Mass Transfer Analysis of Air-Cooled Membrane Distillation Configuration for Desalination

Abstract

1. Introduction

2. Methods

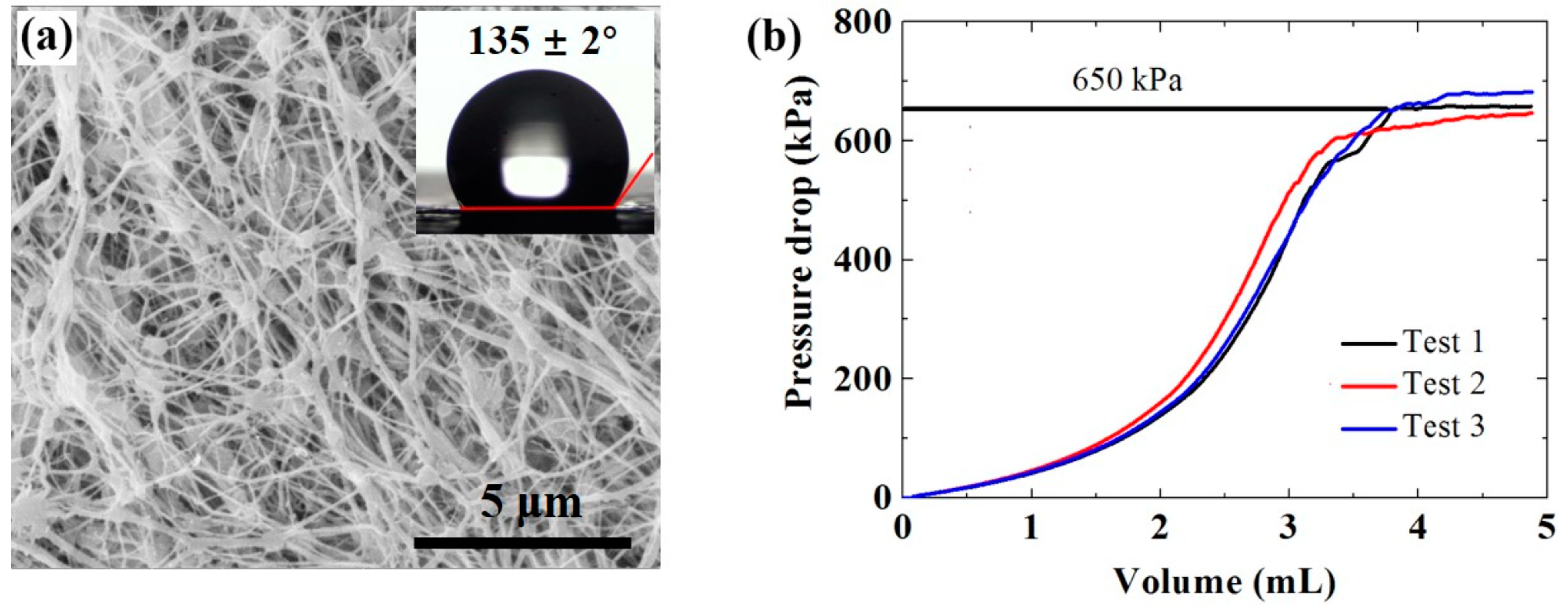

2.1. Membrane Characterization

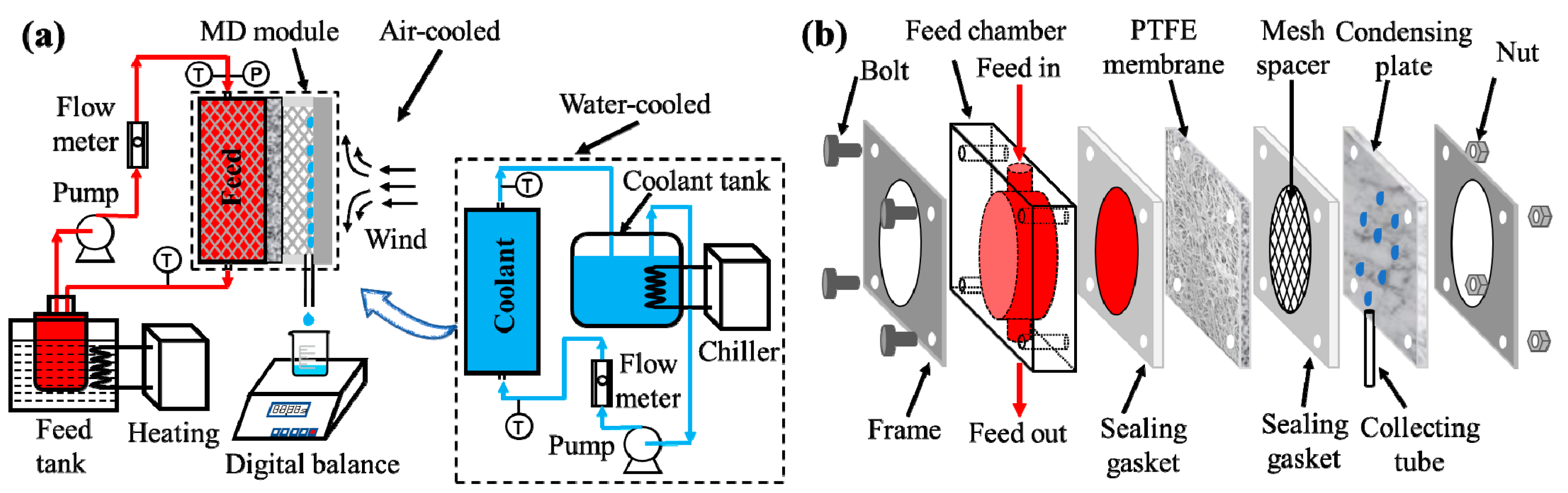

2.2. Membrane Distillation Apparatuses and Tests

3. Results and Discussion

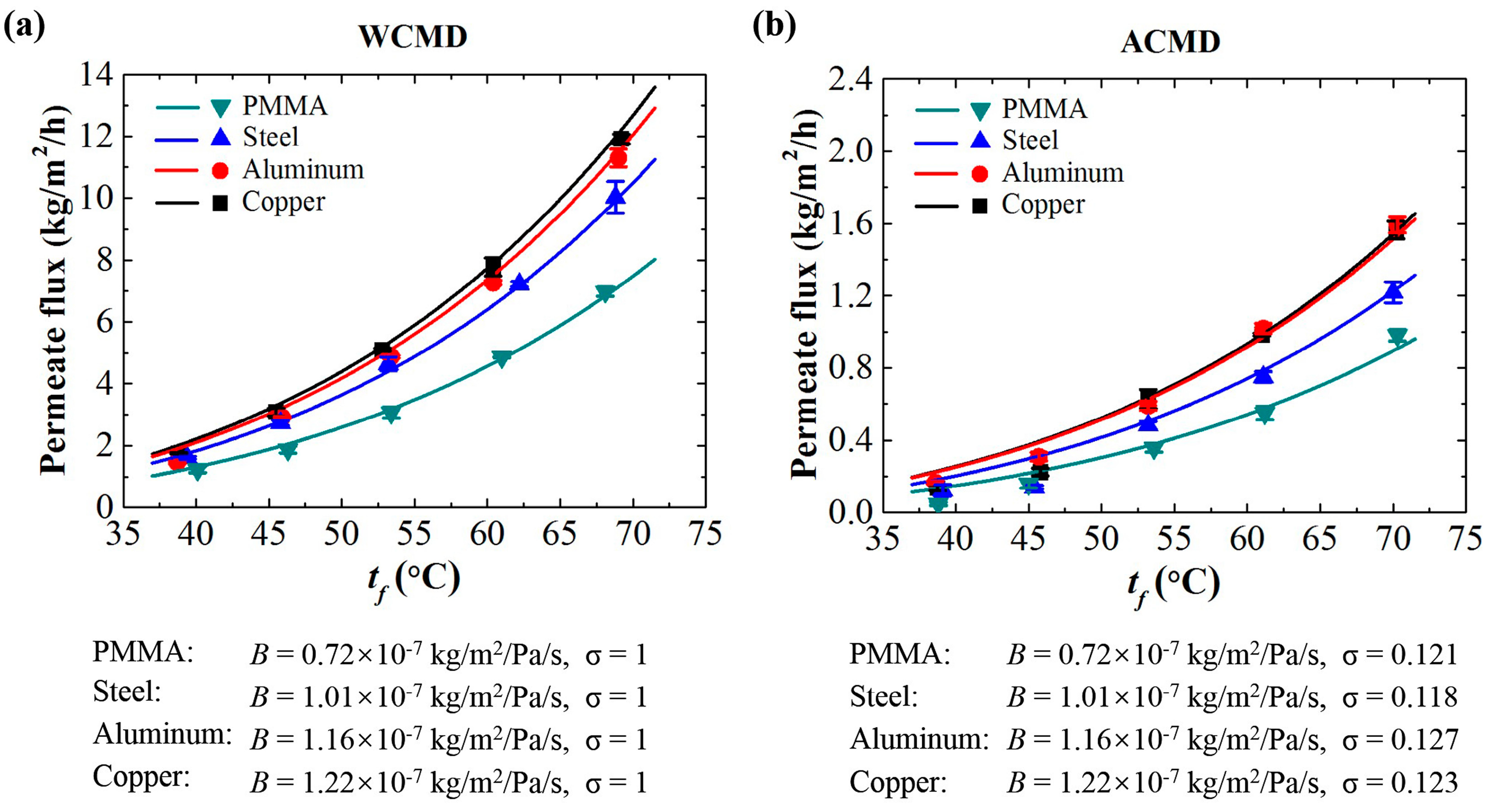

3.1. Feasibility of ACMD Configuration

3.2. Mass Transfer Model for ACMD Configuration

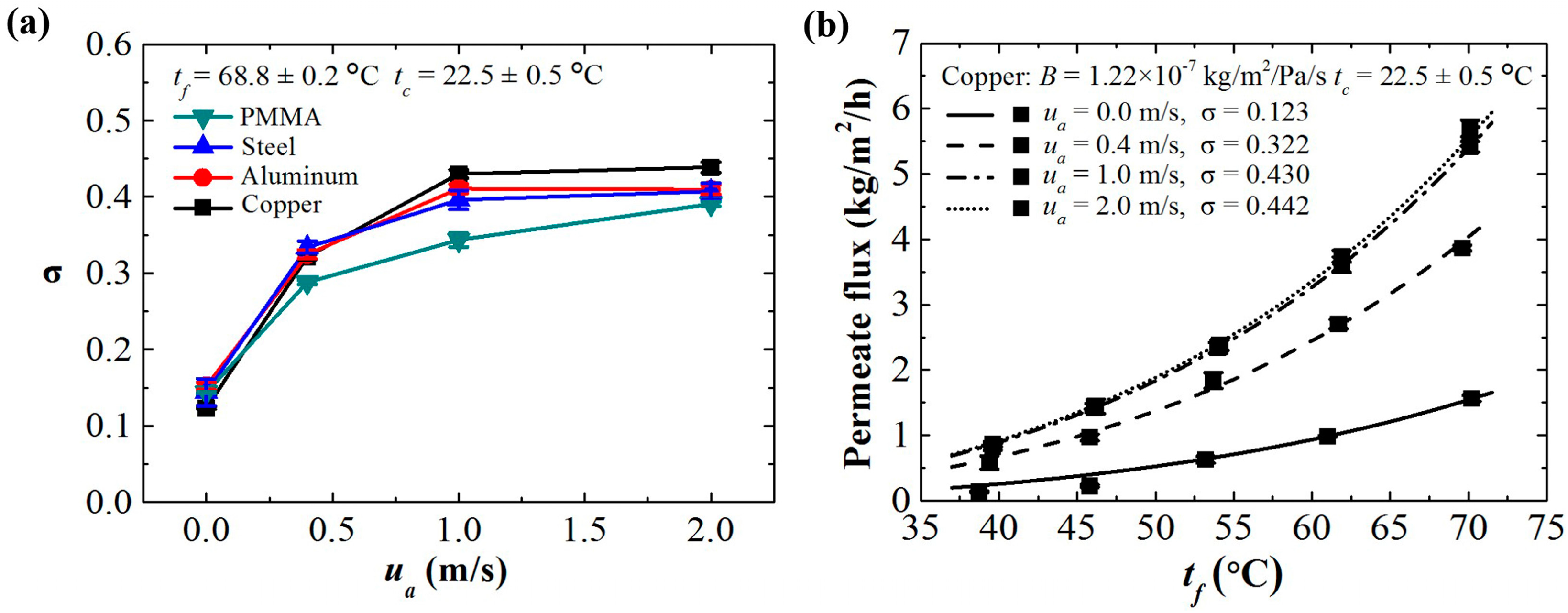

3.3. Capacity Factor and Efficiency Factor

3.4. Forced Convection ACMD

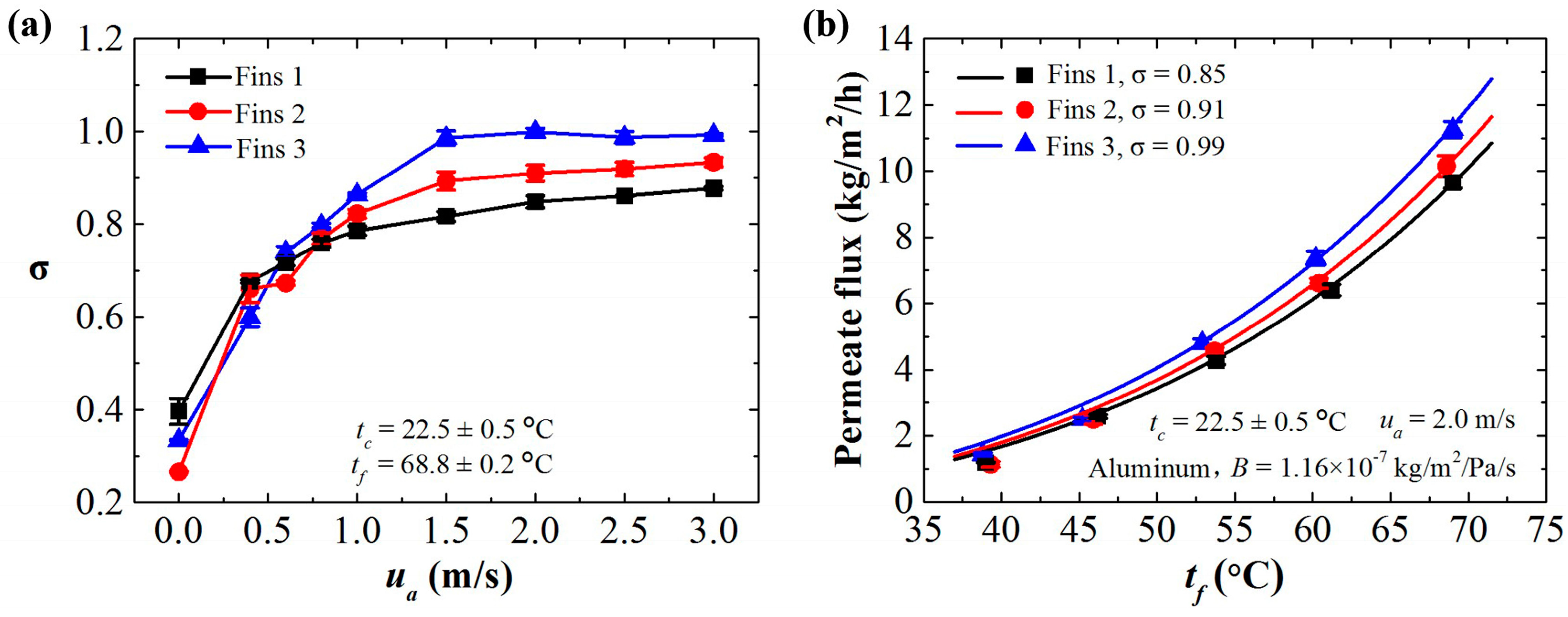

3.5. Effect of Cooling Fins

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | |

| side area of the fins (mm2) | |

| surface area of the substrate (mm2) | |

