Exploration on Optimized Control Way of D-Amino Acid for Efficiently Mitigating Membrane Biofouling of Membrane Bioreactor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up of MBR

2.2. Control Protocols of DAA

2.3. Analytical Methods

2.4. Optimization Approaches

3. Results

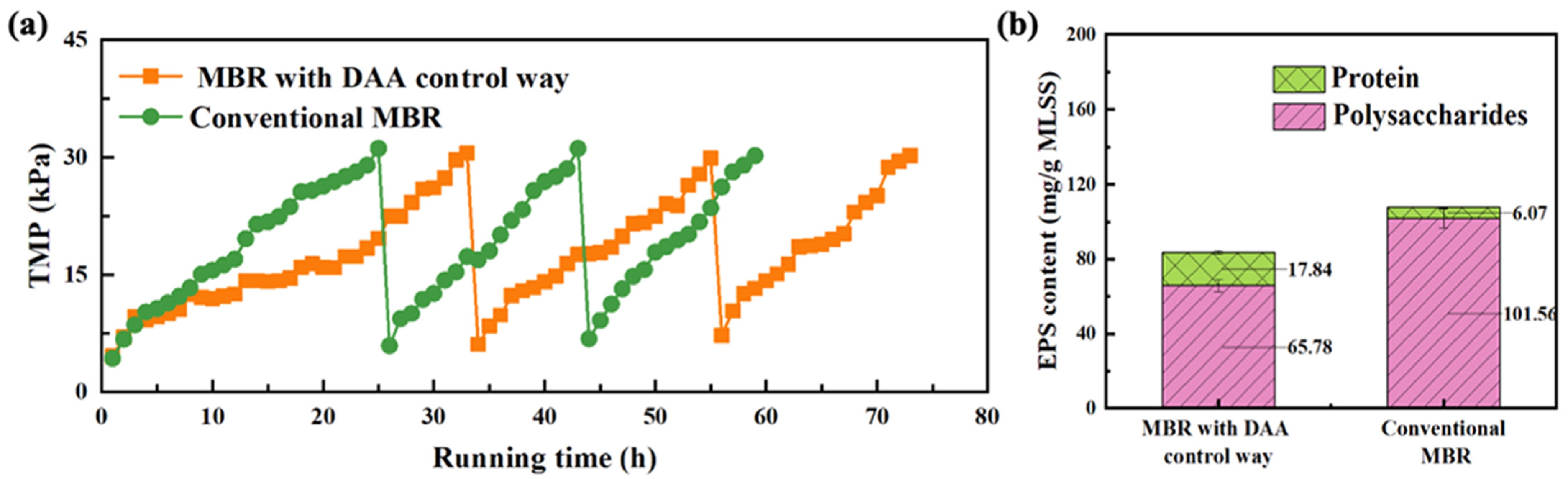

3.1. Anti-Biofouling Performances of MBR with DAA Control Way

3.2. Influences of DAA Control Ways on Anti-Biofouling Performances of MBR

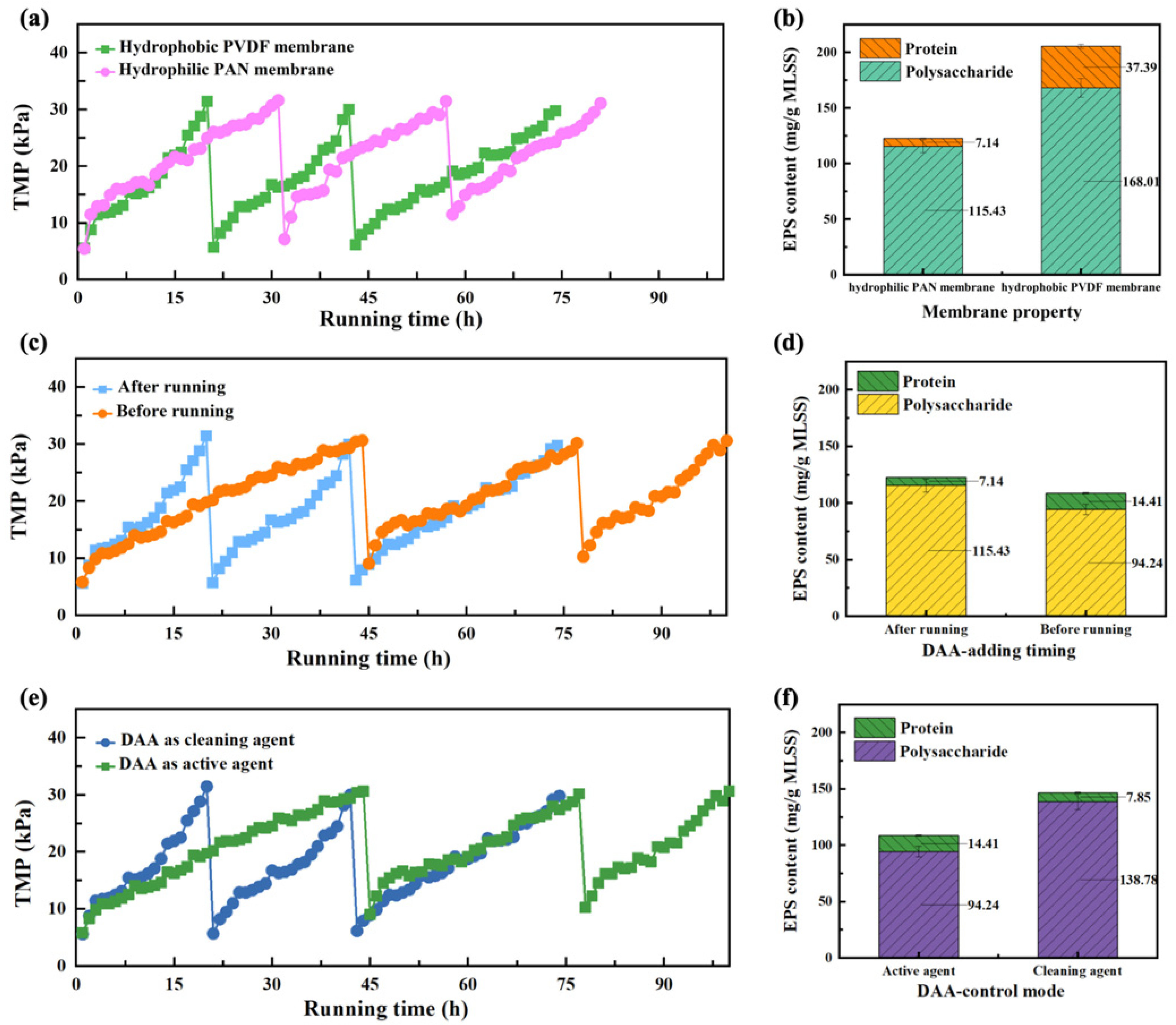

3.2.1. Effects of Membrane Property

3.2.2. Effects of DAA-Adding Timing

