of pollutants from wastewaters: Occurrence, toxicity and circular economy. Chemosphere 2022, 306, 135576. [Google Scholar] [CrossRef] [PubMed]

- González-Camejo, J.; Aparicio, S.; Pachés, M.; Borrás, L.; Seco, A. Comprehensive assessment of the microalgae-nitrifying bacteria competition in microalgae-based wastewater treatment systems: Relevant factors, evaluation methods and control strategies. Algal Res. 2022, 61, 563. [Google Scholar] [CrossRef]

- Honda, R.; Boonnorat, J.; Chiemchaisri, C.; Chiemchaisri, W.; Yamamoto, K. Carbon dioxide capture and nutrients removal utilizing treated sewage by concentrated microalgae cultivation in a membrane photobioreactor. Bioresour. Technol. 2012, 125, 59–64. [Google Scholar] [CrossRef] [PubMed]

- Yadav, G.; Shanmugam, S.; Sivaramakrishnan, R.; Kumar, D.; Mathimani, T.; Brindhadevi, K.; Pugazhendhi, A.; Rajendran, K. Mechanism and challenges behind algae as a wastewater treatment choice for bioenergy production and beyond. Fuel 2020, 285, 119093. [Google Scholar] [CrossRef]

- Blanco-Vieites, M.; Suárez-Montes, D.; Delgado, F.; Álvarez-Gil, M.; Battez, A.H.; Rodríguez, E. Removal of heavy metals and hydrocarbons by microalgae from wastewater in the steel industry. Algal Res. 2022, 64, 700. [Google Scholar] [CrossRef]

- Chin, J.Y.; Chng, L.M.; Leong, S.S.; Yeap, S.P.; Yasin, N.H.M.; Toh, P.Y. Removal of Synthetic Dye by Chlorella vulgaris Microalgae as Natural Adsorbent. Arab. J. Sci. Eng. 2020, 45, 7385–7395. [Google Scholar] [CrossRef]

- Solé, A.; Matamoros, V. Removal of endocrine disrupting compounds from wastewater by microalgae co-immobilized in alginate beads. Chemosphere 2016, 164, 516–523. [Google Scholar] [CrossRef] [PubMed]

- Mojiri, A.; Zhou, J.L.; Ratnaweera, H.; Rezania, S.; Mansoureh, V.N. Pharmaceuticals and personal care products in aquatic environments and their removal by algae-based systems. Chemosphere 2022, 288, 132580. [Google Scholar] [CrossRef] [PubMed]

- Gondi, R.; Kavitha, S.; Kannah, R.Y.; Karthikeyan, O.P.; Kumar, G.; Tyagi, V.K.; Banu, J.R. Algal-based system for removal of emerging pollutants from wastewater: A review. Bioresour. Technol. 2021, 344, 126245. [Google Scholar] [CrossRef]

- Brar, P.K.; Örmeci, B.; Dhir, A. Algae: A cohesive tool for biodiesel production alongwith wastewater treatment. Sustain. Chem. Pharm. 2022, 28, 100730. [Google Scholar] [CrossRef]

- Delanka-Pedige, H.M.K.; Cheng, X.; Munasinghe-Arachchige, S.P.; Bandara, G.L.C.L.; Zhang, Y.; Xu, P.; Schaub, T.; Nirmalakhandan, N. Conventional vs. algal wastewater technologies: Reclamation of microbially safe water for agricultural reuse. Algal Res. 2020, 51, 102022. [Google Scholar] [CrossRef]

- Cai, T.; Park, S.Y.; Li, Y. Nutrient recovery from wastewater streams by microalgae: Status and prospects. Renew. Sustain. Energy Rev. 2013, 19, 360–369. [Google Scholar] [CrossRef]

- Vo, H.N.P.; Ngo, H.H.; Guo, W.; Nguyen, T.M.H.; Liu, Y.; Liu, Y.; Nguyen, D.D.; Chang, S.W. A critical review on designs and applications of microalgae-based photobioreactors for pollutants treatment. Sci. Total Environ. 2019, 651, 1549–1568. [Google Scholar] [CrossRef]

- Goh, P.S.; Wong, K.C.; Ismail, A.F. Membrane technology: A versatile tool for saline wastewater treatment and resource recovery. Desalination 2022, 521, 115377. [Google Scholar] [CrossRef]

- Castro-Muñoz, R.; García-Depraect, O. Membrane-based harvesting processes for microalgae and their valuable-related molecules: A review. Membranes 2021, 11, 585. [Google Scholar] [CrossRef]

- Kumar, R.; Ghosh, A.K.; Pal, P. Synergy of biofuel production with waste remediation along with value-added co-products recovery through microalgae cultivation: A review of membrane-integrated green approach. Sci. Total Environ. 2020, 698, 134169. [Google Scholar] [CrossRef]

- Barros, A.I.; Gonçalves, A.L.; Simões, M.; Pires, J.C.M. Harvesting techniques applied to microalgae: A review. Renew. Sustain. Energy Rev. 2015, 41, 1489–1500. [Google Scholar] [CrossRef]

- Luo, Y.; Le-Clech, P.; Henderson, R.K. Simultaneous microalgae cultivation and wastewater treatment in submerged membrane photobioreactors: A review. Algal Res. 2017, 24, 425–437. [Google Scholar] [CrossRef]

- Ye, Y.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Varjani, S.; Ding, A.; Bui, X.T.; Nguyen, D.P. Bio-membrane based integrated systems for nitrogen recovery in wastewater treatment: Current applications and future perspectives. Chemosphere 2021, 265, 129076. [Google Scholar] [CrossRef]