| mass transfer coefficient of the MD process (kg/m2/Pa/s) | |

| height of the fins (mm) | |

| permeate flux (kg/m2/h) | |

| length of the fins (mm) | |

| number of the fin | |

| saturated vapor pressure | |

| salt rejection ratio | |

| temperature (°C) | |

| velocity (m/s) | |

| width of the fins (mm) | |

| Greek letters | |

| thickness (m) | |

| thickness of the substrate (mm) | |

| the fin pitch (mm) | |

| thickness of the inner fin (mm) | |

| thickness of the outer fin (mm) | |

| thermal conductivity (W/m/K) | |

| specific correction value | |

| temperature correction coefficient | |

| surface area ratio of the condensing plate | |

| Subscripts | |

| a | cooling air |

| c | cooling side |

| cp | condensing plate |

| f | feed side |

| fin | rectangular straight fins |

| w | cooling water |

| Abbreviations | |

| ACMD | air-cooled membrane distillation |

| GMD | gap membrane distillation |

| LEP | liquid entry pressure |

| MD | membrane distillation |

| PMMA | polymethyl methacrylate |

| PTFE | polytetrafluoroethylene |

| RO | reverse osmosis |

| SEM | scanning electron microscope |

| WCA | water contact angle |

| WCMD | water-cooled membrane distillation |

References

- Alkhudhiri, A.; Darwish, N.; Hilal, N. Membrane distillation: A comprehensive review. Desalination 2012, 287, 2–18. [Google Scholar] [CrossRef]

- Drioli, E.; Ali, A.; Macedonio, F. Membrane distillation: Recent developments and perspectives. Desalination 2015, 356, 56–84. [Google Scholar] [CrossRef]

