“Artificial Wood” Lignocellulosic Membranes: Influence of Kraft Lignin on the Properties and Gas Transport in Tunicate-Based Nanocellulose Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

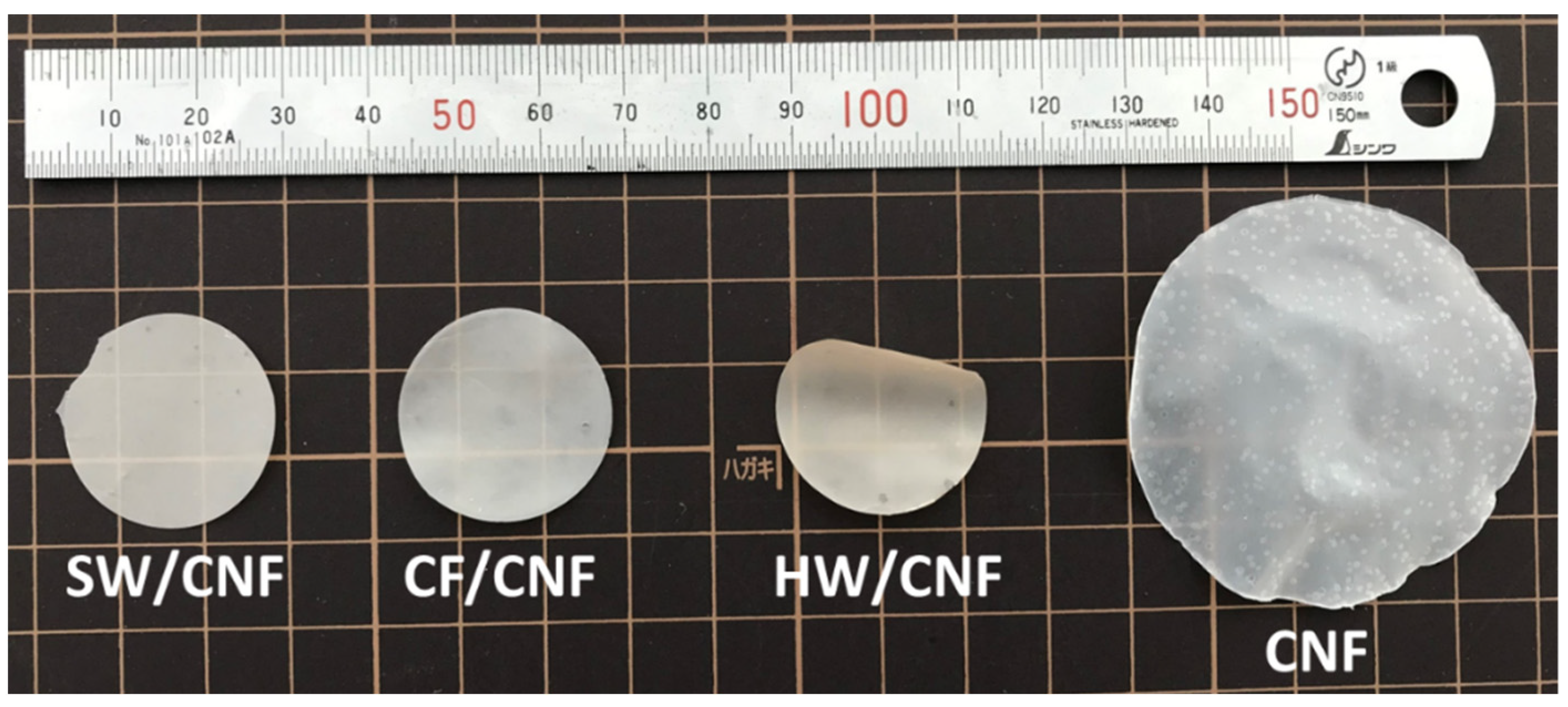

2.2. Preparation of Lignin–Tunicate CNF–Starch Membranes

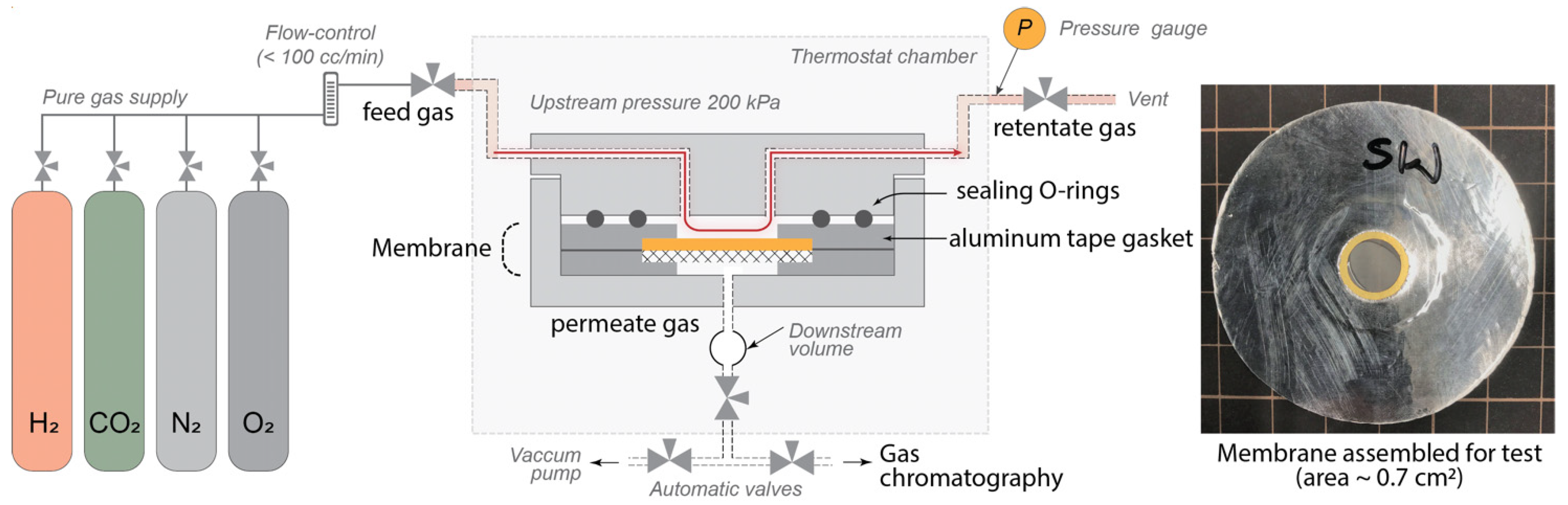

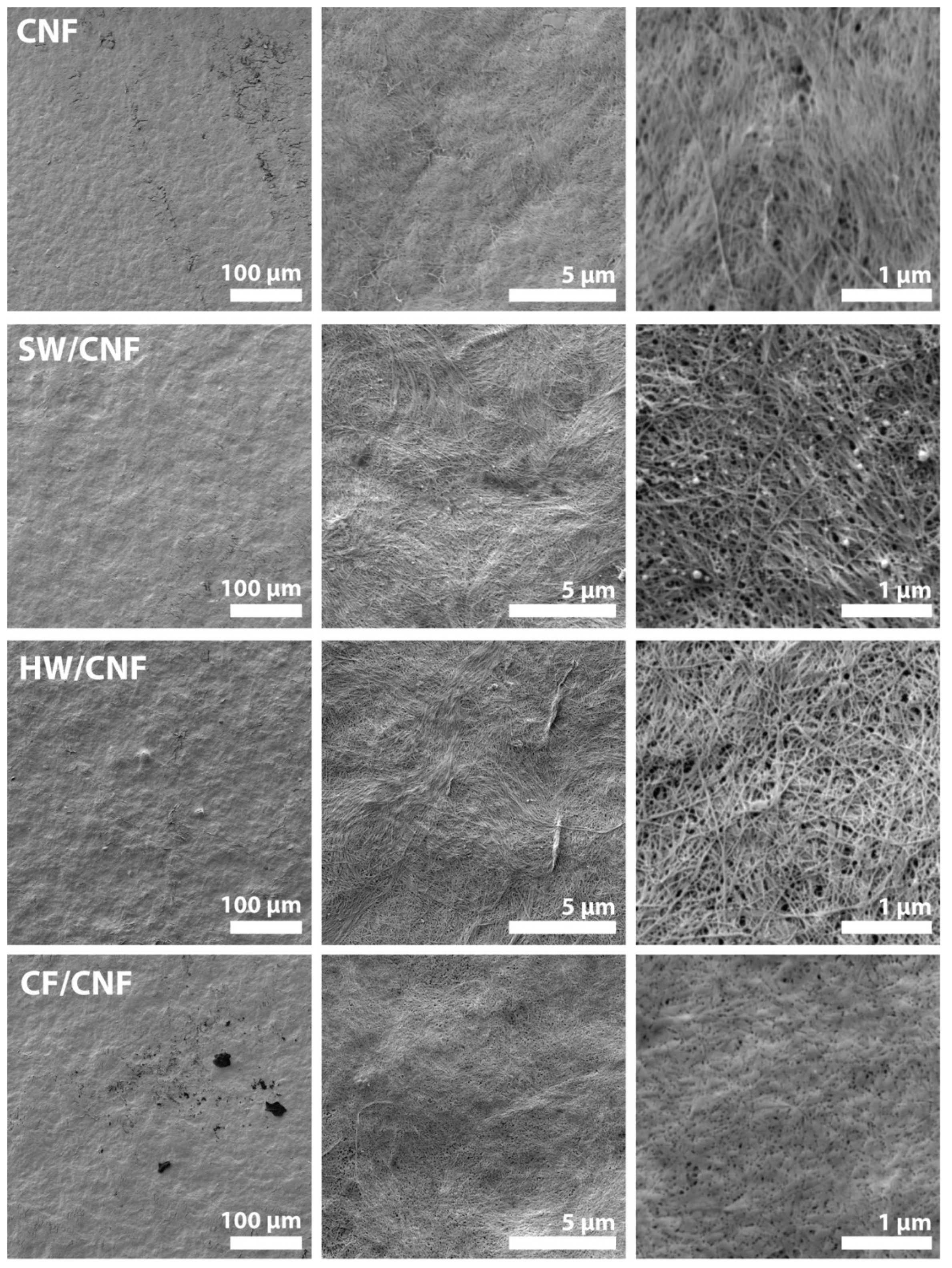