3.2.3. Effects of DAA-Control Mode

3.3. Optimization of DAA Control Ways for Efficient Alleviation of MBR Membrane Biofouling

3.3.1. Clarify the Weight of Different DAA Control Ways by MLR Model

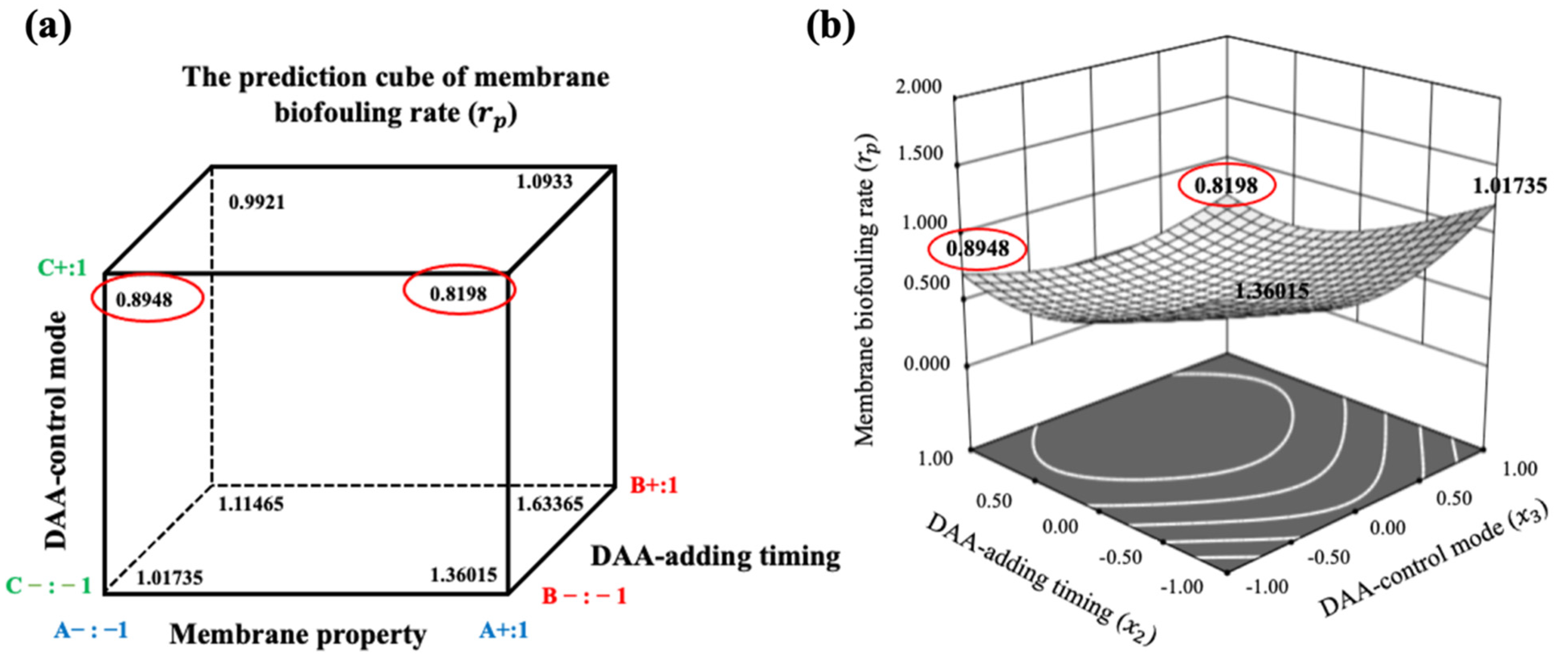

3.3.2. Clarify the Optimization of DAA Control Ways Combination by RSM Model

3.3.3. Model Prediction for Comprehensive Evaluation of MBR Membrane Anti-Biofouling Performances

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ji, J.; Qiu, J.P.; Wai, N.; Wong, F.S.; Li, Y.Z. Influence of organic and inorganic flocculants on physical-chemical properties of biomass and membrane-fouling rate. Water Res. 2010, 44, 1627–1635. [Google Scholar] [CrossRef]

- Meng, F.G.; Zhang, S.Q.; Oh, Y.; Zhou, Z.B.; Shin, H.S.; Chae, S.R. Fouling in membrane bioreactors: An updated review. Water Res. 2017, 114, 151–180. [Google Scholar] [CrossRef]

- Guo, X.Y.; Fan, S.G.; Hu, Y.D.; Fu, X.L.; Shao, H.Q.; Zhou, Q.X. A novel membrane biofouling mitigation strategy of D-amino acid supported by polydopamine and halloysite nanotube. J. Membr. Sci. 2019, 579, 131–140. [Google Scholar] [CrossRef]