- Kundu, S.; Pramanik, B.K.; Halder, P.; Patel, S.; Ramezani, M.; Khairul, M.A.; Marzbali, M.H.; Paz-Ferreiro, J.; Crosher, S.; Short, G.; et al. Source and central level recovery of nutrients from urine and wastewater: A state-of-art on nutrients mapping and potential technological solutions. J. Environ. Chem. Eng. 2022, 10, 107146. [Google Scholar] [CrossRef]

- Lam, K.L.; Zlatanović, L.; van der Hoek, J.P. Life cycle assessment of nutrient recycling from wastewater: A critical review. Water Res. 2020, 173, 115519. [Google Scholar] [CrossRef]

- Priya, E.; Kumar, S.; Verma, C.; Sarkar, S.; Maji, P.K. A comprehensive review on technological advances of adsorption for removing nitrate and phosphate from waste water. J. Water Process Eng. 2022, 49, 103159. [Google Scholar] [CrossRef]

- Bishayee, B.; Chatterjee, R.P.; Ruj, B.; Chakrabortty, S.; Nayak, J. Strategic management of nitrate pollution from contaminated water using viable adsorbents: An economic assessment-based review with possible policy suggestions. J. Environ. Manag. 2022, 303, 114081. [Google Scholar] [CrossRef] [PubMed]

- Gherghel, A.; Teodosiu, C.; de Gisi, S. A review on wastewater sludge valorisation and its challenges in the context of circular economy. J. Clean Prod. 2019, 228, 244–263. [Google Scholar] [CrossRef]

- Pathy, A.; Ray, J.; Paramasivan, B. Challenges and opportunities of nutrient recovery from human urine using biochar for fertilizer applications. J. Clean Prod. 2021, 304, 127019. [Google Scholar] [CrossRef]

- Orner, K.D.; Smith, S.J.; Breunig, H.M.; Scown, C.D.; Nelson, K.L. Fertilizer demand and potential supply through nutrient recovery from organic waste digestate in California. Water Res. 2021, 206, 117717. [Google Scholar] [CrossRef]

- Moges, M.E.; Heistad, A.; Heidorn, T. Nutrient recovery from anaerobically treated blackwater and improving its effluent quality through microalgae biomass production. Water 2020, 12, 592. [Google Scholar] [CrossRef]

- Mishra, S.; Singh, V.; Cheng, L.; Hussain, A.; Ormeci, B. Nitrogen removal from wastewater: A comprehensive review of biological nitrogen removal processes, critical operation parameters and bioreactor design. J. Environ. Chem. Eng. 2022, 10, 107387. [Google Scholar] [CrossRef]

- Liu, X.; Chen, G.; Tao, Y.; Wang, J. Application of effluent from WWTP in cultivation of four microalgae for nutrients removal and lipid production under the supply of CO2. Renew. Energy 2020, 149, 708–715. [Google Scholar] [CrossRef]

- Vazirzadeh, A.; Jafarifard, K.; Ajdari, A.; Chisti, Y. Removal of nitrate and phosphate from simulated agricultural runoff water by Chlorella vulgaris. Sci. Total Environ. 2022, 802, 149988. [Google Scholar] [CrossRef] [PubMed]

- Higgins, B.T.; Gennity, I.; Fitzgerald, P.S.; Ceballos, S.J.; Fiehn, O.; VanderGheynst, J.S. Algal–bacterial synergy in treatment of winery wastewater. NPJ Clean Water 2018, 1, 5. [Google Scholar] [CrossRef]

- Liu, X.Y.; Hong, Y.; Zhao, G.P.; Zhang, H.K.; Zhai, Q.Y.; Wang, Q. Microalgae-based swine wastewater treatment: Strain screening, conditions optimization, physiological activity and biomass potential. Sci. Total Environ. 2022, 807, 151008. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Hong, Y.; Zhai, Q.-Y.; Zhao, G.-P.; Zhang, H.-K.; Wang, Q. Performance and mechanism of Chlorella in swine wastewater treatment: Roles of nitrogen-phosphorus ratio adjustment and indigenous bacteria. Bioresour. Technol. 2022, 358, 127402. [Google Scholar] [CrossRef]

- Morillas-España, A.; Sánchez-Zurano, A.; Lafarga, T.; Morales-Amaral, M.D.M.; Gómez-Serrano, C.; Acién-Fernández, F.G.; González-López, C.V. Improvement of wastewater treatment capacity using the microalga Scenedesmus sp. and membrane bioreactors. Algal Res. 2021, 60, 102516. [Google Scholar] [CrossRef]

- Shayesteh, H.; Vadiveloo, A.; Bahri, P.A.; Moheimani, N.R. Can CO2 addition improve the tertiary treatment of anaerobically digested abattoir effluent (ADAE) by Scenedesmus sp. (Chlorophyta)? Algal Res. 2021, 58, 102379. [Google Scholar] [CrossRef]

- Sınmaz, G.K.; Erden, B.; Şengil, I.A. Cultivation of Chlorella vulgaris in alkaline condition for biodiesel feedstock after biological treatment of poultry slaughterhouse wastewater. Int. J. Environ. Sci. Technol. 2022, 2022, 374. [Google Scholar] [CrossRef]

- Serra-Maia, R.; Bernard, O.; Gonçalves, A.; Bensalem, S.; Lopes, F. Influence of temperature on Chlorella vulgaris growth and mortality rates in a photobioreactor. Algal Res. 2016, 18, 352–359. [Google Scholar] [CrossRef]