2.3. Characterization

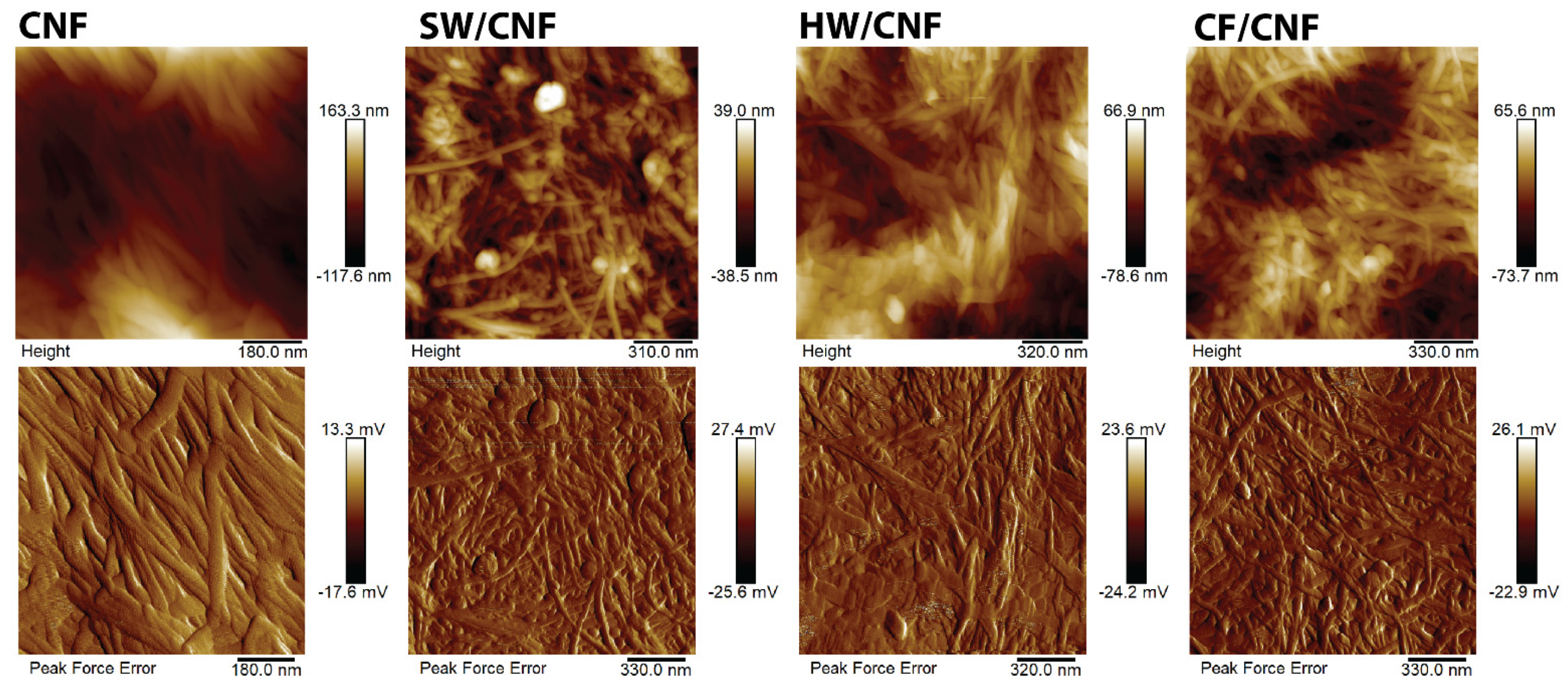

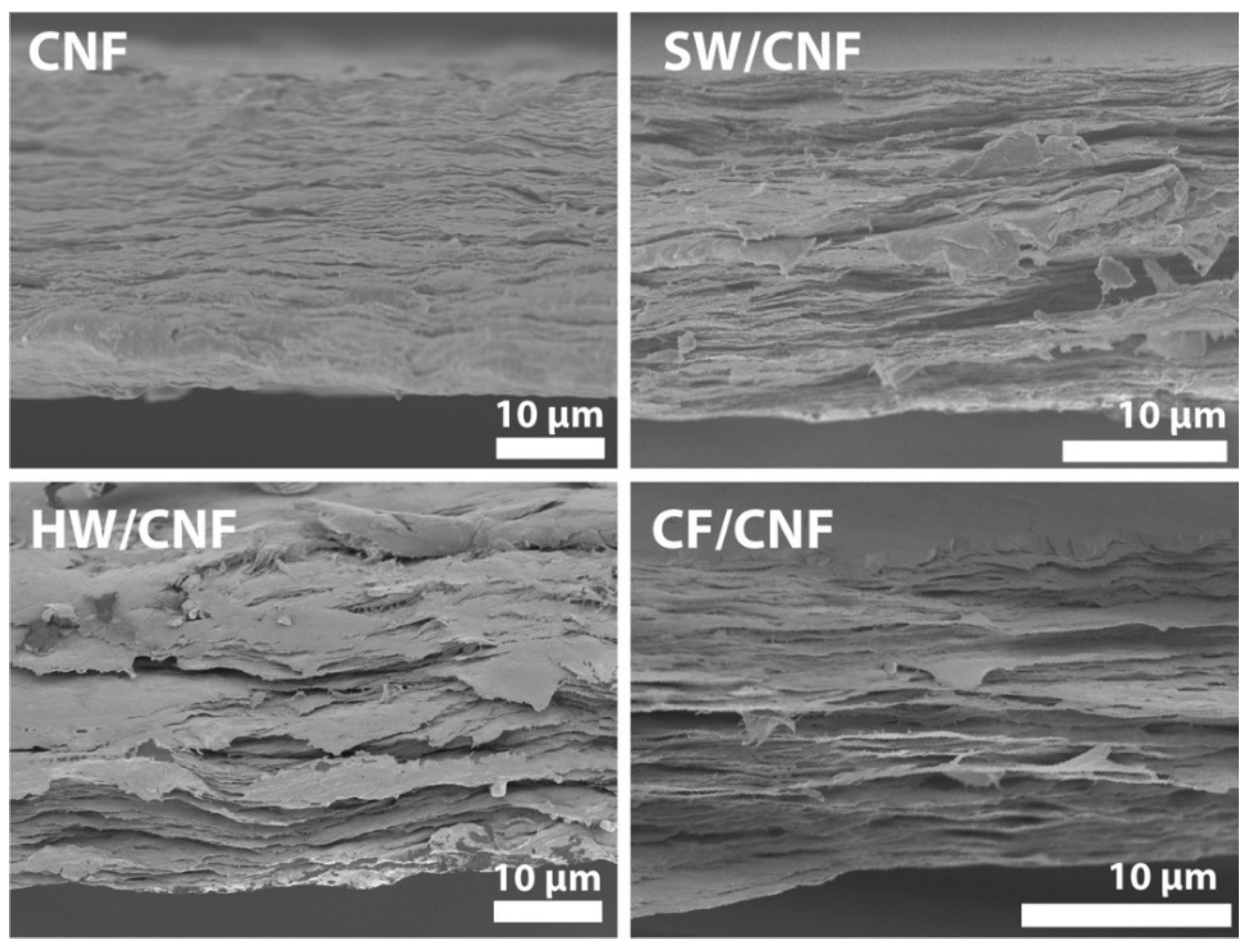

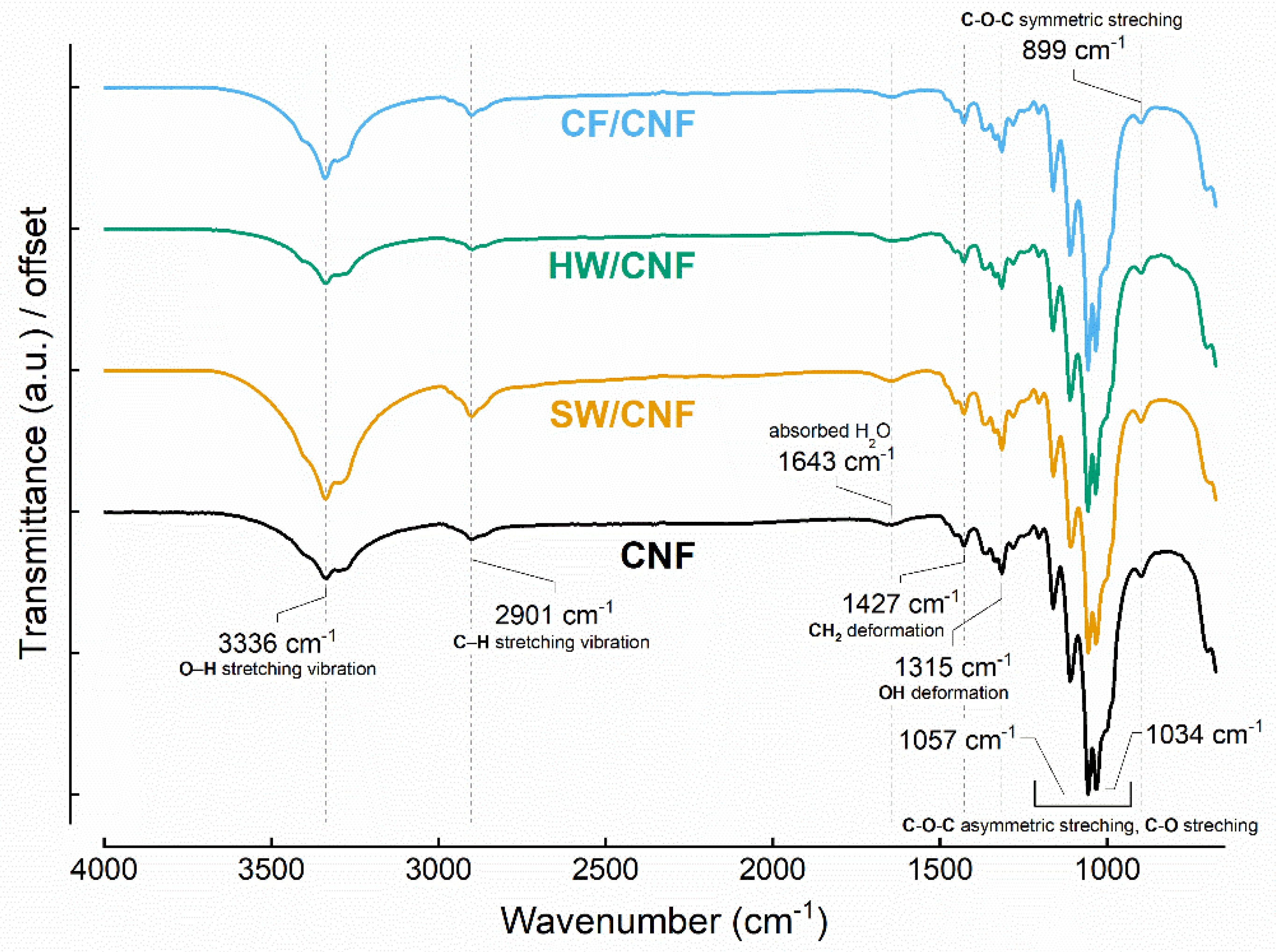

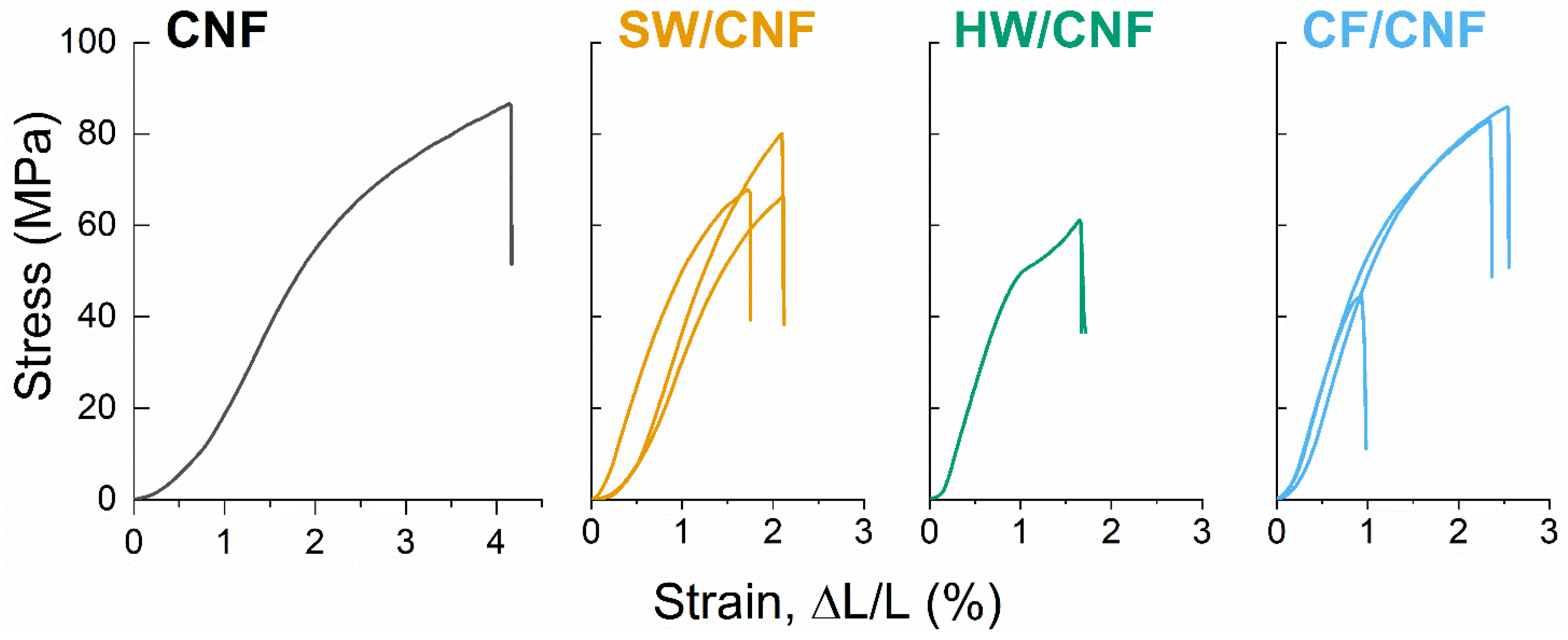

