Membrane-Based Solutions for the Polish Coal Mining Industry

Abstract

1. Introduction

2. Coal Mining Industry

3. Coal Mine Water Utilization

3.1. Coal Mine Water Utilization in Poland

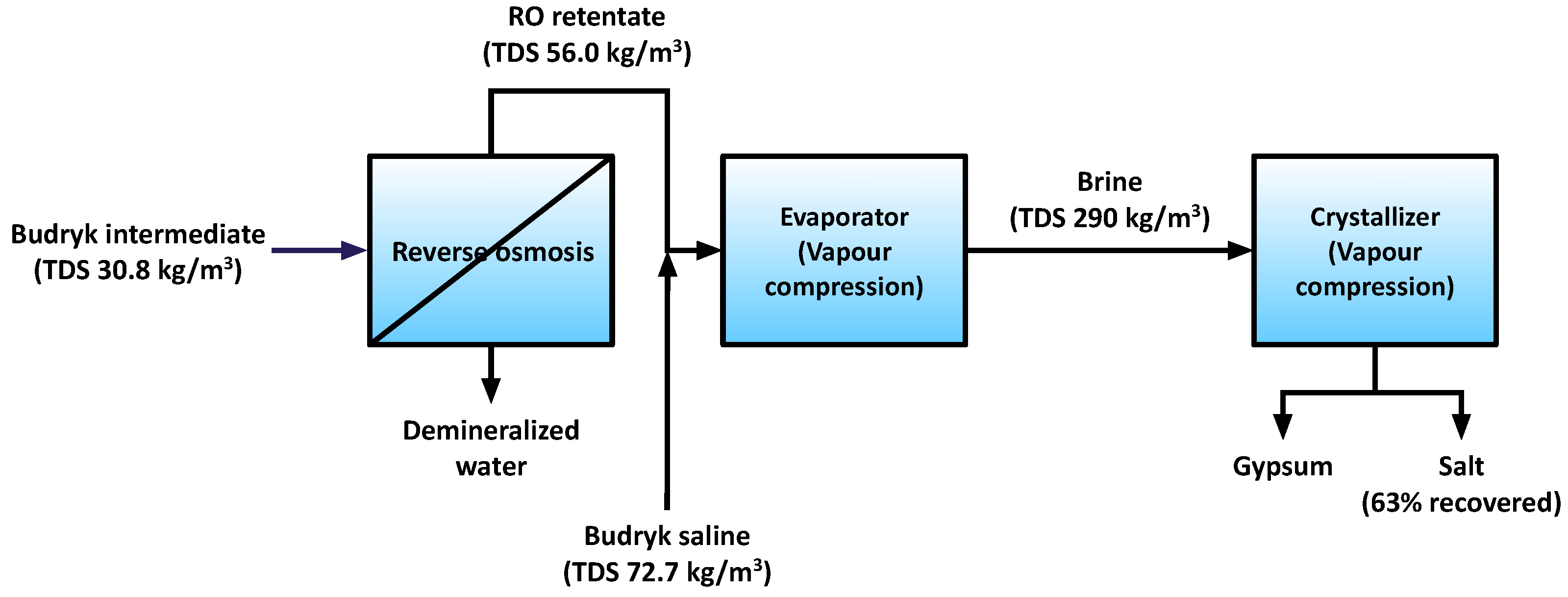

3.1.1. The ZOD Technology

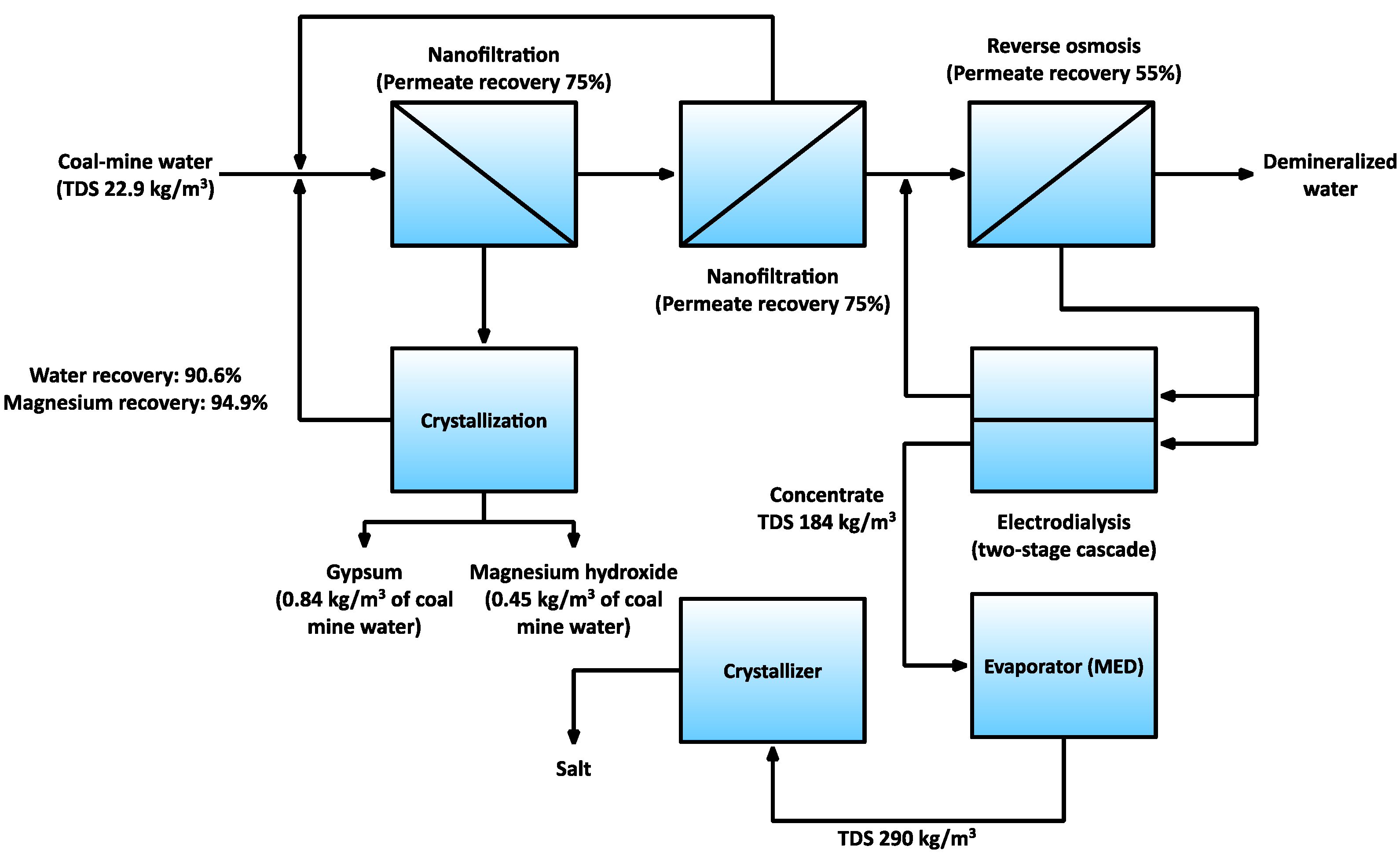

3.1.2. The NF–ED–RO System

3.1.3. The RO–NF System

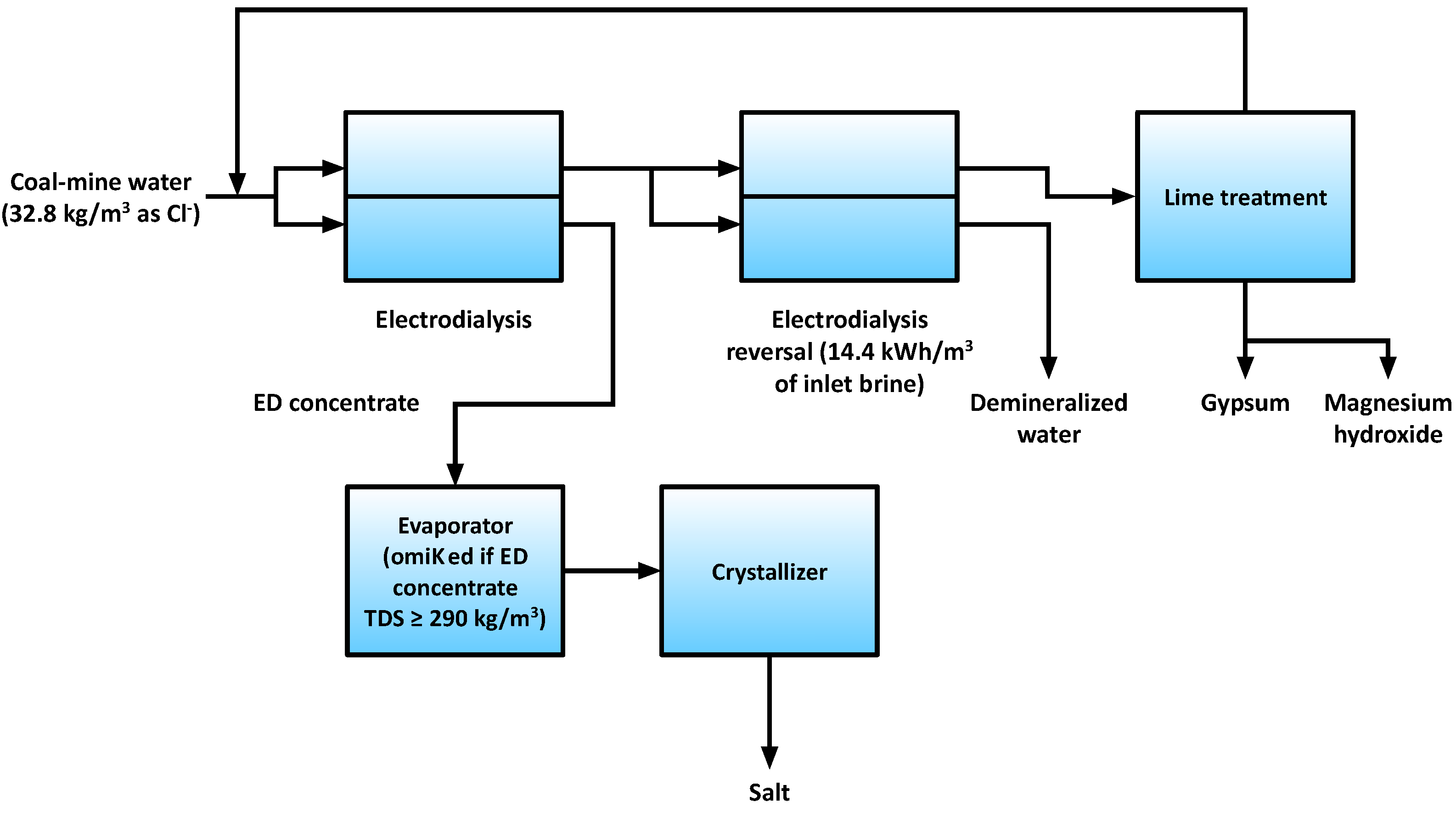

3.1.4. The ED–EDR System

3.1.5. ZERO BRINE Technology

3.1.6. Other Research

4. Prospects for Future Improvement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. 2017 List of Critical Raw Materials for the EU. Communication COM/2017/0490 Final, Brussels 2017. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2017:490:FIN (accessed on 22 June 2021).

- Joint Research Centre. EU Coal Regions: Opportunities and Challenges Ahead (No. EUR 29292 EN); Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Coal Production and Consumption Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:Production_of_hard_coal.jpg (accessed on 10 July 2021).

- Gombert, P.; Sracek, O.; Koukouzas, N.; Gzyl, G.; Valladares, S.T.; Frączek, R.; Klinger, C.; Bauerek, A.; Areces, J.E.Á.; Chamberlain, S.; et al. An Overview of Priority Pollutants in Selected Coal Mine Discharges in Europe. Mine Water Environ. 2019, 38, 16–23. [Google Scholar] [CrossRef]

- European Commission. Directive 2000/60/EC of the European Parliament and of the Council of 23 October 2000 Establishing a Framework for Community Action in the Field of Water Policy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32000L0060 (accessed on 10 July 2021).

