Potential Pitfalls in Membrane Fouling Evaluation: Merits of Data Representation as Resistance Instead of Flux Decline in Membrane Filtration

Abstract

:1. Introduction

- To provide a correct interpretation of the amount of fouling and the impact of fouling on performance;

- To characterize the fouling mechanism and to quantify fouling parameters;

- To isolate effect of manipulated operational conditions or evaluated fouling mitigation measures, such that the observation is primarily a consequence of the investigated factor.

2. Background

2.1. Ideal Cake Filtration

2.2. Cake-Enhanced Concentration Polarization

2.3. Complete Blocking

3. Results

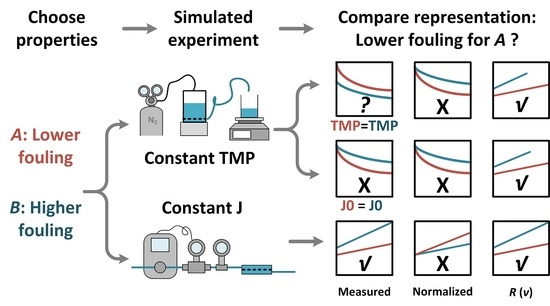

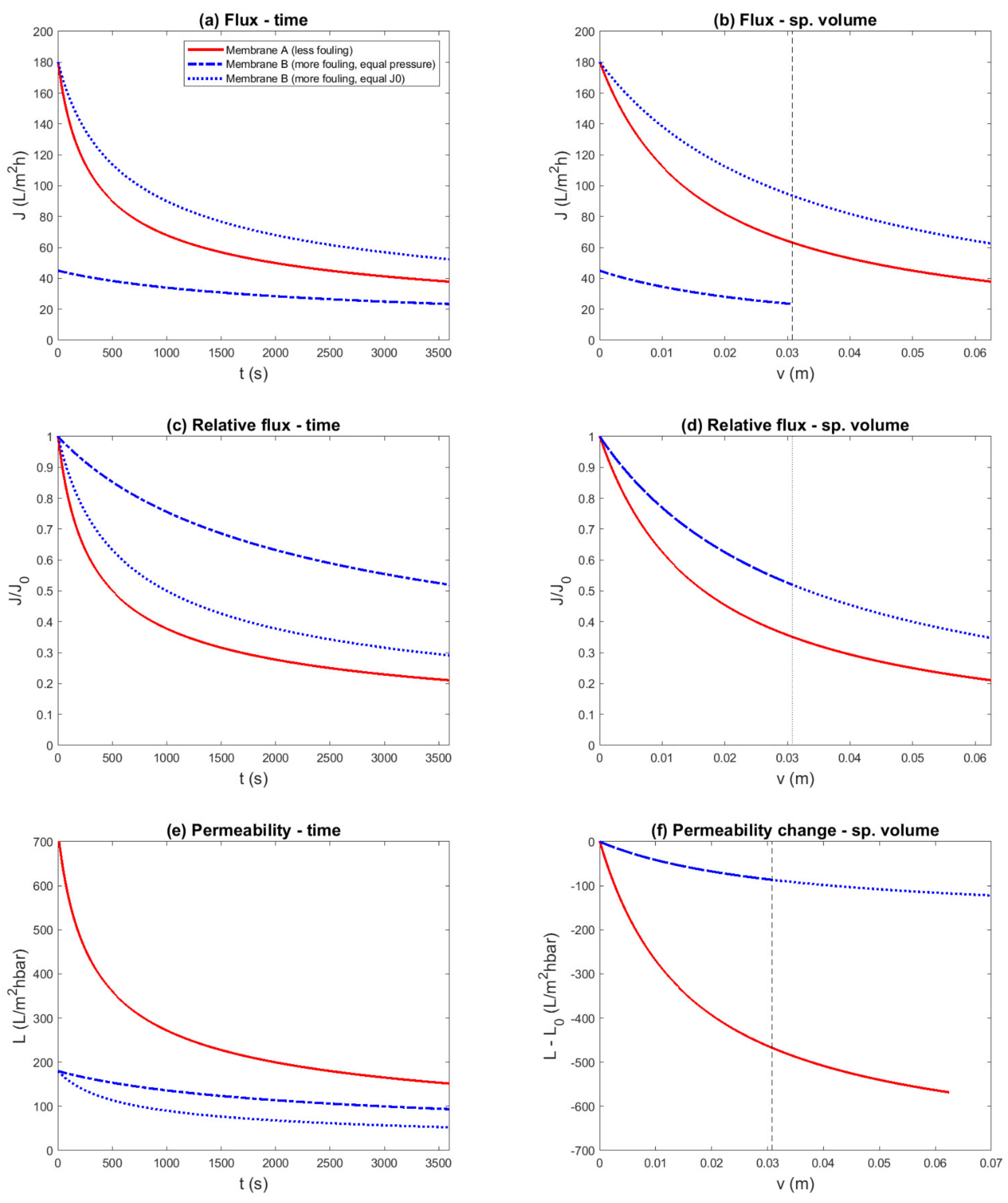

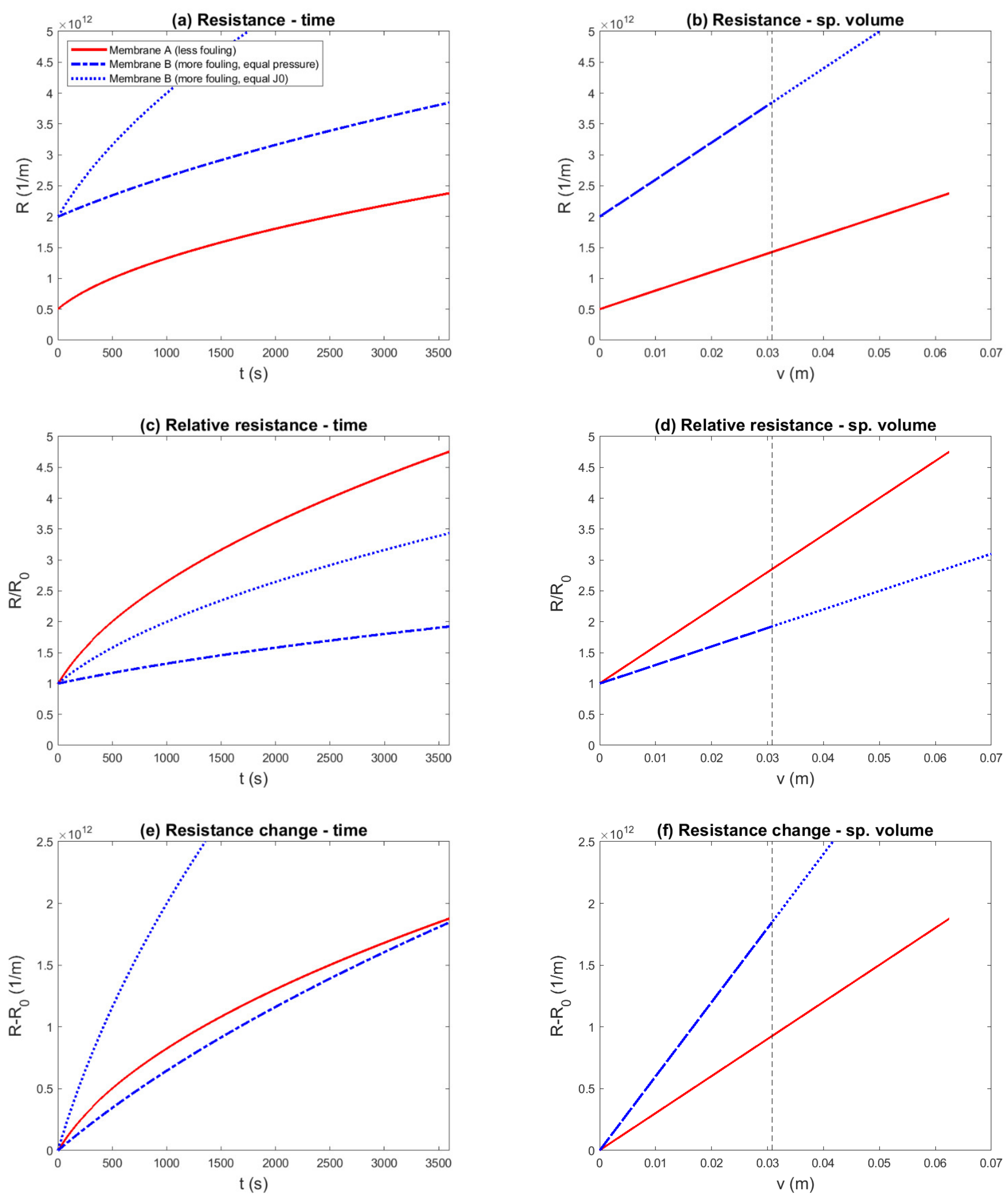

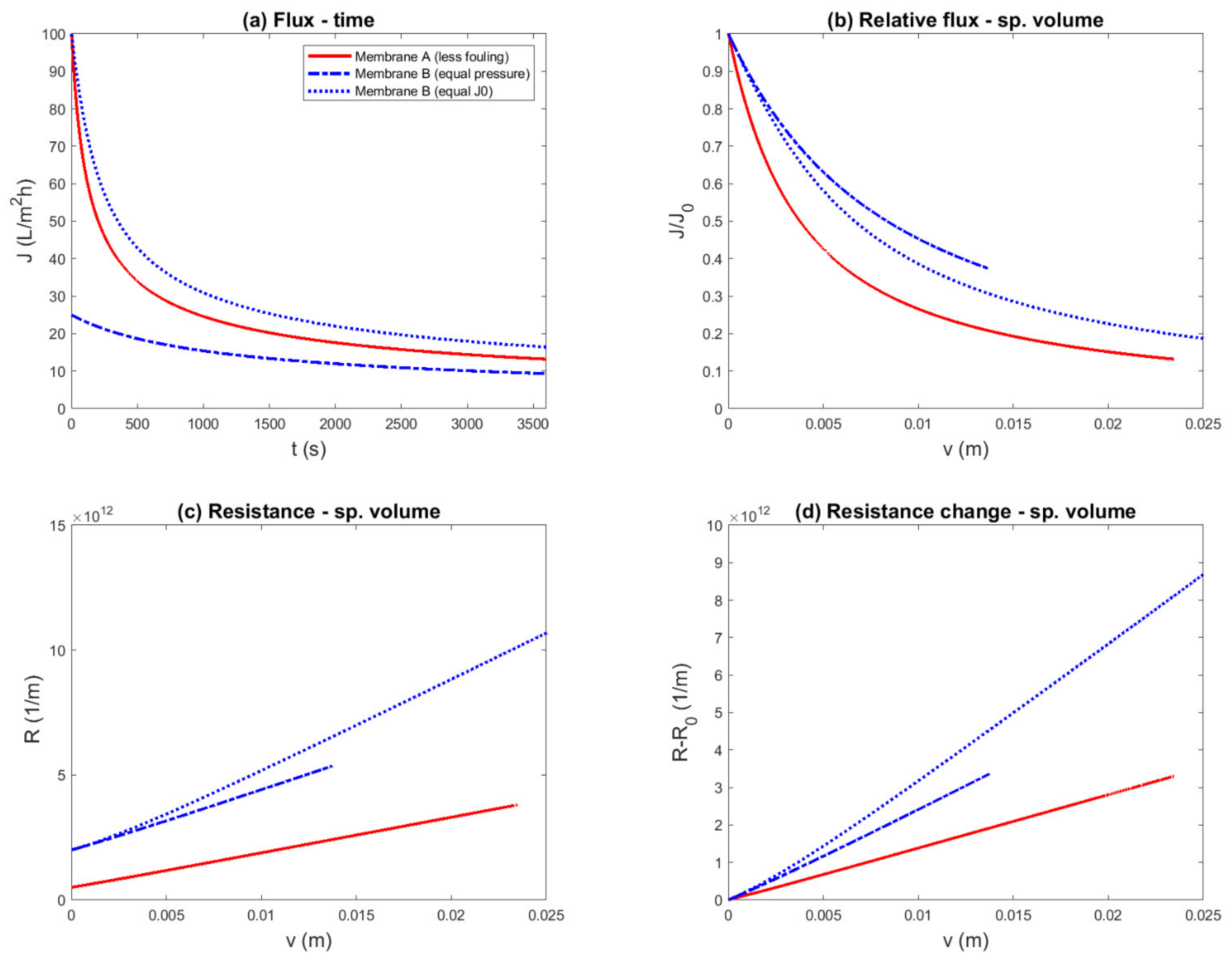

3.1. Constant-Pressure Experiment with Equal Pressure (Cake Filtration)

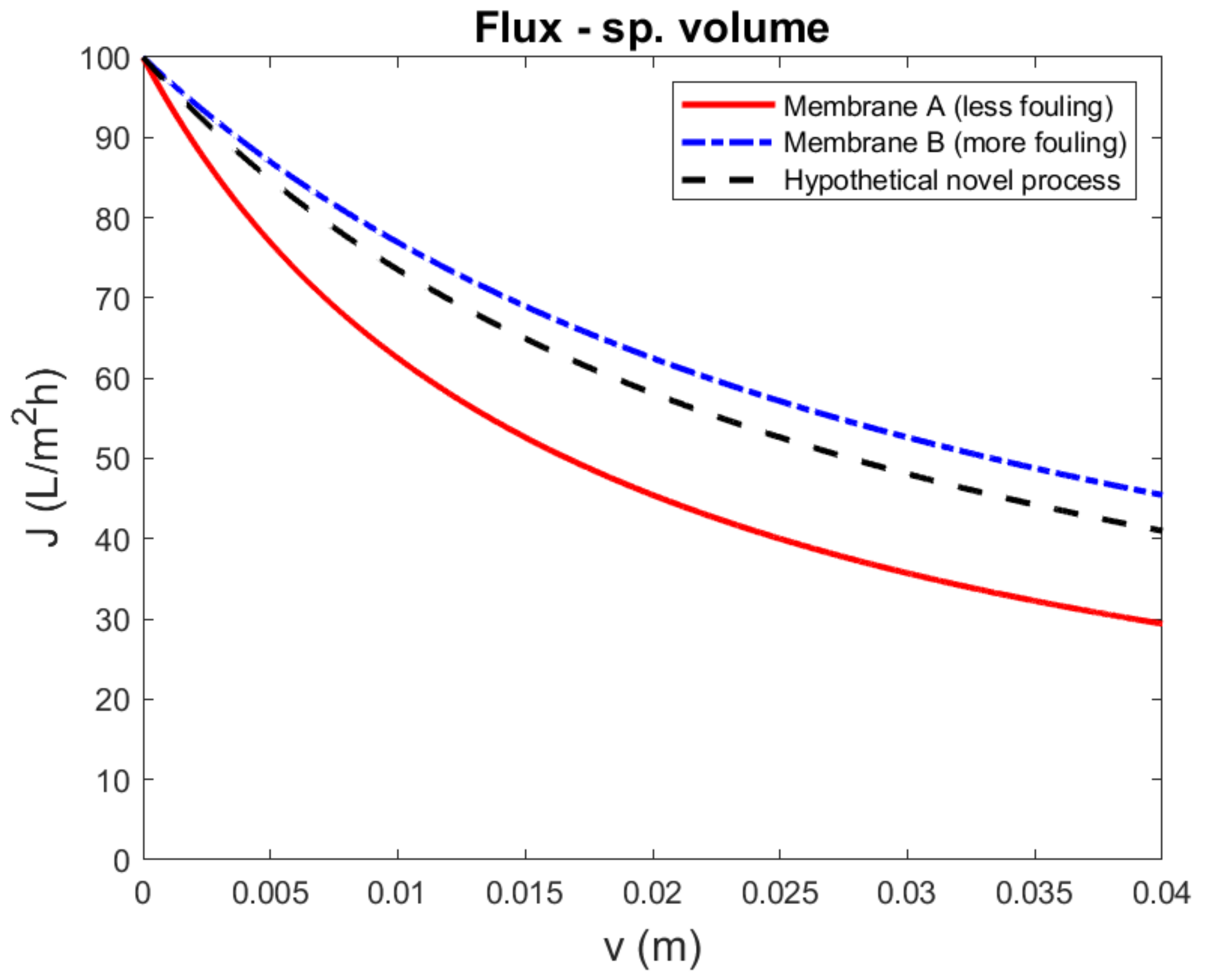

3.2. Implication for Comparing Different Processes

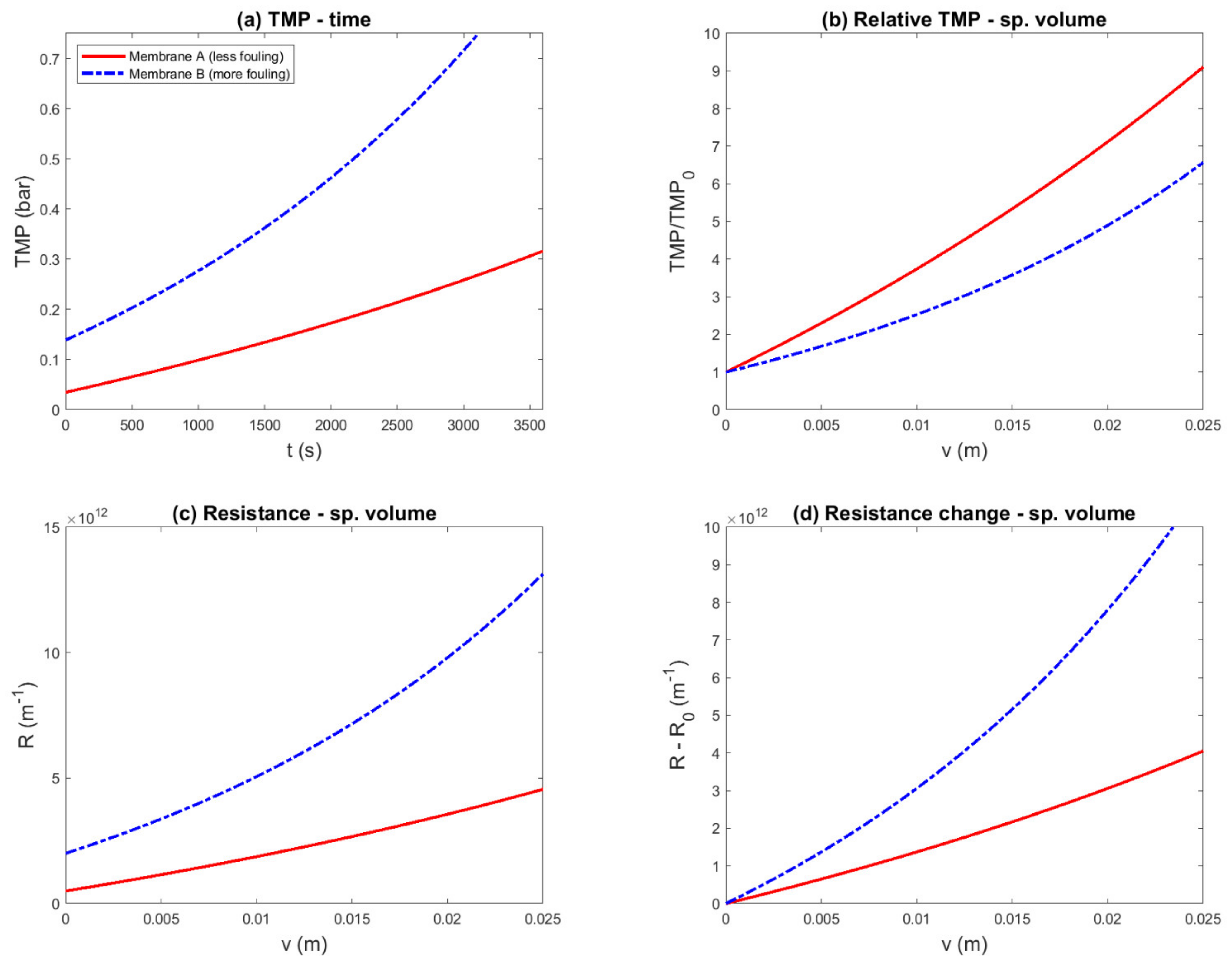

3.3. Constant-Flux Experiment (Cake Filtration)

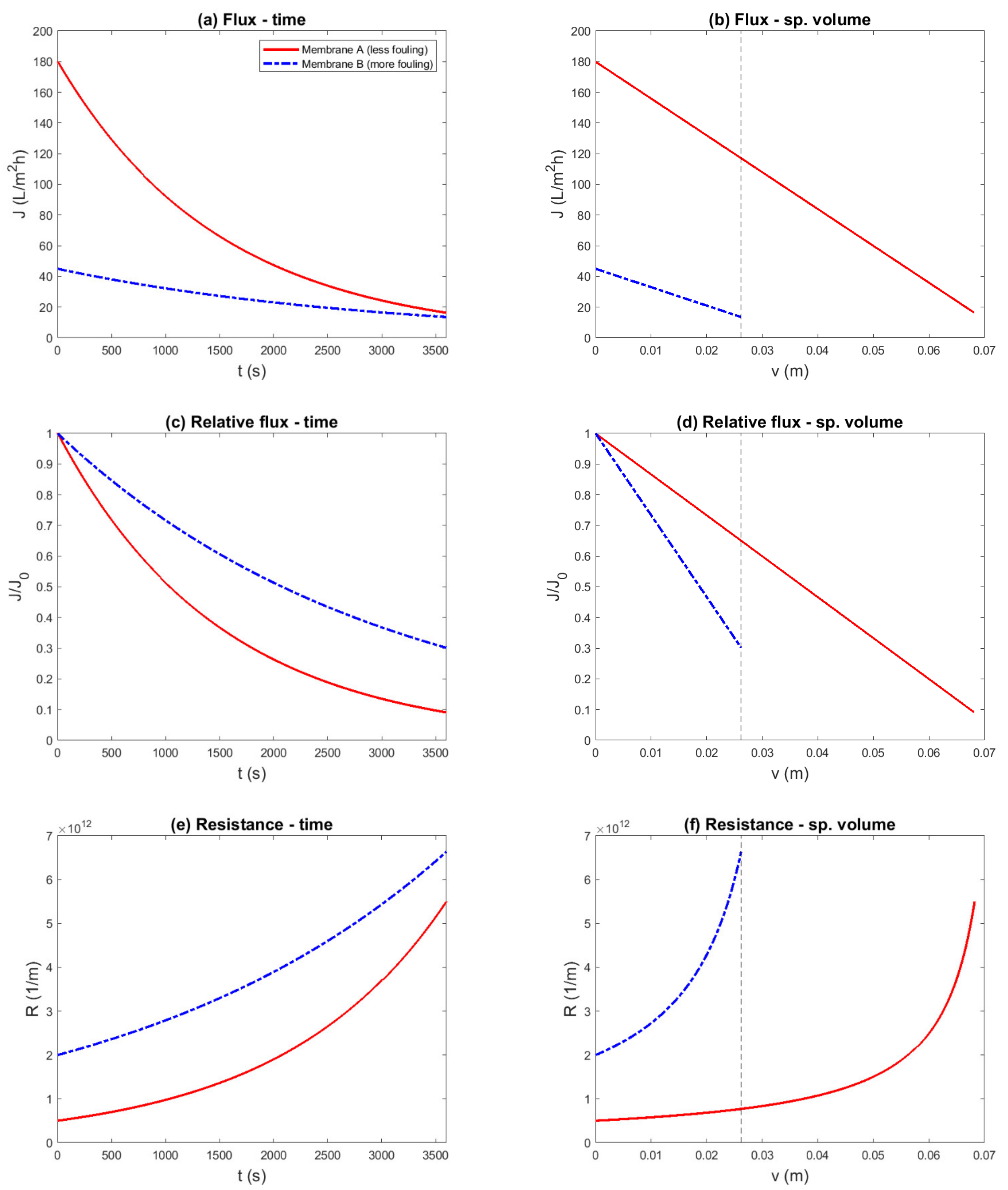

3.4. Cake-Enhanced Concentration Polarization