- Khayet, M. Membranes and theoretical modeling of membrane distillation: A review. Adv. Colloid Interface Sci. 2011, 164, 56–88. [Google Scholar] [CrossRef]

- Miller, J.A.; Lienhard, J.H., V. Impact of extraction on a humidification–dehumidification desalination system. Desalination 2013, 313, 87–96. [Google Scholar] [CrossRef]

- Christ, A.; Regenauer-Lieb, K.; Chua, H.T. Thermodynamic optimisation of multi effect distillation driven by sensible heat sources. Desalination 2014, 336, 160–167. [Google Scholar] [CrossRef]

- Okamoto, Y.; Lienhard, J.H. How RO membrane permeability and other performance factors affect process cost and energy use: A review. Desalination 2019, 470, 114064. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Z.; Lin, S.; Jin, H.; Gao, S.; Zhu, Y.; Jin, J. Nanoparticle-templated nanofiltration membranes for ultrahigh performance desalination. Nat. Commun. 2018, 9, 2004. [Google Scholar] [CrossRef]

- Essalhi, M.; Khayet, M. Application of a porous composite hydrophobic/hydrophilic membrane in desalination by air gap and liquid gap membrane distillation: A comparative study. Sep. Purif. Technol. 2014, 133, 176–186. [Google Scholar] [CrossRef]

- Woo, Y.C.; Tijing, L.D.; Shim, W.-G.; Choi, J.-S.; Kim, S.-H.; He, T.; Drioli, E.; Shon, H.K. Water desalination using graphene-enhanced electrospun nanofiber membrane via air gap membrane distillation. J. Membr. Sci. 2016, 520, 99–110. [Google Scholar] [CrossRef]

- Cong, S.; Guo, F. Janus Nanofibrous Membranes for Desalination by Air Gap Membrane Distillation. ACS Appl. Polym. Mater. 2019, 1, 3443–3451. [Google Scholar] [CrossRef]