- Urych, T.; Chećko, J.; Rosa, M.; Wątor, A. Evaluation of undeveloped hard coal deposits and estimation of hard coal reserves in the Upper Silesian Coal Basin, Poland. J. Sustain. Min. 2020, 19, 230–242. [Google Scholar] [CrossRef]

- Gawlik, L.; Mokrzycki, E. Changes in the Structure of Electricity Generation in Poland in View of the EU Climate Package. Energies 2019, 12, 3323. [Google Scholar] [CrossRef]

- Żuk, P.; Żuk, P.; Pluciński, P. Coal basin in Upper Silesia and energy transition in Poland in the context of pandemic: The socio-political diversity of preferences in energy and environmental policy. Resour. Policy 2021, 71, 101987. [Google Scholar] [CrossRef]

- Kędzior, S.; Dreger, M. Methane occurrence, emissions and hazards in the Upper Silesian Coal Basin, Poland. Int. J. Coal Geol. 2019, 211, 103226. [Google Scholar] [CrossRef]

- Janson, E.; Gzyl, G.; Banks, D. The Occurrence and Quality of Mine Water in the Upper Silesian Coal Basin, Poland. Mine Water Environ. 2009, 28, 232–244. [Google Scholar] [CrossRef]

- Gzyl, G.; Janson, E.; Łabaj, P. Mine Water Discharges in Upper Silesian Coal Basin (Poland). In Assessment, Restoration and Reclamation of Mining Influenced Soils; Bech, J., Bini, C., Pashkevich, M., Eds.; Elsevier Academic Press: London, UK, 2017; pp. 463–486. [Google Scholar]

- Halabowski, D.; Lewin, I.; Buczyński, P.; Krodkiewka, M.; Płaska, W.; Sowa, A.; Buczyńska, E. Impact of the Discharge of Salinised Coal Mine Waters on the Structure of the Macroinvertebrate Communities in an Urban River (Central Europe). Water Air Soil Pollut. 2020, 231, 5. [Google Scholar] [CrossRef]

- Turek, M.; Mrowiec-Białoń, J.; Gnot, W. Utilization of coal mine brines in the chlorine production process. Desalination 1995, 101, 57–67. [Google Scholar] [CrossRef]

- Chen, B.; Yang, S.; Cao, Q.; Qian, Y. Life cycle economic assessment of coal chemical wastewater treatment facing the ‘Zero liquid discharge’ industrial water policies in China: Discharge or reuse? Energy Policy 2020, 137, 111107. [Google Scholar] [CrossRef]

- Kurbiel, J.; Balcerzak, W.; Rybicki, S.M.; Świst, K. Selection of the best desalination technology for highly saline drainage water from coal mines in southern Poland. Desalination 1996, 106, 415–418. [Google Scholar] [CrossRef]

- Squires, R.C.; Cowan, J.A.C.; Wood, F.C. The desalination of coal mine drainage water by reverse osmosis. Desalination 1983, 47, 343–350. [Google Scholar] [CrossRef]

- Du Plessis, G.H.; Swartz, J.A. Tubular reverse osmosis treatment of Secunda mine water: A pilot plant investigation. Water Sci. Tech. 1992, 25, 193–201. [Google Scholar] [CrossRef]

- Chromíková, J.; Matúšková, V.; Thomas, J.; Malíková, P.; Volavková, L. Application of membrane processes for mine water treatment. Inż. Miner. 2014, 15, 181–186. [Google Scholar]

- Sun, X.; Hwang, J.-Y. Desalination of Coal Mine Water with Electrosorption. In Water in Mineral Processing; Drelich, J., Ed.; Society of Mining, Metallurgy, and Exploration: Englewood, CO, USA, 2012; pp. 237–245. [Google Scholar]

- Thiruvenkatachari, R.; Francis, M.; Cunnington, M.; Su, S. Application of integrated forward and reverse osmosis for coal mine wastewater desalination. Sep. Purif. Technol. 2016, 163, 181–188. [Google Scholar] [CrossRef]

- Sivakumar, M.; Ramezanianpour, M.; O’Halloran, G. Brackish water treatment for reuse using vacuum membrane distillation process. Water Supply 2015, 15, 362–369. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Y.; Jing, C. Application Overview of Membrane Separation Technology in Coal Mine Water Resources Treatment in Western China. Mine Water Environ. 2021, 40, 510–519. [Google Scholar] [CrossRef]