- Almutairi, A.W.; El-Sayed, A.E.K.B.; Reda, M.M. Evaluation of high salinity adaptation for lipid bio-accumulation in the green microalga Chlorella vulgaris. Saudi J. Biol Sci. 2021, 28, 3981–3988. [Google Scholar] [CrossRef] [PubMed]

- Kandasamy, S.; Narayanan, M.; He, Z.; Liu, G.; Ramakrishnan, M.; Thangavel, P.; Pugazhendhi, A.; Raja, R.; Carvalho, I.S. Current strategies and prospects in algae for remediation and biofuels: An overview. Biocatal. Agric. Biotechnol. 2021, 35, 102045. [Google Scholar] [CrossRef]

- Touliabah, H.E.S.; El-Sheekh, M.M.; Ismail, M.M.; El-Kassas, H. A Review of Microalgae-and Cyanobacteria-Based Biodegradation of Organic Pollutants. Molecules 2022, 27, 1141. [Google Scholar] [CrossRef]

- Bhardwaj, D.; Bharadvaja, N. Phycoremediation of effluents containing dyes and its prospects for value-added products: A review of opportunities. J. Water Process Eng. 2021, 41, 102080. [Google Scholar] [CrossRef]

- Abdelfattah, A.; Ali, S.S.; Ramadan, H.; El-Aswar, E.I.; Eltawab, R.; Ho, S.-H.; Elsamahy, T.; Li, S.; El-Sheekh, M.M.; Schagerl, M.; et al. Microalgae-based wastewater treatment: Mechanisms, challenges, recent advances, and future prospects. Environ. Sci. Ecotechnol. 2022, 13, 100205. [Google Scholar] [CrossRef]

- Sutherland, D.L.; Ralph, P.J. Microalgal bioremediation of emerging contaminants—Opportunities and challenges. Water Res. 2019, 164, 114921. [Google Scholar] [CrossRef]

- Mondal, S.; Bera, S.; Mishra, R.; Roy, S. Redefining the role of microalgae in industrial wastewater remediation. Energy Nexus 2022, 6, 100088. [Google Scholar] [CrossRef]

- Roostaei, J.; Zhang, Y. Spatially Explicit Life Cycle Assessment: Opportunities and challenges of wastewater-based algal biofuels in the United States. Algal Res. 2017, 24, 395–402. [Google Scholar] [CrossRef]

- Fernández, F.G.A.; Gómez-Serrano, C.; Fernández-Sevilla, J.M. Recovery of Nutrients From Wastewaters Using Microalgae. Front. Sustain. Food Syst. 2018, 2, 59. [Google Scholar] [CrossRef]

- Maizatul, A.Y.; Mohamed, R.M.S.R.; Al-Gheethi, A.A.; Hashim, M.K.A. An overview of the utilisation of microalgae biomass derived from nutrient recycling of wet market wastewater and slaughterhouse wastewater. Int. Aquat. Res. 2017, 9, 177–193. [Google Scholar] [CrossRef]

- Ferreira, A.; Marques, P.; Ribeiro, B.; Assemany, P.; de Mendonça, H.V.; Barata, A.; Oliveira, A.C.; Reis, A.; Pinheiro, H.M.; Gouveia, L. Combining biotechnology with circular bioeconomy: From poultry, swine, cattle, brewery, dairy and urban wastewaters to biohydrogen. Environ. Res. 2018, 164, 32–38. [Google Scholar] [CrossRef] [PubMed]

- Keuter, V.; Deck, S.; Giesenkamp, H.; Gonglach, D.; Katayama, V.T.; Liesegang, S.; Petersen, F.; Schwindenhammer, S.; Steinmetz, H.; Ulbrich, A. Significance and vision of nutrient recovery for sustainable city food systems in germany by 2050. Sustainability 2021, 13, 772. [Google Scholar] [CrossRef]

- Gonçalves, A.L.; Pires, J.C.M.; Simões, M. A review on the use of microalgal consortia for wastewater treatment. Algal Res. 2017, 24, 403–415. [Google Scholar] [CrossRef]

- Monfet, E.; Unc, A. Defining wastewaters used for cultivation of algae. Algal Res. 2017, 24, 520–526. [Google Scholar] [CrossRef]

- Schmidt, J.J.; Gagnon, G.A.; Jamieson, R.C. Microalgae growth and phosphorus uptake in wastewater under simulated cold region conditions. Ecol. Eng. 2016, 95, 588–593. [Google Scholar] [CrossRef]

- Xu, M.; Bernards, M.; Hu, Z. Algae-facilitated chemical phosphorus removal during high-density Chlorella emersonii cultivation in a membrane bioreactor. Bioresour. Technol. 2014, 153, 383–387. [Google Scholar] [CrossRef]

- Ge, S.; Champagne, P. Cultivation of the Marine Macroalgae Chaetomorpha linum in Municipal Wastewater for Nutrient Recovery and Biomass Production. Environ. Sci. Technol. 2017, 51, 3558–3566. [Google Scholar] [CrossRef]

- Nhat, P.V.H.; Ngo, H.H.; Guo, W.S.; Chang, S.W.; Nguyen, D.D.; Nguyen, P.D.; Bui, X.T.; Zhang, X.B.; Guo, J.B. Can algae-based technologies be an affordable green process for biofuel production and wastewater remediation? Bioresour. Technol. 2018, 256, 491–501. [Google Scholar] [CrossRef]

- Luo, Y.; Le-Clech, P.; Henderson, R.K. Assessment of membrane photobioreactor (MPBR) performance parameters and operating conditions. Water Res. 2018, 138, 169–180. [Google Scholar] [CrossRef]