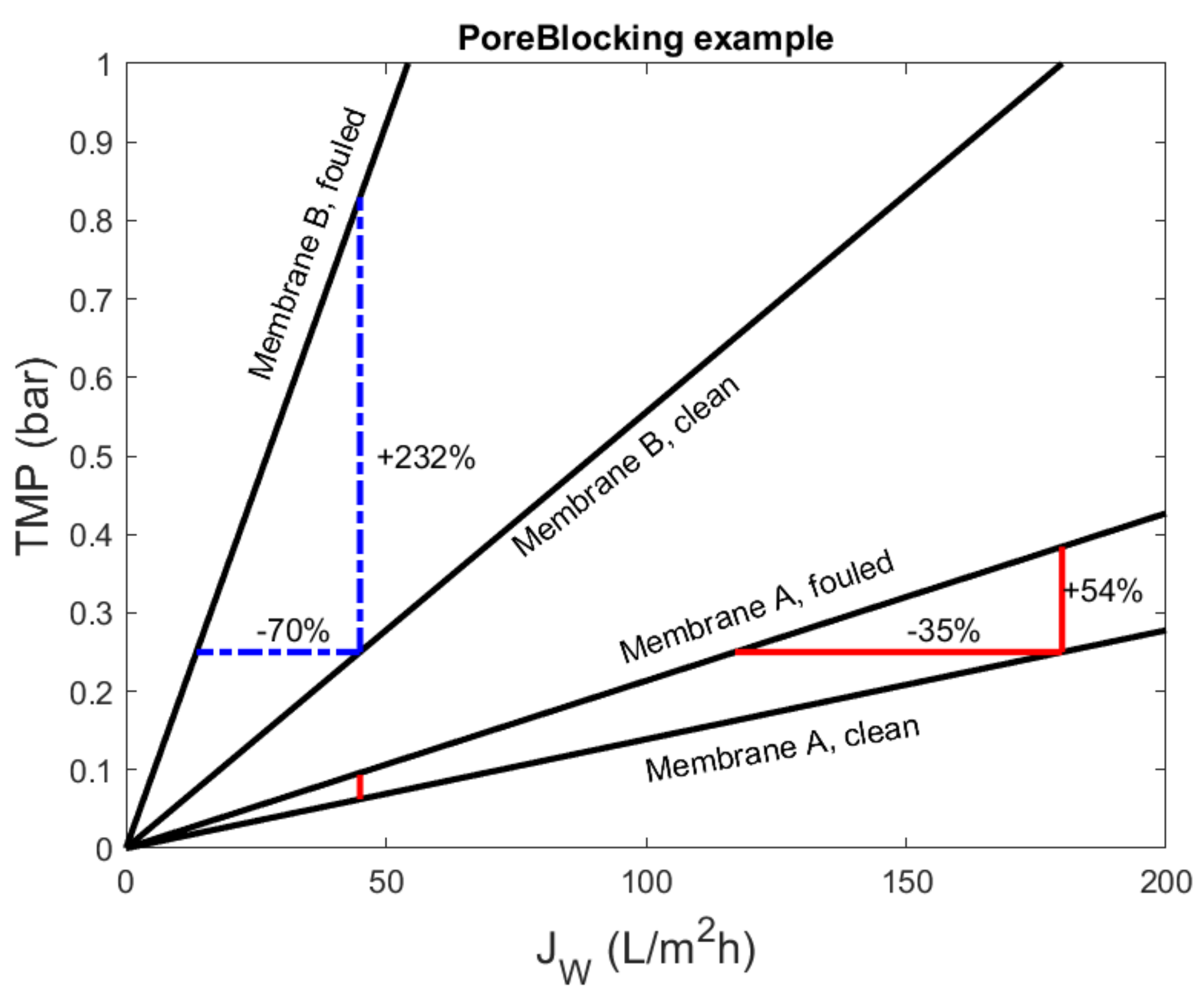

3.5. Constant-Pressure Experiment (Complete Blocking)

4. Discussion

- Volume bias: The constituents that cause membrane fouling are contained in the feed water. Thus, the amount of fouling material on the membrane surface principally depends on the filtered volume. Equivalently, the accumulation rate (as amount of material per unit time) principally depends on the filtration flux. In experiments with constant and equal driving force, differences in flux can occur, which result in corresponding differences in the foulant mass. By plotting the results as a function of time, the difference in fouling load is neglected, and the representation is biased toward the run with the lower filtration flux (Figure 2e vs. Figure 2f).

- Flux bias: The adverse effect of fouling is often exacerbated by a higher filtration flux, due to, for example, polarization phenomena and fouling-layer compression. Thus, even if the experiment and data representation take the difference in filtered volume into account, a bias still exists that favors the run with the lower filtration flux. Note that in our examples