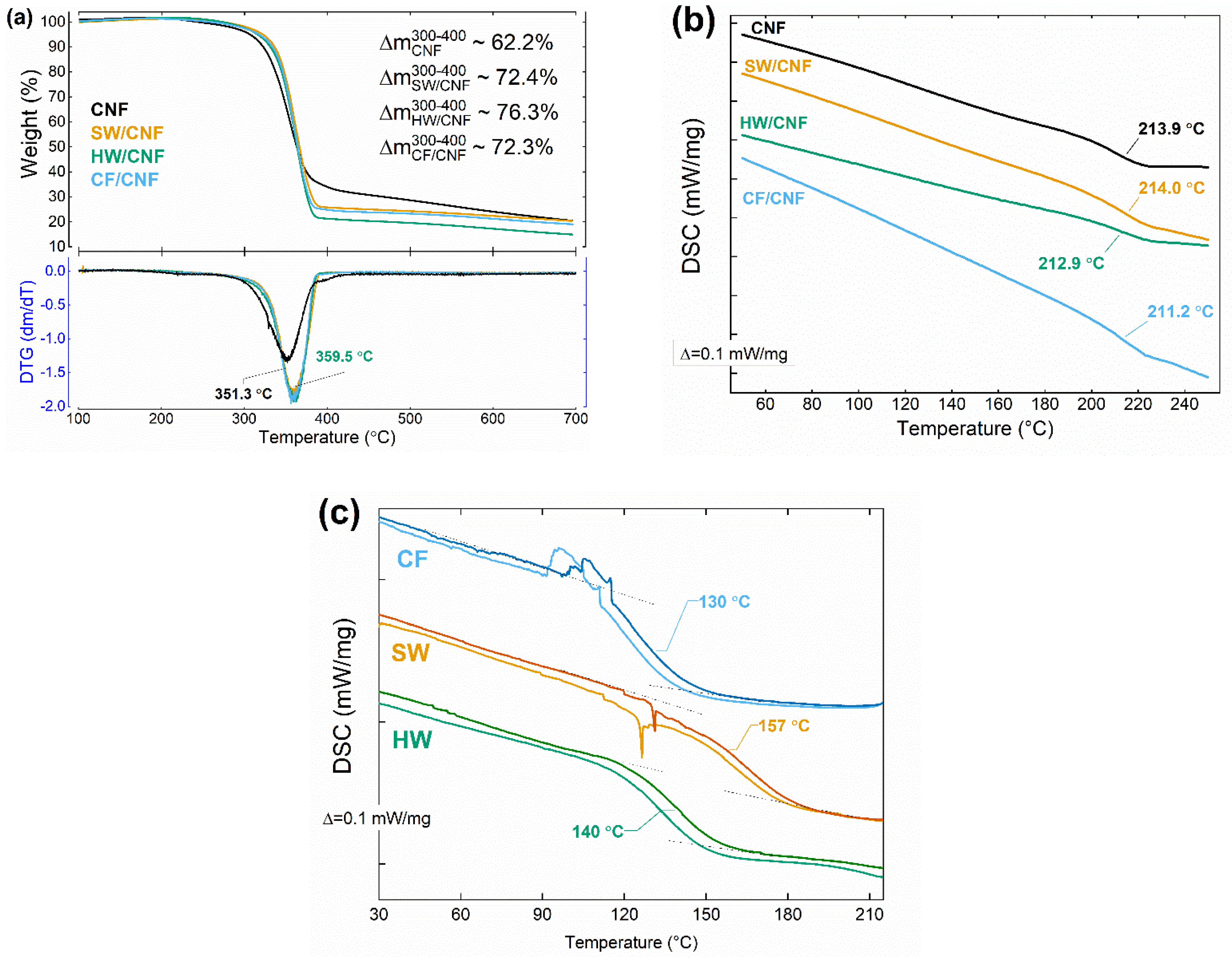

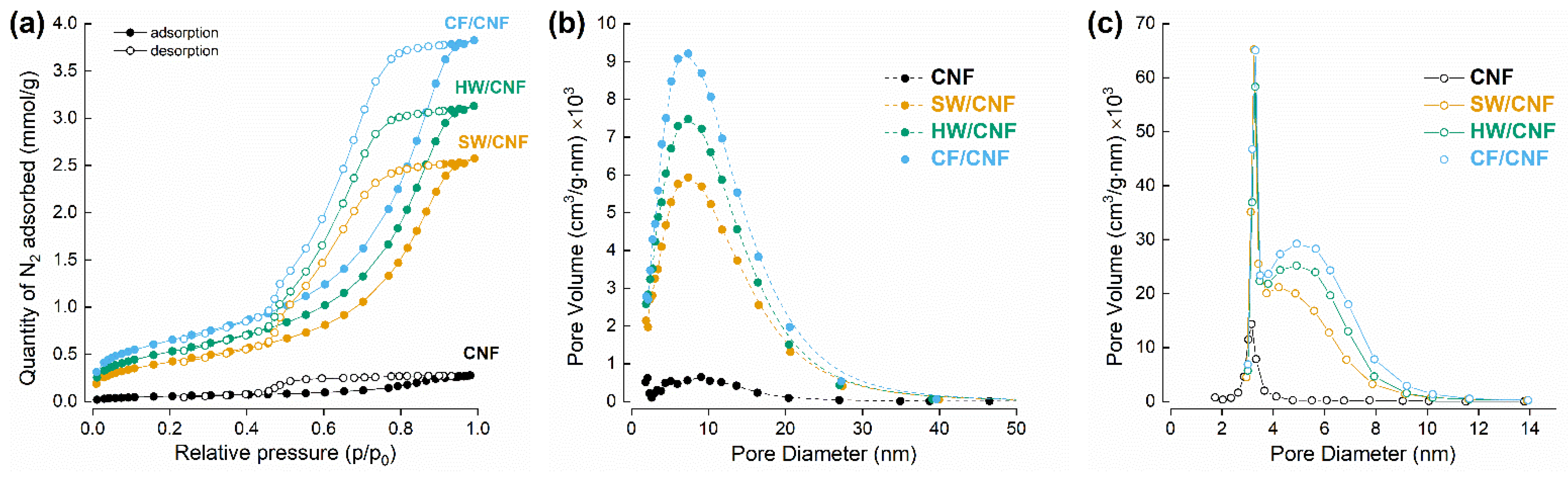

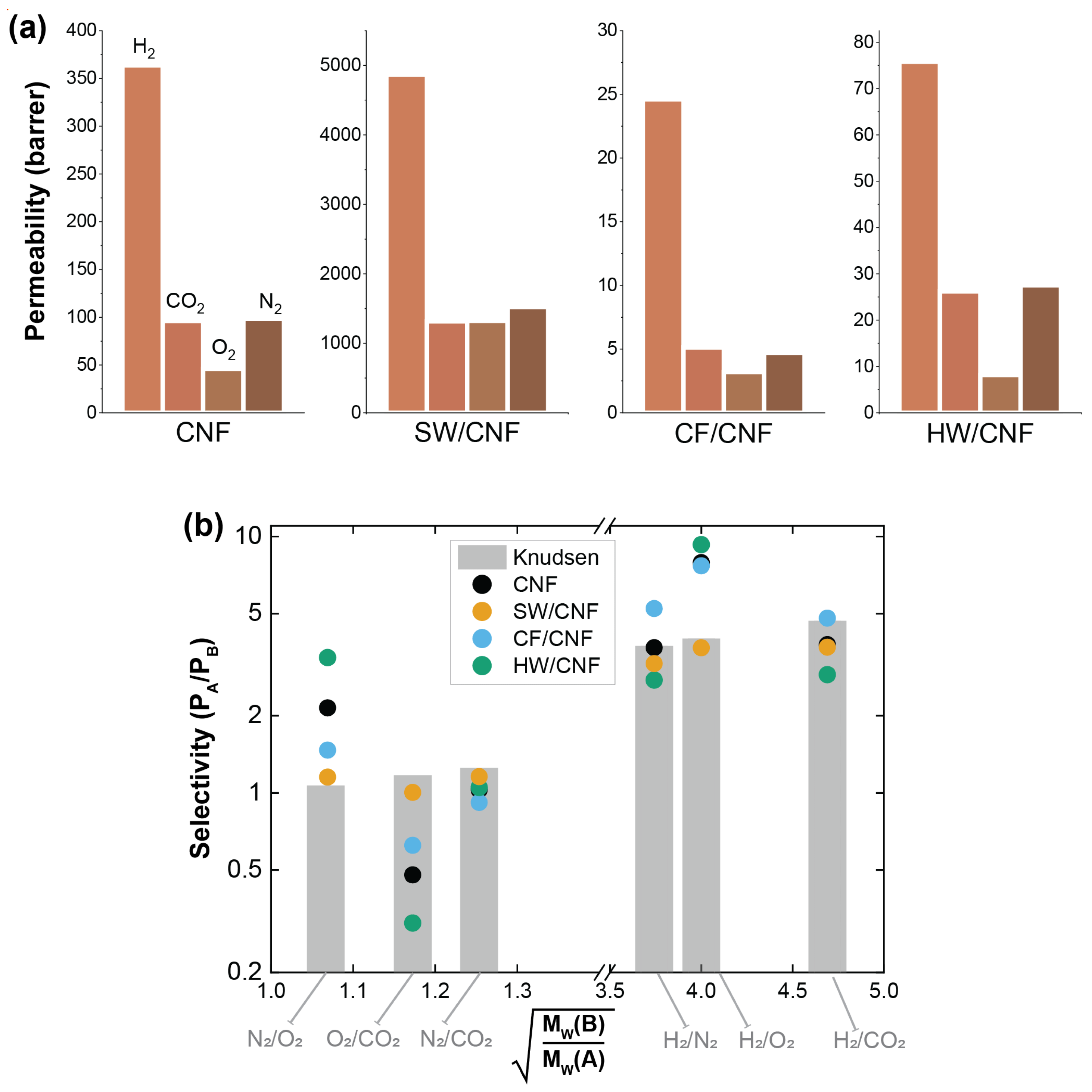

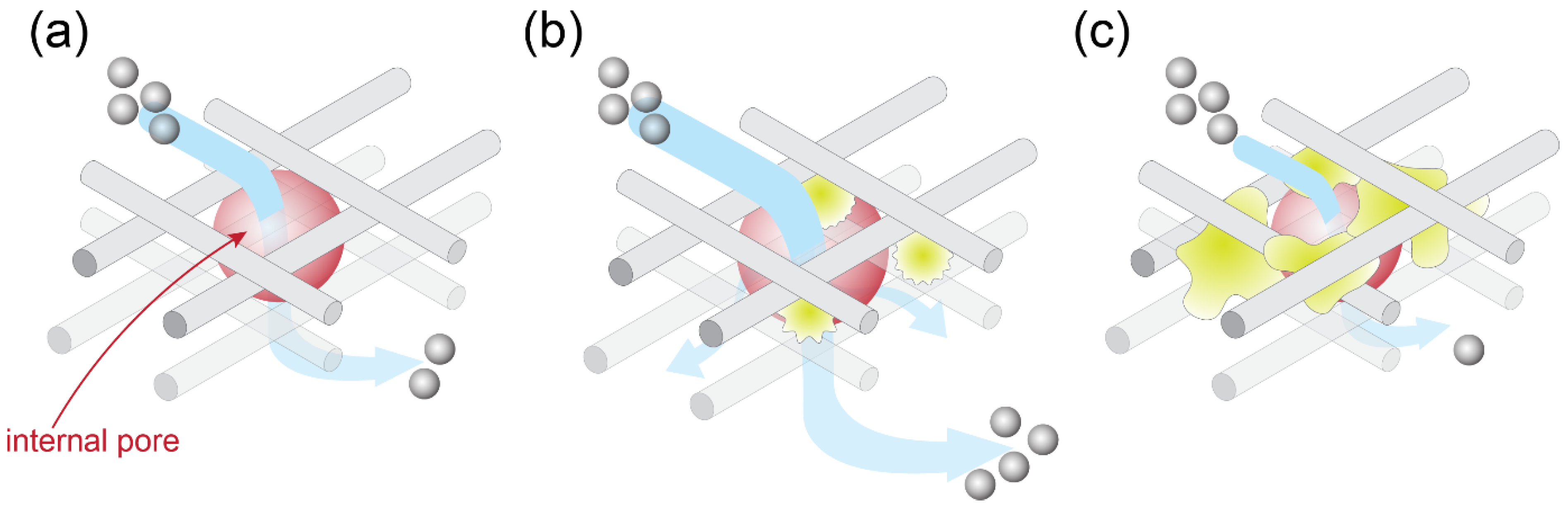

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Membrane Description | Preparation Method | Thickness, µm | Gas Permeability Test | Permeability, Barrer (± SD Where Available) | Ref. | |||