- Song, Y.; Wang, L.; Qiang, X.; Gu, W.; Ma, Z.; Wang, G. The promising way to treat wastewater by microalgae: Approaches, mechanisms, applications and challenges. J. Water Process Eng. 2022, 49, 103012. [Google Scholar] [CrossRef]

- Markou, G.; Depraetere, O.; Vandamme, D.; Muylaert, K. Cultivation of Chlorella vulgaris and Arthrospira platensis with recovered phosphorus from wastewater by means of zeolite sorption. Int. J. Mol. Sci. 2015, 16, 4250–4264. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, V.; Kessler, M.; Fradinho, J.; Oehmen, A.; Reis, M. Achieving nitrogen and phosphorus removal at low C/N ratios without aeration through a novel phototrophic process. Sci. Total Environ. 2021, 793, 148501. [Google Scholar] [CrossRef] [PubMed]

- Vu, M.T.; Vu, H.P.; Nguyen, L.N.; Semblante, G.U.; Johir, M.A.H.; Nghiem, L.D. A hybrid anaerobic and microalgal membrane reactor for energy and microalgal biomass production from wastewater. Environ. Technol. Innov. 2020, 19, 100834. [Google Scholar] [CrossRef]

- Ding, Y.; Guo, Z.; Mei, J.; Liang, Z.; Li, Z.; Hou, X. Investigation into the novel microalgae membrane bioreactor with internal circulating fluidized bed for marine aquaculture wastewater treatment. Membranes 2020, 10, 353. [Google Scholar] [CrossRef]

- Gonçalves, A.L.; Rodrigues, C.M.; Pires, J.C.M.; Simões, M. The effect of increasing CO2 concentrations on its capture, biomass production and wastewater bioremediation by microalgae and cyanobacteria. Algal Res. 2016, 14, 127–136. [Google Scholar] [CrossRef]

- Arumugam, M.; Agarwal, A.; Arya, M.C.; Ahmed, Z. Influence of nitrogen sources on biomass productivity of microalgae Scenedesmus bijugatus. Bioresour. Technol. 2013, 131, 246–249. [Google Scholar] [CrossRef]

- Wu, L.F.; Chen, P.C.; Lee, C.M. The effects of nitrogen sources and temperature on cell growth and lipid accumulation of microalgae. Int. Biodeterior. Biodegrad. 2013, 85, 506–510. [Google Scholar] [CrossRef]

- Markou, G.; Vandamme, D.; Muylaert, K. Microalgal and cyanobacterial cultivation: The supply of nutrients. Water Res. 2014, 65, 186–202. [Google Scholar] [CrossRef]

- Singh, V.; Mishra, V. Evaluation of the effects of input variables on the growth of two microalgae classes during wastewater treatment. Water Res. 2022, 213, 118165. [Google Scholar] [CrossRef]

- Lu, W.; Wang, Z.; Wang, X.; Yuan, Z. Cultivation of Chlorella sp. using raw diary wastewater for nutrient removal and biodiesel production: Characteristics comparison of indoor bench-scale and outdoor pilot-scale cultures. Bioresour. Technol. 2015, 192, 382–388. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimian, A.; Kariminia, H.R.; Vosoughi, M. Lipid production in mixotrophic cultivation of Chlorella vulgaris in a mixture of primary and secondary municipal wastewater. Renew. Energy 2014, 71, 502–508. [Google Scholar] [CrossRef]

- Kumar, B.R.; Mathimani, T.; Sudhakar, M.P.; Rajendran, K.; Nizami, A.S.; Brindhadevi, K.; Pugazhendhi, A. A state of the art review on the cultivation of algae for energy and other valuable products: Application, challenges, and opportunities. Renew. Sustain. Energy Rev. 2021, 138, 110649. [Google Scholar] [CrossRef]

- Torres-Franco, A.F.; Figueredo, C.C.; Barros, L.; Gücker, B.; Boëchat, I.G.; Muñoz, R.; Mota, C.R. Assessment of a deep, LED-enhanced high-rate algal pond for the treatment of digestate. Algal Res. 2021, 59, 102444. [Google Scholar] [CrossRef]

- Jerney, J.; Spilling, K. Large Scale Cultivation of Microalgae: Open and Closed Systems. In Methods in Molecular Biology; Humana Press Inc.: Totowa, NJ, USA, 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Acién, F.G.; Gómez-Serrano, C.; Morales-Amaral, M.M.; Fernández-Sevilla, J.M.; Molina-Grima, E. Wastewater treatment using microalgae: How realistic a contribution might it be to significant urban wastewater treatment? Appl. Microbiol. Biotechnol. 2016, 100, 9013–9022. [Google Scholar] [CrossRef]

- González-Camejo, J.; Barat, R.; Ruano, M.V.; Seco, A.; Ferrer, J. Outdoor flat-panel membrane photobioreactor to treat the effluent of an anaerobic membrane bioreactor. Influence of operating, design, and environmental conditions. Water Sci. Technol. 2018, 78, 195–206. [Google Scholar] [CrossRef]

- Bilad, M.; Discart, V.; Vandamme, D.; Foubert, I.; Muylaert, K.; Vankelecom, I.F. Coupled cultivation and pre-harvesting of microalgae in a membrane photobioreactor (MPBR). Bioresour. Technol. 2014, 155, 410–417. [Google Scholar] [CrossRef]

- Gao, F.; Yang, Z.-H.; Li, C.; Wang, Y.-J.; Jin, W.-H.; Deng, Y.-B. Concentrated microalgae cultivation in treated sewage by membrane photobioreactor operated in batch flow mode. Bioresour. Technol. 2014, 167, 441–446. [Google Scholar] [CrossRef]