for ideal cake filtration and pore blocking, this did not play a role; however, in more complex fouling mechanisms, for example with cake-enhanced concentration polarization, this is highly relevant. This secondary flux effect is related to the difference in flux between two runs, and can be isolated in flux-controlled fouling experiments, in which different factors are compared on an equal filtration flux basis.

- Normalization bias: Relative fouling performance indicators involve normalization of the data by an initial value. In essence, this corresponds to dividing the fouling resistance by the membrane resistance. Thus, this introduces a bias toward a membrane with a higher resistance, simply by dividing the effect of fouling by a larger number (Figure 1c,d). This effect also plays a role in constant-driving-force experiments, in which the initial flux is chosen to be equal and the required difference in driving force is neglected.

- Fouling mechanisms that involve chemical (scaling) or biological conversion may be kinetically limited depending on the conditions. In such cases, it may be more appropriate to use time on the x-axis. In these cases, the concentration at the membrane surface is highly relevant, thus concentration polarization has to be taken into account carefully. In this case, it is especially recommended to utilize flux-controlled experiments, as this removes the distinction between time and specific volume, and equalizes the concentration polarization between runs and during the run.

- In some processes, there is an interplay of driving forces. For example, in membrane distillation, the transport through the membrane is driven by a vapor pressure difference, whereas the transport through the fouling layer is driven by hydraulic pressure. In addition to the hydraulic resistance of the fouling layer, fouling may also enhance polarization phenomena. In such cases, it may not be clear how the resistance of the fouling layer can be determined, or how the fouling effect can be isolated from the intrinsic membrane properties. The experimental protocols discussed in this paper relied on comparing constant-flux or constant-pressure runs. When the fouling mechanism is more complex, a single filtration run under constant conditions may not contain sufficient information about the fouling characteristics, and an extended experimental protocol may be needed [26,29].

