Study on the Actuation Properties of Polyurethane Fiber Membranes Filled with PEG-SWNTs Dielectric Microcapsules

Abstract

1. Introduction

2. Experimental Techniques

2.1. Materials

2.2. Devices

2.3. Synthesis of PEG-SWNTs Dielectric Microcapsules

2.3.1. Formulation Design

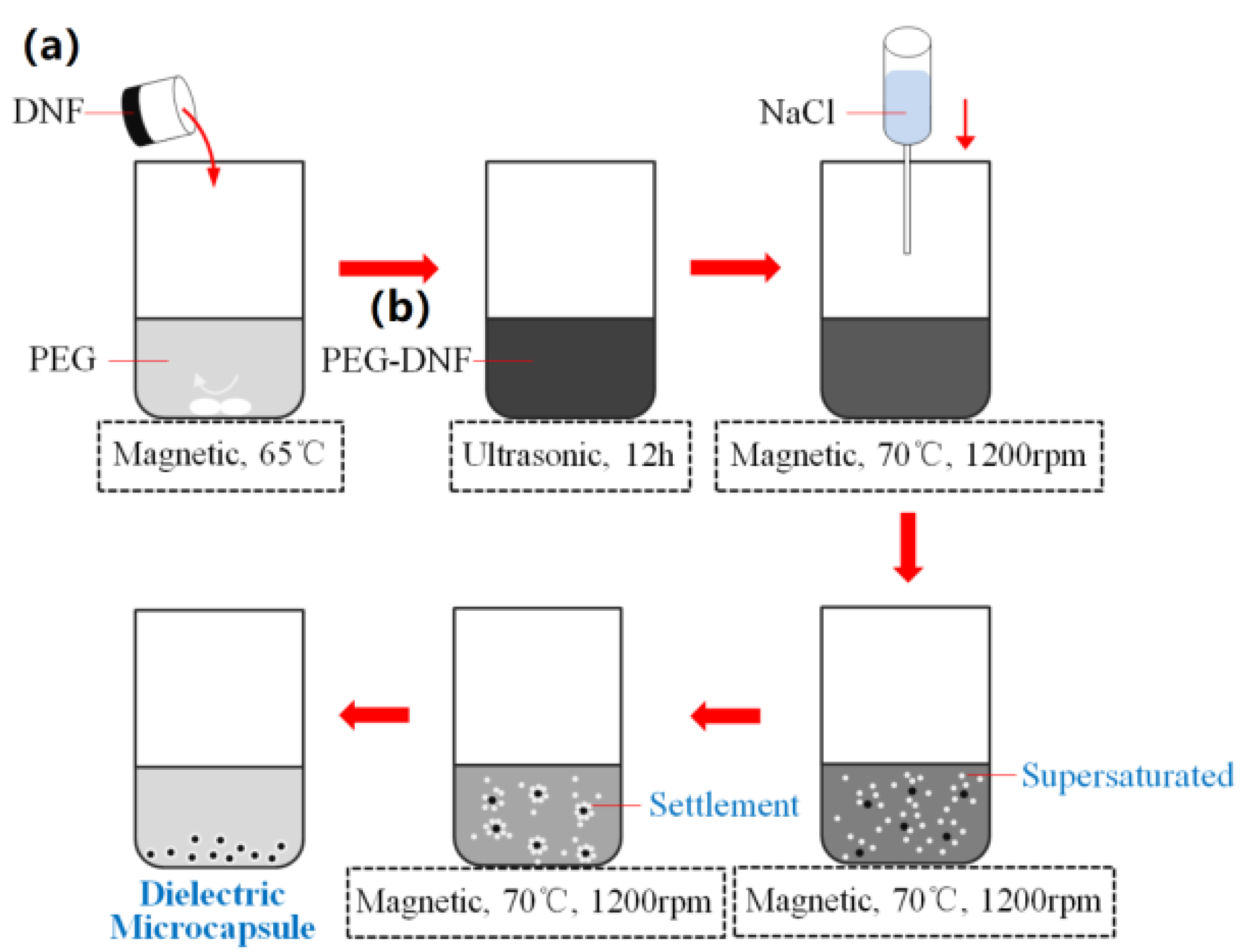

2.3.2. Design Route

2.3.3. Specific Steps

2.4. Preparation of Polyurethane Composite Fiber Membrane Filled with Dielectric Microcapsules

2.4.1. Synthesis of PUDE

2.4.2. Coaxial Spinning Technology and Formula Setting of the Membrane