- Mo, W.; Soh, L.; Werber, J.R.; Elimelech, M.; Zimmerman, J.B. Application of membrane dewatering for algal biofuel. Algal Res. 2015, 11, 1–12. [Google Scholar] [CrossRef]

- Cao, T.N.-D.; Bui, X.-T.; Le, L.-T.; Dang, B.-T.; Tran, D.P.-H.; Vo, T.-K.; Tran, H.-T.; Nguyen, T.-B.; Mukhtar, H.; Pan, S.-Y.; et al. An Overview of Deploying Membrane Bioreactors in Saline Wastewater Treatment from Perspectives of Microbial and Treatment Performance. Bioresour. Technol. 2022, 127831. [Google Scholar] [CrossRef]

- Gargouch, N.; Touchard, R.; Marec, H.; Mouget, J.L.; Pruvost, J.; Massé, A. Submerged membrane photobioreactor for the cultivation of Haslea ostrearia and the continuous extraction of extracellular marennine. Bioresour. Technol. 2022, 350, 126922. [Google Scholar] [CrossRef] [PubMed]

- Yazdanabad, S.K.; Samimi, A.; Shokrollahzadeh, S.; Kalhori, D.M.; Moazami, N.; González, M.J.I.; Sobczuk, T.M.; Grima, E.M. Microalgae biomass dewatering by forward osmosis: Review and critical challenges. Algal Res. 2021, 56, 102323. [Google Scholar] [CrossRef]

- Jafarinejad, S. Forward osmosis membrane technology for nutrient removal/recovery from wastewater: Recent advances, proposed designs, and future directions. Chemosphere 2021, 263, 128116. [Google Scholar] [CrossRef] [PubMed]

- Chia, W.Y.; Chia, S.R.; Khoo, K.S.; Chew, K.W.; Show, P.L. Sustainable membrane technology for resource recovery from wastewater: Forward osmosis and pressure retarded osmosis. J. Water Process Eng. 2021, 39, 101758. [Google Scholar] [CrossRef]

- Wang, Z.; Lee, Y.Y.; Scherr, D.; Senger, R.S.; Li, Y.; He, Z. Mitigating nutrient accumulation with microalgal growth towards enhanced nutrient removal and biomass production in an osmotic photobioreactor. Water Res. 2020, 182, 116038. [Google Scholar] [CrossRef]

- Lee, D.-J.; Hsieh, M.-H. Forward osmosis membrane processes for wastewater bioremediation: Research needs. Bioresour. Technol. 2019, 290, 121795. [Google Scholar] [CrossRef]

- Yang, Y.L.; Wu, Y.; Lu, Y.X.; Cai, Y.; He, Z.; Yang, X.L.; Song, H.L. A comprehensive review of nutrient-energy-water-solute recovery by hybrid osmotic membrane bioreactors. Bioresour. Technol. 2021, 320, 124300. [Google Scholar] [CrossRef]

- Viet, N.D.; Cho, J.; Yoon, Y.; Jang, A. Enhancing the removal efficiency of osmotic membrane bioreactors: A comprehensive review of influencing parameters and hybrid configurations. Chemosphere 2019, 236, 124363. [Google Scholar] [CrossRef]

- Hosseinzadeh, A.; Zhou, J.L.; Navidpour, A.H.; Altaee, A. Progress in osmotic membrane bioreactors research: Contaminant removal, microbial community and bioenergy production in wastewater. Bioresour. Technol. 2021, 330, 124998. [Google Scholar] [CrossRef]

- Sutherland, D.L.; Park, J.; Ralph, P.J.; Craggs, R.J. Improved microalgal productivity and nutrient removal through operating wastewater high rate algal ponds in series. Algal Res. 2020, 47, 101850. [Google Scholar] [CrossRef]

- Silveira, C.F.; de Assis, L.R.; Oliveira, A.P.d.; Calijuri, M.L. Valorization of swine wastewater in a circular economy approach: Effects of hydraulic retention time on microalgae cultivation. Sci. Total Environ. 2021, 789, 147861. [Google Scholar] [CrossRef]

- Xu, M.; Li, P.; Tang, T.; Hu, Z. Roles of SRT and HRT of an algal membrane bioreactor system with a tanks-in-series configuration for secondary wastewater effluent polishing. Ecol. Eng. 2015, 85, 257–264. [Google Scholar] [CrossRef]

- Solmaz, A.; Işık, M. Optimization of membrane photobioreactor; the effect of hydraulic retention time on biomass production and nutrient removal by mixed microalgae culture. Biomass Bioenergy 2020, 142, 105809. [Google Scholar] [CrossRef]

- Zou, H.; Rutta, N.C.; Chen, S.; Zhang, M.; Lin, H.; Liao, B. Membrane Photobioreactor Applied for Municipal Wastewater Treatment at a High Solids Retention Time: Effects of Microalgae Decay on Treatment Performance and Biomass Properties. Membranes 2022, 12, 564. [Google Scholar] [CrossRef]

- Viruela, A.; Robles, Á.; Durán, F.; Ruano, M.V.; Barat, R.; Ferrer, J.; Seco, A. Performance of an outdoor membrane photobioreactor for resource recovery from anaerobically treated sewage. J. Clean Prod. 2018, 178, 665–674. [Google Scholar] [CrossRef]

- González-Camejo, J.; Jiménez-Benítez, A.; Ruano, M.; Robles, A.; Barat, R.; Ferrer, J. Optimising an outdoor membrane photobioreactor for tertiary sewage treatment. J. Environ. Manag. 2019, 245, 76–85. [Google Scholar] [CrossRef]