|---|---|---|---|---|---|---|---|---|

| CO2 | N2 | O2 | H2 | |||||

| Cellulose whiskers (W) from native sisal fibers | casting aqueous solutions in Teflon molds, evaporation at 25 °C, 5 days | ~20 | CVVP a, Δp = 1 bar | 118.8 ± 1.2 | 161.7 ± 3.2 | 140.7 ± 2.7 | — | [44] |

| Microfibrillated cellulose (MFC) from native sisal fibers | 0.100 ± 0.002 | 0.150 ± 0.004 | 0.090 ± 0.001 | — | ||||

| TEMPO-oxidized cellulose nanofibrils with free carboxyl groups (TOCN-COOH) | casting aqueous dispersions of 0.1% (w/v) on PET film followed by drying | ~13 | Differential pressure b | 2.02 × 10−6 | 7.07 × 10−8 | 4.95 × 10−7 | 2.41 × 10−5 | [45] |

| TEMPO-oxidized cellulose nanofibrils with sodium carboxylate groups (TOCN-COONa) | ~13 | 2.03 × 10−6 | 1.18 × 10−7 | 8.57 × 10−7 | 2.46 × 10−4 | |||

| Cellulose nanocrystals (CNC) | Vacuum filtration followed by hot-pressing for 20 min (at 110 °C and 1.1 MPa) | ~30 | Differential pressure b, Δp = 2 bar, r.t. | — | — | — | 1.33 × 10−2 | [12] |

| Cellulose nanofibers (CNF) | ~30 | — | — | — | 3.80 × 10−2 | |||

| Sulfonated cellulose nanofibers (CNF) | ~30 | — | — | — | 1.41 × 10−1 | |||

| Carboxymethyl cellulose (CMC) | casting aqueous dispersions of 2% on stainless-steel substrate followed by vacuum drying | n/a | CVVP a, pure gases, Δp = 1 bar a | 2.50 × 10−5 | 1.02 × 10−5 | — | 1.48 × 10−4 | [46] |

| CNF (tunicate) | casting aqueous dispersions of 0.5% (w/v) in PS molds followed by drying | 37 | Differential pressure b, Δp = 2 bar, r.t. | 96 ± 0.7 | 98.7 ± 0.9 | 46 ± 4.9 | 363.5 ± 12.5 | This work |

| SW/CNF | 22 | 1315 ± 6 | 1523 ± 7 | 1321 ± 19 | 4864 ± 45 | |||

| HW/CNF | 22 | 26.2 ± 0.4 | 27.5 ± 0.4 | 8.2 ± 0.8 | 75.8 ± 3.4 | |||

| CF/CNF | 24 | 5.1 ± 0.2 | 4.7 ± 0.4 | 3.2 ± 0.4 | 24.6 ± 1.3 | |||

References

- Thomas, B.; Raj, M.C.; Athira, B.K.; Rubiyah, H.M.; Joy, J.; Moores, A.; Drisko, G.L.; Sanchez, C. Nanocellulose, a Versatile Green Platform: From Biosources to Materials and Their Applications. Chem. Rev. 2018, 118, 11575–11625. [Google Scholar] [CrossRef] [PubMed]

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Selyanchyn, O.; Selyanchyn, R.; Lyth, S.M. A Review of Proton Conductivity in Cellulosic Materials. Front. Energy Res. 2020, 8, 1–17. [Google Scholar] [CrossRef]

- Trovagunta, R.; Zou, T.; Österberg, M.; Kelley, S.S.; Lavoine, N. Design strategies, properties and applications of cellulose nanomaterials-enhanced products with residual, technical or nanoscale lignin—A review. Carbohydr. Polym. 2021, 254. [Google Scholar] [CrossRef] [PubMed]

- Lavoine, N.; Bergström, L. Nanocellulose-based foams and aerogels: Processing, properties, and applications. J. Mater. Chem. A 2017, 5, 16105–16117. [Google Scholar] [CrossRef]

- Geng, S.; Wei, J.; Jonasson, S.; Hedlund, J.; Oksman, K. Multifunctional Carbon Aerogels with Hierarchical Anisotropic Structure Derived from Lignin and Cellulose Nanofibers for CO2 Capture and Energy Storage. ACS Appl. Mater. Interfaces 2020, 12, 7432–7441. [Google Scholar] [CrossRef]

- Alammar, A.; Park, S.-H.; Ibrahim, I.; Arun, D.; Holtzl, T.; Dumée, L.F.; Lim, H.-N.; Szekely, G. Architecting neonicotinoid-scavenging nanocomposite hydrogels for environmental remediation. Appl. Mater. Today. 2020, 21, 100878. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, Y.; Bian, T.; Zhang, Y.; Li, Z.; Pan, J. Oxidized carbon materials cooperative construct ionic imprinted cellulose nanocrystals films for efficient adsorption of Dy(III). Chem. Eng. J. 2020, 381, 122669. [Google Scholar] [CrossRef]

- Porter, C.J.; Werber, J.R.; Ritt, C.L.; Guan, Y.-F.; Zhong, M.; Elimelech, M. Controlled grafting of polymer brush layers from porous cellulosic membranes. J. Membr. Sci. 2020, 596, 117719. [Google Scholar] [CrossRef]

- Ansaloni, L.; Salas-Gay, J.; Ligi, S.; Baschetti, M.G. Nanocellulose-based membranes for CO2 capture. J. Memb. Sci. 2017, 522, 216–225. [Google Scholar] [CrossRef]

- Bayer, T.; Cunning, B.V.; Selyanchyn, R.; Nishihara, M.; Fujikawa, S.; Sasaki, K.; Lyth, S.M. High temperature proton conduction in nanocellulose membranes: Paper fuel cells. Chem. Mater. 2016, 28, 4805–4814. [Google Scholar] [CrossRef]

- Bayer, T.; Cunning, B.V.; Šmíd, B.; Selyanchyn, R.; Fujikawa, S.; Sasaki, K.; Lyth, S.M. Spray deposition of sulfonated cellulose nanofibers as electrolyte membranes in fuel cells. Cellulose 2021, 0123456789. [Google Scholar] [CrossRef]

- Quellmalz, A.; Mihranyan, A. Citric Acid Cross-Linked Nanocellulose-Based Paper for Size-Exclusion Nanofiltration. ACS Biomater. Sci. Eng. 2015, 1, 271–276. [Google Scholar] [CrossRef] [PubMed]