2.4.3. Specific Steps

2.5. Characterization and Testing

2.5.1. Characterization of Dielectric Microcapsules

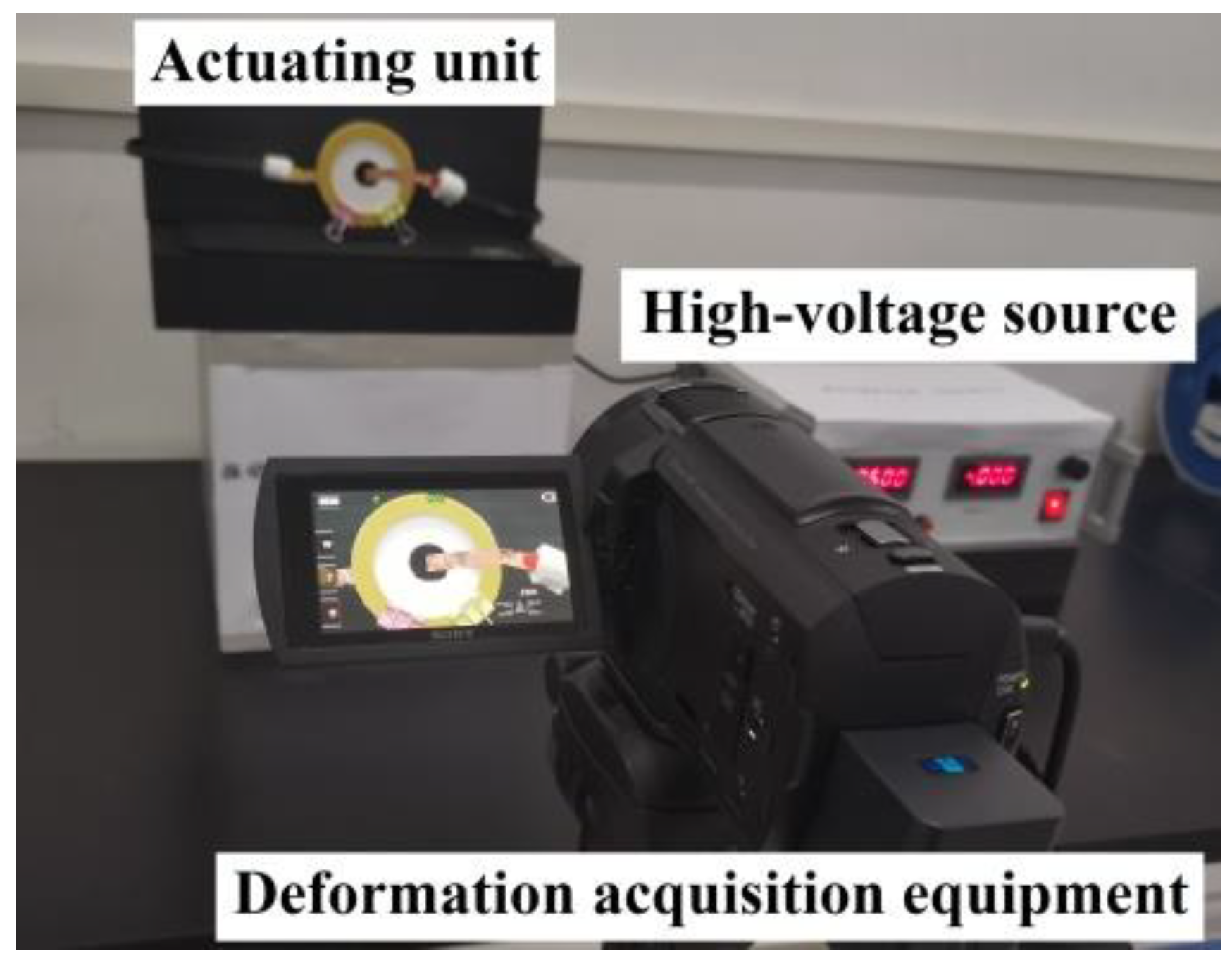

2.5.2. Characterization and Testing of Polyurethane Composite Fiber Membrane

3. Results and Discussion

3.1. Dielectric Microcapsule

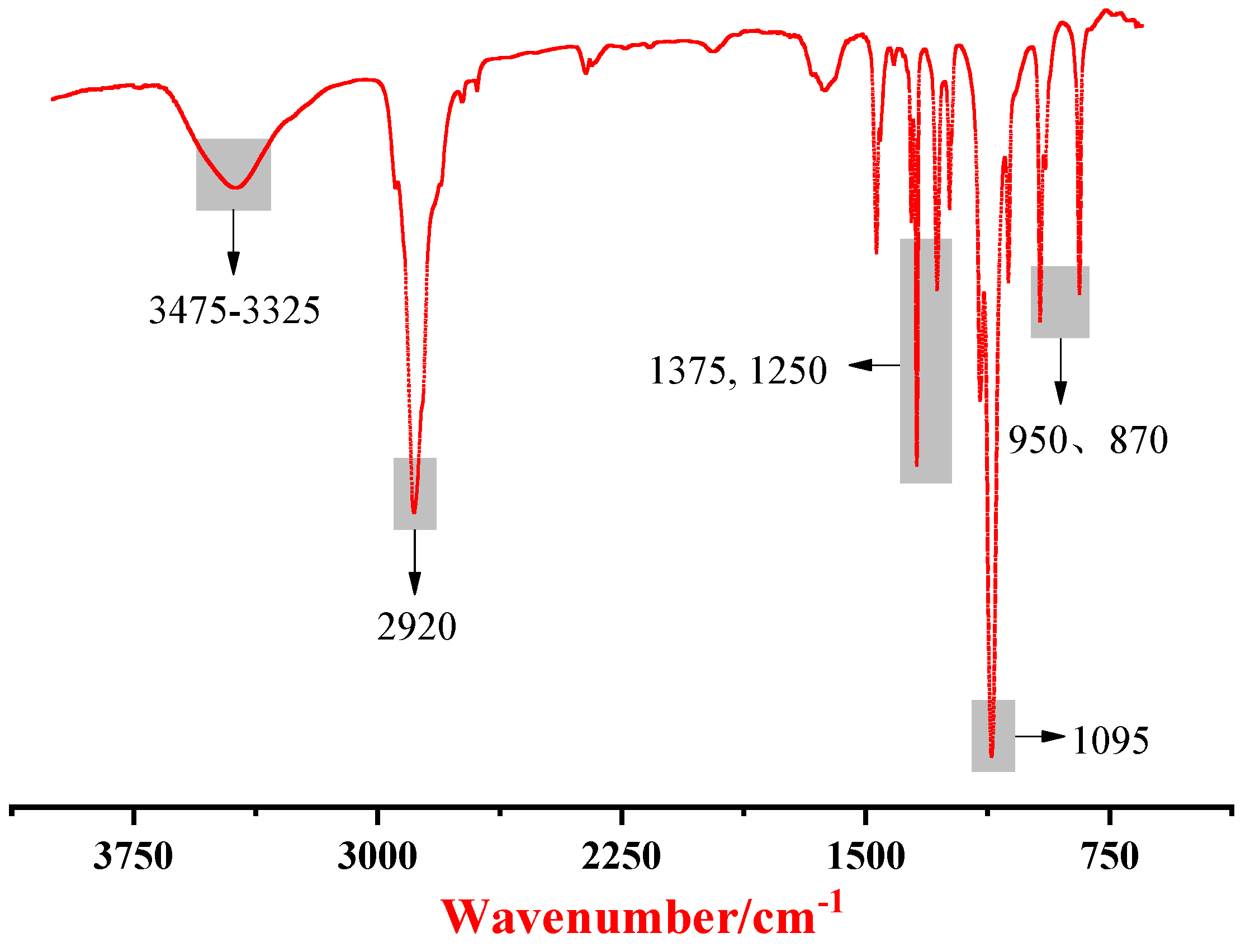

3.1.1. Infrared Spectrum Analysis

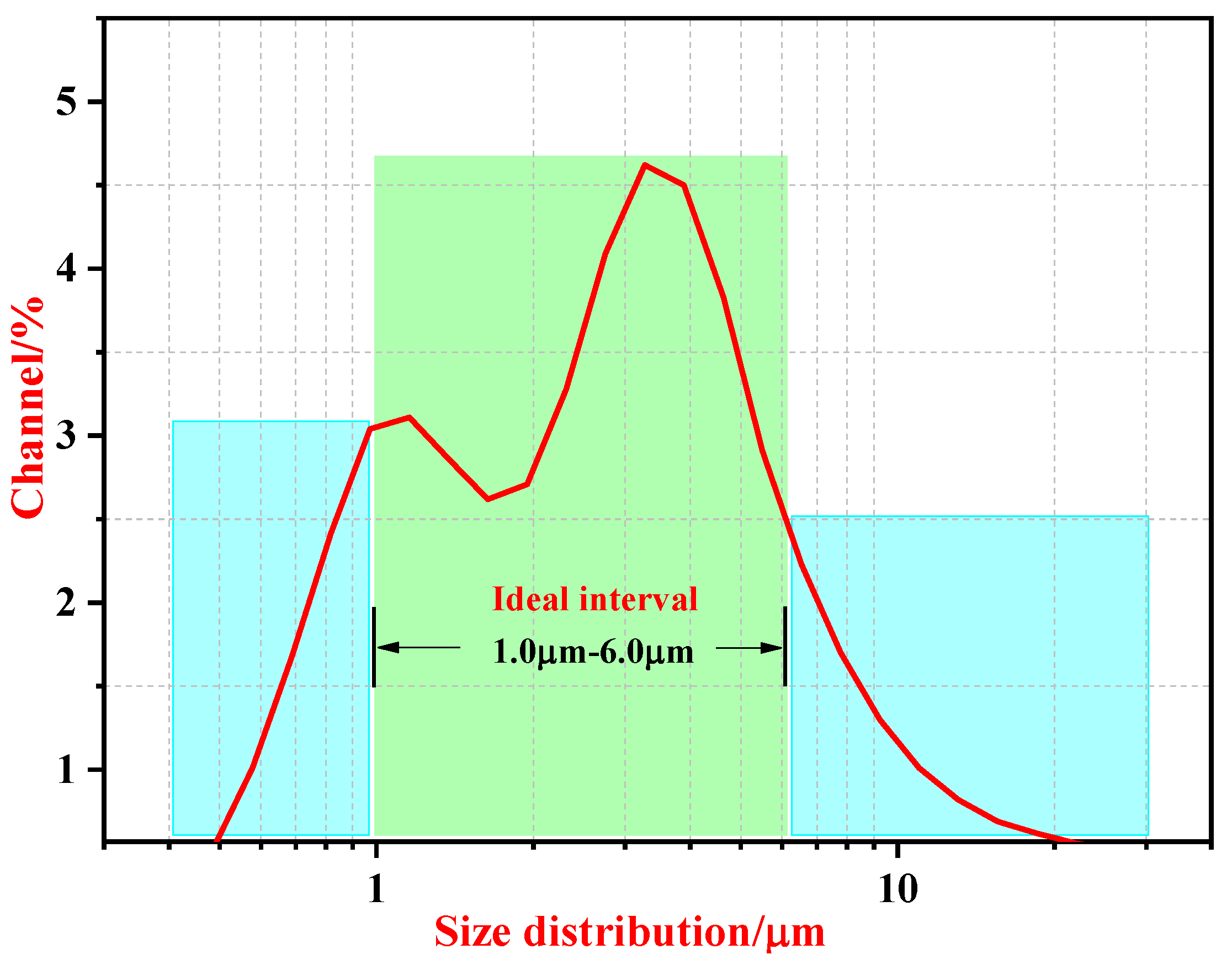

3.1.2. Particle Size Distribution

3.2. Polyurethane Composite Fiber Membranes

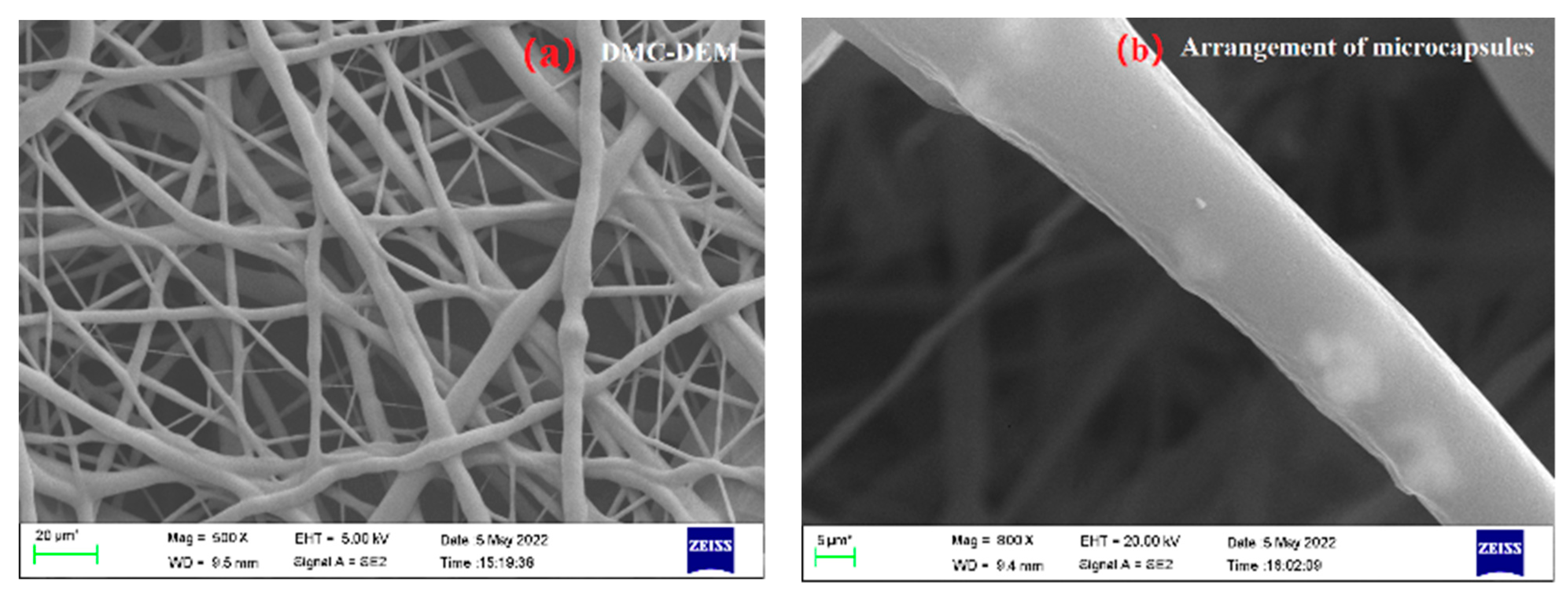