- Drews, A. Membrane fouling in membrane bioreactors-Characterisation, contradictions, cause and cures. J. Membr. Sci. 2010, 363, 1–28. [Google Scholar] [CrossRef]

- Huang, S.J.; Shi, X.Q.; Bi, X.J.; Lee, L.Y.; Ng, H.Y. Effect of ferric hydroxide on membrane fouling in membrane bioreactor treating pharmaceutical wastewater. Bioresour. Technol. 2019, 292, 121852. [Google Scholar] [CrossRef]

- Bagheri, M.; Mirbagheri, S.A. Critical review of fouling mitigation strategies in membrane bioreactors treating water and wastewater. Bioresour. Technol. 2018, 258, 318–334. [Google Scholar] [CrossRef]

- Jiang, B.B.; Sun, X.F.; Wang, L.; Wang, S.Y.; Liu, R.D.; Wang, S.G. Polyethersulfone membranes modified with D-tyrosine for biofouling mitigation: Synergistic effect of surface hydrophility and anti-microbial properties. Chem. Eng. J. 2017, 311, 135–142. [Google Scholar] [CrossRef]

- Miura, Y.; Watanbe, Y.; Okabe, S. Membrane biofouling in pilot-scale membrane bioreactors (MBRs) treating municipal wastewater: Impact of biofilm formation. Environ. Sci. Technol. 2007, 41, 632–638. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.H.; Liu, Y. Biological control of microbial attachment: A promising alternative for mitigating membrane biofouling. Appl. Microbiol. Biotechnol. 2010, 86, 825–837. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.J.; Liu, Y. D-Amino acid mitigated membrane biofouling and promoted biofilm detachment. J. Membr. Sci. 2011, 376, 266–274. [Google Scholar] [CrossRef]

- Yu, C.; Wu, J.J.; Zin, G.; Di Luccio, M.; Wen, D.H.; Li, Q.L. D-Tyrosine loaded nanocomposite membranes for environmental-friendly, long-term biofouling control. Water Res. 2018, 130, 105–114. [Google Scholar] [CrossRef]

- Kolodkin-Gal, I.; Romero, D.; Cao, S.G.; Clardy, J.; Kolter, R.; Losick, R. d-Amino Acids Trigger Biofilm Disassembly. Science 2010, 328, 627–629. [Google Scholar] [CrossRef] [Green Version]

- Hochbaum, A.I.; Kolodkin-Gal, I.; Foulston, L.; Kolter, R.; Aizenberg, J.; Losick, R. Inhibitory Effects of D-Amino Acids on Staphylococcus aureus Biofilm Development. J. Bacteriol. 2011, 193, 5616–5622. [Google Scholar] [CrossRef] [Green Version]

- Caparros, M.; Pisabarro, A.G.; de Pedro, M.A. Effect of D-amino acids on structure and synthesis of peptidoglycan in Escherichia coli. J. Bacteriol. 1992, 174, 5549–5559. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, H.J.; Liu, Y. Reduced microbial attachment by D-amino acid-inhibited AI-2 and EPS production. Water Res. 2011, 45, 5796–5804. [Google Scholar] [CrossRef]

- Yu, C.; Wu, J.J.; Contreras, A.E.; Li, Q.L. Control of nanofiltration membrane biofouling by Pseudomonas aeruginosa using D-tyrosine. J. Membr. Sci. 2012, 423, 487–494. [Google Scholar] [CrossRef]

- Lee, W.; Kang, S.; Shin, H. Sludge characteristics and their contribution to microfiltration in submerged membrane bioreactors. J. Membr. Sci. 2003, 216, 217–227. [Google Scholar] [CrossRef]