- In crossflow filtration, the accumulation of fouling is more loosely related to the filtered volume compared to dead-end filtration. In most cases, it is expected that in a crossflow system, the fouling rate is reduced, since shear and back-diffusion can remove foulants from the fouling layer [35]. However, it is also possible that enhanced mass transfer accelerates transport of foulants toward the membrane [36]. In either case, the effect of the hydrodynamic conditions on the fouling rate is visible by evaluating the amount of fouling per filtered volume.

5. Conclusions

- Relative (normalized) fouling performance indicators, such as relative flux (), relative transmembrane pressure (), relative resistance (), and relative permeability () are not appropriate for fouling quantification.

- It is always appropriate to plot a measured variable (e.g., flux or pressure) as a function of time. However, that does not necessarily mean that performance can be assessed from the resulting plot. Meaningful differences between experimental runs (e.g., different pressures in flux-decline experiments) should be clearly indicated.

- Under the resistances-in-series assumption, the change in resistance () can be used to give a more explicit impression of the fouling by removing the contribution of the membrane. For other fouling indicators, representations based on their change should be avoided (e.g., and ).

- If hydraulic pressure is the main driving force and the fouling mechanism is accumulation of foulant matter from the feed water, it is recommended to represent the fouling data as resistance vs. specific volume. These conditions are commonly encountered in cases in which currently normalized flux decline is shown.

- In flux-decline experiments, differences in filtered volume and secondary effects of the difference in filtration flux should be carefully considered. It is preferable to compare experiments with different driving forces and equal initial flux, rather than experiments with equal driving forces and different initial flux. The flux-decline curve of the latter experiment has similar properties to the relative flux decline, and should not be used directly to assess fouling rate.