3.2.1. Fiber Morphology and Arrangement Trend of Dielectric Microcapsules in Fibers

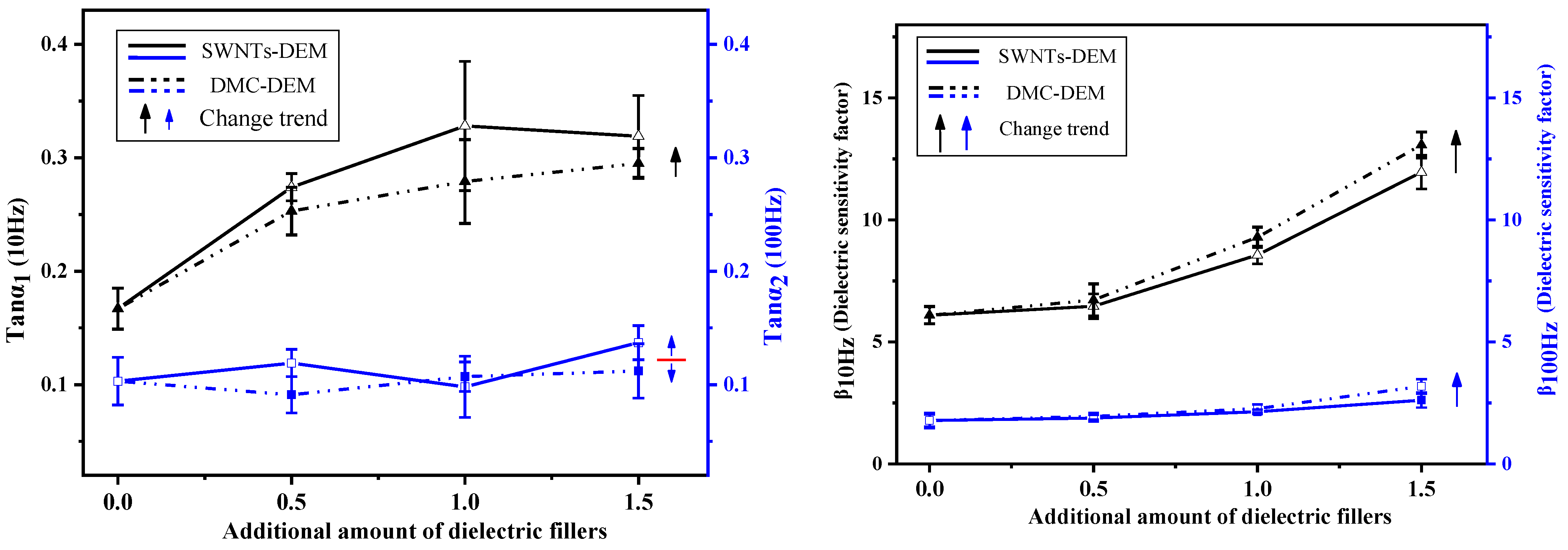

3.2.2. Dielectric Properties

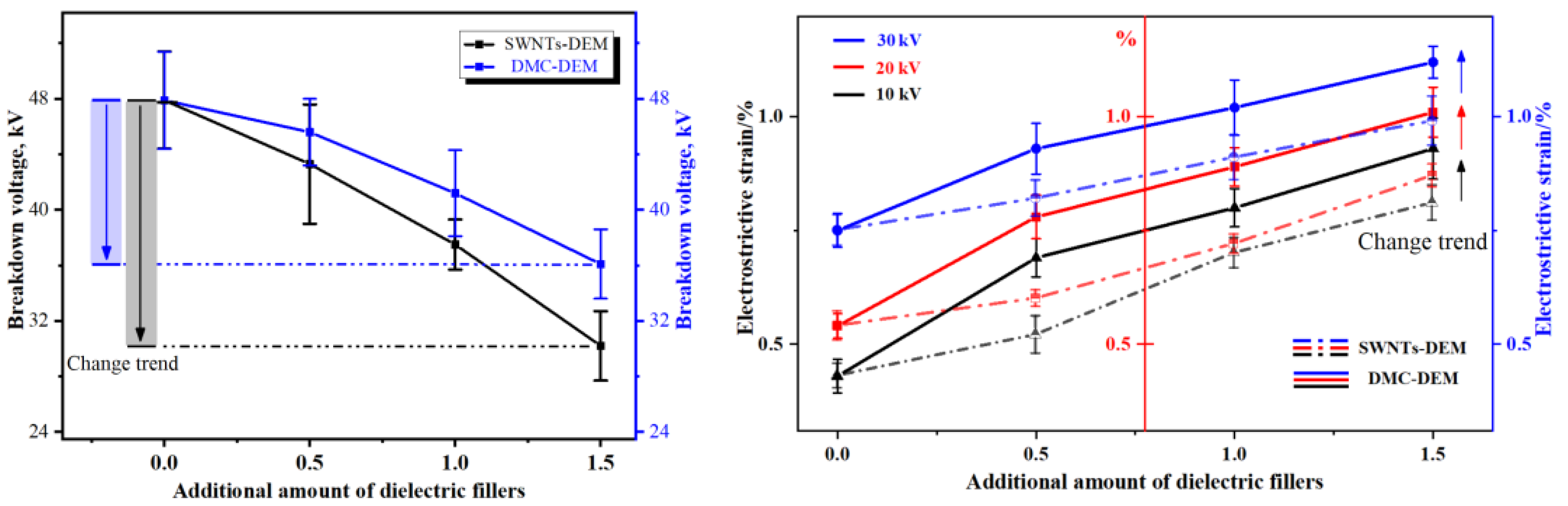

3.2.3. Electrical Deformation Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tugui, C.; Stiubianu, G.T.; Serbulea, M.S.; Cazacu, M. Silicone dielectric elastomers optimized by crosslinking pattern—A simple approach to high-performance actuators. Polym. Chem. 2020, 11, 3271–3284. [Google Scholar] [CrossRef]