- González-Camejo, J.; Aparicio, S.; Jiménez-Benítez, A.; Pachés, M.; Ruano, M.; Borrás, L.; Barat, R.; Seco, A. Improving membrane photobioreactor performance by reducing light path: Operating conditions and key performance indicators. Water Res. 2020, 172, 115518. [Google Scholar] [CrossRef]

- Praveen, P.; Loh, K.C. Nitrogen and phosphorus removal from tertiary wastewater in an osmotic membrane photobioreactor. Bioresour. Technol. 2016, 206, 180–187. [Google Scholar] [CrossRef]

- Praveen, P.; Heng, J.Y.P.; Loh, K.C. Tertiary wastewater treatment in membrane photobioreactor using microalgae: Comparison of forward osmosis & microfiltration. Bioresour. Technol. 2016, 222, 448–457. [Google Scholar] [CrossRef]

- Larronde-Larretche, M.; Jin, X. The Influence of Forward Osmosis Module Configuration on Nutrients Removal and Microalgae Harvesting in Osmotic Photobioreactor. Membranes 2022, 12, 892. [Google Scholar] [CrossRef]

- Low, S.L.; Ong, S.L.; Ng, H.Y. Characterization of membrane fouling in submerged ceramic membrane photobioreactors fed with effluent from membrane bioreactors. Chem. Eng. J. 2016, 290, 91–102. [Google Scholar] [CrossRef]

- Novoa, A.F.; Vrouwenvelder, J.S.; Fortunato, L. Membrane Fouling in Algal Separation Processes: A Review of Influencing Factors and Mechanisms. Front. Chem. Eng. 2021, 3, 422. [Google Scholar] [CrossRef]

- Li, J.Y.; Ni, Z.Y.; Zhou, Z.Y.; Hu, Y.X.; Xu, X.H.; Cheng, L.H. Membrane fouling of forward osmosis in dewatering of soluble algal products: Comparison of TFC and CTA membranes. J. Membr. Sci. 2018, 552, 213–221. [Google Scholar] [CrossRef]

- Mkpuma, V.O.; Moheimani, N.R.; Ennaceri, H. Microalgal dewatering with focus on filtration and antifouling strategies: A review. Algal Res. 2022, 61, 102588. [Google Scholar] [CrossRef]

- Malaguti, M.; Novoa, A.F.; Ricceri, F.; Giagnorio, M.; Vrouwenvelder, J.S.; Tiraferri, A.; Fortunato, L. Control strategies against algal fouling in membrane processes applied for microalgae biomass harvesting. J. Water Process Eng. 2022, 47, 102787. [Google Scholar] [CrossRef]

- Lee, H.; Park, C.; Kim, H.; Park, H.; Hong, S. Role of transparent exopolymer particles (TEP) in initial bacterial deposition and bio fi lm formation on reverse osmosis (RO) membrane. J. Membr. Sci. 2015, 494, 25–31. [Google Scholar] [CrossRef]

- Wang, S.; Tena, F.O.; Dey, R.; Thomsen, C.; Steinweg, C.; Kraemer, D.; Grossman, A.D.; Belete, Y.Z.; Bernstein, R.; Gross, A.; et al. Submerged hollow-fiber-ultrafiltration for harvesting microalgae used for bioremediation of a secondary wastewater. Sep. Purif. Technol. 2022, 289, 120744. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, Q. Algal fouling of microfiltration and ultrafiltration Membranes and control strategies: A review. Sep. Purif. Technol. 2018, 203, 193–208. [Google Scholar] [CrossRef]

- Bagheri, M.; Mirbagheri, S.A. Critical review of fouling mitigation strategies in membrane bioreactors treating water and wastewater. Bioresour. Technol. 2018, 258, 318–334. [Google Scholar] [CrossRef]

- Luo, Y.; Le-Clech, P.; Henderson, R.K. Assessing the performance of membrane photobioreactors (MPBR) for polishing effluents containing different types of nitrogen. Algal Res. 2020, 50, 102013. [Google Scholar] [CrossRef]

- Zhang, M.; Leung, K.T.; Lin, H.; Liao, B. Evaluation of membrane fouling in a microalgal-bacterial membrane photobioreactor: Effects of SRT. Sci. Total Environ. 2022, 839, 156414. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, A.; Kumar, P.S.; Varjani, S.; Jeevanantham, S.; Yaashikaa, P.R.; Thamarai, P.; Abirami, B.; George, C.S. A review on algal-bacterial symbiotic system for effective treatment of wastewater. Chemosphere 2021, 271, 129540. [Google Scholar] [CrossRef] [PubMed]

- You, K.; Ge, F.; Wu, X.; Song, K.; Yang, Z.; Zhang, Q.; Liu, Y.; Ruan, R.; Zheng, H. Nutrients recovery from piggery wastewater and starch wastewater via microalgae-bacteria consortia. Algal Res. 2021, 60, 102551. [Google Scholar] [CrossRef]

- Amini, E.; Babaei, A.; Mehrnia, M.R.; Shayegan, J.; Safdari, M.S. Municipal wastewater treatment by semi-continuous and membrane algal-bacterial photo-bioreactors. J. Water Process Eng. 2020, 36, 101274. [Google Scholar] [CrossRef]

- Radmehr, S.; Rissanen, T.; Kallioinen-Mänttäri, M.; Mänttäri, M. Reducing mechanical aeration in membrane bioreactors by inoculation of algal cells into activated sludge biomass. J. Water Process Eng. 2022, 49, 103047. [Google Scholar] [CrossRef]