- In constant-flux filtration experiments, the effect of the filtration flux on fouling is controlled. Thus, the investigated effects can be better isolated. It is highly recommended that for comparison of membrane-fouling performance, tests should be performed at the same controlled flux and be evaluated for a rise in resistance and driving force.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Malaeb, L.; Ayoub, G.M. Reverse osmosis technology for water treatment: State of the art review. Desalination 2011, 267, 1–8. [Google Scholar] [CrossRef]

- Elimelech, M.; Phillip, W.A. The Future of Seawater Desalination: Energy, Technology, and the Environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef] [PubMed]

- Anis, S.F.; Hashaikeh, R.; Hilal, N. Reverse osmosis pretreatment technologies and future trends: A comprehensive review. Desalination 2019, 452, 159–195. [Google Scholar] [CrossRef] [Green Version]

- Albergamo, V.; Blankert, B.; Cornelissen, E.R.; Hofs, B.; Knibbe, W.-J.; van der Meer, W.; de Voogt, P. Removal of polar organic micropollutants by pilot-scale reverse osmosis drinking water treatment. Water Res. 2019, 148, 535–545. [Google Scholar] [CrossRef]

- Le-Clech, P. Membrane bioreactors and their uses in wastewater treatments. Appl. Microbiol. Biotechnol. 2010, 88, 1253–1260. [Google Scholar] [CrossRef]

- Carstensen, F.; Apel, A.; Wessling, M. In situ product recovery: Submerged membranes vs. external loop membranes. J. Membr. Sci. 2012, 394-395, 1–36. [Google Scholar] [CrossRef]

- Linares, R.V.; Li, Z.; Sarp, S.; Bucs, S.; Amy, G.; Vrouwenvelder, J. Forward osmosis niches in seawater desalination and wastewater reuse. Water Res. 2014, 66, 122–139. [Google Scholar] [CrossRef]

- Gerstandt, K.; Peinemann, K.-V.; Skilhagen, S.E.; Thorsen, T.; Holt, T. Membrane processes in energy supply for an osmotic power plant. Desalination 2008, 224, 64–70. [Google Scholar] [CrossRef]

- Loeb, S. Production of energy from concentrated brines by pressure-retarded osmosis: I. Preliminary technical and economic correlations. J. Membr. Sci. 1976, 1, 49–63. [Google Scholar] [CrossRef]

- Wang, P.; Chung, T.-S. Recent advances in membrane distillation processes: Membrane development, configuration design and application exploring. J. Membr. Sci. 2015, 474, 39–56. [Google Scholar] [CrossRef]

- Ghaffour, N.; Soukane, S.; Lee, J.-G.; Kim, Y.; Alpatova, A. Membrane distillation hybrids for water production and energy efficiency enhancement: A critical review. Appl. Energy 2019, 254, 254. [Google Scholar] [CrossRef]

- Li, H.; Chen, V. Membrane Fouling and Cleaning in Food and Bioprocessing. In Membrane Technology; Cui, Z.F., Muralidhara, H.S., Eds.; Butterworth-Heinemann: Oxford, UK, 2010; pp. 213–254. [Google Scholar]

- Choudhury, M.R.; Anwar, N.; Jassby, D.; Rahaman, S. Fouling and wetting in the membrane distillation driven wastewater reclamation process–A review. Adv. Colloid Interface Sci. 2019, 269, 370–399. [Google Scholar] [CrossRef]

- Tijing, L.; Woo, Y.C.; Choi, J.-S.; Lee, S.; Kim, S.-H.; Shon, H.K. Fouling and its control in membrane distillation—A review. J. Membr. Sci. 2015, 475, 215–244. [Google Scholar] [CrossRef]

- Nagy, E.; Hegedüs, I.; Tow, E.W.; V, J.H.L. Effect of fouling on performance of pressure retarded osmosis (PRO) and forward osmosis (FO). J. Membr. Sci. 2018, 565, 450–462. [Google Scholar] [CrossRef]

- Bucs, S.S.; Linares, R.V.; Vrouwenvelder, J.S.; Picioreanu, C. Biofouling in forward osmosis systems: An experimental and numerical study. Water Res. 2016, 106, 86–97. [Google Scholar] [CrossRef]

- Goosen, M.F.A.; Sablani, S.S.; Al-Hinai, H.; Al-Obeidani, S.; Al-Belushi, R.; Jackson, D. Fouling of Reverse Osmosis and Ultrafiltration Membranes: A Critical Review. Sep. Sci. Technol. 2005, 39, 2261–2297. [Google Scholar] [CrossRef]

- Ghaffour, N.; Qamar, A. Membrane fouling quantification by specific cake resistance and flux enhancement using helical cleaners. Sep. Purif. Technol. 2020, 239, 116587. [Google Scholar] [CrossRef]

- Mulder, M. Basic Principles of Membrane Technology, 2nd ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2000; p. 417. [Google Scholar]

- Hermia, J. Constant pressure blocking filtration laws: Application to power-law non-newtonian fluids. Trans. Inst. Chem. Eng. 1982, 60, 183–187. [Google Scholar]

- Alhadidi, A.; Blankert, B.; Kemperman, A.; Schurer, R.; Schippers, J.; Wessling, M.; Van Der Meer, W. Limitations, improvements and alternatives of the silt density index. Desalination Water Treat. 2013, 51, 1104–1113. [Google Scholar] [CrossRef]

- Alhadidi, A.; Blankert, B.; Kemperman, A.J.B.; Schippers, J.C.; Wessling, M.; van der Meer, W.G.J. Sensitivity of SDI for experimental errors. Desalination Water Treat. 2012, 40, 100–117. [Google Scholar] [CrossRef]

- Alhadidi, A.; Blankert, B.; Kemperman, A.; Schippers, J.; Wessling, M.; Van Der Meer, W. Effect of testing conditions and filtration mechanisms on SDI. J. Membr. Sci. 2011, 381, 142–151. [Google Scholar] [CrossRef]