- Banet, P.; Zeggai, N.; Chavanne, J.; Nguyen, G.T.M.; Chikh, L.; Plesse, C.; Almanza, M.; Martinez, T.; Civet, Y.; Perriard, Y.; et al. Evaluation of dielectric elastomers to develop materials suitable for actuation. Soft Matter 2021, 17, 10786–10805. [Google Scholar] [CrossRef] [PubMed]

- Gupta, U.; Qin, L.; Wang, Y.Z.; Godaba, H.; Zhu, J. Soft robots based on dielectric elastomer actuators: A review. Smart Mater. Struct. 2019, 28, 103002. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Kofod, G. High-Strain Actuator Materials Based on Dielectric Elastomers. Adv. Mater. 2000, 12, 1223–1225. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Soleimani, M.; Menon, C. Preliminary investigation of a balloon-shape actuator based on electroactive elastomers. Smart Mater. Struct. 2010, 19, 047001. [Google Scholar] [CrossRef]

- Terwagne, D.; Brojan, M.; Reis, P.M. Smart Morphable Surfaces for Aerodynamic Drag Control. Adv. Mater. 2014, 26, 6608–6611. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Shea, H.; Floreano, D. Soft biomimetic fish robot madme of dielectric elastomer actuators. Soft Robot. 2018, 5, 466–474. [Google Scholar] [CrossRef]

- Franke, M.; Ehrenhofer, A.; Lahiri, S.; Henke, E.-F.M.; Wallmersperger, T.; Richter, A. Dielectric Elastomer Actuator Driven Soft Robotic Structures with Bioinspired Skeletal and Muscular Reinforcement. Front. Robot. AI 2020, 7, 510757. [Google Scholar] [CrossRef]

- Imamura, H.; Kadooka, K.; Taya, M. A variable stiffness dielectric elastomer actuator based on electrostatic chucking. Soft Matter 2017, 13, 3440–3448. [Google Scholar] [CrossRef]