- Cai, J.; Liu, Z.; Guo, F. Transport Analysis of Anti-Wetting Composite Fibrous Membranes for Membrane Distillation. Membranes 2020, 11, 14. [Google Scholar] [CrossRef]

- Ray, S.S.; Bakshi, H.S.; Dangayach, R.; Singh, R.; Deb, C.K.; Ganesapillai, M.; Chen, S.-S.; Purkait, M.K. Recent Developments in Nanomaterials-Modified Membranes for Improved Membrane Distillation Performance. Membranes 2020, 10, 140. [Google Scholar] [CrossRef]

- Alsaadi, A.; Ghaffour, N.; Li, J.-D.; Gray, S.; Francis, L.; Maab, H.; Amy, G. Modeling of air-gap membrane distillation process: A theoretical and experimental study. J. Membr. Sci. 2013, 445, 53–65. [Google Scholar] [CrossRef]

- Im, B.-G.; Lee, J.-G.; Kim, Y.-D.; Kim, W.-S. Theoretical modeling and simulation of AGMD and LGMD desalination processes using a composite membrane. J. Membr. Sci. 2018, 565, 14–24. [Google Scholar] [CrossRef]

- Cai, J.; Guo, F. Mass transfer during membrane distillation treatment of wastewater from hot-dip galvanization. Sep. Purif. Technol. 2020, 235, 116164. [Google Scholar] [CrossRef]

- Damtie, M.M.; Woo, Y.C.; Kim, B.; Park, K.-D.; Hailemariam, R.H.; Shon, H.K.; Choi, J.-S. Analysis of mass transfer behavior in membrane distillation: Mathematical modeling under various conditions. Chemosphere 2019, 236, 124289. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Dai, X.; Zhao, L.; Gao, L.; Xie, Z.; Zhang, J. Review of Transport Phenomena and Popular Modelling Approaches in Membrane Distillation. Membranes 2021, 11, 122. [Google Scholar] [CrossRef]

- Warsinger, D.E.; Swaminathan, J.; Maswadeh, L.A.; Lienhard, J.H., V. Superhydrophobic condenser surfaces for air gap membrane distillation. J. Membr. Sci. 2015, 492, 578–587. [Google Scholar] [CrossRef]

- Warsinger, D.M.; Swaminathan, J.; Morales, L.L.; Lienhard, J.H., V. Comprehensive condensation flow regimes in air gap membrane distillation: Visualization and energy efficiency. J. Membr. Sci. 2018, 555, 517–528. [Google Scholar] [CrossRef]

- Manawi, Y.M.; Khraisheh, M.; Fard, A.K.; Benyahia, F.; Adham, S. Effect of operational parameters on distillate flux in direct contact membrane distillation (DCMD): Comparison between experimental and model predicted performance. Desalination 2014, 336, 110–120. [Google Scholar] [CrossRef]

- Khayet, M.; Cojocaru, C. Air gap membrane distillation: Desalination, modeling and optimization. Desalination 2012, 287, 138–145. [Google Scholar] [CrossRef]

- Guo, F.; Servi, A.T.; Liu, A.; Gleason, K.K.; Rutledge, G.C. Desalination by Membrane Distillation using Electrospun Polyamide Fiber Membranes with Surface Fluorination by Chemical Vapor Deposition. ACS Appl. Mater. Interfaces 2015, 7, 8225–8232. [Google Scholar] [CrossRef]

- Francis, L.; Ghaffour, N.; Alsaadi, A.A.; Amy, G.L. Material gap membrane distillation: A new design for water vapor flux enhancement. J. Membr. Sci. 2013, 448, 240–247. [Google Scholar] [CrossRef]

- Cai, J.; Yin, H.; Guo, F. Transport analysis of material gap membrane distillation desalination processes. Desalination 2020, 481, 114361. [Google Scholar] [CrossRef]