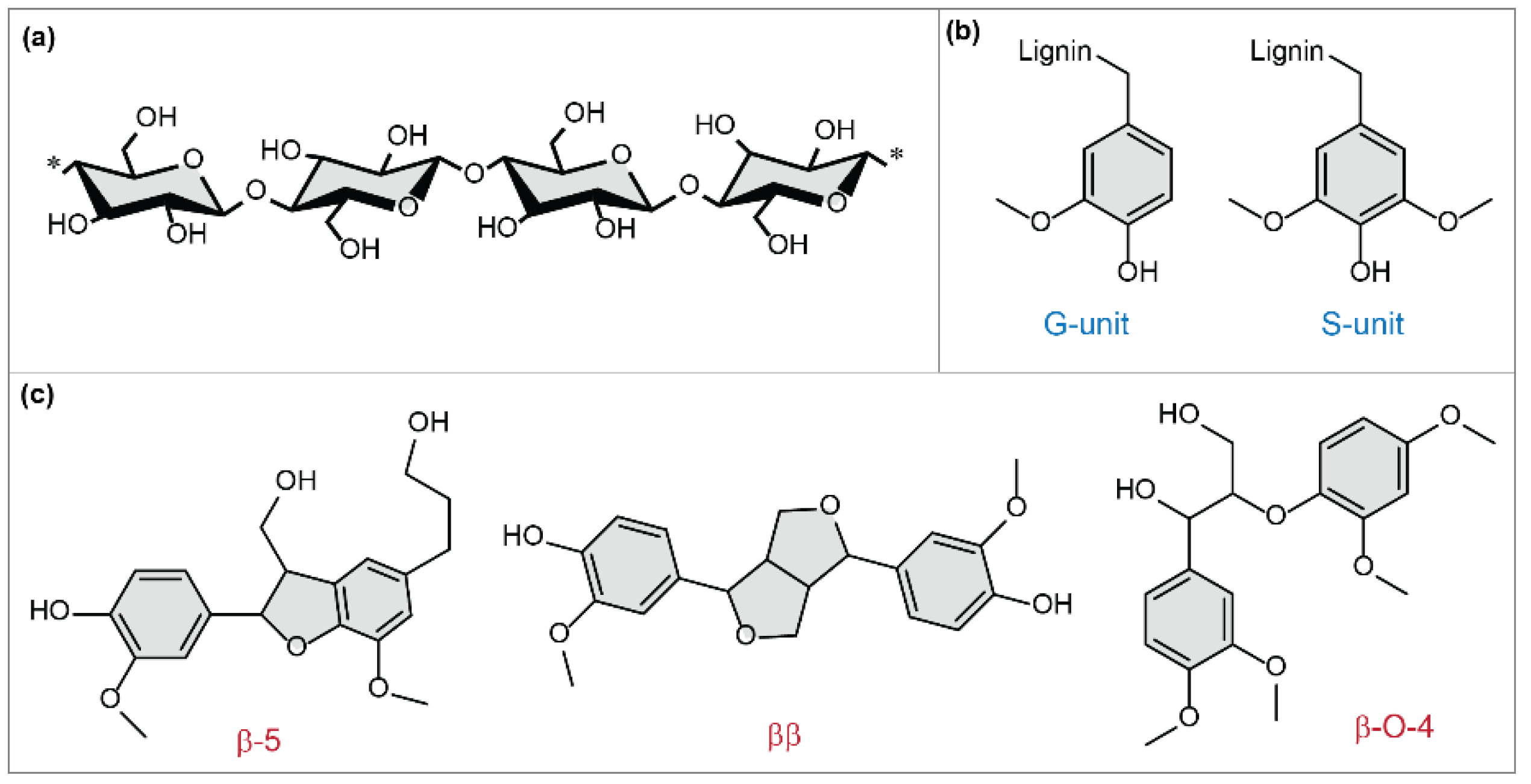

- Gellerstedt, G.L.F.; Henriksson, E.G. Lignins: Major sources, structure and properties. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008; pp. 201–224. ISBN 9780080453163. [Google Scholar] [CrossRef]

- Adler, E. Lignin Chemistry-Past, Present, and Future. Wood. Sci. Technol. 1976, 8, 1–25. [Google Scholar] [CrossRef]

- Schuetz, M.; Benske, A.; Smith, R.A.; Watanabe, Y.; Tobimatsu, Y.; Ralph, J.; Demura, T.; Ellis, B.; Samuels, A.L. Laccases direct lignification in the discrete secondary cell wall domains of protoxylem. Plant Physiol. 2014, 166, 798–807. [Google Scholar] [CrossRef] [PubMed]

- Balakshin, M.Y.; Capanema, E.A.; Sulaeva, I.; Schlee, P.; Huang, Z.; Feng, M.; Borghei, M.; Rojas, O.J.; Potthast, A.; Rosenau, T. New Opportunities in the Valorization of Technical Lignins. ChemSusChem 2020, 1016–1036. [Google Scholar] [CrossRef]

- Dessbesell, L.; Paleologou, M.; Leitch, M.; Pulkki, R.; Xu, C. (Charles) Global lignin supply overview and kraft lignin potential as an alternative for petroleum-based polymers. Renew. Sustain. Energy Rev. 2020, 123. [Google Scholar] [CrossRef]

- Farooq, M.; Zou, T.; Riviere, G.; Sipponen, M.H.; Österberg, M. Strong, Ductile, and Waterproof Cellulose Nanofibril Composite Films with Colloidal Lignin Particles. Biomacromolecules 2019, 20, 693–704. [Google Scholar] [CrossRef] [PubMed]

- Dou, J.; Bian, H.; Yelle, D.J.; Ago, M.; Vajanto, K.; Vuorinen, T.; Zhu, J. Lignin containing cellulose nanofibril production from willow bark at 80 °C using a highly recyclable acid hydrotrope. Ind. Crops Prod. 2019, 129, 15–23. [Google Scholar] [CrossRef]

- Saha, D.; Van Bramer, S.E.; Orkoulas, G.; Ho, H.C.; Chen, J.; Henley, D.K. CO2 capture in lignin-derived and nitrogen-doped hierarchical porous carbons. Carbon N. Y. 2017, 121, 257–266. [Google Scholar] [CrossRef]

- Xu, C.; Strømme, M. Sustainable porous carbon materials derived from wood-based biopolymers for CO2 capture. Nanomaterials 2019, 9, 103. [Google Scholar] [CrossRef]

- Zhao, Y.; Tagami, A.; Dobele, G.; Lindström, M.E.; Sevastyanova, O. The impact of lignin structural diversity on performance of cellulose nanofiber (CNF)-starch composite films. Polymers 2019, 11, 538. [Google Scholar] [CrossRef]

- Tomani, P. The lignoboost process. Cellul. Chem. Technol. 2010, 44, 53–58. [Google Scholar]

- Tagami, A.; Gioia, C.; Lauberts, M.; Budnyak, T.; Moriana, R.; Lindström, M.E.; Sevastyanova, O. Solvent fractionation of softwood and hardwood kraft lignins for more efficient uses: Compositional, structural, thermal, antioxidant and adsorption properties. Ind. Crop. Prod. 2019, 129, 123–134. [Google Scholar] [CrossRef]

- Abbadessa, A.; Oinonen, P.; Henriksson, G. Characterization of Two Novel Bio-based Materials from Pulping Process Side Streams: Ecohelix and CleanFlow Black Lignin. BioResources 2018, 13, 7606–7627. [Google Scholar] [CrossRef]

- Heitner, C.; Dimmel, D.; Schmidt, J. Lignin and Lignans: Advances in Chemistry; CRC press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Zhao, W.W.; Xiao, L.P.; Song, G.Y.; Sun, R.C.; He, L.L.; Singh, S.; Simmons, B.A.; Cheng, G. From lignin subunits to aggregates: Insights into lignin solubilization. Green Chem. 2017, 19, 3272–3281. [Google Scholar] [CrossRef]