- Rachman, R.; Ghaffour, N.; Wali, F.; Amy, G. Assessment of silt density index (SDI) as fouling propensity parameter in reverse osmosis (RO) desalination systems. Desalination Water Treat. 2013, 51, 1091–1103. [Google Scholar] [CrossRef]

- Schippers, J.; Verdouw, J. The modified fouling index, a method of determining the fouling characteristics of water. Desalination 1980, 32, 137–148. [Google Scholar] [CrossRef]

- Futselaar, H.; Blankert, B.; Betlem, B.H.L.; Wessling, M. Method for Monitoring the Degree of Fouling in a Filter. U.S. Patent 7611634, 11 March 2009. [Google Scholar]

- Blankert, B.; Betlem, B.H.; Roffel, B. Dynamic optimization of dead-end membrane filtration. Comput. Aided Chem. Eng. 2006, 21, 1521–1525. [Google Scholar]

- Hoek, E.M.V.; Elimelech, M. Cake-Enhanced Concentration Polarization: A New Fouling Mechanism for Salt-Rejecting Membranes. Environ. Sci. Technol. 2003, 37, 5581–5588. [Google Scholar] [CrossRef]

- Chong, T.H.; Wong, F.; Fane, A. Enhanced concentration polarization by unstirred fouling layers in reverse osmosis: Detection by sodium chloride tracer response technique. J. Membr. Sci. 2007, 287, 198–210. [Google Scholar] [CrossRef]

- Blankert, B.; Kim, Y.; Vrouwenvelder, H.; Ghaffour, N. Facultative hybrid RO-PRO concept to improve economic performance of PRO: Feasibility and maximizing efficiency. Desalination 2020, 478, 114268. [Google Scholar] [CrossRef]

- Kim, Y.; Li, S.; Phuntsho, S.; Xie, M.; Shon, H.K.; Ghaffour, N. Understanding the organic micropollutants transport mechanisms in the fertilizer-drawn forward osmosis process. J. Environ. Manag. 2019, 248, 109240. [Google Scholar] [CrossRef]

- Thorsen, T.; Holt, T. The potential for power production from salinity gradients by pressure retarded osmosis. J. Membr. Sci. 2009, 335, 103–110. [Google Scholar] [CrossRef]

- Salinas-Rodriguez, S.G.; Amy, G.L.; Schippers, J.C.; Kennedy, M.D. The Modified Fouling Index Ultrafiltration constant flux for assessing particulate/colloidal fouling of RO systems. Desalination 2015, 365, 79–91. [Google Scholar] [CrossRef] [Green Version]

- Fane, A.G.; Chong, T.H.; Le-Clech, P. Membrane operations, innovative separations and transformations. In Fouling in Membrane Processes; Drioli, E., Giorno, I., Eds.; Wiley: Hoboken, NJ, USA, 2009; pp. 121–123. [Google Scholar]

- Bacchin, P.; Aimar, P.; Field, R. Critical and sustainable fluxes: Theory, experiments and applications. J. Membr. Sci. 2006, 281, 42–69. [Google Scholar] [CrossRef] [Green Version]

- Vrouwenvelder, J.; Van Paassen, J.; Van Agtmaal, J.; Van Loosdrecht, M.; Kruithof, J.; Vrouwenvelder, J.; Van Paassen, J.; Van Agtmaal, J.; Van Loosdrecht, M.; Kruithof, J. A critical flux to avoid biofouling of spiral wound nanofiltration and reverse osmosis membranes: Fact or fiction? J. Membr. Sci. 2009, 326, 36–44. [Google Scholar] [CrossRef]

| Experimental Condition | Constant Driving Force | Constant Flux | |

|---|---|---|---|

| Equal Initial Flux | Equal Driving Force | Equal Flux | |

| Observation | B has a higher average flux | A has a higher flux | A has a lower driving force |

| (1) Volume bias | Favors A | Favors B | None |

| (2) Flux bias | Favors A | Favors B | None |

| (3) Normalization bias | Favors B Occurs in J(t), J(v), and relative fouling indicators | Favors B Occurs in relative fouling indicators | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blankert, B.; Van der Bruggen, B.; Childress, A.E.; Ghaffour, N.; Vrouwenvelder, J.S. Potential Pitfalls in Membrane Fouling Evaluation: Merits of Data Representation as Resistance Instead of Flux Decline in Membrane Filtration. Membranes 2021, 11, 460. https://doi.org/10.3390/membranes11070460

Blankert B, Van der Bruggen B, Childress AE, Ghaffour N, Vrouwenvelder JS. Potential Pitfalls in Membrane Fouling Evaluation: Merits of Data Representation as Resistance Instead of Flux Decline in Membrane Filtration. Membranes. 2021; 11(7):460. https://doi.org/10.3390/membranes11070460

Chicago/Turabian StyleBlankert, Bastiaan, Bart Van der Bruggen, Amy E. Childress, Noreddine Ghaffour, and Johannes S. Vrouwenvelder. 2021. "Potential Pitfalls in Membrane Fouling Evaluation: Merits of Data Representation as Resistance Instead of Flux Decline in Membrane Filtration" Membranes 11, no. 7: 460. https://doi.org/10.3390/membranes11070460

APA StyleBlankert, B., Van der Bruggen, B., Childress, A. E., Ghaffour, N., & Vrouwenvelder, J. S. (2021). Potential Pitfalls in Membrane Fouling Evaluation: Merits of Data Representation as Resistance Instead of Flux Decline in Membrane Filtration. Membranes, 11(7), 460. https://doi.org/10.3390/membranes11070460