- Han, F.; Ye, W.; Wei, D.; Xu, W.Y.; Du, B.; Wei, Q. Simultaneous nitrification-denitrification and membrane fouling alleviation in a submerged biofilm membrane bioreactor with coupling of sponge and biodegradable PBS carrier. Bioresour. Technol. 2018, 270, 156–165. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.; Li, X.; Zhang, N.; Wen, D.; Liu, C.; Li, Q. Inhibition of biofilm formation by D-tyrosine: Effect of bacterial type and D-tyrosine concentration. Water Res. 2016, 92, 173–179. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Park, S.K.; Kwon, H.; Lee, S.H.; Lee, K.; Nahm, C.H.; Jo, S.J.; Oh, H.S.; Park, P.K.; Choo, K.H.; et al. Crossing the Border between Laboratory and Field: Bacterial Quorum Quenching for Anti-Biofouling Strategy in an MBR. Environ. Sci. Technol. 2016, 50, 1788–1795. [Google Scholar] [CrossRef]

- Ramesh, A.; Lee, D.J.; Lai, J.Y. Membrane biofouling by extracellular polymeric substances or soluble microbial products from membrane bioreactor sludge. Appl. Microbiol. Biotechnol. 2007, 74, 699–707. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.Q.; Bishop, P.L.; Kinkle, B.K. Comparison of extraction methods for quantifying extracellular polymers in biofilms. Water Sci. Technol. 1999, 39, 211–218. [Google Scholar] [CrossRef]

- Madaeni, S.S.; Hasankiadeh, N.T.; Tavakolian, H.R. Modeling and Optimization of Membrane Chemical Cleaning by Artificial Neural Network, Fuzzy Logic, and Genetic Algorithm. Chem. Eng. Commun. 2012, 199, 399–416. [Google Scholar] [CrossRef]

- Wu, J.; Huang, X. Effect of mixed liquor properties on fouling propensity in membrane bioreactors. J. Membr. Sci. 2009, 342, 88–96. [Google Scholar] [CrossRef]

- Alipourzadeh, A.; Mehrnia, M.R.; Sani, A.H.; Babaei, A. Application of response surface methodology for investigation of membrane fouling behaviours in microalgal membrane bioreactor: The effect of aeration rate and biomass concentration. RSC Adv. 2016, 6, 111182–111189. [Google Scholar] [CrossRef]

- Song, W.; Li, J.; Wang, Z.; Fu, C.; Zhang, X.; Feng, J.; Xu, Z.; Song, Q. Degradation of bisphenol A by persulfate coupled with dithionite: Optimization using response surface methodology and pathway. Sci. Total Environ. 2020, 699, 134258. [Google Scholar] [CrossRef]

- Malaeb, L.; Le-Clech, P.; Vrouwenvelder, J.S.; Ayoub, G.M.; Saikaly, P.E. Do biological-based strategies hold promise to biofouling control in MBRs? Water Res. 2013, 47, 5447–5463. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, W.X.; Tang, B.; Ding, J.; Zheng, Y.; Zhang, Z.E. Membrane fouling mechanism of biofilm-membrane bioreactor (BF-MBR): Pore blocking model and membrane cleaning. Bioresour. Technol. 2018, 250, 398–405. [Google Scholar] [CrossRef]

- Zhang, W.X.; Liang, W.Z.; Huang, G.H.; Wei, J.; Ding, L.H.; Jaffrin, M.Y. Studies of membrane fouling mechanisms involved in the micellar-enhanced ultrafiltration using blocking models. RSC Adv. 2015, 5, 48484–48491. [Google Scholar] [CrossRef]

- Lin, H.J.; Zhang, M.J.; Wang, F.Y.; Meng, F.G.; Liao, B.Q.; Hong, H.C.; Chen, J.R.; Gao, W.J. A critical review of extracellular polymeric substances (EPSs) in membrane bioreactors: Characteristics, roles in membrane fouling and control strategies. J. Membr. Sci. 2014, 460, 110–125. [Google Scholar] [CrossRef]