- Sun, L.; Ma, J.; Li, L.; Tian, Y.; Zhang, Z.; Liao, H.; Li, J.; Tang, W.; He, D. Exploring the essential factors of performance improvement in sludge membrane bioreactor technology coupled with symbiotic algae. Water Res. 2020, 181, 115843. [Google Scholar] [CrossRef]

- Chaleshtori, S.N.; Shamskilani, M.; Babaei, A.; Behrang, M. Municipal wastewater treatment and fouling in microalgal-activated sludge membrane bioreactor: Cultivation in raw and treated wastewater. J. Water Process Eng. 2022, 49, 103069. [Google Scholar] [CrossRef]

- Shekhar, M.; Shriwastav, A.; Bose, P.; Hameed, S. Microfiltration of algae: Impact of algal species, backwashing mode and duration of filtration cycle. Algal Res. 2017, 23, 104–112. [Google Scholar] [CrossRef]

- Azizi, S.; Hashemi, A.; Shariati, F.P.; Tayebati, H.; Keramati, A.; Bonakdarpour, B.; Mohammad, M.M. Effect of different light-dark cycles on the membrane fouling, EPS and SMP production in a novel reciprocal membrane photobioreactor (RMPBR) by C. vulgaris species. J. Water Process Eng. 2021, 43, 102256. [Google Scholar] [CrossRef]

- Hosseini, M.K.; Shariati, F.P.; Bonakdarpour, B.; Heydarinasab, A. The effect of mechanical cleaning technology (MCT) on membrane fouling in a novel hybrid membrane photobioreactor (HMPBR) containing Arthrospira platensis (Spirulina). J. Appl. Phycol. 2020, 32, 83–91. [Google Scholar] [CrossRef]

- Chong, W.C.; Mohammad, A.W.; Mahmoudi, E.; Chung, Y.T.; Kamarudin, K.F.; Takriff, M.S. Nanohybrid membrane in algal-membrane photoreactor: Microalgae cultivation and wastewater polishing. Chin. J. Chem. Eng. 2019, 27, 2799–2806. [Google Scholar] [CrossRef]

- Yue, Y.; Li, X.; Sigg, L.; Suter, M.J.F.; Pillai, S.; Behra, R.; Schirmer, K. Interaction of silver nanoparticles with algae and fish cells: A side by side comparison. J. Nanobiotechnol. 2017, 15, 16. [Google Scholar] [CrossRef]

- Ksiązyk, M.; Asztemborska, M.; Stęborowski, R.; Bystrzejewska-Piotrowska, G. Toxic effect of silver and platinum nanoparticles toward the freshwater microalga Pseudokirchneriella subcapitata. Bull. Environ. Contam Toxicol. 2015, 94, 554–558. [Google Scholar] [CrossRef]

- Nezammahalleh, H.; Ghanati, F.; Adams, T.A.; Nosrati, M.; Shojaosadati, S.A. Effect of moderate static electric field on the growth and metabolism of Chlorella vulgaris. Bioresour. Technol. 2016, 218, 700–711. [Google Scholar] [CrossRef]

- Gordalina, M.; Pinheiro, H.M.; Mateus, M.; da Fonseca, M.M.R.; Cesário, M.T. Macroalgae as protein sources—A review on protein bioactivity, extraction, purification and characterization. Appl. Sci. 2021, 11, 7969. [Google Scholar] [CrossRef]

- Zhang, J.; Satti, A.; Chen, X.; Xiao, K.; Sun, J.; Yan, X.; Liang, P.; Zhang, X.; Huang, X. Low-voltage electric field applied into MBR for fouling suppression: Performance and mechanisms. Chem. Eng. J. 2015, 273, 223–230. [Google Scholar] [CrossRef]

- Amini, M.; Mohamedelhassan, E.; Liao, B. The Biological Performance of a Novel Electrokinetic-Assisted Membrane Photobioreactor (EK-MPBR) for Wastewater Treatment. Membranes 2022, 12, 587. [Google Scholar] [CrossRef]

- Corpuz, M.V.A.; Borea, L.; Senatore, V.; Castrogiovanni, F.; Buonerba, A.; Oliva, G.; Ballesteros, F.; Zarra, T.; Belgiorno, V.; Choo, K.H.; et al. Wastewater treatment and fouling control in an electro algae-activated sludge membrane bioreactor. Sci. Total Environ. 2021, 786, 147475. [Google Scholar] [CrossRef]

- Chang, H.X.; Fu, Q.; Huang, Y.; Xia, A.; Liao, Q.; Zhu, X.; Zheng, Y.P.; Sun, C.H. An annular photobioreactor with ion-exchange-membrane for non-touch microalgae cultivation with wastewater. Bioresour. Technol. 2016, 219, 668–676. [Google Scholar] [CrossRef]

- Yaqub, M.; Lee, W. Modeling nutrient removal by membrane bioreactor at a sewage treatment plant using machine learning models. J. Water Process Eng. 2022, 46, 102521. [Google Scholar] [CrossRef]

- Safeer, S.; Pandey, R.P.; Rehman, B.; Safdar, T.; Ahmad, I.; Hasan, S.W.; Ullah, A. A review of artificial intelligence in water purification and wastewater treatment: Recent advancements. J. Water Process Eng. 2022, 49, 102974. [Google Scholar] [CrossRef]

- Arita, C.E.Q.; Peebles, C.; Bradley, T.H. Scalability of combining microalgae-based biofuels with wastewater facilities: A review. Algal Res. 2015, 9, 160–169. [Google Scholar] [CrossRef]