- Mathew, G.; Rhee, J.M.; Nah, C.; Leo, D.J. Effects of silicone rubber on properties of dielectric acrylate elastomer actuator. Polym. Eng. Sci. 2006, 46, 1455–1460. [Google Scholar] [CrossRef]

- Bigges, J.; Danielmeier, K.; Hitzbleck, J.; Krause, J.; Kridl, T.; Nowak, S.; Orselli, E.; Quan, X.; Schapeler, D.; Sutherland, W.; et al. Electroactive polymers: Developments of and perspectives for dielectric elastomers. Angew. Chem. Int. Ed. 2013, 52, 9409–9421. [Google Scholar] [CrossRef]

- Panahi-Sarmad, M.; Zahiri, Z.; Noroozi, M. Graphene-based composite for dielectric elastomer actuator: A comprehensive review. Sens. Actuators A Phys. 2019, 293, 222–241. [Google Scholar] [CrossRef]

- Wongtimnoi, K.; Guiffard, B.; Bogner-Van de Moortèle, A.; Seveyrat, L.; Gauthier, C.; Cavaillé, J.-Y. Improvement of electrostrictive properties of a polyether-based polyurethane elastomer filled with conductive carbon black Composites. Sci. Technol. 2011, 71, 885–892. [Google Scholar]

- Huang, W.S.; Cong, Y.Q.; Lin, B.P.; Wu, J.F.; Li, J.Q.; Hiroshi, O. Study on Electrostrictive Properties of Polyurethane Elastomers. Polyurethane Ind. 2006, 21, 18–21. [Google Scholar]

- Chen, T.; Lin, M.C.; Zhao, Y.Z.; Pan, L.F.; Tang, Q.P. Electromechanical response of polyol-polyurethane blends as dielectric elastomer flexible mirco-actuator material. J. Mater. Sci. 2017, 28, 3560–3570. [Google Scholar] [CrossRef]

- Wang, Y.G.; Zhou, G.S.; Jia, F.; Zhang, J.H. Application and developing trend of polyurethane maerials in commercial vehicle. Chem. Propellants Polym. Mater. 2018, 16, 20–25. [Google Scholar]

- Petcharoen, K.; Sirivat, A. Electrostrictive properties of thermoplastic polyurethane elastomer: Effects of urethane type and soft–hard segment composition. Curr. Appl. Phys. 2013, 13, 1119–1127. [Google Scholar] [CrossRef]

- Calvo, C.T.; Benitez, M.; Larraza, I.; Ugarte, L.; Peña, C.; Eceiza, A. Advanced and traditional processing of thermoplastic polyurethane wastes. Polym. Degrad. Stab. 2022, 198, 109880. [Google Scholar] [CrossRef]

- Galantini, F.; Carpi, F.; Gallone, G. Effects of plasticization of a soft silicone for dielectric elastomer actuation. Smart Mater. Struct. 2013, 22, 104020. [Google Scholar] [CrossRef]

- Renard, C.; Wang, D.R.; Yang, Y.; Xiong, S.L.; Shi, C.Y.; Dang, Z.M. Plasticized thermoplastic polyurethanes for dielectric elastomers with improved electromechanical actuation. J. Appl. Polym. Sci. 2017, 134, 45123. [Google Scholar] [CrossRef]

- Chen, T.; Qiu, J.; Zhu, K.; Wang, J.; Li, J. Copper Phthalocyanine Oligomer Noncovalent Functionalized Graphene-Polyurethane Dielectric Elastomer Composites for Flexible Micro-Actuator. Soft Mater. 2015, 13, 210–218. [Google Scholar] [CrossRef]

- Agarwal, S.; Greiner, A.; Wendorff, J.H. Functional materials by electrospinning of polymers. Prog. Polym. Sci. 2013, 38, 963–991. [Google Scholar] [CrossRef]

| S/N | Instrument | Manufacturer | City |

|---|---|---|---|

| 1 | Constant temperature magnetic stirrer | Meiyingpu Instrument Manufacturing Co., Ltd. | Shanghai, China |

| 2 | Circulating water vacuum pump | Great Wall Technology Industry and Trade Co., Ltd. | Zhengzhou, China |