- Shan, Y. Evaluation of treatment efficiency of coal mine drainage and impact on surrounding waters for selected coal mines. IOP Conf. Ser. Earth Environ. Sci. 2019, 349, 012034. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, H.; He, X.; Guo, S.; Xia, Y.; Zhou, Y.; Liu, K.; Yang, S. Research progress, problems and prospects of mine water treatment technology and resource utilization in China. Crit. Rev. Environ. Sci. Technol. 2019, 50, 331–383. [Google Scholar] [CrossRef]

- Li, T.; Li, J. Concentrated Brine Treatment using New Energy in Coal Mine Evaporation Ponds. IOP Conf. Ser. Earth Environ. Sci. 2017, 100, 012013. [Google Scholar] [CrossRef]

- Ericsson, B.; Hallmans, B. Treatment of saline wastewater for zero discharge at the Debiensko coal mines in Poland. Desalination 1996, 105, 115–123. [Google Scholar] [CrossRef]

- Turek, M.; Laskowska, E.; Mitko, K.; Chorążewska, M.; Dydo, P.; Piotrowski, K.; Jakóbik-Kolon, A. Application of nanofiltration and electrodialysis for improved performance of a salt production plant. Desalin. Water Treat. 2017, 64, 244–250. [Google Scholar] [CrossRef]

- Turek, M.; Laskowska, E.; Mitko, K.; Jakóbik-Kolon, A. Low energy utilization of mine saline water in the integrated membrane- evaporative system. Masz. Górnicze 2018, 36, 39–48. (In Polish) [Google Scholar]

- NANOS Project. Available online: http://nanos-tango2.polsl.pl (accessed on 20 July 2021).

- Laskowska, E.; Turek, M.; Mitko, K.; Dydo, P. Concentration of mine saline water in high-efficiency hybrid RO–NF system. Desalin. Water Treat. 2018, 128, 414–420. [Google Scholar] [CrossRef]

- Turek, M.; Dydo, P.; Klimek, R. Salt production from coal-mine brine in ED–evaporation–crystallization system. Desalination 2005, 184, 439–446. [Google Scholar] [CrossRef]

- Mitko, K.; Turek, M.; Jaroszek, H.; Bernacka, E.; Sambor, M.; Skóra, P.; Dydo, P. Pilot studies on circular economy solution for coal mining sector. Water Res. Ind. 2021. under review. [Google Scholar]

- Report on the Operation and Optimization of the Pilot System for the Treatment of Coal Mine Water. Available online: https://zerobrine.eu/wp-content/uploads/2020/12/D3.5_Report-on-operation_ZEROBRINE_v1.1.pdf (accessed on 23 June 2021).

- Xevgenos, D.; Gzyl, G.; Panteleaki Tourkodimitri, K.; Mitko, K.; Tsalidis, G.A.; Skalny, A.; Mortou, M.; Sapoutzi, D.; Turek, M. Redesigning the coal mine wastewater treatment to enable transition to circular economy practices: The ZERO BRINE and Dębieńsko case studies. In Proceedings of the 16th Conference on Sustainable Development of Energy, Water, and Environment Systems (SDEWES), Dubrovnik, Croatia, 10–15 October 2021. [Google Scholar]

- Pawar, N.D.; Harris, S.; Korevaar, G.; Mitko, K. Valorization of Coal Mine Effluents—Challenges and Economic Opportunities. Water Res. Ind. 2021. under review. [Google Scholar]

- LIFE BRINE-MINING Project. Available online: https://brinemining.eu/en/home/ (accessed on 23 June 2021).