- Zhao, Q.; Yu, Q.; Wang, X.; Li, X.; Li, Y.; Li, L.; Wang, X.; Yu, D.; Ge, B. Efficient treatment of phenol wastewater by co-culture of Chlorella vulgaris and Candida tropicalis. Algal Res. 2022, 65, 102738. [Google Scholar] [CrossRef]

- Marchão, L.; Fernandes, J.R.; Sampaio, A.; Peres, J.A.; Tavares, P.B.; Lucas, M.S. Microalgae and immobilized TiO2/UV-A LEDs as a sustainable alternative for winery wastewater treatment. Water Res. 2021, 203, 117464. [Google Scholar] [CrossRef]

- Subramaniam, M.N.; Goh, P.S.; Kanakaraju, D.; Lim, J.W.; Lau, W.J.; Ismail, A.F. Photocatalytic membranes: A new perspective for persistent organic pollutants removal. Environ. Sci. Pollut. Res. 2022, 29, 12506–12530. [Google Scholar] [CrossRef]

- van den Hende, S.; Beelen, V.; Bore, G.; Boon, N.; Vervaeren, H. Up-scaling aquaculture wastewater treatment by microalgal bacterial flocs: From lab reactors to an outdoor raceway pond. Bioresour. Technol. 2014, 159, 342–354. [Google Scholar] [CrossRef]

- Gao, F.; Cui, W.; Xu, J.P.; Li, C.; Jin, W.H.; Yang, H.L. Lipid accumulation properties of Chlorella vulgaris and Scenedesmus obliquus in membrane photobioreactor (MPBR) fed with secondary effluent from municipal wastewater treatment plant. Renew. Energy 2019, 136, 671–676. [Google Scholar] [CrossRef]

| System | Membrane/Configuration | Microalgae | Wastewater | N Removal Efficiency/Rate | P Removal/Efficiency/Rate | Ref |

|---|---|---|---|---|---|---|

| MPBR | PVDF hollow fiber | Chaetophora sp., Navicula sp. | Synthetic secondary water | 30.25% | 40.58% | [104] |

| MPBR | Flat plate | C. vulgaris | Synthetic municipal wastewater | 76.7% | 66.2% | [105] |

| Pilot outdoor MPBR | Hollow fiber | C. vulgaris, Scenedesmus sp. | Anaerobic MBR effluent | 7.68 mg/L.d | 1.17 mg/L.d | [106] |

| Pilot outdoor MPBR | Hollow fiber | Scenedesmus sp. | Anaerobic MBR effluent | 29.7 mg/L.d | 3.8 mg/L.d | [108] |

| OMPBR | HTI TFC hollow fiber | C. vulgaris | Synthetic tertiary wastewater | 93% | 89% | [109] |

| OMPBR | Flat sheet TFC | C. vulgaris | Synthetic wastewater | 100% | 98.7% | [111] |

| MPBR | Ag/GO PVDF membrane | C. vulgaris | Synthetic municipal wastewater | 92.3% | 66.1% | [132] |

| MPBR | Cellulose ester hollow fiber | C. vulgaris-activated sludge | Raw treatment plant wastewater | 94.36% | 88.37 | [128] |

| MPBR | PVDF flat sheet | C. vulgaris-activated sludge | Synthetic domestic wastewater | 92.7% | 92.4% | [126] |

| Electrokinetic-assisted MPBR | PVDF flat sheet | C. vulgaris | Synthetic municipal wastewater | 41.81% | 97.98% | [138] |

| Electrokinetic-assisted MPBR | PVDF hollow fiber | C. vulgaris-activated sludge | Synthetic municipal wastewater | >98% * | >98% * | [139] |

| Annular two-chamber MPBR | Ion exchange membranes | C. vulgaris | Dairy manure wastewater | 8.95 mg/L.d | 2.31 mg/L.d | [140] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goh, P.S.; Ahmad, N.A.; Lim, J.W.; Liang, Y.Y.; Kang, H.S.; Ismail, A.F.; Arthanareeswaran, G. Microalgae-Enabled Wastewater Remediation and Nutrient Recovery through Membrane Photobioreactors: Recent Achievements and Future Perspective. Membranes 2022, 12, 1094. https://doi.org/10.3390/membranes12111094

Goh PS, Ahmad NA, Lim JW, Liang YY, Kang HS, Ismail AF, Arthanareeswaran G. Microalgae-Enabled Wastewater Remediation and Nutrient Recovery through Membrane Photobioreactors: Recent Achievements and Future Perspective. Membranes. 2022; 12(11):1094. https://doi.org/10.3390/membranes12111094

Chicago/Turabian StyleGoh, Pei Sean, Nor Akalili Ahmad, Jun Wei Lim, Yong Yeow Liang, Hooi Siang Kang, Ahmad Fauzi Ismail, and Gangasalam Arthanareeswaran. 2022. "Microalgae-Enabled Wastewater Remediation and Nutrient Recovery through Membrane Photobioreactors: Recent Achievements and Future Perspective" Membranes 12, no. 11: 1094. https://doi.org/10.3390/membranes12111094

APA StyleGoh, P. S., Ahmad, N. A., Lim, J. W., Liang, Y. Y., Kang, H. S., Ismail, A. F., & Arthanareeswaran, G. (2022). Microalgae-Enabled Wastewater Remediation and Nutrient Recovery through Membrane Photobioreactors: Recent Achievements and Future Perspective. Membranes, 12(11), 1094. https://doi.org/10.3390/membranes12111094