- Pylypchuk, I.V.; Lindén, P.A.; Lindström, M.E.; Sevastyanova, O. New Insight into the Surface Structure of Lignin Nanoparticles Revealed by 1H Liquid-State NMR Spectroscopy. ACS Sustain. Chem. Eng. 2020, 8, 13805–13812. [Google Scholar] [CrossRef]

- Oveissi, F.; Fatehi, P. Characterization of four different lignins as a first step toward the identification of suitable end-use applications. J. Appl. Polym. Sci. 2015, 132, 1–9. [Google Scholar] [CrossRef]

- Chen, C.; Petterson, T.; Illergård, J.; Ek, M.; Wågberg, L. Influence of Cellulose Charge on Bacteria Adhesion and Viability to PVAm/CNF/PVAm-Modified Cellulose Model Surfaces. Biomacromolecules 2019, 20, 2075–2083. [Google Scholar] [CrossRef] [PubMed]

- Wulandari, W.T.; Rochliadi, A.; Arcana, I.M. Nanocellulose prepared by acid hydrolysis of isolated cellulose from sugarcane bagasse. IOP Conf. Ser. Mater. Sci. Eng. 2016, 107. [Google Scholar] [CrossRef]

- Larkin, P.J. (Ed.) Illustrated IR and Raman Spectra Demonstrating Important Functional Groups. In Infrared and Raman Spectroscopy, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 153–210. ISBN 9780128041628. [Google Scholar] [CrossRef]

- Ribca, I.; Jawerth, M.E.; Brett, C.J.; Lawoko, M.; Schwartzkopf, M.; Chumakov, A.; Roth, S.V.; Johansson, M. Exploring the Effects of Different Cross-Linkers on Lignin-Based Thermoset Properties and Morphologies. ACS Sustain. Chem. Eng. 2021. [Google Scholar] [CrossRef]

- Herrera, M.; Thitiwutthisakul, K.; Yang, X.; Rujitanaroj, P.-O.; Rojas, R.; Berglund, L. Preparation and evaluation of high-lignin content cellulose nanofibrils from eucalyptus pulp. Cellulose 2018, 25, 3121–3133. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Williams, R.T. Physisorption hysteresis loops and the characterization of nanoporous materials. Adsorpt. Sci. Technol. 2004, 22, 773–782. [Google Scholar] [CrossRef]

- Shields, J.E.; Lowell, S.; Thomas, M.A.; Thommes, M. Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density; Kluwer Academic Publisher: Boston, MA, USA, 2004; pp. 43–45. [Google Scholar]

- Barret, E.P.; Joyner, L.G.; Halenda, P.P. The Determination of Pore Volume and Area Distributions in Porous Substances. I. Computations from Nitrogen Isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Wijmans, J.; Baker, R. The Solution-Diffusion Model-A Review. JMS 1995, 107, 1–21. [Google Scholar] [CrossRef]

- Baker, R.W. (Ed.) Membrane Transport Theory. In Membrane Technology and Applications, 3rd ed.; Wiley: Hoboken, NJ, USA, 2012; ISBN 978-0-470-74372. [Google Scholar]

- Liang, M.; Liu, Y.; Xiao, B.; Yang, S.; Wang, Z.; Han, H. An analytical model for the transverse permeability of gas diffusion layer with electrical double layer effects in proton exchange membrane fuel cells. Int. J. Hydrog. Energy 2018, 43, 17880–17888. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, W.; Zhang, X.; Long, G.; Fan, J.; Chen, H.; Deng, L. A novel fractal solution for permeability and Kozeny-Carman constant of fibrous porous media made up of solid particles and porous fibers. Powder Technol. 2019, 349, 92–98. [Google Scholar] [CrossRef]

- Belbekhouche, S.; Bras, J.; Siqueira, G.; Chappey, C.; Lebrun, L.; Khelifi, B.; Marais, S.; Dufresne, A. Water sorption behavior and gas barrier properties of cellulose whiskers and microfibrils films. Carbohydr. Polym. 2011, 83, 1740–1748. [Google Scholar] [CrossRef]

- Fukuzumi, H.; Fujisawa, S.; Saito, T.; Isogai, A. Selective permeation of hydrogen gas using cellulose nanofibril film. Biomacromolecules 2013, 14, 1705–1709. [Google Scholar] [CrossRef]

- Zhang, F.; Dou, J.; Zhang, H. Mixed membranes comprising carboxymethyl cellulose (as capping agent and gas barrier matrix) and nanoporous ZIF-L nanosheets for gas separation applications. Polymers 2018, 10, 1340. [Google Scholar] [CrossRef]

- Selyanchyn, R.; Fujikawa, S. Membrane thinning for efficient CO2 capture. Sci. Technol. Adv. Mater. 2017, 18, 816–827. [Google Scholar] [CrossRef] [PubMed]

| Sample | Modulus (MPa) a | Tensile Strain at Break (%) a | Tensile Stress at Break (MPa) a |

|---|---|---|---|

| CNF | 3771 | 4.1 | 86 |

| SW/CNF | 5670 ± 530 | 1.98 ± 0.217 | 71.3 ± 7.6 |

| HW/CNF | 6785 ± 6 | 1.65 ± 0.001 | 61.2 ± 0.0 |

| CF/CNF | 6677 ± 175 | 2.45 ± 0.142 | 84.4 ± 2.0 |

| Sample | SBET, m2/g | Vpores, cm3/g | Dpores (ads), nm | Dpores (des), nm |

|---|---|---|---|---|

| CNF | 4.96 ± 0.14 | 0.009 | 8.1 | 3.3 |

| SW/CNF | 34.7 ± 0.16 | 0.089 | 8.3 | 4.6 |

| HW/CNF | 43.7 ± 0.27 | 0.108 | 8.0 | 4.9 |

| CF/CNF | 53.0 ± 0.22 | 0.132 | 8.1 | 5.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pylypchuk, I.; Selyanchyn, R.; Budnyak, T.; Zhao, Y.; Lindström, M.; Fujikawa, S.; Sevastyanova, O. “Artificial Wood” Lignocellulosic Membranes: Influence of Kraft Lignin on the Properties and Gas Transport in Tunicate-Based Nanocellulose Composites. Membranes 2021, 11, 204. https://doi.org/10.3390/membranes11030204

Pylypchuk I, Selyanchyn R, Budnyak T, Zhao Y, Lindström M, Fujikawa S, Sevastyanova O. “Artificial Wood” Lignocellulosic Membranes: Influence of Kraft Lignin on the Properties and Gas Transport in Tunicate-Based Nanocellulose Composites. Membranes. 2021; 11(3):204. https://doi.org/10.3390/membranes11030204

Chicago/Turabian StylePylypchuk, Ievgen, Roman Selyanchyn, Tetyana Budnyak, Yadong Zhao, Mikael Lindström, Shigenori Fujikawa, and Olena Sevastyanova. 2021. "“Artificial Wood” Lignocellulosic Membranes: Influence of Kraft Lignin on the Properties and Gas Transport in Tunicate-Based Nanocellulose Composites" Membranes 11, no. 3: 204. https://doi.org/10.3390/membranes11030204

APA StylePylypchuk, I., Selyanchyn, R., Budnyak, T., Zhao, Y., Lindström, M., Fujikawa, S., & Sevastyanova, O. (2021). “Artificial Wood” Lignocellulosic Membranes: Influence of Kraft Lignin on the Properties and Gas Transport in Tunicate-Based Nanocellulose Composites. Membranes, 11(3), 204. https://doi.org/10.3390/membranes11030204