- Moghaddam, A.Z.; Ghiamati, E.; Ayati, A.; Ganjali, M.R. Application of the response surface methodology for optimizing the adsorptive removal of chromate using a magnetic crosslinked chitosan nanocomposite. J. Appl. Polym. Sci. 2019, 136, 47077. [Google Scholar] [CrossRef]

- Agarwal, S.; Tyagi, I.; Gupta, V.K.; Dastkhoon, M.; Ghaedi, M.; Yousefi, F.; Asfaram, A. Ultrasound-assisted adsorption of Sunset Yellow CFC dye onto Cu doped ZnS nanoparticles loaded on activated carbon using response surface methodology based on central composite design. J. Mol. Liq. 2016, 219, 332–340. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhao, Y.L. Optimization of photocatalytic degradation of dye wastewater by CuFe2O4/AgBr composite using response surface methodology. Mater. Res. Express 2019, 6, 036109. [Google Scholar] [CrossRef]

| Membrane Properties | Membrane Material | Effective Length (cm) | Membrane Fiber Quantity | Inner Diameter (mm) | Outer Diameter (mm) | Pore Diameter (μm) | Membrane Area (m2) |

|---|---|---|---|---|---|---|---|

| Hydrophilicity | Polyacrylonitrile (PAN) | 10 | 320 | 0.7 | 1.2 | 0.2 | 0.1130 |

| Hydrophobicity | Polyvinylidene Fluoride (PVDF) |

| Control Protocols | Specific Information | |

|---|---|---|

| Membrane property | Hydrophilic PAN membrane | Hydrophobic PVDF membrane |

| DAA-adding timing | Before running (the DAA and microorganisms were cultured for 4 h * and then inoculated into the MBR for operation) | After running (adding DAA when TMP reached 15 kPa during the operation) |

| DAA-control mode | Active agent (adding DAA into the MBR before or after running) | Cleaning agent (after one biofouling-physical cleaning cycle, the membrane module was soaked in DAA solution of 6 mg·L−1 for 4 h *, and then pure water was used for rinsing) |

| Factors | Symbols | Levels | |

|---|---|---|---|

| Low (−1) | High (+1) | ||

| Membrane property | Hydrophilicity | Hydrophobicity | |

| DAA-adding timing | Before running | After running | |

| DAA-control mode | Cleaning agent | Active agent | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Yu, Z.; Zhang, X.; Fan, S.; Gao, H.; Liu, C.; Zhou, Q.; Shao, H.; Wang, L.; Guo, X. Exploration on Optimized Control Way of D-Amino Acid for Efficiently Mitigating Membrane Biofouling of Membrane Bioreactor. Membranes 2021, 11, 612. https://doi.org/10.3390/membranes11080612

Gao Z, Yu Z, Zhang X, Fan S, Gao H, Liu C, Zhou Q, Shao H, Wang L, Guo X. Exploration on Optimized Control Way of D-Amino Acid for Efficiently Mitigating Membrane Biofouling of Membrane Bioreactor. Membranes. 2021; 11(8):612. https://doi.org/10.3390/membranes11080612

Chicago/Turabian StyleGao, Zhan, Zhihao Yu, Xiaoli Zhang, Shougang Fan, Huiyu Gao, Caini Liu, Qixing Zhou, Huaiqi Shao, Lan Wang, and Xiaoyan Guo. 2021. "Exploration on Optimized Control Way of D-Amino Acid for Efficiently Mitigating Membrane Biofouling of Membrane Bioreactor" Membranes 11, no. 8: 612. https://doi.org/10.3390/membranes11080612

APA StyleGao, Z., Yu, Z., Zhang, X., Fan, S., Gao, H., Liu, C., Zhou, Q., Shao, H., Wang, L., & Guo, X. (2021). Exploration on Optimized Control Way of D-Amino Acid for Efficiently Mitigating Membrane Biofouling of Membrane Bioreactor. Membranes, 11(8), 612. https://doi.org/10.3390/membranes11080612