- Micari, M.; Cipollina, A.; Tamburini, A.; Moser, M.; Bertsch, V.; Micale, G. Techno-economic analysis of integrated processes for the treatment and valorisation of neutral coal mine effluent. J. Clean. Prod. 2020, 270, 122472. [Google Scholar] [CrossRef]

- Turek, M.; Dydo, P.; Surma, A. Zero discharge utilization of saline waters from “Wesola” coal mine. Desalination 2005, 185, 275–280. [Google Scholar] [CrossRef]

- Turek, M. Recovery of NaCl from saline mine water in an electrodialysis-evaporation system. Chem. Pap. 2003, 57, 50–52. [Google Scholar]

- Turek, M. Electrodialytic desalination and concentration of coal-mine brine. Desalination 2004, 162, 355–359. [Google Scholar] [CrossRef]

- Turek, M. Comprehensive utilization of brackish water in ED-thermal system. Desalination 2008, 221, 455–461. [Google Scholar] [CrossRef]

- Mitko, K.; Podleśny, B.; Jakóbik-Kolon, A.; Turek, M. Electrodialytic utilization of coal mine brines. Desalin. Water Treat. 2017, 75, 363–367. [Google Scholar] [CrossRef]

- Mitko, K.; Noszczyk, A.; Dydo, P.; Turek, M. Electrodialysis of coal mine water. Water Res. Ind. 2021, 25, 100143. [Google Scholar] [CrossRef]

- Chałupnik, S.; Wysocka, M.; Chmielewska, I.; Samolej, K. Modern technologies for radium removal from water—Polish mining industry case study. Water Res. Ind. 2020, 23, 100125. [Google Scholar] [CrossRef]

- Ostrowski, P.; Pronobis, M.; Remiorz, L. Mine emissions reduction installations. Appl. Therm. Eng. 2015, 84, 390–398. [Google Scholar] [CrossRef]

- Borowski, M.; Życzkowski, P.; Zwolińska, K.; Łuczak, R.; Kuczera, Z. The Security of Energy Supply from Internal Combustion Engines Using Coal Mine Methane—Forecasting of the Electrical Energy Generation. Energies 2021, 14, 3049. [Google Scholar] [CrossRef]

- Ostrowski, P. An installation for integrated utilisation of coal mine emissions of gas with a high concentration of methane, ventilation air and mine water. Rynek Energii 2012, 101, 153–156. [Google Scholar]

- Geo-Metan Project: Pre-Exploitation Collection of Methane from Coal Seams Using Surface Bore Holes. (In Polish). Available online: https://unece.org/fileadmin/DAM/energy/images/CMM/CMM_CE/15._Jureczka_-_Geo-Metan-2019-luty.pdf (accessed on 24 June 2021).

- Furman, T. Uneconomical Methane. The Company Ends the Project. Available online: https://energia.rp.pl/surowce-i-paliwa/29331-nieoplacalny-metan-koncern-konczy-projekt (accessed on 24 June 2021). (In Polish).

- He, X.; Lei, L. Optimizing methane recovery: Techno-economic feasibility analysis of N2-selective membranes for the enrichment of ventilation air methane. Sep. Purif. Technol. 2021, 259, 118180. [Google Scholar] [CrossRef]

- Brinkmann, T.; Scholles, C.; Wind, J.; Wolff, T.; Dengel, A.; Clemens, W. Processing of coal mine gas with low methane concentrations for use in high-temperature fuel cells. Desalination 2008, 224, 7–11. [Google Scholar] [CrossRef][Green Version]

- MINEWATER: Circular Energy Network of the Future. Available online: https://mijnwater.com/en/ (accessed on 10 July 2021).

- Gliklich-Kostrzewa, B. Old mine, new energy. Mine water as a source of heat and cold on the example of Minewater project. Przegląd Górniczy 2019, 75, 1–9. (In Polish) [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitko, K.; Turek, M. Membrane-Based Solutions for the Polish Coal Mining Industry. Membranes 2021, 11, 638. https://doi.org/10.3390/membranes11080638

Mitko K, Turek M. Membrane-Based Solutions for the Polish Coal Mining Industry. Membranes. 2021; 11(8):638. https://doi.org/10.3390/membranes11080638

Chicago/Turabian StyleMitko, Krzysztof, and Marian Turek. 2021. "Membrane-Based Solutions for the Polish Coal Mining Industry" Membranes 11, no. 8: 638. https://doi.org/10.3390/membranes11080638

APA StyleMitko, K., & Turek, M. (2021). Membrane-Based Solutions for the Polish Coal Mining Industry. Membranes, 11(8), 638. https://doi.org/10.3390/membranes11080638