- Swaminathan, J.; Chung, H.W.; Warsinger, D.M.; AlMarzooqi, F.A.; Arafat, H.A.; Lienhard, J.H., V. Energy efficiency of permeate gap and novel conductive gap membrane distillation. J. Membr. Sci. 2016, 502, 171–178. [Google Scholar] [CrossRef]

- Yazgan-Birgi, P.; Ali, M.I.H.; Swaminathan, J.; Lienhard, J.H.; Arafat, H.A. Computational fluid dynamics modeling for performance assessment of permeate gap membrane distillation. J. Membr. Sci. 2018, 568, 55–66. [Google Scholar] [CrossRef]

- Khayet, M. Treatment of radioactive wastewater solutions by direct contact membrane distillation using surface modified membranes. Desalination 2013, 321, 60–66. [Google Scholar] [CrossRef]

- Quist-Jensen, C.; Macedonio, F.; Conidi, C.; Cassano, A.; Aljlil, S.; Alharbi, O.; Drioli, E. Direct contact membrane distillation for the concentration of clarified orange juice. J. Food Eng. 2016, 187, 37–43. [Google Scholar] [CrossRef]

- Laqbaqbi, M.; García-Payo, M.; Khayet, M.; El Kharraz, J.; Chaouch, M. Application of direct contact membrane distillation for textile wastewater treatment and fouling study. Sep. Purif. Technol. 2019, 209, 815–825. [Google Scholar] [CrossRef]

- Xu, S.; Xu, L.; Wu, X.; Wang, P.; Jin, N.; Hu, J.; Zhang, S.; Leng, Q.; Wu, D. Air-gap diffusion distillation: Theory and experiment. Desalination 2019, 467, 64–78. [Google Scholar] [CrossRef]

- Pangarkar, B.L.; Deshmukh, S.K. Theoretical and experimental analysis of multi-effect air gap membrane distillation process (ME-AGMD). J. Environ. Chem. Eng. 2015, 3, 2127–2135. [Google Scholar] [CrossRef]

- Narayan, A.; Pitchumani, R. Analysis of an air-cooled air gap membrane distillation module. Desalination 2020, 475, 114179. [Google Scholar] [CrossRef]

- Cong, S.; Liu, X.; Guo, F. Membrane distillation using surface modified multi-layer porous ceramics. Int. J. Heat Mass Transf. 2019, 129, 764–772. [Google Scholar] [CrossRef]

- Cai, J.; Liu, X.; Zhao, Y.; Guo, F. Membrane desalination using surface fluorination treated electrospun polyacrylonitrile membranes with nonwoven structure and quasi-parallel fibrous structure. Desalination 2018, 429, 70–75. [Google Scholar] [CrossRef]

- Cai, J.; Guo, F. Study of mass transfer coefficient in membrane desalination. Desalination 2017, 407, 46–51. [Google Scholar] [CrossRef]

| Material | Thermal Conductivity (W/m/K) | WCA (°) | |

|---|---|---|---|

| 1 | Copper | 398 | 46 ± 3 |

| 2 | Aluminum | 234 | 65 ± 2 |

| 3 | Steel | 18 | 82 ± 6 |

| 4 | PMMA | 0.18 | 68 ± 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cong, S.; Miao, Q.; Guo, F. Mass Transfer Analysis of Air-Cooled Membrane Distillation Configuration for Desalination. Membranes 2021, 11, 281. https://doi.org/10.3390/membranes11040281

Cong S, Miao Q, Guo F. Mass Transfer Analysis of Air-Cooled Membrane Distillation Configuration for Desalination. Membranes. 2021; 11(4):281. https://doi.org/10.3390/membranes11040281

Chicago/Turabian StyleCong, Shuo, Qingxiu Miao, and Fei Guo. 2021. "Mass Transfer Analysis of Air-Cooled Membrane Distillation Configuration for Desalination" Membranes 11, no. 4: 281. https://doi.org/10.3390/membranes11040281

APA StyleCong, S., Miao, Q., & Guo, F. (2021). Mass Transfer Analysis of Air-Cooled Membrane Distillation Configuration for Desalination. Membranes, 11(4), 281. https://doi.org/10.3390/membranes11040281