| 3 | Vacuum drying oven | Zhuocheng Technology Co., Ltd. | Zhengzhou, China |

| 4 | Electrospinning apparatus | Tongli Co., Ltd. | Shenzhen, China |

| Items | PEG-8000 Solution/phr | SWNTs Suspension/phr | NaCl Solution/phr | |||

|---|---|---|---|---|---|---|

| PEG-8000 | DW | SWNTs | DW | NaCl | DW | |

| 1 | 5 | 5 | 0.20 | 10 | 10 | 30 |

| 2 | 5 | 5 | 0.40 | 10 | 10 | 30 |

| 3 | 5 | 5 | 0.60 | 10 | 10 | 30 |

| Items | Channel 2 | Channel 1 | |||

|---|---|---|---|---|---|

| PUDE | DMF | SWNYs | DMC | ET | |

| DEM | 20 | 80 | / | / | / |

| SWNTs-DEM1 | 0.1 | 50 | |||

| SWNTs-DEM2 | 0.2 | 50 | |||

| SWNTs-DEM3 | 0.3 | 50 | |||

| DMC-DEM1 | / | 2.6 | 50 | ||

| DMC-DEM2 | 2.7 | 50 | |||

| DMC-DEM3 | 2.8 | 50 | |||

| Items | Model | Remarks |

|---|---|---|

| Infrared spectrum analysis | TENSOR27 | Test range is 600 cm−1–3600 cm−1 |

| Morphology analysis | Su8010 | Maximum magnification 2,000,000 times |

| Particle size analysis | QL-1076 | 0.1 μm–600 μm |

| Device | Model | Remarks |

|---|---|---|

| Electron microscope | Zeiss Merlin | Accelerating voltage was 20 kV |

| Samples | 10 Hz | 100 Hz | Y/MPa | β10 Hz | β100 Hz | ||

|---|---|---|---|---|---|---|---|

| ε1″ | Tanα1 | ε2″ | Tanα2 | ||||

| DEM | 14.079 | 0.167 | 4.104 | 0.103 | 2.31 ± 0.06 | 6.095 | 1.777 |

| SWNTs-DEM1 | 17.314 | 0.274 | 5.037 | 0.119 | 2.68 ± 0.06 | 6.460 | 1.879 |

| SWNTs-DEM2 | 26.975 | 0.358 | 6.729 | 0.098 | 3.15 ± 0.06 | 8.563 | 2.136 |

| SWNTs-DEM3 | 41.502 | 0.311 | 9.067 | 0.137 | 3.47 ± 0.06 | 11.960 | 2.613 |

| DMC-DEM1 | 16.325 | 0.263 | 4.731 | 0.091 | 2.43 ± 0.06 | 6.718 | 1.947 |

| DMC-DEM2 | 26.471 | 0.249 | 6.467 | 0.107 | 2.85 ± 0.06 | 9.288 | 2.269 |

| DMC-DEM3 | 39.616 | 0.295 | 9.635 | 0.112 | 3.03 ± 0.06 | 13.074 | 3.180 |

| Samples | Breakdown Voltage/kV | Electrostrictive Strain/% | ||

|---|---|---|---|---|

| 10 kV | 20 kV | 30 kV | ||

| DEM | 47.9 | 0.43 | 0.54 | 0.75 |

| SWNTs-DEM1 | 44.7 | 0.52 | 0.60 | 0.82 |

| SWNTs-DEM2 | 40.9 | 0.70 | 0.72 | 0.91 |

| SWNTs-DEM3 | 37.5 | 0.81 | 0.87 | 0.99 |

| DMC-DEM1 | 45.8 | 0.69 | 0.78 | 0.93 |

| DMC-DEM2 | 42.2 | 0.80 | 0.89 | 1.02 |

| DMC-DEM3 | 38.8 | 0.93 | 1.01 | 1.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, G.; Shuai, C.; Liu, Y.; Yang, X. Study on the Actuation Properties of Polyurethane Fiber Membranes Filled with PEG-SWNTs Dielectric Microcapsules. Membranes 2022, 12, 1026. https://doi.org/10.3390/membranes12101026

Lu G, Shuai C, Liu Y, Yang X. Study on the Actuation Properties of Polyurethane Fiber Membranes Filled with PEG-SWNTs Dielectric Microcapsules. Membranes. 2022; 12(10):1026. https://doi.org/10.3390/membranes12101026

Chicago/Turabian StyleLu, Gang, Changgeng Shuai, Yinsong Liu, and Xue Yang. 2022. "Study on the Actuation Properties of Polyurethane Fiber Membranes Filled with PEG-SWNTs Dielectric Microcapsules" Membranes 12, no. 10: 1026. https://doi.org/10.3390/membranes12101026

APA StyleLu, G., Shuai, C., Liu, Y., & Yang, X. (2022). Study on the Actuation Properties of Polyurethane Fiber Membranes Filled with PEG-SWNTs Dielectric Microcapsules. Membranes, 12(10), 1026. https://doi.org/10.3390/membranes12101026